Disruptive Manufacturing of Oxide Dispersion-Strengthened Steels for Nuclear Applications: Advances, Challenges, and Future Prospects

Abstract

1. Introduction

2. Materials and Microstructural Characteristics of ODS Steels

2.1. Composition and Properties of ODS Steels

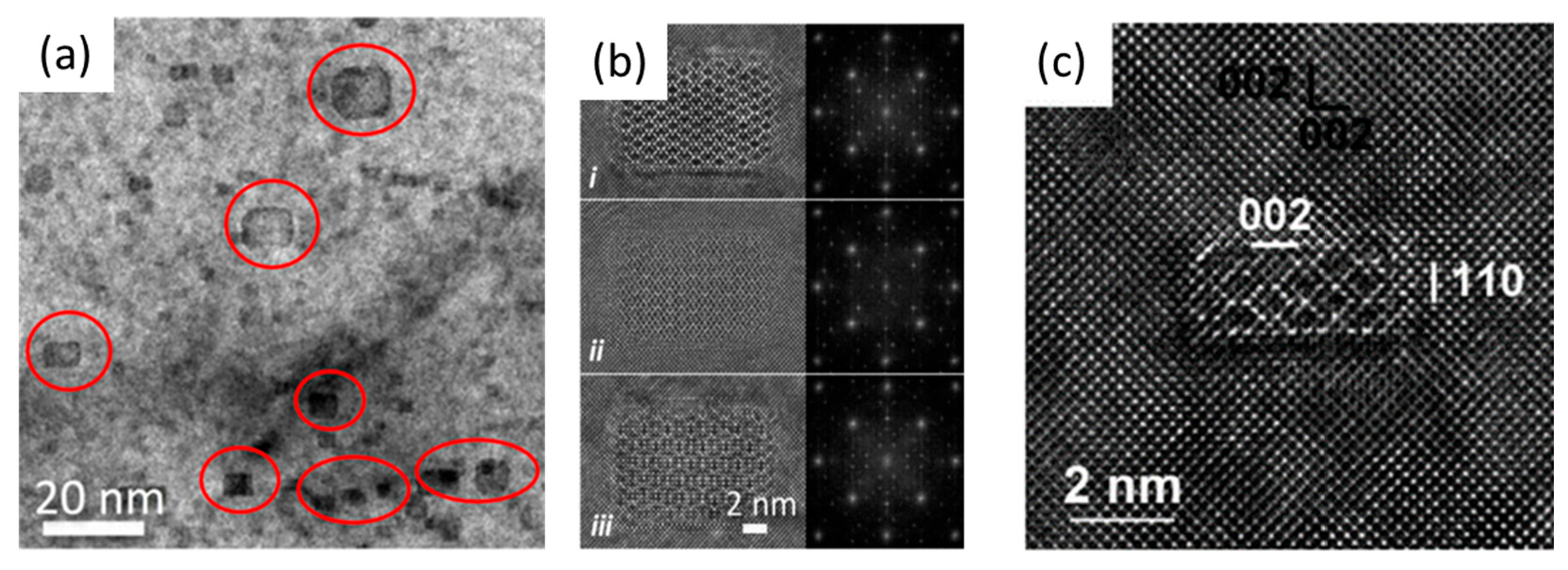

2.2. Role of Oxide Dispersoids in Enhancing Strength

2.3. Microstructural Features: Grain Size, Dispersion, and Stability

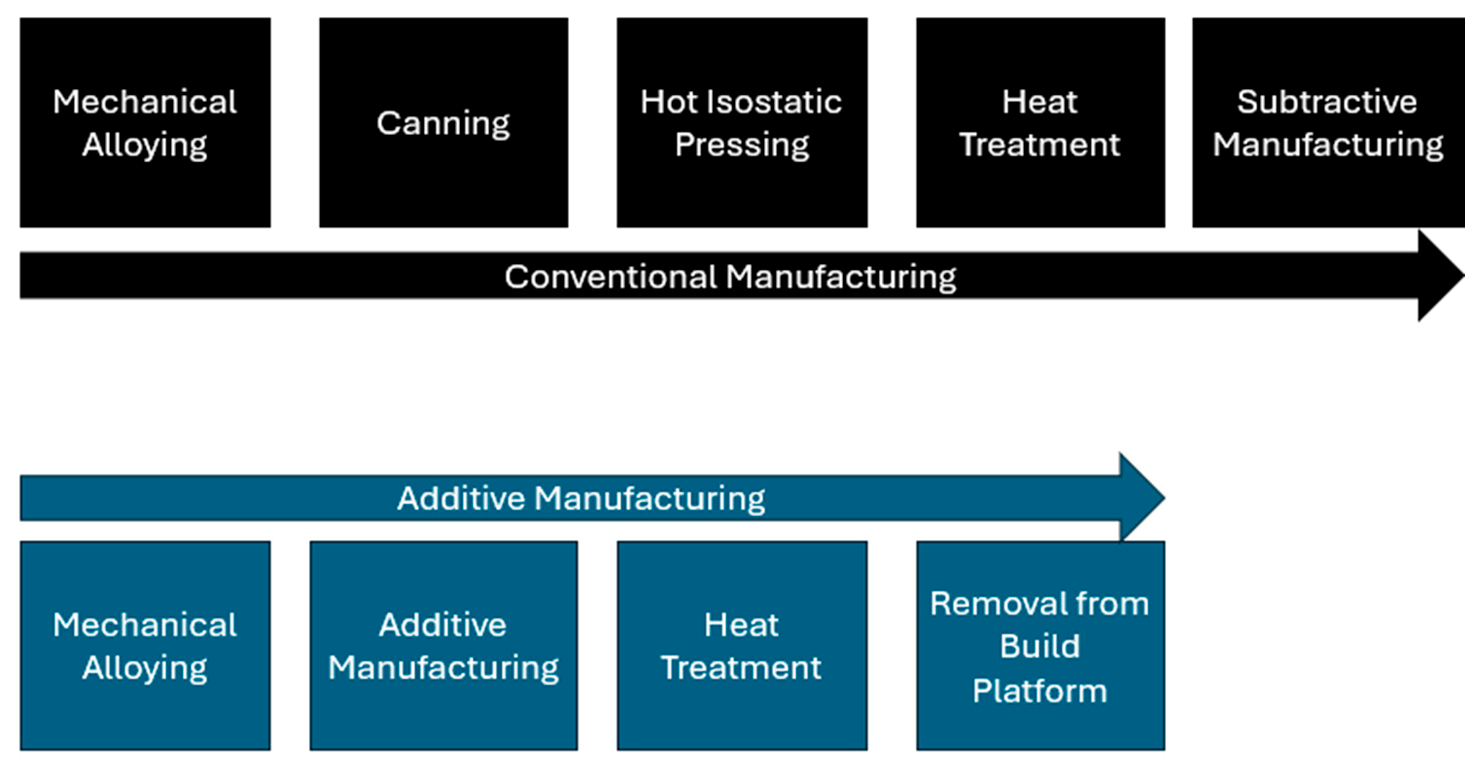

3. Disruptive Manufacturing Techniques for ODS Steels

3.1. Advanced Powder Metallurgy Methods

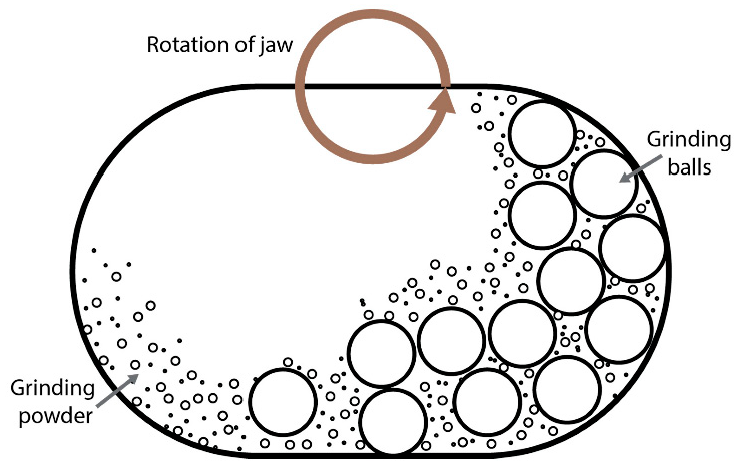

3.1.1. High-Energy Milling

3.1.2. Two-Stage Ball Milling

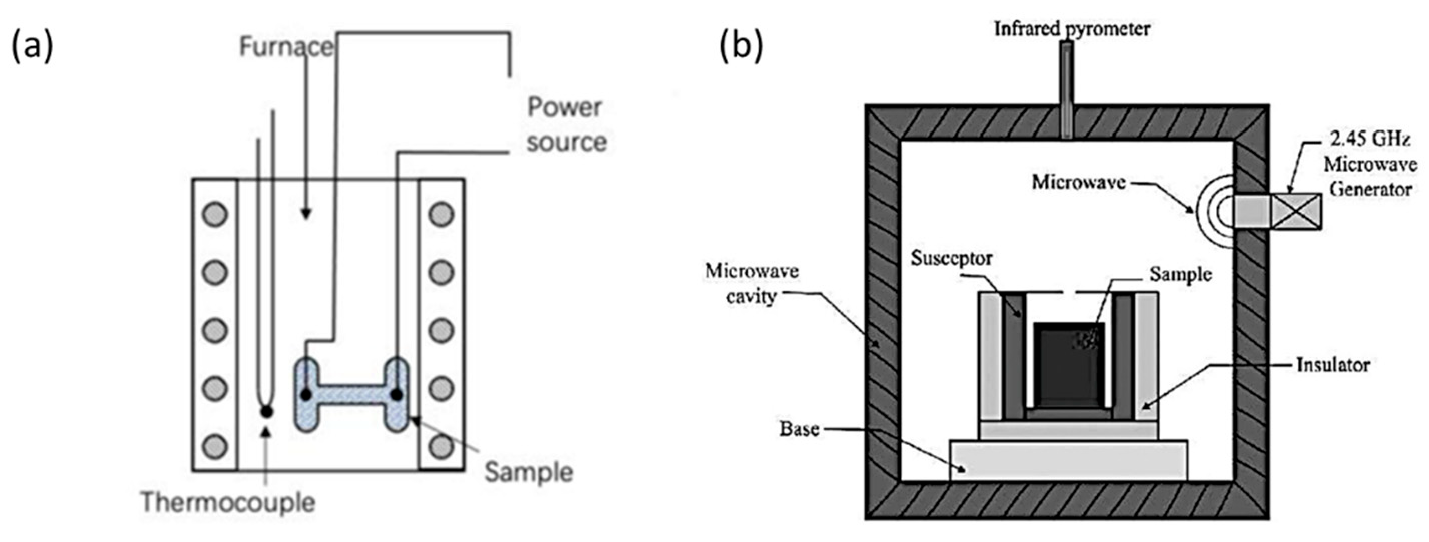

3.1.3. Spark Plasma Sintering (SPS)

3.1.4. Flash Sintering and Microwave Sintering

3.2. Mechanochemical Processing and Cryomilling

3.3. Additive Manufacturing (3D Printing) of ODS Steels

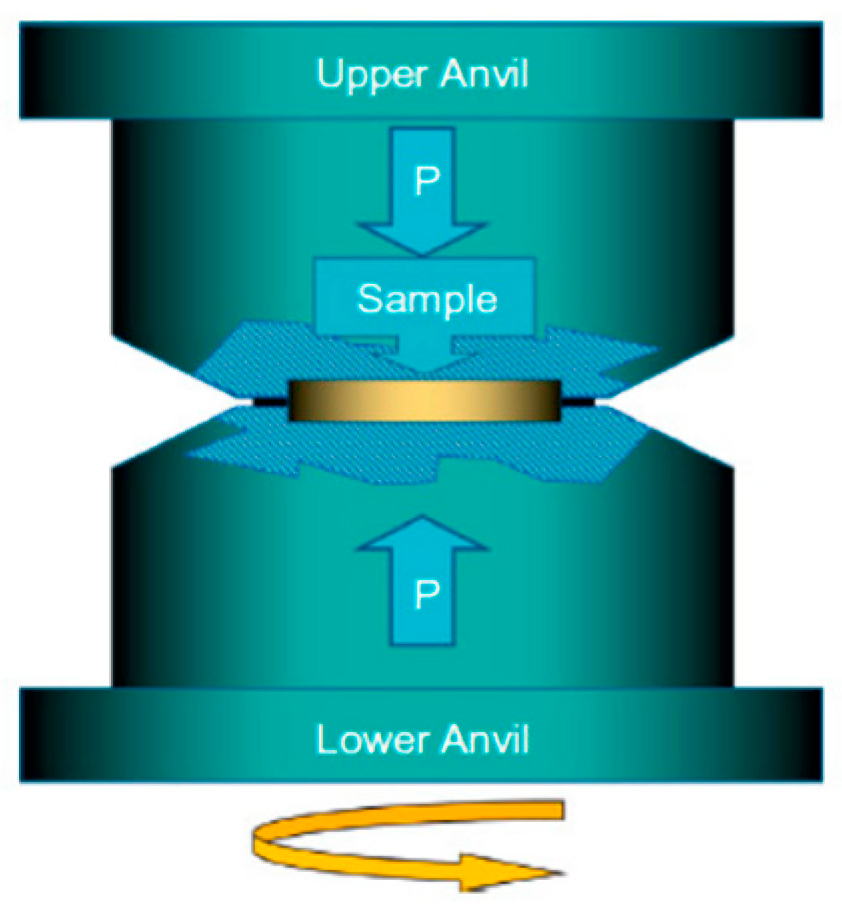

