Development and Application of Software for Calculating the Crack Arrest Toughness of Impurity-Containing Carbon Dioxide Pipelines Based on the BTCM

Abstract

1. Introduction

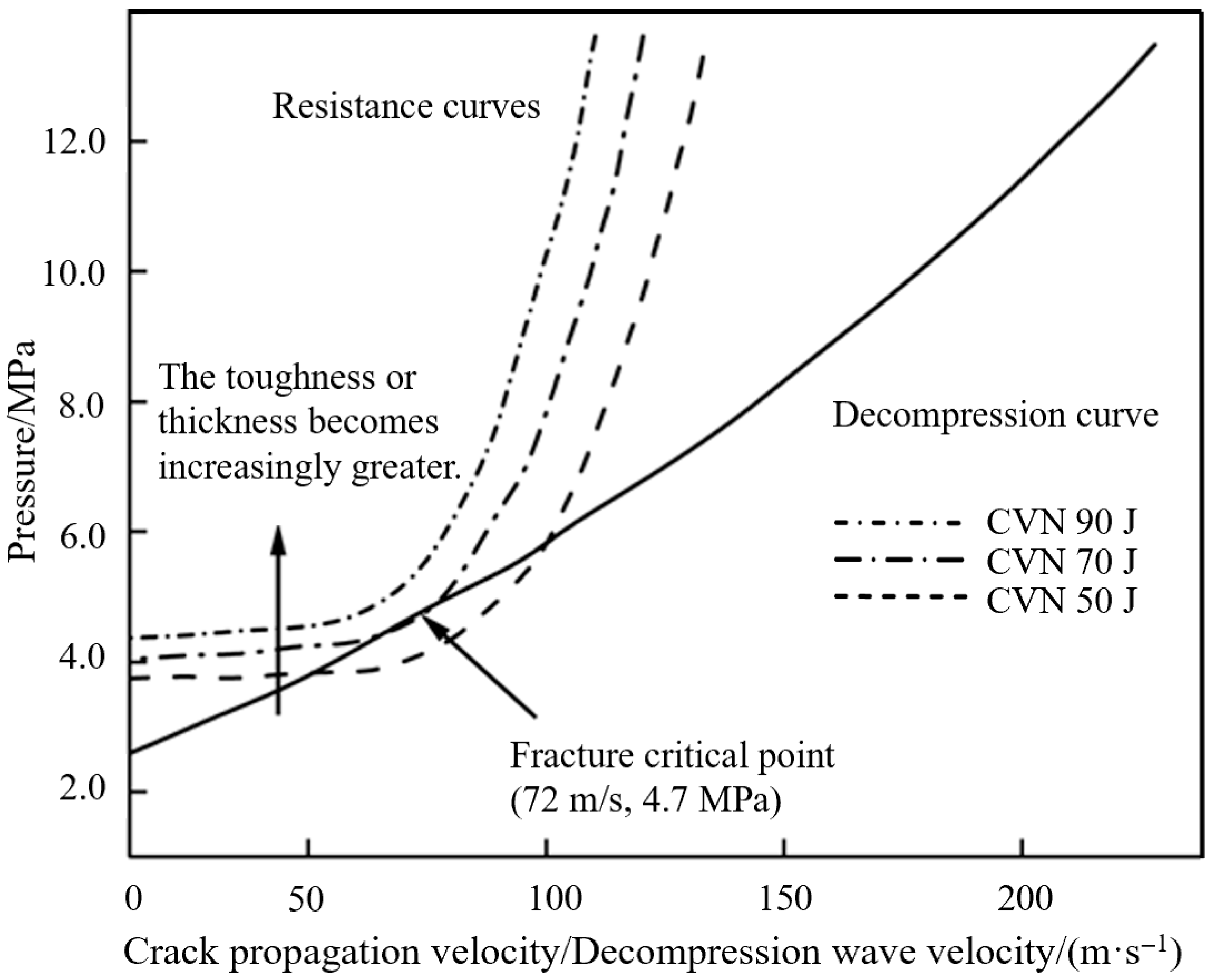

2. Pipeline Fracture Arrest Assessment Model

2.1. Resistance Curve Model

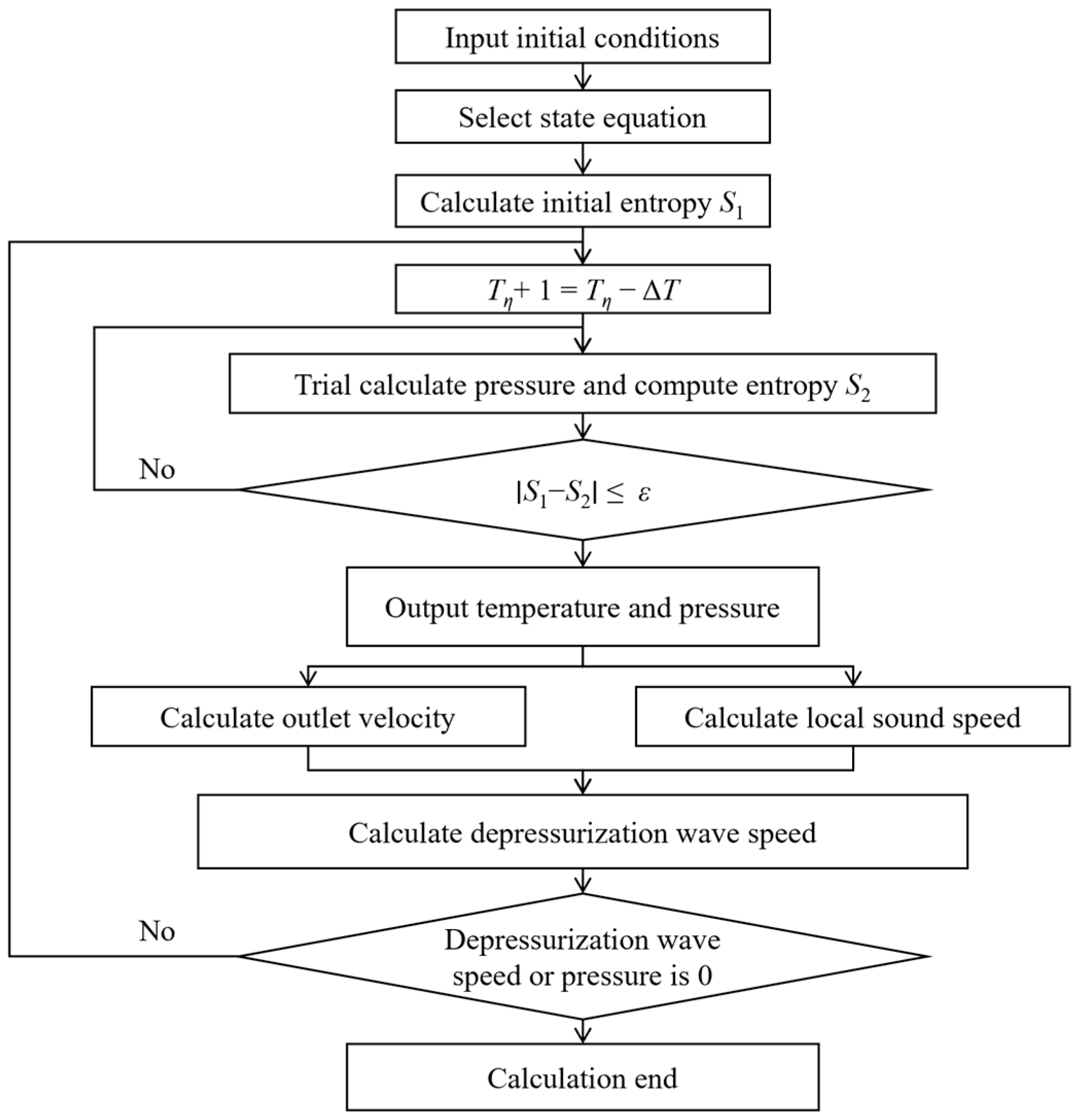

2.2. Decompression Wave Model

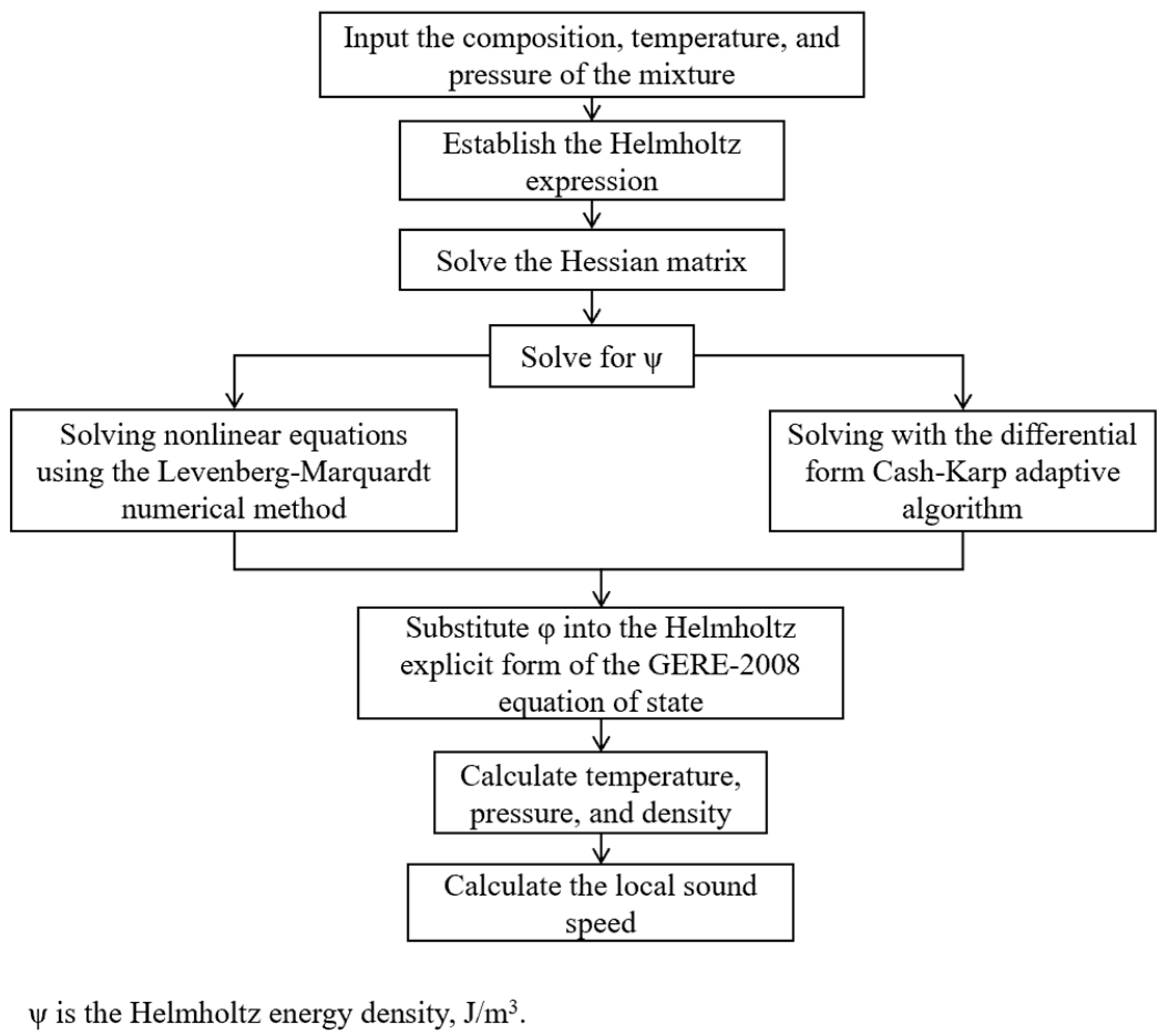

2.2.1. Calculation of Local Sound Speed Based on Isochoric Thermodynamics

2.2.2. Equation of State

- (1)

- PR Equation

- (2)

- HEOS Equation

- (3)

