Distribution Characteristics of Mining-Induced Stress Fields and Surrounding Rock Control Technology in Adjacent Working Faces Within Fold Structure Zones

Abstract

1. Introduction

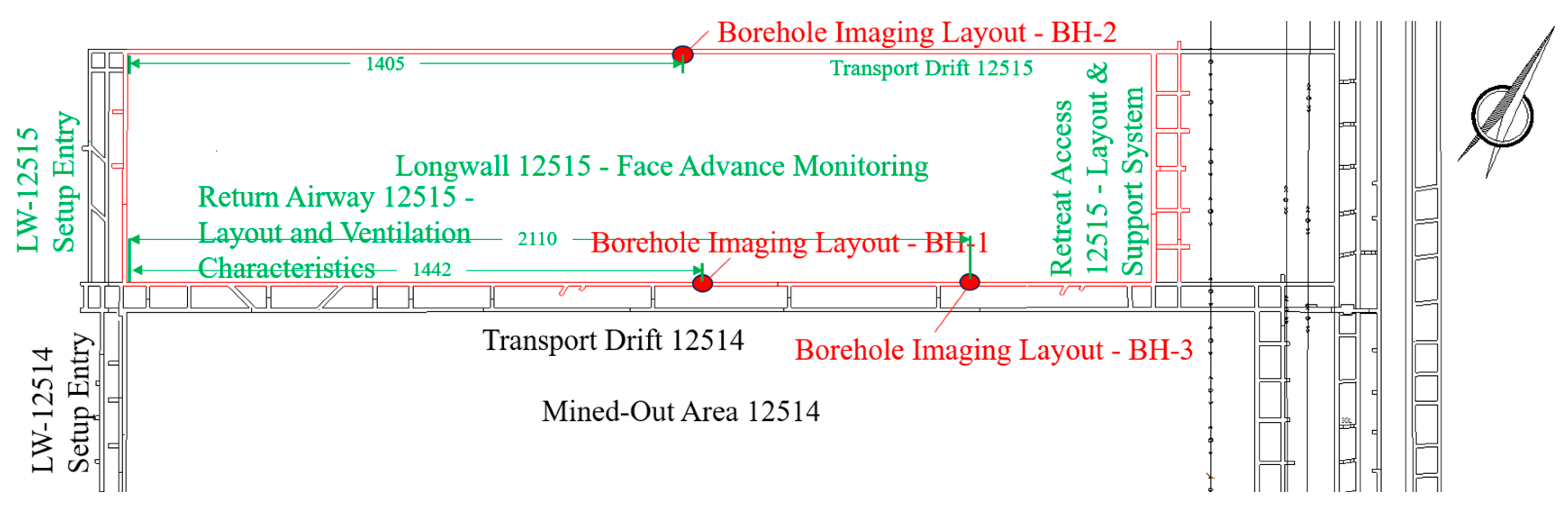