3.4. High-Pressure Torsion and Severe Plastic Deformation Techniques

4. Challenges in Manufacturing ODS Steels

4.1. Homogeneous Dispersion of Oxides

4.2. Control of Microstructure and Grain Growth

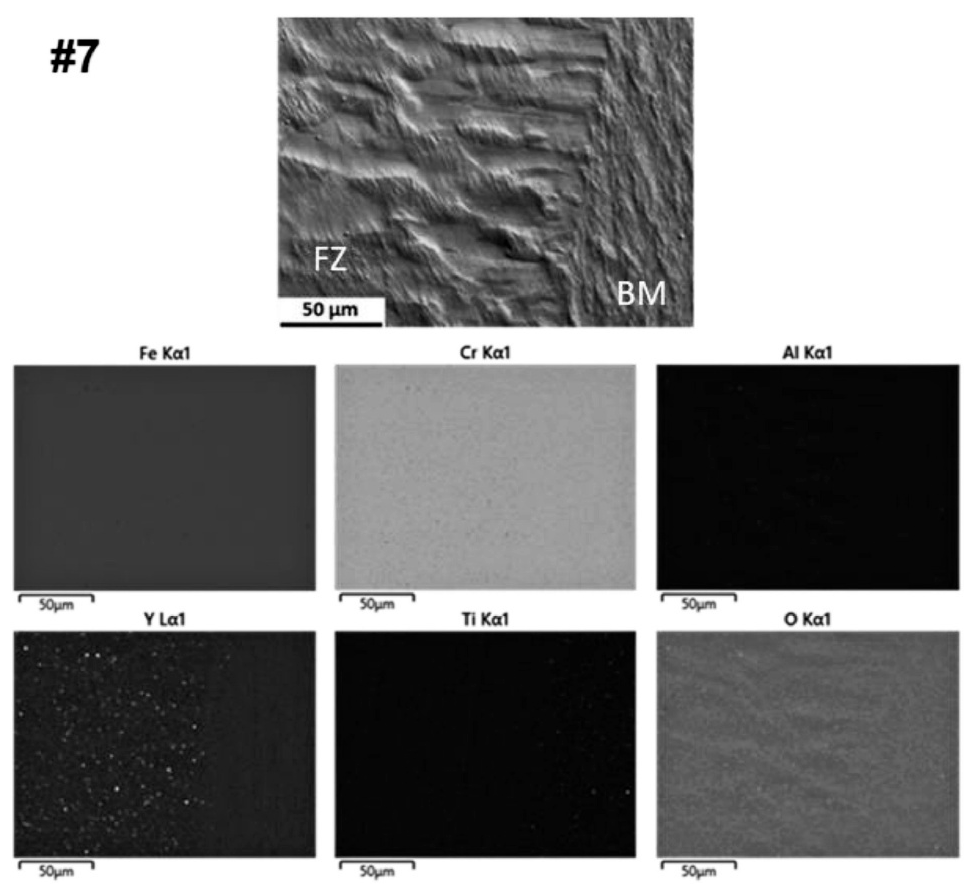

4.3. Joining and Welding Challenges

4.4. Scale-Up and Industrialization Challenges

5. Performance and Testing in Nuclear Environments

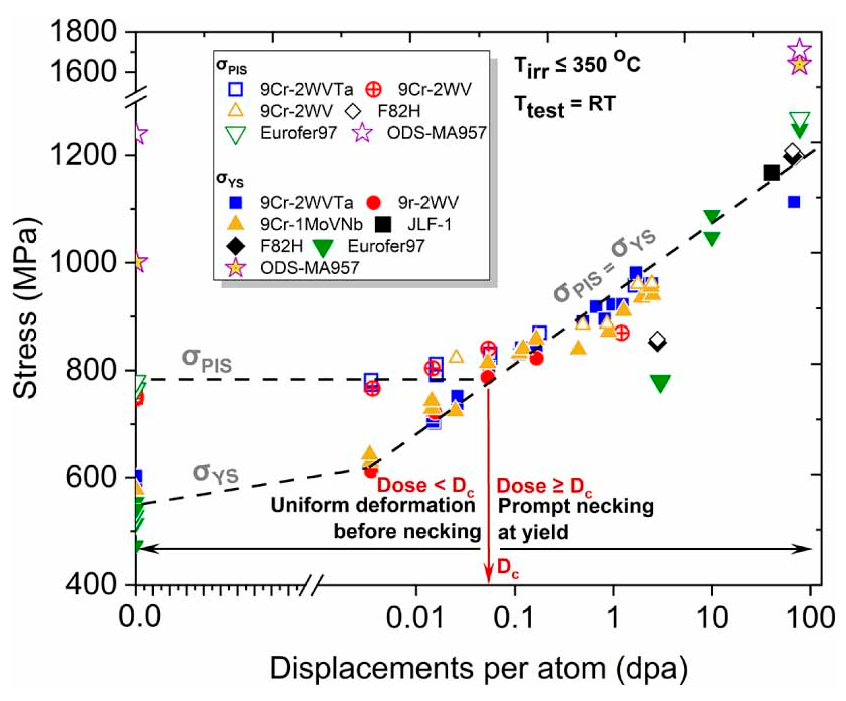

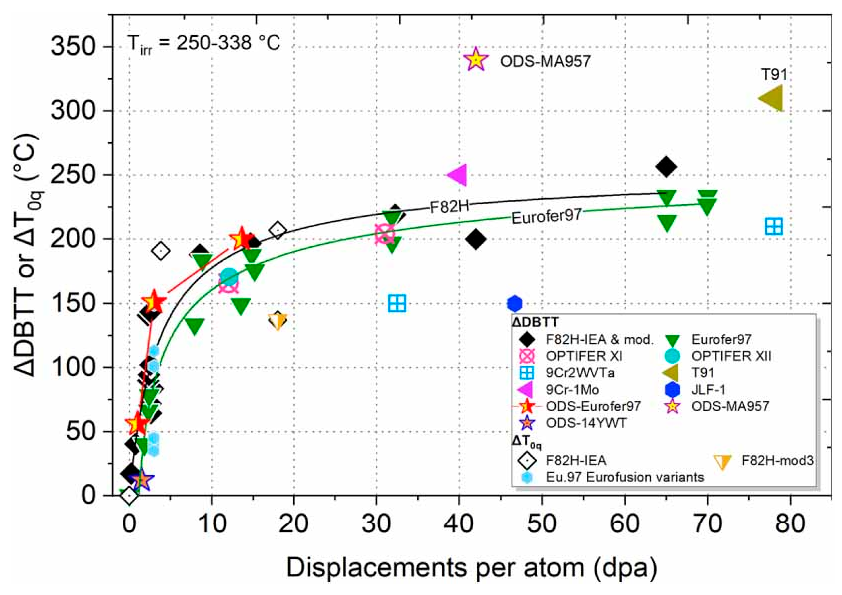

5.1. Radiation Resistance and Tolerance to Neutron Irradiation

5.2. Mechanical Properties: Creep, Fatigue, and Fracture Toughness

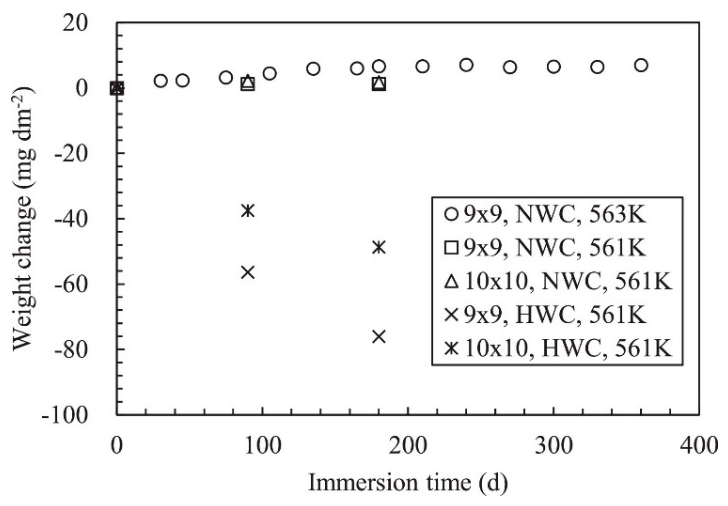

5.3. Thermal Stability and Oxidation Resistance

5.4. Long-Term Performance Under High Temperature and Stress

6. Current Developments and Case Studies

6.1. Notable Advancements in ODS Steel Manufacturing for Nuclear Applications

6.2. Case Studies of ODS Steels in Reactor Components

