Abstract

This review analyzes the critical interdependence among the three key components—ink formulation, printing process parameters, and post-processing—in Three-dimensional (3D) Food Printing (3DFP) and Four-dimensional (4D) Food Printing (4DFP). While extensive research addresses individual phases, a significant opportunity remains to integrate these three pillars systematically to bridge the gap between initial design and final product viability. The analysis reveals that successful 3D printing demands a formulation optimized to resist thermal and mechanical stresses; thus, printability assessments must be extended to include post-processing stability. Conversely, 4D printing intentionally exploits this relationship, utilizing post-processing (e.g., heat or pH) as a strategic trigger to activate programmed deformation. Joint optimization of formulation, printed food microstructure, and final post-processing stages is necessary to produce foods with the desired final quality.

1. Introduction

Three-dimensional (3D) printing, also known as additive manufacturing, is a digitally controlled process that creates three-dimensional objects by depositing materials layer by layer from computer-aided design (CAD) models [1]. This technology has generated significant interest in food engineering due to its potential to customize shape, texture, flavor, and nutritional profile [2,3,4,5]. One of the most relevant applications is personalized nutrition, particularly in designing food to meet specific dietary needs, such as those for individuals with dysphagia. 3D and 4D printing allow for the creation of modified, soft, and easy-to-swallow textures [6,7,8]. Recent research has demonstrated this potential, including the development of quinoa and pea protein-based foods [9] and the use of mycoprotein via coaxial printing [10]. Current research is exploring “inks” from diverse sources, such as jackfruit and wheat flours [5,11] or proteins like surimi [12], optimizing their printability through the addition of hydrocolloids like Astragalus polysaccharide or okra gum [5,11]. The potential extends to the development of functional foods by incorporating bioactive compounds [13,14]. A different approach has been the use of multiphase gels, such as Pickering emulsions and bigels, which enable the stable loading of hydrophilic and lipophilic active ingredients. In these systems, 3D printing can modulate the microstructure to enhance the bioaccessibility of nutrients [15]. Concurrently, Artificial Intelligence (AI) and Machine Learning (ML) are transforming the field, optimizing formulations and predicting material behavior [16], while a growing environmental concern is driving the use of sustainable materials [17].

Scientific reviews in this field have predominantly focused on the production stage, specifically the optimization of ink formulation to achieve printability [5,11]. However, the freshly printed matrix is only an intermediate product; it is the post-processing stage that transforms this intermediate into an edible, palatable, and stable food [18]. This latter stage is critical, as it imposes significant demands on the printed structure and varies depending on the printing technology, requiring heating, cooling, curing, or drying, among other processes [19,20]. The success of a printed food depends on its structure’s resilience during post-processing, implying that the initial formulation must account for this final stage. For example, the viability of surimi inks depends on their ability to withstand freeze–thaw cycles, a challenge researchers address by adding antifreeze peptides [12]. Similarly, hydrocolloids improve the final quality of printed noodles by defining their cooking characteristics [21]. Despite the practical interdependence between formulation, printing process, and post-processing, the existing review literature has addressed these stages separately. It has focused predominantly on food inks, their formulation optimization, and their relationship with printability [5,11], while treating post-processing as a secondary step.

Given that formulation dictates viable printing technologies, and the process determines the requirements and responses to post-processing, it is essential to evaluate printability in conjunction with formulation characteristics and their effect on post-processing stability [22]. The objective of this review is to systematically analyze the intrinsic interrelationship among the three key components, Formulation, Process, and Post-Processing, that govern stability and quality in 3D- and 4D-printed food systems. By exploring 4D printing as a sophisticated form of programmed post-processing, we aim to overcome fragmentation in the existing literature and demonstrate that integrated optimization is essential for bridging the gap between design and product viability.

To ensure a rigorous analysis, we conducted a systematic literature search across high-impact databases (Scopus, Web of Science), focusing on peer-reviewed articles published in the last 7 years (2018–2025). We employed a search strategy combining keywords related to 3D printing technologies, rheology, and post-processing. Following a two-stage screening process (title/abstract and full-text), we selected 123 publications providing quantitative data on the interdependence of these stages to support the conclusions presented herein.

The remainder of this review is organized as follows: Section 2 analyzes the interdependence between formulation and the printing process. Section 3 details the specific technical constraints of Extrusion, Binder Jetting, SLS, and Inkjet Printing. Section 4 explores formulation requirements for post-processing stability. Section 5 examines the impact of printed microstructure. Section 6 introduces 4D Printing concepts. Section 7 and Section 8 analyze specific post-processing strategies for 3D and 4D systems, respectively. Finally, Section 9 addresses study limitations and future perspectives.

2. Formulation and Interdependence with the Printing Process

The formulation of printing inks, also known as food inks, their rheological properties, physical state, and composition are critical factors that determine the technological viability of the printing process. This interdependence between formulation and process is important, as ingredient selection affects the production of a safe, stable, and edible product [18,22,23]. Although this effect extends to post-processing, this section will focus on analyzing how formulation restricts the printing technology and process parameters, thereby determining its printability.

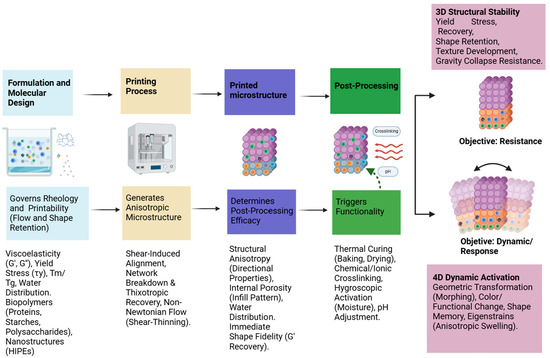

The selection and proper preparation of “food inks” are fundamental steps to ensure the structural integrity and quality of the final product [6,22,24,25,26,27]. Nevertheless, the material properties must often be adjusted, either through pretreatment or additives, to become printable “food inks” [13,22,26,28]. A key example is the addition of hydrocolloids such as Xanthan Gum (XG) to ensure smooth flow through the extrusion nozzle and rapid structural recovery upon deposition [26,29,30]. If the material is a thermoplastic polymer or has a low melting point (e.g., chocolate), researchers use Fused Deposition Modeling (FDM) or Hot-Melt Extrusion (HME); in both cases, the formulation must melt and then rapidly solidify as it drops below its melting temperature [17,22,31]. If the base material is a dry powder (e.g., sugars, starches, fats), Selective Laser Sintering (SLS) or Binder Jetting (BJ) is required. In these cases, characteristics regarding the flowability, particle size, and wettability of the powder formulation become critical factors for precision in these techniques [17,22,32,33]. If the material is a low-viscosity liquid (e.g., inks, aqueous solutions), it is only compatible with Material Jetting (Material Jetting/Inkjet) [31,33,34,35]. The formulation determines the chosen printing technology, which in turn dictates the post-processing stages. The relationship between printing technology (process) and post-processing is hierarchical: the chosen technology, itself conditioned by the formulation, prescribes the necessity, type, and intensity of the finishing operations required to obtain a stable, safe, and edible product. To visualize this relationship, Figure 1 presents a schematic diagram of the critical interdependence among ink formulation, printing process parameters, and post-processing. This conceptual framework illustrates how the printed microstructure serves as the physical link between the initial molecular design and the final objective, whether it be structural stability in 3D printing or dynamic activation in 4D printing.

Figure 1.

Schematic representation of the interdependence among ink formulation, printing process parameters, and post-processing.

This complexity varies depending on the ink’s solidification mechanism: in Hot-Melt Extrusion (HME/FDM), where the material solidifies rapidly upon cooling, the printed objects require minimal or null post-processing, generally limited to controlled cooling to maintain structural rigidity. Conversely, for Room Temperature Extrusion (RTE/DIW), which uses semi-solid pastes and doughs that maintain their shape solely through rheology, thermal post-processing is mandatory to ensure safety, palatability, texture, and shape stability. Post-processing includes thermal treatments such as baking, frying, or steaming, as well as water activity reduction methods, such as drying or lyophilization (freeze-drying)—researchers prefer the latter for maintaining structural integrity [10,17,31,32,33,35,36,37].

