Prevention Against Decrease in the Cooling Efficiency at the Car Engine by Applying Compressed Air to the External Heat Exchange Surfaces of the Car Cooler

Abstract

1. Introduction

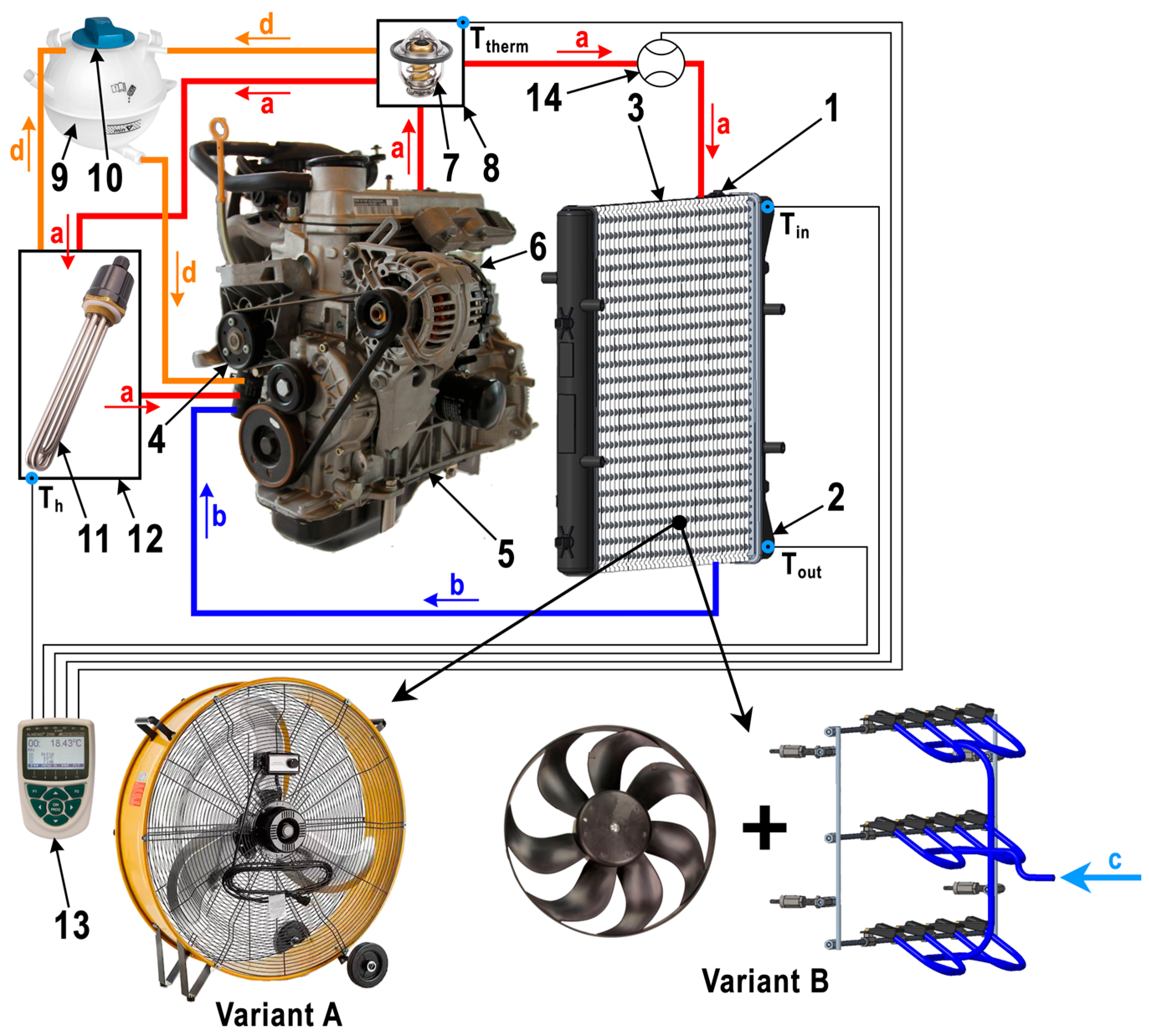

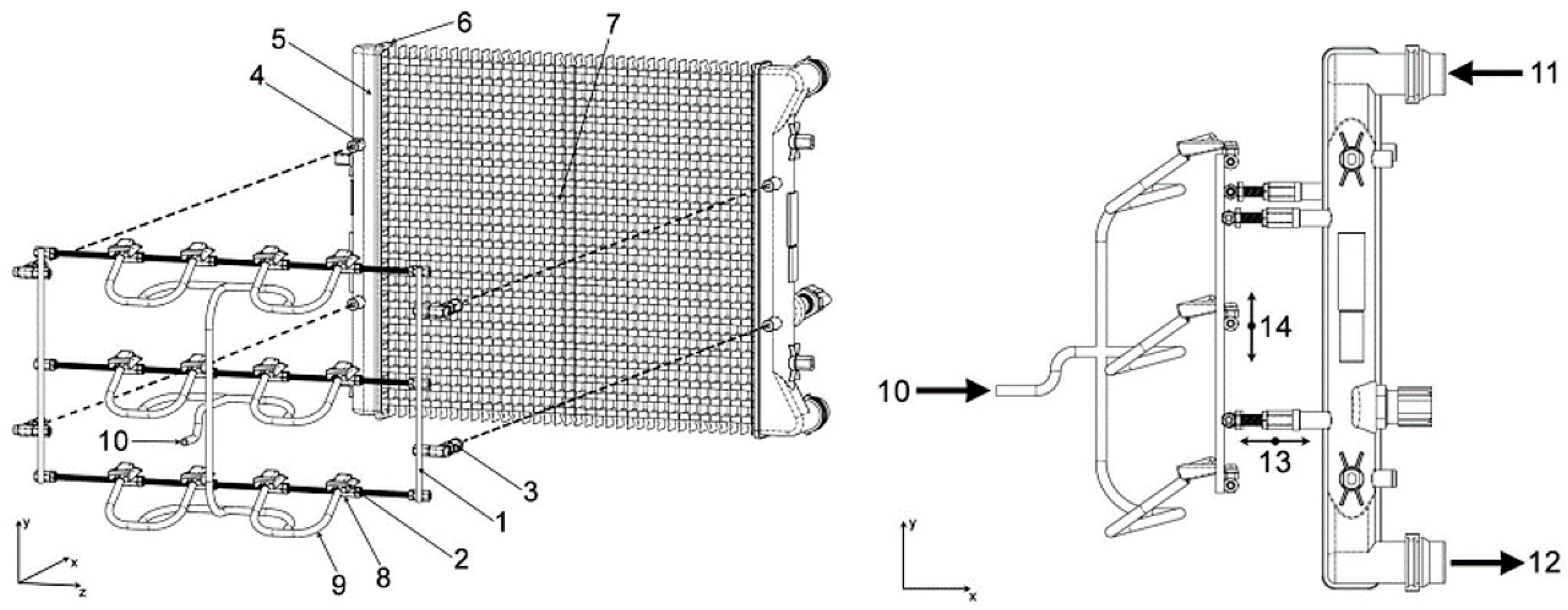

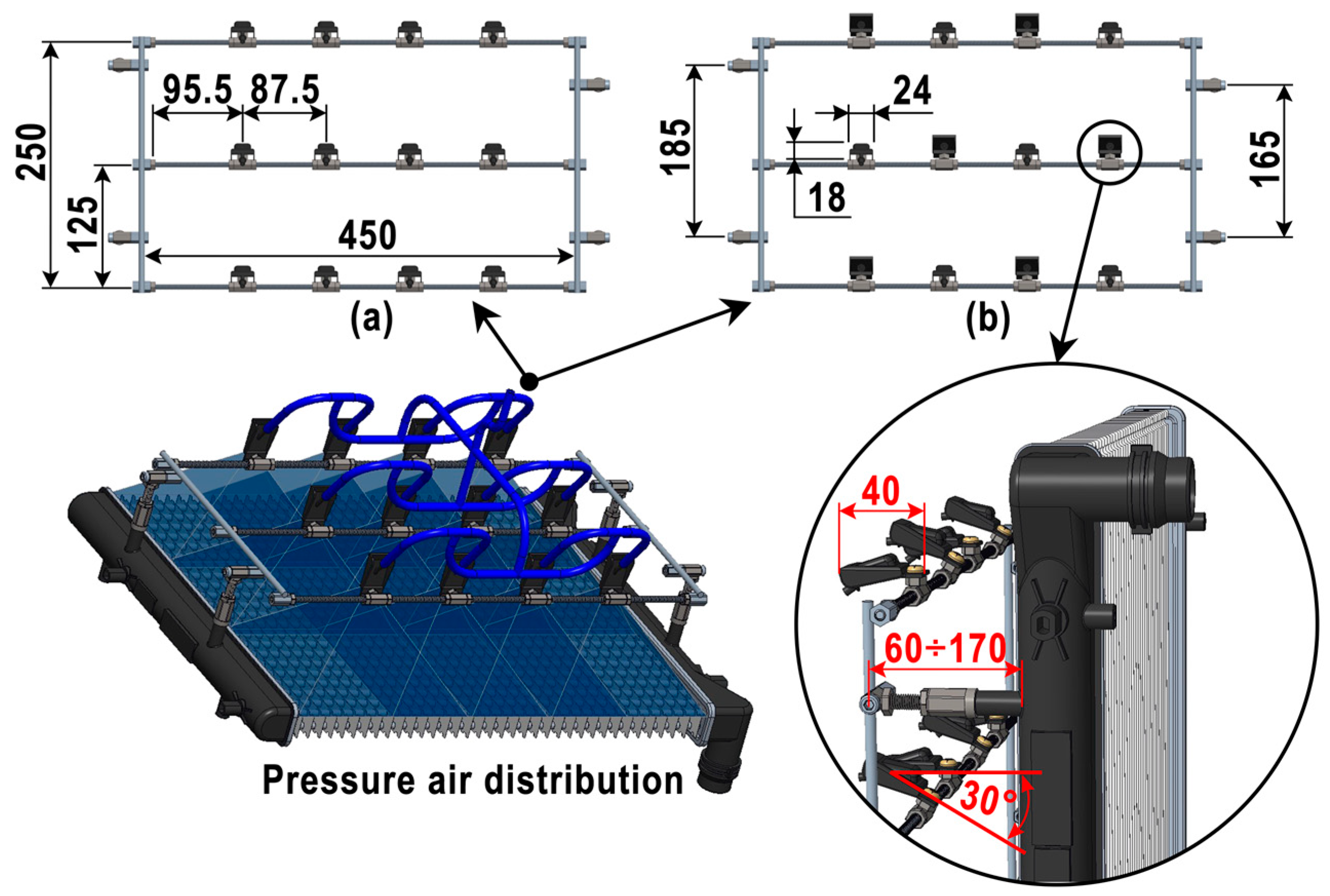

