Abstract

Over the past decade, the development and improvement of artificial intelligence (AI) methods have contributed to its intensive application in many scientific disciplines. Thanks to its numerous advantages, AI has enabled the resolution of many problems in food process engineering and provided the opportunity to address various challenges faced by modern food production. In addition to AI methods, including artificial neural networks (ANNs), numerous chemometric methods (multivariate analysis, calibration and validation, experimental design, predictive modeling, signal processing, etc.) are also of great importance for this field. In some specific fields of food processing engineering, AI can be considered to be the flywheel of innovation, considering its contribution to the process optimization, product development and product design. The innovation, optimization and efficiency in food processing can be achieved through the synergy of artificial intelligence and experimental design. The present review focuses on contemporary and cutting-edge AI and experimental design approaches in food processing engineering and points out their main advantages and disadvantages. Recent applications and achievements in these fields are described and systematically discussed.

1. Introduction

Artificial intelligence (AI) methods, such as machine learning (i.e., artificial neural networks), deep learning, symbolic artificial intelligence, etc., have become very prevalent in various scientific fields, including food engineering [1], medicine [2], agriculture [3], economics [4], psychology [5], biology [6], and many others. Considering that AI simulates a human intelligence in machines that are supposed to learn and think like humans, its potential in the imitation of human intelligence in problem perception and problem-solving is promising [7,8]. Across decades, there has been an increase in the number of scientific articles dealing with various types of applications of AI in many fields; in the last five years, the number of scientific articles, book chapters and conference papers with AI methods applied in engineering, chemistry, biochemistry, genetics, molecular biology, agricultural and biological sciences has more than doubled—it increased from approximately 10,000 (year 2019) to approximately 26,000 (year 2023) (source: SCOPUS data base). This increase in AI application in scientific studies testifies to its increasingly significant utilization.

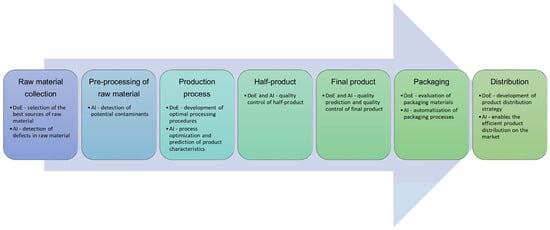

In addition to AI, experimental design (or design of experiments—DoE) has become an indispensable part not only of laboratory analytics, but also at the level of industrial production. DoE has a significant application in the development and optimization of industrial processes (in pharmaceutical technology [9], calibration of car engines [10], in the electronic industry [11], extraction of biologically active compounds [12], waste treatment [13], etc.). Experimental design involves defining a standard reference experiment against which new representative experiments are performed symmetrically with respect to the standard reference experiment [14]. The integration of AI and DoE in food engineering is illustrated in Figure 1.

Figure 1.

The flowchart of a general food production process with examples of application of experimental design (DoE) and artificial intelligence (AI) approaches in each production phase.

As with AI, a similar trend is observable in the application of DoE methods in modern science: the number of publications utilizing DoE methodology has tripled in the last 20 years (from 10,000 to 30,000, source: SCOPUS data base). In food engineering, there are main areas where DoE approaches can be applied: screening (determination of the most influential factors and their appropriate ranges), optimization (detection of optimal operating conditions) and robustness testing (the adjustment of the experimental factors to achieve the robustness) [14,15,16]. The DoE approach has numerous advantages over the traditional COST approach that was based on altering one variable at a time until no further enhancements were detected [14].

Considering the importance of AI and DoE methodologies in modern food production processes, the present review aims to present and describe the contemporary achievements of AI and DoE in modern food production processes, as well as to discuss their main advantages and disadvantages. Since AI and DoE can be considered to be the elements of chemometrics, the integration of these fields is discussed as well. While DoE is centered on designing and conducting experiments, chemometrics is dedicated to analyzing and interpreting the resulting data. Combined, they offer a robust toolkit for advancing scientific research and optimizing industrial processes [17]. In terms of the relationship between chemometrics and artificial intelligence, they enhance each other by combining the power of statistical analysis with advanced computational modeling. This collaboration results in more precise and insightful interpretations of complex chemical data [16,17,18]. Therefore, both AI and DoE can be considered a flywheel of innovations in food processing engineering that have led to outstanding results in process design and optimization.

2. Artificial Intelligence Approaches in Contemporary Food Engineering

2.1. Recent Application of AI-Driven Methods

Artificial intelligence-based approaches offer many solutions to problems that arise in food production. Specifically, these approaches and methods enable the prediction of various production parameters by forming predictive models, as well as the grouping of products of similar quality. There are numerous examples in contemporary scientific literature about the application of AI in solving various challenges in the food industry. Some of them are presented in Table 1.