In Hydrogel Forming Extrusion (HFE), applied to solutions or dispersions of hydrocolloids (soft materials), structural stability is achieved through an induced curing post-processing. This cross-linking process of the polymer chains is essential for conferring mechanical and structural stability to the edible product; ionic cross-linking is the most common physical cross-linking method. An example is alginate, which gels upon interacting with divalent metal cations such as calcium (Ca2+). This technique allows modification of the ink’s strength without using temperature. To overcome the challenge of gravity-induced structural distortion in these soft materials, the post-processing must provide stability during or immediately after deposition (in situ) [21,28,32,34,35,38]. Regarding powder-based technologies, both Selective Laser Sintering (SLS) and Binder Jetting (BJ) require post-processing, in which we remove and recycle unbound powder from the matrix. A part printed via BJ, for example, is initially weak and requires further post-processing, such as heating, baking, or high-temperature curing, to achieve densification and structural reinforcement [21,28,32,34,35]. Finally, in Inkjet Printing (IJP), which handles low-viscosity liquid formulations, post-processing focuses on immediate layer-by-layer curing or solidification, assisted by UV light or low-temperature heat. This is complemented by the rapid drying of the droplets (e.g., with dry gas or alcohol) to ensure precision and prevent uncontrolled merging [21,28,32,34,35].

3. Three-Dimensional (3D) Printing Technologies

3.1. Extrusion-Based Printing

Extrusion-based printing is the most popular and versatile method in 3D food manufacturing. It operates by controllably depositing viscous materials such as pastes, gels, or molten materials layer by layer through a nozzle. The food ink’s rheological properties primarily determine the technology’s viability, acting as the primary limiting factor [22,31,39]. This technique is highly valued in the food industry for its adaptability to a wide range of rheologically complex materials, such as pastes, gels, and doughs, whose formulation demands the ability to exhibit shear-thinning behavior and adequate structural strength [12,21,23,25,26,27].

It is important to classify extrusion by solidification mechanism (HME, HFE, RTE) because the type of curing or hardening of the printed structure determines the necessity and type of post-processing [40]. Hot-Melt Extrusion (HME/FDM) involves materials that melt at elevated temperatures and are extruded but solidify rapidly upon cooling below their melting temperature [40]. Because solidification is almost immediate, HME-printed objects require minimal or null post-processing. A classic example is chocolate printing, where controlled cooling is the key process [22,28,35]. Therefore, post-processing (curing) is an inherent part of the deposition process. Room Temperature Extrusion (RTE/DIW) utilizes pastes, doughs, and gels that rely on their rheological properties (thixotropy, high yield stress) to maintain shape [40]. Since the material is deposited without melting or curing, post-processing is required to ensure safety, palatability, texture, and shape stability, including extensive thermal treatments, such as baking, frying, or steaming, as well as moisture-stabilization methods, such as drying or lyophilization [22]. The HME and HFE processes represent the extremes of solidification during extrusion. However, Room Temperature Extrusion (RTE) is the method that generates the greatest need for thermal post-processing [22,35]. The need for post-processing is a reality for almost all printing techniques, but in the context of extrusion, it varies from minimal (HME) to complex and obligatory (RTE/DIW) [35,38].

The ink must be pseudoplastic (i.e., shear-thinning), meaning its viscosity must decrease significantly when subjected to high shear within the nozzle to ensure smooth, continuous flow without clogging, and it must recover rapidly upon deposition [39,41]. In this regard, viscoelastic behavior is required, with a storage modulus (G′) greater than the loss modulus (G″), and a damping factor (tanδ) ideally between 0.2 and 0.6 [41,42]. Achieving this rheological profile often requires the use of additives or pretreatments. In the category of pastes and purées, for example, the addition of 2% potato starch (PS) to formulations extruded at room temperature (RTE) has been shown to provide the most desirable extrudability and shape retention, achieving a yield stress (τ0) of 312.16 Pa [13,41,43]. Regarding gels, hydrocolloids are key to stability. Yang et al. [37] formulated a lemon juice gel containing 15 g∙100 g−1 potato starch, processed by screw-based extrusion at 80 °C for precision molding. Liu et al. [44] designed a multicomponent system of κ-carrageenan, xanthan gum (XG), and starch that, after being heated to 90 °C and cooled to 4 °C, exhibited enhanced gelling properties and high shape fidelity. Pre-extruded chickpea flour, subjected to prior thermomechanical extrusion for protein denaturation and starch gelatinization, could be printed at room temperature with a high water content (72%) and maintained its structure, with a shear-thinning index between 0.2 and 0.6 [25]. The rheological requirements of printing inks impose critical constraints on the mechanisms and parameters of the printing process. The process involves loading the ‘edible ink’ into a cartridge, syringe, or hopper and forcing it out using one of three main mechanisms selected based on viscosity. These include syringe-based extrusion (piston-driven, ideal for high viscosity), pneumatic extrusion (air-driven, for low viscosity), or screw-based extrusion (continuous material conveyance). Sometimes, materials such as chocolate are heated to melt them and facilitate flow. During printing, the printhead moves along the X-Y axes to trace the design, while the platform adjusts on the Z-axis to build the object’s height [20,42,45,46]. Extrusion printing is the most versatile technique for food printing, as it is compatible with a wide range of viscoelastic materials, including pastes and gels [45,47]. However, the success of extrusion also depends on other critical process parameters besides ink rheology [42,45,48,49,50,51,52], which researchers must calibrate according to the formulation. For example, nozzle diameter is a key factor that determines resolution and precision. A smaller diameter (e.g., 0.8 mm) provides finer resolution but increases shear stress, which can lead to clogging or inconsistent filament. For instance, in rice protein/starch inks, a 0.8 mm diameter resulted in poor performance and clogging. In gels encapsulating probiotics, reducing the diameter to 0.6 mm significantly decreased probiotic viability due to the high shear stress imposed [32,53]. On the other hand, using larger nozzles (1.5 mm or 1.8 mm) reduces resolution but allows for more consistent extruded lines and improves printing speed [11,27]. The distance between the nozzle and the deposited layer (layer height) is critical for adhesion and dimensional stability [31]. Printing quality strongly correlates with the ratio of layer height to nozzle diameter. If this ratio is too low, the material spreads out (a “squeezing effect”); if it is too high, the material does not adhere properly. In Jackfruit/Okra pastes, researchers determined an optimal ratio of 1.2–1.4 (standardized at 1.25). For extruded faba bean flour cubes, a height of 0.749 mm (70% of the diameter) achieved high shape fidelity (>100%) [10]. Printing speed and extrusion rate must be perfectly balanced with the material’s flow to ensure continuous filaments [22]. A speed lower than the optimum causes over-extrusion and “wavy lines”; a speed that is too high causes the “dragging effect” and under-extrusion. In fish surimi, a speed of 32 mm∙s−1 caused filament rupture, while 20 mm‧s−1 caused instabilities [31]. For lemon juice and starch gel, the optimal parameters were a 1 mm nozzle, an extrusion rate of 24 mm3∙s−1, and a speed of 30 mm‧s−1 [38] For raw (RFB) and extruded (EFB) faba bean flour, the optimal speeds were 2470.5 mm∙min−1 and 1505.43 mm‧min−1, respectively [54]. In general, speeds of 20–25 mm∙s−1 produced the best geometric match [54]. Furthermore, the process temperature modulates the ink’s apparent viscosity [38]. The temperature increase generally decreases viscosity. In Vegemite and Marmite pastes, as the temperature increased from 25 °C to 45 °C, the extrusion pressure had to be reduced from 172 kPa to 103 kPa [31,38]. For the high-viscosity raw faba bean flour (RFB), the process required a low temperature (23.18 °C); for the lower-viscosity extruded flour (EFB), researchers used a higher temperature (56.82 °C) to ensure cohesion [54]. Elevated temperatures can also affect functional components; for example, increasing the temperature to 65 °C drastically reduced probiotic viability [53]. The complexity of controlling these parameters highlights the clear and indispensable relationship between formulation and ink rheology. Common process problems, such as clogging, over-extrusion, or inconsistent filaments, occur precisely when the formulation lacks the appropriate rheological balance. Finally, an overarching negative aspect of this technology is its slowness, a barrier to industrial adoption. Scaling up requires optimizing speed, reproducibility, and material handling [33]. A slow manufacturing process contributes to high production costs for large volumes [38].

3.2. Binder Jetting (BJ)

Binder Jetting (BJ) technology binds particles of powder material (e.g., starches, sugars) through the selective deposition of a binder fluid (e.g., aqueous solutions) [26,28,55]. The process relies on a roller that distributes uniform layers of powder, followed by a printhead that jets the binder in accordance with the desired pattern [26,56]. The success of this technique demonstrates a direct dependence on formulation, as physical properties such as particle size, powder flowability, as well as the viscosity and surface tension of the liquid binder determine the printing resolution and the structural integrity of the part. The BJ critically depends on the compatibility and physicochemical properties of both the powder ink and the jetted binder fluid; these factors constitute the primary limiting factor for the precision, resolution, and mechanical stability of the final product [31]. Critical parameters include powder properties—such as particle size, flowability, and wettability and binder properties such as viscosity and density whose simultaneous control is crucial [22,55,56].