6.3. Comparative Analysis with Other High-Performance Materials

7. Future Directions and Opportunities

7.1. Integration with Smart Manufacturing and AI

7.2. Prospects for Enhanced Radiation Tolerance

7.3. Potential Next-Generation Nuclear Reactors

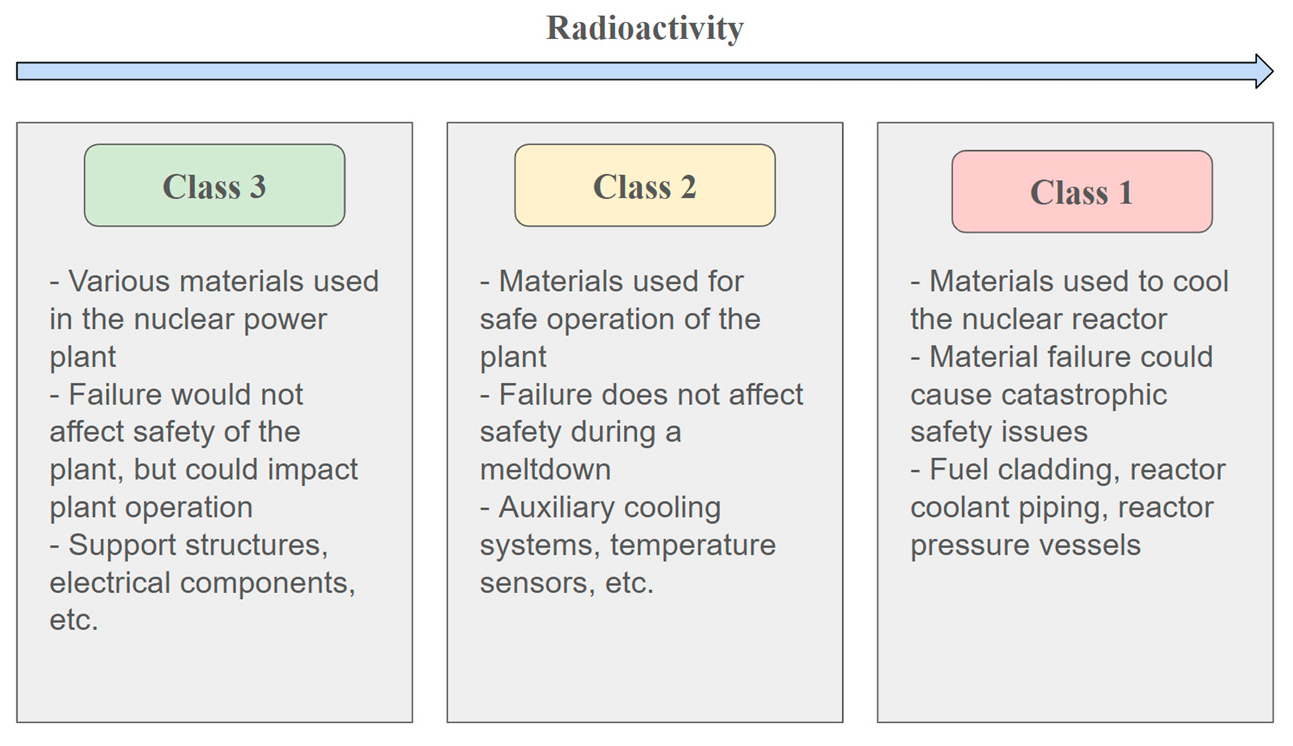

7.4. Policy and Regulatory Implications for Nuclear Materials

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dou, P.; Kimura, A.; Okuda, T.; Inoue, M.; Ukai, S.; Ohnuki, S.; Fujisawa, T.; Abe, F. Effects of Extrusion Temperature on the Nano-Mesoscopic Structure and Mechanical Properties of an Al-Alloyed High-Cr ODS Ferritic Steel. J. Nucl. Mater. 2011, 417, 166–170. [Google Scholar] [CrossRef]

- Durga, P.V.; Nagini, M.; Reddy, A.V.; Bakshi, S.R.; Vijay, R. Effect of Fine Grain Structure and Nano Oxide Dispersoids on Improved Strength and Ductility of Iron Aluminide Based Intermetallics. Metall. Mater. Trans. A 2022, 53, 1597–1603. [Google Scholar] [CrossRef]