Table 1.

The contemporary literature showing the application of various AI approaches in food engineering.

Table 1 shows various spheres in which AI methods were applied. For example, in the study by Fernanda Batista et al. [19], the practical utilization of ANN methodology was presented in regression modeling of texture profile parameters (firmness, cohesiveness, adhesiveness and gumminess) and rheological measures of non-fat yogurt. Here, three ANNs were obtained among which one is aimed to predict texture profile and two to predict theological properties. Generally, the authors conducted a detailed validation and the results pointed out the superiority of the obtained ANNs over previously established MLR models. In the study by Shomope et al. [22] the MLP-ANN was established for the purpose of prediction of biohydrogen yield from organic waste during dark fermentation. The authors developed an effective ANN model based on significant number of the data. The optimal architecture of the ANN was balanced between the model’s complexity and performance. The authors applied five-fold cross-validation and analyzed the limitations of the study. ANN methodology was applied in another study whose aim was optimization of cocoa extraction parameters in order to obtain higher flavanol contents [23]. Here, the authors demonstrated that the ANN model is slightly better than the RSM model in terms of accuracy and predictability. In the study by Ait Hmazi et al. [29] the ANN modeling was applied in the analysis of the influence of relative humidity and temperature on moisture content in couscous grains over time. The resulting data obtained from the ANN model were consistent and in agreement with the experimental data.

Contemporary research, as presented in Table 1, which is based on the application of artificial intelligence methods, highlights that the correct use of these methods greatly facilitates obtaining the desired information from modeled processes, prediction of the desired variables and provides significant time savings. However, there is a discrepancy in terms of training and validation of ANN models in a significant number of studies. Specifically, some research in the literature is not based on a sufficient amount of data to ensure the statistical validity of the modeling. Additionally, “ideal” fitting of the data without first checking the model fit is also an indicator that the resulting models may be questionable and not entirely reliable.

2.2. Validation of AI-Based Results and Ethical Concerns

The validation of the ANNs is a crucial task in estimation of their practical applicability. There are many ways to do so, including the following [31,32,33]:

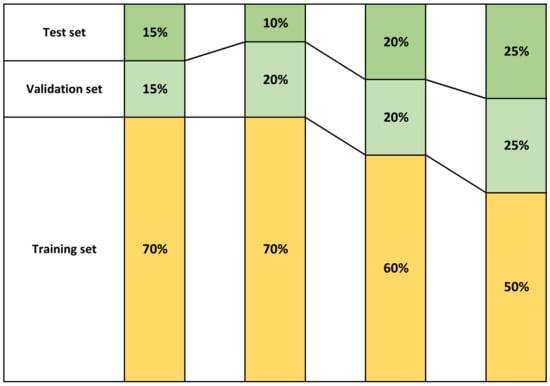

- Cross-validation procedure (internal validation approach) that includes n-folds cross-validation, meaning that the data set is split into n subsets after which the model is trained n times with different subset. Also, splitting the data set into training, test and validation sets is an important step (Figure 2);

Figure 2. The ratio for splitting data into training, validation and test sets for ANN modeling usually found in published researches: the most usual ratio is 70/15/15 and it is usually the best starting point. The ratio 50/25/25 can be advantageous for the ANN modeling of large datasets since it provides a robust validation and testing procedure. The ideal data split ratio depends on the specific needs and context of the modeling task.

Figure 2. The ratio for splitting data into training, validation and test sets for ANN modeling usually found in published researches: the most usual ratio is 70/15/15 and it is usually the best starting point. The ratio 50/25/25 can be advantageous for the ANN modeling of large datasets since it provides a robust validation and testing procedure. The ideal data split ratio depends on the specific needs and context of the modeling task. - The analysis of a so-called confusion matrix in classification procedure (for evaluation of classification performance of the model in terms of true positives, true negatives, false positives and false negatives);

- Calculation of statistical parameters, including Pearson’s determination coefficient (R2), correlation coefficient (R), root mean square error (RMSE), mean absolute error (MAE), mean square error (MSE), etc.;

- Visualization of the learning curves to assess the model’s performance across epochs on both the training and validation datasets. This approach is helpful in detecting overfitting or underfitting;

- Residual analysis, which includes the calculation of differences between experimental and predicted data;

- External validation, which is crucial in testing the “real” applicability of the model. It is based on the application of an external dataset that was not used in the training of ANN.

AI modeling, as performed at today’s level of development in food production and quality control, requires high expertise from the person performing the modeling, good knowledge of AI methods and their limitations and a thorough understanding of all steps involved in detailed validation.

