An Enhanced Workflow for Quantitative Evaluation of Fluid and Proppant Distribution in Multistage Fracture Treatment with Distributed Acoustic Sensing

Abstract

1. Introduction

2. Methodology

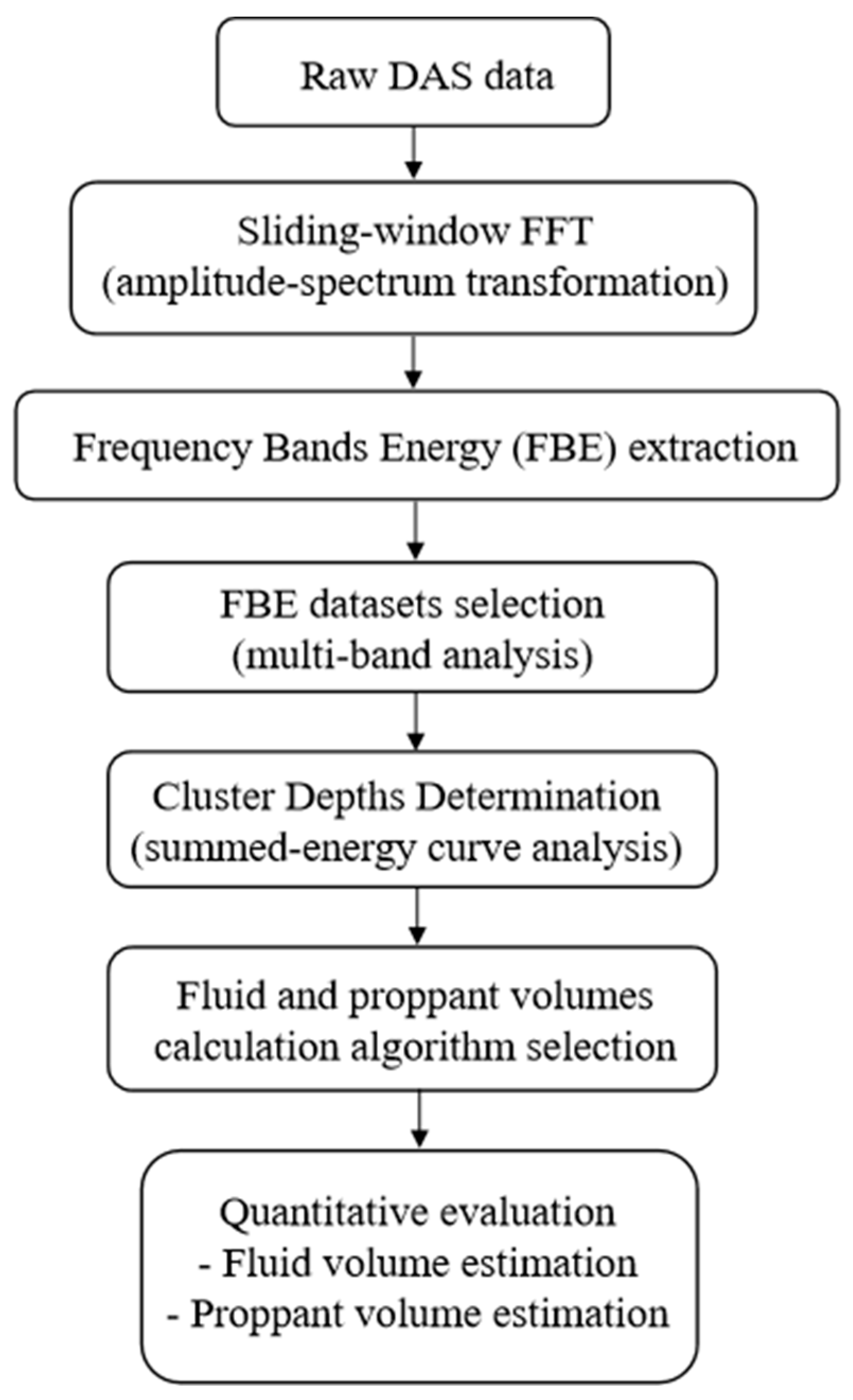

2.1. Overview of the DAS-Based Quantitative Evaluation Workflow

- (1)