- Brandes, M.C.; Kovarik, L.; Miller, M.K.; Mills, M.J. Morphology, Structure, and Chemistry of Nanoclusters in a Mechanically Alloyed Nanostructured Ferritic Steel. J. Mater. Sci. 2012, 47, 3913–3923. [Google Scholar] [CrossRef]

- Sinha, S.K.; Dasgupta, A.; Sivakumar, M.; Ghosh, C.; Raju, S. Unraveling the Complexity of Nano-Dispersoids in the Oxide Dispersion Strengthened Alloy 617. Microsc. Microanal. 2022, 28, 1463–1471. [Google Scholar] [CrossRef]

- Autones, L.; Aubry, P.; Ribis, J.; Leguy, H.; Legris, A.; de Carlan, Y. Assessment of Ferritic ODS Steels Obtained by Laser Additive Manufacturing. Materials 2023, 16, 2397. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, A.; Hoffmann, J.; Litvinov, D.; Aktaa, J. High-Temperature Low-Cycle Fatigue Behavior of a 9Cr-ODS Steel: Part 1—Pure Fatigue, Microstructure Evolution and Damage Characteristics. Mater. Sci. Eng. A 2017, 707, 207–220. [Google Scholar] [CrossRef]

- Güler, Ö.; Albayrak, M.G.; Başgöz, Ö.; Kavaz, E.; Alkarrani, H.; ALMisned, G.; Tekin, H.O. Development and In-Depth Experimental Characterization of Novel TiZrNbHfTaOx Reinforced 316L Stainless Steel for Advanced Nuclear Applications. Nucl. Eng. Des. 2024, 428, 113516. [Google Scholar] [CrossRef]

- Jones, S. Advanced Manufacturing Applied to Nuclear Fusion—Challenges and Solutions. J. Phys. Energy 2023, 5, 042001. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, T.; Bai, Z.; Wang, L.; Gao, W.; Zhang, L. Corrosion Behavior of 14Cr ODS Steel in Supercritical Water: The Influence of Substituting Y2O3 with Y2Ti2O7 Nanoparticles. Corros. Sci. 2020, 163, 108272. [Google Scholar] [CrossRef]

- Oh, S.; Lee, J.S.; Jang, C.; Kimura, A. Irradiation Hardening and Embrittlement in High-Cr Oxide Dispersion Strengthened Steels. J. Nucl. Mater. 2009, 386–388, 503–506. [Google Scholar] [CrossRef]

- Lahcen, E.M.O.; Alcázar, M.M.Á.; Almeida, C.P. New High Strength ODS Eurofer Steel Processed by Mechanical Alloying. Mater. Sci. Eng. A 2021, 817, 141288. [Google Scholar] [CrossRef]

- Sharma, S.K.; Gajević, S.; Sharma, L.K.; Mohan, D.G.; Sharma, Y.; Radojković, M.; Stojanović, B. Significance of the Powder Metallurgy Approach and Its Processing Parameters on the Mechanical Behavior of Magnesium-Based Materials. Nanomaterials 2025, 15, 92. [Google Scholar] [CrossRef] [PubMed]

- Fedoseeva, A.; Dolzhenko, A.; Kaibyshev, R. Thermo-Mechanical Processing as Method Decreasing Delta-Ferrite and Improving the Impact Toughness of the Novel 12% Cr Steels with Low N and High B Contents. Materials 2022, 15, 8861. [Google Scholar] [CrossRef] [PubMed]

- Ukai, S.; Ohtsuka, S.; Kaito, T.; de Carlan, Y.; Ribis, J.; Malaplate, J. 10—Oxide Dispersion-Strengthened/Ferrite-Martensite Steels as Core Materials for Generation IV Nuclear Reactors. In Structural Materials for Generation IV Nuclear Reactors; Yvon, P., Ed.; Woodhead Publishing: Cambridge, UK, 2017; pp. 357–414. ISBN 978-0-08-100906-2. [Google Scholar]

- Kim, T.K.; Noh, S.; Kang, S.H.; Park, J.J.; Jin, H.J.; Lee, M.K.; Jang, J.; Rhee, C.K. Current Status and Future Prospective of Advanced Radiation Resistant Oxide Dispersion Strengthened Steel (ARROS) Development for Nuclear Reactor System Applications. Nucl. Eng. Technol. 2016, 48, 572–594. [Google Scholar] [CrossRef]

- Li, J.; Chen, J.; You, Z.; Deng, L.; Wang, C.; Chen, J.; Xiao, L.; Wang, B. Effect of Annealing Temperature on the Evolution of Microstructure, Texture, and Mechanical Properties of Hot-Rolled 12Cr-ODS Steel. J. Mater. Res. Technol. 2024, 30, 4800–4812. [Google Scholar] [CrossRef]

- Connolly, S. Manufacturing of Oxide Dispersion Strengthened Steels for Nuclear Applications. Ph.D. Thesis, University of Oxford, Oxford, UK, 2018. [Google Scholar]

- Schaeublin, R.; Leguey, T.; Spätig, P.; Baluc, N.; Victoria, M. Microstructure and Mechanical Properties of Two ODS Ferritic/Martensitic Steels. J. Nucl. Mater. 2002, 307–311, 778–782. [Google Scholar] [CrossRef]

- Hilditch, T.B.; de Souza, T.; Hodgson, P.D. 2—Properties and Automotive Applications of Advanced High-Strength Steels (AHSS). In Welding and Joining of Advanced High Strength Steels (AHSS); Shome, M., Tumuluru, M., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 9–28. ISBN 978-0-85709-436-0. [Google Scholar]

- Wang, J.; Liu, S.; Xu, B.; Zhang, J.; Sun, M.; Li, D. Research Progress on Preparation Technology of Oxide Dispersion Strengthened Steel for Nuclear Energy. Int. J. Extreme Manuf. 2021, 3, 032001. [Google Scholar] [CrossRef]

- Glerum, J.A.; Luca, A.D.; Schuster, M.L.; Kenel, C.; Leinenbach, C.; Dunand, D.C. Effect of Oxide Dispersoids on Precipitation-Strengthened Al-1.7Zr (Wt %) Alloys Produced by Laser Powder-Bed Fusion. Addit. Manuf. 2022, 56, 102933. [Google Scholar] [CrossRef]

- Liu, C.; Lu, W.; Xia, W.; Du, C.; Rao, Z.; Best, J.P.; Brinckmann, S.; Lu, J.; Gault, B.; Dehm, G.; et al. Massive Interstitial Solid Solution Alloys Achieve Near-Theoretical Strength. Nat. Commun. 2022, 13, 1102. [Google Scholar] [CrossRef]

- He, B.B.; Hu, B.; Yen, H.W.; Cheng, G.J.; Wang, Z.K.; Luo, H.W.; Huang, M.X. High Dislocation Density–Induced Large Ductility in Deformed and Partitioned Steels. Science 2017, 357, 1029–1032. [Google Scholar] [CrossRef]

- Shen, J.; Nagasaka, T.; Muroga, T.; Yang, H.; Kano, S.; Abe, H. Microstructural Evolution of Two-Way Cold Rolled 12Cr ODS Steel under 1073–1373 K Annealing. Nucl. Mater. Energy 2020, 25, 100792. [Google Scholar] [CrossRef]

- Ribis, J.; Lescoat, M.-L.; Zhong, S.Y.; Mathon, M.-H.; de Carlan, Y. Influence of the Low Interfacial Density Energy on the Coarsening Resistivity of the Nano-Oxide Particles in Ti-Added ODS Material. J. Nucl. Mater. 2013, 442, S101–S105. [Google Scholar] [CrossRef]

- Hirata, A.; Fujita, T.; Wen, Y.R.; Schneibel, J.H.; Liu, C.T.; Chen, M.W. Atomic Structure of Nanoclusters in Oxide-Dispersion-Strengthened Steels. Nat. Mater. 2011, 10, 922–926. [Google Scholar] [CrossRef]

- Wu, Y.; Ciston, J.; Kräemer, S.; Bailey, N.; Odette, G.R.; Hosemann, P. The Crystal Structure, Orientation Relationships and Interfaces of the Nanoscale Oxides in Nanostructured Ferritic Alloys. Acta Mater. 2016, 111, 108–115. [Google Scholar] [CrossRef]

- Svoboda, J.; Horník, V.; Riedel, H. Modelling of Processing Steps of New Generation ODS Alloys. Metall. Mater. Trans. A 2020, 51, 5296–5305. [Google Scholar] [CrossRef]

- Imagawa, Y.; Hashidate, R.; Miyazawa, T.; Onizawa, T.; Ohtsuka, S.; Yano, Y.; Tanno, T.; Kaito, T.; Ohnuma, M.; Mitsuhara, M.; et al. Creep Deformation and Rupture Behavior of 9Cr-ODS Steel Cladding Tube at High Temperatures from 700 °C to 1000 °C. J. Nucl. Sci. Technol. 2024, 61, 762–777. [Google Scholar] [CrossRef]

