Abstract

In this review article, the production of extra neutral alcohol was explored, a specific segment in the alcohol industry, aiming to fill knowledge gaps and provide information on the practical implementation of a Food Defense plan. The understanding of the physical–chemical specifications of alcohol, its applications in food, and the manufacturing and fractionation processes were comprehensively addressed. The critical importance of extra neutral alcohol in various industries, from the production of distilled beverages to food preservation through innovative technologies, was highlighted. When discussing hazards related to food safety, the possibility of system security failures is recognized, emphasizing the need for a Food Defense plan. Additionally, we explored potential contamination methods in the production of extra neutral alcohol, analyzing its miscibility with harmful substances, which is crucial for understanding the implications of chemical contamination. The possibility of deliberate adulteration of beverages and foods requires constant attention to enhance security measures, implement advanced technologies, and proactive monitoring strategies. Ultimately, this article contributes to advancing knowledge at the intersection of extra neutral alcohol production and food safety.

1. Introduction

There is an increasing demand on the food industry to meet customer requirements and export products, particularly in terms of food safety. Consequently, numerous crucial measures have been developed not only to protect consumers but also to preserve the reputation of companies and contribute to the economic stability of the sector.

Food safety is a top priority in the food industry, but the threat of intentional contamination poses a current and significant challenge. The potential for intentional contamination spans the entire food production chain and can result in serious losses for both consumers and industries. The concept of Food Defense thus emerges as a strategic response to safeguard the food production chain against deliberate actions aimed at harming public health and consumer confidence.

Intentional adulteration in foods can encompass all stages of the production, such as the distribution and marketing of food, and ultimately, lead to losses for consumers. This is evident in misleading them into acquiring food with incorrect information, jeopardizing their health and, in extreme cases, leading to loss of life [1]. The dissemination of misleading information about food products may involve practices such as counterfeiting, adulteration, or omission of essential data, further exacerbating the risks associated with food crime.

Given the complexity of threats to food safety, legislation in the United States of America (USA) has evolved in response to critical events. Following the terrorist attack on 11 September 2001, the U.S. Congress enacted the “The Bioterrorism Preparedness and Response Act” in 2002, establishing standards for the food industry related to Food Defense. Subsequently, the “Food Safety Modernization Act” (FSMA) aimed to enhance the safety of the food supply, granting more autonomy to the Food and Drug Administration (FDA) in terms of regulation and oversight of the country’s food safety [2].

Figure 1 illustrates the main milestones in the history of Food Defense, detailing the evolution of legislations and standards implemented over the years. This figure provides a chronological view of the measures taken to strengthen the protection of the food production chain against intentional contaminations, highlighting key events that influenced the creation and updating of Food Defense policies.

Figure 1.

Timeline to identify key Milestones in the history of food defense.

According to the United States Department of Agriculture (USDA), the term Food Defense is defined as “the protection of food products from contamination or adulteration intended to cause public health harm or economic disruption” [3]. The FDA, on the other hand, conceptualizes the term as an “effort to protect food against acts of intentional adulteration or interference” [4], and Publicly Available Specification (PAS) 96:2017 defines it as procedures adopted to ensure the safety of food and beverages and their supply chains against malicious attacks motivated by ideologies that may result in contamination or supply disruptions [5].

To comprehend the importance of a Food Defense plan in the food industry, it is crucial to recognize that food contamination results from deliberate actions by individuals falling into the categories of food hazards, including chemical, biological, physical, and radiological hazards [6]. These intentional threats with ideological motivations pose a significant concern for food safety and security; therefore, addressing this issue requires going beyond traditional approaches to food safety, such as the conventional Hazard Analysis and Critical Control Points (HACCP), which provides a layer of protection against unintentional adulteration but lacks the necessary robustness for the effective detection and mitigation of deliberate contaminations throughout the food supply chain [7]

Thus, to ensure the integrity of the food chain, in addition to HACCP, there is the Vulnerability Assessment and Critical Control Points (VACCP), focusing on detecting food fraud and linked to the term Food Fraud. There is also the Threat Assessment and Critical Control Points (TACCP), mentioned in PAS 96 [5], aiming to protect the food chain against intentional attacks, linked to the term Food Defense. Spink [8] depicts these elements as an “umbrella,” signifying the entire food safety management system.

The TACCP system offers a non-certifiable approach to managing the risks of intentional contamination in food. Adapted from the HACCP system, TACCP seeks to reduce the probability and impact of deliberate attacks, preserve the organization’s reputation, and ensure the effective implementation of food protection measures for customers. This involves forming a specialized team, identifying risks, applying preventive controls, and establishing a crisis management system. The resulting plan must be documented and continually reviewed to ensure its effectiveness in preventing intentional contaminations [9,10].

As stated by Malik [11], HARPC is a complementary of the HACCP system, focusing on intentional risks and food threats with a more preventive approach. This concept is designed to protect food from attacks that may have terrorist motivations or other malicious intentions. The implementation of HARPC involves conducting a risk-based hazard analysis and applying preventive controls to mitigate these risks, with a focus on processes that could be vulnerable to deliberate adulteration. This approach extends beyond traditional food safety practices, adding layers of protection against food crimes and agro-terrorism. The transition from HACCP to HARPC is particularly important in contexts such as neutral spirit production, where process security may be compromised by intentional attacks, and the consequences of such events could be devastating for the industry and consumers.