The powder properties such as with starches, sugars, or proteins must be free-flowing and non-sticky so the roller can spread thin, uniform layers, preventing poor recoating. A low angle of repose (30 °C) is required to ensure adequate flowability [31]. Particle size and distribution directly affect resolution and precision. The pore size distribution in the powder bed is crucial, as it affects the binder’s bonding capacity. A bimodal distribution is ideal, as the smaller particles fill the voids between the larger ones, reducing porosity and increasing mechanical strength [31]. Wettability determines how far the liquid binder disperses within the powder bed. Excessively low wettability can cause detrimental bed rearrangement, whereas excessively high wettability results in “bleeding,” reducing resolution and precision [22,31]. The powder used in BJ must have a moisture content below 6% for optimal behavior [31]. The binder, deposited in small droplets (diameter 100 μm), should preferably have a surface tension below 35 dyn‧cm−1 to prevent excessive spreading outside the target zone. The contact angle controls adhesion; angles below 50° are desirable for optimal compatibility and adhesion between the binder and the substrate. The amount of binder deposited per layer, expressed as saturation, is fundamental; optimal saturation improves bonding and integrity, while excessive saturation (over-saturation) produces weak structures and can lead to collapse [31,38]. Interactions at the powder-binder interface impose critical constraints on the process parameters. The simultaneous control of powder and binder properties is not just a recommendation; it is a process requirement. For example, variation in the powder’s particle size directly influences the pore distribution, which, in turn, affects the binder’s absorption and spreading capacity, thereby impacting the final precision and resolution of the object [31]. Parameters such as layer thickness and the curing temperature during printing are also determining factors, as they affect the balance between build speed and the achievable resolution [38]. Unlike techniques such as HME, where solidification is immediate, the BJ process inherently creates a primary structure (a “green body”) that is mechanically weak, as the initial bonding is achieved only through weak interactions between particles [26,31,40]. The very nature of the process—creating a weak structure held together by a liquid binder—makes extensive and mandatory post-processing the only pathway to obtaining a viable product. This post-processing focuses on two critical areas designed to compensate for the inherent lack of strength. The first is densification and thermal curing; in order to overcome the initial mechanical weakness and ensure structural integrity, the printed part must undergo thermal post-processing. This involves baking, heating, or high-temperature curing to increase mechanical strength and improve dimensional accuracy [26,31,38].

The curing temperature is a critical parameter: higher temperatures lead to faster curing and better mechanical properties, whereas lower temperatures result in slower curing and potentially weaker structures [38]. This step is also necessary to counteract the poor surface finish inherent to the technology. The second area is the removal of surplus powder. A key advantage of BJ is that the unbound powder provides mechanical support during printing, enabling the printing of complex geometries. However, this advantage necessitates a mandatory post-processing step: once printing finishes, operators must remove and recycle the unbound powder for subsequent use [40]. Consequently, the BJ technique, which uses liquid binders on dry powders, requires significantly more post-processing than HME. This post-processing is specifically designed to compensate for the inherent weakness of the initial bond through thermal curing and densification. Without these steps, the printed product would completely lack the stability and mechanical strength necessary for handling and consumption [17,31,40]. Binder Jetting (BJ) enables complex geometries that other technologies cannot achieve without external support structures because its unbound powder bed serves as an innovative, integrated support. However, BJ still requires intensive post-processing, which adds time to the total manufacturing cycle. This geometric freedom comes at the cost of a mandatory thermal consolidation stage and the logistics of powder handling and recycling.

3.3. Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a Powder Bed Fusion (PBF) technology that utilizes a high-power laser to melt selectively, or sinter pulverized materials layer-by-layer, creating a solid object [42,57]. Unlike Binder Jetting (BJ), SLS uses laser light or hot air to directly fuse powder components rather than a liquid binder [35]. The intrinsic properties of the powder material primarily limit the success of SLS; these properties must meet specific requirements for flowability, particle size, and thermal behavior. In the food domain, SLS primarily uses powders with low melting points, such as sugars, fats, cocoa, and starch, relying on the fusion of their lipid or saccharide components [31,32,33,48,58]. A free-flowing powder, ideally with a low angle of repose, is preferred to avoid insufficient recoating, which would compromise the precision and accuracy of the parts [31]. The density and compressibility of the powder are also crucial factors, as they significantly affect how the powder flows within the bin, which, in turn, affects pattern formation when the heat source is applied [31]. SLS, like Binder Jetting, is prone to the formation of voids due to powder shape and potential uneven bonding, which deteriorates mechanical properties. The powder’s wettability is also important for precision processes [31,35]. The fundamental goal is to achieve selective melting or sintering without material decomposition [32]. The nature of the powder material necessitates exact control over the laser parameters, which constitute the most important part of the process. A roller spreads the powder, and the laser scans the cross-section, heating the particles below their melting point to fuse them [22,26,55,56]. The energy density delivered to the powder controls the printing outcome; this density, in turn, depends on the laser power, scan speed, and laser spot diameter [31]. A higher energy density, typically achieved with higher laser power or lower scan speed, results in denser parts with greater mechanical strength due to longer interaction time and improved fusion. Conversely, a lower energy density results in a porous, fragile structure [31]. Reducing the laser spot diameter (e.g., to approximately 0.6 mm improves precision and resolution in the fabrication of colorful and detailed edible objects.

However, this improvement in resolution comes at the expense of a decreased build rate and may reduce the mechanical strength of the printed object [31]. The nature of the starting material (powder) and the solidification mechanism define the relationship between SLS and post-processing. The fundamental advantage of SLS is that the unfused powder acts as a natural support during printing, eliminating the need for additional supports and enabling the fabrication of complex geometries [20,55]. However, this advantage defines the primary post-processing step: once printing finishes, operators must remove and recover the unfused powder (unbound powder) for subsequent use [17,40]. The nature of the SLS process, which provides greater initial strength thanks to laser fusion, significantly simplifies post-processing compared to techniques like Binder Jetting. Whereas BJ requires extensive thermal densification to confer strength, post-processing in SLS is primarily limited to cleaning the support powder [17]. Nonetheless, laser sintering can leave a rough surface on the printed objects. Therefore, post-processing may require additional heating to improve surface smoothness or enhance mechanical strength [31,35,40]. In general, post-processing of 3D objects fabricated with SLS can also include operations such as polishing, sanding, and coating [17,35,40]. The ability of the powder bed to act as a natural and integrated support eliminates the need for dedicated support structures and allows for complex geometries [17,34,35,40]. However, an inherently rougher surface finish is obtained compared to other technologies [17]. While laser fusion confers an initial strength superior to that of BJ and reduces the need for extensive thermal curing, the user must accept that the “as-printed” parts will almost always require a powder removal step and potentially a polishing or heat surface treatment to achieve the desired quality [17,35]. However, due to the granular nature of the raw material and the partial fusion mechanism (sintering), the resulting objects inherently exhibit a higher surface roughness and porosity compared to liquid deposition techniques [17,33,35,42,45].

3.4. Inkjet Printing (IJP)

Inkjet Printing (IJP) technology represents a case where formulation constraints dictate a specialized process and an immediate solidification post-processing. This method deposits micro-droplets of low-viscosity liquid material onto a substrate, establishing an intrinsic relationship between fluid physics, the deposition mechanism, and the need for instantaneous curing [26,55,56,57,59]. Inkjet Printing (IJP) technology operates under formulation constraints, as the process is limited to the deposition of micro-droplets of very low-viscosity liquids [26,55,56,57,59]. Due to this high fluidity, structural integrity depends on an immediate or in situ solidification mechanism (a simultaneous post-processing), such as curing or rapid cooling, to set the material. Therefore, in IJP, there is an intrinsic relationship between formulation, the deposition mechanism (process), and solidification (post-processing). The acceptable viscosity must be in an extremely narrow range, ideally between 2.8 and 6 mPaּּs. Viscosity above this threshold can cause cavitation in the printhead pump, while viscosity below it results in unstable droplet behavior [31]. In addition to viscosity, the process precision critically depends on other interfacial properties such as surface tension, contact angle, and the fluid’s rapid drying rate [22,26,55,56,57]. In the food sector, this limitation restricts formulations to materials such as purées, chocolate, icings, sauces, and dressings that can meet these rheological requirements [33,35]. The low viscosity of these formulations is the primary limiting factor affecting all subsequent stages of the manufacturing chain.