The number of data points in an external set is not fixed. It can vary depending on the total size of the data set and specific needs. This set should be large enough to provide a robust test of the performance of the ANN model. Generally, the size of the external test set may vary from 10% to 30% of the total data.

The studies presented in Table 1 indicate that AI-driven technologies included in quality control systems, predictive and classification or pattern recognition modeling have significantly facilitated food production processes, fraud detection and quality analysis. As AI continues to evolve, its potential to address challenges in food production, distribution and sustainability will play a crucial role in meeting the growing global food demands.

In light of the ethical concerns regarding the application of AI methods in food engineering, it is essential to consider the potential for biases to be exacerbated if the modeling processes are not meticulously monitored and designed. Also, there are possible risks associated with losing control over these AI systems. AI technologies can unintentionally sustain and even intensify existing biases found within the training data. Additionally, understanding and explaining AI models is sometimes challenging since, sometimes, an AI model can be considered to be a “black box”, failing to provide the exact mathematical description of the model or process.

3. Experimental Design Modeling in Contemporary Food Processing and Analysis

3.1. DoE in Recent Research

Various DoE approaches were applied in recent studies for different purposes. The studies listed in Table 2 indicate the application of DoE approaches mostly for optimization of variables for improvement of analytical procedures, development of novel analytical methods for food analysis and improvement of extraction experiments efficacy.

Table 2.

The application of various DoE approaches in contemporary scientific research.

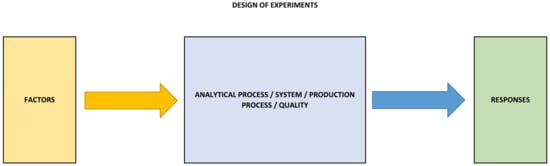

In all the considered studies, the connections between the factors (input variables) and responses (output variables) are well described and analyzed. These two fundamental types of variables (Figure 3) are the most important factors that govern the process or system.

Figure 3.

In DoE, the responses reflect the properties of the analyzed process or system, whilst the factors are manipulation tool that alters the process or system until the desired responses are recorded.

The DoE approach evidently highlighted the optimal experimental conditions in the studies when primary experimental objectives are defined. The conducted screening procedure provided the answers on the question which factors are considered to be the most influential and in what are their optimal ranges. The optimization procedure was conducted differently, depending on the objectives of the study.

On the other hand, the robustness testing related to the factors is not always presented in the published research, particularly in the case of analytical methods. The robustness testing is an important step in DoE since it indicates if the method/model/process is vigorous to small changes in the factors [14]. In the case that the method/model/process in not robust, the alteration of the factor ranges should be considered so the robustness can be claimed. If small changes in factors cause little effect on the responses, the system can be considered to be robust.

3.2. Misuse of DoE Methodology

The main disadvantages of the DoE approach include potential subjective estimations that can affect the results of the modeling (bias), as well as creating some unrealistic situations in the modeling that are not reflecting realistic situations [44,45]. Also, the DoE approach sometimes requires a number of experiments to be conducted, which is time-consuming and requires resources [44,45]. Nevertheless, the numerous advantages of the DoE, as shown in the studies presented in Table 2, overcome the disadvantages.

3.3. Integration of AI and DoE in Food Processing Engineering

The integration of DoE and AI requires initial hypotheses or problems to be defined. Adequate data collection is crucial step so the DoE and AI models can be reliable. There are numerous strategies for data collection, such as random, stratified or systematic data sampling. Also, data standardization methods must be considered. Application of ANNs in conjunction with DoE approaches, the number of experimental runs can be reduced by efficiently exploring the experimental space and identifying the most informative experiments [46]. Particularly, the optimization of experimental conditions can be achieved by ANNs (i.e., prediction of optimal set points for different parameters). Selection of adequate ANN can be performed by various approaches. One of them is the sum of ranking differences (SRD) method, which has been efficiently used in ranking and selection of suitable ANN models [47].

4. Chemometrics and Its Integration with Artificial Intelligence

4.1. Chemometrics Coupled with AI in Modern Research

Contemporary modeling of food processes, food quality control and food safety is based on chemometrics integrated with various AI approaches. These two approaches together, if properly applied and validated, can make the analysis of complex data more efficient and can provide the optimization of food processing operations, enhance food quality control and provide detection of variations in food quality. Several contemporary applications of AI-driven chemometric modeling are presented in Table 3.

Table 3.

AI and chemometric methods in contemporary modeling.

