Study of Mechanisms and Protective Strategies for Polymer-Containing Wastewater Reinjection in Sandstone Reservoirs

Abstract

1. Introduction

2. Overview of the Study Area and Experimental Method Design

2.1. Overview of the Study Area

2.2. Experimental Methods and Principles

2.3. Experimental Sample

2.4. Test Steps

- (1)

- The preparation process for core samples was as follows: For the rock samples collected in the field, drilling and cutting operations were carried out to produce standard cores, with a length of 2.5 to 5 cm and a diameter of 2.5 cm.

- (2)

- The core oil-washing, salt-washing, and drying steps were as follows: Using a solvent extraction method, residual oil and salts were removed from the core. After solvent cleaning, the rock samples were first placed at room temperature for 10 h and then transferred to a constant temperature drying oven, where they underwent ≥24 h of continuous heat drying under simulated formation temperature and pressure conditions. This dual drying process ensured the complete removal of residual pore fluids. The baseline mass parameters of the rock samples were then calibrated using a precision balance.

- (3)

- Basic data measurement: According to the industry standards, such as the SY/T5336-2006 “Core Analysis Methods”, the physical property parameters of the core were measured [34], including the porosity, permeability, and others.

- (4)

- The core saturation process included two key stages: First, the pore fluid was replaced using vacuum saturation with formation water. During the displacement process, dynamic monitoring was carried out to obtain resistivity response data, which were then used to invert the rock electrical parameters (resistivity, resistivity index) using the Archie equation.

- (5)

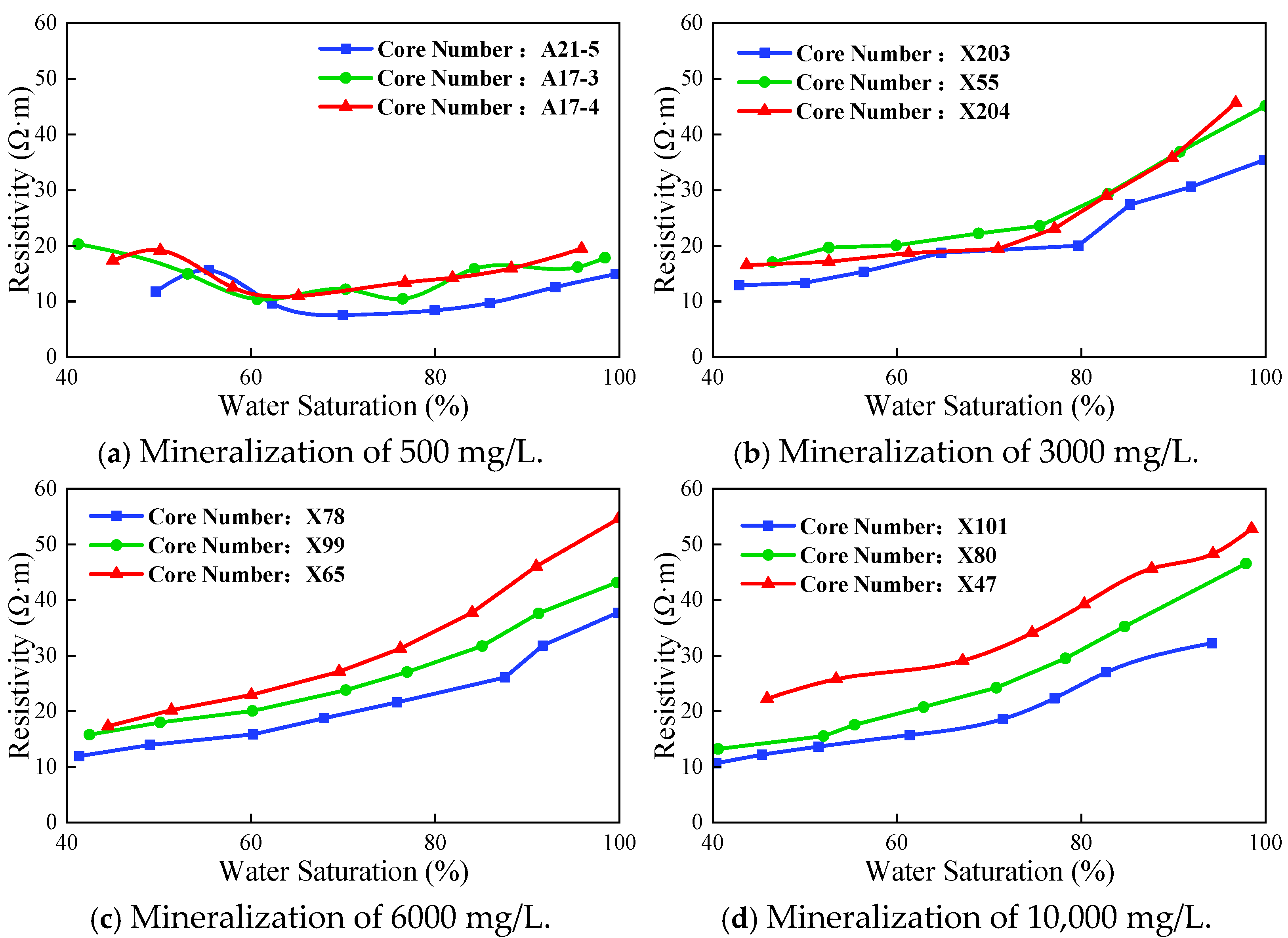

- The resistivity–saturation monitoring scheme for displacement experiments was as follows: Four characteristic mineralization gradient injection water systems were selected for the experiments, with each system used for multiple rounds of displacement experiments on different rock samples. During the experiments, SEM imaging and CT scanning were used to obtain micro-mechanism evidence.