- GERG-2008 Equation

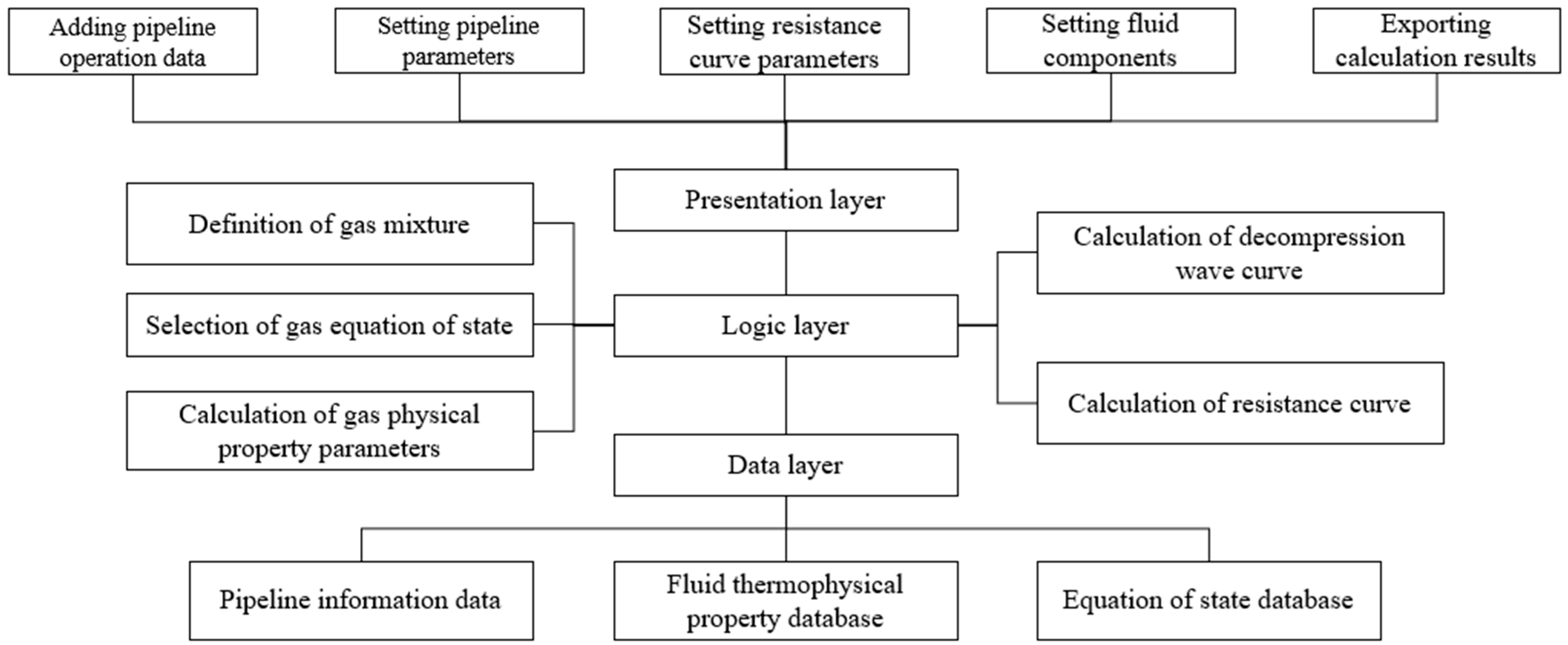

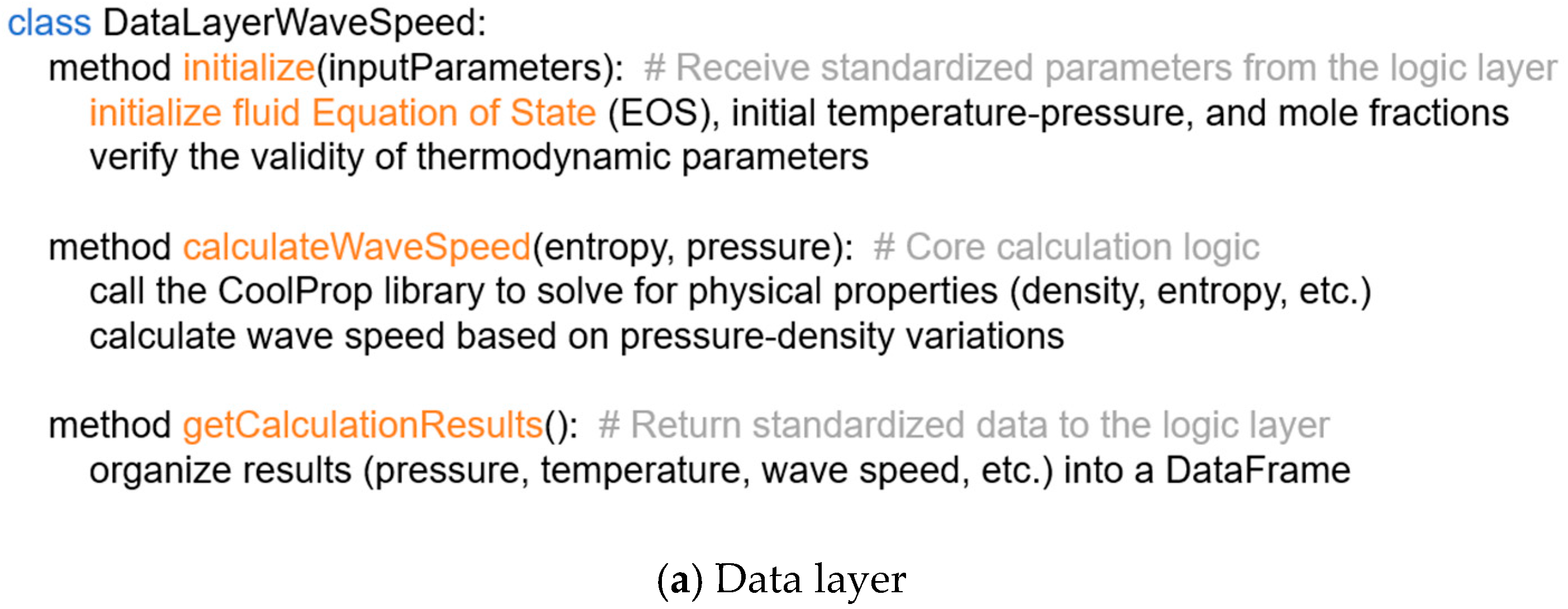

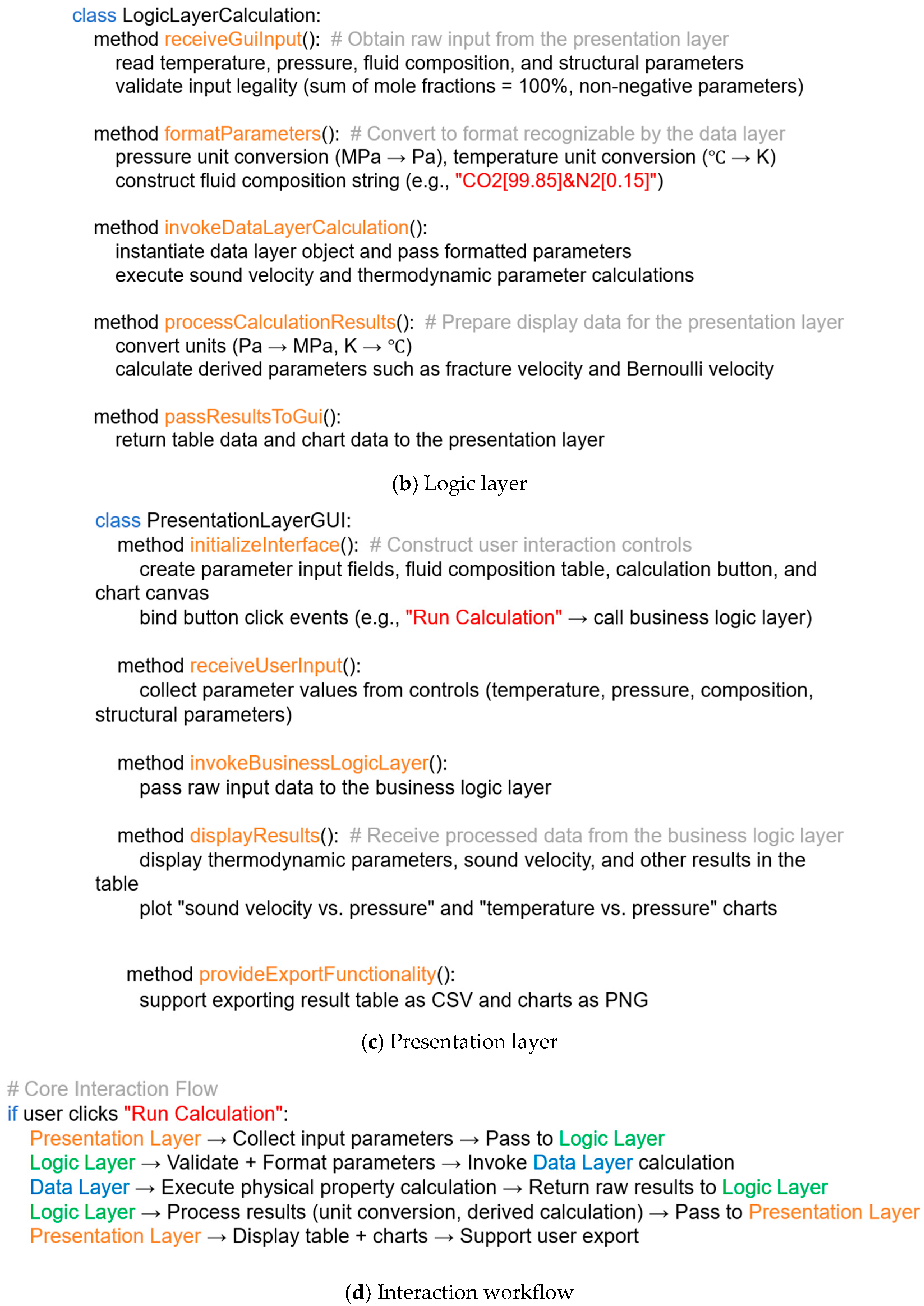

3. Development of Pipeline Fracture Arrest Assessment Software

3.1. Development Environment and Technology

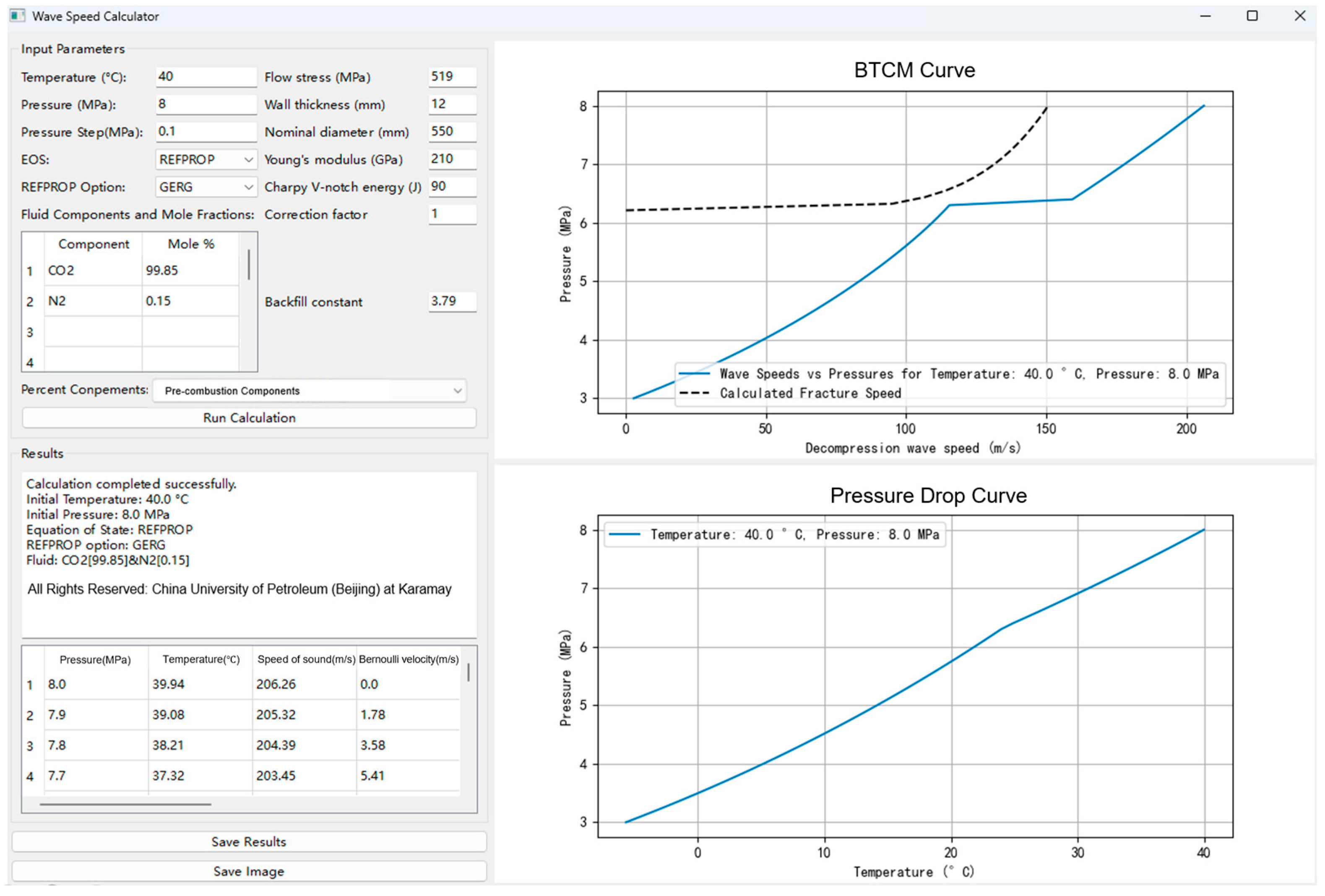

3.2. Software Usage

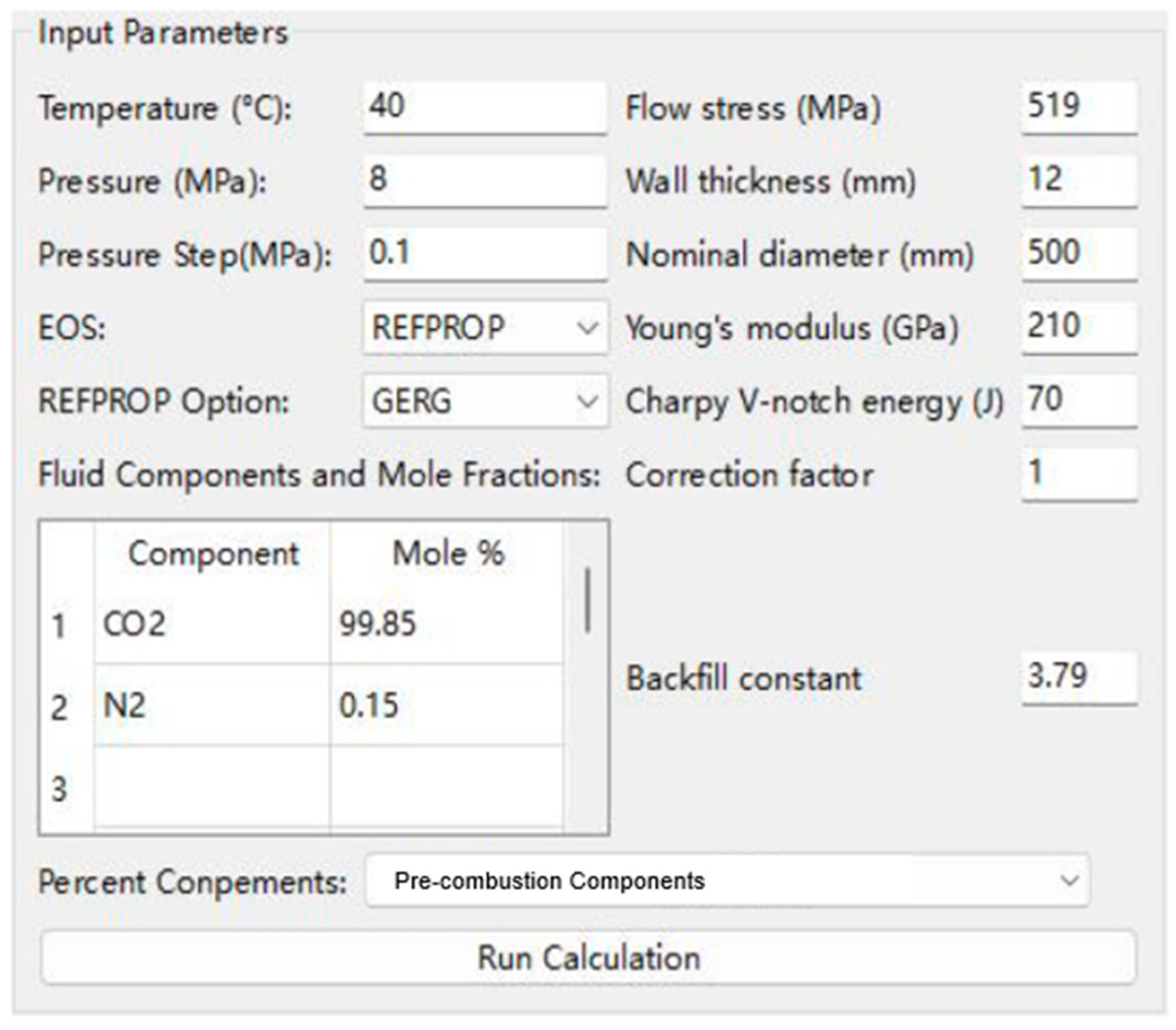