The implementation of Food Defense strategies becomes crucial to protect not only consumers but also the reputation of food companies and the economic stability of the sector [12].

In the context of the extra neutral alcohol sector, which is crucial for various industries such as food, pharmaceuticals, and cosmetics, the application of Food Defense measures plays an equally essential role. As this industry segment expands to meet the growing demands of various markets, ensuring the integrity and safety of products becomes mandatory. Notably, reliability in the quality of extra neutral alcohol is crucial not only for manufacturers and distributors but also for industries that depend on this input.

Attacks to extra neutral alcohol could occur in various stages of process, since the processing of the alcohol is usually made in open areas, which are easy to access. This said, it is important to map every potential area to intentional contamination.

Given this, considering the lack of articles in the area and the importance of having research focused on the topic, it is necessary to map publications from food industries using the Food Defense plan, focusing on both the food industry and the extra neutral alcohol industry worldwide.

This review is necessary due to the increasing risk of intentional contamination in the food production chain, a threat not adequately addressed by traditional food safety practices, such as HACCP. Unlike other reviews, this article specifically explores the implementation of Food Defense plans in the extra neutral alcohol industry, a sector that still lacks focused research.

2. Overview of Food Defense in the Global Food Industry

The food industry plays a vital role in the lives of billions of people worldwide, providing essential foods that sustain our health and well-being.

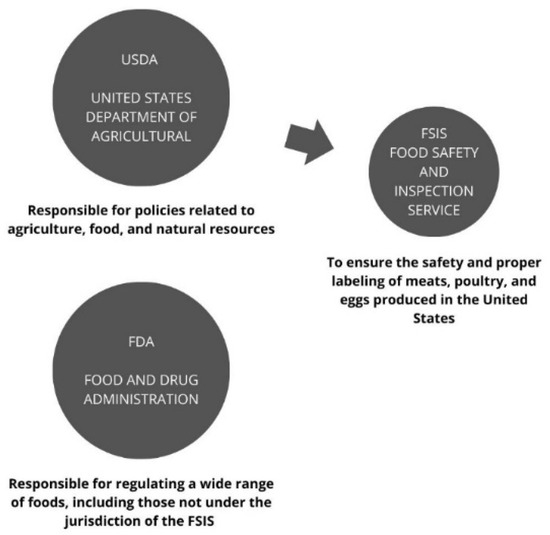

In the USA, there are three main government organizations responsible for food production (Figure 2) [13].

Figure 2.

Main governmental organizations responsible for food production in the USA. The USDA is responsible for policies related to agriculture, food, and natural resources. The FSIS, shown with an arrow from the USDA, operates under it and is responsible for ensuring the safety and proper labeling of meats, poultry, and eggs. The FDA regulates a wide range of other foods not covered by the FSIS.

In this way, in 2016, the implementation of the Food Defense plan became mandatory in facilities regulated by the FDA in the USA. The deadlines for compliance were:

- Large companies: until July 2019;

- Small companies (less than 500 employees): until July 2020;

- Very small companies (with less than USD 10 million in revenue over 3 years): until July 2021 [14].

Additionally, on the FDA’s website, there are training sessions and tools such as mitigation strategies. One of these strategies aim to protect the food supply against intentional adulteration by introducing the “farm-to-fork” concept and raising awareness throughout the process. This ensures that frontline workers protect the chain, considering that food, at this stage, is more susceptible and accessible to intentional contamination. Thus, the food defense plan should be considered from the field to the table [14].

Considering the term “farm”, agro-terrorism should be taken into account. Agro-terrorism is the deliberate introduction of pathogens or chemicals into animals or plants in the agricultural or livestock system with the aim of causing economic damage and generating fear in the population. This action can harm farmers, the agricultural industry, society, and international trade. As a possible guideline, Djurle [15] suggest an analytical methodology for risk and vulnerability analysis, called FORSA, which demonstrates possibilities for preparing and mitigating potential intentional attacks.

An effective alternative to increase awareness of food safety among frontline workers in the food industry is the “Employees FIRST” program. This program was developed to provide specific guidance and training to empower employees to recognize and respond to potential threats to food safety. By implementing Employees FIRST, companies not only strengthen the security of their products but also promote a safer and more informed working environment for all food industry employees [16], similar to the Food Defense 101 (ALERT system) and the “See something, say something” campaign [14] (Table 1).

Table 1.

Training sessions available for employees on the topic of food defense (adapted from Bashura [16]).

It is noticeable that the USA is much more advanced concerning Food Defense compared to Asia, Europe, and Latin America. According to Farias [17], there was a meeting of the Asia Pacific Economic Cooperation (APEC) in 2007 that conducted discussions on the topic, leading to the development of the “Food Defense Principles”.

In Europe, discussions on the topic began with the Publicly Available Specification (PAS) 96, developed by the British Standards Institution (BSI). It covers a range of specific threats such as extortion, malicious contamination, cybercrime, espionage, economically motivated adulteration, and forgery by using TACCP for risk management [5].

Preventive measures against food threats should be considered, even in the military, where there is a meal preparation sector in each organization. This ensures the operational readiness, health, and safety of military personnel [17].

