Abstract

As people pay increasing attention to the clean and efficient mining and utilization of coal resources, efforts to improve the utilization rate of coal, modify coal resources, and carry out coal gasification have become more and more important. The deformation characteristics of lignite, the most appropriate coal type for underground coal gasification, are intricately linked to its mechanical properties, permeability characteristics, and mining efficiency throughout the extraction process. The deformation and pore structure characteristics of lignite from room temperature to 650 °C have been studied through high-temperature triaxial penetration testing systems, NMR, and X-CT. As the temperature increases, the porosity of lignite rises, its mechanical strength decreases, and significant deformation occurs, and high temperatures promote pore development in lignite. The axial deformation of lignite pyrolysis is divided into three stages: the dehydration and degassing at room temperature to ~200 °C, the slow deformation between 200 °C and 300 °C, and the pyrolysis deformation from 300 °C to 650 °C. Significant deformation occurs during both the dehydration degassing and pyrolysis deformation stages. Between 250 °C and 650 °C, a large number of highly interconnected pore networks form. Investigating the deformation and pore structure characteristics of lignite is crucial for elucidating its mechanical and permeability features under varying temperature and pressure conditions.

1. Introduction

Lignite, the principal type of low-rank coal, is a significant energy resource. Lignite is challenging to store because of its elevated water and volatile matter content [1]. At present, the majority of lignite is combusted directly, resulting in considerable pollution from the emission of CO and CO2 into the atmosphere. The advancement of underground coal gasification (UCG) technology presents a significant potential to address the constraints of lignite [2,3,4,5,6].

Lignite experiences significant physical and chemical transformations under the influence of temperature and pressure [7]. The internal structure of lignite can be readily determined by permeability tests. Lignite experiences intricate chemical and physical transformations, including dehydration and pyrolysis, due to temperature and stress. A distinction exists from traditional coal rock deformation [8,9]. The in situ steam injection process of lignite demonstrates that lignite deformation under stress modifies both the direction and magnitude of the stress on the coal seam, as well as alters the material transmission pathway, thereby indicating a correlation between permeability and deformation.

Recent studies have examined the fluctuations of mechanical parameters in both conventional and triaxial circumstances, considering confining pressure and loading path [10,11,12,13,14]. The impact of temperature on the mechanical properties of coal under conditions of temperature and pressure is confined to its effect on coal strength [15]. Research indicates that all metamorphic coal demonstrates a propensity to diminish in strength with rising temperatures, and the pattern varies slightly among coal of different ranks. The rise in temperature augments the flexibility of coal, resulting in alterations to its mechanical behavior and lithology.

The deformation and failure characteristics of coal as a unique organic rock at elevated temperatures significantly differ from those at room temperature [16]. Research conducted by Bustin [17], Jiang Bo [18,19], Liu Junlai [20], and others has demonstrated that elevated temperatures significantly affect the deformation characteristics of both organic (coal) and inorganic rocks. The degree of metamorphism and the presence of volatile gases in coal are the primary factors contributing to its structural deformation. The primary deformation mechanisms of coal are high-rank deformation and low-rank coal toughness. V.L. Shkuratinik integrated uniaxial and triaxial compression tests with acoustic emission to investigate the internal fracture characteristics of coal samples during compression [21,22,23]. Consequently, they conducted further research on the acoustic emission memory effect of anthracite subjected to cyclic loading [24]. A.S. Voznesenskii, Wang Enyuan, and Nie Baisheng [25,26,27] investigated acoustic emission events during various stages of coal sample deformation and the frequency spectrum characteristics of coal fracture acoustic emission, discovering that alterations in the frequency spectrum characteristics of coal acoustic emission are intricately linked to the processes of coal deformation and fracture. Zou Yinhui [28] employed damage theory and defect distribution characteristics to formulate the theoretical model of acoustic emission during coal rock failure.

X-ray computed tomography (X-CT) and nuclear magnetic resonance (NMR) technologies have been extensively employed in experimental investigations of the mesoscopic properties of coal and rock in recent years [29,30,31,32,33]. Zhu Qingzhong et al. [34] employed CT technology to investigate the fracture patterns and permeability of high-rank coal matrices at varying degrees of expansion. The decrease in permeability was mostly attributed to the diminishment of pore size and interconnected porosity. Cheng Ming et al. [35] employed nuclear magnetic resonance (NMR) and X-ray computed tomography (X-CT) methods to investigate the compressibility of pores and fractures in low-rank coal, examining its correlation with heterogeneity and the impact of fracture morphology and mineral composition on compressibility. Zhao Yang et al. [36,37] employed NMR to analyze the pore structures of coal samples. They examined the correlations among pore structure, physical attributes, and the fractal dimension derived from NMR T2 spectra.

Based on the above research, most studies on the pore structure and deformation characteristics of lignite pyrolysis have been conducted under uniaxial stress or low-temperature conditions. There is limited research on triaxial stress or high-temperature triaxial coupling conditions. Therefore, a triaxial stress high-temperature gas heating reaction system was designed and developed. This system allowed us to study the deformation characteristics of lignite pyrolysis under triaxial stress conditions. In addition, we combined NMR technology and X-CT scanning technology to investigate the pore structure characteristics of lignite pyrolysis under triaxial stress conditions. The deformation and pore structure characteristics of lignite pyrolysis with temperature under triaxial stress were obtained, providing a theoretical support for underground coal gasification.

2. Materials and Methods

2.1. Sample Preparation

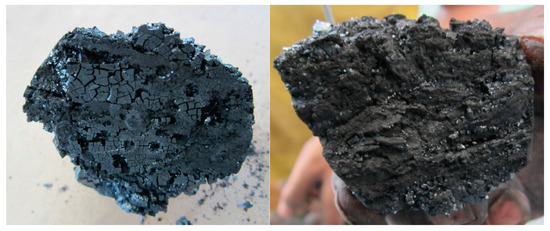

The lignite specimens were sourced from the No. 5 coal seam at the Yuanbaoshan open-pit coal mine located in Chifeng City, Inner Mongolia Autonomous Region, China. The samples were treated and polished to produce cylinders (Φ7 × 10 mm and Φ50 × 100 mm), with both ends ground flat. The lignite specimens are illustrated in Figure 1.

Figure 1.

Lignite samples.

The lignite is located in the lower cretaceous Fuxin formation of the Mesozoic erathem. Proximate and ultimate analyses of lignite were conducted, and the results are listed in Table 1. It is a low-ash and medium-sulfur moderately clean coal, with poor calorific value, poor thermal stability, ash content of 9.17%, moisture of 18.56%, and volatile matter content of 54.6%. It exhibits good chemical reactivity with CO2 and a relatively high tar yield.

Table 1.

Proximate and ultimate analyses of lignite.

2.2. Experimental Equipment and Methods

2.2.1. High-Temperature Triaxial Experiment

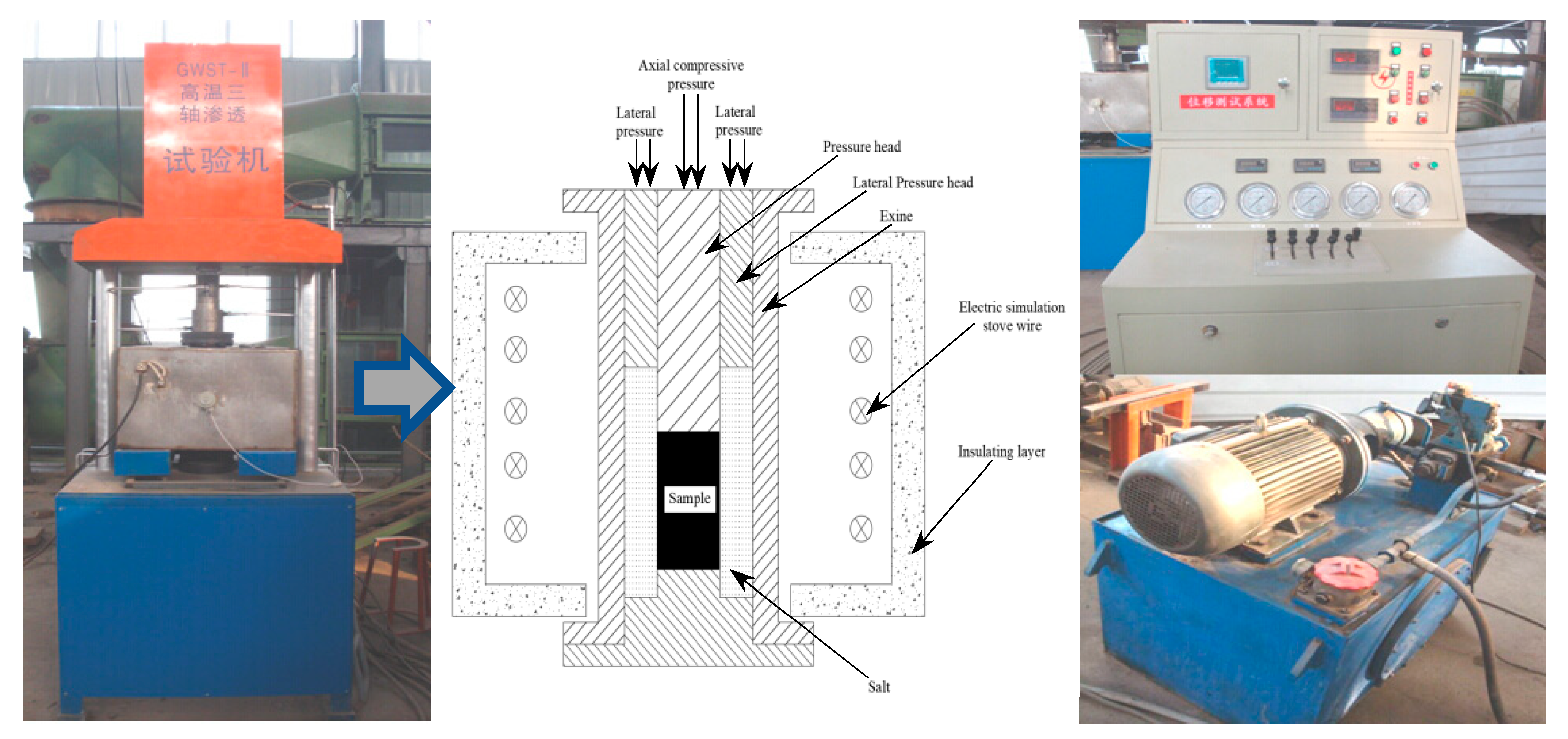

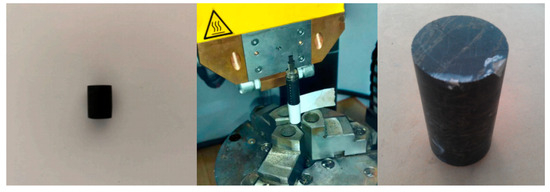

A critical aspect for the successful implementation of underground coal gasification of lignite is a comprehensive investigation of the deformation features and affecting factors of lignite. Current testing apparatus typically operate at below 200 °C [9] and are incapable of systematically assessing the deformation features of lignite during the pyrolysis process at room temperature to 650 °C. The high-temperature triaxial penetration testing system utilized in this experiment, depicted in Figure 2, comprises a power system, a test control system, a temperature measuring and control system, a cooling system, and a permeation chamber. It can heat the sample to 650 °C and also offer insulation and pressurization.