3.2.1. Input Parameter Settings

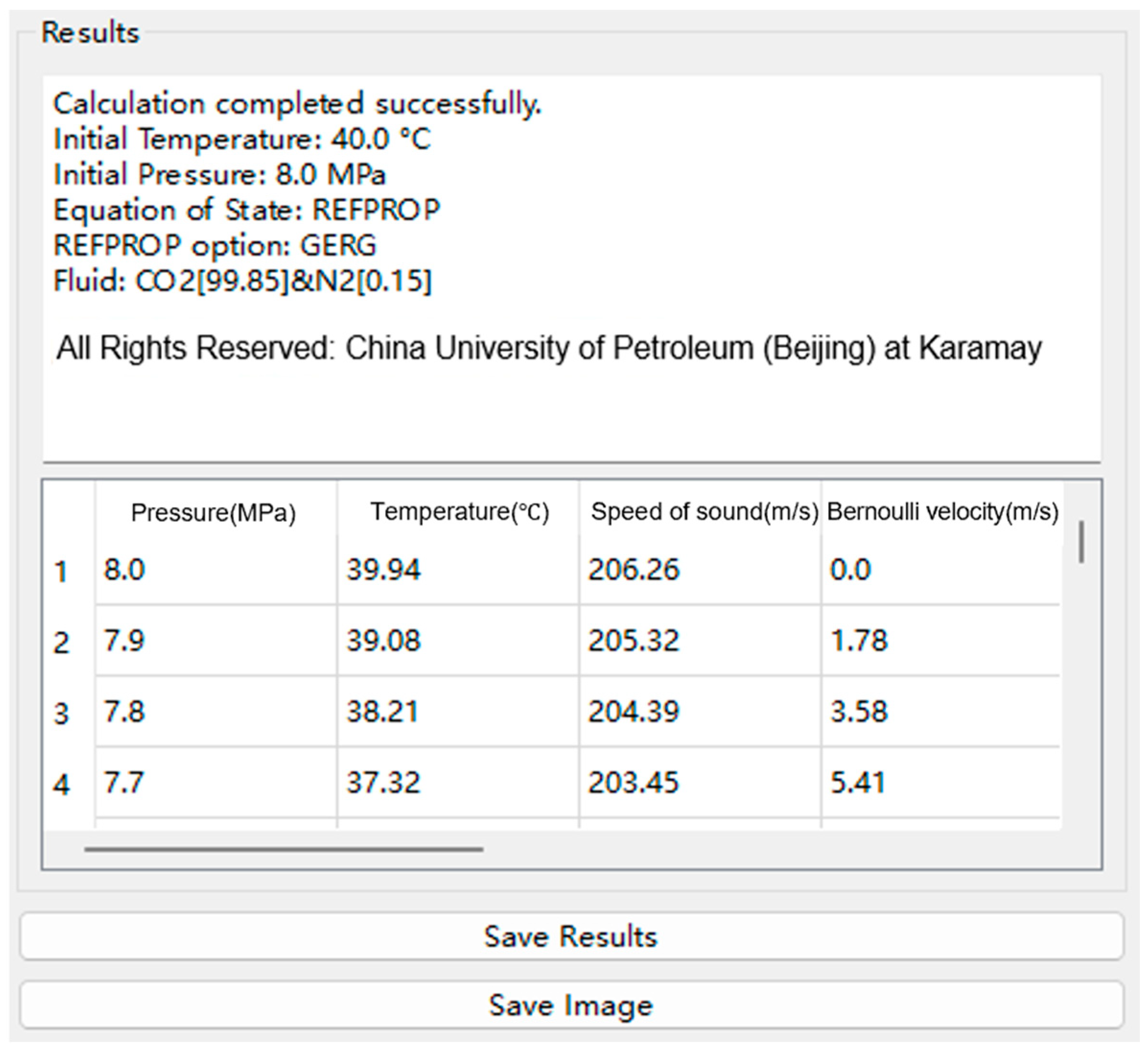

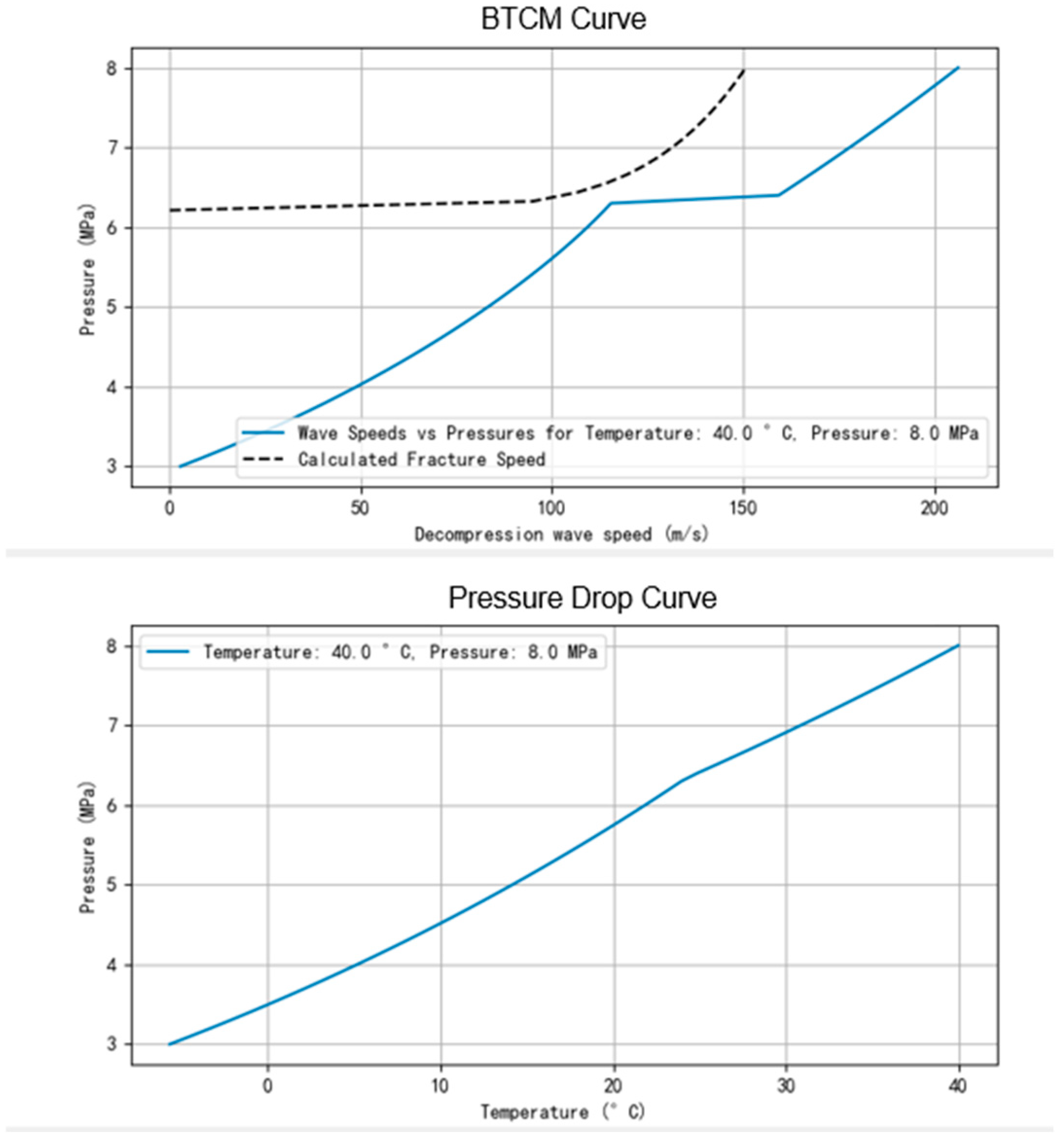

3.2.2. Output Results Visualization

3.3. Software Advantages and Potential Applications

4. Verification of Software Calculation Accuracy

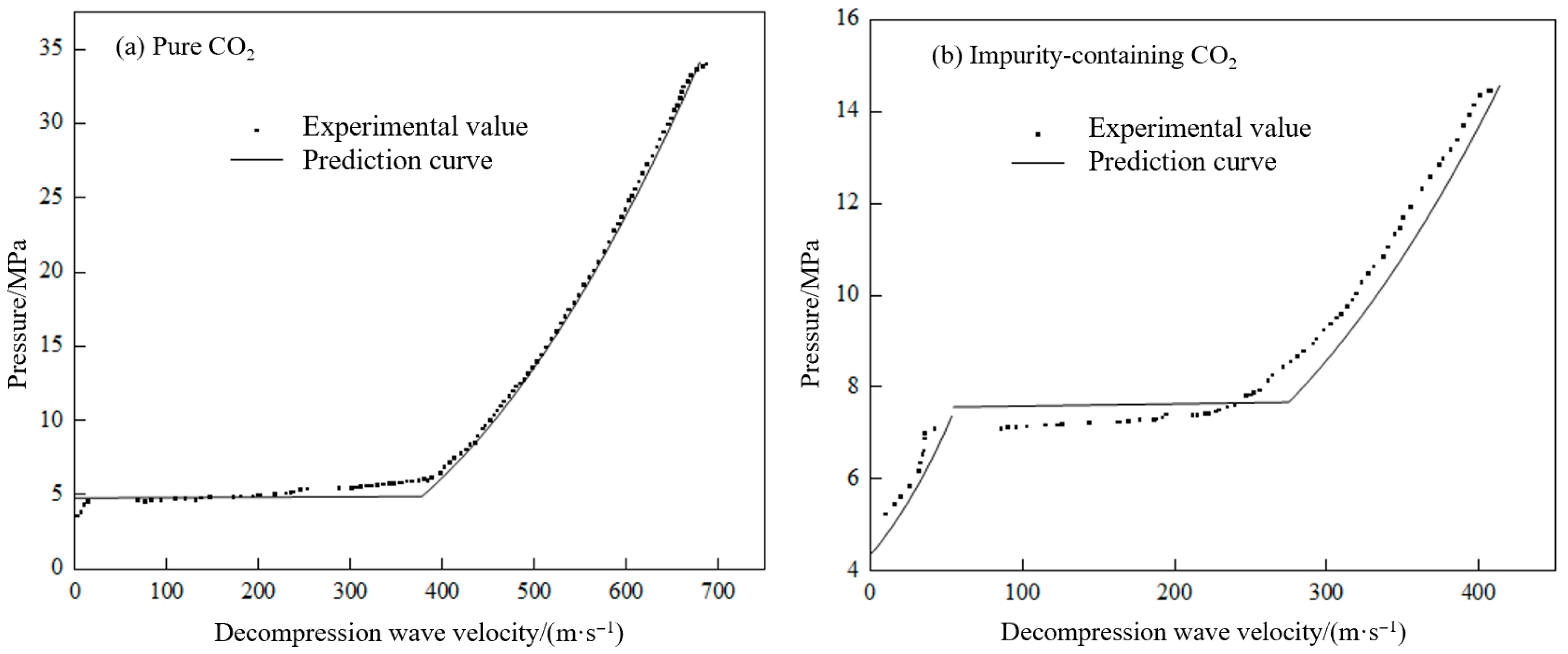

4.1. Experimental Validation of the Decompression Wave Prediction Model