- Odette, G.R. Recent Progress in Developing and Qualifying Nanostructured Ferritic Alloys for Advanced Fission and Fusion Applications. JOM 2014, 66, 2427–2441. [Google Scholar] [CrossRef]

- Odette, G.R.; Cunningham, N.J.; Stan, T.; Alam, M.E.; Carlan, Y.D. Chapter 12—Nano-Oxide Dispersion-Strengthened Steels. In Structural Alloys for Nuclear Energy Applications; Odette, G.R., Zinkle, S.J., Eds.; Elsevier: Boston, MA, USA, 2019; pp. 529–583. ISBN 978-0-12-397046-6. [Google Scholar]

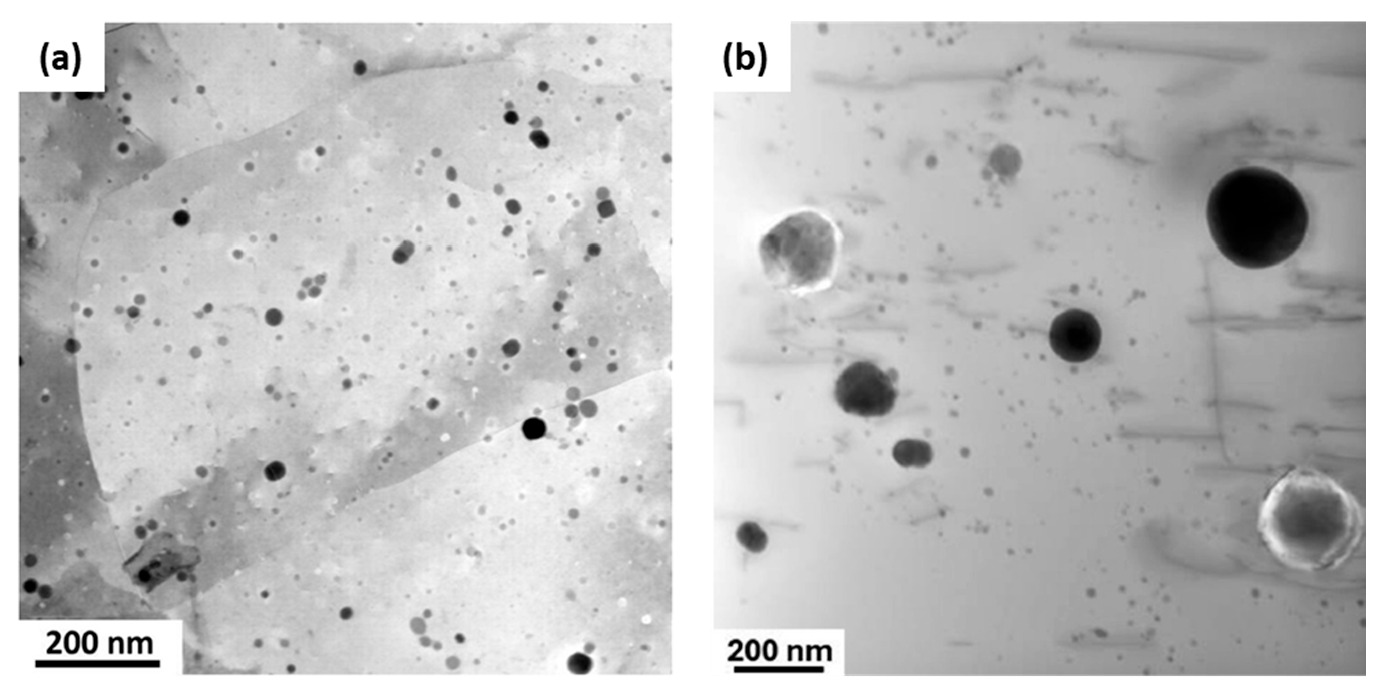

- Lin, Y.-R.; Chen, W.-Y.; Tan, L.; Hoelzer, D.T.; Yan, Z.; Hsieh, C.-Y.; Huang, C.-W.; Zinkle, S.J. Bubble Formation in Helium-Implanted Nanostructured Ferritic Alloys at Elevated Temperatures. Acta Mater. 2021, 217, 117165. [Google Scholar] [CrossRef]

- Odette, G.R. On the Status and Prospects for Nanostructured Ferritic Alloys for Nuclear Fission and Fusion Application with Emphasis on the Underlying Science. Scr. Mater. 2018, 143, 142–148. [Google Scholar] [CrossRef]

- Stan, T.; Wu, Y.; Ciston, J.; Yamamoto, T.; Odette, G.R. Characterization of Polyhedral Nano-Oxides and Helium Bubbles in an Annealed Nanostructured Ferritic Alloy. Acta Mater. 2020, 183, 484–492. [Google Scholar] [CrossRef]

- Salur, E. Structural Evolution of Mechanically Alloyed ODS Steel Powders during Ball Milling and Subsequent Annealing Treatment. Int. Adv. Res. Eng. J. 2022, 6, 80–89. [Google Scholar] [CrossRef]

- Torralba, J.M.; Fuentes-Pacheco, L.; García-Rodríguez, N.; Campos, M. Development of High Performance Powder Metallurgy Steels by High-Energy Milling. Adv. Powder Technol. 2013, 24, 813–817. [Google Scholar] [CrossRef]

- Simondon, E.; Giroux, P.-F.; Ribis, J.; Spartacus, G.; Chaffron, L.; Gloriant, T. Innovative Method of ODS Steels Manufacturing by Direct Introduction of Pyrochlore Phase through Milling. Mater. Charact. 2021, 181, 111461. [Google Scholar] [CrossRef]

- Kim, H.N.; Kim, J.W.; Kim, M.S.; Lee, B.H.; Kim, J.C. Effects of Ball Size on the Grinding Behavior of Talc Using a High-Energy Ball Mill. Minerals 2019, 9, 668. [Google Scholar] [CrossRef]

- Oksiuta, Z.; Baluc, N. Optimization of the Chemical Composition and Manufacturing Route for ODS RAF Steels for Fusion Reactor Application. Nucl. Fusion 2009, 49, 055003. [Google Scholar] [CrossRef]

- Balázsi, C.; Gillemot, F.; Horváth, M.; Wéber, F.; Balázsi, K.; Sahin, F.C.; Onüralp, Y.; Horváth, Á. Preparation and Structural Investigation of Nanostructured Oxide Dispersed Strengthened Steels. J. Mater. Sci. 2011, 46, 4598–4605. [Google Scholar] [CrossRef]

- Tokita, M. Progress of Spark Plasma Sintering (SPS) Method, Systems, Ceramics Applications and Industrialization. Ceramics 2021, 4, 160–198. [Google Scholar] [CrossRef]

- Ninawe, P.S.; Ganesh, S.; Karthik, P.S.; Chandrasekhar, S.B.; Vijay, R. Microstructure and Mechanical Properties of Spark Plasma Sintered Austenitic ODS Steel. Adv. Powder Technol. 2022, 33, 103584. [Google Scholar] [CrossRef]

- deJong, M.; Horn, T.; Kaoumi, D. Review of Solid-State Consolidation Processing Techniques of ODS Steels (Hot Extrusion, Hot Isostatic Pressing, Spark Plasma Sintering, and Stir Friction Consolidation): Resulting Microstructures and Mechanical Properties. JOM 2024, 76, 6252–6276. [Google Scholar] [CrossRef]

- Manière, C.; Lee, G.; Zahrah, T.; Olevsky, E.A. Microwave Flash Sintering of Metal Powders: From Experimental Evidence to Multiphysics Simulation. Acta Mater. 2018, 147, 24–34. [Google Scholar] [CrossRef]

- Biesuz, M.; Grasso, S.; Sglavo, V.M. What’s New in Ceramics Sintering? A Short Report on the Latest Trends and Future Prospects. Curr. Opin. Solid State Mater. Sci. 2020, 24, 100868. [Google Scholar] [CrossRef]

- Manikandan, R.; Raja Annamalai, A. Tungsten Heavy Alloys Processing via Microwave Sintering, Spark Plasma Sintering, and Additive Manufacturing: A Review. Processes 2022, 10, 2352. [Google Scholar] [CrossRef]

- Shabashov, V.A.; Litvinov, A.V.; Sagaradze, V.V.; Kozlov, K.A.; Vil’danova, N.F. Mechanosynthesis of ODS Alloys with an Fcc Lattice on the Basis of the Fe-Ni System. Phys. Met. Metallogr. 2008, 105, 157–167. [Google Scholar] [CrossRef]

- Kushwaha, A.K.; Maccione, R.; John, M.; Lanka, S.; Misra, M.; Menezes, P.L. Influence of Cryomilling on Crystallite Size of Aluminum Powder and Spark Plasma Sintered Component. Nanomaterials 2022, 12, 551. [Google Scholar] [CrossRef]