In the recent scientific literature, as selected and presented in Table 3, it is evident that the integration of chemometrics and artificial intelligence has significantly enhanced the quality control and characterization of food products. Particular attention should be given to the application of chemometric techniques for pattern recognition and classification. In modern studies, techniques such as linear discriminant analysis (LDA), hierarchical cluster analysis (HCA), partial least squares—discriminant analysis (PLS-DA) and principal component analysis (PCA), and other pattern recognition techniques, have been used for the classification of samples to determine adulteration and geographical origin [50,51,52]. Additionally, the reduction in data dimensionality using PCA and LDA has enabled the analysis of combinations of independent variables that influence the separation of samples into different groups.

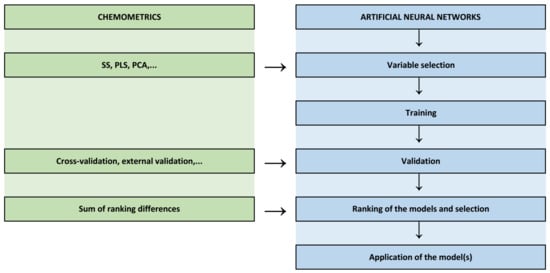

Considering regression modeling, it can be noted that in the published studies, there are various regression approaches used together with artificial intelligence. The influence of chemometrics in regression modeling using artificial intelligence is reflected in the selection of appropriate variables that may be significant for modeling, validation procedures and the calculation of important statistical parameters, as well as the ranking and selection of suitable models. In some novel studies, there is a lack of thorough model validation, including the absence of external validation as a true confirmation of model applicability. In the case of defining a larger number of models, it would be beneficial to conduct a chemometric analysis for ranking predictive models. Figure 4 illustrates the moments in ANN modeling where the integration of chemometrics and ANN modeling occurs to obtain high-quality and reliable ANN models.

Figure 4.

The integration between chemometric approaches and ANN modeling (SS—stepwise selection).

4.2. Disadvantages of AI-Driven Chemometric Modeling

Despite the numerous benefits of chemometric application in AI-driven regression and classification modeling, some disadvantages must be considered. Both fields—chemometrics and AI—require high-level knowledge to be properly applied. The modeling requires a significant amount of high-quality data. The risk of overfitting can also be a problem, as well as limited interpretability. It is worth stressing that a proper statistical evaluation provides reliable evidences about quality of conducted modeling, obtained models and conclusions drawn based on the obtained results. Also, ranking methods, among which is the SRD method, provide good tools for ranking and selection not only of mathematical models, but also the samples based on a priori defined reference ranking.

4.3. Computer Software in AI-Chemometric Modeling

The chemometric and AI modeling requires powerful computer programs, some of which are listed in Table 4. The listed programs provide numerous functions for chemometric and AI-modeling, as well as for design of experiments. AI–chemometric modeling programs are valuable tool for analysis of complex data and creation and validation of predictive models. Most of the programs offer advanced chemometric modeling, providing predictive or classification models that usually outperform some traditional methods.

Table 4.

Selected computer programs for chemometric, AI and DoE modeling.

5. Concluding Remarks

AI and DoE undoubtedly have a great impact on the development of new food production approaches. In recent years, the application of AI escalated, and even initiated certain ethical debates. The future of AI in food production is promising and transformative from the aspects of enhanced automation of processes, sustainable modern food processes, innovative product development and even smart agriculture. Researchers should, for instance, concentrate on creating advanced AI algorithms capable of managing the complex aspects of food production. This encompasses enhancing machine learning models to forecast and optimize food quality and safety. Additionally, it is crucial for researchers to explore AI-driven solutions aimed at minimizing food waste, maximizing resource utilization, as well as reducing environmental impact. The ethical concerns that need further careful consideration are related to data privacy, bias, transparency, job displacement, etc. Additionally, the welfare effect of AI in food processing is much more significant than its potential abuses and problems; therefore, its application is fully justified and desirable.

DoE greatly facilitates the planning and performing of experiments, both at the laboratory level and at the industrial scale. DoE integrates advanced technologies, such as machine learning and big data analysis, in order to facilitate the process optimization and to provide efficient food production.

Based on the contemporary applications of AI and DOE, it can be concluded that these approaches broaden the horizons for modernizing food processing and serve as essential catalysts in modern food production.

Author Contributions

Conceptualization, S.K.; methodology, S.K. and M.K.B.; formal analysis, S.K. and M.K.B.; resources, S.K. and M.K.B.; writing—original draft preparation, S.K. and M.K.B.; writing—review and editing, S.P.-K.; visualization, S.K.; supervision, S.P.-K.; project administration, S.P.-K. All authors have read and agreed to the published version of the manuscript.

