Properties and Optimization Process Using Machine Learning for Recycling of Fly and Bottom Ashes in Fire-Resistant Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Leaching Study

2.2.2. Physical Properties

2.2.3. Fire Test

2.2.4. Mechanical Properties

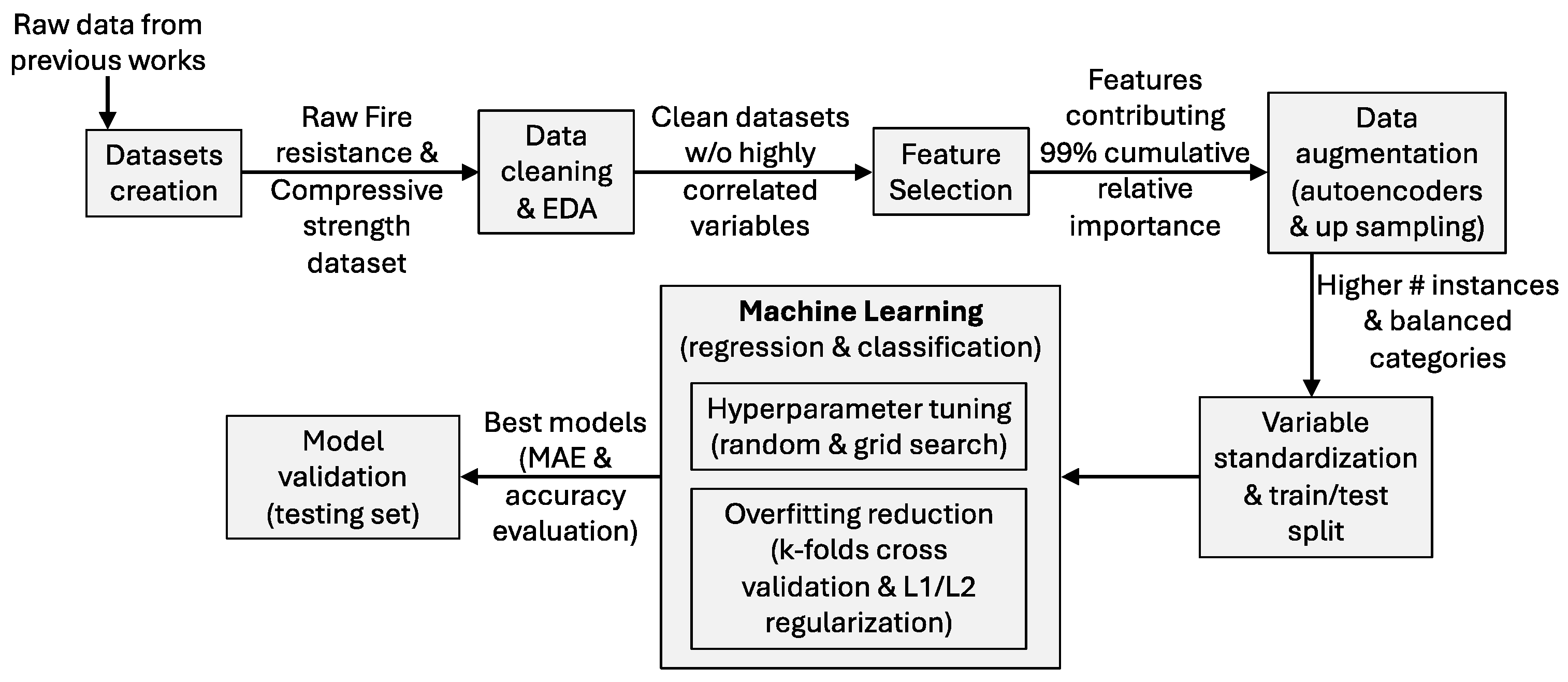

2.2.5. Machine Learning Method

- -

- Creation of datasets

- -

- Data cleaning and exploratory data analysis

- -

- Feature selection

- -

- Data augmentation

- -

- Machine learning algorithms

- -

- Overfitting reduction and hyperparameter tuning

- -

- Model validation

3. Results

3.1. Leaching Behaviour

3.2. Physical Properties

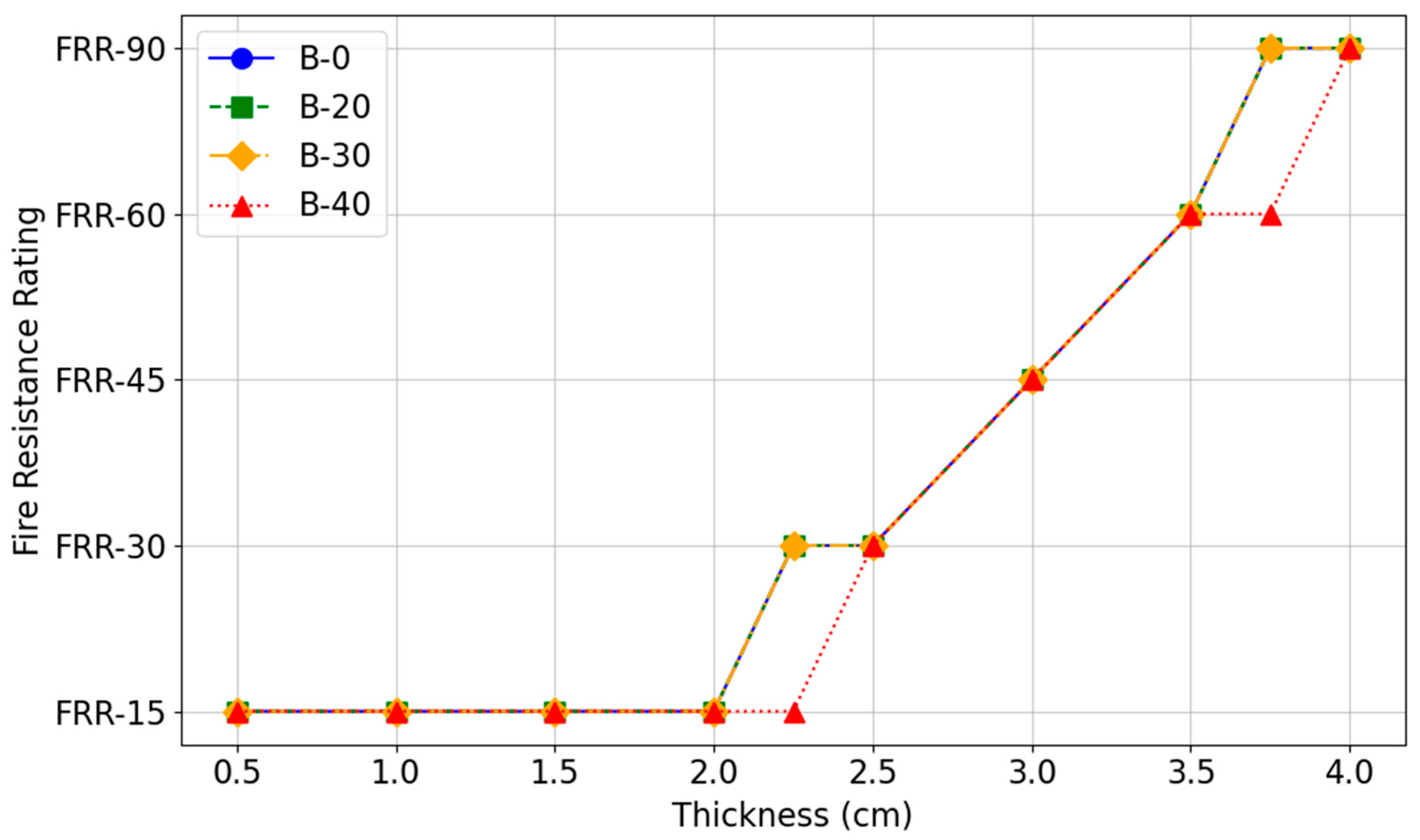

3.3. Fire Insulating Capacity

3.4. Mechanical Properties

4. Machine Learning Modelling Results

4.1. Feature Selection

4.1.1. Fire Resistance Feature

4.1.2. Compression Strength Feature

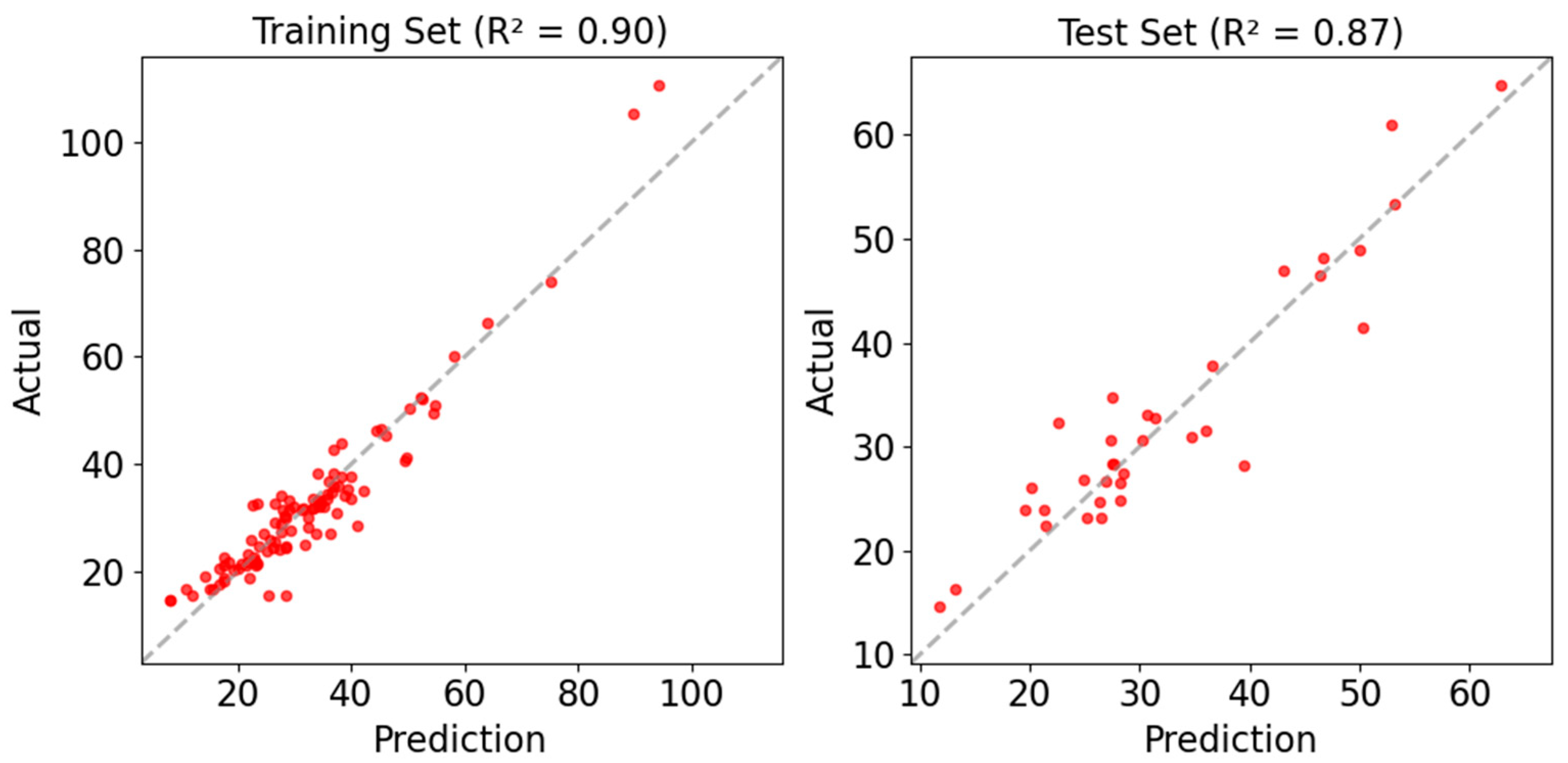

4.2. Regression Model Fitting

4.2.1. Fire Resistance Fitting

4.2.2. Compressive Strength Fitting

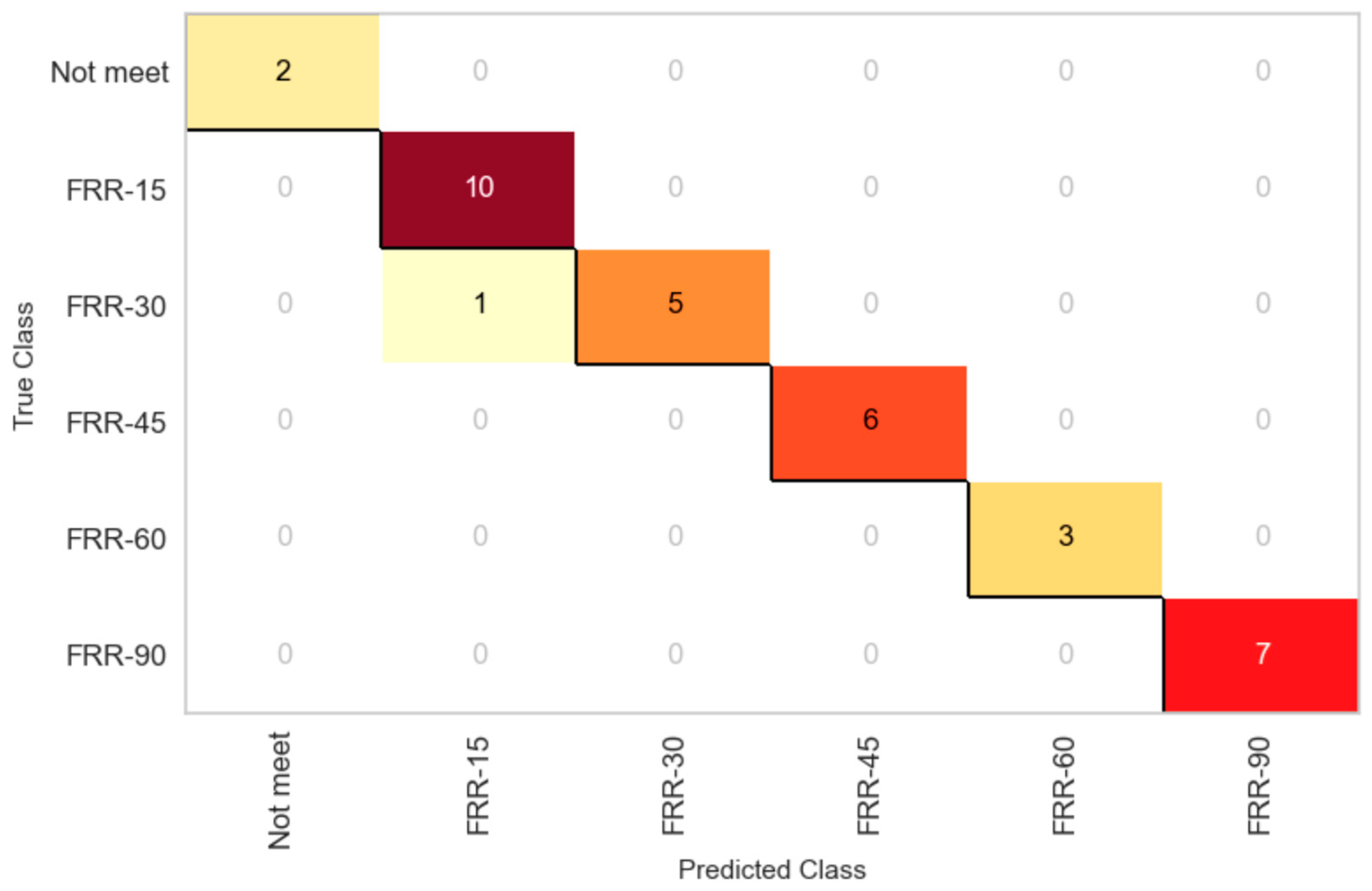

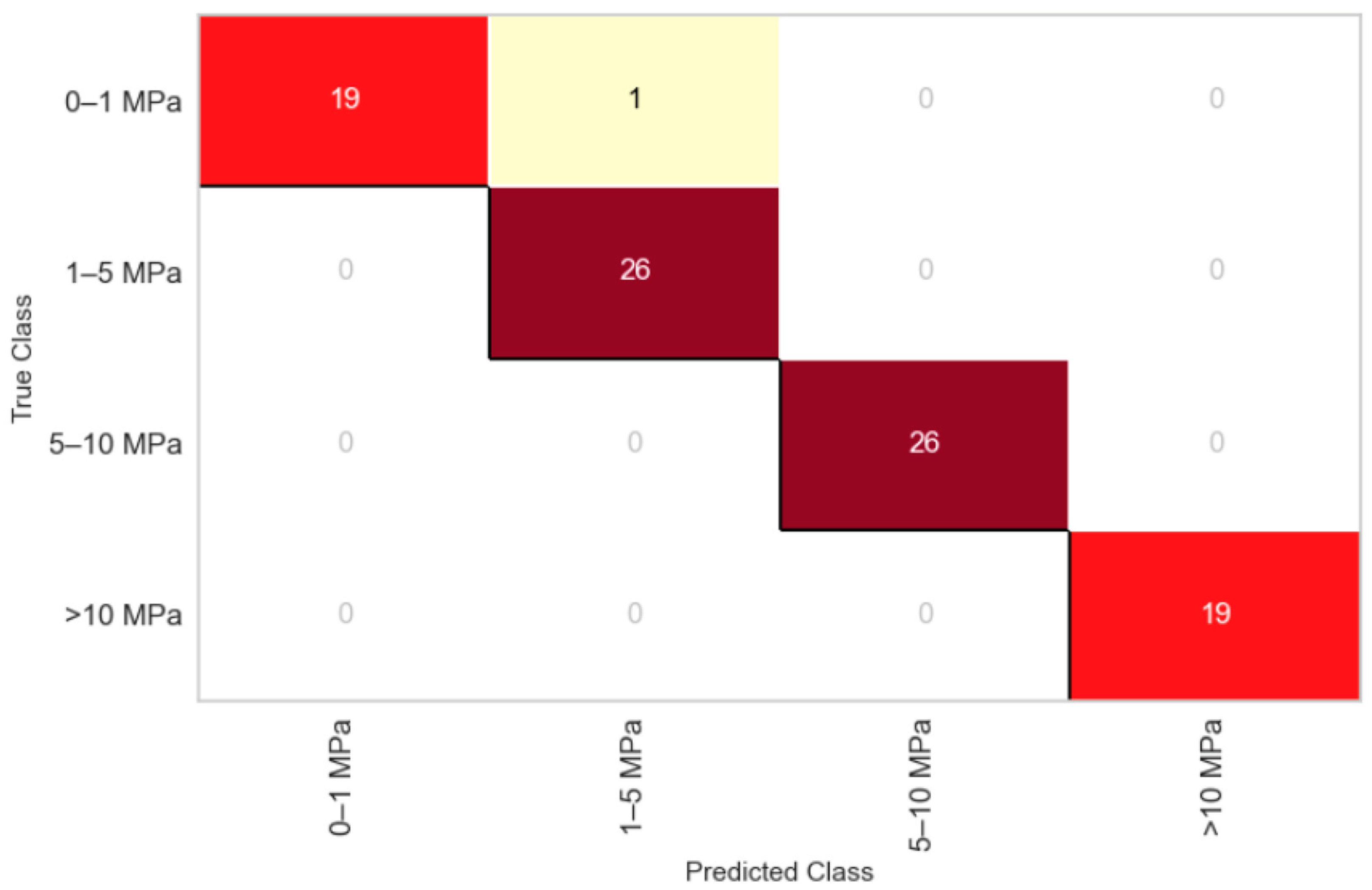

4.3. Classification Model Fitting