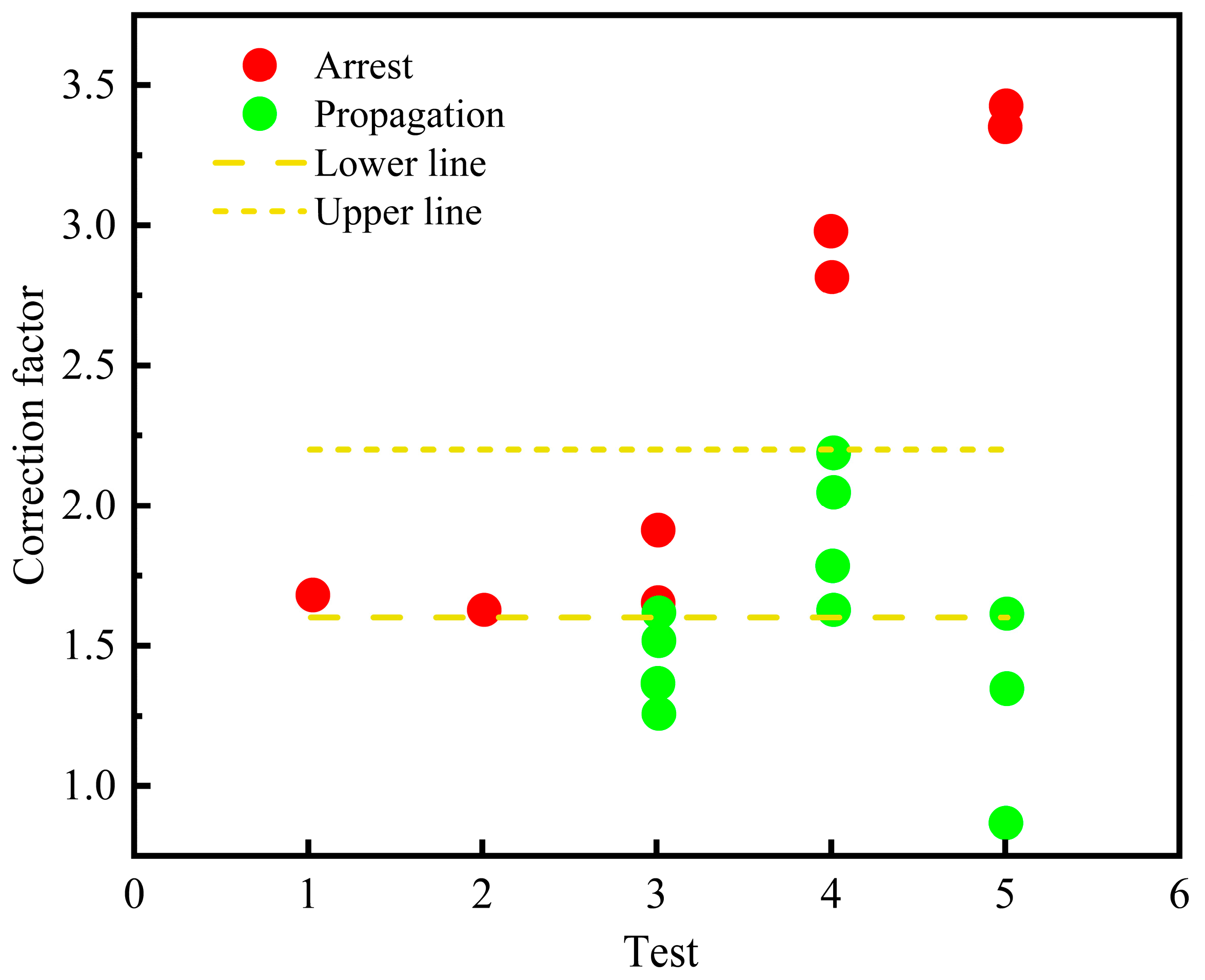

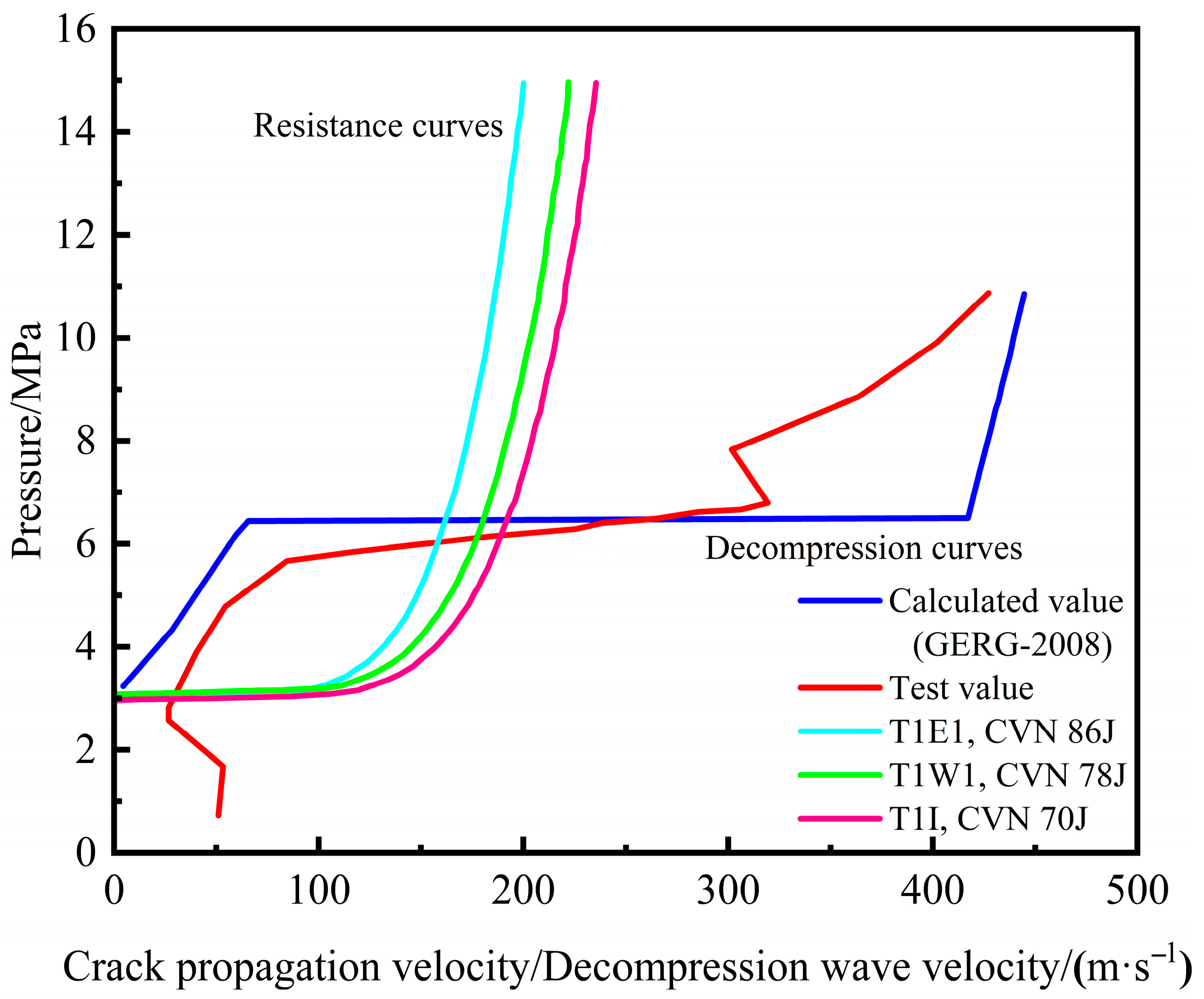

4.2. Engineering Verification of the Pipeline Fracture Arrest Assessment Model

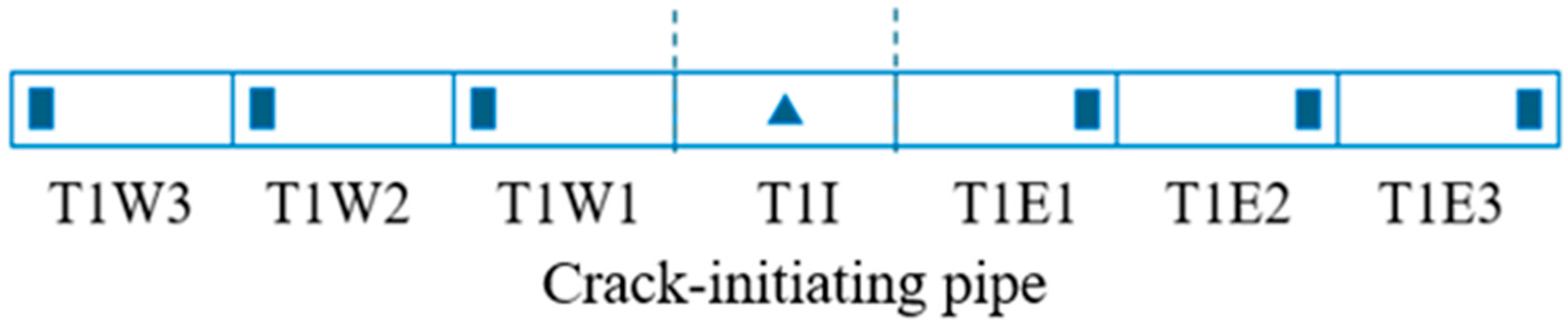

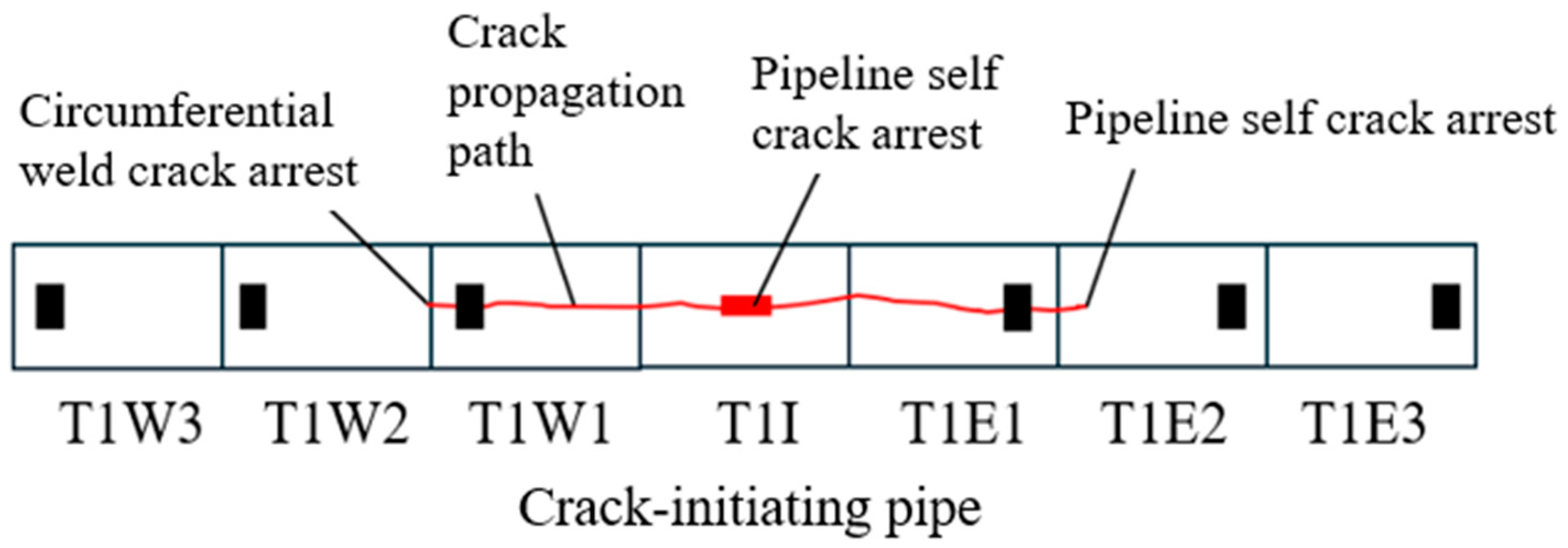

4.2.1. Project Overview

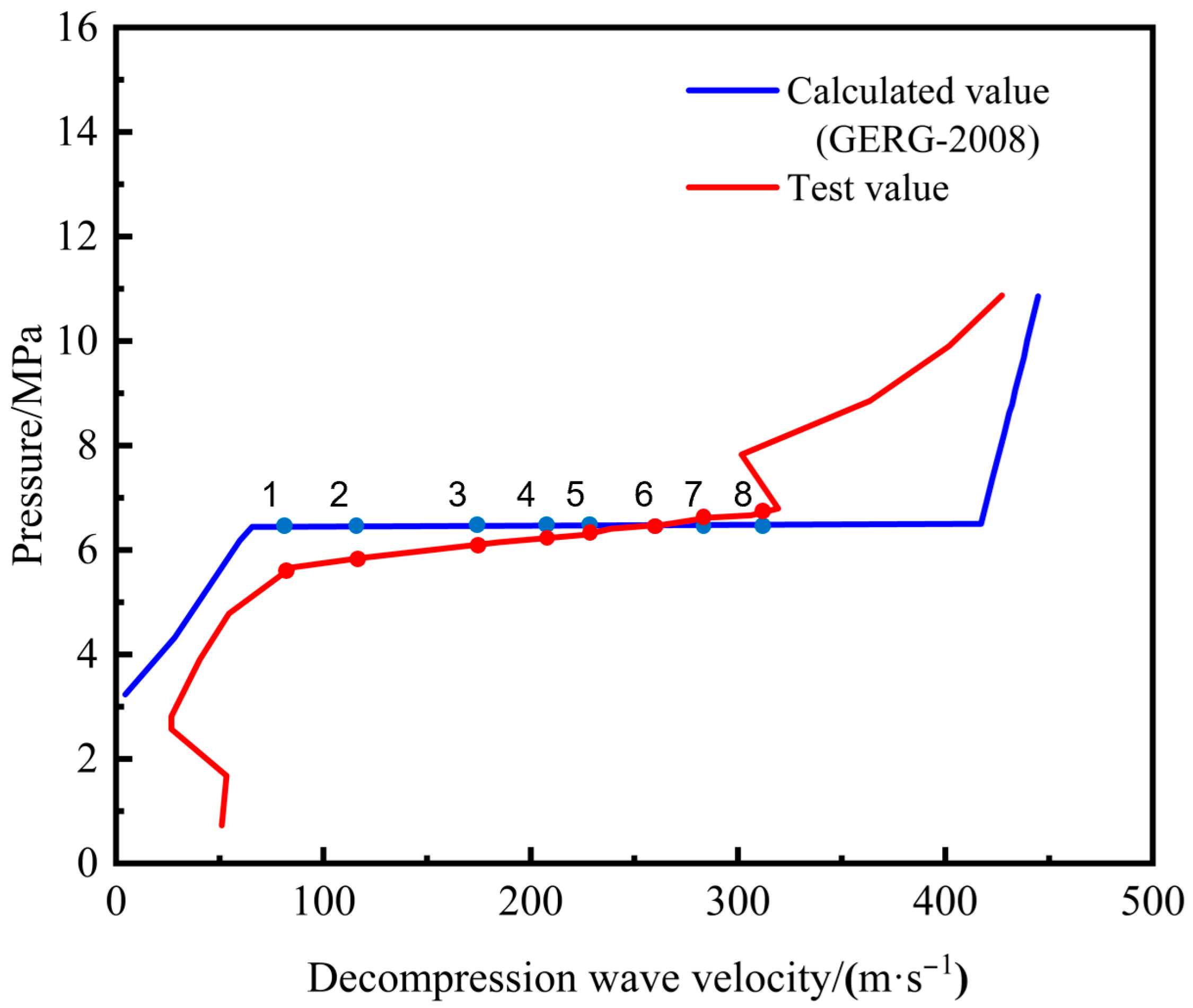

