Stability Analysis of Borehole Walls in Shale Formations of the Huazhuang Block

Abstract

1. Introduction

2. Rock Fabric Characteristic Testing and Mechanical Characteristic Experiments

2.1. Mineral Composition Analysis

2.2. Core Microscopic Characteristics Analysis

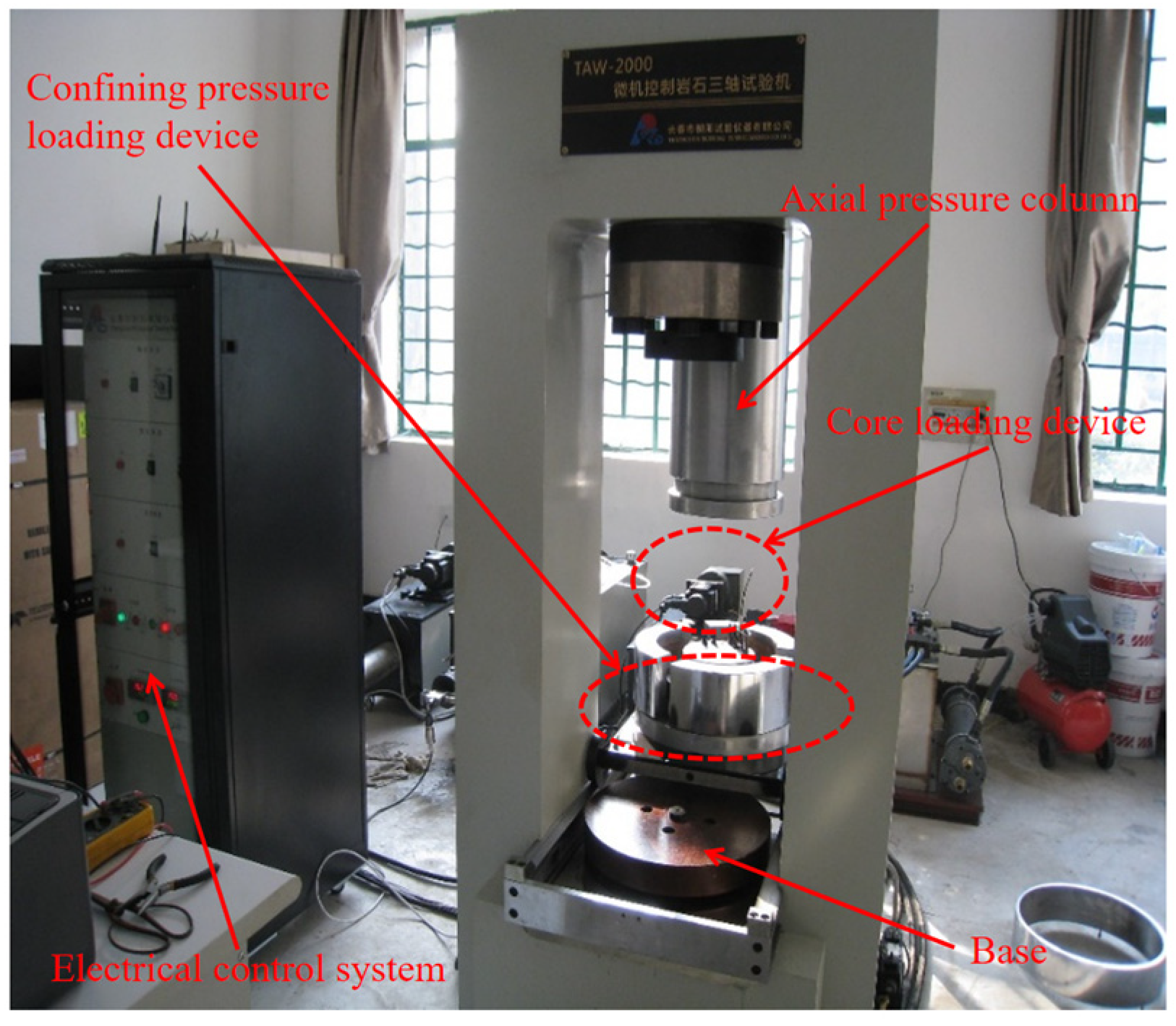

2.3. Rock Mechanics Characteristics Analysis

2.4. Compressive Strength Experiment

3. Prediction Profile Construction and Wellbore Stability Analysis

3.1. Rock Mechanical Parameter Prediction Profile

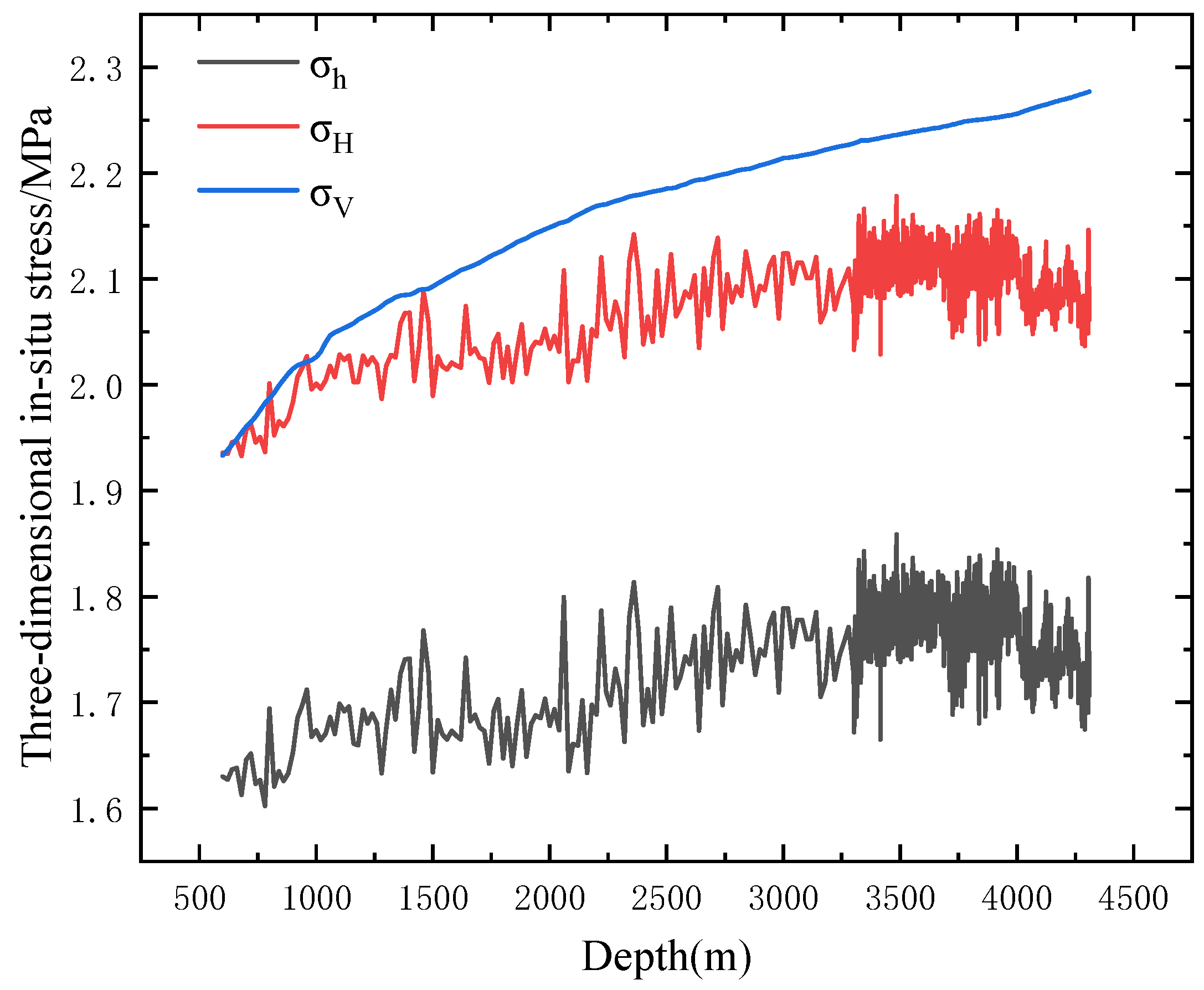

3.2. Prediction of In-Situ Stress Profile

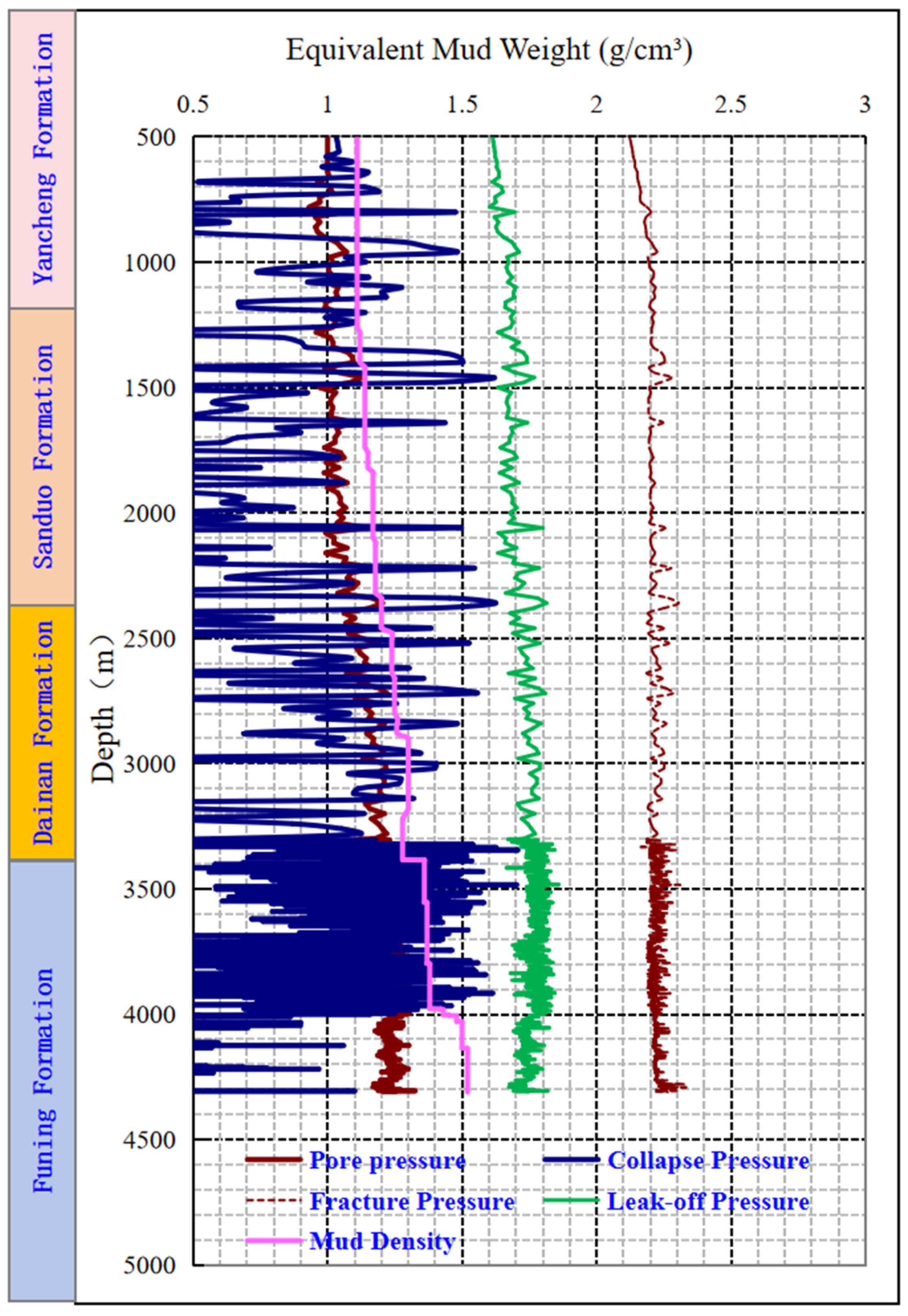

3.3. Four-Pressure Prediction Profile

4. Analysis of Borehole Instability Causes and Countermeasures Recommendations

4.1. Analysis of Drilling Complexities

4.2. Analysis of Borehole Instability Causes

4.3. Drilling Fluid Technical Countermeasures

- (1)

- Determine a reasonable drilling fluid density: Avoid using excessively low-density drilling fluid, which can cause borehole collapse and instability. At the same time, excessively high drilling fluid density may reopen closed micro-fractures, increasing collapse pressure and leading to fluid loss. It is recommended that the drilling fluid density used in the Huazhuang block be adjusted to between 1.183 g/cm3 and 1.5 g/cm3 based on actual field conditions, which can effectively improve wellbore stability in this block.

- (2)

- Enhance the sealing ability of the drilling fluid: Use drilling fluids with a long collapse prevention period and strong shale swelling inhibition properties to achieve borehole stability by preventing external water invasion and controlling internal expansion [24,25]. Reducing the invasion of drilling fluid and filtrate into the formation decreases collapse pressure, improves the pressure-bearing capacity of the formation, and maintains borehole stability.