Figure 2.

High-temperature triaxial testing system.

The test bench can assess the deformation of coal and rock within a temperature range of 25 °C to 650 °C. The lateral pressure of the test bench utilizes a solid pressure transfer mechanism, in which the load is conveyed by sodium chloride composed of very small particles. The axial and confining pressure loads are regulated independently during loading. The sample’s axial deformation is quantified using a dial indicator, while the heating temperature is monitored with a thermocouple. The testing machine has an axial and confining maximum load of 10,000 kN. The maximum axial and confining pressure of the specimen is 25 MPa, and the maximum thermal stability temperature of the sample is 650 °C.

This experiment aims to simulate the temperature and deformation of lignite under their original rock stress state. The burial depth of lignite sample is 300 m, the axial pressure is set to 7.5 MPa, and the lateral pressure is 1.2 times the axial pressure, which is 9 MPa. First, weigh and install the specimen, and purge the internal air by introducing nitrogen. Then, set the axial and confining pressure to 7.5 MPa and 9 MPa, raise the temperature to 25 °C, and maintain the pressure for 4 h. Finally, while keeping the set axial and confining pressures constant, heat the specimen. The applied temperatures are 50 °C, 100 °C, 150 °C, 200 °C, 250 °C, 300 °C, 350 °C, 400 °C, 450 °C, 500 °C, 550 °C, 600 °C, and 650 °C at a rate of 10 °C/min, with each temperature stage maintained for 4 h. During the experiment, measure the specimen’s deformation every 10 min.

2.2.2. Experiment of NMR [32]

NMR is among the most swiftly progressing non-destructive testing methods in recent years. This study employed an NMR analyzer (MicroMR-12-025V, Newman Technology, Suzhou, China) to investigate the pore structure and fluid saturation of coal rock. The device’s primary frequency, probe diameter, and minimum echo time were 12 MHz, 25.4 mm, and 60 μs, respectively.

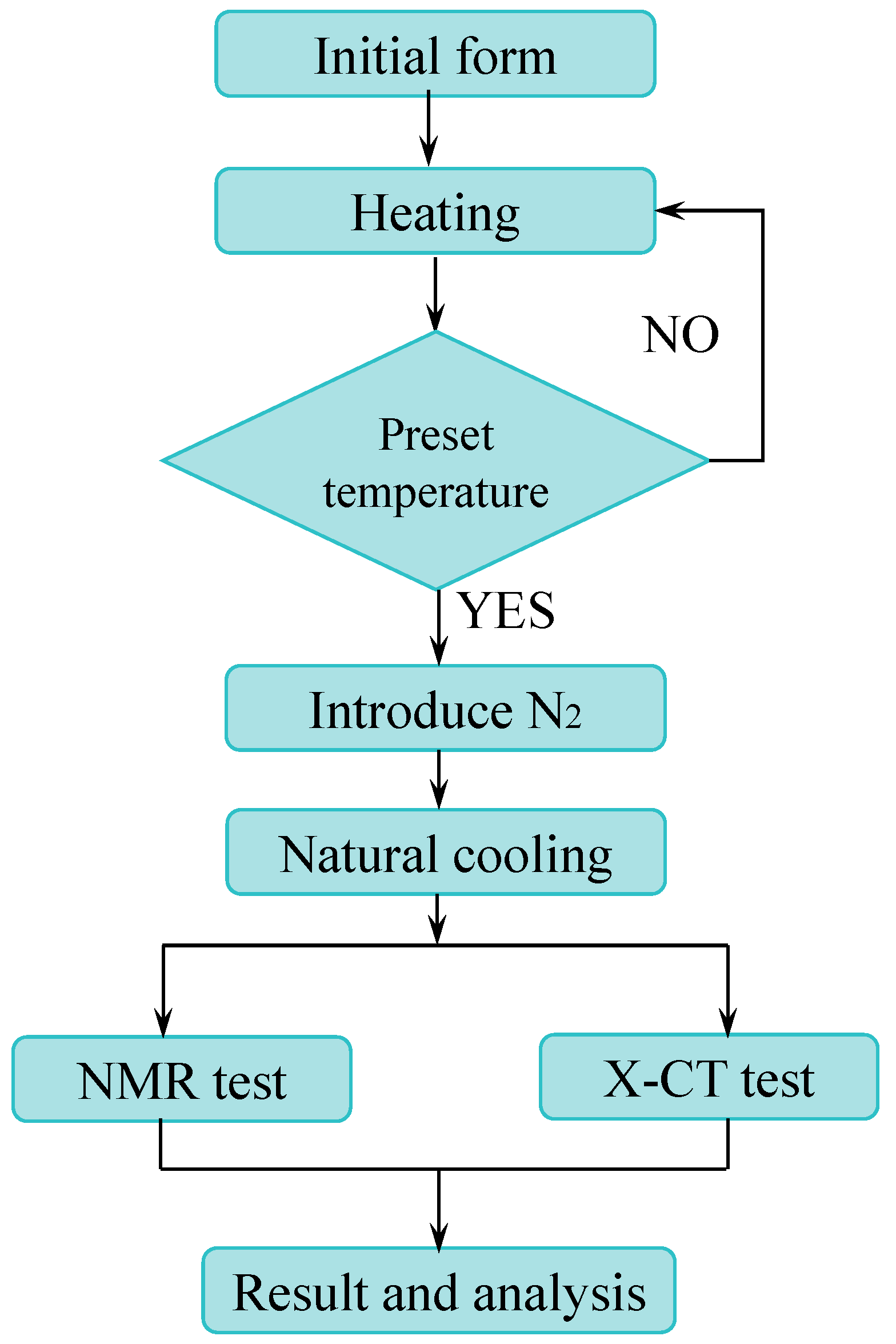

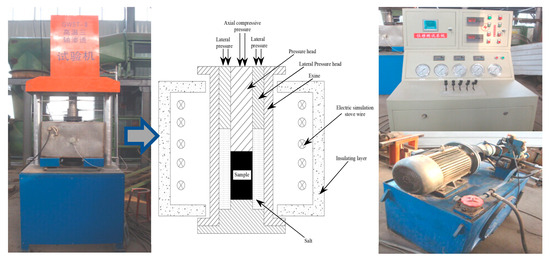

Lignite samples were initially analyzed using NMR at 25 °C, subsequently positioned on the reaction table, and heated to a predetermined temperature (150 °C, 250 °C, 350 °C, or 450 °C) at a rate of 10 °C/min. The temperature was maintained for one hour, and the samples were let to cool naturally under the protection of nitrogen gas. The naturally cooled samples were subsequently extracted and promptly sealed with wax, followed by testing the pertinent parameters using NMR. The specific process is shown in Figure 3.

Figure 3.

Experimental flowchart.

2.2.3. Experiment of X-CT [30]

This experiment utilized the μCT225kVFCB high-precision X-ray computed tomography testing and analysis equipment was developed by taiyuan university of technology and china academy of engineering physics in taiyuan, china. The test system consists of a micro-focus X-ray apparatus, a digital flat panel detector, a high-precision turntable fixture, a machine base, a horizontal movement mechanism, a data acquisition and processing system, and additional components. This technology is applicable for 3D X-CT scanning of diverse metallic and non-metallic materials. The magnification range spans from 1 to 400, the sample diameter runs from 1 to 50 mm, and the resolution of the scanning unit varies from 0.5 to 194 μm. The apparatus can identify pores measuring 0.5 μm in diameter and fractures with a breadth of 1 μm.

The lignite samples were subjected to heating at 150 °C, 250 °C, 350 °C, and 450 °C utilizing a high-temperature gas heating apparatus, maintaining a temperature deviation within 5 °C. The samples were maintained for one hour and subsequently allowed to cool naturally to below 25 °C. The samples were subsequently positioned on a rotating test bench of the μCT225kVFCB high-precision X-CT testing and analysis equipment for scanning, and the results were reconstructed in three dimensions. The specific process is shown in Figure 3.