The strict formulation demands highly specialized printing mechanisms. Printheads can be thermal (TIJ), which use heat to create a vapor bubble that ejects the droplet, or piezoelectric, which utilizes a piezoelectric crystal that vibrates to generate the droplet [22,26,56]. This choice has direct implications for the formulation, as thermal printheads can degrade thermolabile compounds [35,42], adding another constraint to the food ink design. The operating modes, which include Drop-on-Demand (DOD) or Continuous (MJ-CS) [18,42,60,61], along with processing parameters such as printhead type, printing speed, nozzle diameter, and resonance frequency, must be controlled to maintain the precision that characterizes this technology [26,31,38]. The most significant consequence of using low-viscosity materials is that IJP generally lacks sufficient mechanical strength to build self-supporting 3D structures [31]. This intrinsic limitation dictates that its primary application focuses on printing two-dimensional images, such as surface filling or decoration on foods (e.g., cookies, cakes, or pizzas), or on creating complex soft structures with high resolution [31,32,35]. The dependency chain culminates in a post-processing step that is intrinsically intertwined with the deposition process itself. Since the formulation in IJP consists of low-viscosity liquids—whether biopolymers, hydrogels, or inks—the printed structure completely lacks inherent mechanical support, making solidification a mandatory step during deposition. The type of post-processing most associated with IJP focuses on Immediate Layer-by-Layer Curing or Solidification and on droplet management to ensure precision. Curing is typically performed with equipment installed on the printing platform itself, using UV light (for photopolymerizable resins), an optical process (such as exposure to infrared or ultraviolet radiation), or low-temperature heat [26]. In 3D printing systems that use inkjet, each deposited layer has its own curing equipment. This process, although it may sound slow, is performed rapidly because the formed layers are fragile [26].

Post-processing also involves procedures to ensure that uncontrolled material flow does not compromise IJP’s high resolution. Achieving precise, accurate printing requires an appropriate jetting rate and rapid drying of the ink droplets. If we jet too much ink, the droplets can coalesce before drying, resulting in a loss of precision. To accelerate drying, operators can apply a stream of dry gas or add alcohol to the ink [31]. Post-processing in IJP is thus an extension of the deposition process itself, where interlayer curing primarily UV-assisted is the fundamental and mandatory operation that provides stability to 3D structures or layers of liquid material [35]. IJP technology offers resolution and the capability to deposit functional and decorative materials with microscopic precision, making it ideal for personalization and value-added applications in the food industry. However, this benefit is offset by severe limitations in the construction of 3D self-supporting structures and the need for an immediate-curing system integrated into the process. The designer must accept that fluids of a particular viscosity restrict material freedom and that a layer-by-layer solidification process limits the manufacturing speed and adds complexity to the system during the construction of substantial 3D objects. The choice of IJP thus represents a specialization toward high-precision and decorative applications rather than the fabrication of load-bearing food structures. While Food Additive Manufacturing encompasses diverse technologies such as Binder Jetting, Selective Laser Sintering, and Inkjet Printing, this review focuses particularly on Extrusion-Based Printing. This methodological decision responds to the predominance of this technology in scientific literature. Extrusion accounts for the most significant percentage of research in the field, due to its versatility in processing a wide range of semi-solid food materials. To synthesize the technical differences and specific requirements of the 3D printing methods, Table 1 presents a comparative analysis of the 3D printing technologies discussed. This summary classifies compatible formulations, critical process parameters, and mandatory post-processing stages, illustrating the interdependence between the ink’s nature and the necessary stabilization strategy.

Table 1.

Comparative analysis of 3D food printing technologies, compatible formulations, critical process parameters, and mandatory post-processing stages.

4. Formulation Requirements and Their Effect on Post-Processing

The evaluation of success in food additive manufacturing must go beyond geometric fidelity and consider the product’s characteristics after post-processing. “Printability” must, therefore, encompass post-processing stability—the intrinsic ability of a formulation to withstand subsequent treatments and develop the desired textural, organoleptic, and safety properties [22,31]. This section analyzes how ingredient selection and modification, such as hydrocolloids and proteins, are used to create stable microstructural networks that ensure final integrity and quality during thermal and non-thermal operations. If the printed object cannot retain its integrity or develop the desired textural properties after processes such as baking or cooking, the printing process lacks practical value [22,28,65]. The final properties—texture, flavor, aroma, and overall acceptance—depend critically on post-processing-induced transformations, such as protein denaturation and starch gelatinization [22,66,67,68]. Therefore, the designer must intrinsically link formulation design to the selected process and post-processing [33,38]. The selection of hydrocolloids and starches guides their ability to create stable networks during thermal post-processing. For example, Astragalus polysaccharide is incorporated into wheat starch not only to improve molding during printing but also to compete for water and restrict molecular mobility during baking, thereby improving final precision [11]. Similarly, adding okra powder to jackfruit flour increases gel strength and water-holding capacity (WHC), properties crucial for preventing structural collapse during thermal treatments [5]. The literature reports specific material combinations that directly address post-processing challenges; for example, Xanthan Gum and Agar provide the necessary rheology in pea protein to maintain shape after extrusion [69]. Flammulina velutipes polysaccharides (FVPs) stabilize soy protein isolate (SPI) gels, achieving an ideal tanδ that ensures post-deposition dimensional stability [70]. Carrageenan and Gellan Gum are required in peanut protein to form a printable matrix that gels stably [71]. Combinations of xanthan gum, kappa-carrageenan, and konjac glucomannan (KGM) in whey protein improve post-extrusion shape retention [72,73]. Sodium alginate acts as a stabilizer in cricket protein, facilitating a structure that withstands subsequent processing [74]. Carboxymethylcellulose (CMC) in egg yolk emulsions increases viscosity and structural recovery, which is crucial for post-printing stability [75]. Modified Starches, such as pregelatinized starch, improve stiffness and structural recovery in SPI inks, ensuring integrity during thermal curing [67,76]. Proteins develop specific textures when researchers explicitly formulate them for post-processing. For example, researchers designed pea protein in salmon analogs for enzymatic post-processing with transglutaminase (TGA), which induces a stable fibrous structure [77]. Similarly, the whey protein-pectin interaction creates a heat-resistant network that prevents collapse in baked cookies [78].

For freezing applications, the addition of antifreeze peptides to surimi inks protects the protein network during freeze denaturation [12]. Given that native proteins typically form weak gels, modifications are required to achieve post-processing stability. Pea protein (PPI) requires enzymatic hydrolysis or linseed oil to achieve the functionality required for subsequent treatments [69,79]. Soy protein (SPI) is combined with red cabbage powder, pregelatinized starch, or FVPs to enhance its structural resistance after thermal treatment [50,70,76]. Other vegetable proteins (peanut, fermented brown rice, mung bean) are formulated with additives that ensure post-printing stability [66,69,71]. Egg proteins are stabilized with CMC to achieve adequate structural recovery after deposition [75]. Fish proteins are utilized in Pickering emulsions that maintain stability during subsequent processing [80]. Dairy proteins (whey, casein) are combined with hydrocolloids and starches to improve the morphology and final strength of the printed product [67,72,73,81,82,83]. Alternative proteins (insects, mushrooms) are blended with other biopolymers to enhance their rheological and gelling behavior for specific applications [74,84,85]. Qu et al. [9] formulated pea and quinoa protein with XG and CMC specifically to achieve a stable “IDDSI Level 5” texture after printing, providing both texture and safety. Marques et al. [10] used mycoprotein with alginate for “instantaneous post-processing” through CaCl2 cross-linking, where the formulation defines the final texture (hardness) for dysphagia. Rodríguez-Fernández et al. [25] showed that prior extrusion of chickpea flour alters its hydration and rheological behavior, thereby influencing its performance during post-processing. Soundara Rajan et al. [86] quantified how a pea protein-starch formulation responds differently to baking vs. steaming, affecting final properties such as hardness and shrinkage. Dos Santos et al. [87] highlight shape-memory materials (e.g., PLA) in which the formulation contains the transformation mechanism, making “post-processing” an intrinsic, programmed response. Yu et al. [53] describe systems, such as HIPEs and bigels, that enable the stable co-encapsulation of nutrients, ensuring their integrity during and after processing. Kok Wah [16] explores the use of machine learning (ML) to predict formulation behavior during post-processing, accelerating the design of “post-processable” inks.