- (3)

- Since indoor experiments often involve single-point testing and comparison with logging data for model fitting, there is a possibility that model prediction accuracy may be insufficient due to errors in the test data during the modeling process. To improve prediction accuracy, it is recommended to continuously adjust the model based on real-time drilling data and experimental data during the drilling process, in order to determine the most suitable drilling fluid density window and select the most appropriate drilling fluid density. Taking the compressive strength (Pucs) model as an example, when the predicted value at a certain depth is significantly lower than the measured compressive strength of the bottom-hole rock at the same depth, the empirical coefficient can be appropriately increased. The resulting compressive strength curve is then compared with the measured bottom-hole data until the predicted and measured values are reasonably consistent. This method is also applicable to the compressive strength prediction of rocks from different formations and blocks.

5. Conclusions

- (1)

- The Funing Formation’s second and fourth members in the Huazhuang block have a generally loose structure with a high clay content of 40–60%. Occasional calcite-filled tensile fractures are present, and the formation contains a high proportion of water-sensitive minerals. Consequently, water-based drilling fluid poses a significant hydration risk during drilling.

- (2)

- With increasing depth, compressive strength, elastic modulus, and cohesion gradually increase, while the internal friction angle and Poisson’s ratio tend to decrease. Rock mechanical parameters fluctuate significantly both within the same formation and between different formations. Additionally, in-situ stress increases with depth, satisfying the relationship: > > .

- (3)

- Based on the established formation pressure profiles—including pore pressure, collapse pressure, leakage pressure, and fracture pressure—the following trends in mud density windows were identified: Above 3300 m, the equivalent density of formation pore pressure is below 1.20 g/cm3. Below 3300 m, abnormal high pressure is observed, with a maximum equivalent pore pressure density reaching 1.45 g/cm3. The window between collapse pressure and fracture pressure is narrow, particularly in fracture-developed zones, requiring preventive measures against fluid loss. Generally, the deeper the formation, the narrower the safe density window, increasing the likelihood of borehole collapse.

- (4)

- It is recommended to select the optimal mud density within the safe window between collapse pressure and fracture pressure. Adjusting the drilling fluid density to a range between 1.183 g/cm3 and 1.5 g/cm3 can effectively improve the wellbore stability in this block. Additionally, drilling fluid properties should be optimized by using long-duration anti-collapse drilling fluids capable of inhibiting shale swelling, thereby improving sealing performance and enhancing borehole stability.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Guo, Q.; Zhao, C.; Wang, Y.; Yu, J.; Liu, Z.; Chen, N. Potentials and prospects of shale oil-gas resources in major basins of China. Acta Pet. Sin. 2023, 44, 2033. [Google Scholar]

- Qi, W.; Wu, H.; Xie, X.; Lou, Y.; Liu, H. Study on formation rock characteristics and borehole collapse period in northern Jiangsu Basin. China Offshore Oil Gas 2024, 36, 108–118. [Google Scholar]

- Fan, Y.; Huang, W.; Wang, Y.; Guo, J. Mechanism and control measures of wellbore instability of large-sized boreholes in ultra-deep wells in western Sichuan Basin. Nat. Gas Ind. 2024, 44, 116–127. [Google Scholar]

- Gao, S. Wellbore stability evaluation study for continental shale oil reservoir in northern Jiangsu. Sci. Technol. Eng. 2024, 24, 9350–9356. [Google Scholar]

- Zhang, M.; Li, D.; Fan, X. Study on wellbore collapse pressure and instability area around wellbore in broken formation. Fault-Block Oil Gas Field 2024, 319, 16–921. [Google Scholar]

- Wang, Y.; Gao, Y.; Yang, Y. Wellbore stability of deep well in western margin thrust belt of Ordos Basin. Sci. Technol. Eng. 2024, 24, 6691–6700. [Google Scholar]

- Fan, X.; Meng, C.; Zhang, Q. Research progress in the evaluation theory and control technology of wellbore instability in ultra-deep strata. Nat. Gas Ind. 2024, 44, 159–176. [Google Scholar]

- Luo, M.; Gao, D.; Huang, H.; Li, J.; Yang, H.; Zhang, G.; Liu, K. Effects of drilling fluids on shale mechanical properties and wellbore stability. Pet. Drill. Prod. Technol. 2022, 44, 693–700. [Google Scholar]