3. Results

3.1. Deformation Characteristics of Lignite in the High-Temperature Triaxial Experiment

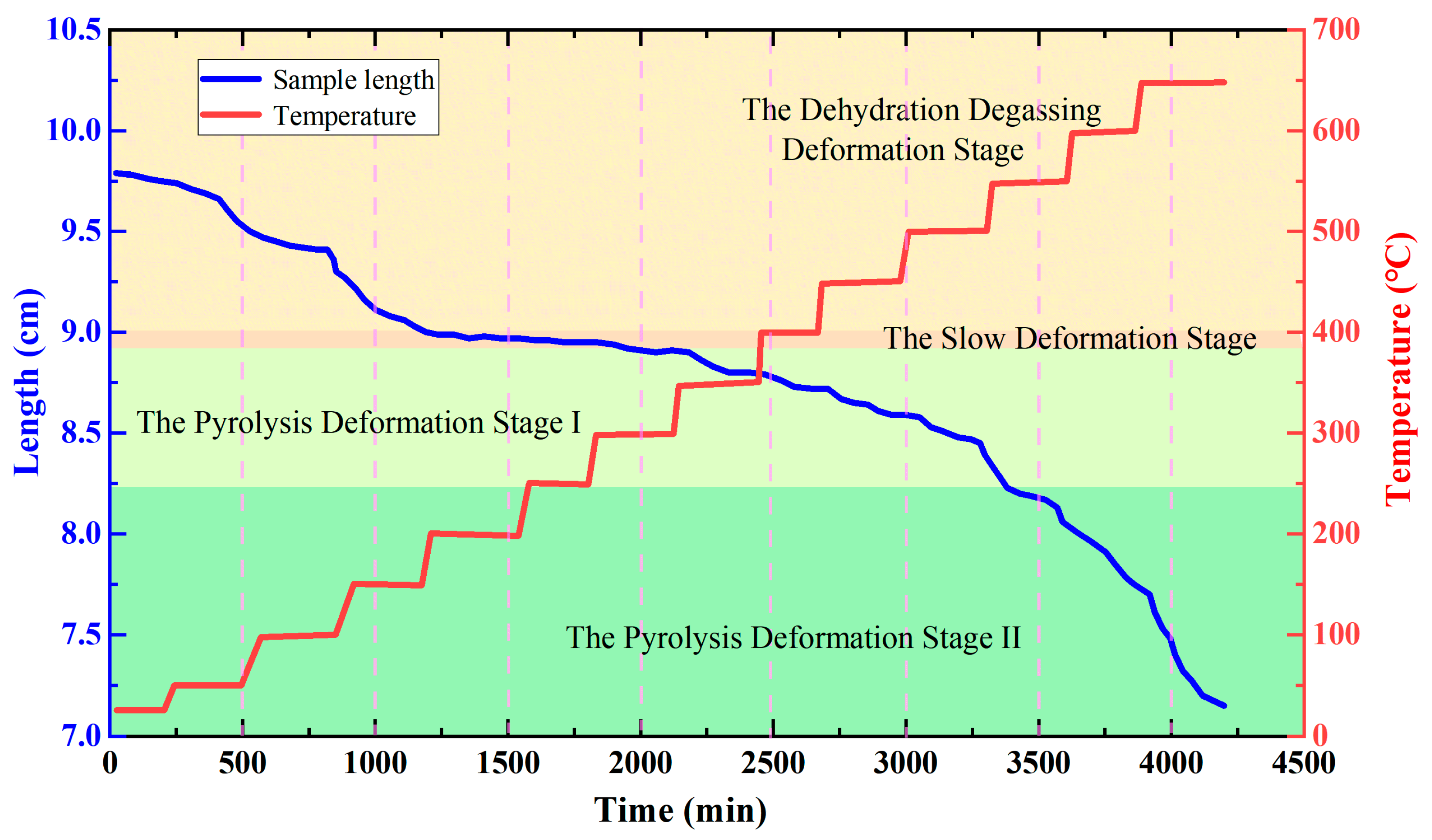

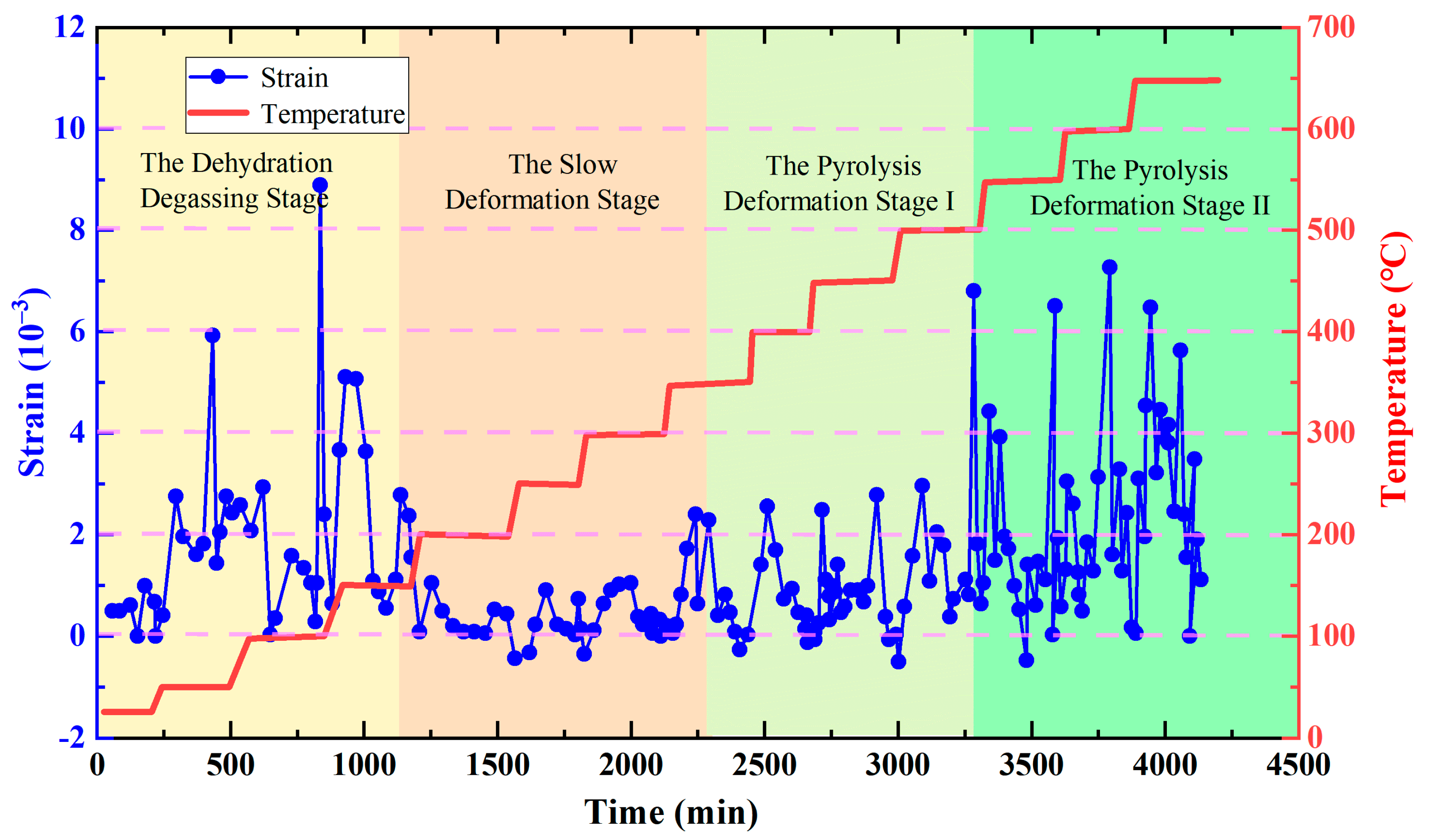

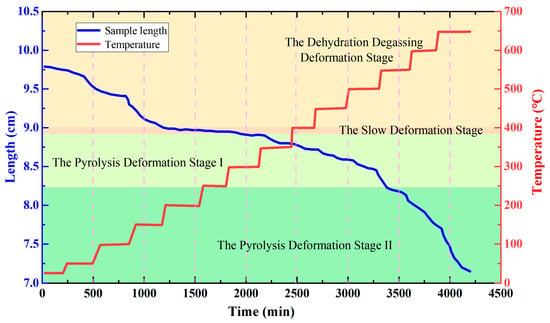

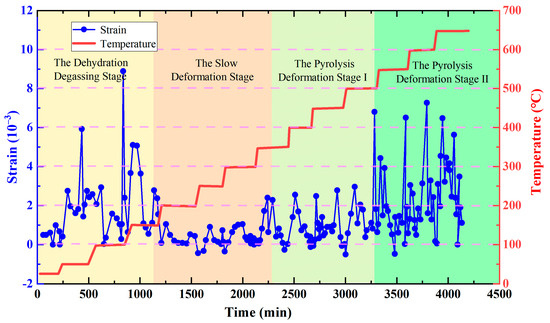

The lignite was heated from room temperature to 650 °C for 4116 min. The relationship curve between the length and strain of the lignite sample and time and temperature during the entire temperature change process was obtained, as shown in Figure 4 and Figure 5. The sample’s maximum heating temperature was 650 °C. The pyrolysis process was categorized into three stages based on the interplay of strain, temperature, and time. The process consisted of three stages: the initial stage involved heating from room temperature to 200 °C, the second stage entailed slow deformation from 200 °C to 300 °C, and the last stage was the pyrolysis deformation from 300 °C to 650 °C. The dial indication revealed variations in the sample’s axial length. The lignite sample was compressed from an initial length of 9.7896 cm to 7.1971 cm, resulting in an overall deformation of 2.5989 cm. The deformation ratio was 26.55 percent.

Figure 4.

Relationship between sample length, temperature, and time during heating.

Figure 5.

Relationship between sample deformation strain, temperature, and time during heating.

- (1)

- The Dehydration Degassing Deformation Stage

The initial stage involved dehydration, degassing, and deformation from the onset of temperature elevation to 1181 min, namely from room temperature to 200 °C. The sample contracted from 9.7896 cm to 8.9981 cm, resulting in a deformation length of 0.7979 cm and a deformation ratio of 8.15%. At this stage, the free water in the lignite evaporated rapidly at around 100 °C, while the bound water was also destroyed as the temperature increased. The extent of lignite deformation was quite pronounced, especially at approximately 100 °C.

- (2)

- The Slow Deformation Stage

This phase mostly pertained to a temperature range of 200 °C to 300 °C, with a corresponding duration of 1181 min to 2167 min. In comparison to a temperature of 200 °C, the axial length of lignite decreased by 0.096 cm, resulting in a deformation ratio of 0.98%. The strain–time curve indicates that the sample underwent expansion during the initial phase of insulation at 250 °C and 300 °C. At this stage, no chemical reactions occurred in the lignite. Under certain confining pressure conditions, the hard particles within the lignite itself are sufficient to resist the external load, preventing the overall coal matrix skeleton from being damaged. The deformation of lignite occurred gradually, with both the overall deformation and the rate of deformation being minimal.

- (3)

- The Pyrolysis Deformation Stage

Upon reaching a temperature of 300 °C, the sample’s deformation transitioned to a new phase, with future deformation mostly influenced by the pyrolysis of the lignite. The deformation process was categorized into two stages: 300 °C to 500 °C and 500 °C to 650 °C. The relevant time intervals were 2367 min to 3298 min and 3298 min to 4116 min, respectively. The ultimate length of the specimen at 650 °C was 7.1971 cm. The total deformation length of the sample was 1.705, and the deformation ratio was 17.42%. The deformation degree of the sample between 300 °C and 500 °C was markedly less than that observed at 500 °C. Between 300 °C and 500 °C, the lignite underwent initial pyrolysis. The carboxyl groups and some oxygen-containing functional groups within the lignite broke, accompanied by the release of various gases. As the temperature rose further to between 500 °C and 650 °C, the lignite underwent further pyrolysis. The macromolecular structure of lignite decomposed, releasing CO2 and CH4. During the initial pyrolysis stage, the lignite skeleton retained relatively high strength and a certain load-bearing capacity, with minimal deformation. During secondary pyrolysis, as the lignite underwent reactions such as polycondensation and flow, the lignite skeleton softened, its load-bearing capacity diminished, and deformation became more pronounced.