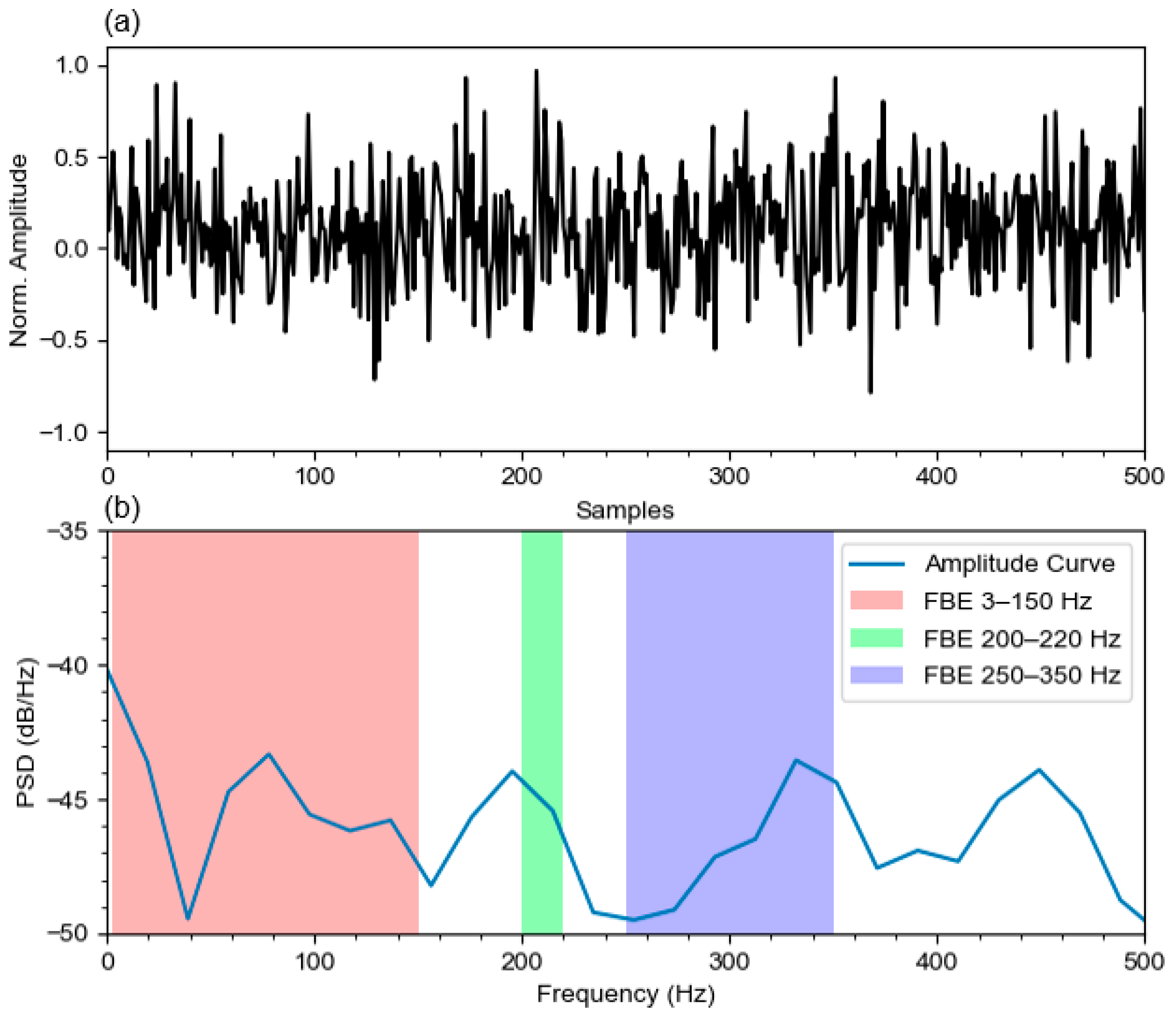

- Sliding-Window FFT: Raw DAS data are converted to the amplitude-spectrum domain via sliding-window FFT. The FFT method can be either the Short-Time Fourier Transform (STFT) [32] or Power Spectral Density (PSD). In practice, the PSD algorithm [33] can be applied to each windowed 1D acoustic signal on a specific channel and repeat this processing by looping over all channels and time windows.

- (2)

- Frequency Band Energy Extraction: For each PSD curve, multi-band energy can be extracted by first clipping the PSD curve between the lower-frequency and upper-frequency bands and, second, summing the clipped curve data. Thus, only one single FBE value is yielded for each time window in Step (1). This is also a downsampling process, and the data volume will be reduced dramatically after FBE extraction. The summation could also be replaced by the Root Mean Squared (RMS) or integral algorithms.

- (3)

- FBE Dataset Selection: We select one optimal FBE dataset from the multi-band FBE datasets. The selection criterion involves finding the frequency band with the highest energy within the active stage depth interval and the lowest energy outside the active stage.