- Zhu, X.; Duan, H.; Sun, Y. Breakthrough and significance of Paleogene continental shale oil exploration in Gaoyou sag, Subei Basin. Acta Pet. Sin. 2023, 44, 1206. [Google Scholar]

- Yan, Z.; Liang, B.; Sun, Y.; Duan, H.; Qiu, X. In-situ stress orientation and main controlling factors of deep shale reservoirs in the second member of Paleogene Funing Formation in Gaoyou Sag, Subei Basin. Pet. Geol. Exp. 2024, 46, 1187–1197. [Google Scholar]

- Qiu, X.; Qian, S.; Yu, W.; Liu, Q. Main achievements, new understanding and technological progress for oil and gas exploration in North Jiangsu Basin during the 12th Five-Year Plan. China Pet. Explor. 2016, 21, 62. [Google Scholar]

- Brown, E.T. ISRM suggested methods. In Rock Characterization Testing and Monitoring; Royal School of Mines: London, UK, 1981. [Google Scholar]

- Zhang, W.; Li, Z.; Shou, X.; Liu, W.; Hu, P.; Zhang, J.; Yang, M. Prediction of anti-drilling properties and bit selection for glutenite formations in Mahu Sag. China Pet. Mach. 2023, 51, 9–15. [Google Scholar]

- Ji, H.; Zhu, L.; Lou, Y. Evaluation and application of rock drillability of deep thermobaric strata in the South China Sea. Sci. Technol. Eng. 2022, 22, 14707–14713. [Google Scholar]

- Guo, J.; Sang, Y.; Meng, B.; Xia, L.; Wang, Y.; Ma, C.; Tan, T.; Yang, B. Study on the Wellbore Instability Mechanism in the Longtan Formation with Soft/Hard Thin Interlayers in the South Sichuan Basin. Processes 2025, 13, 727. [Google Scholar] [CrossRef]

- Mohiuddin, M.A.; Khan, K.; Abdulraheem, A.; Al-Majed, A.; Awal, M.R. Analysis of wellbore instability in vertical, directional, and horizontal wells using field data. J. Pet. Sci. Eng. 2007, 55, 83–92. [Google Scholar] [CrossRef]

- Yang, Y.; Cai, W.; Xing, X. Mechanism and countermeasure of wellbore instability of fractured formation in Bozhong Block. Sci. Technol. Eng. 2023, 23, 9476–9483. [Google Scholar]

- Eaton, B.A. The equation for geopressure prediction from well logs. Soc. Pet. Eng. J. 1975, 15, 371–376. [Google Scholar]

- Zhang, J. Pore pressure prediction from well logs: Methods, modifications, and new approaches. Earth Sci. Rev. 2011, 108, 50–63. [Google Scholar] [CrossRef]

- Li, S.J.; Cui, Z.; Jiang, Z.X.; Shao, Y.; Liao, W.; Li, L. New method for prediction of shale gas content in continental shale formation using well logs. Appl. Geophys. 2016, 13, 393–405. [Google Scholar] [CrossRef]

- Li, L.; Yang, J.; Zhou, B. Rock characteristics and safe drilling cycle of complex formation in middle-deep wells in Bohai. China Offshore Oil Gas 2022, 34, 126–132. [Google Scholar]

- Fan, Y.; Wang, J.; Liu, H.; Wu, P. Formation mechanical properties and wellbore stability of the whole well section in Luzhou block. Sci. Technol. Eng. 2020, 20, 6433–6439. [Google Scholar]

- Li, J.; Weng, H.; Duan, F.; Yan, W.; Tan, Q. Cases of the influence of drilling fluid type on borehole stability and analysis of anti-collapse mechanism. Sci. Technol. Eng. 2019, 19, 161–167. [Google Scholar]

- Moos, D.; Zoback, M.D.; Mastin, L. Predicting mud weight for avoiding wellbore instability in deepwater wells. Int. J. Rock Mech. Min. Sci. 2003, 40, 731–747. [Google Scholar]

