Machine Learning in Carbon Capture, Utilization, Storage, and Transportation: A Review of Applications in Greenhouse Gas Emissions Reduction

Abstract

1. Introduction

- This review systematically covers ML applications across all major CCUS processes—capture, transport, storage, and utilization—rather than focusing only on one segment. Unlike previous work, we distinctly provide representative examples for each category, enhancing the comparative analysis and practical applicability of our findings.

- We conduct a critical review of the current CCUS modeling, simulations, and techniques for optimization of the design and operations of CCUS systems up to 2025.

- We identify the critical parameters/objectives and key findings and evaluate different ML techniques applied during the CCUS process.

- We provide guidance and recommendations for the CCUS stakeholders, in which a detailed outlook on the opportunities for ML and related technologies for further applications in the CCUS field is presented.

2. Background on ML Methods

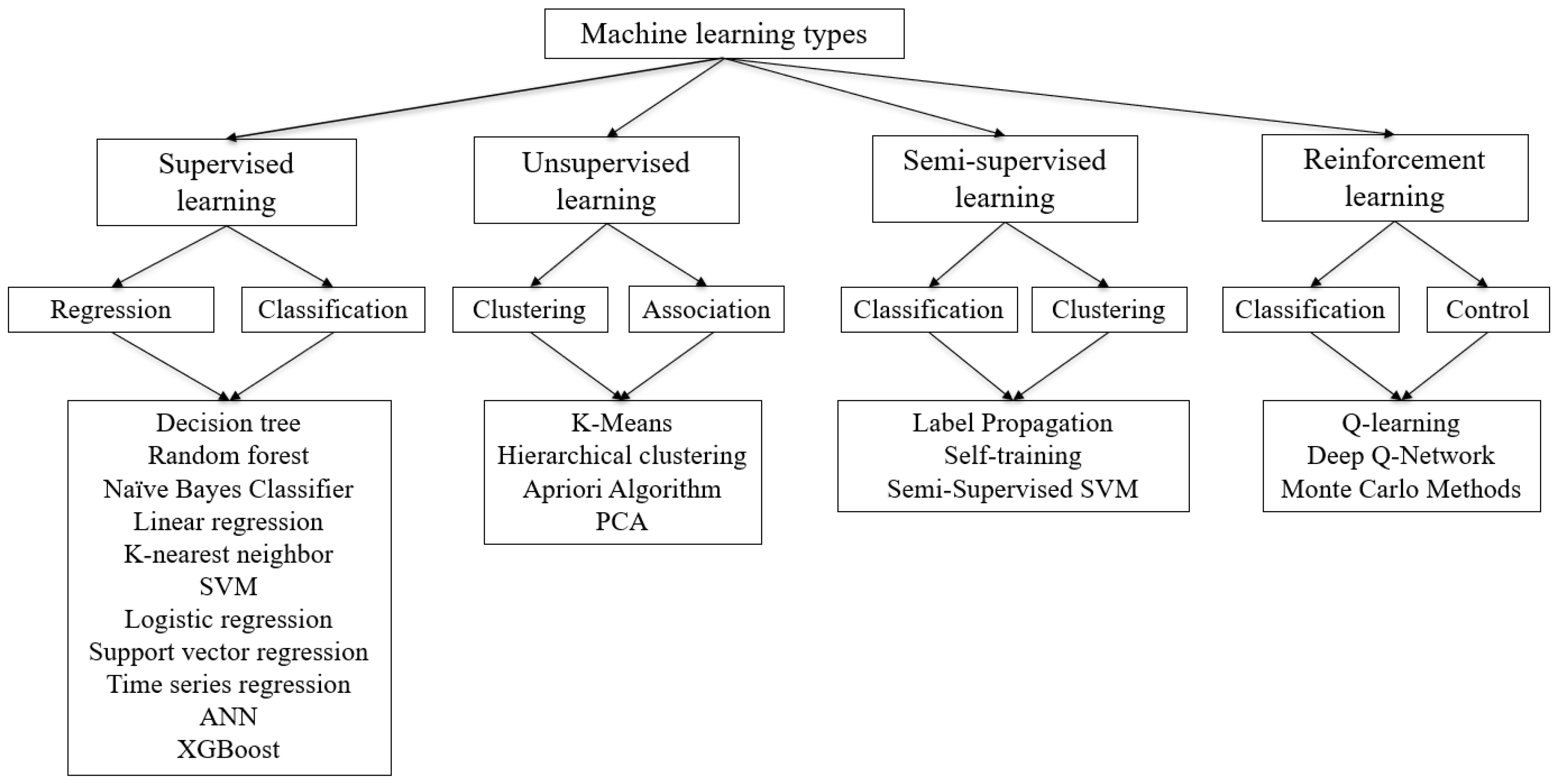

2.1. Categories of ML

- (1)

- Supervised learning: uses labeled datasets to train algorithms, making predictions or decisions based on input–output pairs. This is widely used in CCUS to predict system performance, optimize process parameters, and detect anomalies in real-time data. Examples such as artificial neural networks (ANNs), support vector machines (SVMs), and random forests (RFs) are commonly used to estimate CO2 capture efficiency and optimize storage conditions.

- (2)

- Unsupervised learning: employs unlabeled data to discover hidden patterns or structures. Clustering techniques, such as K-means or hierarchical clustering, can be applied in CCUS for site characterization and reservoir classification, where geological or operational data are used to group storage sites based on their CO2 storage potential or risk profiles.

- (3)

- Semi-supervised learning: combines labeled and unlabeled data to improve learning accuracy when only limited labeled data is available. This can be especially useful in CCUS applications where comprehensive datasets are complex to acquire, such as in novel material discovery for CO2 adsorption and storage.

- (4)

- Reinforcement learning: enables algorithms to make decisions by interacting with an environment and receiving feedback through rewards or penalties. This approach is increasingly being explored for process optimization in CCUS, where it can adapt to dynamic system changes in real time. For instance, reinforcement learning could optimize the injection of CO2 into reservoirs by continuously adjusting parameters to maximize efficiency while minimizing risks such as leakage.

2.2. Popular ML Algorithms in CCUS

- (1)

- ANN: ANN is modeled after the human brain’s neural network, consisting of interconnected nodes (neurons) that can process and learn from data. ANNs are widely used in CCUS for predictive modeling, such as estimating CO2 capture rates, optimizing transport systems, and forecasting reservoir behavior. Deep learning, a more advanced form of ANN, has also been applied to model complex relationships in large datasets, particularly in geological storage and material discovery.

- (2)

- SVM: SVM is a classification technique that seeks to find the hyperplane that best separates data into different categories. In CCUS, SVM has been used for material selection, process optimization, and real-time monitoring of CO2 transport systems. For instance, SVM models have been employed to predict the effectiveness of CO2 sorbents and membranes under varying conditions.

- (3)

- RF: RF is an ensemble learning technique that combines multiple decision trees to improve prediction accuracy and prevent overfitting. It has been used in CCUS for site selection, reservoir classification, and risk analysis, offering robust predictions in cases where data are incomplete or noisy.

- (4)

- XGBoost: XGBoost is a scalable decision-tree-based ensemble method applied in material discovery, optimizing capture processes, and predicting CO2 behavior in storage formations. Its ability to handle missing data and provide essential features makes it a valuable tool for interpreting complex datasets.

- (5)

- DL Models: Deep learning architectures such as convolutional neural networks (CNNs), recurrent neural networks (RNNs), gated recurrent units (GRUs), and long short-term memory (LSTM) networks are well suited for time-series forecasting, image analysis, and large-scale simulations. DL models have been instrumental in monitoring CO2 flow, assessing subsurface CO2 behavior, and processing seismic data in storage sites.

3. Methodology

- Can ML be applied in CCUS, and how can it be applied?

- What are the common ML methods applied in CCUS processes?

- What are the typical input variables, outputs, and objectives of ML models used in each CCUS domain?

- What are the current challenges and opportunities for further integration of ML into CCUS systems?

4. ML in Carbon Capture

4.1. Overview

4.2. ML Application in Carbon Capture

- (1)

- Adsorption: ML significantly optimizes CO2 adsorption processes, where solid materials (adsorbents) capture CO2 from gas streams. By analyzing experimental and simulation data, ML models can predict the performance of different adsorbent materials, such as metal–organic frameworks (MOFs) or zeolites [36], under varying conditions. These models can identify materials with high CO2 uptake, faster regeneration times, and selectivity, significantly speeding up the discovery and design of new adsorbents. Additionally, ML aids in the optimization of operating conditions, such as pressure and temperature, to enhance the efficiency of CO2 capture in industrial processes.