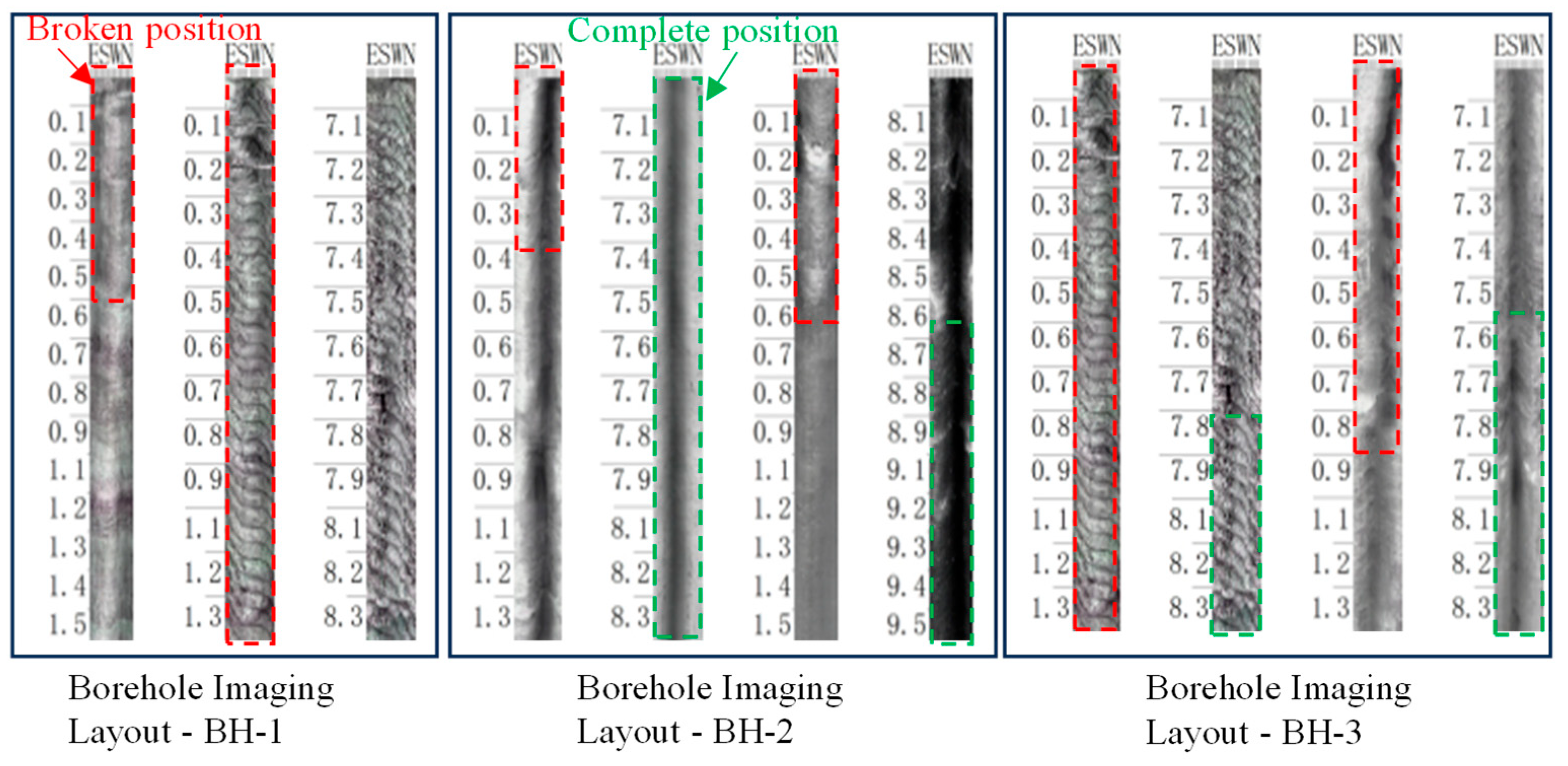

2. Case Study Overview

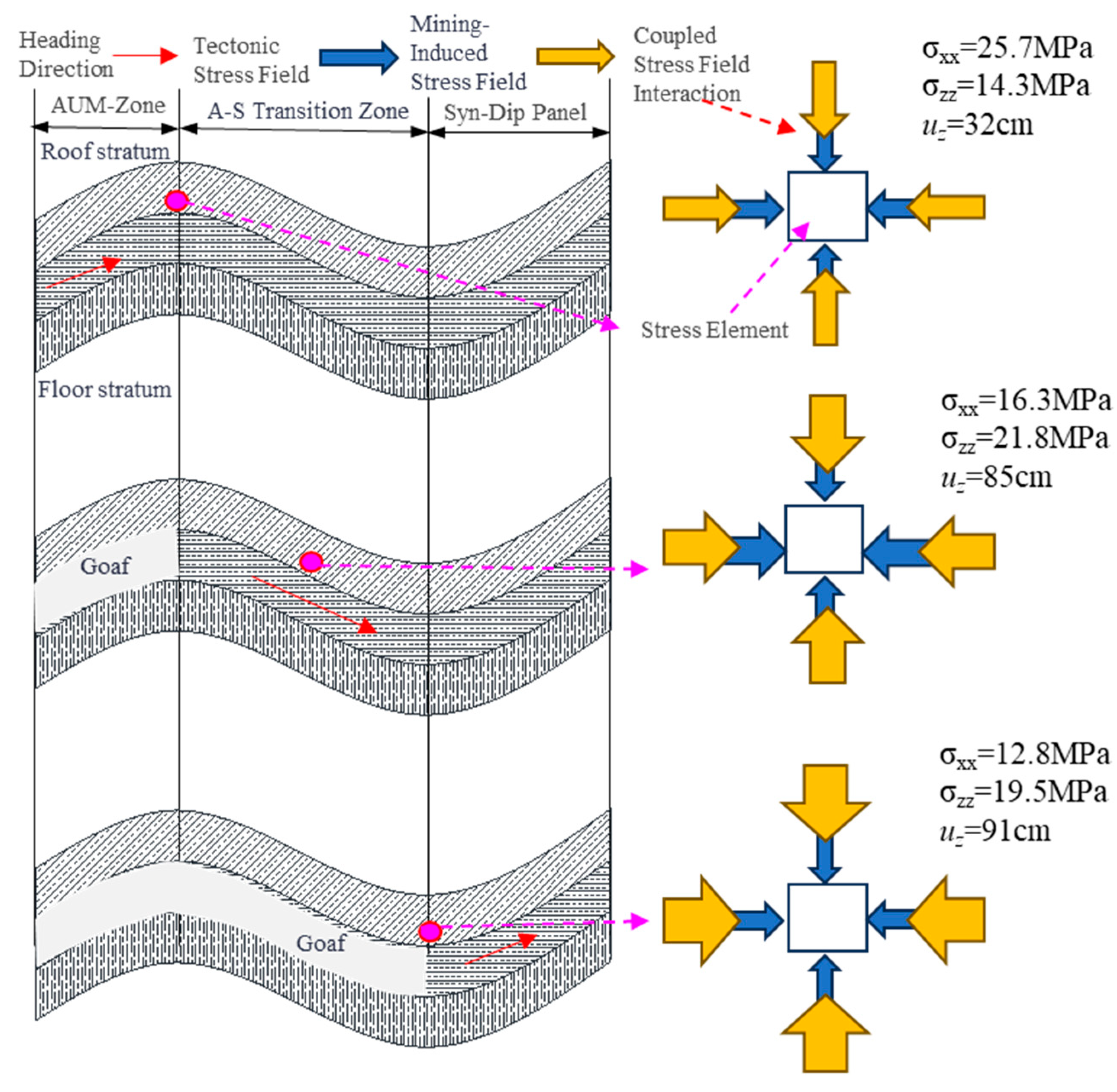

3. Stress Distribution Characteristics and Dynamic Evolution Laws of Adjacent Working Faces in Fold Structure Zones