3. Results and Discussion

3.1. Experimental Results and Characterization of Rock Electric-Phase Drive Analysis Results and Discussion

3.1.1. Analysis of the Results of Rock Electric-Phase Drive Experiments

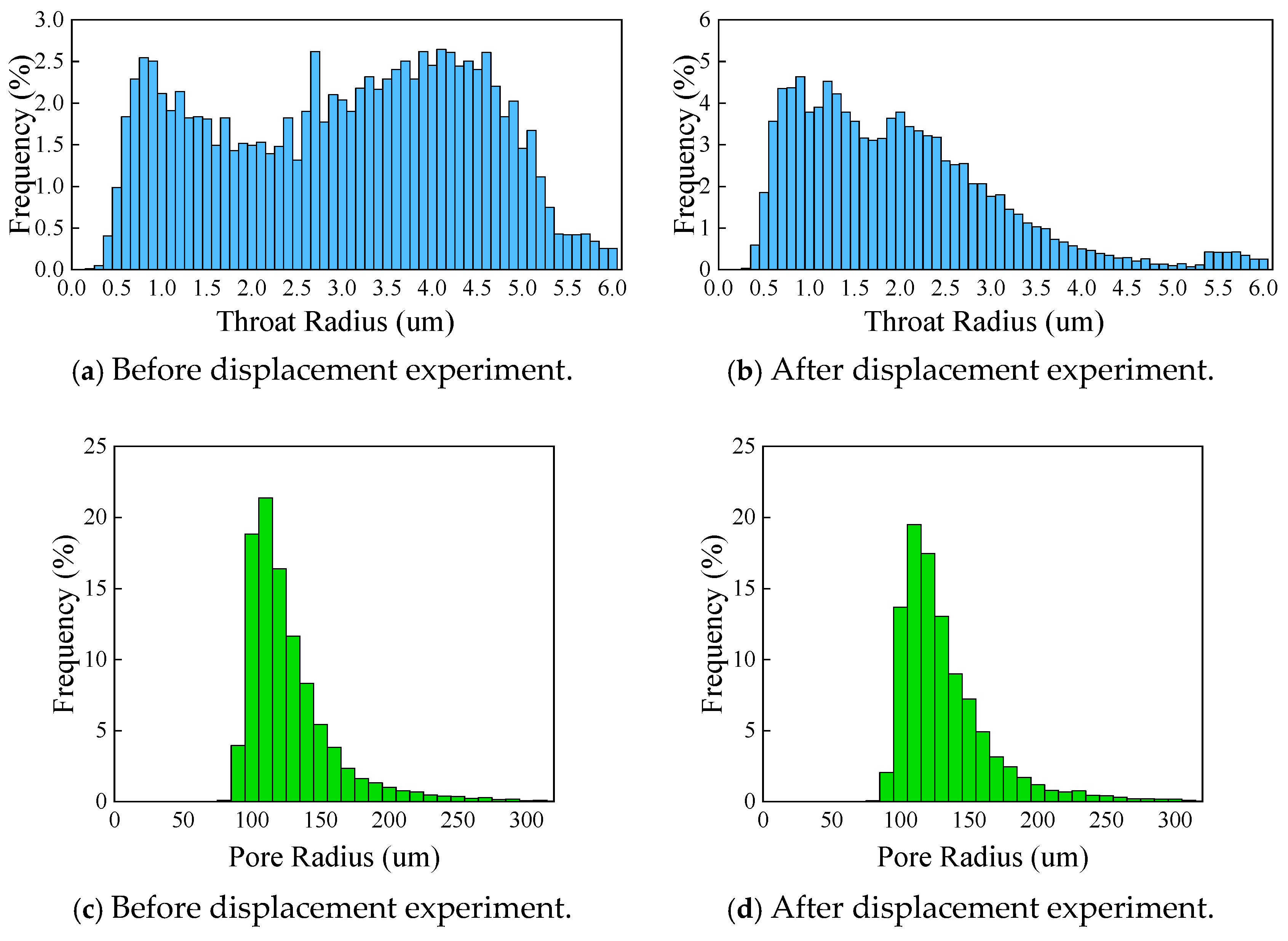

3.1.2. Analysis of Core Throat Changes and Characterization

3.2. Analysis of Factors Affecting Reservoir Damage Induced by Wastewater Displacement

3.2.1. Damage Analysis with Different Water Content Ratios

3.2.2. Analysis of Oil Content Damage to Core Permeability

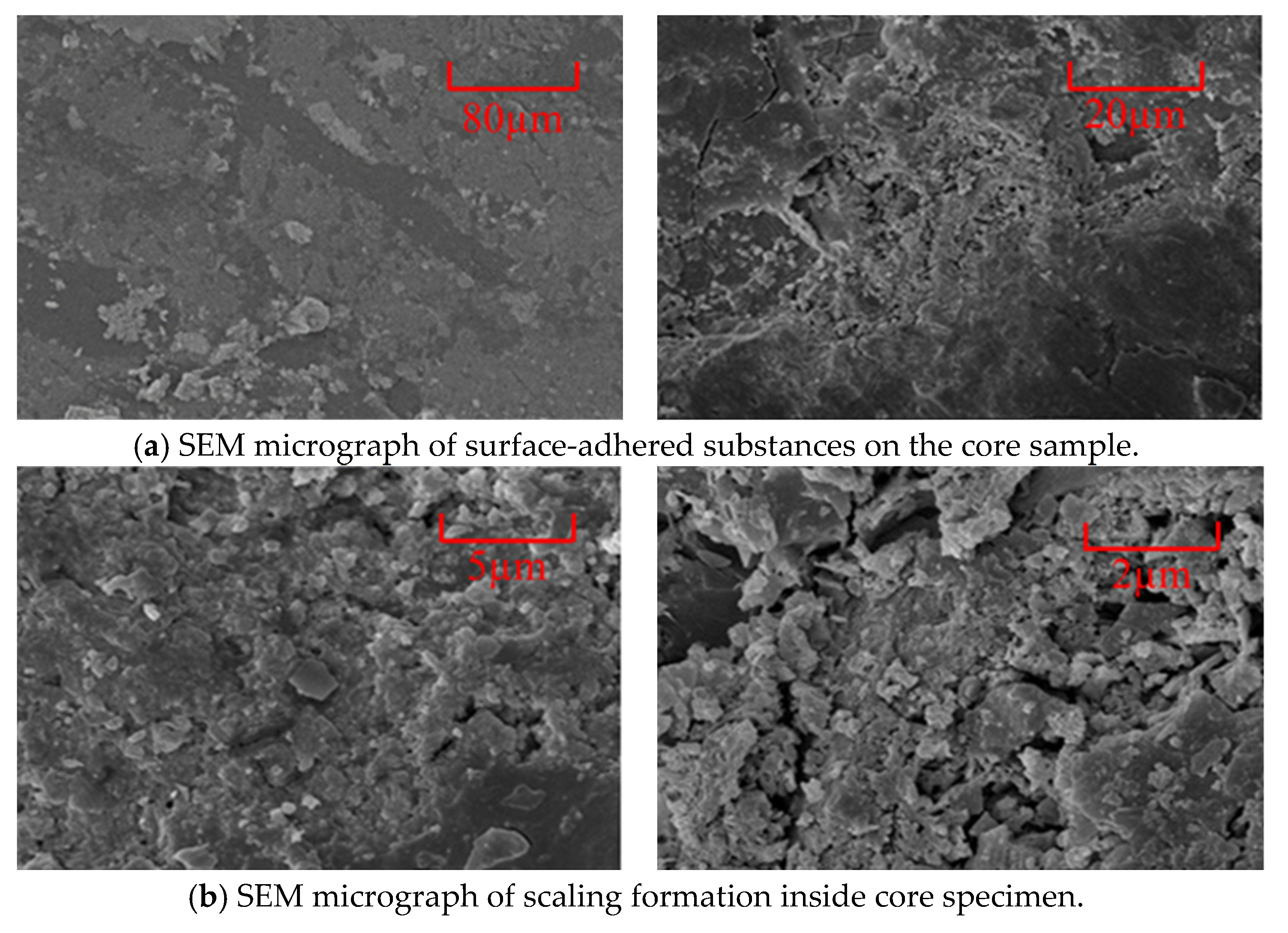

3.3. Damage Mechanism Analysis

3.3.1. Wastewater Mass Spectrometry

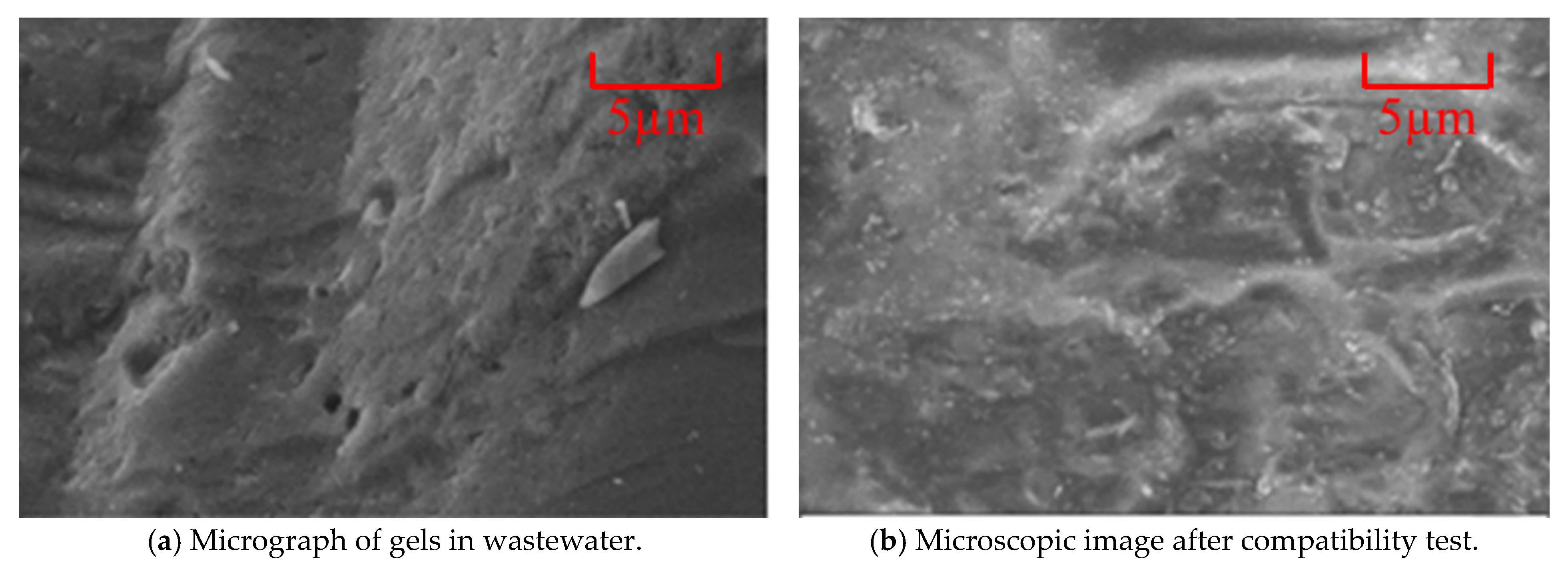

3.3.2. Experiment on the Compatibility of Sewage Water and Freshwater