- (2)

- Absorption: In absorption, CO2 is captured using solvents like amines. Commn amines include monoethanolamine (MEA), diethanolamine (DEA), and methyl diethanolamine (MDEA) [24]. The application of ML models on MEA has been a hot topic for researchers [17,37,38]. ML models can predict the behavior of different solvents under various pressures and temperatures, optimizing the capture and regeneration cycles to reduce energy consumption. These models can also be used to develop new solvent formulations by predicting their CO2 absorption capacity, efficiency, thermal stability, and reaction kinetics. This accelerates the discovery of more energy-efficient solvents for carbon capture. Hosseinpour et al. [22] has summarized a comprehensive review of the absorption-based post-combustion process.

- (3)

- Chemical looping: ML is used to predict the performance of oxygen carriers, such as metal oxides and calcium oxide, by analyzing large datasets to identify materials that offer better reactivity and stability. For example, calcium looping uses CaO as a solid sorbent to capture CO2. It is particularly suitable for large-scale applications like power plants or industrial processes. Readers can reference Song et al. [39] for a comprehensive review of ML applications for chemical looping.

- (4)

- Membrane technologies: Membranes can be classified into three types based on their material composition: (a) polymeric membranes are made from polyimide, polyetherimide, polysulfone, or polyethylene oxide; (b) inorganic membranes are made from ceramics, zeolites, or metallic materials; (c) mixed-matrix membranes are hybrid membranes combining polymeric and inorganic properties [40]. ML is used to predict the performance of membranes for CO2 separation, identifying the best materials for selectivity and permeability. This helps researchers design new membranes that enhance CO2 capture efficiency while minimizing energy costs.

4.3. Summary

5. ML in CO2 Storage

5.1. Overview

- (1)

- Deep saline aquifers are ideal for CO2 storage due to their vast capacity, deep location, and the multiple natural trapping mechanisms they offer. Found at depths greater than 800 m, these aquifers consist of porous rock formations filled with highly saline water, providing ample space to store CO2 under high pressure, where it becomes a supercritical fluid [57]. Impermeable caprock layers prevent CO2 from escaping, while residual trapping, solubility trapping, and mineral trapping ensure long-term containment. Additionally, saline aquifers are widely distributed globally and do not compete with freshwater resources, making them a key option for large-scale carbon sequestration.

- (2)

- Depleted oil reservoirs typically have well-mapped porous rock formations, which provide the necessary pore space to store CO2 after oil production has ceased. The presence of a natural caprock, which initially trapped the oil, also prevents the injected CO2 from escaping [58]. The existing infrastructure from oil operations, such as wells and pipelines, further reduces costs, making depleted oil reservoirs an economically and technically viable option for long-term CO2 storage.

- (3)

- Unmineable coal seams present a viable option for CO2 storage due to their ability to adsorb CO2 onto the surface of the coal, effectively trapping the gas within the rock matrix. In these seams, the CO2 molecules adhere to the micropores of the coal, a process known as adsorption, which securely holds the gas and prevents its migration. While these coal seams are too deep or uneconomical to mine for coal extraction, they can serve a dual purpose by enhancing methane recovery; injecting CO2 can displace methane, allowing for coalbed methane (CBM) extraction as an additional energy resource [44]. The impermeable nature of the coal seams and the adsorption process provide a robust mechanism for long-term CO2 storage, making them a unique and promising geological storage option in areas with abundant unmineable coal deposits. Figure 3 illustrates the different geological formations suitable for underground CO2 storage. A CO2 injection well is shown on the left side of the schematic, while an oil production well is depicted on the right. The diagram includes representations of saline aquifers, depleted oil and gas reservoirs, and unmineable coal seams.

- (4)

- Mineral storage, also known as mineral carbonation, involves the long-term sequestration of CO2 by chemically reacting it with certain minerals to form stable carbonate compounds. This process occurs naturally in rocks rich in minerals like calcium, magnesium, or iron, which react with CO2 to form solid carbonates such as calcite, magnesite, and siderite. Once the CO2 is transformed into these stable mineral forms, it becomes permanently trapped, making this one of the most secure and permanent methods of carbon storage [59]. Although the process occurs naturally over geological timescales, research is focused on accelerating the reaction in suitable formations, like basalt or peridotite, to enhance storage potential. While mineral storage is slower than other methods, it offers a highly secure solution with virtually no risk of CO2 leakage, making it ideal for regions with appropriate geological conditions.

5.2. ML Application in Storage

5.3. Summary

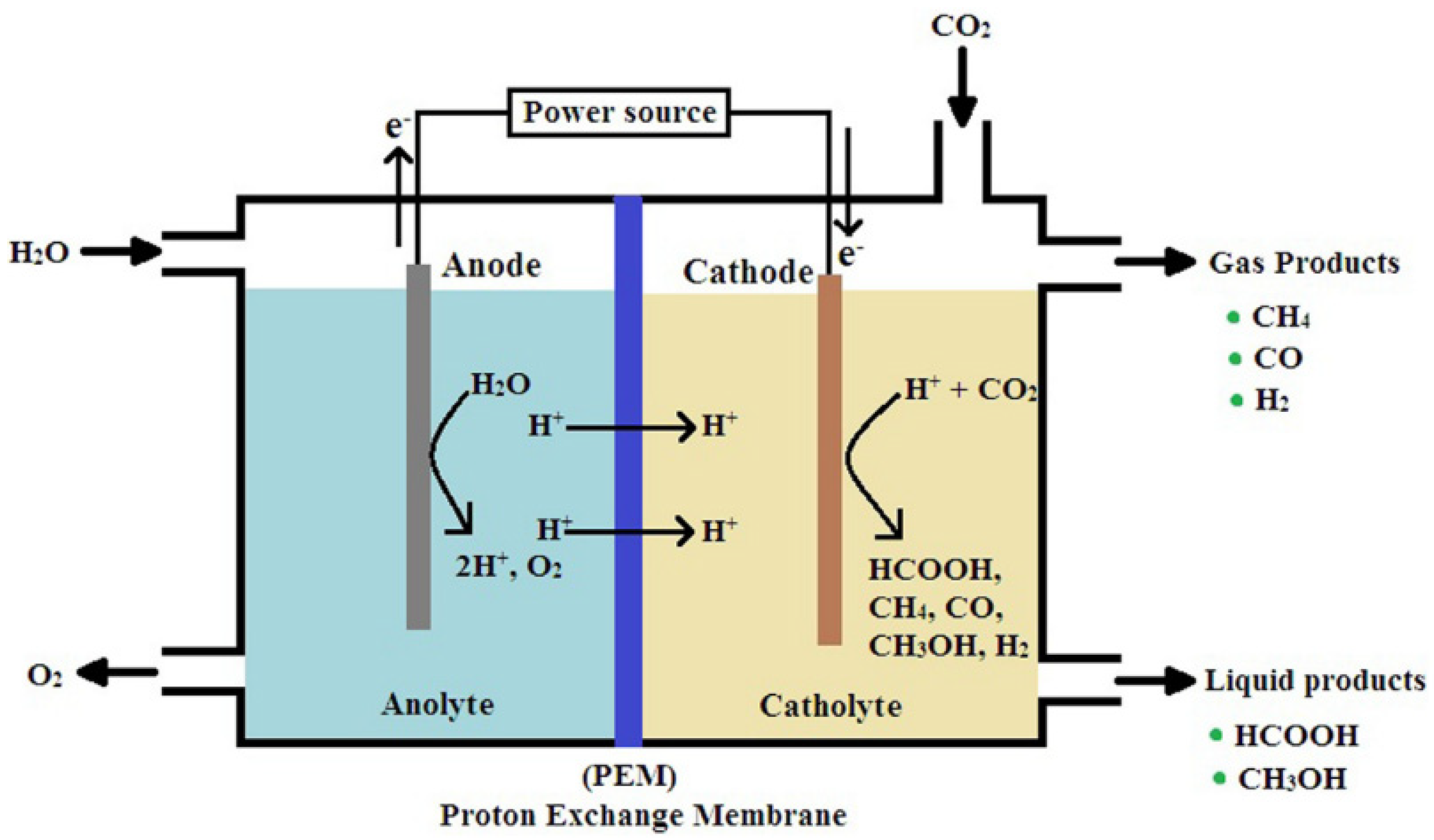

6. ML in CO2 Utilization

6.1. Overview

6.2. ML Application Utilization

6.3. Summary

7. ML in CO2 Transportation

7.1. Overview

7.2. ML Application in Transportation

7.3. Summary

8. Discussion

8.1. Evaluation of Key Findings

- In CO2 capture, ANN and RF are among the most frequently applied ML methods due to their strong predictive capabilities. These models are widely used to predict CO2 adsorption/absorption performance, optimize process conditions, and screen advanced materials. Surface area, pore volume, solvent concentration, and temperature were consistently ranked as influential among input parameters.

