Food Defense in the Extra Neutral Alcohol Industry: Ensuring Safety Against Intentional Contaminations

Abstract

1. Introduction

2. Overview of Food Defense in the Global Food Industry

- Large companies: until July 2019;

- Small companies (less than 500 employees): until July 2020;

- Very small companies (with less than USD 10 million in revenue over 3 years): until July 2021 [14].

3. Key Vulnerabilities and Preventive Strategies in Food Defense

- Assess vulnerabilities;

- Write a plan;

- Prepare a response plan; and

- Manage the plan.

- Develop a Food Defense Plan;

- Implement mitigation strategies and protective measures;

- Test the mitigation strategies and protective measures;

- Review and maintain.

- Risk Analysis: Companies should conduct a comprehensive risk analysis to identify and assess all potential threats to food safety.

- Access Control: Access to critical areas of the factory and production facilities should be restricted to authorized and supervised personnel only.

- Background Checks: Background checks should be conducted for all employees, suppliers, and visitors before granting access to company facilities.

- Employee Training: All employees should be trained in food safety measures, including recognizing signs of potential threats and the actions to take in case of incidents.

- Monitoring: Companies should continuously monitor production facilities, equipment, and raw materials to detect any signs of potential threats.

- Cybersecurity: Companies must ensure the security of information technology (IT) systems and production data to prevent cyberattacks.

- Supplier Control: Companies should ensure that all suppliers and subcontractors adhere to the same strict food defense standards.

- Communication: Establish clear and open communication with employees, suppliers, customers, and partners to share information about potential threats and preventive measures.

4. Importance of Food Defense Plan in the Extra Neutral Alcohol Industry

4.1. Ehanol Production Worldwide

4.2. Types of Alcohol

- Anhydrous Ethyl Alcohol: Used as an additive in fuels, composed of 99.5% pure alcohol and 0.5% water. It is suitable for chemical industries as raw material for paints, varnishes, and solvents.

- Hydrated Ethyl Alcohol: It contains 96% pure alcohol and 4% water, suitable for the chemical and cleaning industries.

- Neutral Ethyl Alcohol or Extra Neutral: Utilized in the production of beverages, foods, cosmetics, and medicines. It does not interfere with the aroma as it is the purest form of alcohol. The production of extra neutral alcohol involves additional purification steps, such as hydroselection and redistillation [35,36].

4.3. Extra Neutral Alcohol Applied in Foods

4.4. Manufacturing and Fractionation of Extra Neutral Alcohol

5. Potential Hazards

- Physical Hazards: Refers to the presence of foreign objects, particles, or physical substances in food that can cause physical harm when consumed. Examples include glass fragments, metal, plastic, wood chips, stones, among others.

- Chemical Hazards: Relates to the presence of unwanted chemicals in food that can pose health risks when ingested. Examples include pesticides, excessive food additives, residues from cleaning products, heavy metals, aflatoxins, among others.

- Biological Hazards: Refers to the presence of microorganisms such as bacteria, viruses, parasites, or fungi in food that can cause diseases when consumed. Examples include Salmonella, E. coli, Listeria monocytogenes, Campylobacter, Norovirus, among others.

Possible Contamination Pathways in the Production of Extra Neutral Alcohol

- Solubility: Ethanol is miscible in water, meaning it dissolves completely in water in all proportions. This property is fundamental in many applications, including the production of alcoholic beverages.

- Boiling and Freezing Points: The boiling point of ethanol is relatively low, about 78.37 °C. This facilitates distillation during the production of alcoholic beverages. The freezing point is −114.1 °C.

- Flammability: Ethanol is flammable. It can catch fire at relatively low temperatures, making it useful as fuel in internal combustion engines and as an ingredient in flammable products.

- Disinfectant and Antiseptic: Alcohol is known for its disinfectant and antiseptic properties. Alcoholic solutions are commonly used to clean and disinfect surfaces and hands.

- Psychoactive Effect: The consumption of ethanol has psychoactive effects. It acts as a depressant of the central nervous system, causing changes in mood, coordination, and judgment.

- Heat Production: Burning alcohol releases heat. This is one of the principles behind the use of alcohol as fuel.

- Toxicity: Alcohol in large quantities can be toxic to the human body. Excessive consumption can lead to health problems, including damage to the liver, nervous system, and other organs.