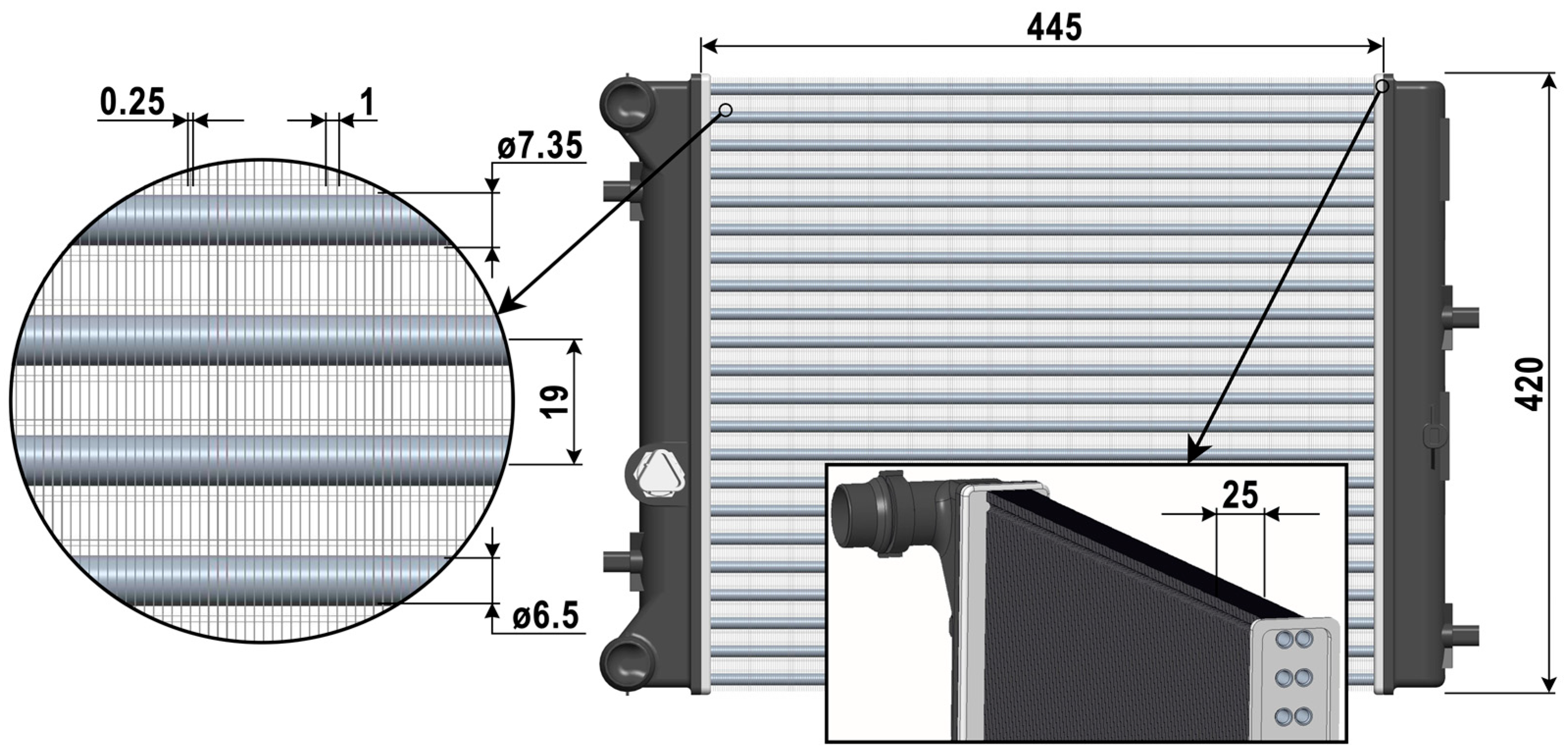

2. Materials and Methods

3. Results and Discussion

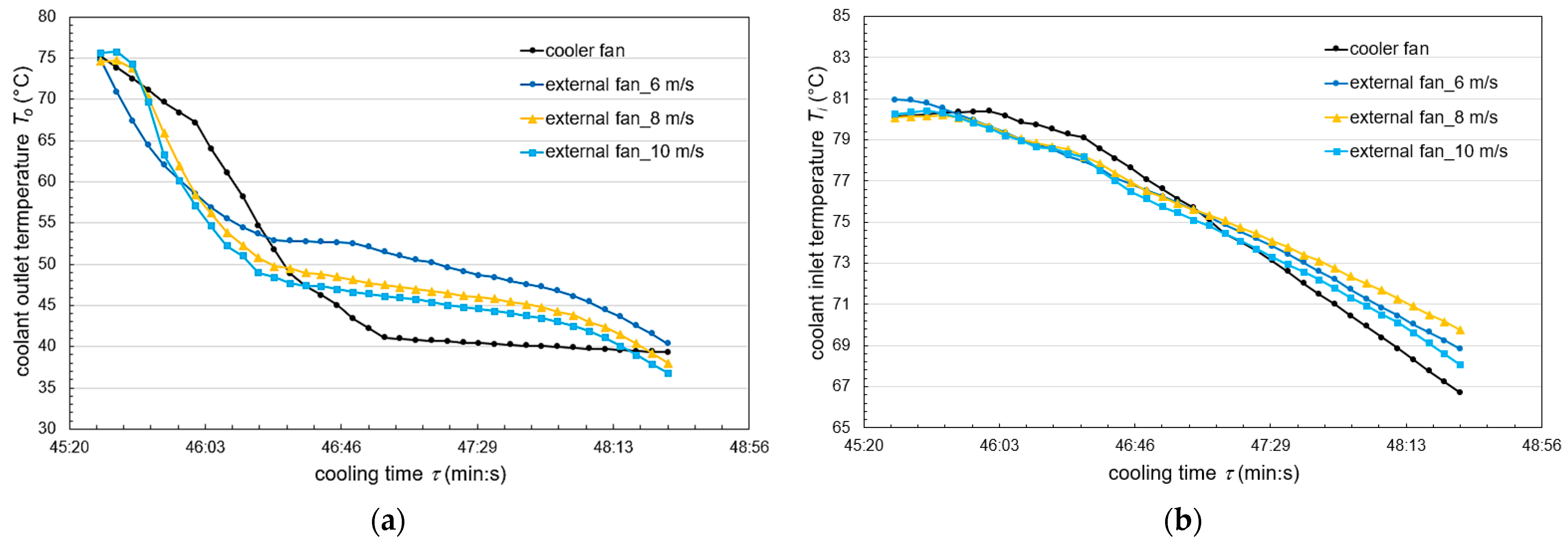

3.1. Comparison of Engine Cooler Cooling by the Cooler Fan and External Fan by Forced Air (Variant B)

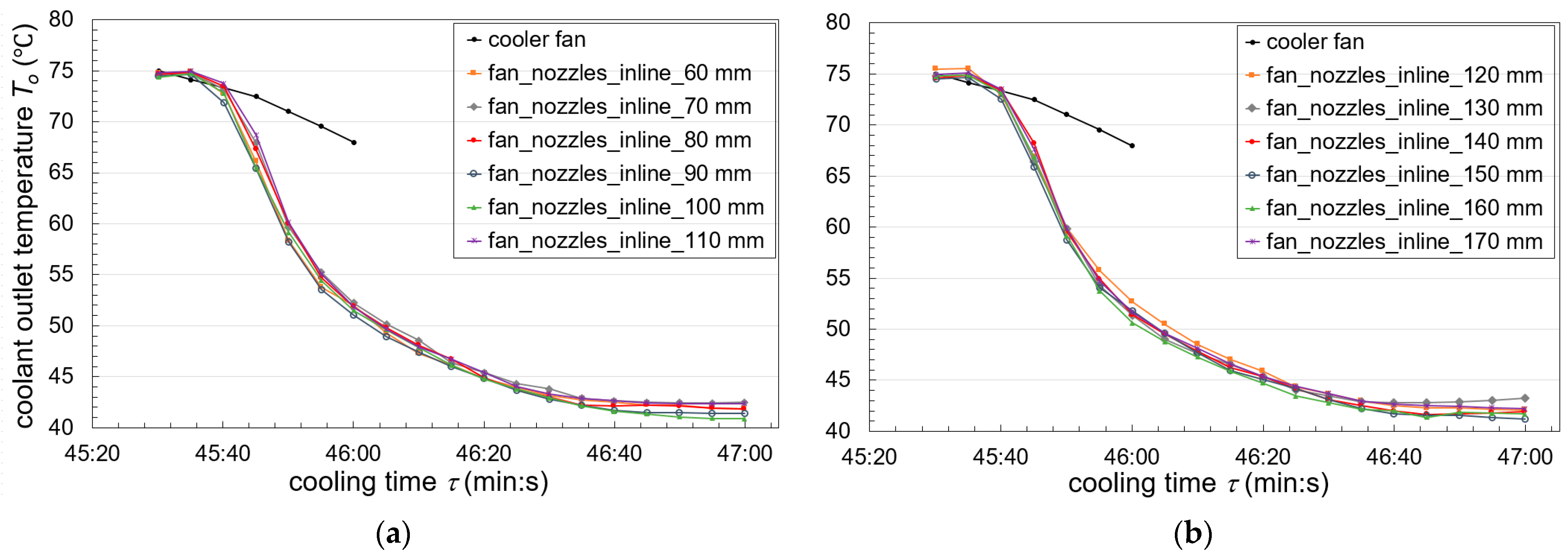