- In storage, ML was primarily used for site characterization, storage capacity estimation, and leakage detection. RF and ensemble models outperformed single regressors in complex reservoir settings. Notably, synthetic datasets derived from simulations were often used to train models when field data were limited.

- In utilization, CO2-EOR emerged as the most mature area for ML integration. Surrogate modeling with ANN, SVR, and XGBoost accelerated optimization of injection strategies and economic forecasting. In chemical conversion, ML has shown promise in catalyst discovery and reaction optimization, particularly when coupled with DFT or high-throughput screening datasets.

- In transportation, pipeline monitoring, anomaly detection, and flow rate estimation are popular topics. Time-series models such as LSTM and DNN were well suited for predicting critical pressure and flow changes in supercritical CO2 pipelines.

8.2. Benefits and Limitations of ML in CCUS

8.3. Further Pathways of ML in CCUS

- (1)

- Hybrid physics-informed ML models: Models will be developed that integrate first-principles equations with data-driven approaches to improve interpretability and generalizability across CCUS applications.

- (2)

- Advanced materials discovery: ML techniques such as deep learning and reinforcement learning will play a crucial role in discovering new materials for CO2 capture (e.g., sorbents, membranes, and catalysts). These models can accelerate the screening and design of materials with higher efficiency, lower cost, and improved stability.

- (3)

- Autonomous CCUS operations: The development of autonomous systems for real-time monitoring and optimization will enable more efficient and cost-effective CCUS operations, especially in CO2 pipeline leakage detection. These systems could dynamically adjust operational parameters based on changing environmental and process conditions, minimizing human intervention and enhancing system resilience.

- (4)

- Integration with the Internet of Things (IoT) and big data: The integration of IoT sensors and big data analytics with ML models will provide unprecedented levels of process control and efficiency. This will enable the collection of real-time data from pipelines, storage sites, and capture facilities, feeding directly into ML algorithms to enhance predictive capabilities and reduce operational risks.

- (5)

- Uncertainty quantification and risk management: Future ML models will focus on uncertainty quantification and risk assessment in CCUS operations, particularly for storage and transportation. By accounting for uncertainties in geological formations and pipeline conditions, ML models can improve the reliability and safety of CO2 storage.

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| ANFIS | Adaptive neuro-fuzzy inference system |

| ANN | Artificial neural network |

| BCLG | Biomass chemical looping gasification |

| BPNN | Backpropagation algorithm neural network |

| BR | Bayesian regularization |

| CFNN | Cascade forward neural network |

| CISM | Conditional input selection module |

| CNN | Convolutional neural network |

| DFT | Density functional theory |

| DL | Deep learning |

| DNN | Deep neural networks |

| DT | Decision tree |

| ELM | Extreme learning machine |

| EOR | Enhanced oil recovery |

| ETR | Extra trees regression |

| FFNN | Feed-forward neural network |

| FN | Function network |

| FOPR | Field oil production rate |

| GBDT | Gradient boosting decision tree |

| GBR | Gradient boost regression |

| GEP | Gene expression programming |

| GMDH | Group method of data handling |

| GPR | Gaussian process regression |

| GRNN | Generalized regression neural network |

| GRU | Gated recurrent units |

| GTB | Gradient tree boosting |

| GWO | Grey wolf optimizer |

| ILSO | Improved lion swarm optimization |

| KNN | K-nearest neighbor |

| KRR | Kernel ridge regression |

| LGB | Light gradient boosting machine |

| LM | Levenberg–Marquardt |

| LR | Linear regression |

| LSO | Lion swarm optimization |

| LSSVM | Least-squares support vector machine |

| LSTM | Long short-term memory |

| LTSA | Lizard tail split algorithm |

| MDEA | N-methyldiethanolamine |

| MEA | Monoethanolamine |

| MLP | Multi-layer perceptron |

| MLR | Multi-layer regression |

| MMP | Minimum miscibility pressure |

| MOF | Metal organic framework |

| NN | Neural network |

| NPV | Net present value |

| PSA | Pressure swing adsorption |

| PSO | Particle swarm optimization |

| RBF | Radial basis function |

| RL | Reinforcement learning |

| RF | Random forest |

| RFE | Recursive feature elimination |

| RNN | Recurrent neural network |

| RSM | Response surface methodology |

| SCG | Scaled conjugate gradient |

| SFLA | Shuffled frog leaping algorithm |

| SGD | Stochastic gradient descent |

| SVM | Support vector machine |

| SVMr | Support vector machine with a radial basis kernel |

| SVR | Support vector regression |

| TDS | Total dissolved solids |

| WAG | Water-alternating-gas |

| XGBoost | Extreme gradient boosting |

References

- Stewart, C.; Hessami, M.-A. A Study of Methods of Carbon Dioxide Capture and Sequestration–the Sustainability of a Photosynthetic Bioreactor Approach. Energy Convers. Manag. 2005, 46, 403–420. [Google Scholar] [CrossRef]

- Metz, B.; Davidson, O.; de Coninck, H.; Loos, M.; Meyer, L. IPCC Special Report on Carbon Dioxide Capture and Storage; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Van Fan, Y.; Perry, S.; Klemeš, J.J.; Lee, C.T. A Review on Air Emissions Assessment: Transportation. J. Clean. Prod. 2018, 194, 673–684. [Google Scholar] [CrossRef]

- Yu, K.M.K.; Curcic, I.; Gabriel, J.; Tsang, S.C.E. Recent Advances in CO2 Capture and Utilization. ChemSusChem 2008, 1, 893–899. [Google Scholar] [CrossRef] [PubMed]

- Koytsoumpa, E.I.; Bergins, C.; Kakaras, E. The CO2 Economy: Review of CO2 Capture and Reuse Technologies. J. Supercrit. Fluids 2018, 132, 3–16. [Google Scholar] [CrossRef]

- IEA. Carbon Capture, Utilisation and Storage—Energy System. Available online: https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage (accessed on 10 January 2025).

- Li, Z.; Hatzignatiou, D.; Ehlig-Economides, C. Carbon Dioxide Storage in a Natural Gas Reservoir under Strong Water Drive. In Proceedings of the 2024 Carbon Capture, Utilization, and Storage Conference, Houston, TX, USA, 9–10 October 2024; American Association of Petroleum Geologists: Tulsa, OK, USA, 2024. [Google Scholar]

- Khan, M.N.; Siddiqui, S.; Thakur, G.C. Recent Advances in Geochemical and Mineralogical Studies on CO2–Brine–Rock Interaction for CO2 Sequestration: Laboratory and Simulation Studies. Energies 2024, 17, 3346. [Google Scholar] [CrossRef]

- Huang, C.-H.; Tan, C.-S. A Review: CO2 Utilization. Aerosol. Air Qual. Res. 2014, 14, 480–499. [Google Scholar] [CrossRef]

- Simonsen, K.R.; Hansen, D.S.; Pedersen, S. Challenges in CO2 Transportation: Trends and Perspectives. Renew. Sustain. Energy Rev. 2024, 191, 114149. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Rukavishnikov, V.S.; Minaev, K.M. Review of Technological Progress in Carbon Dioxide Capture, Storage, and Utilization. Gas Sci. Eng. 2023, 117, 205070. [Google Scholar] [CrossRef]

- Yan, Y.; Borhani, T.N.; Subraveti, S.G.; Pai, K.N.; Prasad, V.; Rajendran, A.; Nkulikiyinka, P.; Asibor, J.O.; Zhang, Z.; Shao, D.; et al. Harnessing the Power of Machine Learning for Carbon Capture, Utilisation, and Storage (CCUS)—A State-of-the-Art Review. Energy Environ. Sci. 2021, 14, 6122–6157. [Google Scholar] [CrossRef]