In Brazil, in 2018, the Food and Nutrition Doctrine of the Armed Forces was approved (Ministry of Defense ordinance 13) aiming to prevent intentional food contamination, ensuring readiness for operational use (Brazil, 2018); however, no unit of the Brazilian Armed Forces has effectively implemented this monitoring and prevention tool in its activities [17]. The authors, however, applied the Food Defense Plan Builder tool, available from the FDA, to identify vulnerable points in the food supply chain of a Brazilian military organization. The results revealed that 60.7% of the action plan demands were met, either fully or partially, providing insight into the effectiveness of the implemented measures.

Based on the consulted references (Table 2), the material includes a variety of sources, such as review articles, scientific data articles, and book chapters. Upon analyzing these sources, it is observed that the focus is primarily on general concepts related to intentional contamination and mitigation strategies in a broad context. However, there is a gap regarding the practical application of a Food Defense plan in a specific segment.

Table 2.

Articles published in the literature on the topic of food defense (2015–2025).

3. Key Vulnerabilities and Preventive Strategies in Food Defense

According to Lorenzen [29], a Food Defense Plan can be developed around four key steps:

- Assess vulnerabilities;

- Write a plan;

- Prepare a response plan; and

- Manage the plan.

On the other hand, FSIS [30] recommends taking the following steps:

- Develop a Food Defense Plan;

- Implement mitigation strategies and protective measures;

- Test the mitigation strategies and protective measures;

- Review and maintain.

Therefore, some preventive measures should be considered when developing this plan, such as:

- Risk Analysis: Companies should conduct a comprehensive risk analysis to identify and assess all potential threats to food safety.

- Access Control: Access to critical areas of the factory and production facilities should be restricted to authorized and supervised personnel only.

- Background Checks: Background checks should be conducted for all employees, suppliers, and visitors before granting access to company facilities.

- Employee Training: All employees should be trained in food safety measures, including recognizing signs of potential threats and the actions to take in case of incidents.

- Monitoring: Companies should continuously monitor production facilities, equipment, and raw materials to detect any signs of potential threats.

- Cybersecurity: Companies must ensure the security of information technology (IT) systems and production data to prevent cyberattacks.

- Supplier Control: Companies should ensure that all suppliers and subcontractors adhere to the same strict food defense standards.

- Communication: Establish clear and open communication with employees, suppliers, customers, and partners to share information about potential threats and preventive measures.

- Contingency Plan: Companies should have a well-defined contingency plan to respond quickly to food defense-related incidents [31,32].

The food industry faces a range of vulnerabilities that could expose it to intentional threats. These vulnerabilities can exist at various stages of the food production process, including the supply of raw materials, manufacturing, packaging, and distribution. For example, the potential for contamination during transportation or unauthorized access to production areas can create significant risks.

Vulnerabilities also extend to the supply chain, where lack of control over suppliers and third-party contractors can lead to weaknesses in food defense measures. Given these risks, it is essential for companies to develop and maintain food defense plans that include risk assessments, monitoring, and employee training to effectively mitigate these vulnerabilities. By addressing these weaknesses, companies can reduce the likelihood of intentional contamination and protect the health and safety of consumers.

The goal is to focus on the extra neutral alcohol production industry, a specific segment within the alcohol sector. Based on the literature review, the intention is to develop a process flowchart, identify potential contamination methods, and highlight vulnerable points throughout this specific process. The purpose is to bridge the knowledge gap by providing information on the practical implementation of a Food Defense plan in this particular context, thereby contributing to the advancement of knowledge in this specific area of the food industry.

4. Importance of Food Defense Plan in the Extra Neutral Alcohol Industry

4.1. Ehanol Production Worldwide

The United States of America and Brazil are the world’s largest ethanol producers, with a combined production of 82% of global output that is followed by the European Union (5%), China (3%), and India (3%) [33].

According to the National Supply Company [34], in Brazil, over 11 million liters of anhydrous ethanol and approximately 16 million liters were estimated to be produced in the 2023/24 harvest (as of August 2023).

4.2. Types of Alcohol

There are different types of alcohol, each applied in a specific segment.

- Anhydrous Ethyl Alcohol: Used as an additive in fuels, composed of 99.5% pure alcohol and 0.5% water. It is suitable for chemical industries as raw material for paints, varnishes, and solvents.

- Hydrated Ethyl Alcohol: It contains 96% pure alcohol and 4% water, suitable for the chemical and cleaning industries.

- Neutral Ethyl Alcohol or Extra Neutral: Utilized in the production of beverages, foods, cosmetics, and medicines. It does not interfere with the aroma as it is the purest form of alcohol. The production of extra neutral alcohol involves additional purification steps, such as hydroselection and redistillation [35,36].

The quality standards for types of alcohol, including those destined for fuel, encompass various aspects beyond the specified alcohol content. The physicochemical specifications for each type of alcohol can be verified in Table 3 and are based on regulations such as ABNT NBR 5992/15639 for specific mass at 20 °C, specific mass at 15.56 °C, alcoholic content at 20 °C, relative density at 20 °C [37]; ABNT NBR 9866 for total acidity [38]; ABNT NBR 10,891 for pH [39]; ABNT NBR 5824 for Barbet [40]; ABNT NBR 7125 for distillation range [41]; ABNT NBR 8911 for residue by evaporation [42]; EUROPEAN PHARMACOPOEIA for UV absorbance [43]; and ABNT NBR 10,260 for acetaldehyde, acetone, ethyl acetate, acetal, n-propanol, isobutanol, n-butanol, and isoamyl alcohol [44].