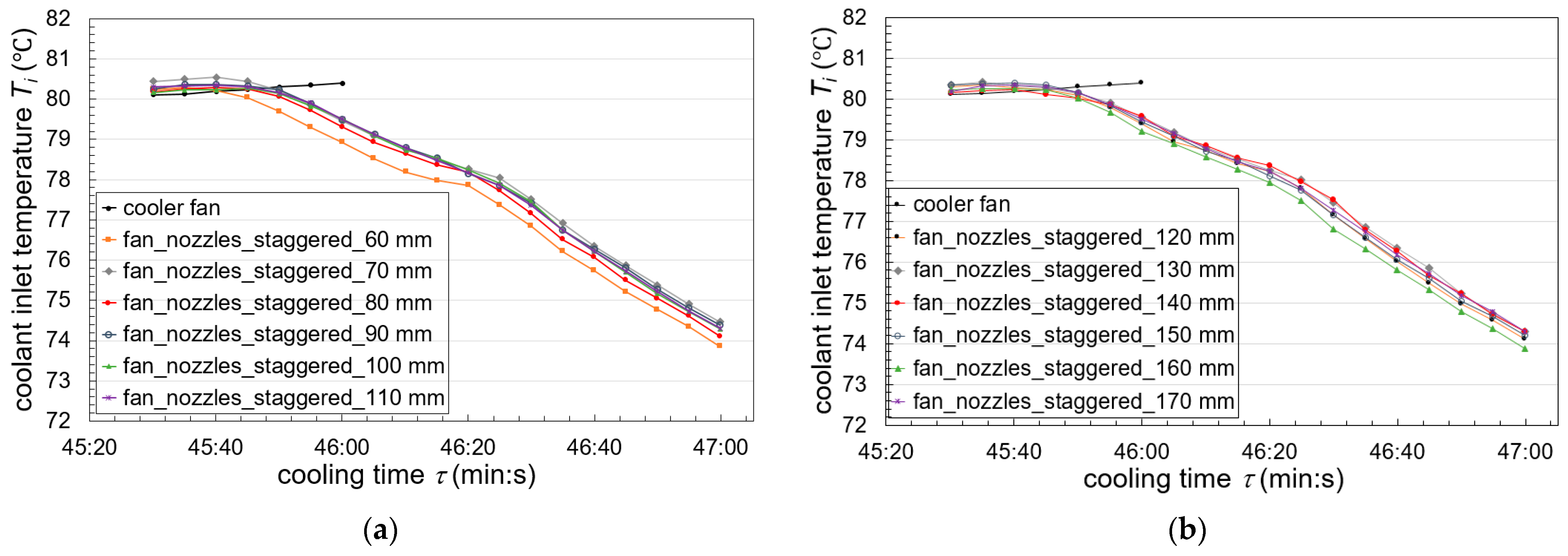

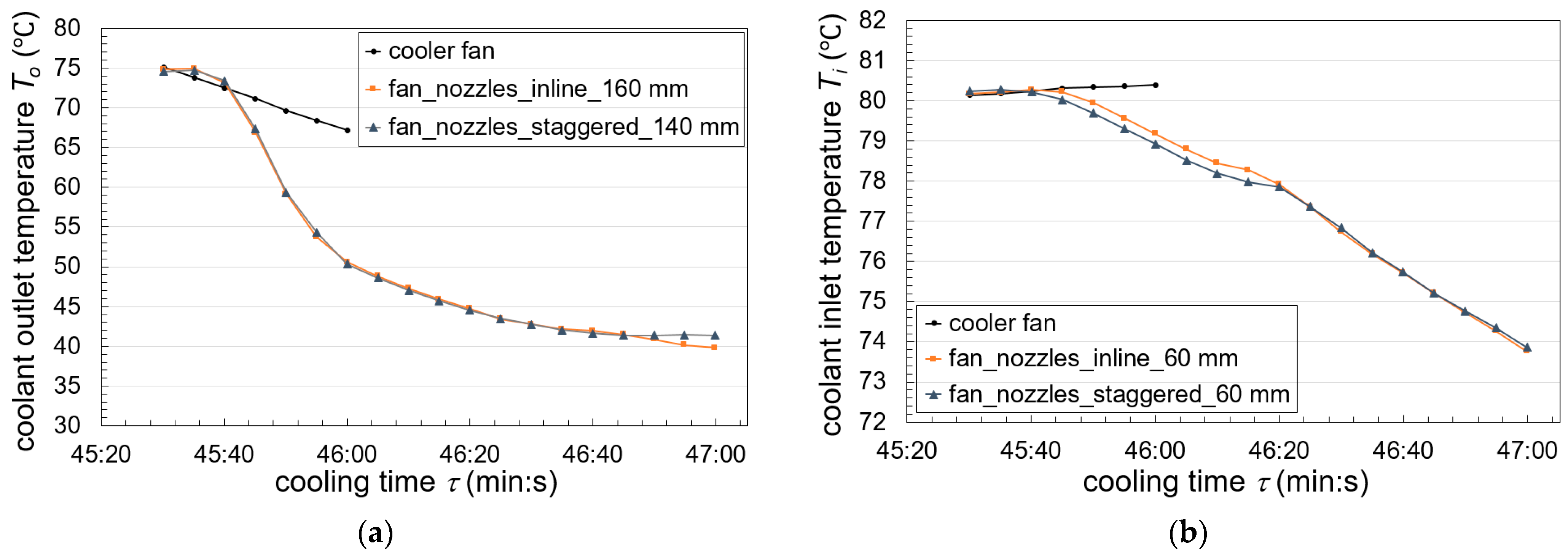

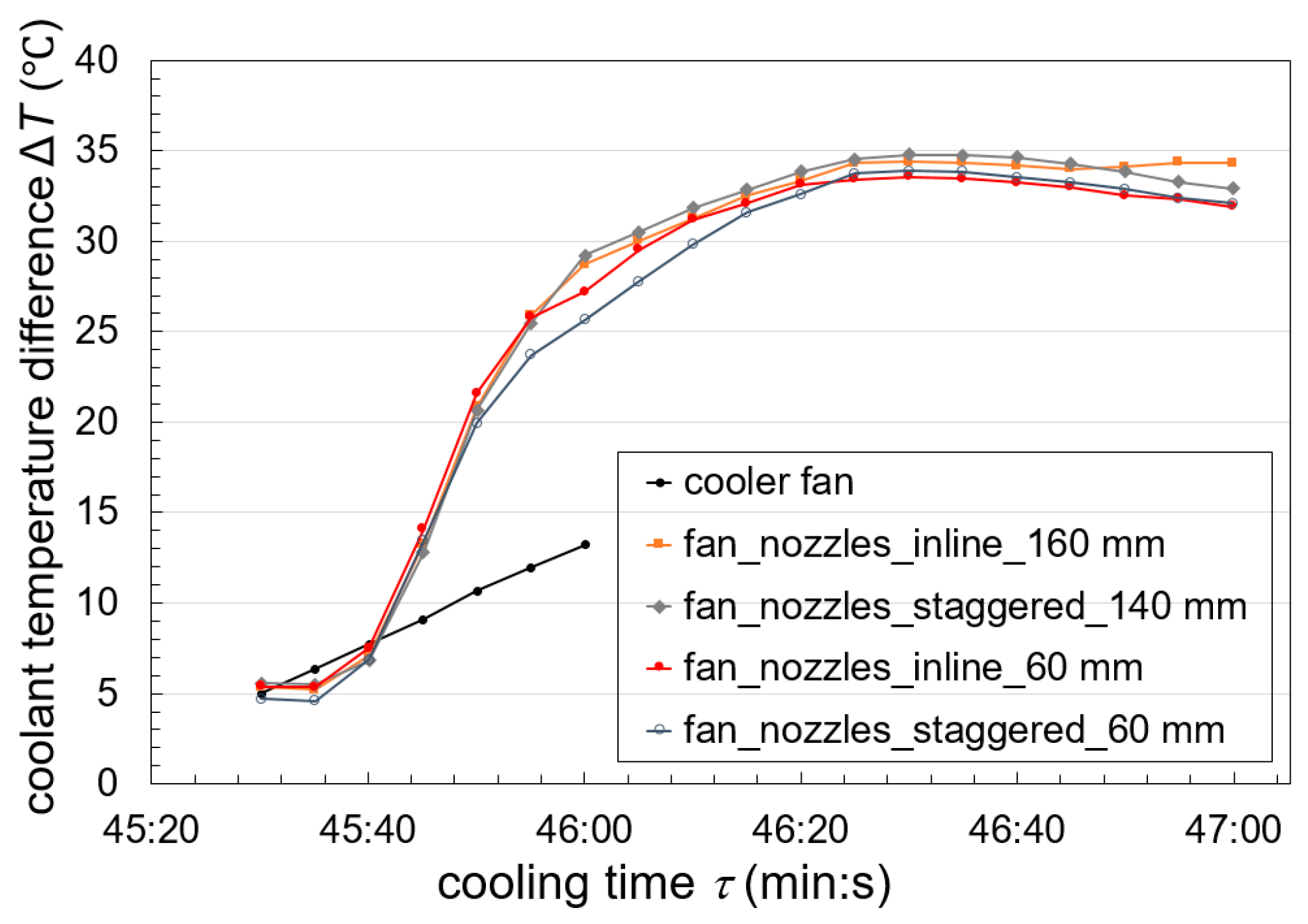

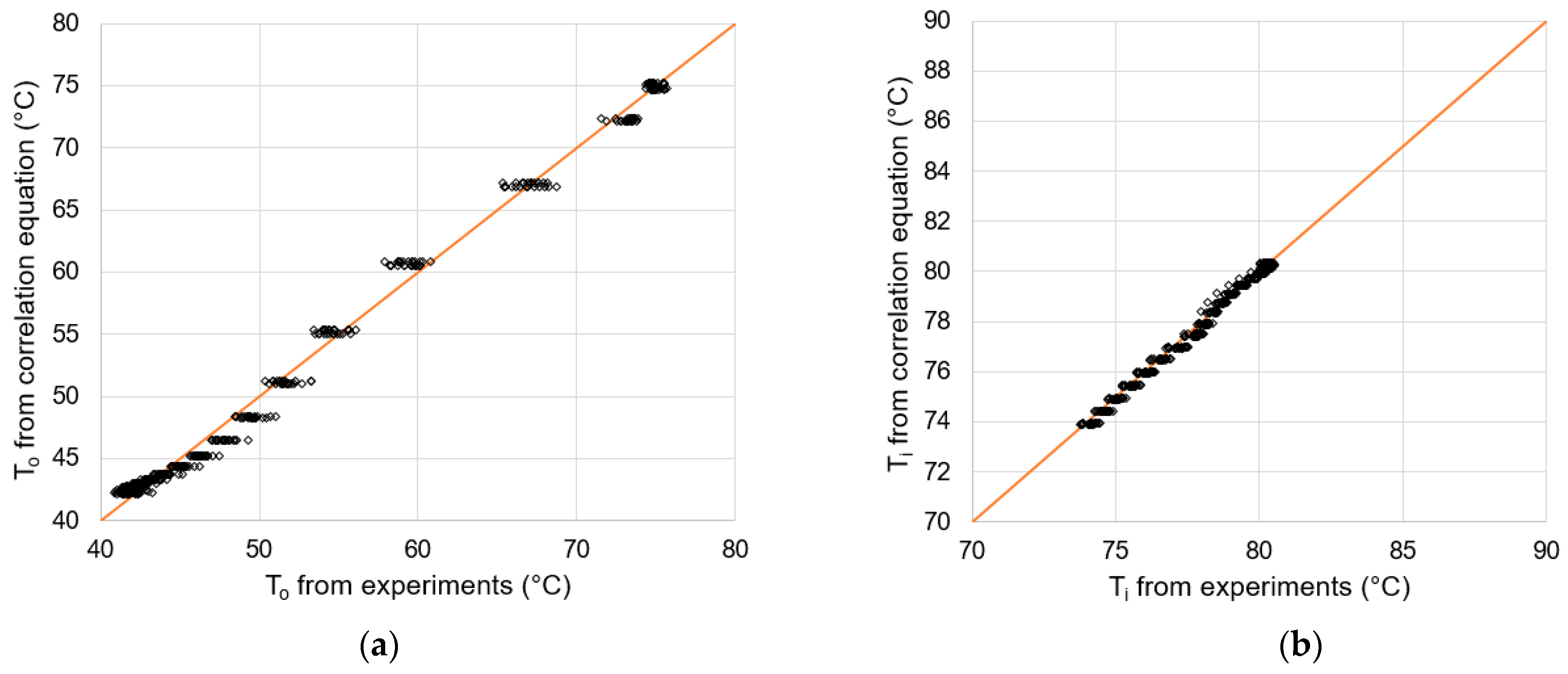

3.2. Comparison of Engine Cooler Cooling by the Cooler Fan and Its Combination with Air Pressure Nozzles (Variant B)

3.3. Practical Application and Advantages of the Pneumatic Nozzle System

- -

- pressure nozzles allow more efficient heat dissipation from the cooler to the surroundings,

- -

- a more uniform airflow over the entire heat exchange surface is achieved compared to the conventional cooler fan; no hotspots are created,

- -

- reduction of the total weight of the cooling circuit, if the vehicle is equipped with a compressed air supply,

- -

- reduction of noise from the rotating blades of conventional cooler fans,

- -

- self-cleaning ability of the outer surfaces of the cooler fins and tubes, which become clogged with impurities during vehicle operation (dust, gravel, sand, feathers, salt, flies, etc.) and thus reduce the efficiency of the cooling process,

- -

- the possibility to use in combination with fans for more efficient cooling process and overall heat transfer (prevention of clogging of heat exchanger surfaces).