3.2. Evolution in Porosity Fissure Structure of Lignite by NMR [32]

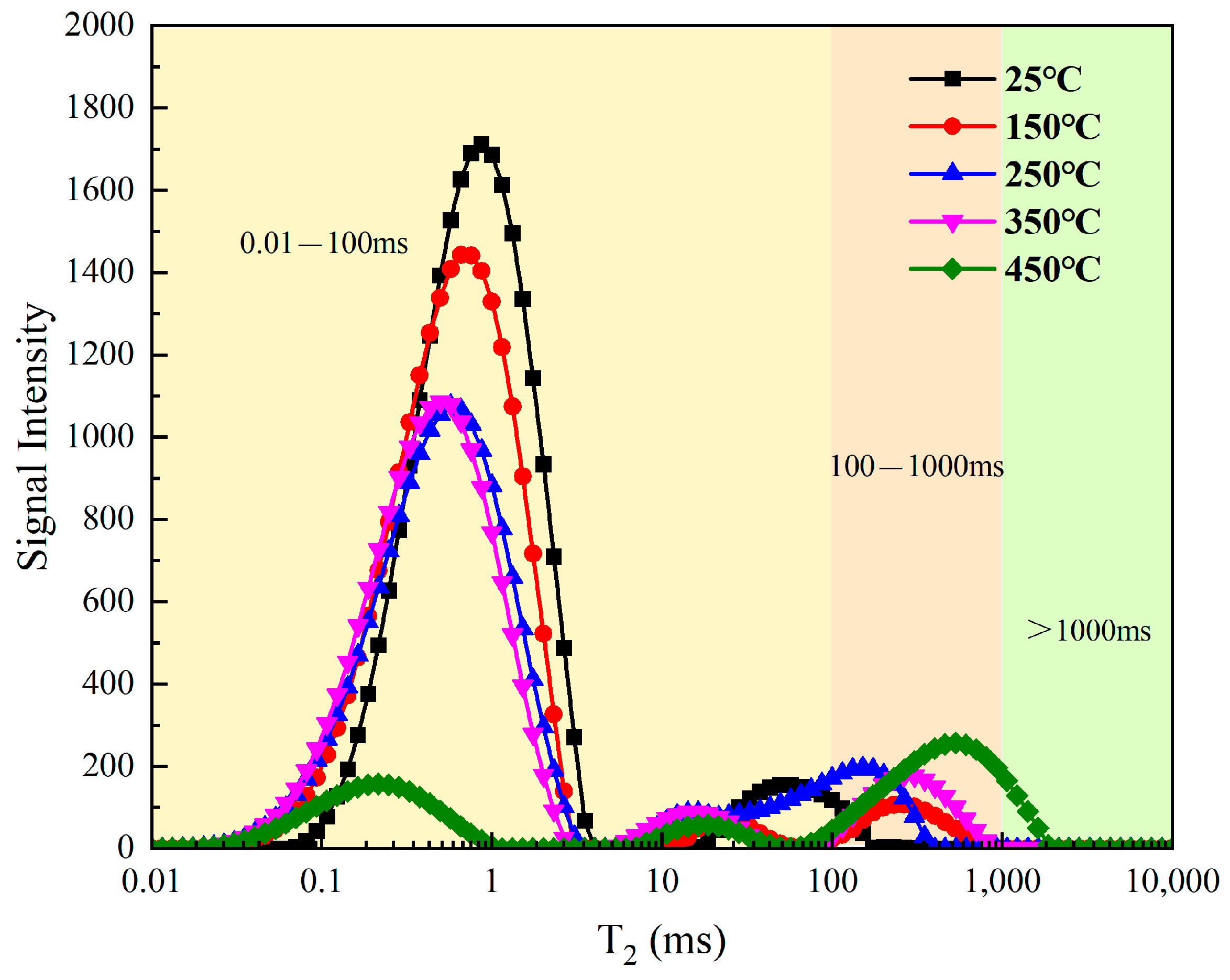

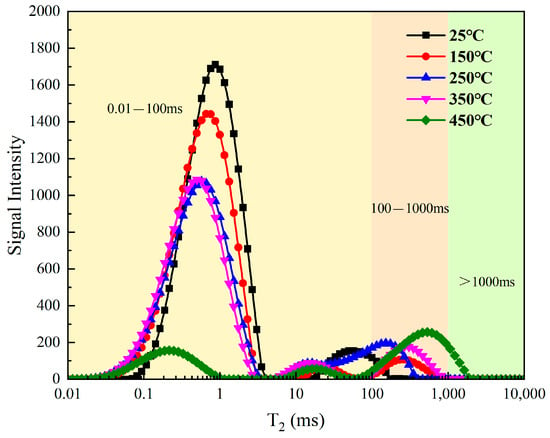

Figure 6 displays the T2 spectra of lignite subjected to various pretreatment temperatures, as acquired through NMR analysis. Significant disparities in signal intensity and T2 time are evident under varying temperature settings. The fundamental idea of NMR T2 spectral analysis of lignite pore fissures is that the lateral relaxation time of the 1H nuclei in the pore fissure water of lignite correlates with the pore radius. Consequently, an increase in pore size correlates with an extended relaxation time, and conversely.

Figure 6.

The T2 spectra of lignite.

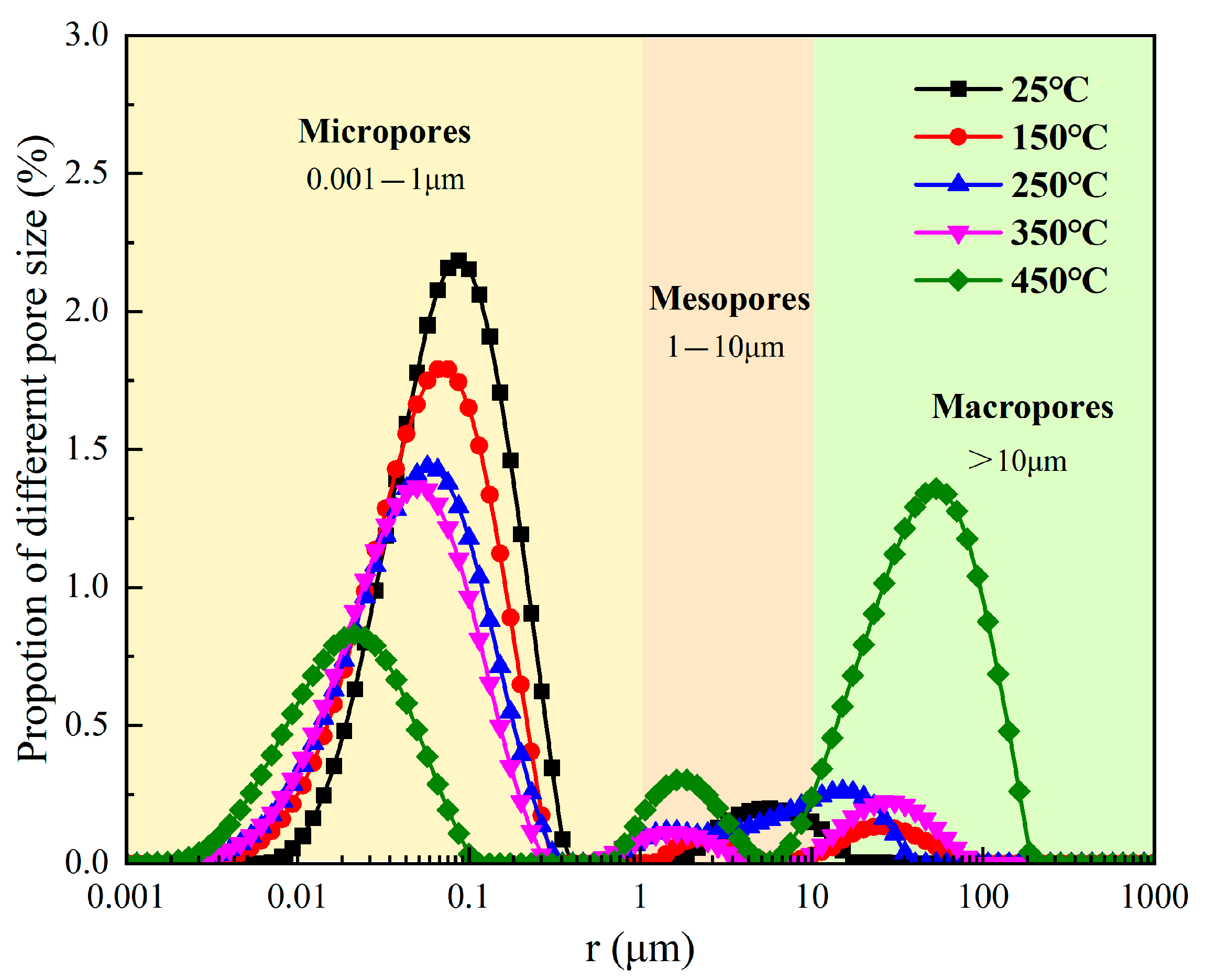

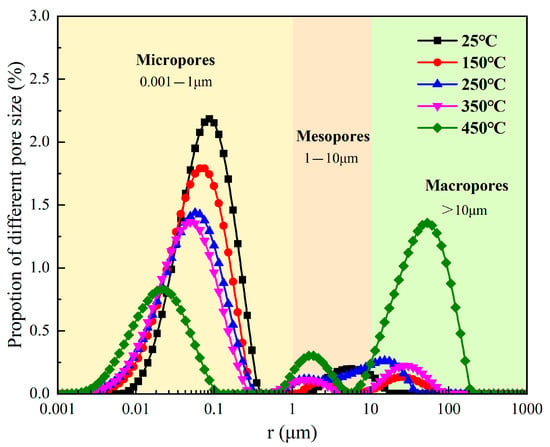

While the T2 spectrum can indicate the general architecture of the pores and fractures within lignite, it requires processing to more correctly characterize the distribution of pore sizes. Consequently, by analyzing the data acquired from NMR, the NMR T2 spectrum is converted into a pore size distribution graph. Figure 7 illustrates the pore size distribution of lignite derived from the lignite T2 spectrum presented in Figure 6.

Figure 7.

Pore size distribution diagram of lignite.