3.3.3. Sewage–Core Compatibility Test

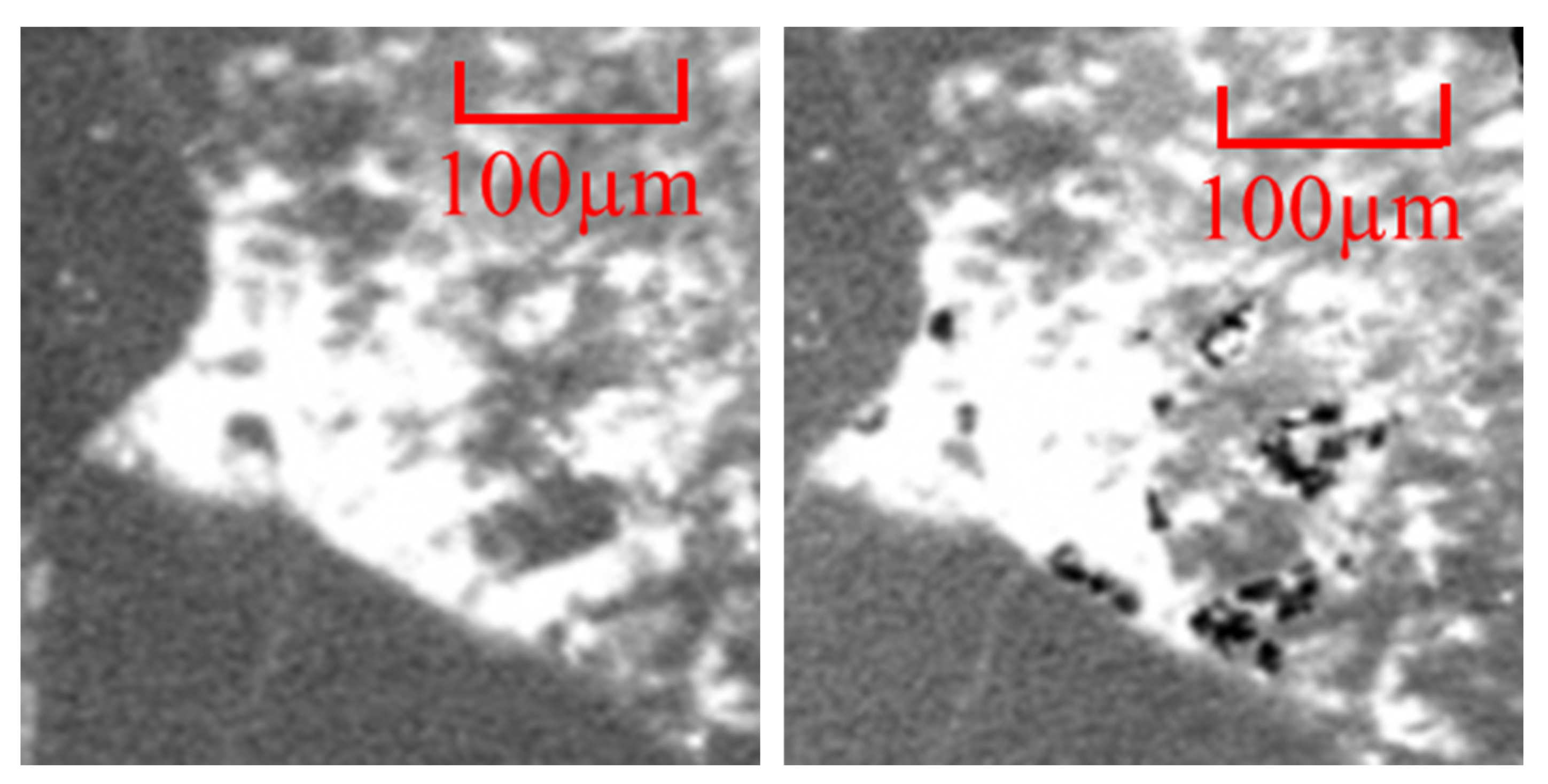

3.3.4. CT Tomography Pressure Occlusion Damage Mechanism

3.4. Research on Wastewater Reinjection Treatment Processes

3.4.1. Wastewater Reinjection Treatment Technologies in Chinese Oilfields

3.4.2. Research on Optimization of Reinjection Treatment Processes

4. Conclusions

- (1)

- The salinity of the injected water significantly affects the resistivity response. When low-salinity wastewater is injected, the curve exhibits a concave shape; under high-salinity injection conditions, the formation resistivity increases significantly with water saturation, showing a distinct high-resistivity characteristic. Regardless of the salinity level, strong waterflooded zones were observed, and due to the lower salinity of the injection water compared to the original formation water, a significant high-resistivity response was detected. After eliminating the influence of calcium-bearing layers, the high-resistivity feature can serve as an important indicator for identifying strongly waterflooded zones.

- (2)

- Wastewater reinjection primarily affected the pore-throat structure of the rock samples, leading to the transformation of medium-sized pore throats (2.5–5.5 µm) into smaller ones (0.5–2.5 µm). The number of small-sized throats increased significantly, with an average frequency rise of 1.894%, while the number of medium-sized throats decreased notably, with an average frequency decline of 2.073%.

- (3)