4.2.2. Comparison of Software Calculation Results

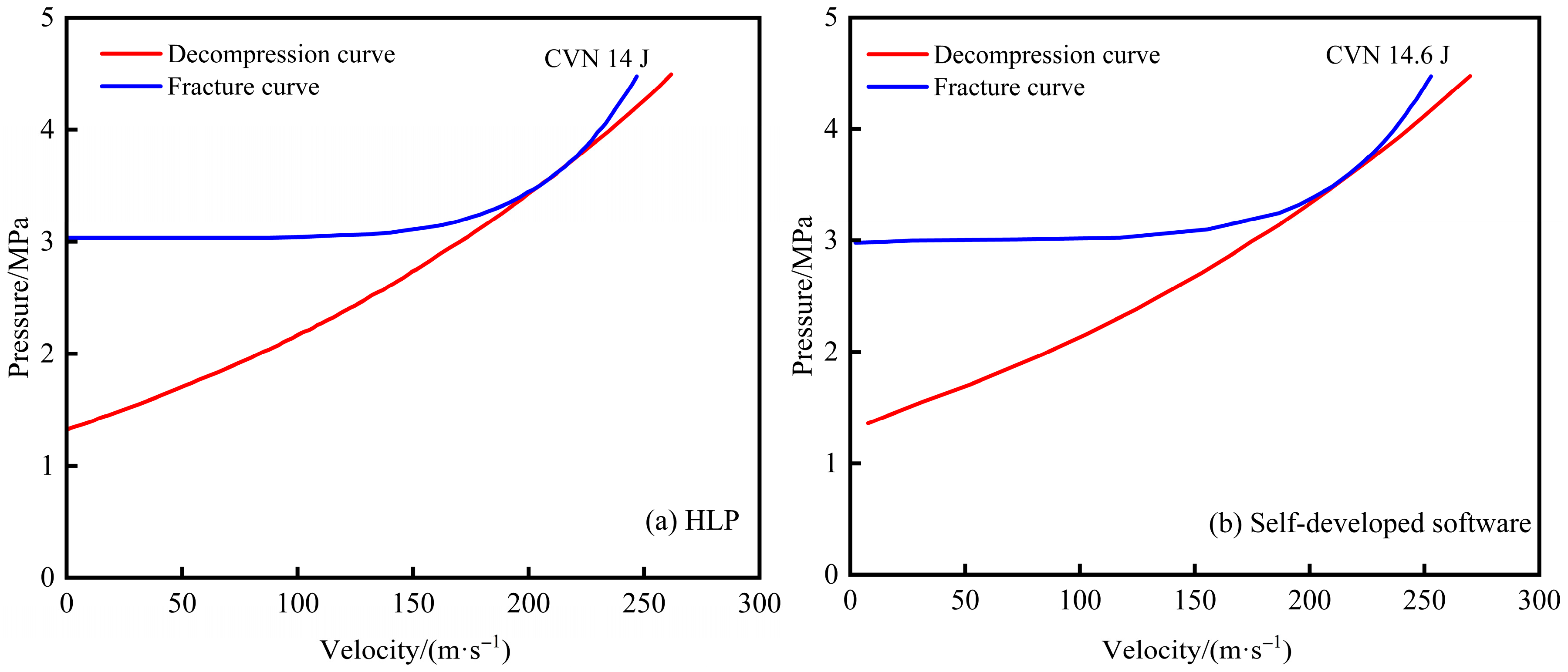

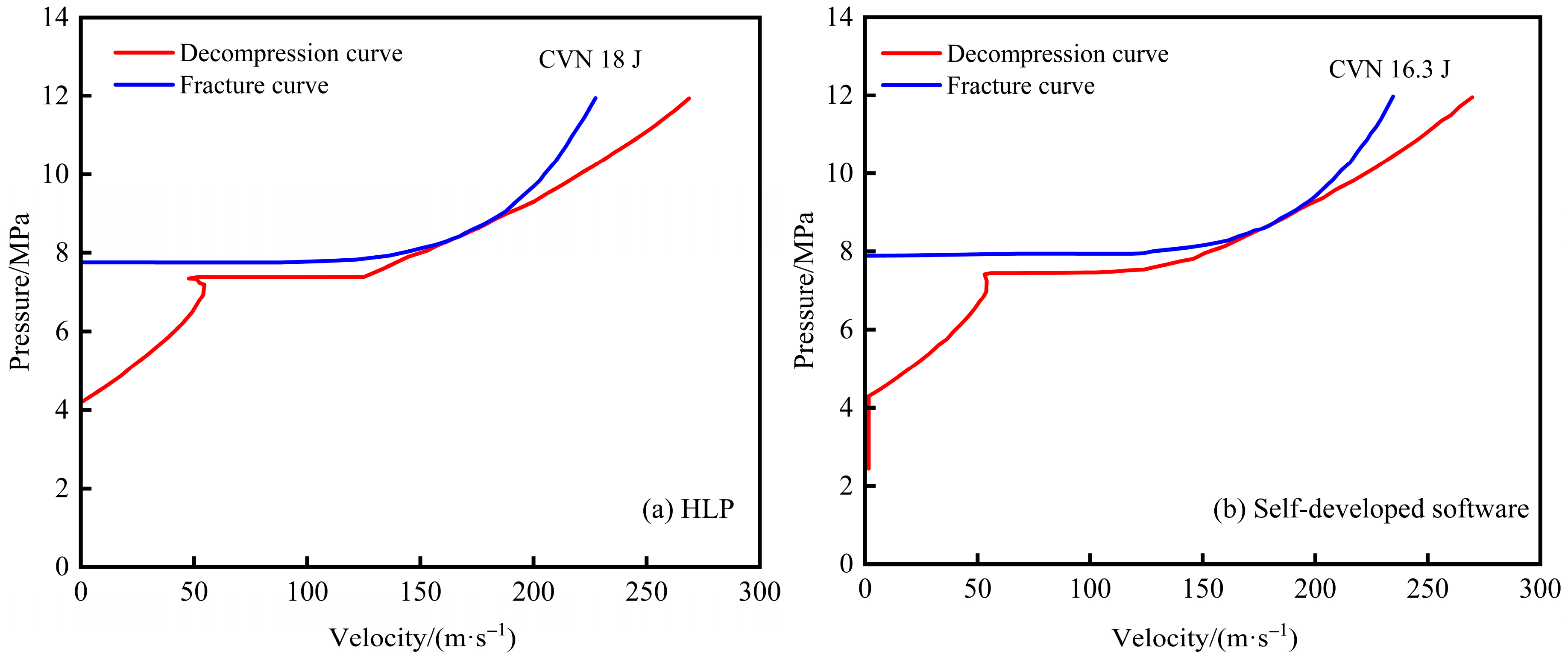

4.3. Comparison with International HLP Model Calculation Results

5. Parameter Sensitivity Analysis

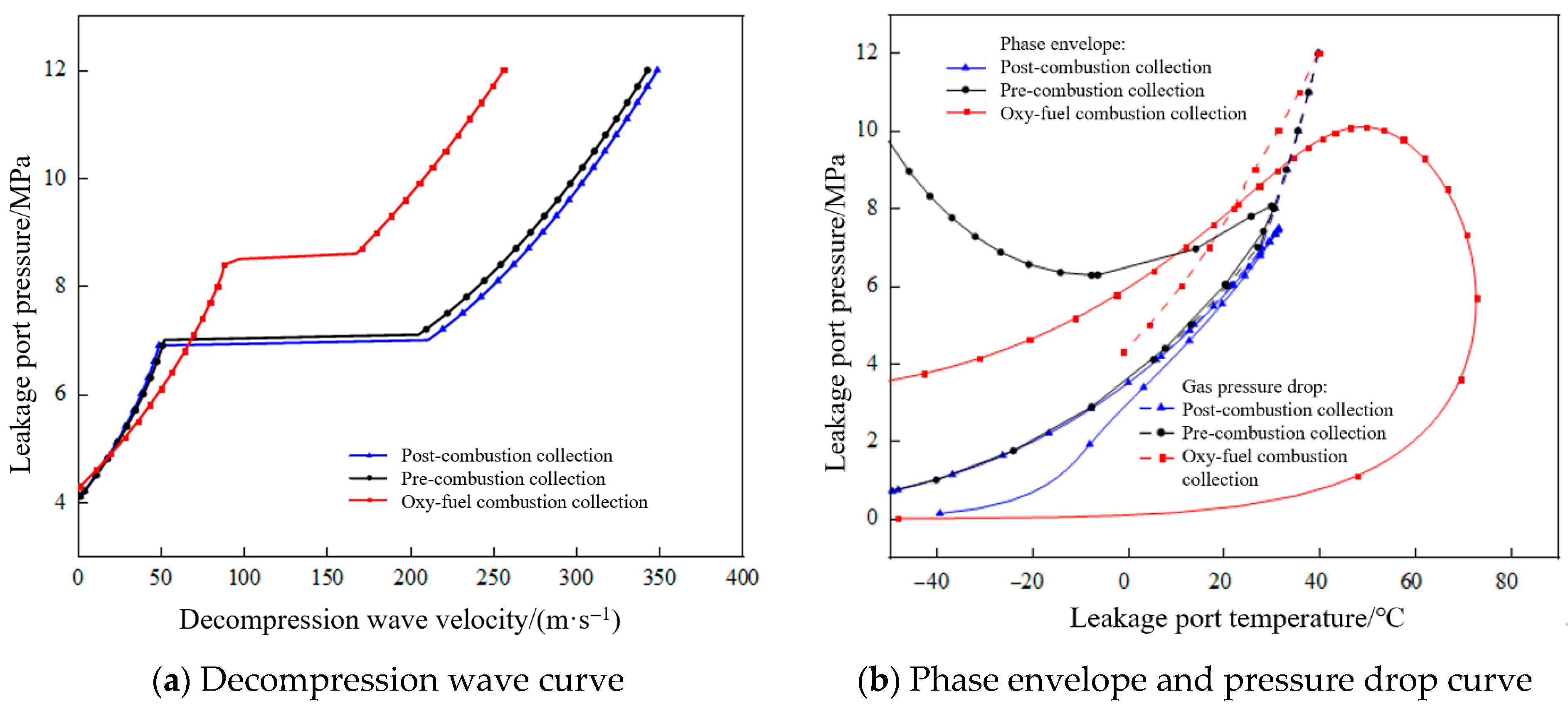

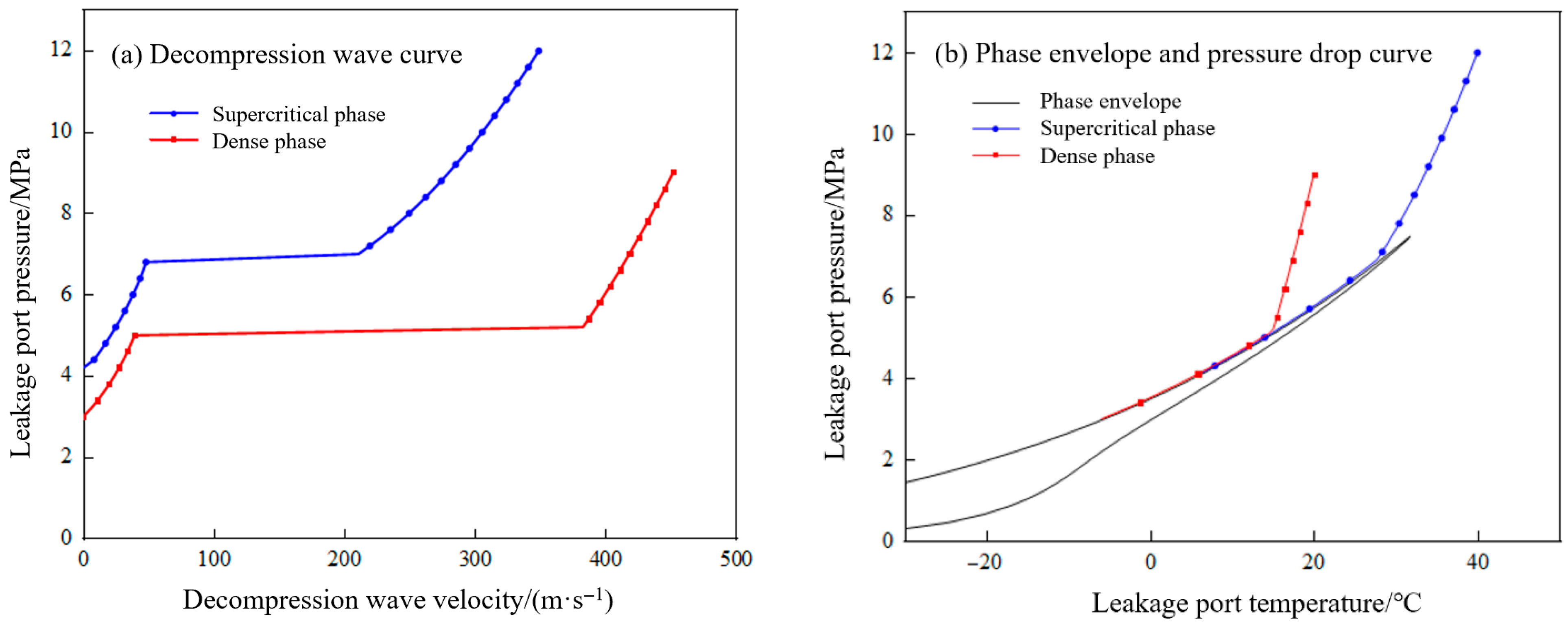

5.1. Decompression Wave Propagation Characteristics