- Polar Character: Due to the presence of the hydroxyl group, ethanol is a polar molecule. This characteristic influences its interactions with other substances [56].

6. Future Recommendations

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wiśniewska, M.Z.; Tarczyńska, A.S.; Ranadheera, C.S. Novel quality assurance systems against intentional contamination in dairy factories. In Dairy Foods: Processing, Quality, and Analytical Techniques; Smith, J., Johnson, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 281–310. [Google Scholar] [CrossRef]

- Huff, A. Food defense. In Encyclopedia of Food Chemistry; Elsevier: London, UK, 2018; pp. 652–656. [Google Scholar] [CrossRef]

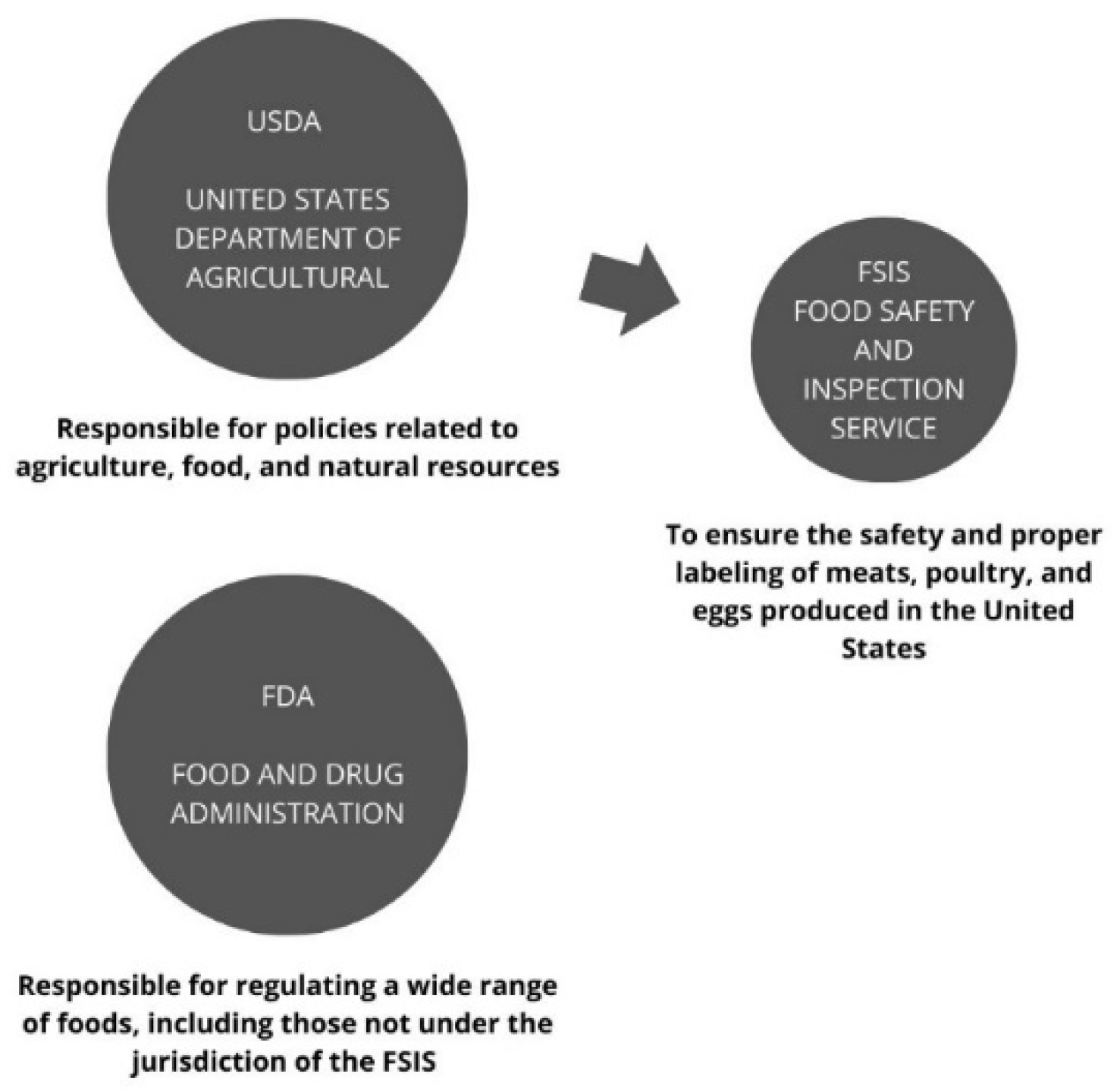

- U.S. Department of Agricultural Food Safety and Inspection Service (USDA). Food Defense Risk Mitigation Tool. Available online: https://www.fsis.usda.gov/food-safety/food-defense-and-emergency-response/food-defense (accessed on 4 September 2023).