5. Effect of Printed Microstructure on Post-Processing

The effectiveness of any post-processing technique depends on the microstructural characteristics of the intermediate part or structure produced by the printing process [69,70,71,72]. Parameters such as infill pattern, layer height, and extrusion speed define a unique physical substrate with specific porosity, density, and mechanical strength, which govern phenomena such as heat and mass transfer and shrinkage during subsequent treatments [20]. This section examines how the geometry and properties created by the printing process affect the organoleptic and structural outcomes of the final product. In 3D Food Printing (3DFP), especially with cereal-based doughs, a post-deposition cooking process, such as baking, steaming, or frying, is often required [20]. During these processes, several transformations take place: chemical reactions, such as Maillard reactions and protein denaturation; physical transformations in color, volume, and texture; and shrinkage and water loss, where, for example, in 3D-printed wheat-based products, the experimental diameter of the samples decreased after cooking [20]. The printed structure’s ability to withstand these transformations defines the ultimate value of the additive manufacturing process. The microstructure formed during printing dictates heat and mass transfer and volatile compound escape, thus determining whether the part cooks uniformly, collapses, cracks, or loses flavor. The selected thermal method directly affects the final properties, but the printed structure mediates this impact. Zhang et al. [78] designed a whey protein–pectin formulation to create a heat-resistant gel network that would prevent collapse during baking. Soundara Rajan et al. [86] (2025) directly compared baking and steaming in pea protein and starch inks, quantifying how these two methods, acting upon the same printed structure, differently affected final hardness, shrinkage, and moisture retention. In products like 3D-printed noodles, the cooking characteristics the leading indicator of quality depend directly on the hydrocolloid formulation in the ink and the printed structure [21].

In cookies, triglycerides regulate the melting point of the deposited layers and, thus, the self-support properties of the material; fatty acids with more atoms have higher melting points. For example, an increase in butter concentration during formulation and processing decreases stability during baking [20]. Increasing the amount of egg yolk in the formulation enhances width stability but diminishes height stability. Protein denaturation caused by the baking temperature significantly affects the material’s viscosity. In baked cookies, researchers observed that the exterior sank. At the same time, the interior geometry remained preserved, indicating shrinkage due to water loss and an increase in porosity, both of which depended on the initial structure created by the printer [20]. Yin et al. [88] printed a chicken paste with different oils. The microstructure of the emulsion, defined by shear in the nozzle during extrusion (process), determined the outcome of baking (post-processing). The addition of soybean oil resulted in smaller droplets, facilitating a more stable interaction between the oil and the protein. This microstructure yielded greater shape precision after baking at 160 °C for 15 min and a fluid loss of 18.9–21.4%. When the same matrix was microwave-heated (280 W for 80 s), researchers achieved greater internal stability, maintaining water retention (losses of 11.6% and 14.6%) and structural integrity. The microwave’s tendency to favor hydrogen and ionic bonding, along with a more uniform heat distribution within the existing microstructure, explained this difference. The microwave-heated samples achieved greater precision (as measured by surrounding size). They better maintained the three-dimensional matrix, which stemmed directly from the lower fluid extrusion enabled by the structure they created [88].

6. 4D Printing

While conventional 3D Printing creates stable structures, 4D Food Printing (4DFP) focuses on designing materials that change shape, texture, or functionality predictably in response to specific stimuli (moisture, heat, pH) applied after Printing, thereby introducing the temporal dimension as a design variable [89,90]. In this technology, the final effect on printed food determines the requirements of the formulation and the parameters of the printing process [91]. The formulation in 4DFP must incorporate programmable materials with a specific responsiveness to post-processing stimuli. Polysaccharides such as carrageenan and gellan gum possess thermo-reversible properties that allow their hydrogels to function as recyclable, printable, edible inks [71]. Controlled structural deformation in 4D Printing (4DFP), such as that observed in alginate- and methylcellulose-based hydrogels, is a mechanism induced by the materials’ moisture sensitivity [92]. These materials, which have a high affinity for water, absorb the liquid and swell, facilitating the formation of a gel network [92]. Oleogels are heat-sensitive, forming or melting at different temperatures, which confers reversible properties to external stimuli [93]. Biphasic systems such as bigels (composed of hydrogels and oleogels) are particularly promising, as they can undergo phase inversion in response to temperature changes, leading to controlled alterations in their shape [93]. The functionality of the inks extends beyond structural changes to encompass visual and monitoring transformations. The sensitivity of natural pigments to changes in pH constitutes a mechanism for achieving color change in 4D Printing [89,92]. Anthocyanins, widely distributed in fruits and vegetables such as purple sweet potato, undergo transitions from the flavonoid form (red) to the alkaline quinone form (blue) with increasing pH [93]. This capability is leveraged to generate spontaneous color changes by printing composite structures with anthocyanin-rich purées and variable-pH purées containing citric acid or sodium bicarbonate [89,94]. Similarly, curcumin demonstrates pH sensitivity, changing from yellow under acidic conditions (pH 3.0–7.0) to orange or red under alkaline conditions [89,93]. This pH sensitivity allows these pigments to be used in 4DFP to monitor the freshness status of the printed food, as the release of volatile compounds during decomposition modifies the ambient pH [84,95,96]. Proteins play a crucial role in forming semi-solid materials for 4DFP [90], where their response to temperature increase forms the basis for shape-shifting functionality and the improvement of the final texture [90,92]. An increase in the protein content of an oat/SPI printing paste directly correlates with an increase in the structure’s bending angle, leading to a more pronounced deformation during post-processing [97]. Thermal activation leverages phase transitions and chemical reactions, such as Maillard or caramelization reactions, that are programmed into the formulation, while the process controls heat transfer and the kinetics of transformation [78]. The printing process in 4DFP must create geometries and microstructures that act as mechanisms to amplify or direct the response to the stimulus during post-processing. Printing parameters, including infill patterns, filament orientation, and layer thickness, are specifically optimized to create microstructures that mechanically channel the post-processing response [97]. 4D-printed products are thus specifically designed to undergo controlled changes in texture, size, shape, color, flavor, or nutrient profile in response to time or specific stimuli [90,98].

7. Post-Processing

Post-processing is the critical stage that transforms the printed structure into edible, palatable food. However, the microstructural and mechanical characteristics of the intermediate structure created during the printing process predetermine its success [20]. The porosity, density, adhesion, and mechanical strength of the printed part act as the substrate that conditions the efficacy of any thermal treatment. The microstructure dictates how heat transfers and how volatiles migrate, defining whether the part cooks uniformly, collapses, or cracks. Therefore, maintaining the three-dimensional shape during cooking is a central challenge at this stage. The solution lies in the joint optimization of the formulation and process parameters so that the structure withstands transformations, such as shrinkage due to water loss, protein denaturation, and Maillard reactions [20].

7.1. Thermal Post-Processing

In baking, the formulation and process must create a stable structure. For example, the addition of bovine gelatin (1.79%) and kappa-carrageenan to chicken snacks was crucial for integrity during baking, as synergistic interactions created additional bonding zones [18,49]. Zhang et al. [78] designed a heat-resistant gel network of whey protein and pectin explicitly to prevent collapse. In cookies, Caporizzi et al. [20] reported that the lipid formulation determines stability; an increase in butter decreased stability, while egg yolk improved dimensional stability in width but not in height. These studies demonstrate that shrinkage and increased porosity depend on the initial structure. Başoğlu et al. [99] found that zucchini and rice inks that went through a freeze–thaw cycle before printing retained a smooth surface after baking, unlike fresh inks, which developed cracks.

Frying imposes severe demands that the formulation must mitigate. Bhuiyan et al. [100] studied fried meat analogs and found that the addition of hydrocolloids (2%) directly impacted dimensional stability and mass loss. Xanthan gum exhibited the highest stability (98.6%), while guar gum yielded the lowest mass loss (5.69%), suggesting that water retention capacity links to frying outcomes. In other meat analogs, the protein source selection (mung bean isolate vs. faba bean or pea) determined superior stability during frying. Air-frying also depends on the formulation-process interrelationship. Feng et al. [101] demonstrated that dietary fiber in yam pastes formed a barrier that facilitated uniform moisture elimination, reducing deformation. Similarly, Liu et al. [102] linked the rheological properties (G′ > G″) of a sweet potato ink to the formation of a precise porous structure that allowed steam to escape, preventing puffing during air-frying. Microwave heating interacts with the microstructure differently from conventional methods. Yin et al. [88] provided a direct comparison of chicken paste. The microstructure of the emulsion, defined by shear in the nozzle, determined a fluid loss of up to 21.4% during conventional baking. In contrast, microwaving (280 W, 80 s) resulted in greater internal stability and a loss of only 11.6%. This was attributed to the formation of distinct chemical bonds and a more uniform heat distribution. Microwave drying has also proven to be superior for nutrient retention. Krishnaraj et al. [103] found that microwave drying (280 W) of high-fiber snacks retained protein and fiber levels similar to those of raw flour, unlike frying, which caused significant losses. Comparative studies confirm that the thermal post-processing method is as important a design variable as the formulation.