- Kushwaha, A.K.; Misra, M.; Menezes, P.L. Manufacturing Bulk Nanocrystalline Al-3Mg Components Using Cryomilling and Spark Plasma Sintering. Nanomaterials 2022, 12, 3618. [Google Scholar] [CrossRef] [PubMed]

- Kushwaha, A.K.; Misra, M.; Menezes, P.L. Effect of Magnesium Dopant on the Grain Boundary Stability of Nanocrystalline Aluminum Powders during Cryomilling. Crystals 2023, 13, 541. [Google Scholar] [CrossRef]

- Verhiest, K.; Almazouzi, A.; Wispelaere, N.D.; Petrov, R.; Claessens, S. Development of Oxides Dispersion Strengthened Steels for High Temperature Nuclear Reactor Applications. J. Nucl. Mater. 2009, 385, 308–311. [Google Scholar] [CrossRef]

- Kim, J.H.; Byun, T.S.; Shin, E.; Seol, J.-B.; Young, S.; Reddy, N.S. Small Angle Neutron Scattering Analyses and High Temperature Mechanical Properties of Nano-Structured Oxide Dispersion-Strengthened Steels Produced via Cryomilling. J. Alloys Compd. 2015, 651, 363–374. [Google Scholar] [CrossRef]

- Bergner, F.; Hilger, I.; Virta, J.; Lagerbom, J.; Gerbeth, G.; Connolly, S.; Hong, Z.; Grant, P.S.; Weissgärber, T. Alternative Fabrication Routes toward Oxide-Dispersion-Strengthened Steels and Model Alloys. Metall. Mater. Trans. A 2016, 47, 5313–5324. [Google Scholar] [CrossRef]

- Oono, N.H.; Ukai, S.; Tominaga, K.; Ebisawa, N.; Tomura, K. Precipitation of Various Oxides in ODS Ferritic Steels. J. Mater. Sci. 2019, 54, 8786–8799. [Google Scholar] [CrossRef]

- Jia, H.; Zhou, Z.; Li, S. A New Strategy for Additive Manufacturing ODS Steel Using Y-Containing Gas Atomized Powder. Mater. Charact. 2022, 187, 111876. [Google Scholar] [CrossRef]

- Wilms, M.B.; Pirch, N.; Gökce, B. Manufacturing Oxide-Dispersion-Strengthened Steels Using the Advanced Directed Energy Deposition Process of High-Speed Laser Cladding. Prog. Addit. Manuf. 2023, 8, 159–167. [Google Scholar] [CrossRef]

- Karch, A.; Sornin, D.; Barcelo, F.; Bosonnet, S.; de Carlan, Y.; Logé, R. Microstructural Characterizations of 14Cr ODS Ferritic Steels Subjected to Hot Torsion. J. Nucl. Mater. 2015, 459, 53–61. [Google Scholar] [CrossRef]

- Chen, J.; Hoffelner, W. Irradiation Creep of Oxide Dispersion Strengthened (ODS) Steels for Advanced Nuclear Applications. J. Nucl. Mater. 2009, 392, 360–363. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, S.; Ding, H.; Hu, P.; Huang, Y.; Zhang, Y. Microstructures, Mechanical Properties and Transformation Behavior in Ni49.6Ti35.4Hf15 Alloy Produced with High-Pressure Torsion. Crystals 2023, 13, 1246. [Google Scholar] [CrossRef]

- Zhang, D.; Darsell, J.T.; Wang, J.; Ma, X.; Grant, G.J.; Anderson, I.E.; Rieken, J.R.; Edwards, D.J.; Setyawan, W.; Horn, T.J.; et al. No Ball Milling Needed: Alternative ODS Steel Manufacturing with Gas Atomization Reaction Synthesis (GARS) and Friction-Based Processing. J. Nucl. Mater. 2022, 566, 153768. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, Z.; Zheng, W.; Jia, H. Mechanical Properties Evaluation and Plastic Instabilities of Fe-9%Cr ODS Steels. Fusion Eng. Des. 2019, 149, 111335. [Google Scholar] [CrossRef]

- Ghasali, E.; Orooji, Y.; Tahamtan, H.; Asadian, K.; Alizadeh, M.; Ebadzadeh, T. The Effects of Metallic Additives on the Microstructure and Mechanical Properties of WC-Co Cermets Prepared by Microwave Sintering. Ceram. Int. 2020, 46, 29199–29206. [Google Scholar] [CrossRef]

- Dawson, H.; Serrano, M.; Cater, S.; Jimenez-Melero, E. Characterization of ODS Steel Friction Stir Welds and Their Abnormal Grain Growth Behaviour. Fusion Eng. Des. 2018, 135, 174–182. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Zinkle, S.J.; Henry, J.; Levine, S.M.; Edmondson, P.D.; Gilbert, M.R.; Tanigawa, H.; Kessel, C.E. Irradiation Damage Concurrent Challenges with RAFM and ODS Steels for Fusion Reactor First-Wall/Blanket: A Review. J. Phys. Energy 2022, 4, 034003. [Google Scholar] [CrossRef]

- Meza, A.; Macía, E.; García-Junceda, A.; Díaz, L.A.; Chekhonin, P.; Altstadt, E.; Serrano, M.; Rabanal, M.E.; Campos, M. Development of New 14 Cr ODS Steels by Using New Oxides Formers and B as an Inhibitor of the Grain Growth. Metals 2020, 10, 1344. [Google Scholar] [CrossRef]

- Bischoff, J.; Motta, A.T. Oxidation Behavior of Ferritic–Martensitic and ODS Steels in Supercritical Water. J. Nucl. Mater. 2012, 424, 261–276. [Google Scholar] [CrossRef]

- Jin, H.J.; Kang, S.H.; Park, S.M.; Kim, T.K. Microstructure Evolution of Ferritic ODS Steel by a Simple Torsion Test. In Proceedings of the Transactions of the Korean Nuclear Society Autumn Meeting, Gyeongju, Republic of Korea, 24–25 October 2013. [Google Scholar]

- Getto, E.; Johnson, M.; Maughan, M.; Nathan, N.; McMahan, J.; Baker, B.; Knipling, K.; Briggs, S.; Hattar, K.; Swenson, M.J. Friction Stir Welding and Self-Ion Irradiation Effects on Microstructure and Mechanical Properties Changes within Oxide Dispersion Strengthened Steel MA956. J. Nucl. Mater. 2022, 567, 153795. [Google Scholar] [CrossRef]

- Dawson, H.; Hughes, J.; Jimenez-Melero, E. Impact of Electron Beam Welding on the Microstructure of PM2000 ODS Steel. Fusion Eng. Des. 2024, 204, 114528. [Google Scholar] [CrossRef]

- Naimi, F.; Niepce, J.-C.; Ariane, M.; Cayron, C.; Calapez, J.; Gentzbittel, J.-M.; Bernard, F. Joining of Oxide Dispersion-Strengthened Steel Using Spark Plasma Sintering. Metals 2020, 10, 1040. [Google Scholar] [CrossRef]

- Fu, J.; Brouwer, J.C.; Hendrikx, R.W.A.; Richardson, I.M.; Hermans, M.J.M. Microstructure Characterisation and Mechanical Properties of ODS Eurofer Steel Subject to Designed Heat Treatments. Mater. Sci. Eng. A 2020, 770, 138568. [Google Scholar] [CrossRef]

- Ralls, A.M.; Daroonparvar, M.; Menezes, P.L. Spark Plasma Sintering of Mg-Based Alloys: Microstructure, Mechanical Properties, Corrosion Behavior, and Tribological Performance. J. Magnes. Alloys 2024, 12, 405–442. [Google Scholar] [CrossRef]

- Jose, S.A.; Kasar, A.K.; Menezes, P.L. Cold Spray Deposition of Cermets: Insights into Bonding Mechanism and Critical Parameters. Int. J. Adv. Manuf. Technol. 2024, 133, 1–23. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, D.; Darsell, J.T.; Ross, K.A.; Ma, X.; Liu, J.; Liu, T.; Prabhakaran, R.; Li, L.; Anderson, I.E.; et al. Manufacturing Oxide Dispersion Strengthened (ODS) Steel Plate via Cold Spray and Friction Stir Processing. J. Nucl. Mater. 2024, 596, 155076. [Google Scholar] [CrossRef]

- Ralls, A.M.; Daroonparvar, M.; Kasar, A.K.; Misra, M.; Menezes, P.L. Influence of Friction Stir Processing on the Friction, Wear and Corrosion Mechanisms of Solid-State Additively Manufactured 316L Duplex Stainless Steel. Tribol. Int. 2023, 178, 108033. [Google Scholar] [CrossRef]

- Ralls, A.M.; Menezes, P.L. Revealing the Fretting Corrosion Degradation Mechanisms of Friction Stir Processed Cold Spray Additively Manufactured Stainless Steel. Int. J. Adv. Manuf. Technol. 2024, 130, 2855–2876. [Google Scholar] [CrossRef]