- Hussin, F.; Md Rahim, S.A.N.; Hatta, N.S.M.; Aroua, M.K.; Mazari, S.A. A Systematic Review of Machine Learning Approaches in Carbon Capture Applications. J. CO2 Util. 2023, 71, 102474. [Google Scholar] [CrossRef]

- Al-Sakkari, E.G.; Ragab, A.; Dagdougui, H.; Boffito, D.C.; Amazouz, M. Carbon Capture, Utilization and Sequestration Systems Design and Operation Optimization: Assessment and Perspectives of Artificial Intelligence Opportunities. Sci. Total Environ. 2024, 917, 170085. [Google Scholar] [CrossRef] [PubMed]

- Jordan, M.I.; Mitchell, T.M. Machine Learning: Trends, Perspectives, and Prospects. Science 2015, 349, 255–260. [Google Scholar] [CrossRef]

- Sheikh, F. Commercialization of Al Reyadah—World’s 1st Carbon Capture CCUS Project from Iron & Steel Industry for Enhanced Oil Recovery CO2-EOR. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 16 November 2021. [Google Scholar]

- Li, F.; Zhang, J.; Oko, E.; Wang, M. Modelling of a Post-Combustion CO2 Capture Process Using Neural Networks. Fuel 2015, 151, 156–163. [Google Scholar] [CrossRef]

- Burns, T.D.; Pai, K.N.; Subraveti, S.G.; Collins, S.P.; Krykunov, M.; Rajendran, A.; Woo, T.K. Prediction of MOF Performance in Vacuum Swing Adsorption Systems for Postcombustion CO2 Capture Based on Integrated Molecular Simulations, Process Optimizations, and Machine Learning Models. Environ. Sci. Technol. 2020, 54, 4536–4544. [Google Scholar] [CrossRef] [PubMed]

- Selveindran, A.; Zargar, Z.; Razavi, S.M.; Thakur, G. Fast Optimization of Injector Selection for Waterflood, CO2-EOR and Storage Using an Innovative Machine Learning Framework. Energies 2021, 14, 7628. [Google Scholar] [CrossRef]

- Zhang, Z.; Vo, D.-N.; Nguyen, T.B.H.; Sun, J.; Lee, C.-H. Advanced Process Integration and Machine Learning-Based Optimization to Enhance Techno-Economic-Environmental Performance of CO2 Capture and Conversion to Methanol. Energy 2024, 293, 130758. [Google Scholar] [CrossRef]

- Rahimi, M.; Moosavi, S.M.; Smit, B.; Hatton, T.A. Toward Smart Carbon Capture with Machine Learning. Cell Rep. Phys. Sci. 2021, 2, 100396. [Google Scholar] [CrossRef]

- Hosseinpour, M.; Shojaei, M.J.; Salimi, M.; Amidpour, M. Machine Learning in Absorption-Based Post-Combustion Carbon Capture Systems: A State-of-the-Art Review. Fuel 2023, 353, 129265. [Google Scholar] [CrossRef]

- Li, N.; Feng, W.; Yu, J.; Chen, F.; Zhang, Q.; Zhu, S.; Hu, Y.; Li, Y. Recent Advances in Geological Storage: Trapping Mechanisms, Storage Sites, Projects, and Application of Machine Learning. Energy Fuels 2023, 37, 10087–10111. [Google Scholar] [CrossRef]

- Gupta, S.; Li, L. The Potential of Machine Learning for Enhancing CO2 Sequestration, Storage, Transportation, and Utilization-Based Processes: A Brief Perspective. JOM 2022, 74, 414–428. [Google Scholar] [CrossRef]

- Surden, H. Machine Learning and Law: An Overview. In Research Handbook on Big Data Law; Edward Elgar Publishing: Cheltenham, UK, 2021. [Google Scholar]

- Zhu, X.; Goldberg, A.B. Introduction to Semi-Supervised Learning; Springer International Publishing: Cham, Switzerland, 2009; ISBN 978-3-031-00420-9. [Google Scholar]

- Zhou, Z.-H. Machine Learning; Springer: Singapore, 2021; ISBN 978-981-15-1966-6. [Google Scholar]

- Du, X.; Salasakar, S.; Thakur, G. A Comprehensive Summary of the Application of Machine Learning Techniques for CO2-Enhanced Oil Recovery Projects. Mach. Learn. Knowl. Extr. 2024, 6, 917–943. [Google Scholar] [CrossRef]

- Mahesh, B. Machine Learning Algorithms—A Review. Int. J. Sci. Res. (IJSR) 2020, 9, 381–386. [Google Scholar] [CrossRef]

- Fu, L.; Ren, Z.; Si, W.; Ma, Q.; Huang, W.; Liao, K.; Huang, Z.; Wang, Y.; Li, J.; Xu, P. Research Progress on CO2 Capture and Utilization Technology. J. CO2 Util. 2022, 66, 102260. [Google Scholar] [CrossRef]

- Liang, Z.H.; Rongwong, W.; Liu, H.; Fu, K.; Gao, H.; Cao, F.; Zhang, R.; Sema, T.; Henni, A.; Sumon, K.; et al. Recent Progress and New Developments in Post-Combustion Carbon-Capture Technology with Amine Based Solvents. Int. J. Greenh. Gas Control 2015, 40, 26–54. [Google Scholar] [CrossRef]

- Jansen, D.; Gazzani, M.; Manzolini, G.; van Dijk, E.; Carbo, M. Pre-Combustion CO2 Capture. Int. J. Greenh. Gas Control 2015, 40, 167–187. [Google Scholar] [CrossRef]

- Toftegaard, M.B.; Brix, J.; Jensen, P.A.; Glarborg, P.; Jensen, A.D. Oxy-Fuel Combustion of Solid Fuels. Prog. Energy Combust. Sci. 2010, 36, 581–625. [Google Scholar] [CrossRef]

- Sodiq, A.; Abdullatif, Y.; Aissa, B.; Ostovar, A.; Nassar, N.; El-Naas, M.; Amhamed, A. A Review on Progress Made in Direct Air Capture of CO2. Environ. Technol. Innov. 2023, 29, 102991. [Google Scholar] [CrossRef]

- Hanson, E.; Nwakile, C.; Hammed, V.O. Carbon Capture, Utilization, and Storage (CCUS) Technologies: Evaluating the Effectiveness of Advanced CCUS Solutions for Reducing CO2 Emissions. Results Surf. Interfaces 2025, 18, 100381. [Google Scholar] [CrossRef]

- Long, J.R.; Yaghi, O.M. The Pervasive Chemistry of Metal–Organic Frameworks. Chem. Soc. Rev. 2009, 38, 1213. [Google Scholar] [CrossRef]

- Wu, X.; Shen, J.; Wang, M.; Lee, K.Y. Intelligent Predictive Control of Large-Scale Solvent-Based CO2 Capture Plant Using Artificial Neural Network and Particle Swarm Optimization. Energy 2020, 196, 117070. [Google Scholar] [CrossRef]

- Ashraf, W.M.; Dua, V. Machine Learning Based Modelling and Optimization of Post-Combustion Carbon Capture Process Using MEA Supporting Carbon Neutrality. Digit. Chem. Eng. 2023, 8, 100115. [Google Scholar] [CrossRef]

- Song, Y.; Teng, S.; Fang, D.; Lu, Y.; Chen, Z.; Xiao, R.; Zeng, D. Machine Learning for Chemical Looping: Recent Advances and Prospects. Energy Fuels 2024, 38, 11541–11561. [Google Scholar] [CrossRef]

- Luis, P.; Van Gerven, T.; Van der Bruggen, B. Recent Developments in Membrane-Based Technologies for CO2 Capture. Prog. Energy Combust. Sci. 2012, 38, 419–448. [Google Scholar] [CrossRef]

- Subraveti, S.G.; Li, Z.; Prasad, V.; Rajendran, A. Machine Learning-Based Multiobjective Optimization of Pressure Swing Adsorption. Ind. Eng. Chem. Res. 2019, 58, 20412–20422. [Google Scholar] [CrossRef]

- Pai, K.N.; Prasad, V.; Rajendran, A. Experimentally Validated Machine Learning Frameworks for Accelerated Prediction of Cyclic Steady State and Optimization of Pressure Swing Adsorption Processes. Sep. Purif. Technol. 2020, 241, 116651. [Google Scholar] [CrossRef]