When Soundara Rajan et al. [86] applied baking and steaming to the same pea protein ink, they obtained significant differences in hardness, shrinkage, and moisture retention. Theagarajan et al. [104] analyzed rice starch inks. Wet-heat methods (steaming, blanching) produced softer, gelatinized textures, with steaming being superior for shape fidelity. Dry-heat methods (toasting, deep-frying) increased hardness and fracturability, but deep-frying best preserved shape. Microwaving, however, resulted in the most significant shrinkage and arching. The authors concluded that while the starch formulation provides the printing functionality, it is the specific post-processing conditions that determine the final microstructure. Finally, other thermal methods, such as sous vide, also reveal this interdependence. Dick et al. [105] utilized dual extrusion to create lean meat structures with internal layers of lard (fat). During sous-vide cooking (75 °C, 30 min), an increase in the content of fat deposited in layers (a process parameter) directly correlated with a higher cooking loss and shrinkage, resulting in a less complex texture.

7.2. Gelation and Curing

Beyond purely thermal post-processing, researchers often engineer final structural stability through chemical, enzymatic, or physical treatment, where the formulation and process interact to create more robust molecular networks.

7.2.1. Enzymatic Treatment

Enzymatic treatment, predominantly using Transglutaminase (TG), is utilized to induce a “paste-to-solid” transformation through covalent bond formation. The success of this method depends on the interrelationship between formulation and process. Wu et al. [77] demonstrated its use in salmon analogs based on pea protein (PP), corn starch (CS), and flaxseed oil (FO). The formulation included TG (0.52 U/g of protein), which was activated in a post-printing incubation stage (55 °C) to induce cross-linking. This structure, already enzymatically cured, remained stable during subsequent thermal treatment (microwaving at 800 W) and exhibited a fibrous texture similar to that of fish muscle. However, the cooked analogs showed greater hardness and gumminess than real salmon, an effect attributed to water loss during the heating of the already cross-linked network [77]. This cure first and heat later strategy is common in foods for dysphagia. Zhu et al. [106] employed TG (0.5% w/w) in a surimi ink to achieve the necessary high printing precision and deformation resistance. Nevertheless, when this type of cured structure is subjected to high-temperature post-processing, such as air frying and steaming, it often leads to structural failure in dysphagia diets. Specifically, the high moisture loss observed during air frying (23.14% loss) and steaming (17.01% loss) causes the contraction of the protein matrix [106], resulting in a denser and stiffer structure. This structural change causes the resulting texture to exceed the hardness limits established by IDDSI standards due to excessive crust formation or protein leaching [106]. In contrast, microwave (5.55% loss) and electric oven heating (4.25% loss) met the criteria. These methods, applied to the enzymatically stabilized structure, maintained internal moisture and an easy-to-chew texture, demonstrating how the initial curing enables the success of thermal post-processing [106].

7.2.2. Laser-Assisted Solidification

Post-processing can also be integrated into the process by applying focused energy. Tong et al. [64] (2024) addressed the instability of meat proteins (surimi) by using Selective Laser Sintering (SLS) as a post-processing method. Following extrusion of the surimi paste, the application of a laser (0.4 J∙mm2) induced localized, instantaneous thermal gelation. This method formed a stable three-dimensional gel network, maximizing dimensional accuracy, hardness, and elasticity. The authors note that this curing approach overcomes the problems of slow heat transfer in traditional processing, which leads to heterogeneous temperature profiles and product deformation.

7.2.3. Ionic Cross-Linking (Chemical Curing)

Ionic cross-linking is a fundamental chemical curing method, especially in alginate systems. Marques et al. [10] analyzed this mechanism in mycoprotein and potassium alginate inks intended for dysphagia. The study combined the process and curing via coaxial printing, cross-linking the ink in situ with a solution of calcium ions (CaCl2 or calcium gluconolactate). In this case, the primary texturization mechanism was chemical: the type and concentration of the cross-linker modulated the final hardness. Calcium gluconolactate produced soft textures (1.3 N), while Calcium Chloride (CaCl2) significantly increased hardness (up to 4.68 N) and cohesiveness. Subsequent thermal post-processing (microwaving at 600 W for 30 s) was not the texturizing agent but a standardized step to simulate consumption conditions. The results also showed an interdependence with formulation: higher alginate concentrations (10%) led to greater cooking loss (10.9%) and shrinkage (10.09%), as the stronger network formed by ionic cross-linking had a reduced capacity to retain water.

7.3. Freeze-Drying and Microstructure Control

Freeze-drying is strategically employed to minimize the structural deformation and degradation of heat-sensitive nutrients that occur during baking or other thermal methods. A key finding with this method is that the formulation, rather than the printing rheology, can be the determining factor in the final texture. Jo et al. [107] investigated this relationship by freeze-drying a red ginseng paste (20% w/w) stabilized with different types and concentrations of starch, such as waxy corn starch (WCS), tapioca starch (TS), and potato starch (PS). The study showed that the mechanical properties (hardness) and microstructure of the resulting freeze-dried snacks were independent of the ink’s initial rheological properties or its “printability”. Instead, the final texture directly depended on the type and concentration of the starch (the formulation). For example, samples containing potato starch (PS), which has a higher amylose content, exhibited lower compression hardness and a porous structure with nonuniform voids. In contrast, samples with WCS and TS produced finer, more homogeneous structures with higher hardness. This study underscores that ingredient selection in the formulation determines the outcome of a specific non-thermal post-processing.

7.4. Freezing and Storage Stability

Post-processing also encompasses storage, a stage at which freezing poses a critical challenge to structural integrity. While initial active cooling is often necessary for immediate post-extrusion shape stability [35], long-term freezing can induce damage. Protein inks, such as surimi, are particularly susceptible to denaturation and water loss during freeze–thaw cycles. Therefore, the formulation must be designed to create a robust network for example, by adding antifreeze peptides to protect the integrity of the protein network during storage [12]. The use of hydrocolloids is a key strategy for maintaining textural stability during these cycles. Dick et al. [108] investigated this interaction in pork meat pastes formulated with and without xanthan gum and guar gum (0.36%), which also facilitates cold Printing. The samples were subjected to a complete cycle of freezing (−18 °C), heating (100 °C for 7 min), and cooling (37 °C) to simulate meal preparation. The results showed significant differences: the control sample (without gums) exhibited a significant reduction in the loss tangent (tanδ) after the cycle, indicating a more solid and elastic behavior at consumption temperature (35 °C). This correlated with greater hardness and cohesiveness, attributed to a severe shrinkage of the protein matrix and water expulsion. In contrast, the samples with hydrocolloids maintained more viscous behavior. Structural analysis revealed that the gums prevented excessive shrinkage of the matrix during heating. This resulted in a less dense final structure with larger cavities, greater water retention, and, consequently, a softer, more flexible texture.

8. Post-Processing in 4D Printing

Unlike 3D Printing, which creates stable structures, 4D Food Printing (4DFP) designs objects with programmed micro- and macro-structures that self-transform in response to a specific stimulus. The mechanism is based on shape-memory materials that, after fabrication, can be programmed and activated by a stimulus to achieve a final shape [87]. Since the final effect is the design objective, this intrinsically determines the requirements of the formulation and the parameters of the process.