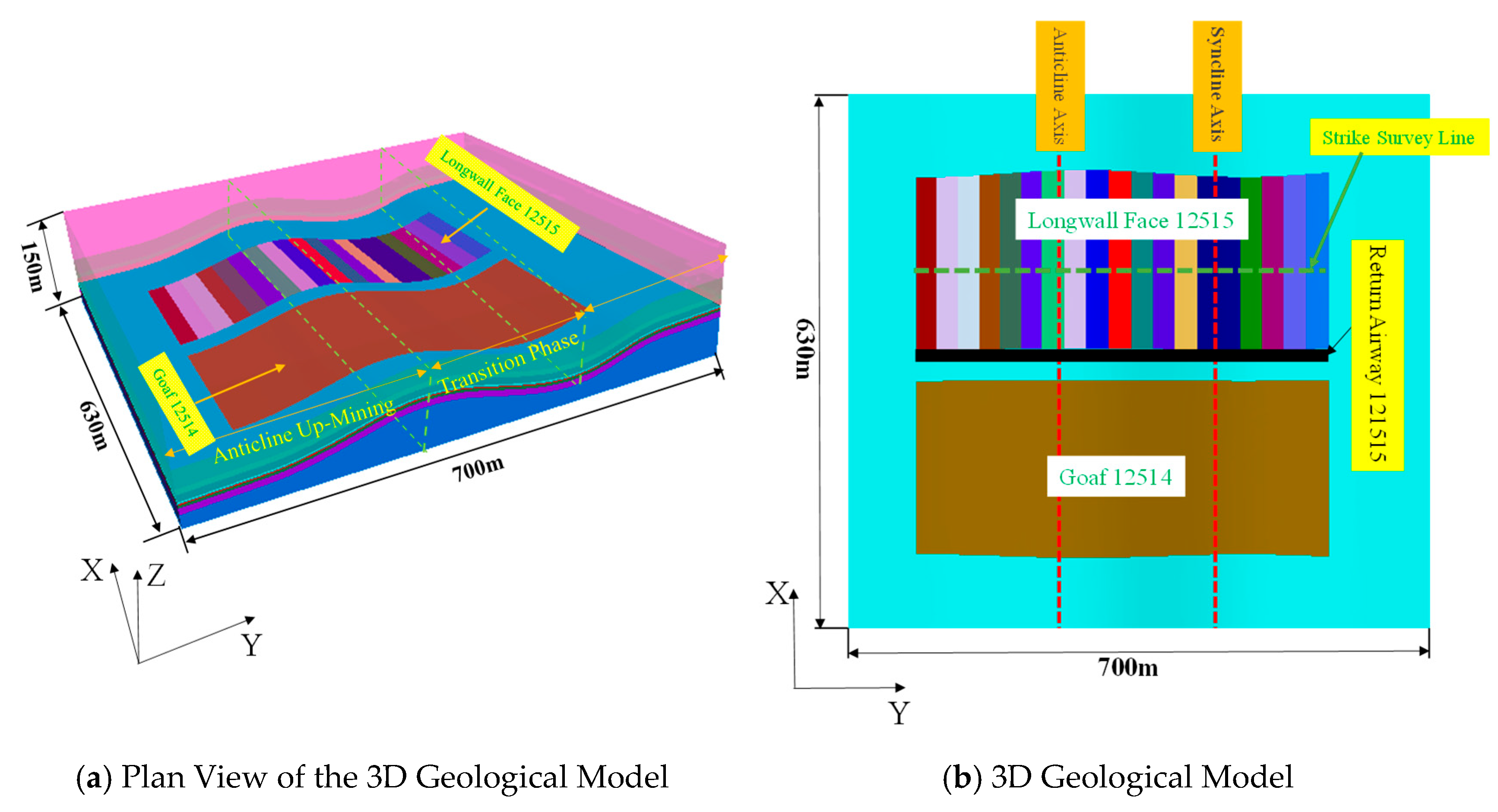

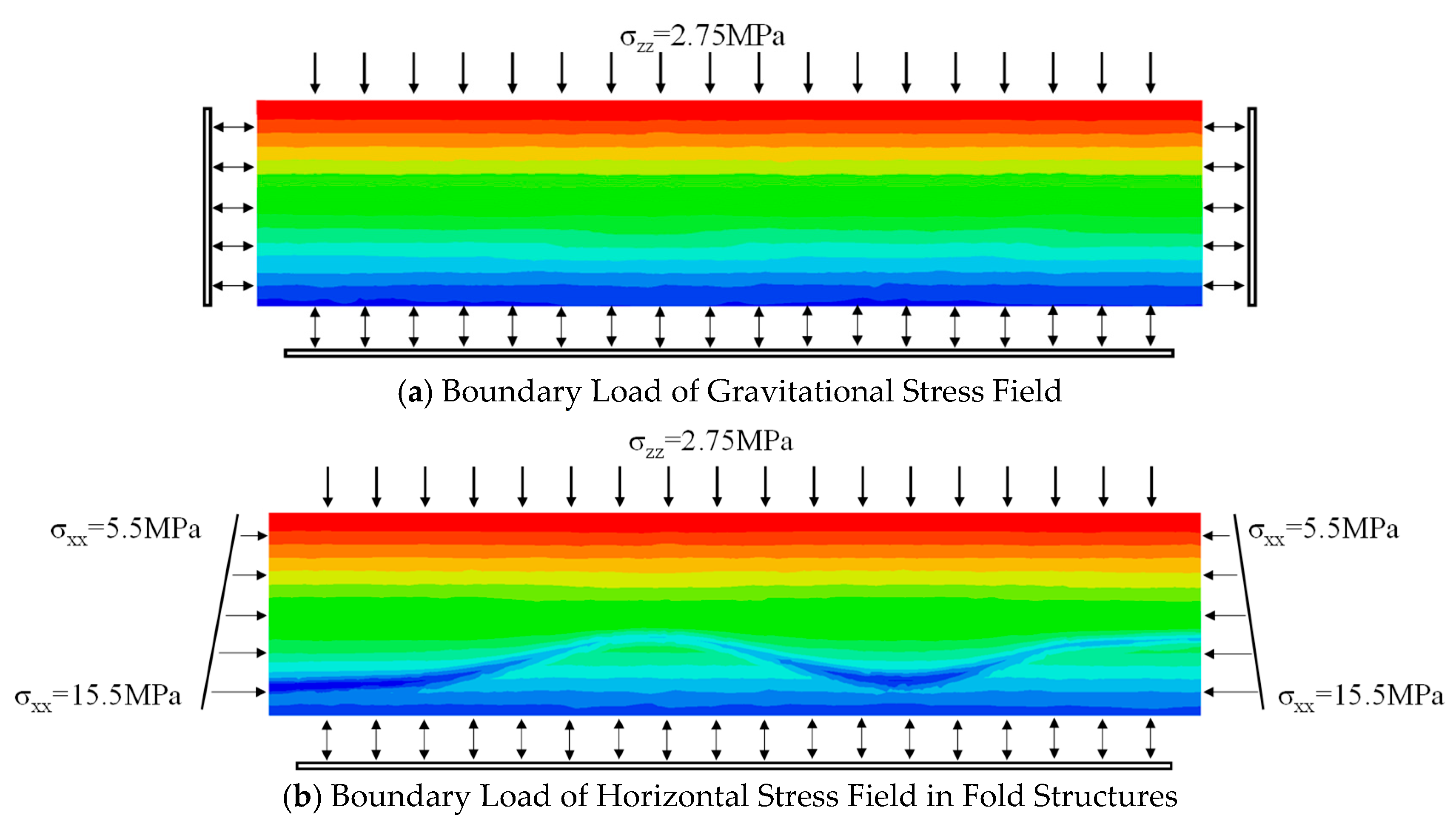

3.1. Establishment of Numerical Model

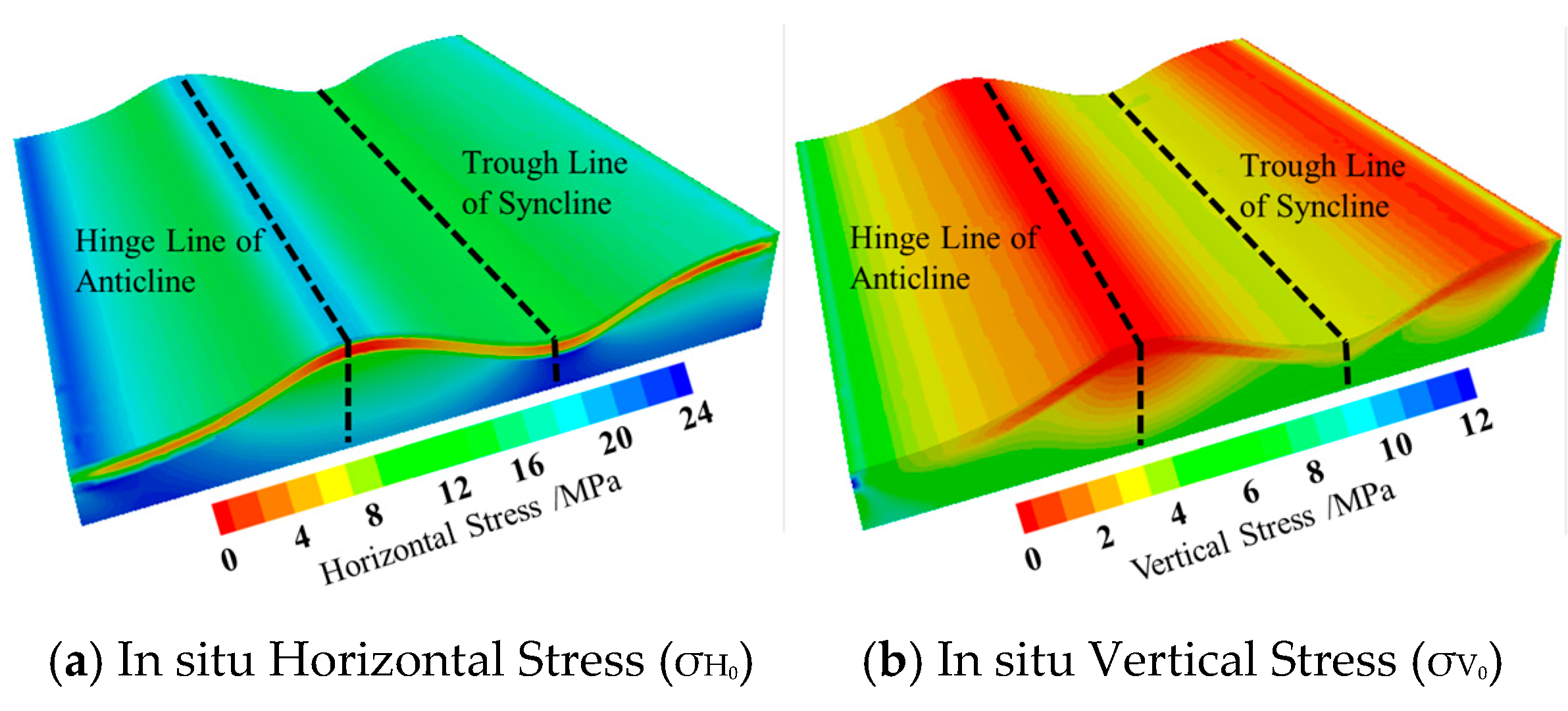