- Yuan, X.; Suvarna, M.; Low, S.; Dissanayake, P.D.; Lee, K.B.; Li, J.; Wang, X.; Ok, Y.S. Applied Machine Learning for Prediction of CO2 Adsorption on Biomass Waste-Derived Porous Carbons. Environ. Sci. Technol. 2021, 55, 11925–11936. [Google Scholar] [CrossRef]

- Alanazi, A.; Ibrahim, A.F.; Bawazer, S.; Elkatatny, S.; Hoteit, H. Machine Learning Framework for Estimating CO2 Adsorption on Coalbed for Carbon Capture, Utilization, and Storage Applications. Int. J. Coal Geol. 2023, 275, 104297. [Google Scholar] [CrossRef]

- Zhang, S.; Dong, H.; Lin, A.; Zhang, C.; Du, H.; Mu, J.; Han, J.; Zhang, J.; Wang, F. Design and Optimization of Solid Amine CO2 Adsorbents Assisted by Machine Learning. ACS Sustain. Chem. Eng. 2022, 10, 13185–13193. [Google Scholar] [CrossRef]

- Yarveicy, H.; Ghiasi, M.M.; Mohammadi, A.H. Performance Evaluation of the Machine Learning Approaches in Modeling of CO2 Equilibrium Absorption in Piperazine Aqueous Solution. J. Mol. Liq. 2018, 255, 375–383. [Google Scholar] [CrossRef]

- Sipöcz, N.; Tobiesen, F.A.; Assadi, M. The Use of Artificial Neural Network Models for CO2 Capture Plants. Appl. Energy 2011, 88, 2368–2376. [Google Scholar] [CrossRef]

- Zhan, J.; Wang, B.; Zhang, L.; Sun, B.-C.; Fu, J.; Chu, G.; Zou, H. Simultaneous Absorption of H2S and CO2 into the MDEA + PZ Aqueous Solution in a Rotating Packed Bed. Ind. Eng. Chem. Res. 2020, 59, 8295–8303. [Google Scholar] [CrossRef]

- Nuchitprasittichai, A.; Cremaschi, S. Optimization of CO2 Capture Process with Aqueous Amines—A Comparison of Two Simulation–Optimization Approaches. Ind. Eng. Chem. Res. 2013, 52, 10236–10243. [Google Scholar] [CrossRef]

- Khan, I.A.; Abba, S.I.; Usman, J.; Jibril, M.M.; Usman, A.G.; Aljundi, I.H. Optimization of CO2 Absorption Rate for Environmental Applications and Effective Carbon Capture. J. Clean. Prod. 2025, 490, 144707. [Google Scholar] [CrossRef]

- Hanak, D.P.; Manovic, V. Economic Feasibility of Calcium Looping under Uncertainty. Appl. Energy 2017, 208, 691–702. [Google Scholar] [CrossRef]

- Tahir, F.; Arshad, M.Y.; Saeed, M.A.; Ali, U. Integrated Process for Simulation of Gasification and Chemical Looping Hydrogen Production Using Artificial Neural Network and Machine Learning Validation. Energy Convers. Manag. 2023, 296, 117702. [Google Scholar] [CrossRef]

- Wang, Z.; Mu, L.; Miao, H.; Shang, Y.; Yin, H.; Dong, M. An Innovative Application of Machine Learning in Prediction of the Syngas Properties of Biomass Chemical Looping Gasification Based on Extra Trees Regression Algorithm. Energy 2023, 275, 127438. [Google Scholar] [CrossRef]

- Situ, Y.; Yuan, X.; Bai, X.; Li, S.; Liang, H.; Zhu, X.; Wang, B.; Qiao, Z. Large-Scale Screening and Machine Learning for Metal–Organic Framework Membranes to Capture CO2 from Flue Gas. Membranes 2022, 12, 700. [Google Scholar] [CrossRef]

- Ahmad, A.L.; Adewole, J.K.; Leo, C.P.; Ismail, S.; Sultan, A.S.; Olatunji, S.O. Prediction of Plasticization Pressure of Polymeric Membranes for CO2 Removal from Natural Gas. J. Membr. Sci. 2015, 480, 39–46. [Google Scholar] [CrossRef]

- Guan, J.; Huang, T.; Liu, W.; Feng, F.; Japip, S.; Li, J.; Wu, J.; Wang, X.; Zhang, S. Design and Prediction of Metal Organic Framework-Based Mixed Matrix Membranes for CO2 Capture via Machine Learning. Cell Rep. Phys. Sci. 2022, 3, 100864. [Google Scholar] [CrossRef]

- Song, Y.; Sung, W.; Jang, Y.; Jung, W. Application of an Artificial Neural Network in Predicting the Effectiveness of Trapping Mechanisms on CO2 Sequestration in Saline Aquifers. Int. J. Greenh. Gas Control 2020, 98, 103042. [Google Scholar] [CrossRef]

- You, J.; Ampomah, W.; Kutsienyo, E.J.; Sun, Q.; Balch, R.S.; Aggrey, W.N.; Cather, M. Assessment of Enhanced Oil Recovery and CO2 Storage Capacity Using Machine Learning and Optimization Framework. In Proceedings of the SPE Europec Featured at 81st EAGE Conference and Exhibition, London, UK, 3–6 June 2019. [Google Scholar]

- Tariq, Z.; Ali, M.; Yan, B.; Sun, S.; Khan, M.; Yekeen, N.; Hoteit, H. Data-Driven Machine Learning Modeling of Mineral/CO2/Brine Wettability Prediction: Implications for CO2 Geo-Storage. In Proceedings of the Middle East Oil, Gas and Geosciences Show, Manama, Bahrain, 19 February 2023. [Google Scholar]

- Liu, M.; Li, Z.; Qi, J.; Meng, Y.; Zhou, J.; Ni, M.; Zhou, X.; Chen, H. Prediction of CO2 Storage in Different Geological Conditions Based on Machine Learning. Energy Fuels 2024, 38, 22340–22350. [Google Scholar] [CrossRef]

- Chen, B.; Harp, D.R.; Lin, Y.; Keating, E.H.; Pawar, R.J. Geologic CO2 Sequestration Monitoring Design: A Machine Learning and Uncertainty Quantification Based Approach. Appl. Energy 2018, 225, 332–345. [Google Scholar] [CrossRef]

- Amar, M.N.; Jahanbani Ghahfarokhi, A. Prediction of CO2 Diffusivity in Brine Using White-Box Machine Learning. J. Pet. Sci. Eng. 2020, 190, 107037. [Google Scholar] [CrossRef]

- Wang, Z.; Dilmore, R.M.; Harbert, W. Inferring CO2 Saturation from Synthetic Surface Seismic and Downhole Monitoring Data Using Machine Learning for Leakage Detection at CO2 Sequestration Sites. Int. J. Greenh. Gas Control 2020, 100, 103115. [Google Scholar] [CrossRef]

- Liu, M.; Fu, X.; Meng, L.; Du, X.; Zhang, X.; Zhang, Y. Prediction of CO2 Storage Performance in Reservoirs Based on Optimized Neural Networks. Geoenergy Sci. Eng. 2023, 222, 211428. [Google Scholar] [CrossRef]

- Hassan Baabbad, H.K.; Artun, E.; Kulga, B. Understanding the Controlling Factors for CO2 Sequestration in Depleted Shale Reservoirs Using Data Analytics and Machine Learning. ACS Omega 2022, 7, 20845–20859. [Google Scholar] [CrossRef]

- Xue, H.; Wang, G.; Gui, X.; Gong, H.; Li, X.; Du, F. A Novel Multidimensional Hybrid Machine Learning Model for CO2 Injection to Separate Coalbed Methane: Comprehensive Prediction of Methane Diffusion Rate, Production Volume, and CO2 Sequestration. Energy Fuels 2024, 38, 17525–17540. [Google Scholar] [CrossRef]

- Zemskova, V.E.; He, T.-L.; Wan, Z.; Grisouard, N. A Deep-Learning Estimate of the Decadal Trends in the Southern Ocean Carbon Storage. Nat. Commun. 2022, 13, 4056. [Google Scholar] [CrossRef]