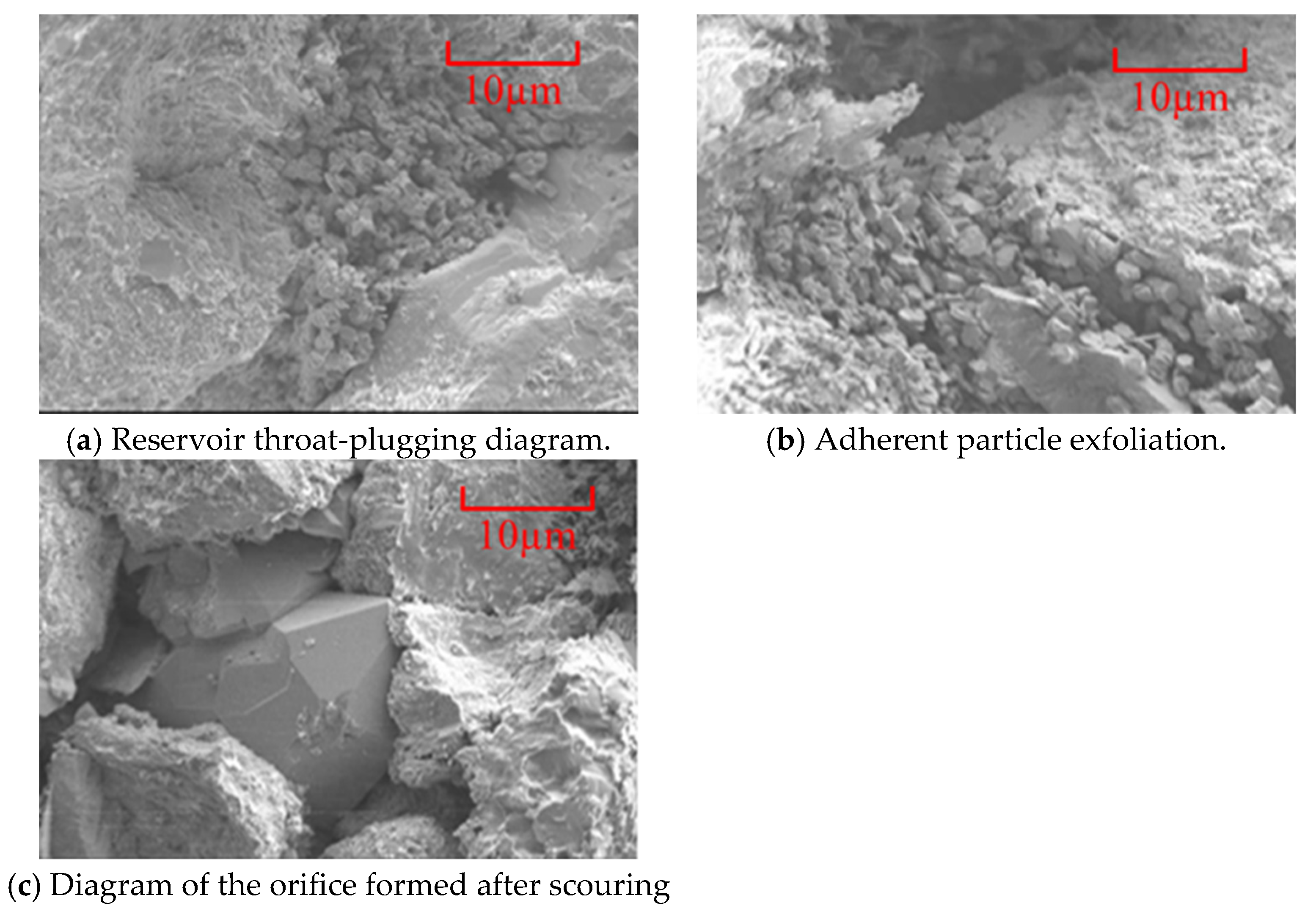

- The compatibility tests of wastewater and freshwater indicated that, during the mixing process, flake-like, block-like, or flocculent suspensions with particle sizes greater than 10 µm were formed. In the core compatibility tests, the particles formed mainly had sizes ranging from 10 to 80 µm. After undergoing processes such as adsorption, aggregation, and deposition, the overall structure became loose and exhibited porous or layered characteristics. These findings suggest that, in the process of wastewater reinjection, analyzing the morphology and particle size distribution of suspended particles can aid in determining the waterflooding status of the reservoir, thus providing a theoretical basis for identifying flooded layers and optimizing injection and production adjustments.

- (4)

- Using comprehensive methods such as water compatibility experiments, wastewater mass spectrometry analyses, and core-scaling characteristics, the primary and secondary causes of reservoir damage in wastewater injection wells were identified. The cascading mechanism of reservoir damage due to wastewater injection was systematically clarified: ① throat blockages caused by suspended solids; ② the chemical precipitation of metal ions; and ③ the expansion of clay minerals. To address these damage issues, a physical–chemical combined deblocking technology was proposed, which first removes suspended solids and particles through multi-stage fine filtration and then uses a weak-acidity organic acid composite agent to inhibit metal ion precipitation and dissolve blockages in the core.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Mineral Content (mg/L) | Sample Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| Well Number | Sub-Layer Number | Sample Number | Depth (m) | Length (cm) | Diameter (cm) | Porosity (%) | Permeability (mD) | |

| Ji+1 | 2 | A21-4 | 2633.20 | 5.986 | 2.512 | 12.32 | 10.67 | |

| 500 | Ji+1 | 2 | A21-5 | 2633.77 | 6.062 | 2.525 | 13.92 | 6.95 |

| 500 | Ji+1 | 6 | B17-3 | 3377.67 | 3.759 | 2.515 | 15.23 | 10.98 |

| 500 | Ji+1 | 6 | B17-4 | 3243.70 | 7.930 | 2.508 | 16.45 | 22.15 |

| 3000 | Ji+1 | 19 | X203 | 2674.62 | 4.190 | 2.475 | 13.88 | 3.10 |

| 3000 | Ji+1 | 13 | X55 | 2681.85 | 4.543 | 2.493 | 14.99 | 13.25 |

| 3000 | Ji+1 | 19 | X204 | 2531.65 | 7.023 | 2.518 | 17.12 | 19.88 |

| 6000 | Ji+1 | 14 | X78 | 2516.00 | 6.860 | 2.502 | 14.55 | 5.42 |

| 6000 | Ji+1 | 16 | X99 | 3239.63 | 5.318 | 2.497 | 15.01 | 11.95 |

| 6000 | Ji+1 | 14 | X65 | 2778.40 | 6.118 | 2.488 | 16.02 | 35.60 |

| 10000 | Ji+1 | 16 | X101 | 3004.29 | 5.662 | 2.495 | 14.75 | 3.05 |

| 10000 | Ji+1 | 14 | X80 | 2650.75 | 3.549 | 2.532 | 17.30 | 8.12 |

| 10000 | Ji+1 | 13 | X47 | 2934.06 | 7.222 | 2.489 | 13.65 | 15.03 |

| Freshwater/ Produced Water Ratio | Sample Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| Well Number | Sub-Layer Number | Sample Number | Depth (m) | Length (cm) | Diameter (cm) | Porosity (%) | Permeability (mD) | |