8.1. Programmed Deformation and Expansion

In 4D Printing, thermal post-processing functions distinctively: it is not merely a cooking step for biological safety but serves primarily as an activation trigger for deformation. While the process ensures safety, its design objective focuses on the microstructure responding predictably to heat. The printing process is designed so that the microstructure responds predictably to heat. Guo et al. [109] demonstrated this principle in starch inks, where the formulation or complete starch gelatinization using microwaving before printing was a crucial prerequisite for the 4D response. The process created the pregelatinized structure, and microwaving at 200 W (post-processing) activated the “flowering” deformation. The key mechanism was “micro puffing”, an expansion caused by the vaporization of water over the predefined starch microstructure. The drying method also functions as a differential stimulus. Dick et al. [63] observed that, in identical 4D structures, hot-air drying caused a greater bending angle (morphing) than freeze-drying. This happens because thermal penetration of hot air induces a heterogeneous moisture distribution in the printed structure, thereby activating the deformation, whereas freeze-drying preserves the microstructure by minimizing volume reduction. In other studies, the formulation is adjusted to modulate the heat response. Lv et al. [110] used sodium alginate in chestnut flours to improve structural stability (high G’ and rapid recovery)—the alginate enhanced water retention during microwaving (200 W), increasing deformation resistance. However, combined infrared and microwave heating of the same alginate formulation resulted in a rigid surface, reducing the desired deformability.

8.2. pH Change

In this case, the printing process (e.g., dual nozzle) deposits a sensitive formulation adjacent to the stimulus. Zhu et al. [111] employed this method for automatic color change. The first structure used potato purée with anthocyanins (the sensitive formulation) printed onto a starch and lemon juice gel (the acidic stimulus). The speed of the post-printing color change (post-processing) directly correlated with the stimulus formulation: a lower starch concentration in the lemon gel facilitated the diffusion of hydrogen ions (H3O+), thereby accelerating the color change. In a second structure, microwaving (post-processing) activated an internal pH change, decomposing sodium bicarbonate in a curcumin emulsion (the formulation) to induce the color change. This formulation improved rheological properties for Printing and, simultaneously, conferred thermal resistance during superheated steam cooking (120 °C, 8 min). After cooking, spraying an alkaline solution (pH 10) activated the pre-programmed color change in the stable formulation, acting as the post-processing stimulus [112].

8.3. Creation of Porous Microstructures

Four-dimensional (4D) Printing is also applied to transform a stable emulsion into a solid macroporous structure, where physical post-processing (the removal of one phase) is the design objective. Shahbazi et al. [113] developed thermo-sensitive high internal phase Pickering emulsions (HIPEs). The formulation (emulsions stabilized with starch nanomaterials) exhibited pseudoplastic rheological properties and rapid structural recovery (82–87%), which formulators designed as optimal for the extrusion process. The post-processing consisted of two programmed physical steps: first, washing with ethanol and water to remove the internal oil phase, and second, freeze-drying to remove the solvent. This post-processing transformed the printed emulsion into the desired 4D macroporous structure, which was the final design objective.

9. Study Limitations and Future Perspectives

A complex series of challenges currently limits the large-scale implementation of three-dimensional (3D) food printing (3DFP) and four-dimensional (4D) food printing (4DFP). A fundamental obstacle lies in the formulation of the inks, which must possess a precise rheological balance: being fluid enough for extrusion (pseudoplastic behavior) while simultaneously having rapid structural recovery (high Storage Modulus (G′)) to resist gravity and prevent collapse [50,90,114]. Technically, the technologies face low production speeds and the difficulty of integrating high-speed, high-resolution capabilities within a single platform, impeding industrial scaling [42,45]. Furthermore, internal flaws and structural distortion compromise dimensional accuracy [115,116]. Post-processing itself, though crucial for 3D stability [117] and 4D stimulus induction [89], inevitably distorts the matrix [63,115], causing shrinkage or expansion that deviates the part from the original digital design [20,117].

These challenges diverge depending on technology. For instance, in 3DFP, researchers face the challenge of maintaining stability and precision across subsequent treatments (e.g., baking, drying) that can cause undesirable deformations [62]. Meanwhile, in 4DFP, the limitation lies in quantifying and controlling the shape change over time when the stimulus (e.g., heat, pH) is applied [97]. 4DFP adds further complexity by requiring predictive models to integrate material properties and geometric parameters to control the transformation dynamics [97,118]. Added to this is the instability of 4D structures and the need for shape-memory systems that enable reversible, repeatable deformations, as many current systems achieve only single, slow transformations [93,109]. To address these limitations, future research perspectives in 3DFP and 4DFP are focusing on process optimization and the integration of advanced technologies to manage or eliminate the complexity of post-processing. A key direction is the integration of Artificial Intelligence (AI) and the Internet of Things (IoT), whose algorithms can predict material behavior and optimize printing parameters in real-time [42,109]. This approach can enable the seamless integration of process and post-processing. Current studies aim to combine printing and cooking in a single machine, using lasers or infrared lamps to selectively and simultaneously thermally stabilize foods as they are printed [80,119]. These thermal stabilization efforts are complemented by the development of new techniques, such as self-gelation during printing via pH or temperature control [120], which aim to minimize unfavorable effects, such as nutrient loss, associated with current methods [121]. In the 4D printing domain, researchers are focusing on materials that enable repeatable, reversible deformation [35]. Finally, commercial success will depend on future research into consumer acceptance and the definition of legal and regulatory frameworks for the safe incorporation of bioactive ingredients [122].

10. Conclusions

The commercial viability of Additive Food Manufacturing fundamentally depends on optimizing the interdependence among ink formulation, printing process parameters, and post-processing. In 3D Printing, printability must include post-processing stability, requiring formulations that resist undesirable phenomena such as shrinkage or collapse during thermal processing. Conversely, 4D Printing intentionally leverages this relationship, designing programmable materials whose functionality is activated by stimuli, such as those provided by the post-processing stage, which serves as the activator of programmed functionality. For industrial scaling, challenges persist in the low production speed and the geometric distortion inherent to post-processing. The future lies in integrating Artificial Intelligence to create predictive models that enable joint optimization of design variables, facilitating the development of in situ curing systems and, in turn, reducing the complexity of later stages—an essential step for the precise and safe manufacturing of functional foods.

Author Contributions

Conceptualization E.J.P.-M. and A.M.C.-G. methodology, E.J.P.-M.; resources E.J.P.-M.; writing—original draft preparation E.J.P.-M. and A.M.C.-G.; writing—review and editing, A.M.C.-G., M.R.d.M., F.A.A. and E.J.P.-M.; visualization, E.J.P.-M. and A.M.C.-G.; supervision, E.J.P.-M.; project administration, E.J.P.-M.; funding acquisition, E.J.P.-M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Ministerio de Ciencia Tecnología e Innovación and the Fondo Nacional de Financiamiento para la Ciencia, la Tecnología y la Innovación “Francisco José de Caldas” by Posdoctoral Fellowship (Convocatoria 934 de 2023—Grant No 112721-306-2023).

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

Author Ezequiel José Pérez-Monterroza was employed by the company Alimentos de la ABIBE S.A.S. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Hai Alami, A.; Ghani Olabi, A.; Khuri, S.; Aljaghoub, H.; Alasad, S.; Ramadan, M.; Ali Abdelkareem, M. 3D Printing in the Food Industry: Recent Progress and Role in Achieving Sustainable Development Goals. Ain Shams Eng. J. 2024, 15, 102386. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, M.; Tang, T.; Adhikari, B.; Li, C. Novel Technologies to Produce Nutritious Texture-Modified Foods for Elderly: Advances, Challenges and Applications. Food Biosci. 2025, 67, 106362. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, H.W.; Park, H.J. Effect of Pea Protein Isolate Incorporation on 3D Printing Performance and Tailing Effect of Banana Paste. LWT 2021, 150, 111916. [Google Scholar] [CrossRef]

- Kim, H.B.; Kim, S.W.; Ko, J.B.; Yang, Y.J.; Oh, G.Y.; Kim, Y.W.; Kim, H.C. Optimization of Extrusion Process for 3D Hard Candy Manufacture. J. Manuf. Process 2021, 71, 580–588. [Google Scholar] [CrossRef]

- Velvika, S.; Swaraj, N.; Shanker, M.A.; Ahmad, F.; Krishnan, V.C.A.; Ghosh, P.; Rana, S.S. A Study on Composites from Okra and Jackfruit Powder as Food Material for 3D Printing. Discov. Appl. Sci. 2025, 7, 677. [Google Scholar] [CrossRef]

- Guo, Z.; Yang, B.; Liang, N.; Huang, X.; Shi, J.; Li, Z.; Paximada, P.; Xiaobo, Z. 4D Printing of Pickering Emulsion: Temperature-Driven Color Changes. J. Food Eng. 2025, 386, 112258. [Google Scholar] [CrossRef]

- Herrera-Lavados, C.; Tabilo-Munizaga, G.; Rivera-Tobar, D.; Carvajal-Mena, N.; Palma-Acevedo, A.; Moreno-Osorio, L.; Pérez-Won, M. Development of Bean-Based Emulgels for 3D Printing Applications: Feasibility for Dysphagia Diets. J. Food Eng. 2023, 358, 111687. [Google Scholar] [CrossRef]