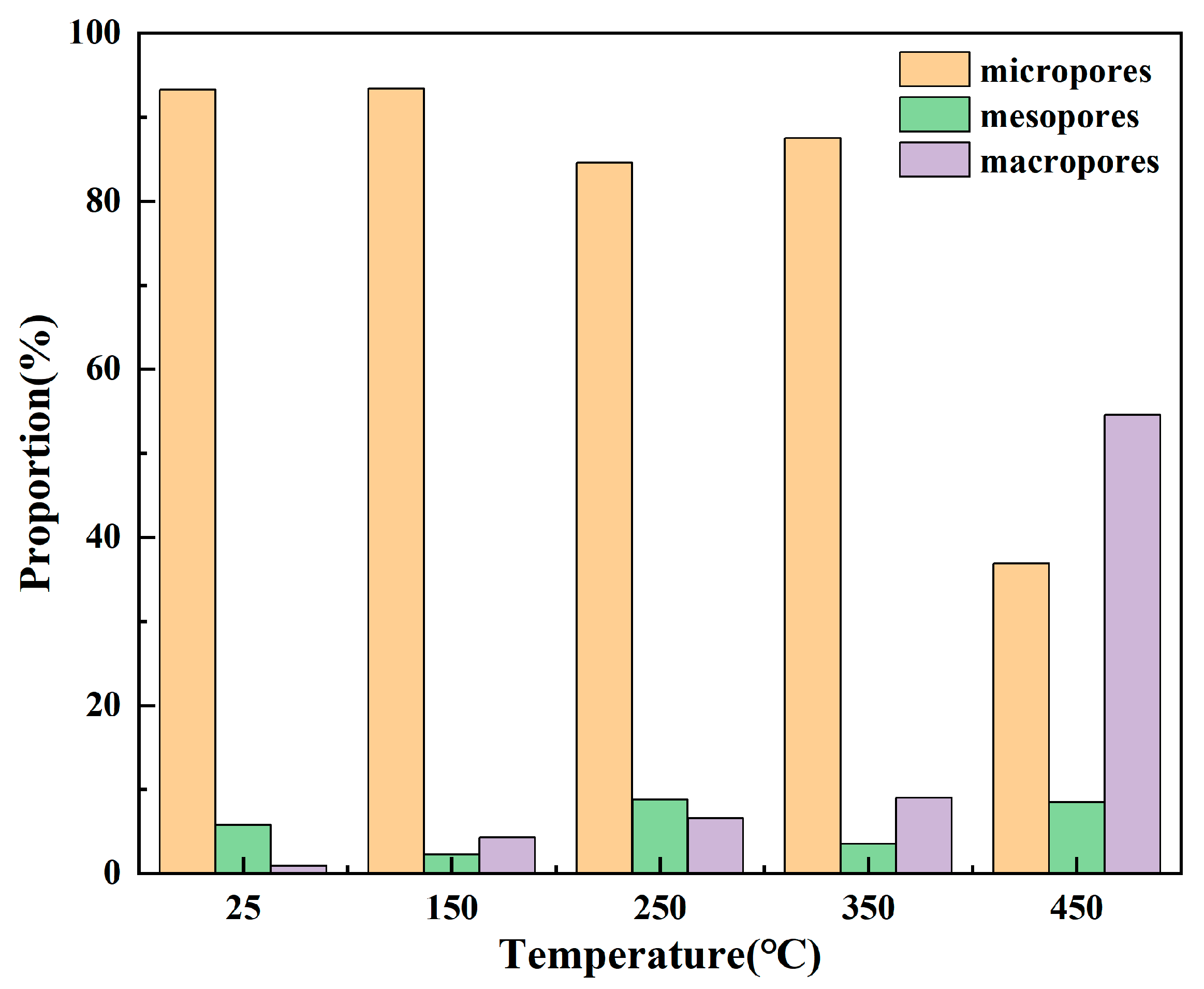

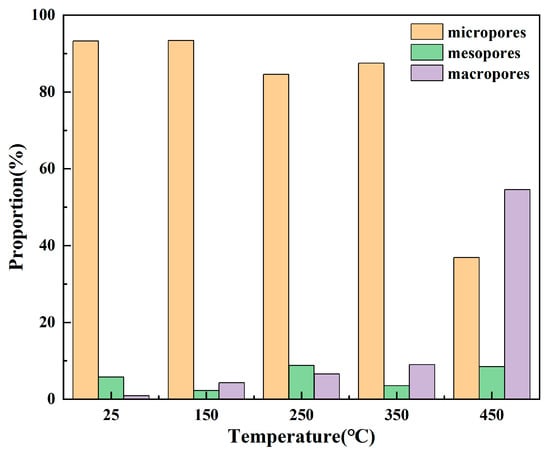

Based on the pore fracture features of lignite’s aperture distribution, the pore cracks in lignite can be classified into three size groups. Pores from 0.001 to 1 μm in diameter are classified as micropores, those measuring 1 to 10 μm are designated as mesopores, and those >10 μm are referred to as macropores or crevices [38]. Figure 8 illustrates a histogram depicting the pore dispersion across varying temperature settings. Figure 7 and Figure 8 illustrate that the lignite was predominantly characterized by small pores at room temperature (25 °C), comprising up to 93.34% of the total pore volume, with a minor presence of mesopores being seen. At a pretreatment temperature of 150 °C, significant cavities emerged in the lignite, although the quantity of mesopores was reduced compared to 25 °C. At pretreatment temperatures of 250 °C and 350 °C, although the pore fissures remain mostly characterized by micropores, the proportion of mesopores to macropores progressively rose. As the temperature increased to 450 °C, macropores supplanted micropores, becoming the predominant feature of the pore fissures in the lignite, constituting over 55%.

Figure 8.

Histograms of pore distribution under different temperature.

The research indicates that the micropores in the lignite predominantly fell within the range of 0.01 to 0.5 μm. As the pretreatment temperature progressively rose, the diameters of the micropores diminished and the proportion of macropores gradually increased. The research indicates that the lignite underwent dehydration and degassing at 150 °C, leading to the formation of many pore fractures. As the pretreatment temperature increased to approximately 250 °C, the volatilization of the lignite generated numerous micropores, while the alteration in mesopores remained minimal. Heat induced intricate physical and chemical interactions inside the lignite, leading to the expansion and amalgamation of micropores, resulting in the formation of new mesopores and macropores, while concurrently reducing the quantity of micropores. The quantity of macropores escalated with warmth, and their openings persisted in enlarging. At around 450 °C, the volatilization of lignite occurred in substantial amounts, leading to the constant increase in pore volumes. At temperatures beyond 300 °C, the lignite became obstructed as it softened and generated tar, leading to a substantial decrease in the overall pore count.

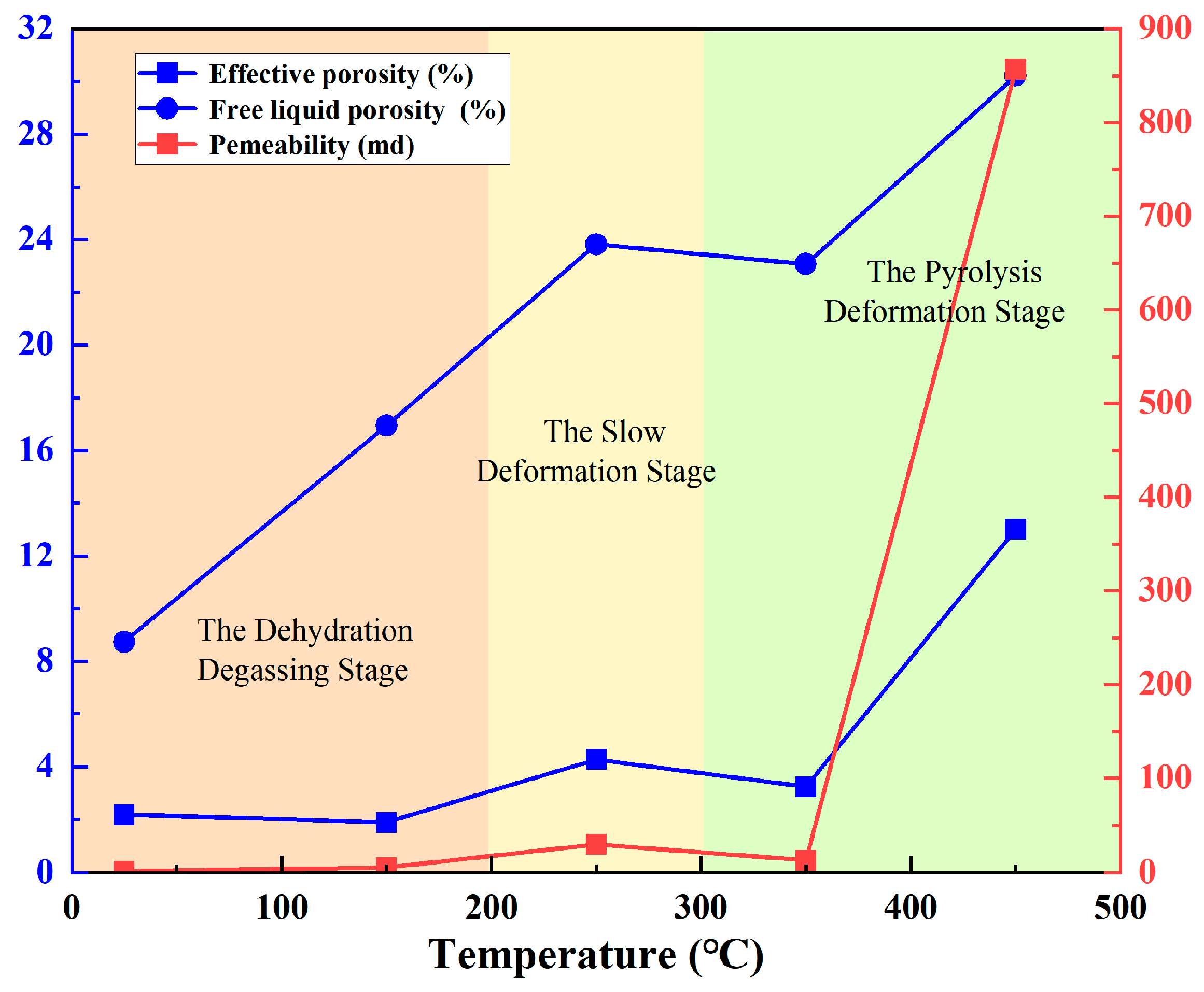

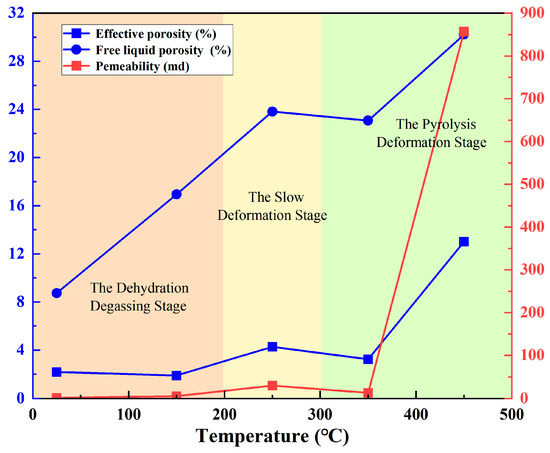

Based on the Coates model, the T2 cutoff value was selected according to the relevant data measured by NMR to calculate permeability, and the parameters related to pore fractures in lignite obtained from NMR testing are shown in Table 2 and Figure 9.