Table 3.

Physicochemical specifications of extra neutral alcohol, hydrated ethyl alcohol, and anhydrous ethyl alcohol [37,38,39,40,41,42,43,44,45].

When comparing the results of physicochemical analyses (Table 3), among the types of produced alcohol, it is noted that the total acidity of extra neutral alcohol (3 to 12 mg/L) is lower compared to that of hydrated ethyl alcohol and anhydrous ethyl alcohol (maximum 30 mg/L), which is expected, since a lower acidity is desirable when alcohol is used in the production of food and beverages.

Bedryk [46] conducted a study on the purification of food-grade alcohol using cyclic distillation columns. After validating the experiment on an industrial scale under optimal conditions, they concluded that there is a complete removal of isopropanol, aldehydes, and ethers/esters from the bottom product (heavier and lower purity fraction collected at the end of the distillation process).

4.3. Extra Neutral Alcohol Applied in Foods

Globally, the main objectives when purifying alcohol for use in foods are to achieve an effectively pure product with the lowest possible impurity content and maximize the yield of final products [46]. Neutral alcohol can be described as a distilled product obtained from fermentation with a minimum ethanol content of 95 to 96% by volume, possessing no characteristic odor or flavor. In the United States, neutral alcohol is distilled to an alcohol content of 96% or more by volume (ABV), while in the European Union, the minimum alcohol strength after distillation is 96% ABV [47].

Manufacturers of alcoholic beverages in various countries choose to use higher-quality extra neutral alcohol (ENA) to minimize odor and present the beverage as an option that does not require the addition of water or soda to make it palatable. This approach also opens the possibility of targeting this product to consumers of higher-quality alcoholic beverages [48].

Extra neutral alcohol plays a fundamental role as a base ingredient in the production of vodka, whiskey, gin, and liqueurs. In addition to its presence in these distilled beverages, it is also used in the production of vinegar and apple cider. Moreover, it serves as a solvent for flavoring [49].

Conservation technology, including a modified atmosphere and the use of ethanol spray on foods, is not new. This ancient practice aims to extend the shelf life of products. Additionally, the ethanol used is considered Generally Recognized as Safe (GRAS). Examples of modified atmosphere packaging use include the study by Blakistone [50], where alcohol spray was applied before packaging bakery products and pizzas, serving to extend the shelf life by not only being antimicrobial but also slowing down the aging process. Another study by Davies [51] focused on stabilizing tortellini (an Italian pasta product) by reducing water activity and gentle thermal processing, along with the use of a modified atmosphere or ethanol vapor during storage, combined with moderately low temperatures.

A more recent technology is ethanol emission, which is the controlled release of ethanol in specific environments, usually to preserve food. This technology uses sachets or films that slowly emit ethanol vapor into the internal atmosphere of the packaging [52,53]. In this case, ethanol acts as an antimicrobial agent against fungi such as Aspergillus and Penicillium; bacteria such as Salmonella spp., Staphylococcus spp., and Escherichia coli; and yeasts such as Saccharomyces cerevisiae, preventing food deterioration and extending its shelf life. By regulating ethanol release, this approach contributes to product preservation without the need for additional modified atmosphere maintenance. The use of ethanol emitters has been explored in various studies to extend the shelf life of food products, such as baked goods (which are heated before consumption) and dried fish [52,53].

4.4. Manufacturing and Fractionation of Extra Neutral Alcohol

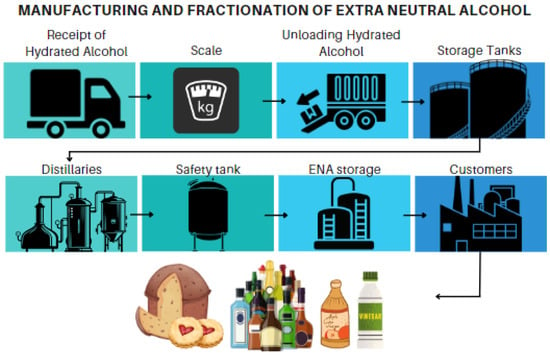

Considering an extra neutral alcohol production industry located in the interior of the State of São Paulo, the following fractionation manufacturing scheme is observed (Figure 3). The alcohol production industry receives hydrated alcohol from suppliers; subsequently, the truck is weighed, and if it is approved by quality control, the truck is unloaded into storage tanks. Afterward, the hydrated alcohol is directed to the distilleries—where all processes are controlled. The next step is to place the alcohol in safety tanks. The standard is verified through physicochemical analyses in the laboratory by the quality control team; if it is non-compliant, the alcohol returns for reprocessing at the distillery. Once approved, the extra neutral alcohol is transferred to the storage tank. Thus, the extra neutral alcohol is packaged for customers who are food industries producing alcoholic beverages, bakery products, cider, vinegar, among others.

Figure 3.

Production and fractionation of extra neutral alcohol.

Despite the precautions taken in the production and fractionation process of extra neutral alcohol, it is essential to recognize the possibility of system security failures, making the production chain vulnerable to undesirable events. The potential threat of intentional contamination by malicious agents underscores the need for a robust Food Defense plan. Strict controls aim not only to prevent accidental failures but also to protect against criminal actions that could compromise the integrity of extra neutral alcohol. In this scenario, it is important for the industry to continue enhancing its security measures, implementing proactive strategies and advanced monitoring technologies to mitigate the risks associated with potential criminal activities that may jeopardize the product’s quality and safety.