- Li, C.; Yu, X.; Wang, Y.; Prakash, S.; Dong, X. Innovative 3D Printed Multigrain Rice and Silver Carp Surimi Diets: Rheological, Textural, and Nutritional Solutions for the Elderly with Dysphagia. Food Biosci. 2024, 62, 105314. [Google Scholar] [CrossRef]

- Qu, G.; Yang, F.; Zhang, J.; Liu, F.; He, X.; Gao, Y.; Sun, S. High Methoxy Pectin Regulates Quinoa Protein Isolate-Tannic Acid Complex to Stabilized High Internal Phase Emulsion via Non-Covalent Interactions for Enhanced 3D-Printed Foods. Food Chem. 2025, 492, 145497. [Google Scholar] [CrossRef]

- Marques, A.M.; Oliveira, S.M.; Martins, A.J.; Bourbon, A.I.; Rousta, N.; Taherzadeh, M.J.; Teixeira, J.A.; Cerqueira, M.A.; Pastrana, L.M. Use of a Coaxial Nozzle-Assisted 3D Printing and Ionic Crosslinking to Control the Texture of a Mycoprotein-Based Food Product. Future Foods 2025, 11, 100530. [Google Scholar] [CrossRef]

- Xia, G.; Tao, L.; Zhang, S.; Hao, X.; Ou, S. An Optimization Study of 3D Printing Technology Utilizing a Hybrid Gel System Based on Astragalus Polysaccharide and Wheat Starch. Processes 2024, 12, 1898. [Google Scholar] [CrossRef]

- Tian, H.; Chen, X.; Wu, J.; Wu, J.; Huang, J.; Cai, X.; Wang, S. Nondestructive Frozen Protein Ink: Antifreeze Mechanism, Processability, and Application in 3D Printing. Int. J. Biol. Macromol. 2024, 277, 134009. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, D.; Wei, G.; Ma, Y.; Bhandari, B.; Zhou, P. 3D Printed Milk Protein Food Simulant: Improving the Printing Performance of Milk Protein Concentration by Incorporating Whey Protein Isolate. Innov. Food Sci. Emerg. Technol. 2018, 49, 116–126. [Google Scholar] [CrossRef]

- Schiell, C.; Portanguen, S.; Scislowski, V.; Astruc, T.; Mirade, P.S. Investigation into the Physicochemical and Textural Properties of an Iron-Rich 3D-Printed Hybrid Food. Foods 2023, 12, 1375. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, M.; Mujumdar, A.S.; Li, J. AI-Based Additive Manufacturing for Future Food: Potential Applications, Challenges and Possible Solutions. Innov. Food Sci. Emerg. Technol. 2024, 92, 103599. [Google Scholar] [CrossRef]

- Kok Wah, J.N. AI-Driven 3D and 4D Food Printing: Innovations for Sustainability, Personalization, and Global Applications. Food Rev. Int. 2025, 1–29. [Google Scholar] [CrossRef]

- Agrawal, K.; Bhat, A.R. Advances in 3D Printing with Eco-Friendly Materials: A Sustainable Approach to Manufacturing. RSC Sustain. 2025, 3, 2582–2604. [Google Scholar] [CrossRef]

- Pallottino, F.; Hakola, L.; Costa, C.; Antonucci, F.; Figorilli, S.; Seisto, A.; Menesatti, P. Printing on Food or Food Printing: A Review. Food Bioproc Tech. 2016, 9, 725–733. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Guo, C.; Zheng, W.; Cao, S.; Lu, H.; Mo, H.; Li, H. 3d Printing of Shiitake Mushroom Incorporated with Gums as Dysphagia Diet. Foods 2021, 10, 2189. [Google Scholar] [CrossRef]

- Caporizzi, R.; Derossi, A.; Severini, C. Cereal-Based and Insect-Enriched Printable Food: From Formulation to Postprocessing Treatments. Status and Perspectives. In Fundamentals of 3D Food Printing and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 93–116. ISBN 9780128145647. [Google Scholar]

- Zhao, R.; Xia, B.; Khan, A.; Chang, Y.; Guo, X.; Liu, Y.; Huang, X.; Wang, C. Fabrication, Characterization, and Application in 3D Printing of High Internal Phase Emulsion Stabilized by Alkaline Thermal Treated Pea Protein and Pectin Complex. Food Res. Int. 2025, 211, 116506. [Google Scholar] [CrossRef]

- Mudau, M.; Adebo, O.A. Three Dimensional (3D)-Printed Foods: A Review of Recent Advances in Their Ingredients, Printing Techniques, Food Printers, Post-Processing Methods, Consumer Acceptance and Safety. J. Food Process Eng. 2024, 47, e14621. [Google Scholar] [CrossRef]

- Zhu, W.; Iskandar, M.M.; Baeghbali, V.; Kubow, S. Three-Dimensional Printing of Foods: A Critical Review of the Present State in Healthcare Applications, and Potential Risks and Benefits. Foods 2023, 12, 3287. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Ahmadzadeh, S.; Schöberl, H.; Ubeyitogullari, A. Optimizing Printability of Rice Protein-Based Formulations Using Extrusion-Based 3D Food Printing. Food Sci. Nutr. 2025, 13, e4713. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, I.; Maldonado-Rosas, R.; Serrano-Sandoval, S.N.; Mendoza-Cachú, D.; Gutierrez-Uribe, J.A.; Tejada-Ortigoza, V. Generating 3D Food Printing Materials through Extrusion Cooking: Printability and Rheological Properties of Omega-3-Enriched and Chickpea Flours Formulations. Food Bioprod. Process. 2025, 151, 287–299. [Google Scholar] [CrossRef]

- Sharma, M.; Parihar, P.; Dubey, A.D.; Shukla, S.S.; Soni, R. Additive Manufacturing in the Food Industry: Innovations in Customised Fabrication and Personalised Nutrition. Food Humanit. 2024, 3, 100402. [Google Scholar] [CrossRef]

- Ukkunda, N.S.; Santhoshkumar, P.; Moses, J.A. Impact of Different Natural Sweeteners on 3D Printability and Post-Printing Quality of Marzipan. Future Foods 2025, 11, 100557. [Google Scholar] [CrossRef]

- Pulatsu, E.; Su, J.W.; Lin, J.; Lin, M. Factors Affecting 3D Printing and Post-Processing Capacity of Cookie Dough. Innov. Food Sci. Emerg. Technol. 2020, 61, 102316. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Dai, Q.; Xu, D.; Hu, L.; Li, H.; Hati, S.; Chitrakar, B.; Yao, L.; Mo, H. Pea Protein-Xanthan Gum Interaction Driving the Development of 3D Printed Dysphagia Diet. Food Hydrocoll. 2023, 139, 108497. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Ruan, M.; Liao, Y.; Wang, Z.; Zeng, Y.; Li, H.; Hu, L.; Mo, H. 3D Printed Dysphagia Diet Using Pea Protein Gel Modified by Xanthan Gum with Different Pyruvate Group Content. Food Chem. X 2025, 25, 102121. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Wang, Y. 3D Printing: Printing Precision and Application in Food Sector. Trends Food Sci. Technol. 2017, 69, 83–94. [Google Scholar] [CrossRef]

- Abedini, A.; Sohrabvandi, S.; Sadighara, P.; Hosseini, H.; Farhoodi, M.; Assadpour, E.; Alizadeh Sani, M.; Zhang, F.; Seyyedi-Mansour, S.; Jafari, S.M. Personalized Nutrition with 3D-Printed Foods: A Systematic Review on the Impact of Different Additives. Adv. Colloid. Interface Sci. 2024, 328, 103181. [Google Scholar] [CrossRef]

- Arshad, R.; Saqib, A.; Sharif, H.R.; Liaqat, A.; Xu, B. Recent Advances in 3D Food Printing: Therapeutic Implications, Opportunities, Potential Applications, and Challenges in the Food Industry. Food Res. Int. 2025, 203, 115791. [Google Scholar] [CrossRef]

- Sahil Panjabrao, A.; Hamid; Dash, K.K.; Kathuria, D.; Shams, R.; Chavan, P.; Mukarram, S.A.; Kovács, B. Sustainable 3D-Printed Food Packaging from Agricultural Waste: A Review of Materials, Properties, and Applications. J. Agric. Food Res. 2025, 22, 102061. [Google Scholar] [CrossRef]