Funding

The present research is financed in the framework of the project of Provincial Secretariat for Higher Education and Scientific Research of AP Vojvodina (Project: Molecular engineering and chemometric tools: Towards safer and greener future (No. 002902513 2024 09418 003 000 000 001 04 002) and the project of the Ministry of Science, Technological Development and Innovation (Project No. 451-03-137/2025-03/200134)).

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhao, S.; Adade, S.Y.S.; Wang, Z.; Jiao, T.; Ouyang, Q.; Li, H.; Chen, Q. Deep learning and feature reconstruction assisted vis-NIR calibration method for on-line monitoring of key growth indicators during kombucha production. Food Chem. 2025, 463, 141411. [Google Scholar] [CrossRef] [PubMed]

- Mares, V.; Nehemy, M.B.; Bogunovic, H.; Frank, S.; Reiter, G.S.; Schmidt-Erfurth, U. AI-based support for optical coherence tomography in age-related macular degeneration. Int. J. Retin. Vitr. 2024, 10, 31. [Google Scholar] [CrossRef] [PubMed]

- Ali, T.; Rehman, S.U.; Ali, S.; Mahmood, K.; Aparicio Obregon, S.; Calderón Iglesias, R.; Khurshaid, T.; Ashraf, I. Smart agriculture: Utilizing machine learning and deep learning for drought stress identification in crops. Sci. Rep. 2024, 14, 30062. [Google Scholar] [CrossRef] [PubMed]

- Sunitha, M.; Durairaj, M.; Rajalingam, A.; Khalidah Mohd Yusoff, S.; Hari Chandra Prasad, S.; Lakshmi Malluvalasa, S.N.; Kiran, A. Socioeconomic Changes Based Climate Training for Agricultural Application Using Deep Learning Model. Remote Sens. Earth Syst. Sci. 2024, 7, 399–410. [Google Scholar] [CrossRef]

- Qu, Y.; Zhang, Y.; Zhou, X.; Wang, L.; Zhu, X.; Jin, S.; Zhuang, S. Constructing a Predictive Model for Psychological Distress of Young- and Middle-Aged Gynaecological Cancer Patients. J. Eval. Clin. Pract. 2025, 31, e14244. [Google Scholar] [CrossRef]

- Hu, X.; Li, J.; Liu, T. Alg-MFDL: A multi-feature deep learning framework for allergenic proteins prediction. Anal. Biochem. 2025, 697, 115701. [Google Scholar] [CrossRef]

- Naveed Uddin, M. Cognitive science and artificial intelligence: Simulating the human mind and its complexity. Cogn. Comput. Syst. 2019, 1, 113–116. [Google Scholar] [CrossRef]

- Vinicius, G.; Maria, K.; Borges Ferreira da Silva, A. Applications of Artificial Neural Networks. In Chemical Problems: Artificial Neural Networks—Architectures and Applications; InTech: Houston TX, USA, 2013. [Google Scholar] [CrossRef]

- Đuriš, J.; Ibrić, S.; Đurić, Z. Experimental design application interpretation in pharmaceutical technology. In Computer-Aided Applications in Pharmaceutical Technology; Woodhead Publishing: Sawston, UK, 2013; pp. 31–56. [Google Scholar]

- Mohan, B.; AlRamadan, A.S.; Al-Qahtani, Y.; Viollet, Y.; Badra, J. Development cycle time reduction using design of experiments and machine learning-based optimization framework. Fuel 2022, 324, 124671. [Google Scholar] [CrossRef]

- Montgomery, D.; Bert Keats, J.; Perry, L.A.; Thompson, J.R.; Messina, W.S. Using statistically designed experiments for process development and improvement: An application in electronics manufacturing. Robot. Comput. -Integr. Manuf. 2000, 16, 55–63. [Google Scholar] [CrossRef]

- Fernandes, C.; Aliaño-González, M.J.; Cid Gomes, L.; Bernin, D.; Gaspar, R.; Fardim, P.; Reis, M.S.; Alves, L.; Medronho, B.; Rasteiro, M.G.; et al. Lignin extraction from acacia wood: Crafting deep eutectic solvents with a systematic D-optimal mixture-process experimental design. Int. J. Biol. Macromol. 2024, 280, 135936. [Google Scholar] [CrossRef]

- Benjelloun, M.; Miyah, Y.; Ssouni, S.; Iaich, S.; El-habacha, M.; Lagdali, S.; Saka, K.; Iboustaten, E.M.; Addi, A.A.; Lairini, S.; et al. Capparis spinosa L waste activated carbon as an efficient adsorbent for crystal violet toxic dye removal: Modeling, optimization by experimental design, and ecological analysis. Chin. J. Chem. Eng. 2024, 71, 283–302. [Google Scholar] [CrossRef]