A continuous commitment to robust food safety practices not only safeguards the industry’s reputation but also protects end consumers from possible adverse consequences.

5. Potential Hazards

For food safety, food defense, and food fraud, related hazards are categorized in the same way; the distinction lies in the mode of action employed by those seeking to cause contamination, whether intentional or not, as mentioned earlier. Hazards are classified into four categories:

- Physical Hazards: Refers to the presence of foreign objects, particles, or physical substances in food that can cause physical harm when consumed. Examples include glass fragments, metal, plastic, wood chips, stones, among others.

- Chemical Hazards: Relates to the presence of unwanted chemicals in food that can pose health risks when ingested. Examples include pesticides, excessive food additives, residues from cleaning products, heavy metals, aflatoxins, among others.

- Biological Hazards: Refers to the presence of microorganisms such as bacteria, viruses, parasites, or fungi in food that can cause diseases when consumed. Examples include Salmonella, E. coli, Listeria monocytogenes, Campylobacter, Norovirus, among others.

- Radiological Hazards: Relates to the presence of ionizing radiation in food, which can pose health risks due to exposure to radioactivity. Examples include radioactive contamination due to nuclear accidents, such as the leakage of radioactive materials [22,24,54].

Considering these hazards, it is possible to explore the ways in which the production of extra neutral alcohol can be contaminated. This analysis is crucial for the implementation of effective practices for food safety, encompassing not only physical, chemical, biological, and radiological hazards but also considering specific contamination scenarios at this stage of the production process.

In this way, a detailed understanding of these hazards allows the development of preventive and control strategies to ensure the integrity and quality of extra neutral alcohol.

Possible Contamination Pathways in the Production of Extra Neutral Alcohol

For malicious individuals, water proves to be an accessible and potentially effective means of contamination, affecting not only the water’s quality but also serving as a contamination vehicle that reaches workers. As highlighted by McKay [55], the theoretical profile of a hazardous water contaminant would include being a disease-causing agent, in addition to having characteristics such as being odorless, tasteless, colorless, resistant to water treatment processes, stable (not susceptible to hydrolysis), water-soluble, and having a low LD50, that is, a high toxicity.

Khan [54] emphasizes the concern about the possibility of intentional contamination of water supplies, a vector that can be used in terrorist attacks. This apprehension is due to the critical need for water in all sectors of industrialized societies, and even a brief interruption can cause significant damage to the community. The author also reports an incident related to technological advancement, exemplified by cyber threats. A concrete case occurred in Florida, where criminals managed to access water treatment and distribution systems, altering the amount of sodium hydroxide used in treatment to toxic levels. This highlights how water, when manipulated maliciously, can not only compromise its quality but also pose a direct threat to workers who depend on this vital resource.

Examining its chemical characteristics, alcohol, or ethanol (C2H5OH), belongs to a class of organic compounds characterized by the presence of a hydroxyl functional group (-OH) attached to a carbon atom. Its most significant properties include:

- Solubility: Ethanol is miscible in water, meaning it dissolves completely in water in all proportions. This property is fundamental in many applications, including the production of alcoholic beverages.

- Boiling and Freezing Points: The boiling point of ethanol is relatively low, about 78.37 °C. This facilitates distillation during the production of alcoholic beverages. The freezing point is −114.1 °C.

- Flammability: Ethanol is flammable. It can catch fire at relatively low temperatures, making it useful as fuel in internal combustion engines and as an ingredient in flammable products.

- Disinfectant and Antiseptic: Alcohol is known for its disinfectant and antiseptic properties. Alcoholic solutions are commonly used to clean and disinfect surfaces and hands.

- Psychoactive Effect: The consumption of ethanol has psychoactive effects. It acts as a depressant of the central nervous system, causing changes in mood, coordination, and judgment.

- Heat Production: Burning alcohol releases heat. This is one of the principles behind the use of alcohol as fuel.

- Toxicity: Alcohol in large quantities can be toxic to the human body. Excessive consumption can lead to health problems, including damage to the liver, nervous system, and other organs.

- Polar Character: Due to the presence of the hydroxyl group, ethanol is a polar molecule. This characteristic influences its interactions with other substances [56].

Given this, it becomes crucial to consider the various forms of deliberate contamination. The mixing of ethanol with harmful substances, some more miscible than others, can lead to chemical contamination. This situation presents potential harm when contaminated substances are ingested by humans.

Online resources provide information on the miscibility and solubility of ethanol with different solvents [57,58,59].

Various chemical contaminants detected in alcoholic beverages was compiled and divided them into metals, pesticides, mycotoxins, volatile organic compounds, chemicals generated during processing, industrial contaminants, photoinitiators, phthalates, and illegal additives and adulterants [59].

The articles by NX He [60] and Pelegrín [61] are not focused on intentional contamination; however, the situation of Food Defense must be taken into account, where there is the possibility of the unauthorized addition of harmful substances or deliberate adulteration of beverages.

6. Future Recommendations

Considering all the information discussed in this article, it is necessary to create laws for countries that do not yet have a mandatory implementation of Food Defense in the food industry. The absence of specific regulations leaves gaps that can be exploited for intentional contaminations, jeopardizing consumer safety and product integrity. Standardized and mandatory laws would ensure a uniform and effective approach to protection against intentional threats, strengthening food safety globally.