- Food and Drug Administration. Food Defense. Available online: https://www.fda.gov/food/food-defense (accessed on 4 September 2023).

- BSI Group. PAS 96:2017—Guide to Protecting and Defending Food and Drink from Deliberate Attack. Available online: https://www.bsigroup.com/en-GB/PAS-96/ (accessed on 13 October 2023).

- Food and Drug Administration. Mitigation Strategies to Protect Food Against Intentional Adulteration: Guidance for Industry; Food and Drug Administration: Spring, MD, USA, 2019. Available online: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/draft-guidance-industry-mitigation-strategies-protect-food-against-intentional-adulteration (accessed on 4 September 2023).

- Komitopoulou, E. Defending the Food Supply Chain. SGS Food Safety & Quality. Available online: https://mygfsi.com/blog/defending-the-food-supply-chain/ (accessed on 4 September 2023).

- Spink, J.W. The GFSI food fraud prevention compliance development & requirements: A ten-year review. Trends Food Sci. Technol. 2023, 138, 766–773. [Google Scholar] [CrossRef]

- Sousa Severino, P.R. Food Defense e a sua Relação com as Normas IFS V6, BRC V7 e FSSC 22000. Master’s Thesis, Engenharia Alimentar-Qualidade e Segurança Alimentar, Universidade de Lisboa, Lisbon, Portugal, 2016. [Google Scholar]

- Cavalheiro, L.G.; Cavalheiro, F.G.; de Azevedo Ruiz, V.L.; Kushida, M.M. Food defense e publicly available specification 96/2017. Segur. Aliment. Nutr. 2021, 28, e021002. [Google Scholar] [CrossRef]

- Malik, S.; Krishnaswamy, K.; Mustapha, A. Hazard Analysis and Risk-Based Preventive Controls (HARPC): Current Food Safety and Quality Standards for Complementary Foods. Foods 2021, 10, 2199. [Google Scholar] [CrossRef] [PubMed]

- Lopes, L.O.; Silva, R.; Guimarães, J.T.; Coutinho, N.M.; Castro, B.G.; Pimentel, T.C.; Duarte, M.C.K.H.; Freitas, M.Q.; Esmerino, E.A.; Sant’Ana, A.S.; et al. Food defense: Perceptions and attitudes of Brazilian dairy companies. J. Dairy Sci. 2020, 103, 8675–8682. [Google Scholar] [CrossRef]

- U.S. Department of Agricultural Food Safety and Inspection Service (USDA). Food Safety and Inspection Service (FSIS). Available online: https://www.usda.gov/our-agency/agencies (accessed on 29 September 2023).

- Food and Drug Administration. Food Defense Awareness for Front-Line Employees: Front Line Employee’s Role in food Defense. Available online: https://www.cfsanappsexternal.fda.gov/scripts/FDTraining/course_02/module_01/lesson_01/FD02_01_020.cfm (accessed on 4 September 2023).

- Djurle, A.; Young, B.; Berlin, A.; Vågsholm, I.; Blomström, A.L.; Nygren, J.; Kvarnheden, A. Addressing biohazards to food security in primary production. Food Secur. 2022, 14, 1475–1497. [Google Scholar] [CrossRef]

- Bashura, J.P. Food defense-“Back to the basics”. In Building the Future of Food Safety Technology; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar] [CrossRef]

- Farias de Abreu, V.L.; Silva, R.; Luchese, R.; Monteiro, S.S.; Esmerino, E.A.; Mathias, S.P. Impact assessment of the implementation of food defense plan in a Brazilian army military organization. Food Control 2020, 118, 107288. [Google Scholar] [CrossRef]

- Aguiar, D.R.; Kushida, M.M.; Paiva, L.C. Food defense: Gerenciamento de riscos e aplicação de ferramenta CARVER + SHOCK em frigorífico. CIAGRO 2020, 1, 709–724. [Google Scholar] [CrossRef]