| Ji+2 | 1 | A1-1 | 2854 | 5.986 | 2.512 | 11.12 | 9.20 | |

| 1:0 | Ji+2 | 1 | A1-2 | 2854.5 | 6.062 | 2.525 | 12.76 | 12.68 |

| 1:0 | Ji+2 | 1 | A1-3 | 2855 | 3.759 | 2.515 | 14.21 | 12.85 |

| 1:1 | Ji+2 | 1 | A1-4 | 2855.5 | 7.930 | 2.508 | 14.45 | 13.02 |

| 1:1 | Ji+2 | 1 | A1-5 | 2856 | 4.190 | 2.475 | 14.12 | 13.15 |

| 1:3 | Ji+2 | 1 | A1-6 | 2856.5 | 4.543 | 2.493 | 15.93 | 13.24 |

| 1:3 | Ji+2 | 1 | A1-7 | 2857 | 7.023 | 2.518 | 16.01 | 13.33 |

| 1:5 | Ji+2 | 1 | A1-8 | 2857.5 | 6.860 | 2.502 | 12.34 | 13.41 |

| 1:5 | Ji+2 | 1 | A1-9 | 2858 | 5.318 | 2.497 | 11.89 | 13.47 |

| 0:1 | Ji+2 | 1 | A1-10 | 2858.5 | 6.118 | 2.488 | 13.12 | 13.50 |

| 0:1 | Ji+2 | 1 | A1-11 | 2859 | 5.662 | 2.495 | 14.11 | 13.08 |

| Oil Concentration (mg/L) | Sample Properties | |||||||

| Well Number | Sub-Layer Number | Sample Number | Depth (m) | Length (cm) | Diameter (cm) | Porosity (%) | Permeability (mD) | |

| 60 | Ji+2 | 1 | A1-12 | 2860 | 4.562 | 2.502 | 11.88 | 12.88 |

| 20 | Ji+2 | 1 | A1-13 | 2860.5 | 4.862 | 2.512 | 12.91 | 12.91 |

| 20 | Ji+2 | 1 | A1-14 | 2861 | 4.760 | 2.511 | 13.13 | 12.05 |

| 40 | Ji+2 | 1 | A1-15 | 2861.5 | 5.822 | 2.500 | 12.44 | 13.33 |

| 40 | Ji+2 | 1 | A1-16 | 2862 | 4.630 | 2.872 | 12.22 | 13.12 |

| 60 | Ji+2 | 1 | A1-17 | 2862.5 | 4.989 | 2.492 | 14.41 | 12.22 |

| 60 | Ji+2 | 1 | A1-18 | 2863 | 5.222 | 2.542 | 11.15 | 13.02 |

References

- Liu, H.; Pei, X.H.; Luo, K.; Sun, F.C.; Zheng, L.C.; Yang, Q.H. Current status and trend of separated layer water flooding in China. Petrol. Explor. Dev. 2013, 40, 785–790. [Google Scholar] [CrossRef]

- Sun, H.; Yang, Y.; Wang, H.; Wang, J.; Wu, G.; Cui, Y.; Yu, Q. Distribution characteristics of remaining oil in extra-high water cutreservoirs and new technologies for enhancing oil recovery. J. China Univ. Pet. 2023, 47, 90–102. (In Chinese) [Google Scholar]

- Rajbongshi, A.; Gogoi, S.B. A review on oilfield produced water and its treatment technologies. Pet. Res.-China 2024, 9, 640–656. [Google Scholar] [CrossRef]

- Zhao, C.S.; Ren, Q.L.; Li, P.J. Low permeability reservoir water displacing oil and water flooding characteristic curve theory. Appl. Mech. Mater. 2014, 556–562, 4701–4704. [Google Scholar] [CrossRef]

- Hu, W.R.; Wei, Y.; Bao, J.W. Development of the theory and technology for low permeability reservoirs in China. Petrol. Explor. Dev. 2018, 45, 685–697. [Google Scholar] [CrossRef]

- Chen, B.; Zhao, L.; Wang, C.S.; Chen, S.J.; Wu, X.Y.; Li, Q.; Zuo, Q.Q. The analysis of formation of polymer-containing oily sludge produced during the wastewater treatment in offshore oilfield. Energy Sci. Eng. 2018, 6, 675–682. [Google Scholar] [CrossRef]

- Liu, Y.G.; Chen, H.X.; Tang, H.M.; Feng, Y.T.; Pang, M. Mechanism of scaling on reservoir formation damage by polymer-containing wastewater re-injection. Desalination Water Treat. 2019, 139, 7–13. [Google Scholar] [CrossRef]

- Chen, H.X.; Tang, H.M.; Duan, M.; Liu, Y.G.; Liu, M.; Zhao, F. Oil-water separation property of polymer-contained wastewater from polymer-flooding oilfields in Bohai Bay, China. Environ. Technol. 2015, 36, 1373–1380. [Google Scholar] [CrossRef]

- Peng, P.; Guo, S.H.; Li, L.H.; Jin, H.; Ge, Z.W.; Guo, L.J. Supercritical water gasification mechanism of polymer-containing oily sludge. Int. J. Hydrogen Energy 2021, 46, 26834–26847. [Google Scholar] [CrossRef]

- Jia, J. Identification of Water-Flooded Layers and Evaluation of Flooded Levels in Fractured Tight Sand Oil Reservoir. Processes 2024, 12, 2426. [Google Scholar] [CrossRef]

- Liu, J.Z.; Liu, X.Y.; Guo, L.F.; Shi, G.N.; Du, H. Application of Random Forests Classifier in Water Flooded Layer Identification. In Proceedings of the 2nd IYSF Academic Symposium on Artificial Intelligence and Computer Engineering, Xi’an, China, 8–10 October 2021; Volume 12079. [Google Scholar]

- Yi, X.D.; Zhang, M.L.; Qin, L.B.; Lin, J.H. Reservoir water flooding evaluation based on electromagnetic wave logging permittivity and conductivity inversion. J. Appl. Geophys. 2023, 216, 105159. [Google Scholar]