Furthermore, the “FDA’s New Era of Smarter Food Safety Blueprint” represents a significant opportunity to incorporate themes such as Food Defense and Food Fraud. This initiative promotes the use of digital technologies, artificial intelligence, and traceability tools to detect and respond to threats in real-time concerning food safety. The inclusion of specific guidelines for Food Defense and Food Fraud can provide an additional layer of protection, allowing for the early detection of intentional contaminations and the prevention of fraud throughout the supply chain.

Protecting the food production chain against intentional contaminations is crucial not only for food safety but also for preserving consumer trust and the reputation of companies. This article contributes to advancing knowledge in this area by providing a foundation of information for future research. The continuous improvement and adaptation of Food Defense measures are essential to meet emerging challenges and ensure food safety in an increasingly interconnected world that is vulnerable to new threats.

Author Contributions

Formal analysis, I.F.P.; Resources, I.F.P. and T.G.C.B.; Writing—review and editing, I.F.P.; Supervision, E.S.K. and M.M.K.; Project administration, E.S.K. and M.M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Acknowledgments

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001. The publication was funded by the Fundação de Estudos Agrários Luiz de Queiroz (FEALQ) and Universidade de São Paulo.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wiśniewska, M.Z.; Tarczyńska, A.S.; Ranadheera, C.S. Novel quality assurance systems against intentional contamination in dairy factories. In Dairy Foods: Processing, Quality, and Analytical Techniques; Smith, J., Johnson, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 281–310. [Google Scholar] [CrossRef]

- Huff, A. Food defense. In Encyclopedia of Food Chemistry; Elsevier: London, UK, 2018; pp. 652–656. [Google Scholar] [CrossRef]

- U.S. Department of Agricultural Food Safety and Inspection Service (USDA). Food Defense Risk Mitigation Tool. Available online: https://www.fsis.usda.gov/food-safety/food-defense-and-emergency-response/food-defense (accessed on 4 September 2023).

- Food and Drug Administration. Food Defense. Available online: https://www.fda.gov/food/food-defense (accessed on 4 September 2023).

- BSI Group. PAS 96:2017—Guide to Protecting and Defending Food and Drink from Deliberate Attack. Available online: https://www.bsigroup.com/en-GB/PAS-96/ (accessed on 13 October 2023).

- Food and Drug Administration. Mitigation Strategies to Protect Food Against Intentional Adulteration: Guidance for Industry; Food and Drug Administration: Spring, MD, USA, 2019. Available online: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/draft-guidance-industry-mitigation-strategies-protect-food-against-intentional-adulteration (accessed on 4 September 2023).

- Komitopoulou, E. Defending the Food Supply Chain. SGS Food Safety & Quality. Available online: https://mygfsi.com/blog/defending-the-food-supply-chain/ (accessed on 4 September 2023).

- Spink, J.W. The GFSI food fraud prevention compliance development & requirements: A ten-year review. Trends Food Sci. Technol. 2023, 138, 766–773. [Google Scholar] [CrossRef]

- Sousa Severino, P.R. Food Defense e a sua Relação com as Normas IFS V6, BRC V7 e FSSC 22000. Master’s Thesis, Engenharia Alimentar-Qualidade e Segurança Alimentar, Universidade de Lisboa, Lisbon, Portugal, 2016. [Google Scholar]

- Cavalheiro, L.G.; Cavalheiro, F.G.; de Azevedo Ruiz, V.L.; Kushida, M.M. Food defense e publicly available specification 96/2017. Segur. Aliment. Nutr. 2021, 28, e021002. [Google Scholar] [CrossRef]

- Malik, S.; Krishnaswamy, K.; Mustapha, A. Hazard Analysis and Risk-Based Preventive Controls (HARPC): Current Food Safety and Quality Standards for Complementary Foods. Foods 2021, 10, 2199. [Google Scholar] [CrossRef] [PubMed]

- Lopes, L.O.; Silva, R.; Guimarães, J.T.; Coutinho, N.M.; Castro, B.G.; Pimentel, T.C.; Duarte, M.C.K.H.; Freitas, M.Q.; Esmerino, E.A.; Sant’Ana, A.S.; et al. Food defense: Perceptions and attitudes of Brazilian dairy companies. J. Dairy Sci. 2020, 103, 8675–8682. [Google Scholar] [CrossRef]

- U.S. Department of Agricultural Food Safety and Inspection Service (USDA). Food Safety and Inspection Service (FSIS). Available online: https://www.usda.gov/our-agency/agencies (accessed on 29 September 2023).

- Food and Drug Administration. Food Defense Awareness for Front-Line Employees: Front Line Employee’s Role in food Defense. Available online: https://www.cfsanappsexternal.fda.gov/scripts/FDTraining/course_02/module_01/lesson_01/FD02_01_020.cfm (accessed on 4 September 2023).