- Zhang, J. Borehole stability analysis accounting for anisotropies in drilling to weak bedding planes. J. Pet. Sci. Eng. 2013, 103, 129–144. [Google Scholar] [CrossRef]

| Sample ID | Stratigraphic Interval | Full-Rock Mineral Content (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Quartz | Potassium Feldspar | Plagioclase | Siderite | Iron Dolomite | Dolomite | Calcite | Pyrite | Total Clay | Gypsum | ||

| Q | Kfs | Ab | Sid | Ank | Dol | Cal | Py | Clays | Gyp | ||

| 1-4/10 | E1f4 | 25.2 | 2.1 | 6.3 | 0.0 | 3.2 | 0.0 | 5.7 | 2.1 | 55.4 | 0.0 |

| 1-8/10 | 33.2 | 2.0 | 8.7 | 1.1 | 3.9 | 0.0 | 3.4 | 0.0 | 47.6 | 0.0 | |

| X-1 | 25.6 | 2.0 | 4.2 | 0.0 | 0.0 | 4.0 | 12.5 | 1.1 | 49.0 | 1.6 | |

| 5-15/40 | E1f2 | 36.6 | 0.7 | 6.5 | 0.0 | 1.2 | 0.0 | 1.6 | 0.0 | 53.4 | 0.0 |

| 4-30/57 | 28.8 | 0.0 | 3.6 | 1.8 | 0.0 | 0.8 | 19.5 | 0.9 | 44.6 | 0.0 | |

| Well No. | Sampe ID | Well Depth (m) | Stratigraphic Interval | Relative Content of Different Clay Mineral Types | ||||

|---|---|---|---|---|---|---|---|---|

| Illite-Smectite Mixed Layer | Illite | Kaolinite | Chlorite | Illite-Smectite Ratio | ||||

| % | % | % | % | S%(I/S) | ||||

| Well Huaye 7 | 1-4/10 | 3385.3 | E1f4 | 60 | 36 | / | 4 | 17 |

| Well Huaye 7 | 1-8/10 | 3386 | 55 | 38 | / | 6 | 17 | |

| Well Huaye 7 | 5-15/40 | 3997.7 | E1f2 | 50 | 43 | / | 7 | 20 |

| Well Huaye 7 | 4-30/57 | 3988.1 | 49 | 44 | / | 6 | 20 | |

| Block | Stratigraphy | Sample No. | Depth (m) | Density (g/cm3) | Elastic Modulus (GPa) | Poisson’s Ratio | Uniaxial Compressive Strength (MPa) | Cohesion (MPa) | Internal Friction Angle (°) | Confining Pressure (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|

| Hua zhuang | E1f2 | H-1 | 3984.41–3984.56 | 2.703 | 44.18 | 0.202 | 98.29 | 37.16 | 15.8 | 0 |

| H-5 | 3984.85–3985 | 2.653 | 24.53 | 0.318 | 154.23 | 32 | ||||

| H-2 | 3984.41–3984.56 | 2.672 | 35.76 | 0.203 | 99.85 | 38.65 | 14.51 | 0 | ||

| H-6 | 3971.46–3971.56 | 2.664 | 27.45 | 0.341 | 153.24 | 32 | ||||

| H-3 | 3984.41–3984.56 | 2.647 | 33.49 | 0.243 | 100.98 | 38.41 | 15.48 | 0 | ||

| H-7 | 3984.85–3985 | 2.642 | 25.15 | 0.316 | 156.28 | 32 | ||||

| H-4 | 3984.65–3984.75 | 2.618 | 18.61 | 0.389 | 97.11 | 37.1 | 15.23 | 0 | ||

| H-8 | 3984.65–3984.75 | 2.609 | 18.55 | 0.311 | 151.92 | 32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Gao, S.; Tang, Z.; Zhang, Y.; Wu, H.; Cheng, W. Stability Analysis of Borehole Walls in Shale Formations of the Huazhuang Block. Processes 2025, 13, 1151. https://doi.org/10.3390/pr13041151

Li D, Gao S, Tang Z, Zhang Y, Wu H, Cheng W. Stability Analysis of Borehole Walls in Shale Formations of the Huazhuang Block. Processes. 2025; 13(4):1151. https://doi.org/10.3390/pr13041151

Chicago/Turabian StyleLi, Daqi, Shuyang Gao, Zhichuan Tang, Yayun Zhang, Huimei Wu, and Wei Cheng. 2025. "Stability Analysis of Borehole Walls in Shale Formations of the Huazhuang Block" Processes 13, no. 4: 1151. https://doi.org/10.3390/pr13041151

APA StyleLi, D., Gao, S., Tang, Z., Zhang, Y., Wu, H., & Cheng, W. (2025). Stability Analysis of Borehole Walls in Shale Formations of the Huazhuang Block. Processes, 13(4), 1151. https://doi.org/10.3390/pr13041151