4.3.1. Fire Resistance Rating

4.3.2. Compressive Strength Rating

4.4. Model Application

5. Conclusions

- -

- The use of BA does not present any leaching problems, FA presents a moderate leaching content of Mo, which could invalidate its use in some European countries, due to the wide variety of different limits established in these countries, even using the same test in all of them.

- -

- The addition of BA reduces the bulk density due to higher particle size of the BA, slightly decreasing the fire resistance of the panel, mainly due to the decrease in the slope, especially after the evaporation plateau. This significantly decreased the compressive strength, although the flexural strength did not decrease excessively due to the action of the polypropylene fibers in all compositions.

- -

- The regression models for fire resistance (t180) reached r2 up to about 0.85. The classification results for the fire resistance rating (FRR) showed high accuracy (96%) so the use of machine learning seems a good option to optimize the design of a material (using simple parameters: composition and thickness), reducing time and costs of the trials.

- -

- The prediction of compressive strength is not as good as t180, which may indicate that more input parameters are necessary (granulometry or porosity, chemical composition of some key components in the hardening of the materials). However, compressive strength classification performs well for some models, like decision tree, reaching up to 99% accuracy using simple parameters.

- -

- These models can be useful not only for predicting the values of the t180 or Rc variables (or the classes to which they belong in the classification problem), thereby reducing the need for experimental testing.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sharma, V.; Dash, S.; Gupta, P. Comprehensive Review of Fly Ash: Environmental Impact and Applications. Environ. Qual. Manag. 2024, 34, e22338. [Google Scholar] [CrossRef]

- Lu, X.; Liu, B.; Zhang, Q.; Wen, Q.; Wang, S.; Xiao, K.; Zhang, S. Recycling of Coal Fly Ash in Building Materials: A Review. Minerals 2023, 13, 25. [Google Scholar] [CrossRef]