3.2. Initial In Situ Stress Distribution Characteristics in Fold Structure Zones

3.3. Stress Distribution Characteristics in Adjacent Gob Areas of Fold Structure Zones

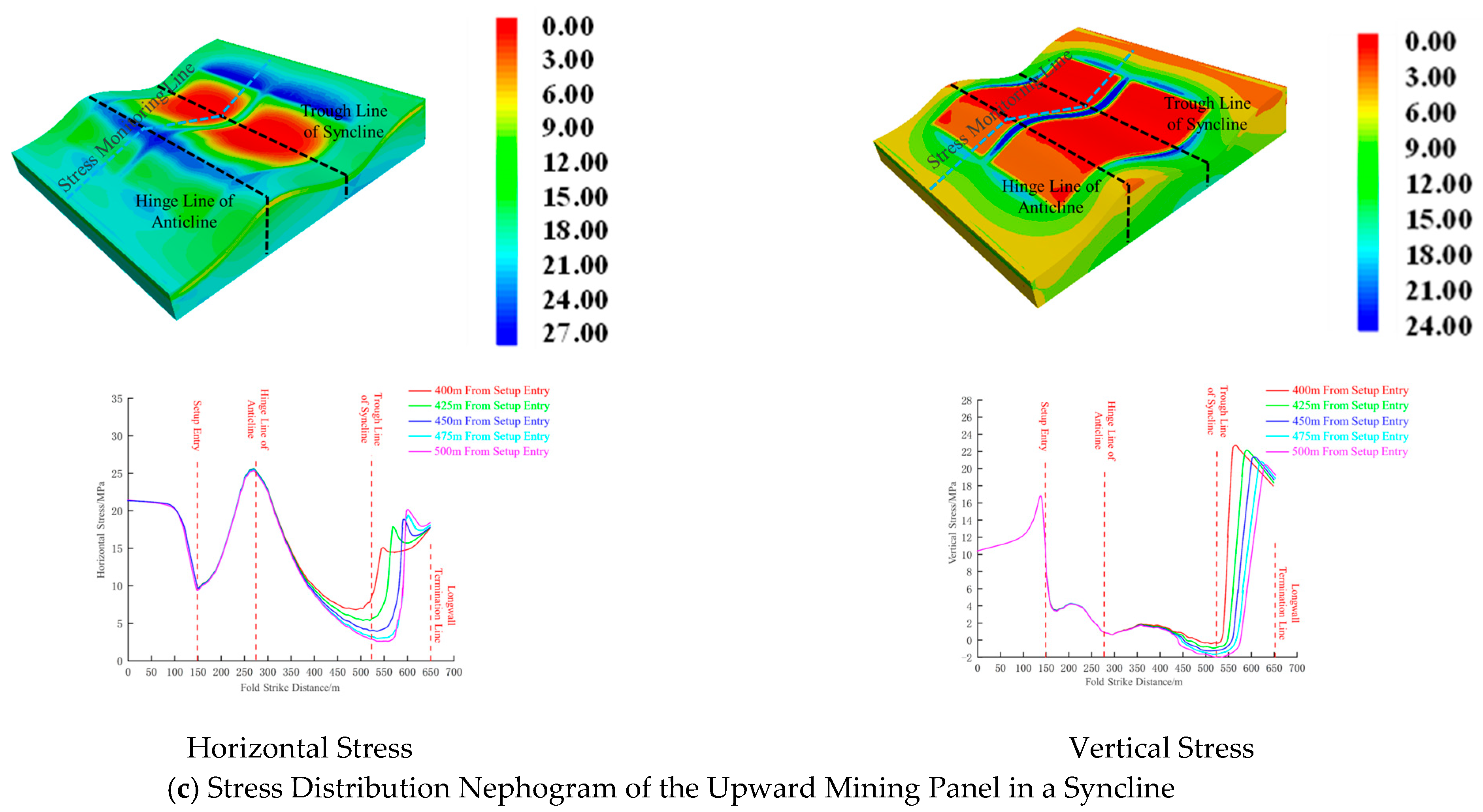

3.4. Stress Distribution Characteristics During Mining in the Current Working Face of Fold Structure Zones

4. Evolution Patterns and Mechanism Analysis of Surrounding Rock Failure and Instability During Mining in Fold Structure Zones