5.1.1. Gas Composition

5.1.2. Initial Phase State

5.1.3. Pipeline Initial Pressure

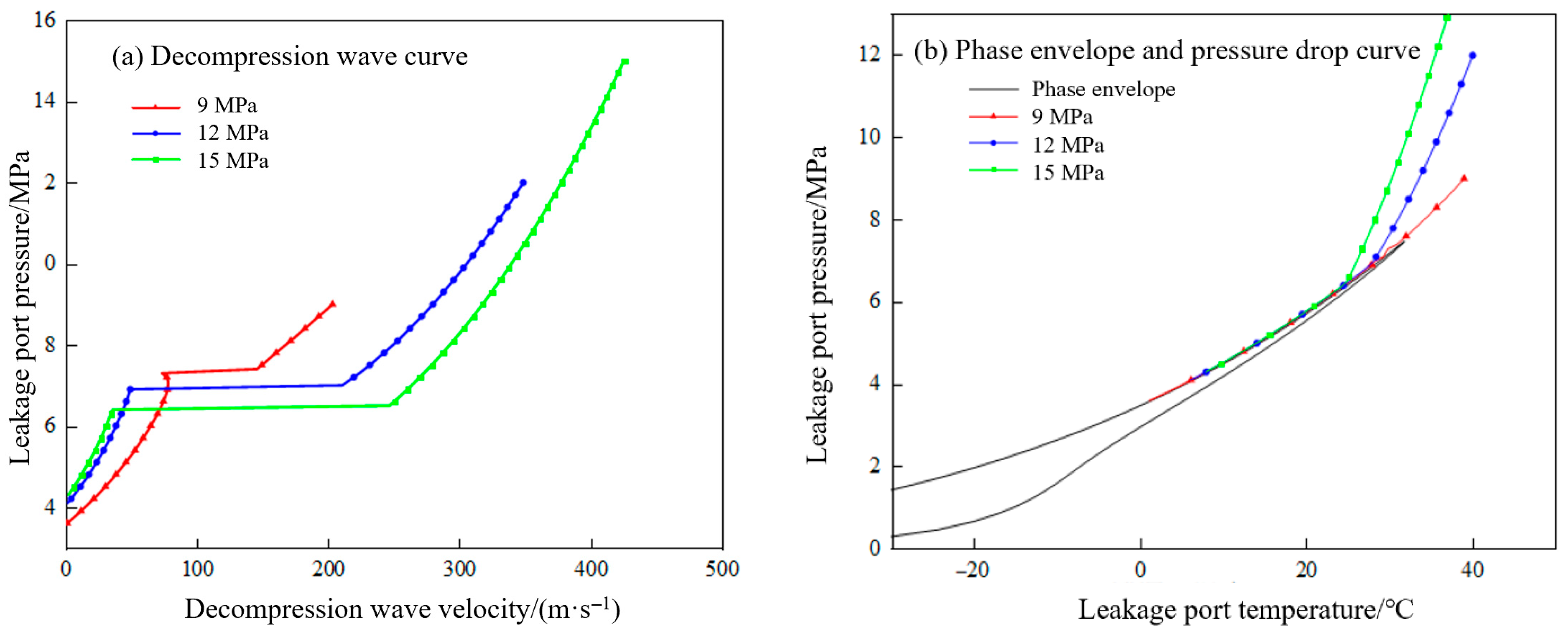

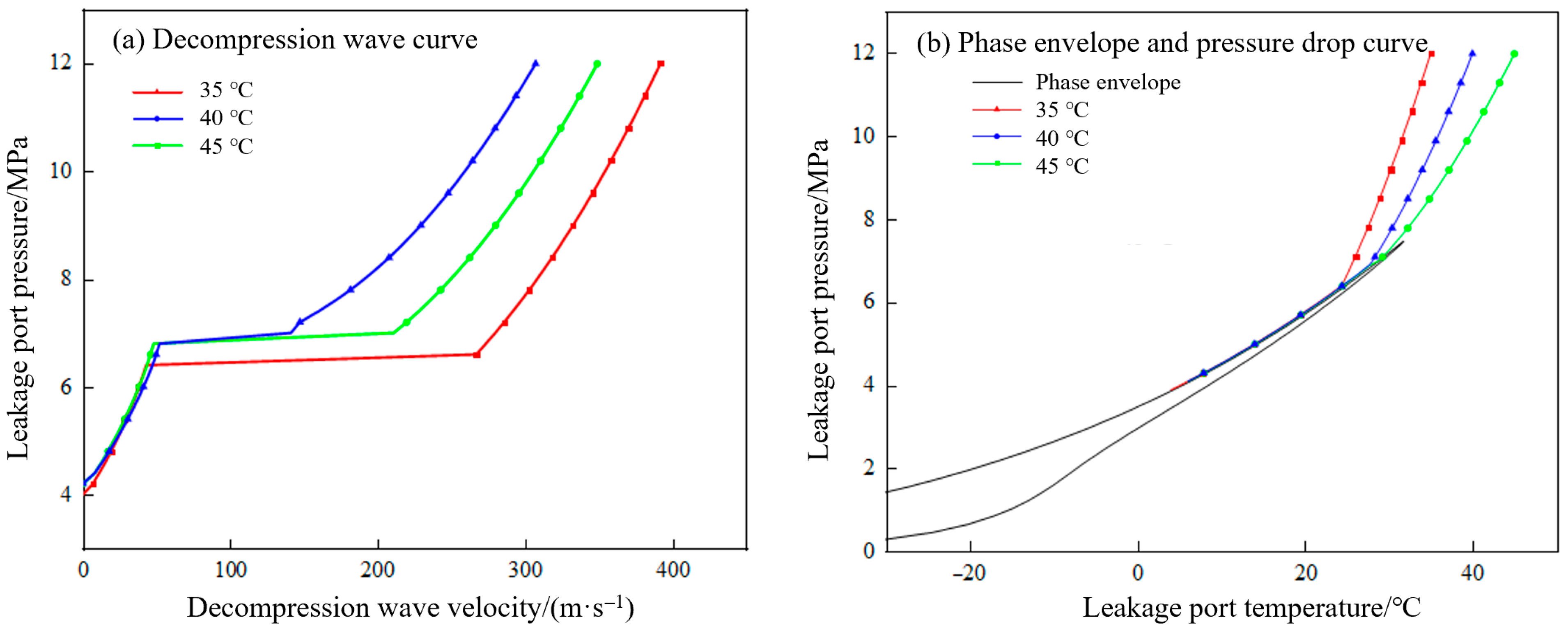

5.1.4. Pipeline Initial Temperature

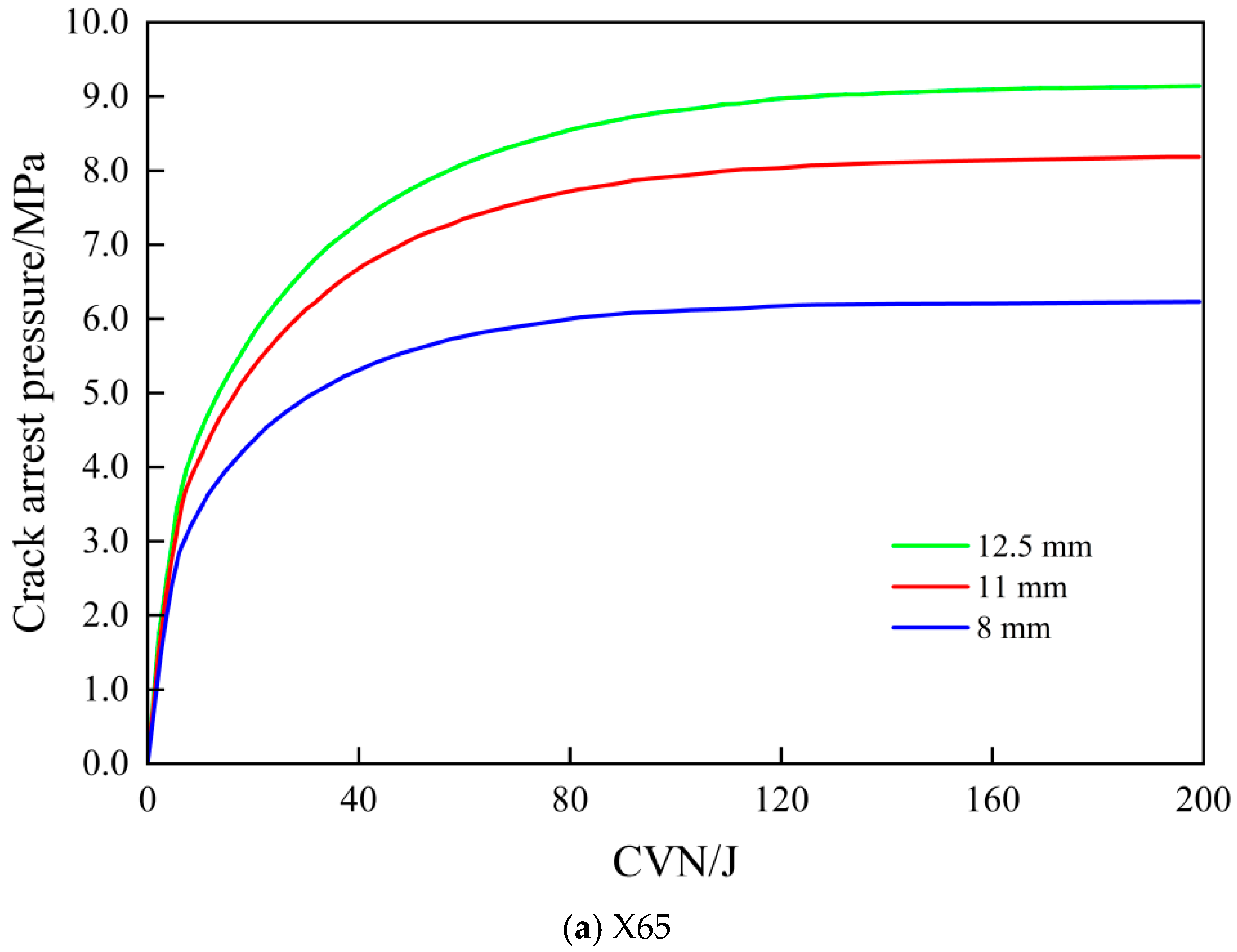

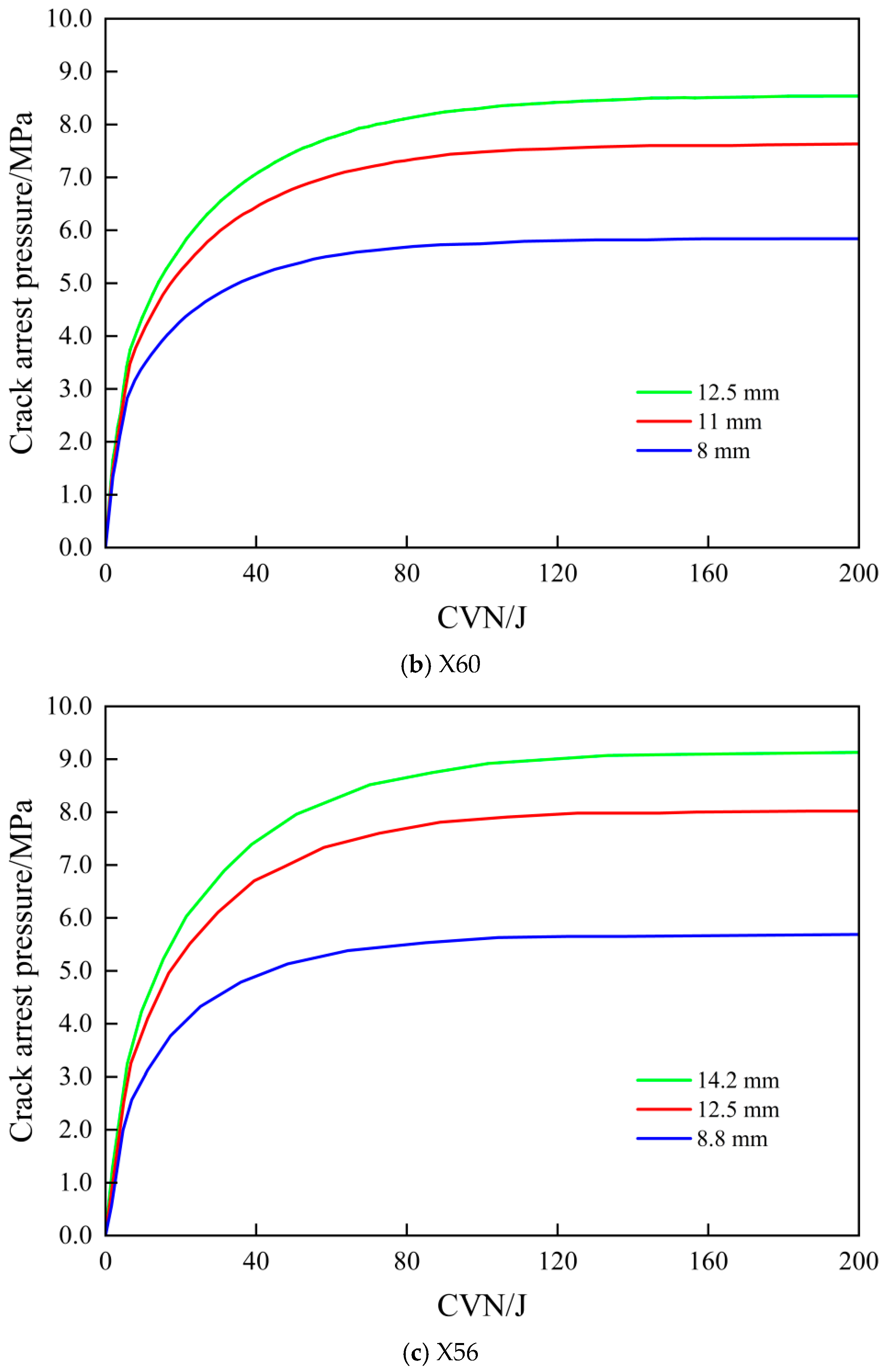

5.2. Pipe Material Toughness Analysis

6. Conclusions and Prospects

- (1)