- Romero, S.B. Food Defense: Evaluation and Application of the CARVER+Shock Tool in the Dairy Industry in Brazil. Master’s Thesis, University of São Paulo, São Paulo, Brazil, 2017. [Google Scholar]

- Lorenzen, C.L.; Hendrickson, M.K.; Weaber, R.L.; Clarke, A.D.; Shannon, M.C.; Savage-Clarke, K.L. Food Defense: Protecting the Food Supply from Intentional Harm, 1st ed.; University of Missouri Extension: Columbia, MO, USA, 2009; pp. 1–40. Available online: https://extension.missouri.edu/publications/mp914 (accessed on 4 September 2023).

- Manning, L.; Soon, J.M. Food Safety, Food Fraud, and Food Defense: A Fast Evolving Literature. J. Food Sci. 2016, 81, R823–R834. [Google Scholar] [CrossRef]

- Brainard, J.; Hunter, P. Contextual factors among indiscriminate or large attacks on food or water supplies, 1946–2015. Health Secur. 2015, 14, 19–28. [Google Scholar] [CrossRef]

- Moerman, F. Food Defense. In Food Control and Biosecurity; Academic Press: Cambridge, MA, USA, 2018; Volume 16, pp. 135–223. [Google Scholar] [CrossRef]

- Manning, L. Food defence: Refining the taxonomy of food defence threats. Trends Food Sci. Technol. 2019, 85, 107–115. [Google Scholar] [CrossRef]

- Praia, E.F.; Henriques, A.R. Assessing the implementation of food defense requirements in industrial meat-based food processors. Braz. J. Food Technol. 2021, 24, e2020201. [Google Scholar] [CrossRef]

- de Melo Andrade, E.L.I.; de Oliveira, G.C.; Silva, O.F. Food Defense—Do conceito às atuais exigências do mercado internacional. Res. Soc. Dev. 2021, 10, e201101724175. [Google Scholar] [CrossRef]

- Jurica, K.; Brčić Karačonji, I.; Lasić, D.; Bursać Kovačević, D.; Putnik, P. Unauthorized food manipulation as a criminal offense: Food authenticity, legal frameworks, analytical tools and cases. Foods 2021, 10, 2570. [Google Scholar] [CrossRef]

- Larson, R.B. Food safety concerns and food defense support: A cross-cultural study. J. Risk Res. 2023, 26, 113–132. [Google Scholar] [CrossRef]

- Lorenzen, C.L.; Hendrickson, M.K.; Weaber, R.L.; Clarke, A.D.; Shannon, M.C.; Savage-Clarke, K.L. Food Defense: Protecting the Food Supply from Intentional Harm; University of Missouri Extension: Columbia, MO, USA, 2013. [Google Scholar]

- FSIS. Functional Food Defense Plans. Available online: https://www.fsis.usda.gov/food-safety/food-defense-and-emergency-response/food-defense/functional-food-defense-plans (accessed on 26 January 2024).

- Lorenzen, C.L.; Cutter, C.N. Creating a Food Defense/Response Plan in Food Processing Facilities. In Food Protection and Security: Preventing and Mitigating Contamination During Food Processing and Production; Holcomb, S.R., Buzby, J.C., Eds.; Elsevier Inc.: Cambridge, MA, USA, 2017; pp. 43–60. [Google Scholar]

- Foundation FSSC. FSSC 22000 Scheme—Food Safety Management System Certification Version 6.0; Foundation FSSC: Gorinchem, The Netherlands, 2023; Available online: https://www.fssc.com/schemes/fssc-22000/documents/fssc-22000-version-6/ (accessed on 26 January 2024).

- Renewable Fuels Association (RFA). Annual Ethanol Production. Available online: https://ethanolrfa.org/markets-and-statistics/annual-ethanol-production (accessed on 4 September 2023).

- Companhia Nacional de Abastecimento (CONAB). Cana-de-Açúcar—Indústria. Available online: https://www.conab.gov.br/info-agro/safras/serie-historica-das-safras/itemlist/category/893-cana-de-acucar-industria (accessed on 5 October 2023).

- Raízen. Etanol: O que é e Como é Usado no Brasil. Available online: https://www.raizen.com.br/blog/etanol#:~:text=Etanol%20Anidro%20Industrial%20e%20Neutro&text=Atualmente%20a%20lei%20autoriza%20na,a%20industriais%20farmac%C3%AAuticas%20e%20aliment%C3%ADcias (accessed on 15 November 2023).