- Gomaa, S.; Soliman, A.A.; Mohamed, A.; Emara, R.; Attia, A.M. New Correlation for Calculating Water Saturation Based on Permeability, Porosity, and Resistivity Index in Carbonate Reservoirs. ACS Omega 2022, 7, 3549–3556. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.H.; Pan, B.Z.; Zhang, L.H.; Lei, J.; Fan, Y.F.; Ruhan, A.; Yan, D.D.; Zhao, Y.Q. A study on water saturation predictions in igneous reservoirs based on the relationship between the transverse relaxation time and the resistivity index. J. Petrol. Sci. Eng. 2022, 208, 109519. [Google Scholar] [CrossRef]

- Han, Y.J.; Zhou, C.C.; Yu, J.; Li, C.L.; Hu, F.L.; Xu, H.J.; Yuan, C. Experimental investigation on the effect of wettability on rock-electricity response in sandstone reservoirs. Fuel 2019, 239, 1246–1257. [Google Scholar] [CrossRef]

- Liu, G.F.; Wang, H.L.; Tang, J.C.; Liu, Z.K.; Yang, D.Y. Effect of wettability on oil and water distribution and production performance in a tight sandstone reservoir. Fuel 2023, 341, 127680. [Google Scholar] [CrossRef]

- Wu, F.; Wen, Z.; Yao, C.; Wang, X.H.; Xi, Y.P.; Cong, L.L. Numerical Simulation of the Influence of Pore Structure on Resistivity, Formation Factor and Cementation Index in Tight Sandstone. Acta Geol. Sin.-Engl. 2020, 94, 290–304. [Google Scholar] [CrossRef]

- Sun, Z.H.; Mehmani, A.; Torres-Verdín, C. Pore-Scale Investigation of the Electrical Resistivity of Saturated Porous Media: Flow Patterns and Porosity Efficiency. J. Geophys. Res.-Solid Earth 2021, 126, e2021JB022608. [Google Scholar] [CrossRef]

- Suman, R.J.; Knight, R.J. Effects of pore structure and wettability on the electrical resistivity of partially saturated rocks—A network study. Geophysics 1997, 62, 1151–1162. [Google Scholar] [CrossRef]

- Bian, H.L.; Guan, J.; Mao, Z.Q.; Ju, X.D.; Han, G.Q. Pore structure effect on reservoir electrical properties and well logging evaluation. Appl. Geophys. 2014, 11, 374–383. [Google Scholar] [CrossRef]

- Frota, R.A.; Tanscheit, R.; Vellasco, M. Fuzzy logic for control of injector wells flow rates under produced water reinjection. J. Petrol. Sci. Eng. 2022, 215, 110574. [Google Scholar] [CrossRef]

- Delanka-Pedige, H.M.K.; Zhang, Y.Y.; Young, R.B.; Wang, H.Y.; Hu, L.; Danforth, C.; Xu, P. Safe reuse of treated produced water outside oil and gas fields? A review of current practices, challenges, opportunities, and a risk-based pathway for produced water treatment and fit-for-purpose reuse. Curr. Opin. Chem. Eng. 2023, 42, 100973109057. [Google Scholar] [CrossRef]

- van den Hoek, P.J.; Matsuura, T.; de Kroon, M.; Gheissary, G. Simulation of produced water reinjection under fracturing conditions. SPE Prod. Oper. 1999, 14, 166–176. [Google Scholar] [CrossRef]

- Ochi, J.; Dexheimer, D.; Corpel, P.V. Produced-Water-Reinjection Design and Uncertainties Assessment. SPE Prod. Oper. 2014, 29, 192–203. [Google Scholar] [CrossRef]

- Abou-Sayed, A.S.; Zaki, K.S.; Wang, G.; Sarfare, M.D.; Harris, M.H. Produced water management strategy and water injection best practices: Design, performance, and monitoring. SPE Prod. Oper. 2007, 22, 59–68. [Google Scholar] [CrossRef]

- Sun, Z.X.; Xu, Y.; Yao, J.; Sun, Z.L.; Liu, J.R. Numerical simulation of produced water reinjection technology for water-soluble gas recovery. J. Nat. Gas. Sci. Eng. 2014, 21, 700–711. [Google Scholar] [CrossRef]

- Wrobel, J.S.; Nachbin, A.; Marchesin, D. Numerical simulation of injectivity loss in stratified reservoirs. Commun. Numer. Methods Eng. 2007, 23, 507–520. [Google Scholar] [CrossRef]

- Yin, S. Numerical analysis of thermal fracturing in subsurface cold water injection by finite element methods. Int. J. Numer. Anal. Methods Geomech. 2013, 37, 2523–2538. [Google Scholar] [CrossRef]

- Jin, X.; Wei, Y.X.; Hu, S.Y.; Li, K.Q.; Xu, L.Z.; Shang, Y.B.; Zong, Y.K.; Shi, X.; Xu, L.; Bai, X.; et al. Significance of ozonation on surfactant-polymer flooding produced water coagulation: Water quality deterioration inhibition, high-standard reinjection and mechanism. Sep. Purif. Technol. 2024, 328, 125035. [Google Scholar] [CrossRef]

- Alhomadhi, E.S.; Almobaraky, M.A.; Alahaidib, I.A. Using polyester fiber media for treating produced oily water at different oil concentrations. Oil Gas-Eur. Mag. 2019, 45, 174–179. [Google Scholar]

- Buret, S.; Nabzar, L.; Jada, A. Water Quality and Well Injectivity: Do Residual Oil-in-Water Emulsions Matter? SPE J. 2010, 15, 557–568. [Google Scholar] [CrossRef]

- Azizov, I.; Dudek, M.; Oye, G. Emulsions in porous media from the perspective of produced water re-injection-A review. J. Pet. Sci. Eng. 2021, 206, 109057. [Google Scholar] [CrossRef]

- SY/T 5385-2007; Geological Technical Requirements for Trial Production of Conventional Oil Reservoirs. National Development and Reform Commission: Beijing, China, 2007.

- SY/T 5336-2023; Core Analysis Methods. National Energy Administration: Beijing, China, 2023.