- Computational software for determining the fracture arrest toughness of CO2 pipelines containing impurities has been developed. Centered on the Battelle Two-Curve Method (BTCM) and incorporating various thermodynamic models such as the Peng-Robinson (PR) and Helmholtz Energy Equation of State (HEOS) equations, this software successfully couples the effects of impurities on both the fluid decompression behavior of CO2 and the material toughness of the pipe. It can accurately determine the fracture arrest toughness boundary for a specific pipe material under given operating conditions. The calculated pressure plateau shows an error within 5% compared to decompression wave test data and full-scale burst test data. The calculated minimum toughness value exhibits an error within 10% compared to results from the international HLP model.

- (2)

- For post-combustion captured CO2 and pre-combustion captured CO2, the pressure drop curves follow the bubble point line and dew point line, respectively, during decompression. In contrast, oxy-fuel combustion captured CO2 shows approximately 26% lower initial decompression wave velocity and about 22% higher pressure plateau. As decompression progresses, the fluid inside the pipe no longer follows the vapor-liquid equilibrium line but directly enters the two-phase region. Compared to the dense phase, supercritical CO2 exhibits a saturation pressure at the intersection of the pressure drop curve and the CO2 bubble point line that is about 26% higher, resulting in a higher pressure plateau. Under different initial pressures of 9 MPa, 12 MPa, and 15 MPa, the pressure plateaus are 7.4 MPa, 7.0 MPa, and 6.4 MPa, respectively. Under different initial temperatures of 35 °C, 40 °C, and 45 °C, the pressure plateaus are approximately 6.5 MPa, 6.9 MPa, and 6.9 MPa, respectively. Lower operating temperatures and higher operating pressures can effectively reduce the pressure plateau.

- (3)

- This software can be used as an auxiliary tool for calculating and evaluating the crack arrest toughness of supercritical CO2 pipelines, providing data support for pipe material selection and operating condition optimization. During application, the recommended value range for the minimum correction factor is 1.6–2.2. Since the core model of the developed software is built based on existing test data and theoretical derivations, it cannot fully replicate the complex operating environment of pipelines in actual engineering. Without verification by professional engineers in combination with specific scenarios, it shall not replace full-scale burst tests as the basis for final decision-making.

- (4)

- Future work plans include introducing more advanced dynamic fracture mechanics models to describe the microscopic mechanisms of crack tip propagation more precisely. We intend to integrate more complex Equations of State (EOS) and a broader impurity database into the software to enhance its predictive capability under extreme compositions or operating conditions. Concurrently, we will study the feasibility of deploying the software at pipeline control centers and develop interfaces with SCADA systems. This upgrade would shift the software from offline manual input to real-time data interaction. By utilizing sensors to monitor gas composition, operational pressure, and temperature at different pipeline sections in real-time, and employing intelligent pigs for periodic wall thickness inspection, the software could enable real-time, continuous fracture arrest assessment for pipelines. Setting alarm thresholds and triggering warnings would provide a means for predicting pipeline safety risks.

- (5)

- In the next step, the software will be developed to include a solver for calculating the minimum toughness required to arrest pipeline crack propagation. The tangent point between the fracture velocity curve and the decompression curve of supercritical CO2 pipelines occurs in the pressure plateau region. Therefore, it is not necessary to determine the complete decompression wave velocity curve when measuring the crack arrest toughness of supercritical CO2 pipelines; it only needs to be ensured that the crack arrest pressure (the intercept of the crack propagation velocity curve on the pressure axis) is higher than the saturation pressure (consistent with the pressure plateau region on the gas decompression curve). Generally, the pipeline’s operating pressure, temperature, medium composition, and other parameters are design input conditions that cannot be easily modified, yet they are key factors for determining the decompression curve. To meet the pipeline crack arrest toughness requirements under the established decompression curve and determine the minimum toughness required to prevent pipeline crack propagation, optimization can be achieved by adjusting pipeline material properties (especially fracture toughness and minimum yield strength) and wall thickness. Of course, in engineering practice, the optimal pipe specification should also be ultimately determined by considering factors such as the price of different steel grades and the quality assurance of welding processes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Van Vuuren, D.P.; Stehfest, E.; Gernaat, D.E.; Van Den Berg, M.; Bijl, D.L.; De Boer, H.S.; Daioglou, V.; Doelman, J.C.; Edelenbosch, O.Y.; Harmsen, M.; et al. Alternative pathways to the 1.5 C target reduce the need for negative emission technologies. Nat. Clim. Change 2018, 8, 391–397. [Google Scholar] [CrossRef]

- Peters, G.P.; Andrew, R.M.; Canadell, J.G.; Friedlingstein, P.; Jackson, R.B.; Korsbakken, J.I.; Le Quéré, C.; Peregon, A. Carbon dioxide emissions continue to grow amidst slowly emerging climate policies. Nat. Clim. Change 2019, 10, 3–6. [Google Scholar] [CrossRef]

- Höhne, N.; Gidden, M.J.; Elzen, M.D.; Hans, F.; Fyson, C.; Geiges, A.; Jeffery, M.L.; Gonzales-Zuñiga, S.; Mooldijk, S.; Hare, W.; et al. Wave of net zero emission targets opens window to meeting the Paris Agreement. Nat. Clim. Change 2021, 11, 820–822. [Google Scholar] [CrossRef]

- Grubler, A.; Wilson, C.; Bento, N.; Boza-Kiss, B.; Krey, V.; McCollum, D.L.; Rao, N.D.; Riahi, K.; Rogelj, J.; De Stercke, S.; et al. A low energy demand scenario for meeting the 1.5 °C target and sustainable development goals without negative emission technologies. Nat. Energy 2018, 3, 515–527. [Google Scholar] [CrossRef]

- Chaudhry, A.U.; Abdullah, F.T.; Khan, M.S.; Rabbani, H.S.; Lal, B. Feasibility of Long-Distance Transportation of Captured CO2 using Transmission Pipelines: An Overview of Techno-economic Models. In Gas Hydrate in Carbon Capture, Transportation and Storage; CRC Press: Boca Raton, FL, USA, 2024; pp. 33–43. [Google Scholar]

- Joarder, M.S.A.; Islam, M.S.; Hasan, M.H.; Kutub, A.; Kabir, M.F.; Rashid, F.; Joarder, T.A. A comprehensive review of carbon dioxide capture, transportation, utilization, and storage: A source of future energy. Environ. Sci. Pollut. Res. 2025, 32, 9299–9332. [Google Scholar] [CrossRef]

- Akinmoladun, A.; Tomomewo, O.S. Advances and future perspectives in post-combustion carbon capture technology using chemical absorption process: A review. Carbon Capture Sci. Technol. 2025, 16, 100461. [Google Scholar] [CrossRef]

- Ighomuaye, E.; Asimatey, P.D.; Annankra, J.A. Strategies for Industrial Integration of Carbon Capture, Utilization, and Storage Technologies: A Critical Review. J. Eng. Comput. Sci. 2025, 4, 284–293. [Google Scholar]

- Chen, L.; Hu, Y.; Liu, Z.; Yan, X.; Yu, S.; Ding, J.; Liu, P.; Yu, J.; Chen, S. Experimental research on the fracture and arrest process of supercritical CO2 pipelines. Int. J. Press. Vessel. Pip. 2024, 212, 105314. [Google Scholar] [CrossRef]

- Yu, S.; Yan, X.; He, Y.; Yu, J.; Chen, S. Study on the leakage morphology and temperature variations in the soil zone during large-scale buried CO2 pipeline leakage. Energy 2023, 288, 129674. [Google Scholar] [CrossRef]

- Xi, D.; Lu, H.; Xu, Z.-D.; Jiang, X.; Peng, H.; Fang, H. Prevention of natural gas pipeline cracking. In Advances in Natural Gas: Formation, Processing, and Applications; Volume 6: Natural Gas Transportation and Storage; Elsevier: Amsterdam, The Netherlands, 2024; pp. 293–313. [Google Scholar]

- Gu, X.T.; Guo, Y. Crack Arrest Toughness of High Grade Gas Pipeline. Mater. Sci. Forum 2017, 898, 758–765. [Google Scholar] [CrossRef]

- Zhen, Y.; Jiao, Z.; Cao, Y.; Niu, R. Unified correlation of constraints with crack arrest toughness for high-grade pipeline steel. Int. J. Press. Vessel. Pip. 2021, 193, 104454. [Google Scholar] [CrossRef]

- Botros, K.K.; Geerligs, J.; Rothwell, B.; Robinson, T. Measurements of decompression wave speed in pure carbon dioxide and comparison with predictions by equation of state. J. Press. Vessel. Technol. 2015, 138, 031302. [Google Scholar] [CrossRef]

- Botros, K.K.; Igi, S.; Kondo, J. Measurements of decompression wave speed in natural gas containing 2–8%(mole) hydrogen by a specialized shock tube. In Proceedings of the 2016 11th International Pipeline Conference, Calgary, AB, Canada, 26–30 September 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016; Volume 50275, p. V003T05A001. [Google Scholar]

- Cosham, A.; Jones, D.G.; Armstrong, K.; Allason, D.; Barnett, J. The decompression behaviour of carbon dioxide in the dense phase. In Proceedings of the 2012 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; Volume 45141, pp. 447–464. [Google Scholar]

- Cosham, A.; Jones, D.G.; Armstrong, K.; Allason, D.; Barnett, J. Analysis of a dense phase carbon dioxide full-scale fracture propagation test in 24 inch diameter pipe. In Proceedings of the 2016 11th International Pipeline Conference, Calgary, AB, Canada, 26–30 September 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016; Volume 50275, p. V003T05A012. [Google Scholar]

- Zhang, Z.; Lu, Z.; Wang, J.; Liu, D.; Xiao, C.; Fan, D. Effects of initial flow velocity on decompression behaviours of GLE CO2 upstream and downstream the pipeline. Int. J. Greenh. Gas Control 2022, 118, 103690. [Google Scholar] [CrossRef]

- Picard, D.J.; Bishnoi, P.R. The importance of real-fluid behavior in predicting release rates resulting from high-pressure sour-gas pipeline ruptures. Can. J. Chem. Eng. 1989, 67, 3–9. [Google Scholar] [CrossRef]

- Aursand, E.; Aursand, P.; Hammer, M.; Lund, H. The influence of CO2 mixture composition and equations of state on simulations of transient pipeline decompression. Int. J. Greenh. Gas Control 2016, 54, 599–609. [Google Scholar] [CrossRef]

- Jie, H.E.; Xu, B.P.; Wen, J.X.; Cooper, R.; Barnett, J. Predicting the decompression characteristics of carbon dioxide using computational fluid dynamics. In Proceedings of the 2012 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; Volume 45141, pp. 585–595. [Google Scholar]

- Botros, K.K.; Geerligs, J.; Rothwell, B.; Robinson, T. Effects of Argon as the primary impurity in anthropogenic carbon dioxide mixtures on the decompression wave speed. Can. J. Chem. Eng. 2016, 95, 440–448. [Google Scholar] [CrossRef]

- Guo, X.; Xu, S.; Chen, G.; Yan, X.; Cao, Q. Fracture criterion and control plan on CO2 pipelines: Theory analysis and full-bore rupture (FBR) experimental study. J. Loss Prev. Process. Ind. 2021, 69, 104394. [Google Scholar] [CrossRef]

- Gu, S.; Li, Y.; Teng, L.; Wang, C.; Hu, Q.; Zhang, D.; Ye, X.; Wang, J.; Iglauer, S. An experimental study on the flow characteristics during the leakage of high pressure CO2 pipelines. Process. Saf. Environ. Prot. 2019, 125, 92–101. [Google Scholar] [CrossRef]

- Teng, L.; Zhang, D.; Li, Y.; Wang, W.; Wang, L.; Hu, Q.; Ye, X.; Bian, J.; Teng, W. Multiphase mixture model to predict temperature drop in highly choked conditions in CO2 enhanced oil recovery. Appl. Therm. Eng. 2016, 108, 670–679. [Google Scholar] [CrossRef]

- Dakhel, A.Y.; Lukács, J. Full-scale tests of transporting pipeline sections—A review and consequences to our investigations. Des. Mach. Struct. 2023, 13, 24–44. [Google Scholar] [CrossRef]

- Maxey, W.A. Long shear fractures in CO2 lines controlled by regulating saturation, arrest pressures. Oil Gas J. 1986, 84, 31. [Google Scholar]