4. Conclusions

- -

- The inline nozzles arrangement with the cooler fan achieved a decrease in To of 0.76 to 1.02 times and Ti of 0.98 to 1.00 times compared to cooling by the single cooler fan, respectively;

- -

- The staggered nozzle arrangement with the cooler fan achieved a decrease in To of 0.78 to 1.03 times and Ti of 0.98 to 1.01 times compared to cooling by the single cooler fan, respectively;

- -

- The earlier the To is decreased, the more intense the heat dissipation process and the more efficient the engine cooling;

- -

- When considering the temperature differences at the inlet and outlet of the cooler, the To was higher by up to 26.03 °C and 26.22 °C when using a single cooler fan compared to the inline nozzles and cooler fan and staggered nozzles and cooler fan configurations, respectively;

- -

- Changing the distance of the nozzles from the cooler has the effect of decreasing the inlet and outlet temperatures of the cooler while cooling it. The nozzles reduced the cooler outlet temperatures, with a difference between the maximum and minimum To values of, on average, 1.6 °C and 1.87 °C, and between the maximum and minimum Ti values of, on average, 0.43 °C and 0.56 °C during the cooling process for the inline and staggered configurations, respectively;

- -

- The higher temperature difference represents a more intensive heat dissipation by the cooler;

- -

- The system of air pressure nozzles in combination with the cooler fan (Variant B) causes an improvement in the cooling process compared to a single cooler fan.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| d | distance between the cooler and nozzles (mm) |

| ΔT | temperature difference (°C) |

| G12+ | type of the coolant |

| Th | temperature in the heater (°C) |

| Ti | temperature in the inlet pipe of the cooler (°C) |

| To | temperature in the outlet pipe of the cooler (°C) |

| Ttherm | temperature in the thermostatic valve (°C) |

| τ | cooling time (min:s) |

References

- Che Sidik, N.A.; Witri Mohd Yazid, M.N.A.; Mamat, R. Recent advancement of nanofluids in engine cooling system. Renew. Sustain. Energy Rev. 2017, 75, 137–144. [Google Scholar] [CrossRef]

- Bigdeli, M.B.; Fasano, M.; Cardellini, A. A review on the heat and mass transfer phenomena in nanofluid coolants with special focus on automotive applications. Renew. Sustain. Energy Rev. 2016, 60, 1615–1633. [Google Scholar] [CrossRef]

- Leong, K.Y.; Saidur, R.; Kazi, S.N.; Hamun, A.H. Performance investigation of an automotive car radiator operated with nanofluid-based coolants (nanofluid as a coolant in a radiator). Appl. Therm. Eng. 2010, 30, 2685–2692. [Google Scholar] [CrossRef]

- Chen, X.; Yu, X.; Lu, Y.; Huang, R.; Liu, Z.; Huang, Y.; Roskilly, A.P. Study of different cooling structures on the thermal status of an Internal Combustion Engine. Appl. Therm. Eng. 2017, 116, 419–432. [Google Scholar] [CrossRef]

- Fontanesi, S.; Giacopini, M. Multiphase CFD–CHT optimization of the cooling jacket and FEM analysis of the engine head of a V6 diesel engine. Appl. Therm. Eng. 2013, 52, 293–303. [Google Scholar] [CrossRef]

- Mukkamala, Y. Contemporary trends in thermo-hydraulic testing and modeling of automotive radiators deploying nano-coolants and aerodynamically efficient air-side fins. Renew. Sustain. Energy Rev. 2017, 76, 1208–1229. [Google Scholar] [CrossRef]

- Pang, S.C.; Kalam, M.A.; Masjuki, H.H.; Hazrat, M.A. A review on air flow and coolant flow circuit in vehicles’ cooling system. Int. J. Heat Mass Transf. 2012, 55, 6295–6306. [Google Scholar] [CrossRef]

- Cipollone, R.; Battista, D.; Gualtieri, A. A novel engine cooling system with two circuits operating at different temperatures. Energy Conv. Manag. 2013, 75, 581–592. [Google Scholar] [CrossRef]

- Cipollone, R.; Battista, D. Sliding vane rotary pump in engine cooling system for automotive sector. Appl. Therm. Eng. 2015, 76, 157–166. [Google Scholar] [CrossRef]

- Chastain, J.; Wagner, J.; Eberth, J. Advanced engine cooling–Components, testing and observations. IFAC Proc. Vol. 2010, 43, 294–299. [Google Scholar] [CrossRef]

- Said, Z.; Assad, M.E.H.; Hachicha, A.A.; Bellos, E.; Abdelkareem, M.A.; Alazaizeh, D.Z.; Bashria, A.A. Enhancing the performance of automotive radiators using nanofluids. Renew. Sustain. Energy Rev. 2019, 112, 183–194. [Google Scholar] [CrossRef]

- Mohamed, E.S. Development and analysis of a variable position thermostat for smart cooling system of a light duty diesel vehicles and engine emissions assessment during NEDC. Appl. Therm. Eng. 2016, 99, 358–372. [Google Scholar] [CrossRef]

- Haghighat, A.K.; Roumi, S.; Madani, N.; Bahmanpour, D.; Olsen, M.G. An intelligent cooling system and control model for improved engine thermal management. Appl. Therm. Eng. 2018, 128, 253–263. [Google Scholar] [CrossRef]

- Subhedar, D.G.; Ramani, B.M.; Gupta, A. Experimental investigation of heat transfer potential of Al2O3/Water-Mono Ethylene Glycol nanofluids as a car radiator coolant. Case Stud. Therm. Eng. 2018, 11, 26–34. [Google Scholar] [CrossRef]

- Kulkarni, D.P.; Vajjha, R.S.; Das, D.K.; Oliva, D. Application of aluminum oxide nanofluids in diesel electric generator as jacket water coolant. Appl. Therm. Eng. 2008, 28, 774–1781. [Google Scholar] [CrossRef]

- Arora, N.; Gupta, M. An updated review on application of nanofluids in flat tubes radiators for improving cooling performance. Renew. Sustain. Energy Rev. 2020, 134, 110242. [Google Scholar] [CrossRef]

- Park, M.; Lee, D. Sources of broadband noise of an automotive cooling fan. Appl. Acoust. 2017, 118, 66–75. [Google Scholar] [CrossRef]