- Empresa Brasileira de Pesquisa Agropecuária (EMBRAPA). Neutro. Available online: https://www.embrapa.br/produtos-e-servicos/etanol (accessed on 15 November 2023).

- IBGE—Instituto Brasileiro de Geografia e Estatística. Levantamento Sistemático da Produção Agrícola. Cana-de-Açúcar. Available online: https://www.ibge.gov.br/ (accessed on 5 October 2023).

- Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP). Etanol: Histórico e Produção. Available online: https://www.gov.br/anp/pt-br/assuntos/etanol (accessed on 15 November 2023).

- Smeets, E.; Faaij, A.; Lewandowski, I.; Turkenburg, W.A. A bottom-up assessment and review of global bio-energy potentials to 2050. Prog. Energy Combust. Sci. 2007, 33, 56–106. [Google Scholar] [CrossRef]

- Target Normas. Available online: https://www.target.com.br/produtos/normas-tecnicas/34370/nbr5824-acetona-alcoois-etilico-e-metilico-determinacao-do-tempo-de-reducao-de-permanganato-metodo-de-barbet (accessed on 16 April 2025).

- Ministério de Minas e Energia (MME). Produção de Biocombustíveis No Brasil. Available online: https://www.gov.br/mme/pt-br/assuntos/energia/biocombustiveis (accessed on 15 November 2023).

- União da Indústria de Cana-de-Açúcar (UNICA). Produção e Mercado de Biocombustíveis No Brasil. Available online: https://www.unica.com.br/estatisticas/mercado/ (accessed on 15 November 2023).

- Ministério da Agricultura, Pecuária e Abastecimento (MAPA). Etanol de milho: O Futuro da Produção de Biocombustíveis No Brasil. Available online: https://www.gov.br/agricultura/pt-br (accessed on 25 October 2023).

- ABNT. NBR 10260:2012; Álcool Etílico—Determinação dos Teores de Acetal, Acetaldeído, Acetato de Etila, Acetona, Álcool Metílico, Álcoois Superiores e Benzeno por Cromatografia Gasosa. Brazilian National Standards Organization: Rio de Janeiro, Brazil, 2012.

- Álcool Etílico Extra Neutro. Available online: https://www.alcoolferreira.com.br/produtos.php (accessed on 13 October 2023).

- Bedryk, O.; Shevchenko, A.; Mishchenko, O.S.; Maleta, V.N.; Kiss, A.A. Industrial experience in using cyclic distillation columns for food grade alcohol purification. Chem. Eng. Res. Des. 2023, 192, 102–109. [Google Scholar] [CrossRef]

- Black, K.; Walker, G. Yeast Fermentation for Production of Neutral Distilled Spirits. Appl. Sci. 2023, 13, 4927. [Google Scholar] [CrossRef]

- Maitin, B.K. Indian whiskies. In Whisky and Other Spirits: Technology, Production and Marketing; Academic Press: Cambridge, MA, USA, 2022; pp. 75–86. [Google Scholar] [CrossRef]

- Sasma, B.V. Extra Neutral Alcohol. 2023. Available online: https://sasmabv.com/products/extra-neutral-alcohol/ (accessed on 4 September 2023).

- Blakistone, B.A. Principles and Applications of Modified Atmosphere Packaging of Foods. In Principles and Applications of Modified Atmosphere Packaging of Foods; Springer: New York, NY, USA, 1998. [Google Scholar] [CrossRef]

- Davies, A.R. New Methods of Food Preservation. In New Methods of Food Preservation; Springer: New York, NY, USA, 1995. [Google Scholar] [CrossRef]

- Galić, K.; Gabrić, D.; Ćurić, D. Packaging and the Shelf Life of Bread. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Mexis, S.F.; Kontominas, M.G. Packaging: Active Food Packaging. In Encyclopedia of Food Microbiology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 999–1005. [Google Scholar] [CrossRef]

- Khan, A.A. Intentional Contamination of Water Supplies. In Ciottone’s Disaster Medicine; Elsevier: Amsterdam, The Netherlands, 2024; pp. 986–990. [Google Scholar] [CrossRef]

- MCKay, C.; Scharman, E.J. Intentional and inadvertent chemical contamination of food, water, and medication. Emerg. Med. Clin. N. Am. 2015, 33, 153–177. [Google Scholar] [CrossRef]

- National Center for Biotechnology Information (PubChem). Ethanol. 2023. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Ethanol (accessed on 5 October 2023).