Table 2.

The pore fracture-related parameters of lignite based on NMR testing.

Figure 9.

The effective porosity, free liquid porosity, and permeability of lignite under different temperature based on an NMR test.

Based on the analysis of the nuclear magnetic resonance test data, as the lignite temperature increased from 25 °C to 250 °C, its effective porosity rose from 8.73% to 23.82%, and permeability increased from 1.37 md to 29.80 md under dehydration and degassing effects. When the temperature reached 350 °C, the porosity and permeability decreased due to the softening of the lignite, and the production of tar, partial pores, and fractures became blocked, with the porosity being 13.07% and the permeability being 13.08 md. At 450 °C, due to lignite pyrolysis, the internal hard particles underwent thermal cracking, resulting in large fractures at the micrometer scale or above. The void ratio and permeability significantly increased, with the porosity reaching 30.22% and the permeability reaching 856.99 md.

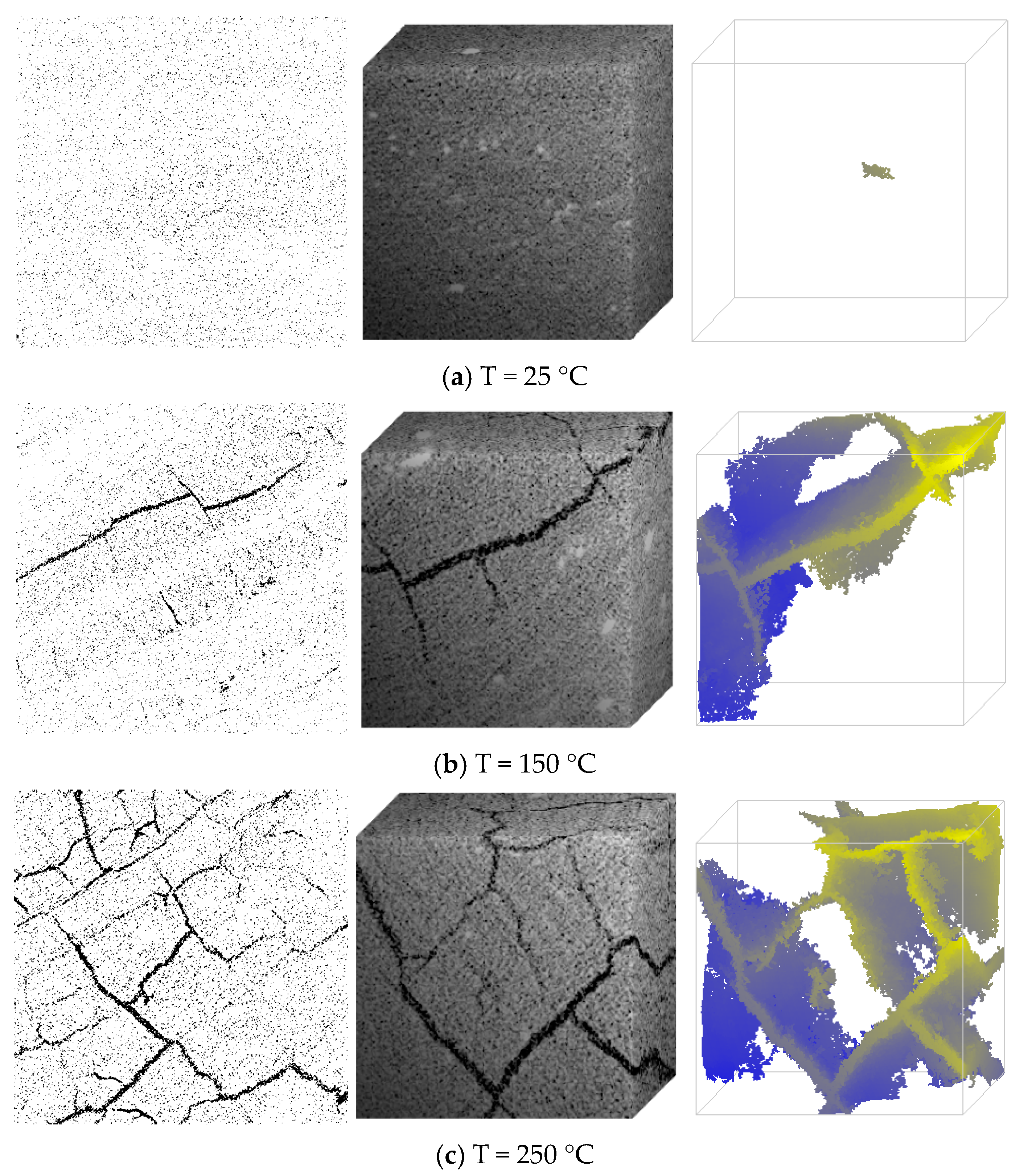

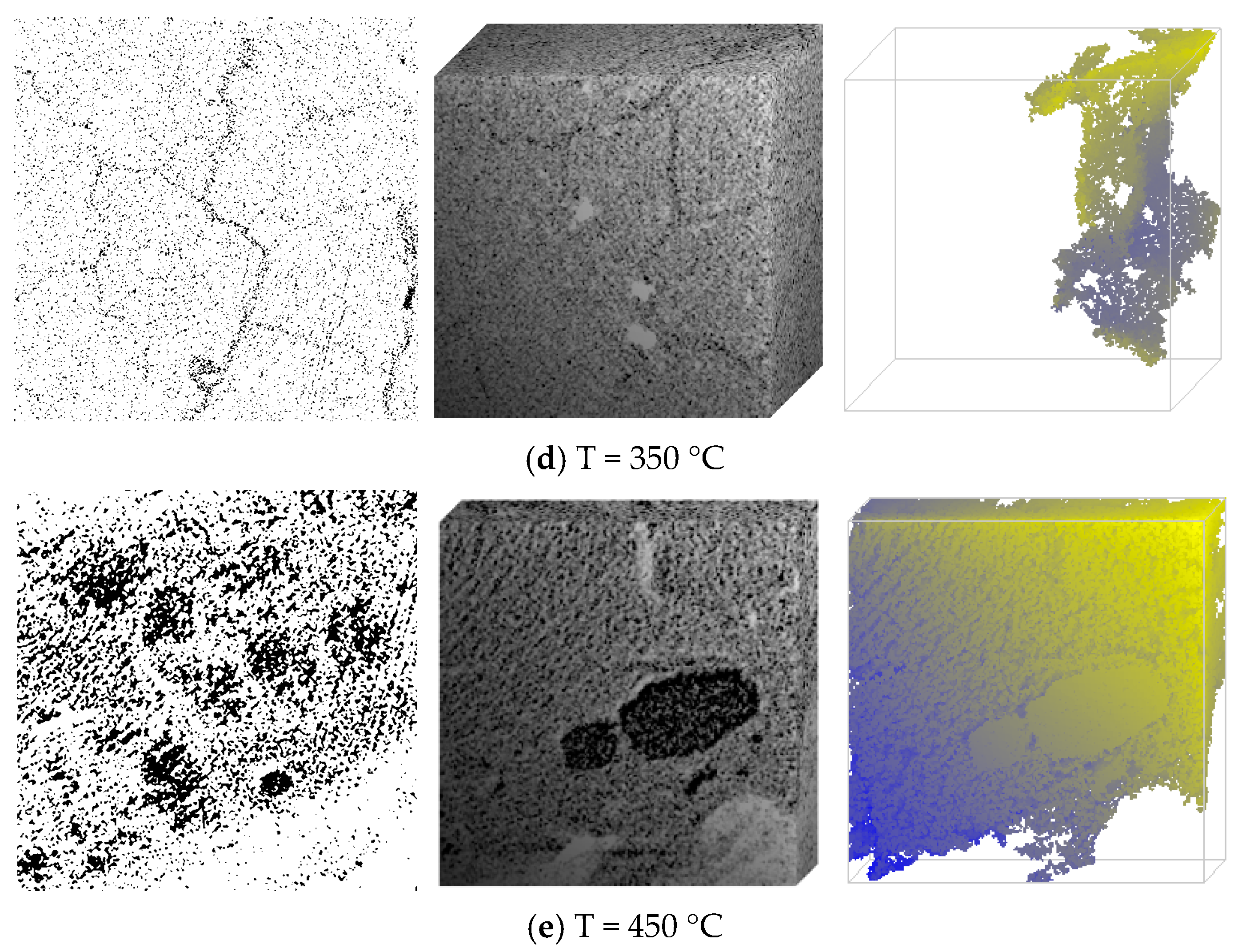

3.3. Evolution in Porosity Fissure Structure of Lignite by X-CT [30]

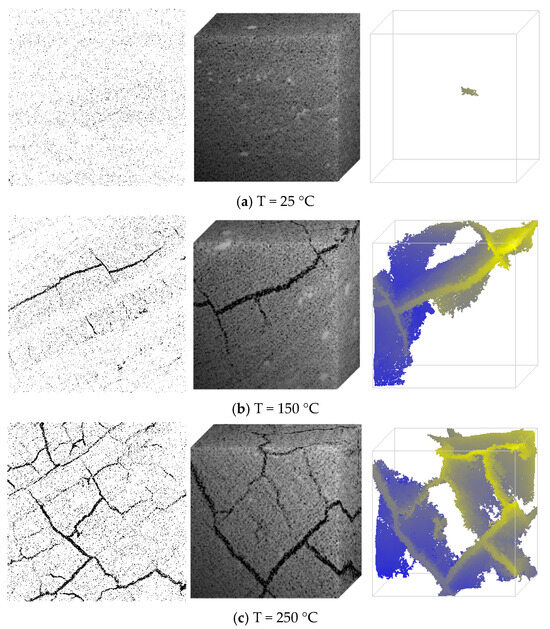

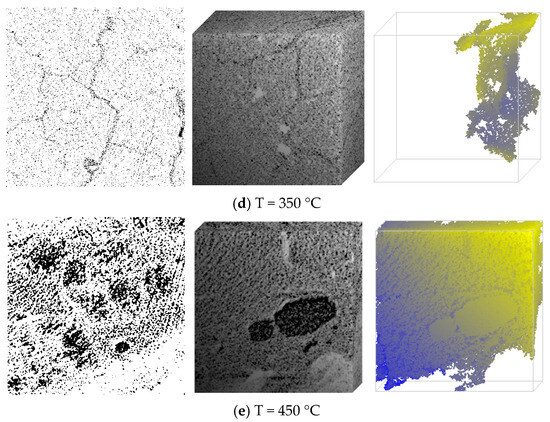

A two-dimensional image can be insightful and convey information regarding the evolutionary patterns of individual pores and fractures; nevertheless, it is limited in its ability to depict the geographical distribution of lignite pores and fractures. Consequently, a 3D reconstruction of the CT picture was executed. Figure 10 illustrates the three-dimensional reconstructed grayscale computed tomography images of lignite subjected to various temperature treatments, together with images of the biggest pore clusters.