- Vilakazi, A.Q.; Ndlovu, S.; Chipise, L.; Shemi, A. The Recycling of Coal Fly Ash: A Review on Sustainable Developments and Economic Considerations. Sustainability 2022, 14, 1958. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.; Li, A.; Zhou, N. Reutilisation of Coal Gangue and Fly Ash as Underground Backfill Materials for Surface Subsidence Control. J. Clean. Prod. 2020, 254, 120113. [Google Scholar] [CrossRef]

- Shaheen, S.M.; Hooda, P.S.; Tsadilas, C.D. Opportunities and Challenges in the Use of Coal Fly Ash for Soil Improvements—A Review. J. Environ. Manag. 2014, 145, 249–267. [Google Scholar] [CrossRef]

- Luna, Y.; Arenas, C.G.; Cornejo, A.; Leiva, C.; Vilches, L.F.; Fernández-Pereira, C. Recycling By-Products from Coal-Fired Power Stations into Different Construction Materials. Int. J. Energy Environ. Eng. 2014, 5, 387–397. [Google Scholar] [CrossRef]

- Chindasiriphan, P.; Meenyut, B.; Orasutthikul, S.; Jongvivatsakul, P.; Tangchirapat, W. Influences of High-Volume Coal Bottom Ash as Cement and Fine Aggregate Replacements on Strength and Heat Evolution of Eco-Friendly High-Strength Concrete. J. Build. Eng. 2023, 65, 105791. [Google Scholar] [CrossRef]