- Al-Mamoori, A.; Krishnamurthy, A.; Rownaghi, A.A.; Rezaei, F. Carbon Capture and Utilization Update. Energy Technol. 2017, 5, 834–849. [Google Scholar] [CrossRef]

- Yuan, S.; Ma, D.; Li, J.; Zhou, T.; Ji, Z.; Han, H. Progress and Prospects of Carbon Dioxide Capture, EOR-Utilization and Storage Industrialization. Pet. Explor. Dev. 2022, 49, 955–962. [Google Scholar] [CrossRef]

- Green, D.W.; Willhite, P.G. Enhanced Oil Recovery. Henry, L. Doherty Memorial Fund of AIME, Society of Petroleum Engineers: Richardson, TX, USA, 1998; Volume 6. [Google Scholar]

- Huang, Y.F.; Huang, G.H.; Dong, M.Z.; Feng, G.M. Development of an Artificial Neural Network Model for Predicting Minimum Miscibility Pressure in CO2 Flooding. J. Pet. Sci. Eng. 2003, 37, 83–95. [Google Scholar] [CrossRef]

- Sinha, U.; Dindoruk, B.; Soliman, M. Prediction of CO2 Minimum Miscibility Pressure MMP Using Machine Learning Techniques. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 31 August–4 September 2020. [Google Scholar]

- Singh, G.; Davudov, D.; Al-Shalabi, E.W.; Malkov, A.; Venkatraman, A.; Mansour, A.; Abdul-Rahman, R.; Das, B. A Hybrid Neural Workflow for Optimal Water-Alternating-Gas Flooding. In Proceedings of the SPE Reservoir Characterization and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 24–26 January 2023. [Google Scholar]

- Junyu, Y.; William, A.; Qian, S. Optimization of Water-Alternating-CO2 Injection Field Operations Using a Machine-Learning-Assisted Workflow. In Proceedings of the SPE Reservoir Simulation Conference, On-Demand, 26 October 2021. [Google Scholar]

- Rostami, A.; Arabloo, M.; Lee, M.; Bahadori, A. Applying SVM Framework for Modeling of CO2 Solubility in Oil during CO2 Flooding. Fuel 2018, 214, 73–87. [Google Scholar] [CrossRef]

- Bhattacherjee, R.; Botchway, K.; Pashin, J.C.; Chakraborty, G.; Bikkina, P. Developing Statistical and Machine Learning Models for Predicting CO2 Solubility in Live Crude Oils. Fuel 2024, 368, 131577. [Google Scholar] [CrossRef]

- Nwachukwu, A.; Jeong, H.; Sun, A.; Pyrcz, M.; Lake, L.W. Machine Learning-Based Optimization of Well Locations and WAG Parameters under Geologic Uncertainty. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Ahmadi, M.A.; Zendehboudi, S.; James, L.A. Developing a Robust Proxy Model of CO2 Injection: Coupling Box–Behnken Design and a Connectionist Method. Fuel 2018, 215, 904–914. [Google Scholar] [CrossRef]

- Karacan, C.Ö. A Fuzzy Logic Approach for Estimating Recovery Factors of Miscible CO2-EOR Projects in the United States. J. Pet. Sci. Eng. 2020, 184, 106533. [Google Scholar] [CrossRef]

- Le Van, S.; Chon, B.H. Evaluating the Critical Performances of a CO2–Enhanced Oil Recovery Process Using Artificial Neural Network Models. J. Pet. Sci. Eng. 2017, 157, 207–222. [Google Scholar] [CrossRef]

- Van, S.L.; Chon, B.H. Effective Prediction and Management of a CO2 Flooding Process for Enhancing Oil Recovery Using Artificial Neural Networks. J. Energy Resour. Technol. 2018, 140, 032906. [Google Scholar] [CrossRef]

- Xu, X.; Moulijn, J.A. Mitigation of CO2 by Chemical Conversion: Plausible Chemical Reactions and Promising Products. Energy Fuels 1996, 10, 305–325. [Google Scholar] [CrossRef]

- Taheri Najafabadi, A. CO2 Chemical Conversion to Useful Products: An Engineering Insight to the Latest Advances toward Sustainability. Int. J. Energy Res. 2013, 37, 485–499. [Google Scholar] [CrossRef]

- Saravanan, A.; Senthil Kumar, P.; Vo, D.-V.N.; Jeevanantham, S.; Bhuvaneswari, V.; Anantha Narayanan, V.; Yaashikaa, P.R.; Swetha, S.; Reshma, B. A Comprehensive Review on Different Approaches for CO2 Utilization and Conversion Pathways. Chem. Eng. Sci. 2021, 236, 116515. [Google Scholar] [CrossRef]

- Onsree, T.; Tippayawong, N. Machine Learning Application to Predict Yields of Solid Products from Biomass Torrefaction. Renew. Energy 2021, 167, 425–432. [Google Scholar] [CrossRef]

- Song, Y.; Yang, K.; Chen, J.; Wang, K.; Sant, G.; Bauchy, M. Machine Learning Enables Rapid Screening of Reactive Fly Ashes Based on Their Network Topology. ACS Sustain. Chem. Eng. 2021, 9, 2639–2650. [Google Scholar] [CrossRef]

- You, J.; Ampomah, W.; Morgan, A.; Sun, Q.; Huang, X. A Comprehensive Techno-Eco-Assessment of CO2 Enhanced Oil Recovery Projects Using a Machine-Learning Assisted Workflow. Int. J. Greenh. Gas Control 2021, 111, 103480. [Google Scholar] [CrossRef]

- Nwachukwu, A.; Jeong, H.; Pyrcz, M.; Lake, L.W. Fast Evaluation of Well Placements in Heterogeneous Reservoir Models Using Machine Learning. J. Pet. Sci. Eng. 2018, 163, 463–475. [Google Scholar] [CrossRef]

- Sedighi, M.; Mohammadi, M.; Ameli, F.; Amiri-Ramsheh, B.; Hemmati-Sarapardeh, A. A Comparative Study of Machine Learning Frameworks for Predicting CO2 Conversion into Light Olefins. Fuel 2025, 379, 133017. [Google Scholar] [CrossRef]

- Zhong, M.; Tran, K.; Min, Y.; Wang, C.; Wang, Z.; Dinh, C.-T.; De Luna, P.; Yu, Z.; Rasouli, A.S.; Brodersen, P.; et al. Accelerated Discovery of CO2 Electrocatalysts Using Active Machine Learning. Nature 2020, 581, 178–183. [Google Scholar] [CrossRef]

- Iwama, R.; Takizawa, K.; Shinmei, K.; Baba, E.; Yagihashi, N.; Kaneko, H. Design and Analysis of Metal Oxides for CO2 Reduction Using Machine Learning, Transfer Learning, and Bayesian Optimization. ACS Omega 2022, 7, 10709–10717. [Google Scholar] [CrossRef]

- Phromphithak, S.; Onsree, T.; Tippayawong, N. Machine Learning Prediction of Cellulose-Rich Materials from Biomass Pretreatment with Ionic Liquid Solvents. Bioresour. Technol. 2021, 323, 124642. [Google Scholar] [CrossRef]

- Onyebuchi, V.E.; Kolios, A.; Hanak, D.P.; Biliyok, C.; Manovic, V. A Systematic Review of Key Challenges of CO2 Transport via Pipelines. Renew. Sustain. Energy Rev. 2018, 81, 2563–2583. [Google Scholar] [CrossRef]

- Smith, E.; Morris, J.; Kheshgi, H.; Teletzke, G.; Herzog, H.; Paltsev, S. The Cost of CO2 Transport and Storage in Global Integrated Assessment Modeling. Int. J. Greenh. Gas Control 2021, 109, 103367. [Google Scholar] [CrossRef]

- Svensson, R.; Odenberger, M.; Johnsson, F.; Strömberg, L. Transportation Systems for CO2–Application to Carbon Capture and Storage. Energy Convers. Manag. 2004, 45, 2343–2353. [Google Scholar] [CrossRef]

- Kim, J.; Yoon, H.; Hwang, S.; Jeong, D.; Ki, S.; Liang, B.; Jeong, H. Real-Time Monitoring of CO2 Transport Pipelines Using Deep Learning. Process Saf. Environ. Prot. 2024, 181, 480–492. [Google Scholar] [CrossRef]