- Cosham, A.; Jones, D.G.; Armstrong, K.; Allason, D.; Barnett, J. Ruptures in gas pipelines, liquid pipelines and dense phase carbon dioxide pipelines. In Proceedings of the 2012 9th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; Volume 45141, pp. 465–482. [Google Scholar]

- Cosham, A.; Jones, D.G.; Armstrong, K.; Allason, D.; Barnett, J. Analysis of two dense phase carbon dioxide full-scale fracture propagation tests. In Proceedings of the 2014 10th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2014; American Society of Mechanical Engineers: New York, NY, USA, 2014; Volume 46124, p. V003T07A003. [Google Scholar]

- Biagio, M.D.; Lucci, A.; Mecozzi, E.; Spinelli, C.M. Fracture propagation prevention on CO2 pipelines: Full scale experimental testing and verification approach. In Proceedings of the Pipeline Technology Conference, Berlin, Germany, 1–5 May 2017. [Google Scholar]

- Linton, V.; Leinum, B.H.; Newton, R.; Fyrileiv, O. CO2SAFE-ARREST: A full-scale burst test research program for carbon dioxide pipelines—Part 1: Project overview and outcomes of test 1. In Proceedings of the 2018 12th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 51883, p. V003T05A008. [Google Scholar]

- Michal, G.; Davis, B.; Østby, E.; Lu, C.; Røneid, S. CO2SAFE-ARREST: A Full-Scale Burst Test Research Program for Carbon Dioxide Pipelines—Part 2: Is the BTCM Out of Touch with Dense-Phase CO2. In Proceedings of the 2018 12th International Pipeline Conference, Calgary, AB, Canada, 24–28 September 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 51883, p. V003T05A009. [Google Scholar]

- Zhang, D.; Wang, R.; Ouyang, X.; Fu, Y.; Wang, H.; Yan, F.; Liu, X. Experimental study of the full-scale burst failure behavior of carbon dioxide steel pipeline. J. Pipeline Sci. Eng. 2025, 5, 100221. [Google Scholar] [CrossRef]

- Chen, L.; Hu, Y.; Yang, K.; Yan, X.; Yu, S.; Yu, J.; Chen, S. Fracture process characteristic study during fracture propagation of a CO2 transport network distribution pipeline. Energy 2023, 283, 129060. [Google Scholar] [CrossRef]

- ISO 27913:2024; Carbon Dioxide Capture, Transportation And geological Storage—Pipeline Transportation Systems. International Organization for Standardization (ISO): Geneva, Switzerland, 2024.

- Maxey, W.; Kiefner, J.; Eiber, R.; Duffy, A. Ductile fracture initiation, propagation, and arrest in cylindrical vessels. In Fracture Toughness: Part II; ASTM International: West Conshohocken, PA, USA, 1972; pp. 70–81. [Google Scholar]

- Rothwell, A.B. The application of the Battelle “Short Formula” to the determination of ductile fracture arrest toughness in gas pipelines. In Proceedings of the 2000 3rd International Pipeline Conference, Calgary, AB, Canada, 1–5 October 2000; American Society of Mechanical Engineers: New York, NY, USA, 2000; Volume 40245, p. V001T02A019. [Google Scholar]

- Chen, L.; Hu, Y.; Yang, K.; Yan, X.; Yu, S.; Yu, J.; Chen, S. Experimental study of decompression wave characteristics and steel pipe applicability of supercritical CO2 pipeline. Gas Sci. Eng. 2023, 121, 205203. [Google Scholar] [CrossRef]

- Gu, S.; Li, Y.; Teng, L.; Hu, Q.; Zhang, D.; Ye, X.; Wang, C.; Wang, J.; Iglauer, S. A new model for predicting the decompression behavior of CO2 mixtures in various phases. Process. Saf. Environ. Prot. 2018, 120, 237–247. [Google Scholar] [CrossRef]

- Mahgerefteh, H.; Brown, S.; Martynov, S. A study of the effects of friction, heat transfer, and stream impurities on the decompression behavior in CO2 pipelines. Greenh. Gases Sci. Technol. 2012, 2, 369–379. [Google Scholar] [CrossRef]

- Terenzi, A. Influence of real-fluid properties in modeling decompression wave interacting with ductile fracture propagation. Oil Gas Sci. Technol. 2005, 60, 711–719. [Google Scholar] [CrossRef]

- Teng, L.; Li, Y.; Zhao, Q.; Wang, W.; Hu, Q.; Ye, X.; Zhang, D. Decompression characteristics of CO2 pipelines following rupture. J. Nat. Gas Sci. Eng. 2016, 36, 213–223. [Google Scholar] [CrossRef]

- Botros, K.K.; Geerligs, J.; Fletcher, L.; Rothwell, B.; Venton, P.; Carlson, L. Effects of pipe internal surface roughness on decompression wave speed in natural gas mixtures. In Proceedings of the 8th International Pipeline Conference, Calgary, AB, Canada, 27 September–1 October 2010; Volume 44212, pp. 907–922. [Google Scholar]

- Lund, H. Relaxation Models for Two-Phase Flow with Applications to CO2 Transport. Ph.D. Thesis, NTNU—Institutt for Energi- og Prosessteknikk (EPT), Trondheim, Norway, 2013. [Google Scholar]

- Flåtten, T.; Lund, H. Relaxation two-phase flow models and the subcharacteristic condition. Math. Model. Methods Appl. Sci. 2011, 21, 2379–2407. [Google Scholar] [CrossRef]

- Bell, I.H.; Deiters, U.K. On the construction of binary mixture p-x and T-x diagrams from isochoric thermodynamics. AIChE J. 2018, 64, 2745–2757. [Google Scholar] [CrossRef]

- Peng, D.Y.; Robinson, D.B. A new two-constant equation of state. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Simão, J.S.D.; Emmanuel, L.; João, A.A.; Manuel, E.J.L.; Nzinga, E.J.; Cangue, F.R.; Barros, A.A.C. Analysis of the thermodynamic behavior of gaseous mixtures using equations of state. S. Afr. J. Chem. Eng. 2024, 49, 339–347. [Google Scholar] [CrossRef]

- Kunz, O.; Wagner, W. The GERG-2008 wide-range equation of state for natural gases and other mixtures: An expansion of GERG-2004. J. Chem. Eng. Data 2012, 57, 3032–3091. [Google Scholar] [CrossRef]

| Test Name | Steel Grade | Diameter/mm | Wall Thickness/mm | Pressure/MPa | Temperature/°C | CO2 Concentration | Fracture Propagation Velocity/(m·s−1) | Type of Crack Arrest |

|---|---|---|---|---|---|---|---|---|

| Battelle 1 [27] | X70 | 510 | 11.1 | 14 | 42.3 | 100% | - | Crack arrestor/ Without crack arrestor |

| Battelle 2 [27] | X52 | 510 | 7.6 | 9 | 34.9 | 100% | - | Crack arrestors at both ends |

| COOLTRANS 1 [28] | X65 | 914 | 25.4 | 14.8 | 16.8 | 100% | 90–140 | Ductile fracture arrest |

| COOLTRANS 2 [29] | X65 | 914 | 25.4 | 15.1 | 8.2 | 100% | 80–120 | Ductile fracture arrest |

| COOLTRANS 3 [17] | X65 | 610 | 19.70 | 15 | 15.2 | 87.5% | 100–130 | Ductile fracture arrest |

| SARCO2 1 [17] | X65 | 610 | 12.2/13.7 | 13 | 13 | 96.2% | 110–130 | Circumferential weld crack arrest |

| SARCO2 2 [30] | X65 | 610 | 12.5–13.7 | 12.7 | 17.8 | 94% | 105–137 | Crack arrestor/ Ductile fracture arrest |

| CO2SAFE-ARREST 1 [31] | X65 | 610 | 13.7 | 15 | 11.6 | 91.1% | 75–130 | Ductile fracture arrest |

| CO2SAFE-ARREST 2 [32] | X65 | 610 | 14.25–15 | 14.9 | 12.7 | 89.8% | 50–270 | Ductile fracture arrest |

| PipeChina [33] | X65 | 610 | 7–7.6 | 11.8 | 13.7 | 95% | 100–250 | Ductile fracture arrest |

| Test 1 | Test 2 | Test 3 | Test 4 | Test 5 | |

|---|---|---|---|---|---|

| Test name | SARCO2 1 | SARCO2 2 | NG 1 | NG 2 | NG 3 |

| Outer diameter/mm | 610 | 610 | 914 | 914 | 610 |

| Wall thickness/mm | 12.7–13.7 | 12.5–13.7 | 25.4 | 25.4 | 19.1 |

| Test pressure/MPa | 12.95 | 12.77 | 14.83 | 15.06 | 15.02 |

| Test temperature/°C | 13 | 17 | 13.1 | 10.5 | 15.0 |

| Gas composition | CO2: 96.2% N2: 3.8% | CO2: 94.0% N2: 6.0% | CO2: 90.9% H2: 1.0% N2: 4.0% O2: 1.8% CH4: 2.2% | CO2: 93.7% H2: 1.1% N2: 3.4% O2: 0.0% CH4: 1.8% | CO2: 90.3% H2: 1.1% N2: 6.6% O2: 0.0% CH4: 2.0% |

| Saturation pressure/MPa | 6.1 | 7.2 | 8.06 | 7.38 | 7.38 |

| Correction factor of arrest (min) | 1.68 | 1.62 | 1.65 | 2.81 | 3.35 |

| Pipe No. | Length/m | Wall Thickness/m | Average CVN/J | Yield Strength/MPa |

|---|---|---|---|---|

| T1E3 | 11.93 | 7.6 | 156 | 550 |

| T1E2 | 11.68 | 7.2 | 140 | 502 |

| T1E1 | 11.91 | 7.0 | 86 | 548 |

| T1I | 11.92 | 7.0 | 70 | 583 |

| T1W1 | 11.90 | 7.0 | 78 | 586 |

| T1W2 | 11.69 | 7.2 | 156 | 526 |

| T1W3 | 11.64 | 7.6 | 148 | 536 |

| No. | Decompression Wave Velocity/(m·s−1) | Calculated Pressure/MPa | Experimental Pressure/MPa | Error |

|---|---|---|---|---|

| 1 | 84.51 | 6.45 | 5.66 | 13.80% |

| 2 | 116.90 | 6.45 | 5.84 | 10.38% |

| 3 | 184.63 | 6.45 | 6.15 | 4.84% |

| 4 | 225.48 | 6.45 | 6.29 | 2.50% |

| 5 | 238.67 | 6.45 | 6.41 | 0.62% |

| 6 | 264.56 | 6.45 | 6.49 | 0.65% |

| 7 | 285.43 | 6.45 | 6.62 | 2.64% |

| 8 | 316.20 | 6.45 | 6.66 | 3.27% |

| Average error | - | - | - | 4.87% |

| Mixture Units | Molar Percentage/% |

|---|---|

| Ar | 0.0055 |

| CO | 0.589 |

| CO2 | 91.4619 |

| C1 | 0.0121 |

| H2 | 0.2697 |

| H2S | 0.0001 |

| N2 | 7.6617 |

| Mixture Units | Molar Percentage/% |

|---|---|

| CO2 | 99.5 |

| N2 | 0.5 |

| Carbon Capture Method | Component Concentration (Vol. Fraction)/% | ||||||

|---|---|---|---|---|---|---|---|

| CO2 | N2 | O2 | Ar | H2S | CO | H2 | |

| Pre-Combustion Capture | 96.00 | 0.32 | 0 | 0 | 1.84 | 0.22 | 1.62 |

| Post-Combustion Capture | 99.85 | 0.15 | 0 | 0 | 0 | 0 | 0 |

| Oxy-Fuel Combustion Capture | 91.00 | 4.20 | 1.8 | 3.00 | 0 | 0 | 0 |

| Steel Grade | Outer Diameter/mm | Wall Thickness/mm | Arrest Pressure/MPa (80–200 J) | Meets Arrest Requirement? (Arrest Pressure > 8 MPa) |

|---|---|---|---|---|

| X65 | 355.6 | 8.0 | 5.6–5.8 | No |

| X65 | 355.6 | 11.0 | 7.5–8.0 | No |

| X65 | 355.6 | 12.5 | 8.4–9.1 | Yes |

| X60 | 355.6 | 8.0 | 5.3–5.4 | No |

| X60 | 355.6 | 11.0 | 7.1–7.5 | No |

| X60 | 355.6 | 12.5 | 8.0–8.5 | Yes |

| X56 | 355.6 | 8.8 | 5.5–5.7 | No |

| X56 | 355.6 | 12.5 | 7.7–8.1 | No |

| X56 | 355.6 | 14.2 | 8.7–9.2 | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wang, D.; Jiang, X.; Yu, Y.; Xing, X. Development and Application of Software for Calculating the Crack Arrest Toughness of Impurity-Containing Carbon Dioxide Pipelines Based on the BTCM. Processes 2025, 13, 3807. https://doi.org/10.3390/pr13123807

Li X, Wang D, Jiang X, Yu Y, Xing X. Development and Application of Software for Calculating the Crack Arrest Toughness of Impurity-Containing Carbon Dioxide Pipelines Based on the BTCM. Processes. 2025; 13(12):3807. https://doi.org/10.3390/pr13123807

Chicago/Turabian StyleLi, Xinze, Dezhong Wang, Xingyu Jiang, Yuetian Yu, and Xiaokai Xing. 2025. "Development and Application of Software for Calculating the Crack Arrest Toughness of Impurity-Containing Carbon Dioxide Pipelines Based on the BTCM" Processes 13, no. 12: 3807. https://doi.org/10.3390/pr13123807

APA StyleLi, X., Wang, D., Jiang, X., Yu, Y., & Xing, X. (2025). Development and Application of Software for Calculating the Crack Arrest Toughness of Impurity-Containing Carbon Dioxide Pipelines Based on the BTCM. Processes, 13(12), 3807. https://doi.org/10.3390/pr13123807