- Certain, A.; Kuchibhatla, S.; Shutthanandan, V.; Hoelzer, D.T.; Allen, T.R. Radiation Stability of Nanoclusters in Nano-Structured Oxide Dispersion Strengthened (ODS) Steels. J. Nucl. Mater. 2013, 434, 311–321. [Google Scholar] [CrossRef]

- Lescoat, M.-L.; Ribis, J.; Chen, Y.; Marquis, E.A.; Bordas, E.; Trocellier, P.; Serruys, Y.; Gentils, A.; Kaïtasov, O.; de Carlan, Y.; et al. Radiation-Induced Ostwald Ripening in Oxide Dispersion Strengthened Ferritic Steels Irradiated at High Ion Dose. Acta Mater. 2014, 78, 328–340. [Google Scholar] [CrossRef]

- Kurpaska, L.; Jozwik, I.; Lewandowska, M.; Jagielski, J. The Effect of Ar-Ion Irradiation on Nanomechanical and Structural Properties of ODS RAF Steels Manufactured by Using HIP Technique. Vacuum 2017, 145, 144–152. [Google Scholar] [CrossRef]

- Kocks, U.F. The Theory of an Obstacle-Controlled Yield Strength—Report after an International Workshop. Mater. Sci. Eng. 1977, 27, 291–298. [Google Scholar] [CrossRef]

- Han, X.; Zhang, C.; Niu, M.; Ding, Z.; Jang, J.; Wang, T.; Kimura, A. A Comparison Study of Change in Hardness and Microstructures of a Zr-Added FeCrAl ODS Steel Irradiated with Heavy Ions. Mater. Sci. Eng. A 2022, 841, 143050. [Google Scholar] [CrossRef]

- Kassner, M.E. Fundamentals of Creep in Metals and Alloys; Butterworth-Heinemann: Oxford, UK, 2015; ISBN 0-08-099432-6. [Google Scholar]

- Garud, Y.S. Low Temperature Creep and Irradiation Creep in Nuclear Reactor Applications: A Critical Review. Int. J. Press. Vessels Pip. 2016, 139–140, 137–145. [Google Scholar] [CrossRef]

- Ren, J.; Yu, L.; Liu, C.; Ma, Z.; Li, H.; Wang, Z.; Liu, Y.; Wang, H. Creep Properties, Microstructural Evolution, and Fracture Mechanism of an Al Added High Cr ODS Steel during Creep Deformation at 600 °C. J. Nucl. Mater. 2022, 558, 153376. [Google Scholar] [CrossRef]

- Petit, J. Fatigue of Materials and Structures: Fundamentals- Influence of Environment. In Fatigue of Materials and Structures: Fundamentals; Wiley, ISTE Ltd.: London, UK, 2010; pp. 401–455. [Google Scholar]

- Koo, G.-H.; Lee, S.-Y.; Seo, J.-H.; Song, K.-H.; Choi, G.-S.; Sohn, M.-S. A Study on Creep-Fatigue Evaluation of Nuclear Cladded Components by ASME-III Division 5. Energies 2023, 16, 2898. [Google Scholar] [CrossRef]

- Das, A.; Viehrig, H.W.; Bergner, F.; Heintze, C.; Altstadt, E.; Hoffmann, J. Effect of Microstructural Anisotropy on Fracture Toughness of Hot Rolled 13Cr ODS Steel—The Role of Primary and Secondary Cracking. J. Nucl. Mater. 2017, 491, 83–93. [Google Scholar] [CrossRef]

- Zheng, P.; Li, Y.; Zhang, J.; Shen, J.; Nagasaka, T.; Muroga, T.; Abe, H. On the Thermal Stability of a 9Cr-ODS Steel Aged at 700 °C up to 10000 h—Mechanical Properties and Microstructure. Mater. Sci. Eng. A 2020, 783, 139292. [Google Scholar] [CrossRef]

- Xia, Y.P.; Wang, X.P.; Zhuang, Z.; Sun, Q.X.; Zhang, T.; Fang, Q.F.; Hao, T.; Liu, C.S. Microstructure and Oxidation Properties of 16Cr–5Al–ODS Steel Prepared by Sol–Gel and Spark Plasma Sintering Methods. J. Nucl. Mater. 2013, 432, 198–204. [Google Scholar] [CrossRef]

- Pint, B.A.; Wright, I.G. Long-Term High Temperature Oxidation Behavior of ODS Ferritics. J. Nucl. Mater. 2002, 307–311, 763–768. [Google Scholar] [CrossRef]

- Zhao, Z.; Cao, Y.; Zhang, Y.; Fu, A.; Zhang, R.; Zhong, Y.; Li, J.; Fang, Q.; Liu, B.; Liu, Y. Creep Behavior of a Novel ODS Ferrite Steel Reinforced with Ultra-Fine Y2(Zr0.6, Ti0.4)2O7 Particles. Mater. Charact. 2024, 215, 114231. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, H.; Wu, Y.; Huang, H.; Zhu, X.; Zhang, Y.; Zhu, H.; Yuan, X.; Chen, Q.; Wang, S.; et al. Solving Oxygen Embrittlement of Refractory High-Entropy Alloy via Grain Boundary Engineering. Mater. Today 2022, 54, 83–89. [Google Scholar] [CrossRef]

- Wirth, F.; Arpagaus, S.; Wegener, K. Analysis of Melt Pool Dynamics in Laser Cladding and Direct Metal Deposition by Automated High-Speed Camera Image Evaluation. Addit. Manuf. 2018, 21, 369–382. [Google Scholar] [CrossRef]

- Wilms, M.B.; Rittinghaus, S.-K.; Goßling, M.; Gökce, B. Additive Manufacturing of Oxide-Dispersion Strengthened Alloys: Materials, Synthesis and Manufacturing. Prog. Mater. Sci. 2023, 133, 101049. [Google Scholar] [CrossRef]

- Yeom, H.; Hoelzer, D.; Maloy, S.; Sridharan, K. Cold Spray Manufacturing of Oxide-Dispersion Strengthened (ODS) Steels Using Gas-Atomized and Ball-Milled 14YWT Powders. J. Nucl. Mater. 2023, 574, 154187. [Google Scholar] [CrossRef]

- Ralls, A.M.; Daroonparvar, M.; Sikdar, S.; Rahman, M.H.; Monwar, M.; Watson, K.; Kay, C.M.; Menezes, P.L. Tribological and Corrosion Behavior of High Pressure Cold Sprayed Duplex 316 L Stainless Steel. Tribol. Int. 2022, 169, 107471. [Google Scholar] [CrossRef]

- Monette, Z.; Kasar, A.K.; Daroonparvar, M.; Menezes, P.L. Supersonic Particle Deposition as an Additive Technology: Methods, Challenges, and Applications. Int. J. Adv. Manuf. Technol. 2020, 106, 2079–2099. [Google Scholar] [CrossRef]

- Alam, M.E.; Pal, S.; Fields, K.; Maloy, S.A.; Hoelzer, D.T.; Odette, G.R. Tensile Deformation and Fracture Properties of a 14YWT Nanostructured Ferritic Alloy. Mater. Sci. Eng. A 2016, 675, 437–448. [Google Scholar] [CrossRef]

- Stier, O. Fundamental Cost Analysis of Cold Spray. J. Therm. Spray Technol. 2014, 23, 131–139. [Google Scholar] [CrossRef]

- Rieth, M.; Dürrschnabel, M.; Bonk, S.; Pintsuk, G.; Aiello, G.; Henry, J.; de Carlan, Y.; Ghidersa, B.-E.; Neuberger, H.; Rey, J.; et al. Impact of Materials Technology on the Breeding Blanket Design—Recent Progress and Case Studies in Materials Technology. Fusion Eng. Des. 2021, 166, 112275. [Google Scholar] [CrossRef]

- Sakamoto, K.; Miura, Y.; Ukai, S.; Oono, N.H.; Kimura, A.; Yamaji, A.; Kusagaya, K.; Takano, S.; Kondo, T.; Ikegawa, T.; et al. Development of Accident Tolerant FeCrAl-ODS Fuel Cladding for BWRs in Japan. J. Nucl. Mater. 2021, 557, 153276. [Google Scholar] [CrossRef]

- Funch, C.V.; Proust, G. Laser-Based Additive Manufacturing of Refractory Metals and Their Alloys: A Review. Addit. Manuf. 2024, 94, 104464. [Google Scholar] [CrossRef]

- John, M.; Ralls, A.M.; Misra, M.; Menezes, P.L. Effect of Ultrasonic Impact Peening on Stress Corrosion Cracking Resistance of Austenitic Stainless-Steel Welds for Nuclear Canister Applications. J. Nucl. Mater. 2023, 584, 154590. [Google Scholar] [CrossRef]