- Wang, L.; Yan, Y.; Wang, X.; Wang, T.; Duan, Q.; Zhang, W. Mass Flow Measurement of Gas-Liquid Two-Phase CO2 in CCS Transportation Pipelines Using Coriolis Flowmeters. Int. J. Greenh. Gas Control 2018, 68, 269–275. [Google Scholar] [CrossRef]

- Su, Y.; Li, J.; Yu, B.; Zhao, Y.; Yao, J. Fast and Accurate Prediction of Failure Pressure of Oil and Gas Defective Pipelines Using the Deep Learning Model. Reliab. Eng. Syst. Saf. 2021, 216, 108016. [Google Scholar] [CrossRef]

- Yang, H.; Lu, L.; Tsai, K. Machine Learning Based Predictive Models for CO2 Corrosion in Pipelines with Various Bending Angles. In Proceedings of the SPE Annual Technical Conference and Exhibition? Virtual, 26–29 October 2020. [Google Scholar]

- Shao, D.; Yan, Y.; Zhang, W.; Sun, S.; Sun, C.; Xu, L. Dynamic Measurement of Gas Volume Fraction in a CO2 Pipeline through Capacitive Sensing and Data Driven Modelling. Int. J. Greenh. Gas Control 2020, 94, 102950. [Google Scholar] [CrossRef]

- Sleiti, A.K.; Al-Ammari, W.A.; Vesely, L.; Kapat, J.S. Carbon Dioxide Transport Pipeline Systems: Overview of Technical Characteristics, Safety, Integrity and Cost, and Potential Application of Digital Twin. J. Energy Resour. Technol. 2022, 144, 092106. [Google Scholar] [CrossRef]

- Lu, H.; Ma, X.; Huang, K.; Fu, L.; Azimi, M. Carbon Dioxide Transport via Pipelines: A Systematic Review. J. Clean. Prod. 2020, 266, 121994. [Google Scholar] [CrossRef]

| Process | Material | References | Methods | Inputs | Output(s) | Key Findings |

|---|---|---|---|---|---|---|

| Adsorption | Activated carbon | Subraveti et al. [41] | ANN-based NSGA-II | Adsorption time, low pressure, feed velocity | CO2 recovery and purity during PSA | The ANN with NSGA-II optimization provides a systematic trade-off analysis and lower computational cost. |

| Zeolite 13X | Pai et al. [42] | DT, RF, SVM, GPR, ANN | Adsorption time, low pressure, intermediate pressure, feed velocity | Prediction of CO2 purity, recovery, energy consumption, productivity, and cyclic steady state profiles. | GPR-based models provided highly accurate forecasts with an adjusted R2 > 0.98. | |

| MOF | Burns et al. [18] | RF, GBDT, GA | Adsorption metrics, geometric properties, process parameters | CO2 purity, recovery, parasitic, productivity | ML can classify MOFs with an accuracy of 91%; N2 adsorption behavior is the strongest predictor. | |

| Biomass waste-derived porous carbon | Yuan et al. [43] | GBDT, LGB, XGBoost | Surface area, total pore volume, micropore volume, carbon/hydrogen/nitrogen/oxygen content, temperature, pressure | CO2 adsorption capacity | GBDT-based models provided highly accurate predictions with R2 > 0.9. Micropore volume was identified as the most critical factor influencing CO2 adsorption capacity. | |

| Coalbed | Alanazi et al. [44] | DT, RF, GBR, KNN, ANN, FN, ANFIS | Coal composition and operation conditions | CO2 adsorption capacity | RF provided the highest prediction accuracy, with R2 ≈ 0.99. | |

| Solid amine-functionalized porous adsorbent | Zhang et al. [45] | RF | Amine loading, amine type, pore volume, pore size, specific surface area | CO2 adsorption capacity | RF provided accurate predictions with R2 = 0.99; amine loading was the most critical factor affecting CO2 adsorption performance, followed by pore volume. | |

| Absorption | Piperazine | Yarveicy et al. [46] | ANN, ANFIS, LSSVM, AdaBoost-CART | Temperature, CO2 partial pressure, piperazine concentration | CO2 loading capacity | AdaBoost-CART was the best-performing model with R2 = 0.9934. |

| MEA | Sipocz et al. (2011) [47] | ANN | Mass% of CO2, mass flow, temperature, reboiler duty, solvent circulation rate, solvent lean load, CO2 removal efficiency | Mass flow of CO2 captured, rich load, specific duty | The ANN models accurately replicate the CO2 capture process modeled by the process simulator CO2SIM, with errors below 0.2% for the closed-loop system. | |

| MDEA and Piperazine | Zhan et al. [48] | ANN | MDEA and PZ concentration, liquid volumetric flow rate, high gravity factor, temperature | H2S and CO2 absorption efficiency, mass-transfer coefficient | The addition of PZ significantly enhances CO2 absorption. The ANN model has accurate prediction with a deviation within ±10%. | |

| MEA, MDEA, TEA, DGA, DEA | Nuchitprasittichai and Cremaschi [49] | ANN | Solvent circulation rate, concentration of primary/secondary/tertiary amine, reboiler duty, temperature, number of stages in the absorber/stripper column | CO2 capture cost | RSM and ANN can optimize CO2 capture, but ANN is better for handling complex relationships. Blended amines performed better than single amines in cost reduction and efficiency. | |

| K2CO3 (with various promoters) | Khan et al. [50] | GPR, SVM, RF | pH, contact time, pressure, temperature, concentration, type and concentration of promoter, CO2 loading rate and concentration | CO2 absorption rate and efficiency | GPR performed best with R2 = 0.9958; Adding promoters (e.g., Piperazine, MEA) significantly enhanced CO2 absorption. | |

| Chemical looping | Calcium oxide | Hanak and Manovic [51] | ANN | Process variables, economic variables, scale and size variables, operating parameters | Levelized cost of electricity, specific total capital requirement | ANN-based stochastic economic assessment provides a more reliable feasibility evaluation than traditional deterministic methods. |

| Oxygen carrier (Mn-, Ni-, Ca-) | Tahir et al. [52] | ANN (with LM, BR, SCG) | Gasifier temperature, gasifying agent, steam-to-biomass ratio, oxygen carriers used, equivalence ratio, biomass type, moisture content of biomass, pressure | Syngas composition, O2 transport capacity of O2 carrier, H2 production efficiency, CO2 capture efficiency | ANN-BR performed best with R2 = 0.999; Ca-based oxygen carriers were the best for hydrogen production and CO2 capture. | |

| Oxygen carrier (Fe2O3, Al2O₃, SiO2 | Wang et al. [53] | ETR, RF, ANN | Biomass feedstock properties, oxygen carrier composition, operational conditions | H2/CO ratio, gas yield, carbon conversion efficiency, CO yield, H2 yield, CH₄ yield | ETR outperformed RF and ANN, achieving R2 > 0.88 for all target variables; BCLG with Fe-based oxygen carriers is effective for CO2 capture and hydrogen production. | |

| Membrane | Metal–organic framework | Situ et al. [54] | SVM, KNN, DT, RF, GBDT, LGBM, XGBoost | Largest cavity diameter, pore-limiting diameter, volumetric surface area, fractional free volume, density, pore size distribution percentage | Permeability of CO2, N2, and O2 in MOF membranes, selectivity for CO2/N2 and CO2/O2 gas pairs | XGBoost was selected as the best-performing model. Gas permeability is strongly influenced by MOF structure. |

| Polymeric membrane | Ahmad et al. [55] | SVR | Fractional free volume, glass transition temperature | Plasticization pressure during membrane separation | The SVR model successfully predicted plasticization pressure with R2 = 0.8837 for training data and R2 = 0.9433 for testing. | |

| Mixed-matrix | Guan et al. [56] | RF | MOF structure properties, polymer properties, membrane properties, operating conditions | Relative CO2 permeability, relative CO2/CH₄ selectivity, relative CO2/N2 selectivity, Young’s modulus | MOF pore size and surface area were the most influential factors affecting gas permeability and selectivity. |

| Storage Method | References | Methods | Inputs | Objectives | Key Findings |

|---|---|---|---|---|---|

| Saline aquifer | Song et al. [57] | ANN | Geological and reservoir parameters (depth, permeability, porosity, salinity, etc.), synthetic datasets from simulation, and real field data. | Residual trapping index, solubility trapping index, total trapping index | ANN model achieved high predictive accuracy with R2 = 0.9847 for up to 300 years post-injection. |