- Sigma-Aldrich. Solvent Miscibility Chart. 2023. Available online: https://www.sigmaaldrich.com/US/en/technical-documents/technical-article/analytical-chemistry/purification/solvent-miscibility-table (accessed on 5 October 2023).

- California State University Stanislaus. Solvent Miscibility Table. 2023. Available online: https://www.csustan.edu/sites/default/files/groups/Chemistry/Drake/documents/solvent_miscibility_table.pdf (accessed on 5 October 2023).

- Solvent Polarity Table. Available online: https://www.grace.umd.edu/~zhangx/html/solvent3.html (accessed on 23 October 2024).

- He, N.X.; Bayen, S. An overview of chemical contaminants and other undesirable chemicals in alcoholic beverages and strategies for analysis. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3916–3950. [Google Scholar] [CrossRef]

- Pelegrín, C.J.; Flores, Y.; Jiménez, A.; Garrigós, M.C. Recent trends in the analysis of chemical contaminants in beverages. Beverages 2020, 6, 32. [Google Scholar] [CrossRef]

| Food Defense 101 | See Something, Say Something Campaign | Employees FIRST |

|---|---|---|

| A: alert | The “See Something, Say Something” campaign encourages the public to report suspicious activities to the authorities, engaging people in crime and public safety threat prevention. By reporting unusual behavior, citizens assist authorities in identifying potential threats, thereby preventing security incidents. | F: Follow company food defense plan and procedures |

| L: look | I: Inspect your work area and surrounding areas | |

| E: employees | R: Recognize anything out of ordinary | |

| R: reports | S: Secure all ingredients, supplies, and finished product | |

| T: threat | T: Tell management if you notice anything unusual or suspicious |

| Subject | Area | Authors |

|---|---|---|

| Food defense and the PAS 96:2017 standard [5] in protecting the Brazilian animal-based food supply chain from intentional threats | Supply chain | Cavalheiro et al., 2017 [10] |

| Risk management of food defense and the application of the CARVER + SHOCK tool in slaughterhouses. | Tool for food defense | Aguiar; Kushida, 2020 [18] |

| Protection against intentional threats to food safety, using the CARVER + Shock tool in the Brazilian dairy industry. | Tool for food defense | Romero, 2017 [19] |

| Manual on Food Defense Focused on Intentional Food Contamination | Food | Weaber; Clarke; Carlson Shannon, 2009 [20] |

| Positive Feedback from the Implementation of Food Defense Plans | Food | Manning.; Soon, 2016 [21] |

| Study of Attacks and Their Consequences on Food and Water from 1946 to Mid-2015 | Food and water | Brainard; Hunter, 2016 [22] |

| The Importance of Creating a Pre and Post-Processing Food Defense Plan, Considering Intentional Contaminations | Food | Lorenzen; Cutter, 2017 [13] |

| Guide for Food Industries and Authorities to Prevent Intentional Attacks on Food | Food | Moerman, 2018 [23] |

| Development of an Effective Food Defense Plan in the Food Industry | Food | Manning, 2019 [24] |

| The Evolution of Food Defense and the Emergence of Food Terrorism | Food | Bashura, 2020 [16] |

| Verification of Food Safety in Brazilian Dairy Industries | Dairy | Lopes et al., 2020 [11] |

| Implementation of a Food Defense Plan for the Brazilian Army | Military supplies | Farias et al., 2020 [17] |

| Assessment of the Implementation of a Food Defense Plan in a Meat Processing Industry and Comparison of Vulnerabilities with an Industry in Portugal Already Implementing Adequate Measures | Meat processing | Manning; Soon, 2021 [25] |

| FDA’s Initiatives to Defend the Food Chain from Intentional Contaminations, and the Significance of Training Skilled Professionals in the Field | Food | Andrade; Oliveira; Silva, 2021 [26] |

| Unauthorized Food Handling and the descriptions of the criminal aspect of food fraud incidents | Food | Jurica et al., 2021 [27] |