- Djurle, A.; Young, B.; Berlin, A.; Vågsholm, I.; Blomström, A.L.; Nygren, J.; Kvarnheden, A. Addressing biohazards to food security in primary production. Food Secur. 2022, 14, 1475–1497. [Google Scholar] [CrossRef]

- Bashura, J.P. Food defense-“Back to the basics”. In Building the Future of Food Safety Technology; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar] [CrossRef]

- Farias de Abreu, V.L.; Silva, R.; Luchese, R.; Monteiro, S.S.; Esmerino, E.A.; Mathias, S.P. Impact assessment of the implementation of food defense plan in a Brazilian army military organization. Food Control 2020, 118, 107288. [Google Scholar] [CrossRef]

- Aguiar, D.R.; Kushida, M.M.; Paiva, L.C. Food defense: Gerenciamento de riscos e aplicação de ferramenta CARVER + SHOCK em frigorífico. CIAGRO 2020, 1, 709–724. [Google Scholar] [CrossRef]

- Romero, S.B. Food Defense: Evaluation and Application of the CARVER+Shock Tool in the Dairy Industry in Brazil. Master’s Thesis, University of São Paulo, São Paulo, Brazil, 2017. [Google Scholar]

- Lorenzen, C.L.; Hendrickson, M.K.; Weaber, R.L.; Clarke, A.D.; Shannon, M.C.; Savage-Clarke, K.L. Food Defense: Protecting the Food Supply from Intentional Harm, 1st ed.; University of Missouri Extension: Columbia, MO, USA, 2009; pp. 1–40. Available online: https://extension.missouri.edu/publications/mp914 (accessed on 4 September 2023).

- Manning, L.; Soon, J.M. Food Safety, Food Fraud, and Food Defense: A Fast Evolving Literature. J. Food Sci. 2016, 81, R823–R834. [Google Scholar] [CrossRef]

- Brainard, J.; Hunter, P. Contextual factors among indiscriminate or large attacks on food or water supplies, 1946–2015. Health Secur. 2015, 14, 19–28. [Google Scholar] [CrossRef]

- Moerman, F. Food Defense. In Food Control and Biosecurity; Academic Press: Cambridge, MA, USA, 2018; Volume 16, pp. 135–223. [Google Scholar] [CrossRef]

- Manning, L. Food defence: Refining the taxonomy of food defence threats. Trends Food Sci. Technol. 2019, 85, 107–115. [Google Scholar] [CrossRef]

- Praia, E.F.; Henriques, A.R. Assessing the implementation of food defense requirements in industrial meat-based food processors. Braz. J. Food Technol. 2021, 24, e2020201. [Google Scholar] [CrossRef]

- de Melo Andrade, E.L.I.; de Oliveira, G.C.; Silva, O.F. Food Defense—Do conceito às atuais exigências do mercado internacional. Res. Soc. Dev. 2021, 10, e201101724175. [Google Scholar] [CrossRef]

- Jurica, K.; Brčić Karačonji, I.; Lasić, D.; Bursać Kovačević, D.; Putnik, P. Unauthorized food manipulation as a criminal offense: Food authenticity, legal frameworks, analytical tools and cases. Foods 2021, 10, 2570. [Google Scholar] [CrossRef]

- Larson, R.B. Food safety concerns and food defense support: A cross-cultural study. J. Risk Res. 2023, 26, 113–132. [Google Scholar] [CrossRef]

- Lorenzen, C.L.; Hendrickson, M.K.; Weaber, R.L.; Clarke, A.D.; Shannon, M.C.; Savage-Clarke, K.L. Food Defense: Protecting the Food Supply from Intentional Harm; University of Missouri Extension: Columbia, MO, USA, 2013. [Google Scholar]

- FSIS. Functional Food Defense Plans. Available online: https://www.fsis.usda.gov/food-safety/food-defense-and-emergency-response/food-defense/functional-food-defense-plans (accessed on 26 January 2024).

- Lorenzen, C.L.; Cutter, C.N. Creating a Food Defense/Response Plan in Food Processing Facilities. In Food Protection and Security: Preventing and Mitigating Contamination During Food Processing and Production; Holcomb, S.R., Buzby, J.C., Eds.; Elsevier Inc.: Cambridge, MA, USA, 2017; pp. 43–60. [Google Scholar]

- Foundation FSSC. FSSC 22000 Scheme—Food Safety Management System Certification Version 6.0; Foundation FSSC: Gorinchem, The Netherlands, 2023; Available online: https://www.fssc.com/schemes/fssc-22000/documents/fssc-22000-version-6/ (accessed on 26 January 2024).

- Renewable Fuels Association (RFA). Annual Ethanol Production. Available online: https://ethanolrfa.org/markets-and-statistics/annual-ethanol-production (accessed on 4 September 2023).

- Companhia Nacional de Abastecimento (CONAB). Cana-de-Açúcar—Indústria. Available online: https://www.conab.gov.br/info-agro/safras/serie-historica-das-safras/itemlist/category/893-cana-de-acucar-industria (accessed on 5 October 2023).

- Raízen. Etanol: O que é e Como é Usado no Brasil. Available online: https://www.raizen.com.br/blog/etanol#:~:text=Etanol%20Anidro%20Industrial%20e%20Neutro&text=Atualmente%20a%20lei%20autoriza%20na,a%20industriais%20farmac%C3%AAuticas%20e%20aliment%C3%ADcias (accessed on 15 November 2023).

- Empresa Brasileira de Pesquisa Agropecuária (EMBRAPA). Neutro. Available online: https://www.embrapa.br/produtos-e-servicos/etanol (accessed on 15 November 2023).