| Amar & Ghahfarokhi [62] | GMDH, GEP, RF, DT | Temperature, pressure, viscosity of the solvent. | CO2 diffusivity coefficients in brine | The GEP model performed best with R2 = 0.9979; temperature is the most influential factor. | |

| Wang et al. [63] | LinearSVM, RNN, SVMr, DNN | Synthetic seismic features, pore pressure, TDS. | CO2 saturation levels at three depths | For different depths, the model performs differently; seismic features were the most important for detecting CO2 saturation. | |

| Depleted oil & gas fields | Liu et al. [64] | BPNN-ILSO, BP-GWO, BP-SFLA | Vertical-horizontal ratio, dimensionless dip parameter group, CO2–oil mobility ratio, buoyancy effect, initial oil saturation. | CO2 storage coefficient | BPNN-ILSO model significantly outperformed traditional BP networks and other optimization-based models. |

| Selveindran et al. [19] | AdaBoost, RF, ANN, ridge regression | Geological and well properties, injection parameters, production parameters. | Incremental oil production, CO2 storage capacity, revenue metrics | The stacked learner outperformed individual models; time-of-flight is a critical feature | |

| Hassan et al. [65] | MLR, RF, regression tree, GBM, bagging | Reservoir parameters, operational parameters. | Cumulative CO2 injected | RF provided the best predictive accuracy; operational parameters have a greater impact. | |

| Unmineable coal seam | Alanazi et al. [44] | DT, RF, GBR, KNN, ANN, FN, ANFIS | Moisture content, ash content, volatile matter, fixed carbon content, vitrinite reflectance, pressure, temperature. | CO2 adsorption capacity in coal formations | RF, GBR, and KNN were the most reliable models, with RF achieving the best accuracy. |

| Xue et al. [66] | SVM-RFE-LSTA-ELM | Time, gas injection volume, inlet pressure, CH4 concentration, mixed gas flow rate. | CH4 diffusion rates, CH4 cumulative production, and CO2 sequestration | The developed SVM-RFE-LTSA-ELM model outperformed all baseline models | |

| Ocean | Zemskova et al. [67] | CNNs, RNNs | Sea surface temperature, flow velocity at the surface, near-surface wind velocity, surface particle pressure of CO2. | Dissolved inorganic carbon (DIC) concentration in the Southern Ocean up to 4 km depth | DIC concentration decreased in the ocean interior during the 1990s–2000s; DIC increased near the surface during the 2010s. |

| Mineral | Tariq et al. [59] | FFNN | Temperature, pressure, mineral type. | Advancing/receding contact angles of minerals/CO2/brine system | FFNN successfully predicted wettability behavior with R2 = 0.981; Pressure had the most significant influence on the contact angle. |

| Category | References | Methods | Inputs | Output(s) | Key Findings |

|---|---|---|---|---|---|

| CO2-EOR | Huang et al. [71] | ANN | Pure CO2 (TR, xvol, MWC5+, xint), impure CO2 (yH2S, yN2, yCH4, ySO2, Fimp). | MMP of CO2-oil | ANN showed high accuracy in predicting MMP for pure and impure CO2 and is better than other statistical models. |

| You et al. [87] | Gaussian SVR—PSO | FOPR*2, gas cycle*5, water cycle*5. | Hydrocarbon recovery + CO2 sequestration volume + NPV | The proposed method can optimize the WAG process with high accuracy. | |

| Nwachukwu et al. [88] | XGBoost | Well-to-well pairwise connectivity, injector block k and ϕ, initial injector block saturations. | Total profit, cumulative oil/gas produced, net CO2 stored. | Quick evaluation of well placement with 1000 simulation runs and R2 = 0.92. | |

| Chemical conversion | Sedighi et al. [89] | CFNN, GRNN, MLP, RBF | Temperature, space velocity (gas hourly space velocity). | CO2 conversion efficiency, CO2 selectivity, light olefin selectivity. | GRNN was best for CO2 conversion, CFNN was best for CO selectivity. |

| Zhong et al. [90] | GPR with DFT | Material dataset, surface adsorption data, catalyst properties. | Predicted CO adsorption energy, optimized catalyst candidates. | GPR and DFT calculations can rapidly screen and optimize electrocatalyst materials. | |

| Iwama et al. [91] | GPR, RF, Bayesian optimization | Metal oxide compositions, material descriptors, experimental conditions, oxygen vacancy formation energy. | CO2 conversion efficiency, H2 conversion efficiency, predicted optimal metal oxides. | ML models can effectively predict CO2 conversion efficiency; Cu- and Ga-based metal oxides are the most effective for CO2 reduction. | |

| Biomass | Onsree and Tippayawong [85] | GTB, KRR, LR, DT, RF, KNN, SVM | Biomass properties, torrefaction conditions. | Yield of torrefied biomass. | GTB achieved the highest prediction accuracy; torrefaction temperature and residence time were the most critical factors. |

| Phromphithak et al. [92] | RF, SVM, GB | Biomass properties, pretreatment conditions, ionic liquid solvent features, catalyst loading. | Cellulose enrichment factor (CEF), solid recovery (SR). | RF outperformed other models, achieving an R2 of 0.94 for CEF and 0.84 for SR; biomass composition and pretreatment conditions are key factors. | |

| New materials | Song et al. [86] | ANN | CaO, Al2O₃, SiO2, Fe2O₃, MgO, total alkali content. | Mass fraction of amorphous phase, network topology parameter, fly ash reactivity classification. | ANN enables rapid and accurate fly ash screening; fly ash reactivity is strongly influenced by chemical composition. |

| References | Methods | Inputs | Output(s) | Key Findings |

|---|---|---|---|---|

| Kim et al. [96] | MLP, LSTM, CISM-LSTM | Mass flow rate, pressure, temperature, time series data, operational conditions. | Predicted pipeline conditions (normal vs. abnormal), detection of anomalies, confidence intervals for normal operation ranges, critical alarm event detection | CISM–LSTM outperformed MLP and standard LSTM in detecting leaks and hydrates. Application to the East Sea gas field CO2 pipeline shows effectiveness. |

| Yang et al. [99] | LightGBM, MLPNN | Flow velocity, pH, CO2 concentration, pipe inner diameter, pipe bend angle, pipe bend radius, temperature. | Yearly maximum CO2 corrosion rate. | The LightGBM model achieved an R2 of 0.9985, while MLPNN achieved an R2 of 0.9931. |

| Wang et al. [97] | LSSVM | Apparent mass flow rate, observed fluid density, damping factor, differential pressure sensor readings, flow regime classification. | Corrected total CO2 mass flow rate, CO2 gas volume fraction. | LSSVM models improve CO2 mass flow rate measurement accuracy; flow pattern-based LSSVM further enhances performance. |

| Shao et al. [100] | BPNN, RBFNN, LSSVM | Capacitance readings from 12 electrodes inside pipeline, capacitance normalization values, electrode configurations, flow conditions. | Gas volume fraction (GVF). | RBFNN provides the best performance for GVF estimation. |

| Su et al. [98] | DNN | Pipeline material, defect length/depth/width, pipeline outer diameter, wall thickness. | Failure pressure of defective pipelines. | The DNN model achieves an average prediction error of 2.38%, significantly lower than traditional empirical formulas. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, X.; Khan, M.N.; Thakur, G.C. Machine Learning in Carbon Capture, Utilization, Storage, and Transportation: A Review of Applications in Greenhouse Gas Emissions Reduction. Processes 2025, 13, 1160. https://doi.org/10.3390/pr13041160

Du X, Khan MN, Thakur GC. Machine Learning in Carbon Capture, Utilization, Storage, and Transportation: A Review of Applications in Greenhouse Gas Emissions Reduction. Processes. 2025; 13(4):1160. https://doi.org/10.3390/pr13041160

Chicago/Turabian StyleDu, Xuejia, Muhammad Noman Khan, and Ganesh C. Thakur. 2025. "Machine Learning in Carbon Capture, Utilization, Storage, and Transportation: A Review of Applications in Greenhouse Gas Emissions Reduction" Processes 13, no. 4: 1160. https://doi.org/10.3390/pr13041160

APA StyleDu, X., Khan, M. N., & Thakur, G. C. (2025). Machine Learning in Carbon Capture, Utilization, Storage, and Transportation: A Review of Applications in Greenhouse Gas Emissions Reduction. Processes, 13(4), 1160. https://doi.org/10.3390/pr13041160