- Ericksson, L.; Johansson, E.; Kettaneh-Wold, N.; Wikstrom, C.; Wold, S. Design of Experiments, Principles and Applications; Umetric Academy: Umea, Sweden, 2008. [Google Scholar]

- Archana Devi, T.; Rahul, R.; Melvin Joshua, H.; Naveen, N.; Karthik, P. Formulation of plant-based meat alternatives and its optimization by experimental design using response surface methodology. Sustain. Food Technol. 2024, 2, 1139–1151. [Google Scholar] [CrossRef]

- Shirzad, K.; Joodaky, A. Enhancing sustainable food packaging design: A machine learning approach to predict ventilated corrugated paperboard strength. Biosyst. Eng. 2024, 247, 26–41. [Google Scholar] [CrossRef]

- Giannetti, V.; Marini, F.; Boccacci Mariani, M.; Livi, G. Accelerated solvent extraction for liquid chromatographic determination of carotenoids in durum wheat pasta: A chemometric approach using statistical experimental design. Microchem. J. 2023, 190, 108650. [Google Scholar] [CrossRef]

- Grijalva, J.; Huang, T.Y.; Yu, J.; Buzzini, P.; Williams, D.; Tyler Davidson, J.; Monjardez, G. Analysis of major cannabinoids using Raman microscopy, density functional theory, chemometrics and a novel artificial intelligence approach. Talanta Open 2024, 10, 100337. [Google Scholar] [CrossRef]

- Fernanda Batista, L.; Suprani Marques, C.; Clarissa dos Santos Pires, A.; Antônio Minim, L.; de Fátima Ferreira Soares, N.; Cristina Teixeira Ribeiro Vidigal, M. Artificial neural networks modeling of non-fat yogurt texture properties: Effect of process conditions and food composition. Food Bioprod. Process 2021, 126, 164–174. [Google Scholar] [CrossRef]

- Wu, X.; Yan, H.; Cao, Y.; Yuan, Y. Prediction acrylamide contents in fried dough twist based on the application of artificial neural network. Food Chem. X 2024, 24, 102007. [Google Scholar] [CrossRef]

- Ghorbanizamani, F. A combinatorial approach to chicken meat spoilage detection using color-shifting silver nanoparticles, smartphone imaging, and artificial neural network (ANN). Food Chem. 2025, 468, 142390. [Google Scholar] [CrossRef]

- Shomope, I.; Tawalbeh, M.; Al-Othman, A.; Almomani, F. Predicting biohydrogen production from dark fermentation of organic waste biomass using multilayer perceptron artificial neural network (MLP–ANN). Comput. Chem. Eng. 2025, 192, 108900. [Google Scholar] [CrossRef]

- Beeler, N.; Hühn, T.; Rohn, S.; Colombi, R. Development and optimization of a cocoa extraction treatment by means of the response surface methodology (RSM) and artificial neural networks (ANN). Ind. Crops Prod. 2024, 222, 119610. [Google Scholar] [CrossRef]

- Hossein Nargesi, M.; Amiriparian, J.; Bagherpour, H.; Kheiralipour, K. Detection of different adulteration in cinnamon powder using hyperspectral imaging and artificial neural network method. Results Chem. 2024, 9, 101644. [Google Scholar] [CrossRef]

- Çetin, N.; Ropelewska, E.; Noutfia, Y.; Günaydın, S. Recognition performance of different artificial neural networks for distinguishing banana slices subjected to different combinations of pretreatment and microwave drying. Food Control 2024, 163, 110488. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Qenawy, M.; Li, J.; El-Sharkawy, M.; Du, D. Predictive modeling of garlic quality in hybrid infrared-convective drying using artificial neural networks. Food Bioprod. Process 2024, 145, 226–238. [Google Scholar]

- Liu, M.; Yang, Z.; Wen, J.; Ma, Z.; Sun, L.; Wang, M.; Ren, X. The effect of honey as an excipient in the processing of traditional chinese medicine based on chemical profiling, artificial neural network, and virtual screening: Cortex Mori as an example. Arabian J. Chem. 2024, 17, 105519. [Google Scholar] [CrossRef]

- Zou, Y.; Wu, J.; Wang, X.; Morales, K.; Liu, G.; Manzardo, A. An improved artificial neural network using multi-source data to estimate food temperature during multi-temperature delivery. J. Food Eng. 2023, 351, 111518. [Google Scholar] [CrossRef]

- Ait Hmazi, F.; Bagar, H.; Madani, A.; Mrani, I. A novel approach for modelling and predicting the drying kinetics of couscous grains using artificial neural networks. J. Food Compos. Anal. 2024, 132, 106301. [Google Scholar] [CrossRef]