| Intentional Contaminations in the Dairy Industry and the Significance of Applying Tools to Ensure Food Quality and Safety, Along with Product Traceability | Dairy industry | Wiśniewska; Tarczyńska; Ranadheera, 2022 [1] |

| Identification and Prevention of Possible Microbiological Hazards in Livestock and Vegetable Primary Production | Food production | Djurle et al., 2022 [15] |

| A 10-Year Evolution of Food Fraud prevention to Understand and Identify Food Fraud Incidents | Food | Spink, 2023 [8] |

| Consumer Concerns about Food Safety After Inquiring About Intentional and Unintentional Food Contaminations, Along with Their Health Risks | Food | Larson, 2023 [28] |

| Unit | Alcohol Extra Neutral | Hydrated Ethyl Alcohol | Anhydrous Ethyl Alcohol | |

|---|---|---|---|---|

| Aspect | - | clear. flammable liquid free from impurities | clear. flammable liquid free from impurities | clear. flammable liquid free from impurities |

| good. characteristic | good. characteristic | good. characteristic | ||

| Specific Mass 20 °C [37] | g/cm3 | 0.8037–0.8071 | 0.8076–0.8110 | Maximum 0.7915 |

| Specific Mass 15.56 °C [37] | g/cm3 | 0.8075–0.8109 | 0.8114–0.8147 | Maximum 0.7953 |

| Alcoholic Content 20 °C [37] | INPM (%p/p) | 94.00–95.20 | 92.60–93.80 | Minimum 99.30 |

| Alcoholic Content 20 °C [37] | °GL (%v/v) | 96.10–97.00 | 95.10–96.00 | Minimum 99.60 |

| Relative Density 20 °C [37] | 0.8051–0.8085 | |||

| Total Acidity [38] | mg/L | 3–12 | Maximum 30 | Maximum 30 |

| pH [39] | 6.0–8.0 | |||

| Barbet [40] | minutos | Minimum 35 | ||

| Distillation Range [41] | °C | |||

| Initial [41] | °C | Minimum 75.0 | Minimum 75.0 | Minimum 75.0 |

| Final [41] | °C | Minimum 85.0 | Maximum 85.0 | Maximum 85.0 |

| Residue By Evaporation [42] | mg/100 mL | Minimum 2.5 | Maximum 2.5 | Maximum 2.5 |

| Absorbance Uv [43] | 240 Nm: Maximum 0.40 | |||

| Absorbance Uv [43] | 250–260 Nm: Maximum 0.30 | |||

| Absorbance Uv [43] | 270–340 Nm: Maximum 0.10 | |||

| Acetaldehyde [44] | mg/L | Maximum 10.0 | ||

| Acetone [44] | mg/L | Maximum 10.0 | ||

| Ethyl Acetate [44] | mg/L | Maximum 10.0 | ||

| Acetal [44] | mg/L | Maximum 10.0 | ||

| N-Propanol [44] | mg/L | Maximum 10.0 | ||

| Isobutanol [44] | mg/L | Maximum 10.0 | ||

| N-Butanol [44] | mg/L | Maximum 10.0 | ||

| Isoamyl Alcohol [44] | mg/L | Maximum 10.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pizarro, I.F.; Barbosa, T.G.C.; Kushida, M.M.; Kamimura, E.S. Food Defense in the Extra Neutral Alcohol Industry: Ensuring Safety Against Intentional Contaminations. Processes 2025, 13, 1243. https://doi.org/10.3390/pr13041243

Pizarro IF, Barbosa TGC, Kushida MM, Kamimura ES. Food Defense in the Extra Neutral Alcohol Industry: Ensuring Safety Against Intentional Contaminations. Processes. 2025; 13(4):1243. https://doi.org/10.3390/pr13041243

Chicago/Turabian StylePizarro, Isabely Fernanda, Thayná Gomes Camargo Barbosa, Marta Mitsui Kushida, and Eliana Setsuko Kamimura. 2025. "Food Defense in the Extra Neutral Alcohol Industry: Ensuring Safety Against Intentional Contaminations" Processes 13, no. 4: 1243. https://doi.org/10.3390/pr13041243

APA StylePizarro, I. F., Barbosa, T. G. C., Kushida, M. M., & Kamimura, E. S. (2025). Food Defense in the Extra Neutral Alcohol Industry: Ensuring Safety Against Intentional Contaminations. Processes, 13(4), 1243. https://doi.org/10.3390/pr13041243