- Bustinza, O.F.; Molina, L.M.; Vendrell-Herrero, F.; Opazo-Basaez, M. AI-Enabled Smart Manufacturing Boosts Ecosystem Value Capture: The Importance of Servitization Pathways within Digital-Intensive Industries. Int. J. Prod. Econ. 2024, 277, 109411. [Google Scholar] [CrossRef]

- Deng, L.; Wang, C.; Luo, J.; Tu, J.; Guo, N.; Xu, H.; He, P.; Xia, S.; Yao, Z. Preparation and Property Optimization of FeCrAl-Based ODS Alloy by Machine Learning Combined with Wedge-Shaped Hot-Rolling. Mater. Charact. 2022, 188, 111894. [Google Scholar] [CrossRef]

- Wu, Q.; Yang, F.; Lv, C.; Liu, C.; Tang, W.; Yang, J. In-Situ Quality Intelligent Classification of Additively Manufactured Parts Using a Multi-Sensor Fusion Based Melt Pool Monitoring System. Addit. Manuf. Front. 2024, 3, 200153. [Google Scholar] [CrossRef]

- Jyeniskhan, N.; Shomenov, K.; Ali, M.H.; Shehab, E. Exploring the Integration of Digital Twin and Additive Manufacturing Technologies. Int. J. Lightweight Mater. Manuf. 2024, 7, 860–881. [Google Scholar] [CrossRef]

- Zhang, Z.; Pantleon, W. Response of Oxide Nanoparticles in an Oxide Dispersion Strengthened Steel to Dynamic Plastic Deformation. Acta Mater. 2018, 149, 235–247. [Google Scholar] [CrossRef]

- Deng, L.; Luo, J.; Tu, J.; Hu, R.; Guo, N.; Zeng, W.; Wang, C.; He, P.; Zhang, Y. Achieving Excellent Mechanical Properties of ODS Steel by Y2O3 Addition. Mater. Sci. Eng. A 2023, 872, 145008. [Google Scholar] [CrossRef]

- Rogozhkin, S.V.; Bogachev, A.A.; Nikitin, A.A.; Vasiliev, A.L.; Presnyakov, M.Y.; Tomut, M.; Trautmann, C. TEM Analysis of Radiation Effects in ODS Steels Induced by Swift Heavy Ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2021, 486, 1–10. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Boutard, J.L.; Hoelzer, D.T.; Kimura, A.; Lindau, R.; Odette, G.R.; Rieth, M.; Tan, L.; Tanigawa, H. Development of next Generation Tempered and ODS Reduced Activation Ferritic/Martensitic Steels for Fusion Energy Applications. Nucl. Fusion 2017, 57, 092005. [Google Scholar] [CrossRef]

- Marques Pereira, V. ODS Steels for Nuclear Applications: Thermal Stability of the Microstructure and Evolution of Defects. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2022. [Google Scholar]

- Labib, A.; Harris, M.J. Learning How to Learn from Failures: The Fukushima Nuclear Disaster. Eng. Fail. Anal. 2015, 47, 117–128. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, J.; Chen, S.; Li, Y.; Wang, J.; Wang, F. A New Method for Safety Classification of Structures, Systems and Components by Reflecting Nuclear Reactor Operating History into Importance Measures. Nucl. Eng. Technol. 2022, 54, 1336–1342. [Google Scholar] [CrossRef]

- Basavaraju, C.; Lambin, J. Section III: Subsections NC and ND—Class 2 and 3 Components. In Online Companion Guide to the ASME Boiler & Pressure Vessel Codes; ASME Press: New York, NY, USA, 2020; ISBN 978-0-7918-6198-1. [Google Scholar]

- Endorsement Review Of ASME B&PV Code Section III, Division 5, “High Temperature Reactors”|NRC.Gov. Available online: https://www.nrc.gov/reactors/new-reactors/advanced/modernizing/guidance/asme-bpv-code-section3-div5.html#issuance (accessed on 20 December 2024).

- NUREG-0800|NRC.Gov. Available online: https://www.nrc.gov/reading-rm/doc-collections/nuregs/staff/sr0800/index.html (accessed on 20 December 2024).

| Operating Temperature (°C) | Fracture Toughness with Room-Temperature Milling (MPa) | Fracture Toughness with −150 °C Milling (MPa) |

|---|---|---|

| 25 (Room Temp.) | 60 | 40 |

| 300 | 80 | 35 |

| 500 | 55 | 20 |

| 700 | 72 | 38 |

| Technique | Advantages | Disadvantages | Reference |

|---|---|---|---|

| High-energy milling | Induces lattice distortions and movement of nano-oxides through the steel matrix | Increases dislocation density in crystal structure without further post-processing | [36,39] |

| Two-stage ball milling | Reduces dislocation density and uniformly distributes nano-oxides | Requires precise control over transition from ferrite to austenite phase between stages | [40] |

| Spark plasma sintering | High powder densification, lower operating temperature, energy-efficient process | Relatively high discharge and sintering times | [42] |

| Flash sintering | Shorter discharge time, high powder densification | High electrical conductivity of ODS steel can lead to thermal runaway effects | [44] |

| Microwave sintering | Accelerated densification, reduced thermal runaway effects, shorter sintering time | Full effects on ODS steels have yet to be properly explored | [62] |

| Mechanochemical processing | Converts unstable oxides into strength-enhancing nano-oxides | Required usage of severe plastic deformation can lead to inhomogeneous material properties | [47] |

| Cryomilling | Reduces heat generation, uniformly distributes nano-oxides, can improve fracture toughness | Induces embrittling of material if temperature is too low, leading to worse material properties | [48,51] |

| Laser powder bed fusion | Creation of complex geometries with minimal waste material | Produces parts with lower tensile strength if paired with coarse-grain powders | [54] |

| High-speed laser cladding | Smaller laser and melt pool create uniform distribution of nano-oxides; prevents premature cooling | Energy-intensive process, difficult to implement on larger scale | [56] |

| High-pressure torsion | Nanoscale grain refinement to improve material properties | Radial dependency on torsional strain, leads to inhomogeneous hardness distribution | [57,60] |

| Composition | Particle Size, P (µm) | Crystallite Size, L (µm) | HV0.2 |

|---|---|---|---|

| 14AI-Ti-ODS | 38 | 11.94 | 320 |

| 14AI-Ti-ODS-B | 73 | 11.99 | 345 |

| 14AI-X-ODS | 38 | 11.60 | 425 |

| 14AI-X-ODS-B | 54 | 11.40 | 420 |

| Cr | Al | Ti | Y | O | C | N | Fe |

|---|---|---|---|---|---|---|---|

| 18.6 | 5.5 | 0.54 | 0.39 | 0.09 | 0.04 | 0.006 | Bal. |

| Material | Oxide Layer (µm) |

|---|---|

| Al-containing 16Cr-ODS steel | 5–10 |

| Al-free 16Cr-ODS steel | 25 |

| 304 Stainless steel | 85 |

| Steel Type | Yield Stress at 100 dpa (MPa) | Vickers Microhardness at 450 °C (HV), ×9.8 MPa | Uniform Elongation at 80 dpa (%) | Total Elongation at 80 dpa (%) | Swelling (%) |

|---|---|---|---|---|---|

| ODS-MA957 | 1700 | 450 | 1.00 | 5.00 | 0.00 |

| Eurofer97 | 1300 | 225 | 0.30 | 6.50 | 0.75 |

| F82H | 1190 | 415 | 0.25 | 8.50 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murphy, C.; Buksa, S.; Day, J.; Felix-Lopez, A.; Antony Jose, S.; Menezes, P.L. Disruptive Manufacturing of Oxide Dispersion-Strengthened Steels for Nuclear Applications: Advances, Challenges, and Future Prospects. Processes 2025, 13, 1572. https://doi.org/10.3390/pr13051572

Murphy C, Buksa S, Day J, Felix-Lopez A, Antony Jose S, Menezes PL. Disruptive Manufacturing of Oxide Dispersion-Strengthened Steels for Nuclear Applications: Advances, Challenges, and Future Prospects. Processes. 2025; 13(5):1572. https://doi.org/10.3390/pr13051572

Chicago/Turabian StyleMurphy, Cory, Shaina Buksa, Joey Day, Argelia Felix-Lopez, Subin Antony Jose, and Pradeep L. Menezes. 2025. "Disruptive Manufacturing of Oxide Dispersion-Strengthened Steels for Nuclear Applications: Advances, Challenges, and Future Prospects" Processes 13, no. 5: 1572. https://doi.org/10.3390/pr13051572

APA StyleMurphy, C., Buksa, S., Day, J., Felix-Lopez, A., Antony Jose, S., & Menezes, P. L. (2025). Disruptive Manufacturing of Oxide Dispersion-Strengthened Steels for Nuclear Applications: Advances, Challenges, and Future Prospects. Processes, 13(5), 1572. https://doi.org/10.3390/pr13051572