Figure 10.

Scanning binary image (left), 3D reconstructed grayscale CT image (middle), and maximum pore cluster image (right) of lignite under different temperature treatments.

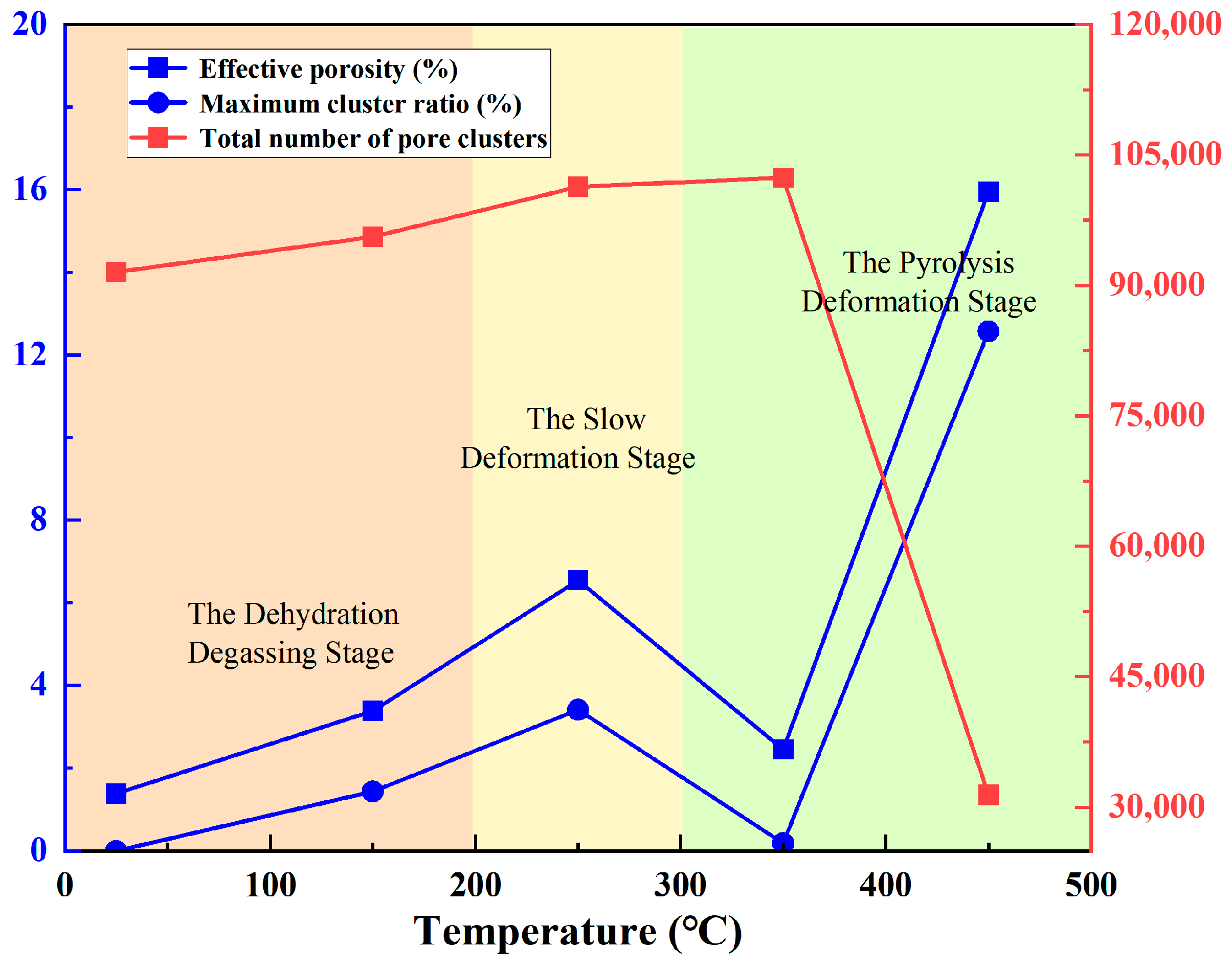

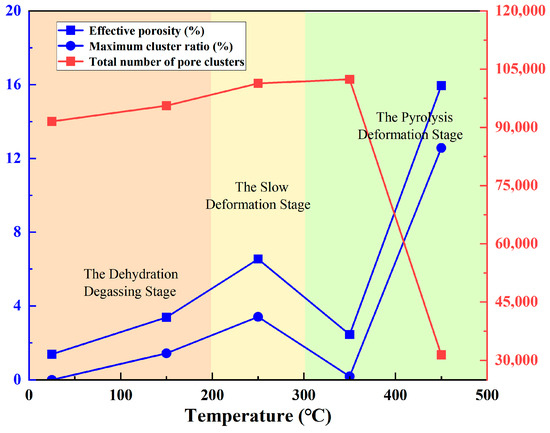

3D reconstructed CT pictures help elucidate the development of pores and fractures in lignite under varying thermal treatments. Consequently, 3D reconstruction and data extraction were conducted on the binarized picture to quantitatively assess the development of the lignite pores and cracks. The primary structural parameters of the pores and fractures are presented in Table 3, while the variation in these properties at different temperatures is illustrated in Figure 11.

Table 3.

Structural properties of the pores and fractures in lignite, as depicted in the 3D reconstructed image.

Figure 11.

The effective porosity, maximum cluster ratio, and total number of pore clusters of lignite under different temperatures based on an X-CT test.

As the temperature rose, the porosity and the maximum cluster ratio initially increased, subsequently decreased, and then rose again. The total number of pore clusters initially rose and subsequently declined. At 25 °C, the maximum cluster ratio was 0%. Despite the comparatively high number of pore clusters at 25 °C, these clusters were predominantly tiny and poorly interconnected; hence, the percolation probability of lignite at this temperature was low. At 150 °C, the water and partially adsorbed gases (CO2, CH4, and N2) of the lignite were released, new pores and fractures were formed, the connectivity of pore clusters increased, the porosity of lignite was 3.38%, and the maximum cluster ratio was 1.43%. At 250 °C, the predominant pore cluster, created by the interlinking of smaller pore clusters, nearly encompassed the entire area, the porosity of lignite was 6.54%, and the maximum cluster ratio was 3.41%. As the temperature escalated, at 350 °C, the lignite entered the initial stage of pyrolysis and softened, producing and releasing several volatile gases and tar, which blocked the pores, and the porosity decreased by 4.09%. The porosity of the lignite was merely 2.45%, and the maximum cluster ratio was 0.185%. At 450 °C, the semi-coke generated from lignite pyrolysis underwent further heating and conversion into coke, leading to the release of significant quantities of gas, the pores and fractures within the lignite were effectively interconnected, and the density of coke escalated while the volume diminished. The maximum cluster ratio was 12.57%, and the porosity was 16.02%.

4. Discussion

These observations indicate that lignite, a complex organic rock, experiences substantial alterations in its internal structure due to variations in temperature and time, and its deformation under certain three-dimensional stress demonstrates a discernible pattern. The deformation law and mechanism of lignite under temperature and pressure are outlined as follows:

Within the temperature range of room temperature to 200 °C, lignite comprises a significant quantity of hard particles, specifically inorganic constituents. As temperature rises, the internal composition of lignite will also increase, and the thermal cracking of lignite is induced by the thermal expansion coefficient among various components, commonly known as the thermal cracking of lignite. At temperatures below 200 °C, the deformation behavior of lignite differs not only from that of other rocks but also from that of other hard coals [39,40]. Lignite exhibits swelling within certain temperature ranges. Nonetheless, in comparison to the internal moisture and partial gas release in lignite, the impact of coal expansion under triaxial pressure is inferior compared to that resulting from dehydration. In particular, as the temperature attains 100 °C, the dehydration of lignite accelerates, and its deformation exhibits no variability throughout the dehydration process. The water in the lignite transforms into vapor, leading to steam accumulation that generates pressure. This pressure forces some cracks in the lignite to penetrate, resulting in decreased pressure within the lignite and subsequent fluctuations and deformation of its structure.

Within the temperature range of 200 °C to 300 °C, lignite dehydration is largely accomplished, and owing to the comparatively low temperature, lignite does not see significant pyrolysis reactions. The carboxyl group starts to decompose with warmth, although the reaction’s effect on the overall lignite structure is minimal, and the particle deformation in lignite results in its overall expansion. Consequently, the deformation of lignite is minimal, and its internal porosity nearly attains the maximum value, aligning with the permeability properties of lignite at elevated temperatures, specifically reaching a peak between the range of 250 °C to 300 °C.

The pyrolysis process of lignite within the temperature range of 300 °C to 650 °C can be categorized into two distinct stages. The initial stage primarily involves the pyrolysis reaction, occurring within a temperature range of 300 °C to 650 °C, whereas temperatures beyond 500 °C are classified as the second stage. These two stages correspond to the primary and secondary pyrolysis of lignite. The axial deformation of lignite indicates that secondary pyrolysis occurs at a far faster rate than primary pyrolysis. The lignite structure retains significant strength throughout the initial pyrolysis, while the second stage involves the polycondensation reaction of lignite pyrolysis. Lignite will inevitably soften, melt, flow, and expand across the temperature spectrum, ultimately solidifying as a colloidal entity, including gas, liquid, and solid phases. Lignite exhibits the greatest deformation and the most pronounced deformation within this temperature range, concurrently aligning with the significant fluctuations in lignite permeability seen in this range. This phase represents the critical temperature segment for lignite injection, as evidenced by the high-temperature region. The test results regarding the internal particle condition and permeability of lignite indicate that the skeleton retains significant support capacity, as illustrated in Figure 12.

Figure 12.

Cross section and internal cracks of the specimen after triaxial testing.

Through high-temperature triaxial experiments using NMR and X-CT, the deformation and pore characteristics of lignite pyrolysis were studied. The deformation and pore development patterns of lignite under temperature and pressure effects were obtained. As temperature increases, the porosity of lignite rises, its mechanical strength decreases, and significant deformation occurs. High temperatures promote pore development in lignite. Between 250 °C and 650 °C, a large number of highly interconnected pore networks form. Investigating the deformation and pore structure characteristics of lignite is crucial for elucidating its mechanical and permeability features under varying temperature and pressure conditions.