- Ali, T.; Buller, A.S.; Abro, F.u.R.; Ahmed, Z.; Shabbir, S.; Lashari, A.R.; Hussain, G. Investigation on Mechanical and Durability Properties of Concrete Mixed with Silica Fume as Cementitious Material and Coal Bottom Ash as Fine Aggregate Replacement Material. Buildings 2022, 12, 44. [Google Scholar] [CrossRef]

- Mohammed, S.A.; Koting, S.; Katman, H.Y.B.; Babalghaith, A.M.; Abdul Patah, M.F.; Ibrahim, M.R.; Karim, M.R. A Review of the Utilization of Coal Bottom Ash (CBA) in the Construction Industry. Sustainability 2021, 13, 8031. [Google Scholar] [CrossRef]

- Caetano, H.; Laím, L.; Santiago, A.; Durães, L.; Shahbazian, A. Development of Passive Fire Protection Mortars. Appl. Sci. 2022, 12, 2093. [Google Scholar] [CrossRef]

- Li, J.; Zhuang, X.; Leiva, C.; Cornejo, A.; Font, O.; Querol, X.; Moeno, N.; Arenas, C.; Fernández-Pereira, C. Potential Utilization of FGD Gypsum and Fly Ash from a Chinese Power Plant for Manufacturing Fire-Resistant Panels. Constr. Build. Mater. 2015, 95, 910–921. [Google Scholar] [CrossRef]

- Zheng, S.; Chen, M.; Liu, T.; Yang, G.; Jiang, G.; Gu, H. Research on Compressive Strength and Thermal Conductivity of Lightweight Phosphogypsum-Based Composite Cementitious Materials. Constr. Build. Mater. 2024, 436, 136955. [Google Scholar] [CrossRef]

- Du, J.; Tian, L.; Qi, M.; Zhang, C.; Di, H.; Zhi, X.; Zhu, J. Revealing Maleic Acid Role in the Preparation of α-Hemihydrate Gypsum from Titanium Gypsum through Experiments and DFT Calculations. Sci. Total Environ. 2023, 897, 166405. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Shi, Z.; Wang, Z.; Dong, J.; Wang, X.; Zhao, X. Microstructure and Performances of Sludge Soil Stabilized by Fluorogypsum-Based Cementitious Binder. Constr. Build. Mater. 2022, 325, 126702. [Google Scholar] [CrossRef]

- Rashad, A.M. Vermiculite as a Construction Material—A Short Guide for Civil Engineer. Constr. Build. Mater. 2016, 125, 53–62. [Google Scholar] [CrossRef]

- Singh, M.; Garg, M. Perlite-Based Building Materials—A Review of Current Applications. Constr. Build. Mater. 1991, 5, 75–81. [Google Scholar] [CrossRef]

- Leiva, C.; Vilches, L.F.; Vale, J.; Fernández-Pereira, C. Influence of the Type of Ash on the Fire Resistance Characteristics of Ash-Enriched Mortars. Fuel 2005, 84, 1433–1439. [Google Scholar] [CrossRef]

- Leiva, C.; Gómez-Barea, A.; Vilches, L.F.; Ollero, P.; Vale, J.; Fernández-Pereira, C. Use of Biomass Gasification Fly Ash in Lightweight Plasterboard. Energy Fuels 2007, 21, 361–367. [Google Scholar] [CrossRef]

- Sakkas, K.; Nomikos, P.; Sofianos, A.; Panias, D. Utilisation of FeNi-Slag for the Production of Inorganic Polymeric Materials for Construction or for Passive Fire Protection. Waste Biomass Valorization 2014, 5, 403–410. [Google Scholar] [CrossRef]

- Peceño, B.; Pérez-Soriano, E.M.; Luna-Galiano, Y.; Leiva, C. The Incorporation of Ladle Furnace Slag in Fire Insulating Gypsum-Based Materials. Fire 2023, 6, 416. [Google Scholar] [CrossRef]

- Guedri, A.; Abdallah, F.; Mefteh, N.; Hamdi, N.; Baeza-Urrea, O.; Wagner, J.-F.; Zagrarni, M.F. Addition of Phosphogypsum to Fire-Resistant Plaster Panels: A Physic–Mechanical Investigation. Inorganics 2023, 11, 35. [Google Scholar] [CrossRef]

- Peceño, B.; Luna-Galiano, Y.; Varela, F.; Alonso-Fariñas, B.; Leiva, C. Study of a Fire-Resistant Plate Containing Fly Ashes Generated from Municipal Waste Incinerator: Fire and Mechanical Characteristics and Environmental Life Cycle Assessment. Materials 2024, 17, 1813. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Martinez, J.D.; Moreno, V.; González-Arias, J.; Peceño Capilla, B.; Baena-Moreno, F.M.; Leiva, C. A Circular Economy Perspective: Recycling Wastes through the CO2 Capture Process in Gypsum Products. Fire Resistance, Mechanical Properties, and Life Cycle Analysis. Fire 2024, 7, 365. [Google Scholar] [CrossRef]

- Salazar, P.A.; Fernández, C.L.; Luna-Galiano, Y.; Sánchez, R.V.; Fernández-Pereira, C. Physical, Mechanical and Radiological Characteristics of a Fly Ash Geopolymer Incorporating Titanium Dioxide Waste as Passive Fire Insulating Material in Steel Structures. Materials 2022, 15, 8493. [Google Scholar] [CrossRef]

- Peceño, B.; Alonso-Fariñas, B.; Vilches, L.F.; Leiva, C. Study of Seashell Waste Recycling in Fireproofing Material: Technical, Environmental, and Economic Assessment. Sci. Total Environ. 2021, 790, 148102. [Google Scholar] [CrossRef]

- Ma, D.-X.; Yin, G.-Z.; Ye, W.; Jiang, Y.; Wang, N.; Wang, D.-Y. Exploiting Waste towards More Sustainable Flame-Retardant Solutions for Polymers: A Review. Materials 2024, 17, 2266. [Google Scholar] [CrossRef] [PubMed]