- Ramírez-Brewer, D.; Quintana, S.E.; García-Zapateiro, L.A. Modeling and optimization of microwave-assisted extraction of total phenolics content from mango (Mangifera indica) peel using response surface methodology (RSM) and artificial neural networks (ANN). Food Chem. X 2024, 22, 101420. [Google Scholar] [CrossRef]

- Garkani-Nejad, Z. Use of Self-Training Artificial Neural Networks in a QSRR Study of a Diverse Set of Organic Compounds. Chroma 2009, 70, 869–874. [Google Scholar] [CrossRef]

- Fatemi Mohammad, H.; Ghorbannezhad, Z. Estimation of the volume of distribution of some pharmacologically important compounds from their structural descriptors. J. Serb. Chem. Soc. 2011, 76, 1003–1014. [Google Scholar]

- Kuppusamy, Y.; Jayaseelan, R.; Pandulu, G.; Sathish Kumar, V.; Murali, G.; Dixit, S.; Vatin, N.I. Artificial Neural Network with a Cross-Validation Technique to Predict the Material Design of Eco-Friendly Engineered Geopolymer Composites. Materials 2022, 15, 3443. [Google Scholar] [CrossRef]

- Elik, A.; Altunay, N. Optimization of magnetic ionic based dispersive liquid-liquid microextraction of cadmium in water and food samples using experimental design prior to flame atomic absorption spectrophotometry. Sustain. Chem. Pharm. 2022, 27, 100697. [Google Scholar] [CrossRef]

- Altunay, N.; Elik, A. Ultrasound-assisted alkanol-based nanostructured supramolecular solvent for extraction and determination of cadmium in food and environmental samples: Experimental design methodology. Microchem. J. 2021, 164, 105958. [Google Scholar] [CrossRef]

- Atfaoui, K.; Ettouil, A.; Fadil, M.; Asmaa, O.; Inekach, S.; Ouhssine, M.; Zarrouk, A. Controlled fermentation of food industrial wastes to develop a bioorganic fertilizer by using experimental design methodology. J. Saudi Soc. Agric. Sci. 2021, 20, 544–552. [Google Scholar] [CrossRef]

- Subrahanyam Seetha, B.; Ganneru, S.; Thati, R.; Krishna Reddy Mudiam, M. Experimental design of non-ionic hydrophobic DES-DLLME coupled with injector port silylation-GC–MS/MS for the quantitative determination of 13 bisphenols in food samples. Food Chem. 2023, 405, 134778. [Google Scholar] [CrossRef]

- Chakraborty, A.; Jayaseelan, K. Analytical quality by design aided RP-HPLC method for the estimation of sunset yellow in commercial food samples employing green ultrasound assisted extraction: Greenness, blueness and whiteness evaluation. Green. Anal. Chem. 2025, 12, 100183. [Google Scholar] [CrossRef]

- Arroyo-Cerezo, A.; Jiménez-Carvelo, A.M.; López-Ruíz, R.; Tello-Liébana, M.; Cuadros-Rodríguez, L. Optimising the acquisition conditions of high information quality low-field NMR signals based on a cutting-edge approach applying information theory and Taguchi’s experimental designs—Virgin olive oil as an application example. Anal. Chim. Acta 2024, 1332, 343350. [Google Scholar] [CrossRef]

- Gürkan Yüksek, A.; Elik, A.; Altunay, N. Rapid and safe determination of vitamin B1 in dairy products, fruits, nuts and vitamin tablets: Combination of natural deep eutectic solvents, experimental design and artificial intelligence. J. Food Compos. Anal. 2024, 131, 106222. [Google Scholar] [CrossRef]

- Gielens, D.R.S.; Haesaert, L.; De Schepper, C.F.; Langenaeken, N.A.; Galant, A.; Kantor, P.A.; Courtin, C.M. Assessing the occurrence of barley starch annealing under heat, moisture and time conditions relevant for kilning: An experimental design approach. Food Hydrocoll. 2025, 159, 110705. [Google Scholar] [CrossRef]

- Altunay, N.; Elik, A.; Tuzen, M.; Farooque Lanjwani, M.; Reza Afshar Mogaddam, M. Determination and extraction of acrylamide in processed food samples using alkanol-based supramolecular solvent-assisted dispersive liquid-liquid microextraction coupled with spectrophotometer: Optimization using factorial design. J. Food Compos. Anal. 2023, 115, 105023. [Google Scholar] [CrossRef]