- Daqing Oilfield, CNPC. Design Code for Surface Engineering Construction of Daqing Oilfield (Q/SY DQ 0639-2015) [S]; Daqing Oilfield Co., Ltd.: Daqing, China, 2015. [Google Scholar]

- Chen, Q.; Gao, Q.; Wang, X.P.; Xia, J.C.; Zhang, S.D.; Tang, K.; Li, C.T. Research Progress and Prospect of Polymerized Wastewater Treatment Technology. Water & Wastewater Engineering. Water Wastewater Eng. 2025, 61, 169–176. (In Chinese) [Google Scholar]

- Chen, W.J.; Jing, B.; Tan, G.R.; Meng, F.X.; Zhang, J.; Yin, X.Q. Research on the optimization of polymer-bearing wastewater treatment process in offshore oilfields. Ind. Water Treat. 2016, 36, 80–83. (In Chinese) [Google Scholar]

- Li, Q.; Yin, X.Q.; Zhai, L.; Jing, B. Field Test of Electrochemical Treatment of Wastewater Containing Polymer in Offshore Oilfield. Oil Gas Field Surf. Eng. 2016, 42, 78–81. [Google Scholar]

- Wang, S.; Yu, Z.C.; Zhong, L.B.; Han, L.; Niu, Y.L.; Li, Z.; Wu, J. Degradation of Polymer-Containing Produced Water by Fe Complex-UV Catalyzed Ozonation. Acta Pet. Sin. (Pet. Process. Sect.) 2016, 32, 981–986. (In Chinese) [Google Scholar]

- Lv, Z.F.; Zhan, F.T.; Wang, Z.X.; Zhang, S.D. Separation and composition characterization of acidic components in waterproduced by polymer flooding in Gudao Oilfield. J. Fuel Chem. Technol. 2008, 36, 588–593. (In Chinese) [Google Scholar]

- Wang, Q.J.; Yang, X.Y.; Li, J.; Wang, Q.H.; Gui, Y.f.; Pei, M.; Shi, Q.; Chen, C.M. Thoughts and suggestions on collaborative treatment of pollutant sources in oilfield production processes: An example taking the inhibition of oil mud formation in the treatment process of polymer flooding produced water. Chin. J. Environ. Eng. 2024, 18, 1475–1479. (In Chinese) [Google Scholar]

- Jia, C.Q.; Hu, J.C.; Sepehrnoori, K. Numerical Studies of Unstable Fingering Flow in a Water-Oil System. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, Oklahoma, USA, 21–23 April 2024; p. D031S016R002. [Google Scholar]

- Mohammadi, L.; Rahdar, A.; Bazrafshan, E.; Dahmardeh, H.; Susan, M.A.; Kyzas, G.Z. Petroleum Hydrocarbon Removal from Wastewaters: A Review. Processes 2020, 8, 447. [Google Scholar] [CrossRef]

- Yu, J.F.; Chen, H.; Cao, Y.F.; Wen, M.; Zhai, X.P.; Zhang, X.T.; Hao, T.C.; Peng, J.L.; Zhu, W.T. Experimental Evaluation of Blockage Resistance and Position Caused by Microparticle Migration in Water Injection Wells. Processes 2024, 12, 2275. [Google Scholar] [CrossRef]

- Wen, H.; Guo, X.M.; Zhang, D.; Wei, G.M.; Wang, W.; Fan, S.X.; Zhang, W.J. Response characteristics of coal microstructure with liquid CO2 acidizing treatment: An experimental study. J. Loss Prev. Process 2023, 85, 105175. [Google Scholar] [CrossRef]

| Core Number | Clear Water/ Sewage Ratio | Ka (mD) | Kr (mD) | I (%) |

|---|---|---|---|---|

| A1-2 | 1:0 | 12.68 | 9.20 | 27.41% |

| A1-3 | 1:0 | 12.85 | 9.52 | 25.89% |

| A1-4 | 1:1 | 13.02 | 9.97 | 23.36% |

| A1-5 | 1:1 | 13.15 | 9.54 | 27.41% |

| A1-6 | 1:3 | 13.24 | 9.34 | 29.40% |

| A1-7 | 1:3 | 13.33 | 10.08 | 24.37% |

| A1-8 | 1:5 | 13.41 | 9.18 | 31.54% |

| A1-9 | 1:5 | 13.47 | 8.79 | 34.72% |

| A1-10 | 0:1 | 13.50 | 10.99 | 18.52% |

| A1-11 | 0:1 | 13.08 | 11.04 | 15.54% |

| Core Number | Oil Content (mg/L) | Ka (mD) | Kr (mD) | I (%) |

|---|---|---|---|---|

| A1-13 | 20 | 12.91 | 12.22 | 5.32% |

| A1-14 | 20 | 12.05 | 11.49 | 4.58% |

| A1-15 | 40 | 13.33 | 12.04 | 9.62% |

| A1-16 | 40 | 13.12 | 11.97 | 8.74% |

| A1-17 | 60 | 12.22 | 10.09 | 17.41% |

| A1-18 | 60 | 13.02 | 10.90 | 16.27% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Dong, L.; Wang, Y.; Wang, L. Study of Mechanisms and Protective Strategies for Polymer-Containing Wastewater Reinjection in Sandstone Reservoirs. Processes 2025, 13, 1511. https://doi.org/10.3390/pr13051511

Cao J, Dong L, Wang Y, Wang L. Study of Mechanisms and Protective Strategies for Polymer-Containing Wastewater Reinjection in Sandstone Reservoirs. Processes. 2025; 13(5):1511. https://doi.org/10.3390/pr13051511

Chicago/Turabian StyleCao, Jie, Liqiang Dong, Yuezhi Wang, and Liangliang Wang. 2025. "Study of Mechanisms and Protective Strategies for Polymer-Containing Wastewater Reinjection in Sandstone Reservoirs" Processes 13, no. 5: 1511. https://doi.org/10.3390/pr13051511

APA StyleCao, J., Dong, L., Wang, Y., & Wang, L. (2025). Study of Mechanisms and Protective Strategies for Polymer-Containing Wastewater Reinjection in Sandstone Reservoirs. Processes, 13(5), 1511. https://doi.org/10.3390/pr13051511