- Valanides, M.; Aivaliotis, K.; Oikonomopoulou, K.; Fikardos, A.; Savva, P.; Sakkas, K.; Nicolaides, D. Geopolymerization of Recycled Glass Waste: A Sustainable Solution for a Lightweight and Fire-Resistant Material. Recycling 2024, 9, 16. [Google Scholar] [CrossRef]

- Vilches, L.F.; Leiva, C.; Olivares, J.; Vale, J.; Fernández, C. Coal Fly Ash-Containing Sprayed Mortar for Passive Fire Protection of Steel Sections. Mater. Construcción 2005, 55, 25. [Google Scholar] [CrossRef]

- Rane, N.L.; Mallick, S.K.; Kaya, O.; Rane, J. Applications of Deep Learning in Healthcare, Finance, Agriculture, Retail, Energy, Manufacturing, and Transportation: A Review. In Applied Machine Learning and Deep Learning: Architectures and Techniques; Deep Science Publishing: Fresno, CA, USA, 2024; pp. 132–152. [Google Scholar] [CrossRef]

- Ranjana, R.; Rao, B.N.K.; Raja, J.; Challa, N.P.; Madhavi, K.R. Machine Learning and Computer Vision—Beyond Modeling, Training, and Algorithms. In Explainable Artificial Intelligence (XAI); The Institution of Engineering and Technology: Perth, Australia, 2024; pp. 293–307. [Google Scholar] [CrossRef]

- Chandra, S.P.; Hajra, M.; Ghosh, M. Supervised Classification Algorithms in Machine Learning: A Survey and Review. In Emerging Technology in Modelling and Graphics; Springer: Singapore, 2020; pp. 99–111. [Google Scholar] [CrossRef]

- Naeem, S.; Ali, A.; Anam, S.; Ahmed, M.M. An Unsupervised Machine Learning Algorithms: Comprehensive Review. Int. J. Comput. Digit. Syst. 2023, 13, 911–921. [Google Scholar] [CrossRef]

- Najjar, E.; Majeed Breesam, A. Supervised Machine Learning a Brief Survey of Approaches. Al-Iraqia J. Sci. Eng. Res. 2023, 2, 71–82. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, S.; Li, Z.; Wang, L.; Shi, Y.; Luo, Q. Machine Learning-Based Model for Prediction of Elastic Modulus of Calcium Hydroxide in Oil Well Cement Under High-Temperature High-Pressure Conditions. Processes 2025, 13, 344. [Google Scholar] [CrossRef]

- ASTM D3682-21; Standard Test Method for Major and Minor Elements in Combustion Residues from Coal Utilization Processes by Atomic Spectrometry. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- EN 196-2; Methods of Testing Cement. Part 2: Chemical Analysis of Cement. European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- EN 450-1; Fly Ash for Concrete. Part 1: Definitions, Specifications and Conformity Criteria. European Comittee for Standardization (CEN): Brussels, Belgium, 2013.

- EN 13279-1:2009; Gypsum Binders and Gypsum Plasters—Part 1: Definitions and Requirements. European Committee for Standardization (CEN): Brussels, Belgium, 2009.

- Leiva, C.; Vilches, L.F.; Vale, J.; Fernández-Pereira, C. Fire Resistance of Biomass Ash Panels Used for Internal Partitions in Buildings. Fire Saf. J. 2009, 44, 622–628. [Google Scholar] [CrossRef]

- EN 12457-4:2003; Characterization of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges. European Committee for Standardization (CEN): Brussels, Belgium, 2003.

- EN 520:2005+A1:2010; Gypsum Plasterboards—Definitions, Requirements and Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- UNE 102042:2023; Gypsum Plasters. Other Test Methods. Asociación Española de Normalización (UNE): Madrid, Spain, 2023.

- EN 196-3; Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness. European Committee for Standardization (CEN): Brussels, Belgium, 2017.

- EN 1363-1:2021; Fire Resistance Tests—Part 1: General Requirements. European Committee for Standardization (CEN): Brussels, Belgium, 2021.

- EN 1015-11; Methods of Test for Mortar for Masonary—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 2000.

- EN 13279-2; Gypsum Binders and Gypsum Plasters—Part 2: Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- EN 13501-2:2009+A1:2010; Fire Classification of Construction Products and Building Elements—Part 2: Classification Using Data from Fire Resistance Tests, Excluding Ventilation Services. European Committee for Standardization (CEN): Brussels, Belgium, 2010.

- Cheung, T.-H.; Yeung, D.-Y. A Survey of Automated Data Augmentation for Image Classification: Learning to Compose, Mix, and Generate. IEEE Trans. Neural Netw. Learn. Syst. 2024, 35, 13185–13205. [Google Scholar] [CrossRef]

- Ali, Y.A.; Awwad, E.M.; Al-Razgan, M.; Maarouf, A. Hyperparameter Search for Machine Learning Algorithms for Optimizing the Computational Complexity. Processes 2023, 11, 349. [Google Scholar] [CrossRef]

- European Commission. Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste; European Commission: Brussels, Belgium, 1999; Available online: https://eur-lex.europa.eu/eli/dir/1999/31/oj (accessed on 16 March 2025).

- Córdoba, P.; Diego, R. Oxy-Coal Combustion Fly Ashes: Leachability of Inorganic Trace Contaminants. Energy Fuels 2019, 33, 4531–4541. [Google Scholar] [CrossRef]

- EN 12457-2; Characterization of Waste—Leaching; Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/Kg for Material with Particle Size below 4 Mm (Without or with Size Reduction). European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- Blasenbauer, D.; Huber, F.; Lederer, J.; Quina, M.J.; Blanc-Biscarat, D.; Bogush, A.; Bontempi, E.; Blondeau, J.; Chimenos, J.M.; Dahlbo, H.; et al. Legal Situation and Current Practice of Waste Incineration Bottom Ash Utilisation in Europe. Waste Manag. 2020, 102, 868–883. [Google Scholar] [CrossRef]

- Ministero dell’Ambiente e della Tutela del Territorio. Individuazione dei Rifiuti non Pericolosi Sottoposti Alle Procedure Semplificate di Recupero, ai Sensi Degli Articoli 31 e 33 del Decreto Legislativo 5 Febbraio 1997, N. 22; Ministero dell’Ambiente e della Tutela del Territorio: Rome, Italy, 2006.