- Drabińska, N.; Jeleń, H.H. Optimisation of headspace solid-phase microextraction with comprehensive two-dimensional gas chromatography–time of flight mass spectrometry (HS-SPME–GC × GC–ToFMS) for quantitative analysis of volatile compounds in vegetable oils using statistical experimental design. J. Food Compos. Anal. 2022, 110, 104595. [Google Scholar]

- Costa, N. Design of experiments—Overcome hindrances and bad practices. TQM J. 2019, 31, 772–789. [Google Scholar] [CrossRef]

- Lamidi, S.; Olalere, R.; Yekinni, A.; Adesina, K. Design of Experiments (DOE): Applications and Benefits in Quality Control and Assurance. In Industrial Engineering and Management; IntechOpen: London, UK, 2024. [Google Scholar]

- González-Hernández, J.L.; Canedo, M.M.; Encinar, S. Combining artificial neural networks and experimental design to prediction of kinetic rate constants. J. Math. Chem. 2013, 51, 1634–1653. [Google Scholar] [CrossRef]

- Kovačević, S.Z.; Podunavac-Kuzmanović, S.O.; Jevrić, L.R.; Djurendić, E.A.; Ajduković, J.J.; Gadžurić, S.B.; Vraneš, M.V. How to rank and discriminate artificial neural networks? Case study: Prediction of anticancer activity of 17-picolyl and 17-picolinylidene androstane derivatives. J. Iran. Chem. Soc. 2016, 13, 499–507. [Google Scholar] [CrossRef]

- Yao, Z.; Zhang, X.; Nie, P.; Lv, H.; Yang, Y.; Zou, W.; Yang, L. Identification of Milk Adulteration in Camel Milk Using FT-Mid-Infrared Spectroscopy and Machine Learning Models. Foods 2023, 12, 4517. [Google Scholar] [CrossRef]

- Choi, J.Y.; Hee Park, S.; Lee, M.A.; Bae Chung, Y.; Hee Yang, J.; Cho, J.S.; Gi Min, S. Chemometrics and neural networks for estimating the chilling injury severity of kimchi cabbage (Brassica rapa L. ssp. pekinensis) based on hyperspectral images. LWT—Food Sci. Technol. 2024, 207, 116601. [Google Scholar] [CrossRef]

- Sitorus, A.; Lapcharoensuk, R. Discrimination model of geographical area from coconut milk by near-infrared spectroscopy: Exploration in tandem with classical chemometrics, machine learning, and deep learning. Microchem. J. 2024, 206, 111538. [Google Scholar] [CrossRef]

- Wang, J.; Qian, J.; Xu, M.; Ding, J.; Yue, Z.; Zhang, Y.; Dai, H.; Liu, X.; Pi, F. Adulteration detection of multi-species vegetable oils in camellia oil using Raman spectroscopy: Comparison of chemometrics and deep learning methods. Food Chem. 2025, 463, 141314. [Google Scholar] [CrossRef]

- Wang, S.; Bai, R.; Long, W.; Wan, X.; Zhao, Z.; Fu, H.; Yang, J. Rapid qualitative and quantitative detection for adulteration of Atractylodis Rhizoma using hyperspectral imaging combined with chemometric methods. Spectrochim. Acta, Part. A 2025, 327, 125426. [Google Scholar] [CrossRef]

- Ong, P.; Yeh, C.W.; Tsai, I.; Lee, W.J.; Wang, Y.J.; Chuang, Y.K. Evaluation of convolutional neural network for non-destructive detection of imidacloprid and acetamiprid residues in chili pepper (Capsicum frutescens L.) based on visible near-infrared spectroscopy. Spectrochim. Acta, Part. A 2023, 303, 123214. [Google Scholar] [CrossRef]

- Yu, S.; Huang, X.; Wang, L.; Wang, Y.; Jiao, X.; Chang, X.; Tian, X.; Ren, Y.; Zhang, X. Characterization of the volatile flavor profiles of black garlic using nanomaterial-based colorimetric sensor array, HS-SPME-GC/MS coupled with chemometrics strategies. Food Chem. 2024, 458, 140213. [Google Scholar] [CrossRef]

- NCSS, LLC. NCSS 2023 Statistical Software. 2023. Available online: https://www.ncss.com/software/ncss/ (accessed on 5 March 2025).

- TIBCO Software Inc. Data Science Workbench, version 14. 2020. Available online: https://www.tibco.com/ (accessed on 5 March 2025).

- The MathWorks Inc. MATLAB version: 9.13.0 (R2022b). 2022. Available online: https://www.mathworks.com (accessed on 5 March 2025).

- Minitab, LLC. Minitab. 2021. Available online: https://www.minitab.com (accessed on 5 March 2025).

- Sartorius AG. MODDE. 2024. Available online: https://www.sartorius.com (accessed on 5 March 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).