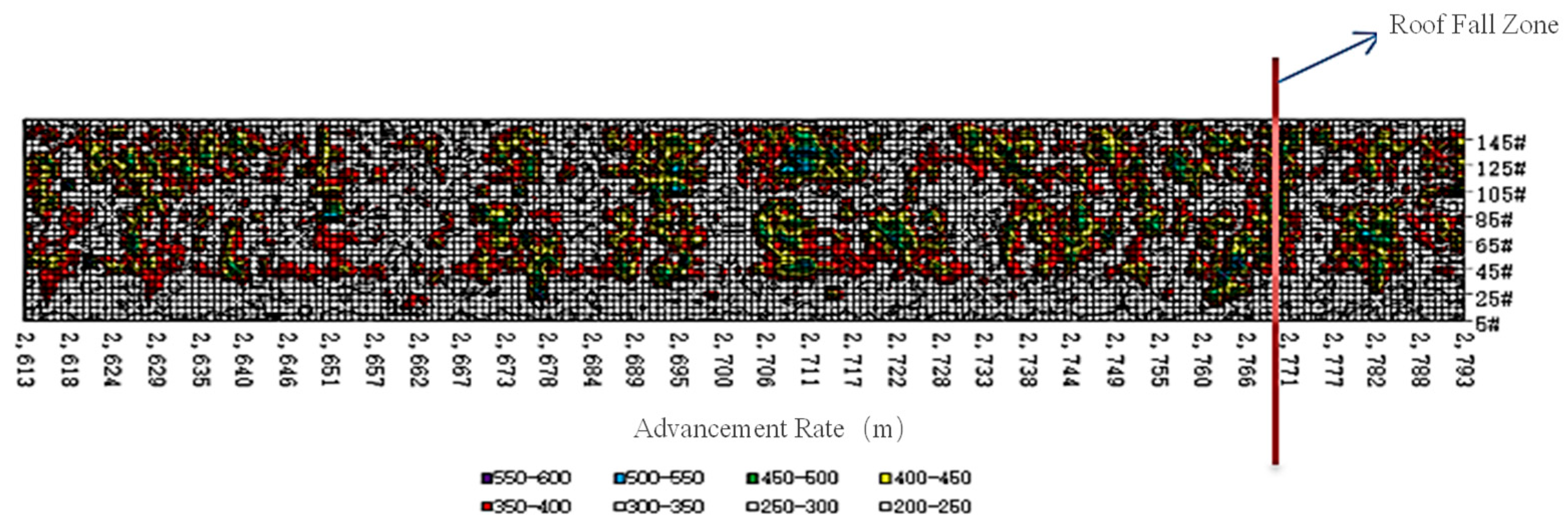

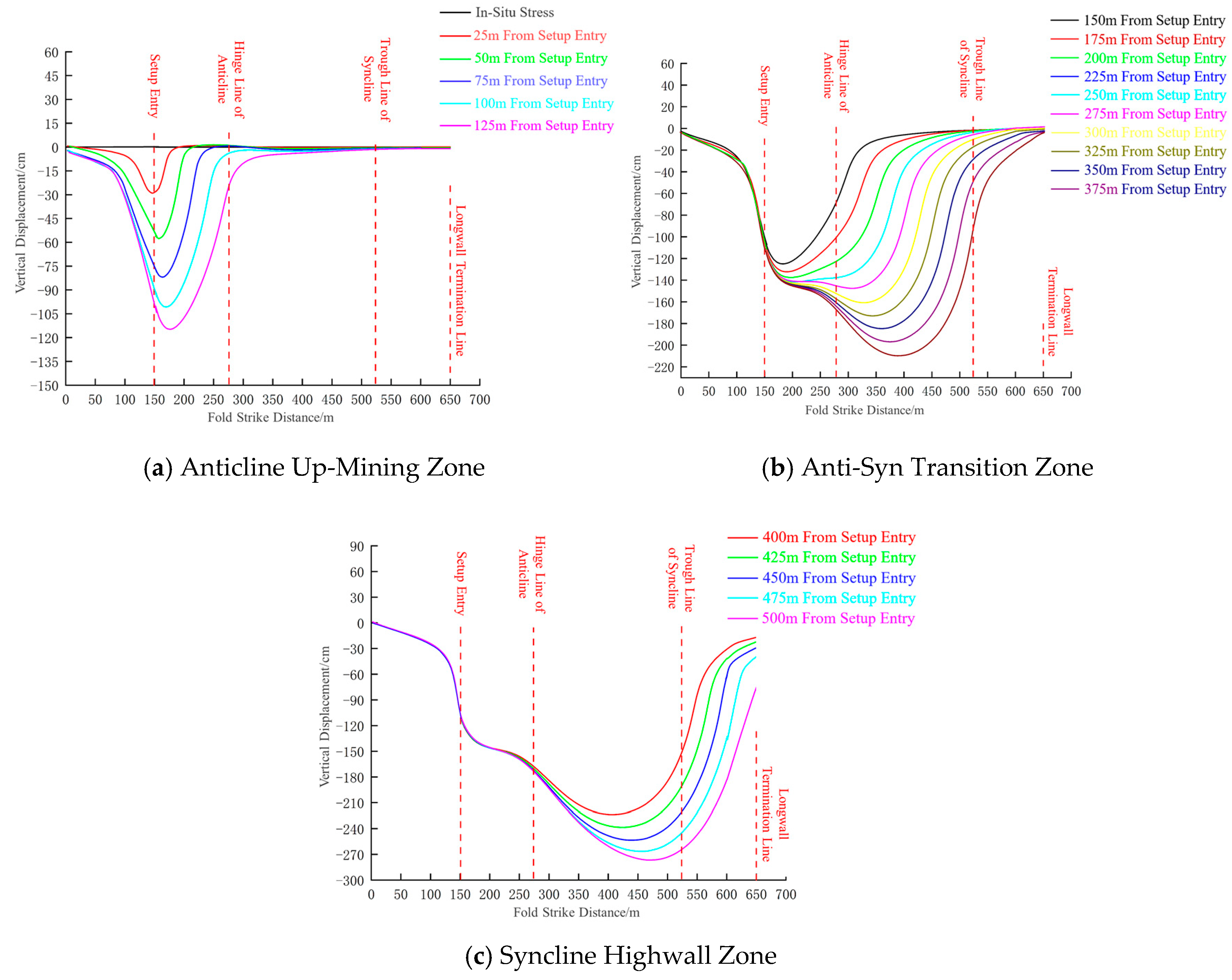

4.1. Evolution Patterns of Immediate Roof Displacement in Fold Structure Working Faces

4.2. Mechanism of Surrounding Rock Failure and Instability During Mining in Fold Structure Working Faces

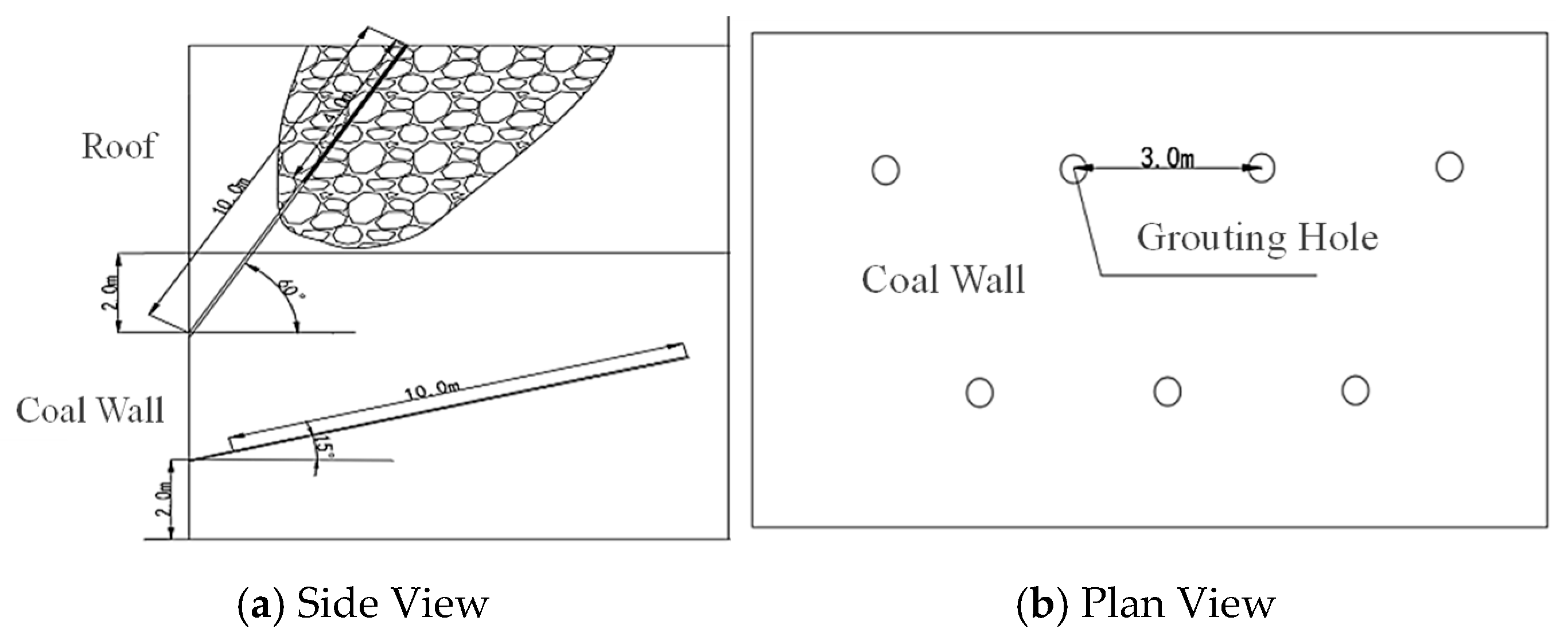

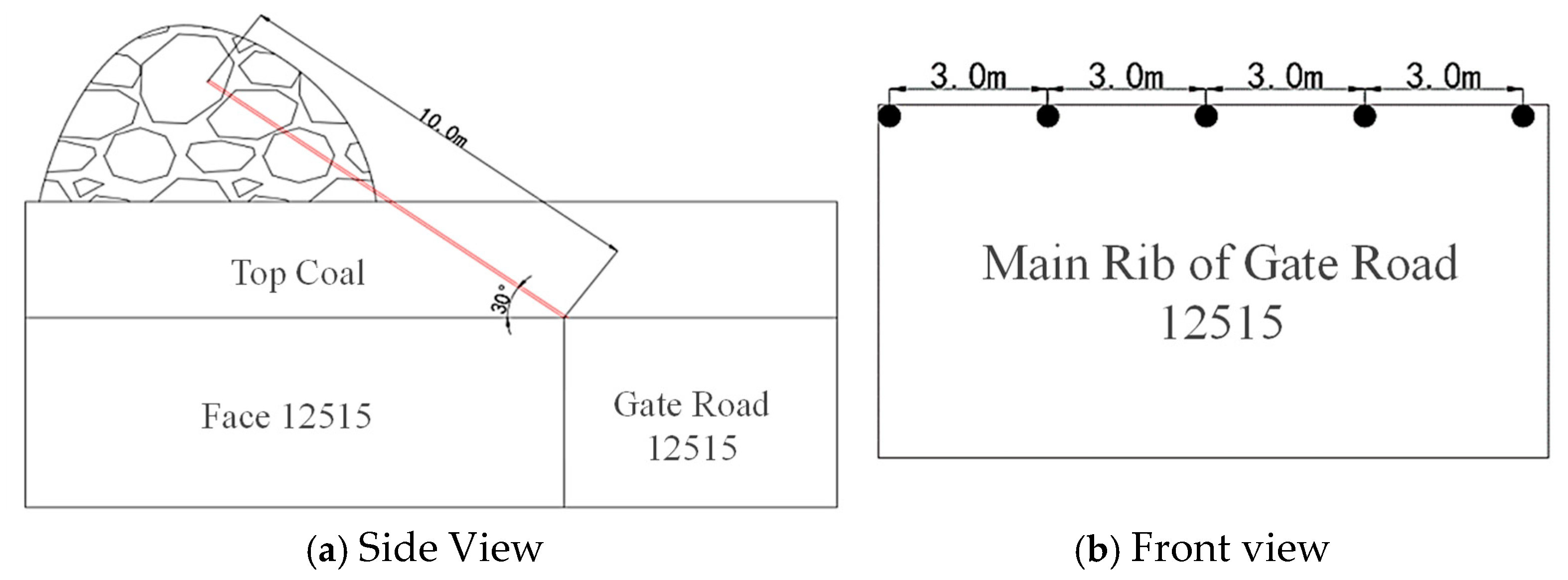

5. Surrounding Rock Control Technology for Mining in Fold Structure Zones

5.1. Principles of Surrounding Rock Control in Mining Faces Within Fold Structural Zones

5.2. Surrounding Rock Control Strategy for Roadways in Fold Structural Zones

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Cao, A.; Guo, W.; Dou, L.; Wen, Y.; Xue, C.; Hu, Y.; Lv, D. Rock burst mechanism and characteristics of roadway in “fault-fold” area. J. Min. Saf. Struct. Eng. 2023, 40, 69–81+90. [Google Scholar]

- Kang, H.; Wu, Z.; Gao, F.; Ju, W. Effect of geological structures on in-situ stress distribution in underground coal mines. Chin. J. Rock Mech. Eng. 2012, 31 (Suppl. S1), 2674–2680. [Google Scholar]

- Wang, H.; Deng, D.; Jang, C.; Shi, R.; Yan, X. Study on evolution characteristics of uneven stress field in mining induced fold tectonic area. Coal Sci. Technol. 2020, 48, 59–69. [Google Scholar]

- Hu, G.-D.; Cui, H.-Q.; Guan, J. Numerical simulation of stress distribution in small foldof coal seam. J. Saf. Environ. 2016, 16, 54–57. [Google Scholar]

- He, H.; Dou, L.; Gong, S.; Zhou, P.; Xue, Z.; Jiang, H. Research on Seismicity in High Tectonic Stress Zones. J. China Univ. Min. Technol. 2011, 40, 7–13. [Google Scholar]

- Wang, C.; Jiang, F.; Liu, J. The Controlling Effect of Structures on Rockburst and Case Analysis. J. China Coal Soc. 2012, 37 (Suppl. S2), 263–268. [Google Scholar]