- Ministry of the Environment, Lithuanian Government. SAKYMAS—Dėl Atliekų Deginimo Įrenginiuose Ir Bendro Atliekų Deginimo Įrenginiuose Susidariusių Pelenų Ir Šlako Tvarkymo Reikalavimų Patvirtinimo—2016 m. Lapkričio 25 d. Nr. D1-80; Ministry of the Environment, Lithuanian Government: Vilnius, Lithuania, 2016.

- Generalitat de Catalunya. Num. 2181-13.3.1996 Ordre de 15 de Febrer de 1996, Sobre Valorització d’ Escóries; Department de Medi Ambient, Ed.; Department de Medi Ambient: Catalunya, Spain, 1995.

- DL 183/2009; Waste Disposal at Landfills. Transposition to the Portuguese Law of Council. Directive 1999/31/CE. Government of Portugal: Lisboa, Portugal, 2009.

- Doleželová, M.; Scheinherrová, L.; Krejsová, J.; Keppert, M.; Černý, R.; Vimmrová, A. Investigation of Gypsum Composites with Different Lightweight Fillers. Constr. Build. Mater. 2021, 297, 123791. [Google Scholar] [CrossRef]

- Caetano, H.; Vilhena, L.; Ramalho, A.; Santiago, A.; Laím, L.; Monteiro, E. Mechanical Characterisation of Gypsum-Based Passive Fire Protection Mortars with Micro and Nano Silica Particles. Appl. Sci. 2024, 14, 8612. [Google Scholar] [CrossRef]

- EN 12859; Gypsum Blocks Definitions, Requirements and Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- Álvarez, M.; Ferrández, D.; Morón, C.; Atanes-Sánchez, E. Characterization of a New Lightened Gypsum-Based Material Reinforced with Fibers. Materials 2021, 14, 1203. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | TiO2 | P2O5 | SO3 | Loss On Ignition (LOI) | Specific Gravity (g/cm3) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FA | 48.7 | 24.3 | 7.9 | 0.07 | 1.8 | 2.3 | 0.7 | 3.7 | 1.5 | 0.4 | 0.02 | 6.6 | 2.7 |

| BA | 52.3 | 25.1 | 9.2 | 0.07 | 1.8 | 2.4 | 0.7 | 3.7 | 1.5 | 0.3 | 0.03 | 1.1 | 2.3 |

| Bottom Ash | Fly Ash | Gypsum | Vermiculite | Polypropilene Fibers | Water/Solid Ratio | |

|---|---|---|---|---|---|---|

| B-0 | 0 | 60 | 30 | 9.5 | 0.5 | 0.4 |

| B-20 | 20 | 40 | 30 | 9.5 | 0.5 | 0.4 |

| B-30 | 30 | 30 | 30 | 9.5 | 0.5 | 0.4 |

| B-40 | 40 | 20 | 30 | 9.5 | 0.5 | 0.4 |

| Algorithm Type | Hyperparameter | Minimal Value | Maximum Value | Other |

|---|---|---|---|---|

| Decision tree | Max depth | 1 | 30 | |

| Random forest | Number of Estimators | 1 | 100 | |

| Max depth | 1 | 50 | ||

| Max features | Sqrt | 7 | ||

| Ridge | Alpha | 0.1 | 20 | |

| Lasso | Alpha | 0.1 | 20 | |

| k-Neighbors | Number of Neighbors | 1 | 15 | |

| Weights | Uniform, distance | |||

| Gradient boosting | Loss | Squared error | ||

| Learning rate | 0.01 | 1 | ||

| Number of Estimators | 1 | 30 | ||

| Max depth | 5 | 30 | ||

| Max features | Sqrt | 8 | ||

| Subsample | 0.1 | 1 | ||

| XG boost | Learning rate | 0.001 | 0.5 | |

| Number of Estimators | 10 | 200 | ||

| Max depth | 1 | 20 | ||

| Multilayer perceptron | Hidden layer size | (4, 4) | (32, 32) | |

| Activation | ReLU | |||

| Solver | Adam | |||

| Alpha | 0.0 | 0.1 | ||

| Validation fraction | 0.05 | 0.15 | ||

| Max iterations | 10,000 | |||

| Learning rate | 0.001 | 0.5 | ||

| Early stopping | True |

| Algorithm Type | Hyperparameter | Minimal Value | Maximum Value | Other |

|---|---|---|---|---|

| Decision tree | Max depth | 1 | 20 | |

| Random forest | Numbers of Estimators | 1 | 100 | |

| Max depth | 1 | 50 | ||

| Max features | Sqrt | 6 | ||

| Ridge | Alpha | 0.1 | 5 | |

| Logistic regression | C | 0.1 | 5 | |

| k-Neighbors | Number of Neighbors | 1 | 15 | |

| Weights | Uniform, distance | |||

| Gradient boosting | Loss | Log loss | ||

| Learning rate | 0.05 | 1 | ||

| # Estimators | 5 | 30 | ||

| Max depth | 15 | 30 | ||

| Max features | Sqrt | 8 | ||

| Subsample | 0.5 | 1 | ||

| XG boost | Learning rate | 0.01 | 1 | |

| Number of Estimators | 100 | 200 | ||

| Max depth | 1 | 20 | ||

| Multilayer perceptron | Hidden layer size | (4, 4) | (32, 32) | |

| Activation | ReLU | |||

| Solver | Adam | |||

| Alpha | 0.05 | 0.3 | ||

| Validation fraction | 0.05 | 0.3 | ||

| Max iterations | 10,000 | |||

| Learning rate | 0.001 | 0.1 | ||

| Early stopping | True |

| Regulation. | BA | FA | EULFD | Italy | Lithuania | Wallonia (Belgium) | Catalonia (Spain) | |