5. Conclusions

This article studied the deformation and pore structure characteristics of lignite under triaxial stress from room temperature to 650 °C through high-temperature triaxial experiments using NMR and X-CT. The following conclusions were drawn:

- (1)

- As temperature increases, the porosity of lignite rises, its mechanical strength decreases, and significant deformation occurs, and high temperatures promote pore development in lignite.

- (2)

- The axial deformation of lignite pyrolysis is divided into three stages: dehydration and degassing at room temperature to ~200 °C, slow deformation between 200 °C and 300 °C, and pyrolysis deformation from 300 °C to 650 °C.

- (3)

- Significant deformation occurs during both the dehydration degassing and pyrolysis deformation stages. Between 250 °C and 650 °C, a large number of highly interconnected pore networks form.

Author Contributions

F.Z.: investigation, conceptualization, data curation, formal analysis, writing—original draft, writing—review and editing. S.N.: conceptualization, writing—review and editing. J.H.: data curation. K.Z.: data curation. Z.Q.: writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The author Shiwei Niu was employed by Xinwen Mining Group Co., Ltd. The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Li, C. Advances in the Science of Victorian Brown Coal; Elsevier: Amsterdam, The Netherlands, 2004. [Google Scholar]

- Akbarzadeh, H.; Chalaturnyk, R.J. Structural changes in coal at elevated temperature pertinent to underground coal gasification: A review. Int. J. Coal Geol. 2014, 131, 126–146. [Google Scholar] [CrossRef]

- Bhutto, A.W.; Bazmi, A.A.; Zahedi, G. Underground coal gasification: From fundamentals to applications. Progress. Energyand Combust. Sci. 2013, 39, 189–214. [Google Scholar] [CrossRef]

- Li, C.-Z. Some recent advances in the understanding of the pyrolysis and gasification behaviour of Victorian brown coal. Fuel 2007, 86, 1664–1683. [Google Scholar] [CrossRef]

- Mokhahlane, L.S.; Gomo, M.; Vermeulen, D. Temperature and electrical conductivity stratification in the underground coal gasification zone and surrounding aquifers at the Majuba pilot plant. J. S. Afr. Inst. Min. Metall. 2018, 101, 1053–1058. [Google Scholar] [CrossRef]

- Shafirovich, E.; Varma, A. Underground coal gasification: A brief review of current status. Ind. Eng. Chem. Res. 2009, 48, 7865–7875. [Google Scholar] [CrossRef]

- Li, B.; Yang, K.; Ren, C.; Li, J.; Xu, J. An adsorption-permeability model of coal with slippage effect under stress and temperature coupling condition. J. Nat. Gas Sci. Eng. 2019, 71, 102983. [Google Scholar] [CrossRef]

- Zhao, Y.; Wan, Z.; Zhang, Y.; Qu Fang, X.G.; Wei, X.J.; Ma, W. Research and Development of 20MN servo controlled high temperature and high pressure rock mass triaxial testing machine. Chin. J. Rock Mech. Eng. 2008, 27, 1–8. [Google Scholar]

- Perera, M.S.A.; Ranjith, P.G.; Choi, S.K.; Airey, D. Investigation of temperature effect on permeability of naturally fractured black coal for carbon dioxide movement: An experimental and numerical study. Fuel 2012, 94, 596–605. [Google Scholar] [CrossRef]

- Liu, B.; Zhan, Z.; Cui, Z. Experimental study on compression and failure of coal under compression. J. Coal Sci. 1983, 2, 51–61. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, B. Testing of mechanical parameters of coal and rock of different coal ranks. Chin. J. Rock Mech. Eng. 2000, 19, 860–862. [Google Scholar]

- Su, C.; Zhai, X.; Li, Y.; Li, S.; Liu, Z. Analysis of deformation and strength of coal samples under triaxial compression. Chin. J. Rock Mech. Eng. 2006, 25 (Suppl. S1), 2963–2968. [Google Scholar]

- Hou, Q.; Zhai, Y.; Han, Y.; Li, X. Discussion on the mechanism of deformation and gas production of coal. Geol. Notif. 2014, 5, 715–722. [Google Scholar]

- Yang, Y. Basic experimental study on strength, deformation and microseismic characteristics of coal and rock. Chin. J. Rock Mech. Eng. 2006, 25, 1728. [Google Scholar]

- Zhou, J.; Wang, G.; Shao, Z. Research on high temperature and high pressure experimental deformation of coal. J. China Coal Soc. 1994, 19, 324–332. [Google Scholar]

- Ma, Z.; Mao, X.; Li, Y. Experimental study on the effect of temperature on coal mechanical properties. Mine Press. Roof Manag. 2005, 22, 46–48. [Google Scholar]

- Bustin, R.M.; Ross, J.V.; Moffat, I. Vitrinite anisotropy under differential stress and high confining pressure and temperature: Preliminary observation. Int. J. Coal Geol. 1986, 6, 343–351. [Google Scholar] [CrossRef]

- Jiang, B.; Qin, Y.; Jin, F. Experimental study on high temperature and high pressure of coal deformation. J. China Coal Soc. 1997, 22, 82–86. [Google Scholar]

- Jiang, B.; Qin, Y.; Jin, F. Deformation characteristics of coal ultrastructure under high temperature and high pressure. Geol. Sci. 1998, 33, 18–25. [Google Scholar]

- Liu, J.; Yang, G.; Ma, R. Macro- and microscopic mechanical behaviour of flow of coal samples experimentally deformed at high temperatures and pressures. Chin. Sci. Bull. 2005, 50 (Suppl. S1), 56–63. [Google Scholar] [CrossRef]

- Dong, F.; Feng, Z.; Yang, D.; Lu, X. Study on thermal deformation characteristics of Jimsar oil shale in Xinjiang under high temperature triaxial stress. Coal Eng. 2019, 51, 103–106. [Google Scholar]

- Shkuratnik, V.L.; Filimonov, Y.L.; Kuchurin, S.V. Regularities of acoustic emission in coal samples under triaxial compression. J. Ming Sci. 2005, 41, 44–52. [Google Scholar] [CrossRef]

- Shkuratnik, V.L.; Filimonov, Y.L.; Kuchurin, S.V. Experimental investigations into acoustic emission in coal samples under uniaxial loading. J. Ming Sci. 2004, 40, 458–464. [Google Scholar] [CrossRef]

- Shkuratnik, V.L.; Kuchurin, S.V.; Vinnikov, V.A. Regularities of acoustic emission and thermoemission memory effect in coal specimens unde rvarying thermal conditions. J. Ming Sci. 2007, 43, 394–403. [Google Scholar] [CrossRef]

- Voznesenskii, A.S.; Tavostin, M.N. Acoustic emission of coal in the postlimiting deformation state. J. Ming Sci. 2005, 41, 291–297. [Google Scholar] [CrossRef]

- Nie, B.; He, X.; Wang, E.; Dou, L.; Liu, Z.; Sa, Z. Study on Electromagnetic Radiation and Acoustic Emission in Coal Shear Failure Process. J. China Univ. Min. Technol. 2002, 31, 65–67. [Google Scholar]

- Wang, E.; He, X.; Liu, Z.; Li, Z. Study on the spectral characteristics of acoustic emission of coal body fracture. J. China Coal Soc. 2004, 29, 289–292. [Google Scholar]

- Zuo, J.; Xie, H.; Zhou, H.; Peng, S. Experimental research on thermal cracking of sandstone under different temperatures. Chin. J. Geophys. 2007, 50, 1150–1155. [Google Scholar]

- Wang, D.; Zeng, F.; Wei, J.; Zhang, H.; Wu, Y.; Wei, Q. Quantitative analysis of fracture dynamic evolution in coal subjected to uniaxial and triaxial compression loads based on industrial CT and fractal theory. J. Pet. Sci. Eng. 2021, 196, 108051. [Google Scholar] [CrossRef]

- Liu, W.; Niu, S.; Tang, H. Structural characteristics of pores and fractures during lignite pyrolysis obtained from X-ray computed tomography. J. Pet. Sci. Eng. 2023, 220, 111150. [Google Scholar] [CrossRef]

- Wang, D.; Tian, X.; Wei, J.; Zhang, H.; Yao, B.; Zhang, H.; Chen, C. Fracture evolution and nonlinear seepage characteristic of gas-bearing coal using Xray computed tomography and the lattice Boltzmann method. J. Pet. Sci. Eng. 2022, 211, 110144. [Google Scholar] [CrossRef]

- Liu, W.; Niu, S.; Tang, H.; Zhou, K. Pore structure evolution during lignite pyrolysis based on nuclear magnetic resonance. Case Stud. Therm. Eng. 2021, 26, 101125. [Google Scholar] [CrossRef]

- Asadi, I.; Ji, G.; Baghban, M.H. Evaluating the effective thermal conductivity of cement mortar through X-ray scanning. Case Stud. Therm. Eng. 2023, 41, 102686. [Google Scholar] [CrossRef]

- Zhu, Q.; Wang, X.; Zuo, Y.; Pan, J.; Ju, Y.; Su, X.; Yu, K. Numerical simulation of matrix swelling and its effects on fracture structure and permeability for a high-rank coal based on X-ray micro-CT image processing techniques. Energy Fuel 2020, 34, 10801–10809. [Google Scholar] [CrossRef]

- Cheng, M.; Fu, X.; Kang, J. Compressibility of different pore and fracture structures and its relationship with heterogeneity and minerals in low-rank coal reservoirs: An experimental study based on nuclear magnetic resonance and microCT. Energy Fuel 2020, 34, 10894–10903. [Google Scholar] [CrossRef]

- Zhao, Y.; Lin, B.; Liu, T.; Zheng, Y.; Sun, Y.; Zhang, G.; Li, Q. Multifractal analysis of coal pore structure based on NMR experiment: A new method for predicting T2 cutoff value. Fuel 2021, 283, 119338. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Y. Comparative evaluation of pore structure heterogeneity in low-permeability tight sandstones using different fractal models based on NMR technology: A case study of benxi formation in the central ordos basin. Energy Fuel 2020, 34, 13924–13942. [Google Scholar] [CrossRef]

- Zhou, S.; Lin, B. The Theory of Gas Flow and Storage in Coal Seams; China Coal Industry Publishing House: Beijing, China, 1998. [Google Scholar]

- Qu, F. Experimental Study on Pyrolysis and Mechanical Properties of Coal In Situ; University of Mining and Technology: Xuzhou, China, 2007. [Google Scholar]

- Xie, K. Domain Reactivity of Coal; Science Press: Beijing, China, 2002. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).