- Wang, Z.; Kang, H.; Lin, J. Research on the Influence of Folded Structure Stress on Roadway Support. Coal Sci. Technol. 2011, 39, 25–28. [Google Scholar]

- Jing, G. Research on Stress Evolution and Rockburst Incubation in Thick Coal Seam Mining in Folded Structure Zones. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2017. [Google Scholar]

- Chen, G. The Mechanism of the Effect of Maximum Horizontal Stress on Rockburst and Its Application. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2009. [Google Scholar]

- Wang, S.; Zhang, X. The Relationship Between Geological Structures and Stress in Coal Mine Roadways. J. China Coal Soc. 2008, 33, 738–742. [Google Scholar]

- Guo, C.; Zhang YJiang, L.; Sun, D.; Xiong, T.; Du, Y.; Zheng, G. Rockburst Mechanism and Suitable Tunnel Section in Deep-Buried Tunnels in Folded Structures. Chin. J. Rock Mech. Eng. 2012, 31 (Suppl. S1), 2758–2766. [Google Scholar]

- Shi, Q.; Pan, Y.; Li, Y. Typical Cases of Rockburst in China and Analysis. Coal Min. 2005, 10, 13–17. [Google Scholar]

- Zhou, Y.; Lin, G.; Gong, F.; Liu, S.; Zhang, D. Changes in the Maximum Principal Stress and Horizontal Strain During the Deformation of a Single Fold and Influencing Factors. Geotecton. Metallog. 2007, 31, 37–43. [Google Scholar]

- Wang, J. The Impact of Folds and Flexures on Coal Seam Mining in Yangmei No. 5 Mine. Coal Min. 2015, 20, 20–22. [Google Scholar]

- Cao, A.; Xue, C.; Wu, Y.; Wang, S.; Guo, W. Mechanism and Prevention of Rockburst in Coal Mining in Folded Structure Zones. Coal Sci. Technol. 2021, 49, 82–87. [Google Scholar]

- Chen, M. The Impact of Folded Structures on Coal Seam Mining. Inn. Mong. Coal Econ. 2017, 10, 5–6. [Google Scholar]

- Wu, Y. Research on the Stress Field Distribution and Evolution of Overburden Spatial Structure in Folded Structure Zones. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2018. [Google Scholar]

- Bu, W.; Xu, H.; Zhao, Y. Analysis of Overburden Deformation and Stress in Folded Structures Based on Curved Beam Theory. J. Min. Saf. Eng. 2019, 36, 827–833. [Google Scholar]

- Liu, B.; Li, X.; Xie, C. Numerical Experimental Analysis of Coal Mining Subsidence in Folded Structure Zones. Jiangxi Coal Sci. Technol. 2016, 3, 12–15. [Google Scholar]

- Tian, C.; Yang, Z.; Li, G. Three-Dimensional Similarity Simulation of Mining Pressure in Large-Height Working Faces in Folded Structure Zones. J. Heilongjiang Univ. Sci. Technol. 2023, 33, 861–868. [Google Scholar]

- Tang, L.; Tu, S.; Tu, H.; Zhang, L.; Li, W.; Miao, K.; Zhao, H.; Ma, J. Mining stress evolution law and control technology of surrounding rock in fold structure area. J. Min. Saf. Eng. 2024, 1–11. Available online: http://kns.cnki.net/kcms/detail/32.1760.TD.20240412.1751.002.html (accessed on 5 May 2025).

- Lu, C.; Zhang, X.; Xiao, Z.; Wang, C.; Wang, B.; Zhou, T.; Li, H.; He, Z. Study on controlling law of fold structure on evolution of mining stress in deep mines. Coal Sci. Technol. 2020, 48, 44–50. [Google Scholar]

| Name of Stratum | The Angle of Internal Friction/(°) | Shear Modulus of Elasticity/GPa | Bulk Modulus/GPa | Cohesion/MPa | Tensile Strength/MPa | Density Kg/m−3 |

|---|---|---|---|---|---|---|

| Siltstone | 38 | 8.1 | 10.8 | 3.5 | 3.20 | 2480 |

| Fine Sandstone | 42 | 13.5 | 18.0 | 15.3 | 3.50 | 2490 |

| Sandy Mudstone | 29 | 1.7 | 2.3 | 2.0 | 1.30 | 2350 |

| Gritstone | 34 | 2.9 | 4.2 | 5.0 | 1.90 | 2560 |

| Coal | 26 | 1.5 | 1.8 | 1.3 | 1.22 | 1930 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Li, G.; Wang, W.; Liu, H.; Wang, R.; Zhang, H.; Yuan, S. Distribution Characteristics of Mining-Induced Stress Fields and Surrounding Rock Control Technology in Adjacent Working Faces Within Fold Structure Zones. Processes 2025, 13, 1534. https://doi.org/10.3390/pr13051534

Wang J, Li G, Wang W, Liu H, Wang R, Zhang H, Yuan S. Distribution Characteristics of Mining-Induced Stress Fields and Surrounding Rock Control Technology in Adjacent Working Faces Within Fold Structure Zones. Processes. 2025; 13(5):1534. https://doi.org/10.3390/pr13051534

Chicago/Turabian StyleWang, Jingya, Gao Li, Wencai Wang, Hu Liu, Rui Wang, Hao Zhang, and Shengxiao Yuan. 2025. "Distribution Characteristics of Mining-Induced Stress Fields and Surrounding Rock Control Technology in Adjacent Working Faces Within Fold Structure Zones" Processes 13, no. 5: 1534. https://doi.org/10.3390/pr13051534

APA StyleWang, J., Li, G., Wang, W., Liu, H., Wang, R., Zhang, H., & Yuan, S. (2025). Distribution Characteristics of Mining-Induced Stress Fields and Surrounding Rock Control Technology in Adjacent Working Faces Within Fold Structure Zones. Processes, 13(5), 1534. https://doi.org/10.3390/pr13051534