- Krishna, S.R.; Krishna, A.R.; Ramji, K. Reduction of motor fan noise using CFD and CAA simulations. Appl. Acoust. 2011, 72, 982–992. [Google Scholar] [CrossRef]

- Rynell, A.; Chevalier, M.; Abom, M.; Efraimsson, G. A numerical study of noise characteristics originating from a shrouded subsonic automotive fan. Appl. Acoust. 2018, 140, 110–121. [Google Scholar] [CrossRef]

- Pradhan, P.; Singh, D. Review on air suspension system. Mater. Today Proc. 2023, 81, 486–488. [Google Scholar] [CrossRef]

- Zhao, N.; Li, S.; Yang, J. A review on nanofluids: Data-driven modeling of thermalphysical properties and the application in automotive radiator. Renew. Sustain. Energy Rev. 2016, 66, 596–616. [Google Scholar] [CrossRef]

- Eskandary, K.P.; Khajepour, A.; Wong, A.; Ansari, A. Analysis and optimization of air suspension system with independent height and stiffness tuning. Int. J. Automot. Technol. 2016, 17, 807–816. [Google Scholar] [CrossRef]

- Sun, X.; Cai, Y.; Chen, L.; Liu, Y.; Wang, S. Vehicle height and posture control of the electronic air suspension system using the hybrid system approach. Mobil. Vehicle Mech. 2016, 54, 328–352. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H. Height and leveling control of automotive air suspension system using sliding mode approach. IEEE Trans. Veh. 2011, 60, 2027–2041. [Google Scholar]

- Rajko, L.; Koleda, P.; Barcik, S.; Koleda, P. Technical and technological factors’ effects on quality of the machined surface and energetic efficiency when planar milling heat-treated meranti wood. BioResources 2021, 16, 7884–7900. [Google Scholar] [CrossRef]

- Fang, Y.; Lu, Y.; Yu, X.; Roskilly, A.P. Experimental study of a pneumatic engine with heat supply to improve the overall performance. Appl. Therm. Eng. 2018, 134, 78–85. [Google Scholar] [CrossRef]

- Wasbari, F.; Bakar, R.A.; Gan, L.M.; Tahir, M.M.; Yusof, A.A. A review of compressed-air hybrid technology in vehicle system. Renew. Sustain. Energy Rev. 2017, 67, 935–953. [Google Scholar] [CrossRef]

- Marvania, D.; Subudhi, S. A comprehensive review on compressed air powered engine. Renew. Sustain. Energy Rev. 2017, 70, 1119–1130. [Google Scholar] [CrossRef]

- Fang, Y.; Lu, Y.; Roskilly, A.P.; Yu, X. A review of compressed air energy systems in vehicle transport. Energy Strategy Rev. 2021, 33, 100583. [Google Scholar] [CrossRef]

- Wang, X.; Liu, C.; Dong, Q.; Zhao, J.; Lai, C.; Lin, J.; Ji, J.; Liu, M. Numerical simulation of radial duel-stage nozzle vortex cooling at the leading edge of a gas turbine blade. Appl. Therm. Eng. 2025, 260, 125017. [Google Scholar] [CrossRef]

- Yang, W.; Sang, X.; Chen, B. Numerical simulation of closed-cycle R410A flash spray cooling with multiple nozzles on a large heat exchange surface. Appl. Therm. Eng. 2025, 268, 125878. [Google Scholar] [CrossRef]

- Su, C.-Q.; Wang, S.; Liu, X.; Tao, Q.; Wang, Y.-P. Experimental and numerical investigation on spray cooling of radiator in fuel cell vehicle. Energy Rep. 2022, 8, 1283–1294. [Google Scholar] [CrossRef]

- Fordon, A.G.; Soria, F.; Woodruff, E.; Brewer, C.; Xu, Y.; Putnam, S.A. Multi-nozzle, common-rail based, piezo-actuated, pulsed spray cooling testbed. Int. J. Heat Mass Transf. 2025, 241, 126596. [Google Scholar] [CrossRef]

| Cooling Time τ (min:s) | Inline and Cooler Fan (Average of Distances) | Staggered and Cooler Fan (Average of Distances) | Cooler Fan | |

|---|---|---|---|---|

| To (°C) | 46:00 | 51.66 | 51.60 | 67.97 |

| 47:00 | 41.94 | 41.75 | ||

| Ti (°C) | 46:00 | 79.35 | 79.41 | 80.39 |

| 47:00 | 74.06 | 74.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lipnický, M.; Brodnianská, Z.; Kotšmíd, S.; Beňo, P. Prevention Against Decrease in the Cooling Efficiency at the Car Engine by Applying Compressed Air to the External Heat Exchange Surfaces of the Car Cooler. Processes 2025, 13, 582. https://doi.org/10.3390/pr13020582

Lipnický M, Brodnianská Z, Kotšmíd S, Beňo P. Prevention Against Decrease in the Cooling Efficiency at the Car Engine by Applying Compressed Air to the External Heat Exchange Surfaces of the Car Cooler. Processes. 2025; 13(2):582. https://doi.org/10.3390/pr13020582

Chicago/Turabian StyleLipnický, Marek, Zuzana Brodnianská, Stanislav Kotšmíd, and Pavel Beňo. 2025. "Prevention Against Decrease in the Cooling Efficiency at the Car Engine by Applying Compressed Air to the External Heat Exchange Surfaces of the Car Cooler" Processes 13, no. 2: 582. https://doi.org/10.3390/pr13020582

APA StyleLipnický, M., Brodnianská, Z., Kotšmíd, S., & Beňo, P. (2025). Prevention Against Decrease in the Cooling Efficiency at the Car Engine by Applying Compressed Air to the External Heat Exchange Surfaces of the Car Cooler. Processes, 13(2), 582. https://doi.org/10.3390/pr13020582