- IBGE—Instituto Brasileiro de Geografia e Estatística. Levantamento Sistemático da Produção Agrícola. Cana-de-Açúcar. Available online: https://www.ibge.gov.br/ (accessed on 5 October 2023).

- Agência Nacional do Petróleo, Gás Natural e Biocombustíveis (ANP). Etanol: Histórico e Produção. Available online: https://www.gov.br/anp/pt-br/assuntos/etanol (accessed on 15 November 2023).

- Smeets, E.; Faaij, A.; Lewandowski, I.; Turkenburg, W.A. A bottom-up assessment and review of global bio-energy potentials to 2050. Prog. Energy Combust. Sci. 2007, 33, 56–106. [Google Scholar] [CrossRef]

- Target Normas. Available online: https://www.target.com.br/produtos/normas-tecnicas/34370/nbr5824-acetona-alcoois-etilico-e-metilico-determinacao-do-tempo-de-reducao-de-permanganato-metodo-de-barbet (accessed on 16 April 2025).

- Ministério de Minas e Energia (MME). Produção de Biocombustíveis No Brasil. Available online: https://www.gov.br/mme/pt-br/assuntos/energia/biocombustiveis (accessed on 15 November 2023).

- União da Indústria de Cana-de-Açúcar (UNICA). Produção e Mercado de Biocombustíveis No Brasil. Available online: https://www.unica.com.br/estatisticas/mercado/ (accessed on 15 November 2023).

- Ministério da Agricultura, Pecuária e Abastecimento (MAPA). Etanol de milho: O Futuro da Produção de Biocombustíveis No Brasil. Available online: https://www.gov.br/agricultura/pt-br (accessed on 25 October 2023).

- ABNT. NBR 10260:2012; Álcool Etílico—Determinação dos Teores de Acetal, Acetaldeído, Acetato de Etila, Acetona, Álcool Metílico, Álcoois Superiores e Benzeno por Cromatografia Gasosa. Brazilian National Standards Organization: Rio de Janeiro, Brazil, 2012.

- Álcool Etílico Extra Neutro. Available online: https://www.alcoolferreira.com.br/produtos.php (accessed on 13 October 2023).

- Bedryk, O.; Shevchenko, A.; Mishchenko, O.S.; Maleta, V.N.; Kiss, A.A. Industrial experience in using cyclic distillation columns for food grade alcohol purification. Chem. Eng. Res. Des. 2023, 192, 102–109. [Google Scholar] [CrossRef]

- Black, K.; Walker, G. Yeast Fermentation for Production of Neutral Distilled Spirits. Appl. Sci. 2023, 13, 4927. [Google Scholar] [CrossRef]

- Maitin, B.K. Indian whiskies. In Whisky and Other Spirits: Technology, Production and Marketing; Academic Press: Cambridge, MA, USA, 2022; pp. 75–86. [Google Scholar] [CrossRef]

- Sasma, B.V. Extra Neutral Alcohol. 2023. Available online: https://sasmabv.com/products/extra-neutral-alcohol/ (accessed on 4 September 2023).

- Blakistone, B.A. Principles and Applications of Modified Atmosphere Packaging of Foods. In Principles and Applications of Modified Atmosphere Packaging of Foods; Springer: New York, NY, USA, 1998. [Google Scholar] [CrossRef]

- Davies, A.R. New Methods of Food Preservation. In New Methods of Food Preservation; Springer: New York, NY, USA, 1995. [Google Scholar] [CrossRef]

- Galić, K.; Gabrić, D.; Ćurić, D. Packaging and the Shelf Life of Bread. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Mexis, S.F.; Kontominas, M.G. Packaging: Active Food Packaging. In Encyclopedia of Food Microbiology, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 999–1005. [Google Scholar] [CrossRef]

- Khan, A.A. Intentional Contamination of Water Supplies. In Ciottone’s Disaster Medicine; Elsevier: Amsterdam, The Netherlands, 2024; pp. 986–990. [Google Scholar] [CrossRef]

- MCKay, C.; Scharman, E.J. Intentional and inadvertent chemical contamination of food, water, and medication. Emerg. Med. Clin. N. Am. 2015, 33, 153–177. [Google Scholar] [CrossRef]

- National Center for Biotechnology Information (PubChem). Ethanol. 2023. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Ethanol (accessed on 5 October 2023).

- Sigma-Aldrich. Solvent Miscibility Chart. 2023. Available online: https://www.sigmaaldrich.com/US/en/technical-documents/technical-article/analytical-chemistry/purification/solvent-miscibility-table (accessed on 5 October 2023).

- California State University Stanislaus. Solvent Miscibility Table. 2023. Available online: https://www.csustan.edu/sites/default/files/groups/Chemistry/Drake/documents/solvent_miscibility_table.pdf (accessed on 5 October 2023).

- Solvent Polarity Table. Available online: https://www.grace.umd.edu/~zhangx/html/solvent3.html (accessed on 23 October 2024).

- He, N.X.; Bayen, S. An overview of chemical contaminants and other undesirable chemicals in alcoholic beverages and strategies for analysis. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3916–3950. [Google Scholar] [CrossRef]

- Pelegrín, C.J.; Flores, Y.; Jiménez, A.; Garrigós, M.C. Recent trends in the analysis of chemical contaminants in beverages. Beverages 2020, 6, 32. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).