|---|---|---|---|---|---|---|---|---|

| Application | Inert Landfill | Non-Hazardous | Construction Materials | Civil Engineering | Base Layer | Road Sub-Base | ||

| As | 0.006 | 0.21 | 0.5 | 2 | 0.5 | - | 1 | 1 |

| Ba | 0.004 | 0.065 | 20 | 100 | 0.052 | 0.03 | - | - |

| Cd | <0.001 | <0.001 | 0.04 | 1 | 0.5 | 2 | 1 | 1 |

| Cr | <0.001 | 0.071 | 0.5 | 10 | 0.5 | 1.5 | - | - |

| Cu | <0.001 | 0.0008 | 2 | 50 | 0.01 | 0.001 | 20 | 20 |

| Hg | <0.01 | <0.01 | 0.01 | 0.2 | - | - | 0.2 | - |

| Mo | 0.009 | 0.827 | 0.5 | 10 | 0.1 | 0.4 | 1.5 | - |

| Ni | 0.005 | 0.0009 | 0.4 | 10 | 0.5 | 0.5 | 2 | - |

| Pb | <0.001 | <0.001 | 0.5 | 10 | - | - | 2 | 5 |

| Sb | <0.001 | 0.046 | 0.06 | 0.7 | 30 | 3 | 1.98 | |

| Se | <0.001 | 0.041 | 0.1 | 0.5 | 0.5 | |||

| Zn | <0.001 | <0.001 | 4 | 50 | 0.052 | 0.03 | 9.2 | 20 |

| PARAMETER | B-0 | B-20 | B-30 | B-40 |

|---|---|---|---|---|

| Bulk density (kg/m3) | 1093 ± 80 | 1047 ± 35 | 1030 ± 45 | 1004 ± 21 |

| Free water (%) | 6.0 ± 0.2 | 6.3 ± 0.2 | 6.8 ± 0.2 | 7.5 ± 0.2 |

| Water absorption(%) | 16.7 ± 1.3 | 19.4 ± 1.7 | 21.2 ± 2.0 | 26.7 ± 2.1 |

| pH | 9.5 ± 0.2 | 10.0 ± 0.3 | 10.1 ± 0.3 | 9.6 ± 0.3 |

| Volume stability (mm) | 0.5 ± 0.1 | 0.5 ± 0.1 | 0.6 ± 0.1 | 0.7 ± 0.1 |

| Parameter | B-0 | B-20 | B-30 | B-40 |

|---|---|---|---|---|

| Rc (before the fire) (MPa) | 2.0 ± 0.3 | 1.5 ± 0.2 | 1.3 ± 0.2 | 1.0 ± 0.3 |

| Rc (after the fire) (MPa) | 0.9 ± 0.1 | 0.8 ± 0.1 | 0.7 ± 0.1 | 0.7 ± 0.1 |

| Rf (before the fire) (MPa) | 0.84 ± 0.06 | 0.80 ± 0.05 | 0.72 ± 0.04 | 0.53 ± 0.04 |

| Rf (after the fire) (MPa) | 0.29 ± 0.03 | 0.22 ± 0.03 | 0.19 ± 0.03 | 0.14 ± 0.03 |

| Superficial hardness (before the fire) (Shore C) | 66 ± 5 | 56 ± 6 | 41 ± 4 | 28 ± 2 |

| After the fire on exposed surface (Shore C) | 19 ± 2 | 14 ± 2 | 12 ± 1 | 9 ± 1 |

| After the fire on non-exposed surface (Shore C) | 30 ± 2 | 21 ± 3 | 18 ± 2 | 15 ± 2 |

| RI (mm) | 13.8 ± 0.6 | 14.5 ± 0.5 | 14.8 ± 0.5 | 15.3 ± 0.5 |

| Parameter | B-0 | B-20 | B-30 | B-40 |

|---|---|---|---|---|

| t180 (actual) (min) | 28.2 | 26.9 | 25.9 | 25.3 |

| t180 (prediction) (min) | 28.4 | 29.3 | 28.8 | 23.2 |

| Error (%) | 0.7 | 9.1 | 11.2 | −8.5 |

| Parameter | B-0 | B-20 | B-30 | B-40 |

|---|---|---|---|---|

| Rc (actual) (MPa) | 2.02 | 1.50 | 1.26 | 0.98 |

| Rc (prediction) (MPa) | 1.15 | 0.93 | 0.90 | 0.86 |

| Error (%) | −42.9 | −38.3 | −28.2 | −11.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guirado, E.; Ruiz Martinez, J.D.; Campoy, M.; Leiva, C. Properties and Optimization Process Using Machine Learning for Recycling of Fly and Bottom Ashes in Fire-Resistant Materials. Processes 2025, 13, 933. https://doi.org/10.3390/pr13040933

Guirado E, Ruiz Martinez JD, Campoy M, Leiva C. Properties and Optimization Process Using Machine Learning for Recycling of Fly and Bottom Ashes in Fire-Resistant Materials. Processes. 2025; 13(4):933. https://doi.org/10.3390/pr13040933

Chicago/Turabian StyleGuirado, Elena, Jaime Delfino Ruiz Martinez, Manuel Campoy, and Carlos Leiva. 2025. "Properties and Optimization Process Using Machine Learning for Recycling of Fly and Bottom Ashes in Fire-Resistant Materials" Processes 13, no. 4: 933. https://doi.org/10.3390/pr13040933

APA StyleGuirado, E., Ruiz Martinez, J. D., Campoy, M., & Leiva, C. (2025). Properties and Optimization Process Using Machine Learning for Recycling of Fly and Bottom Ashes in Fire-Resistant Materials. Processes, 13(4), 933. https://doi.org/10.3390/pr13040933