- (4)

- Cluster Depth Determination. The top and bottom depth intervals of active perforation clusters are defined according to the minima points on the summed FBE curve, allowing for the extraction of cluster-specific FBE profiles over time.

- (5)

- Fluid and Proppant Volume Calculation Algorithm Selection: We select an optimal system of equations derived from either empirical or physics-based models.

- (6)

- Quantitative Evaluation: Converting FBE metrics into flow rates using the algorithm selected in Step (5), followed by time integration to obtain cumulative injection volumes.

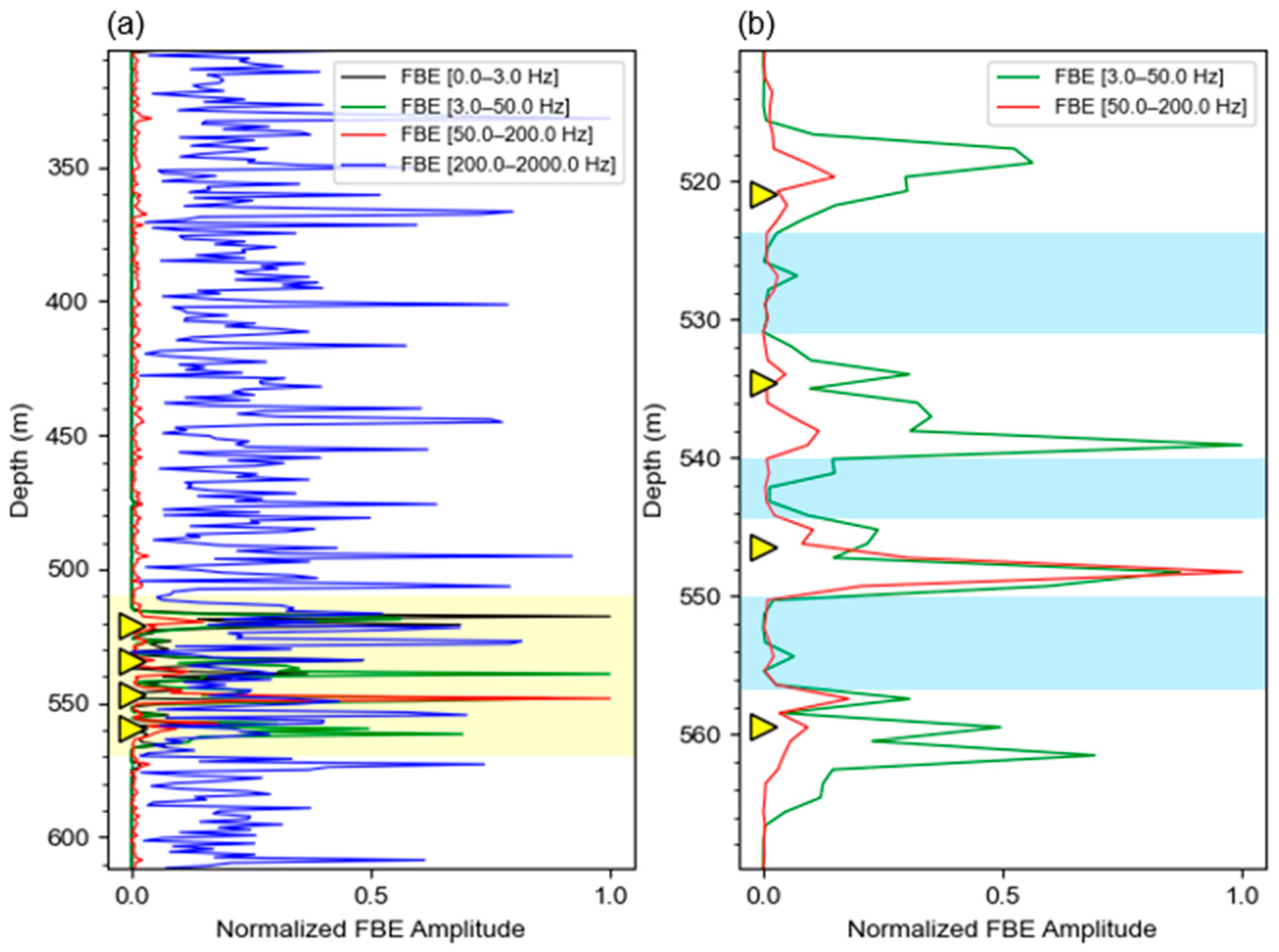

2.2. Uncertainty I: FBE Dataset Selection

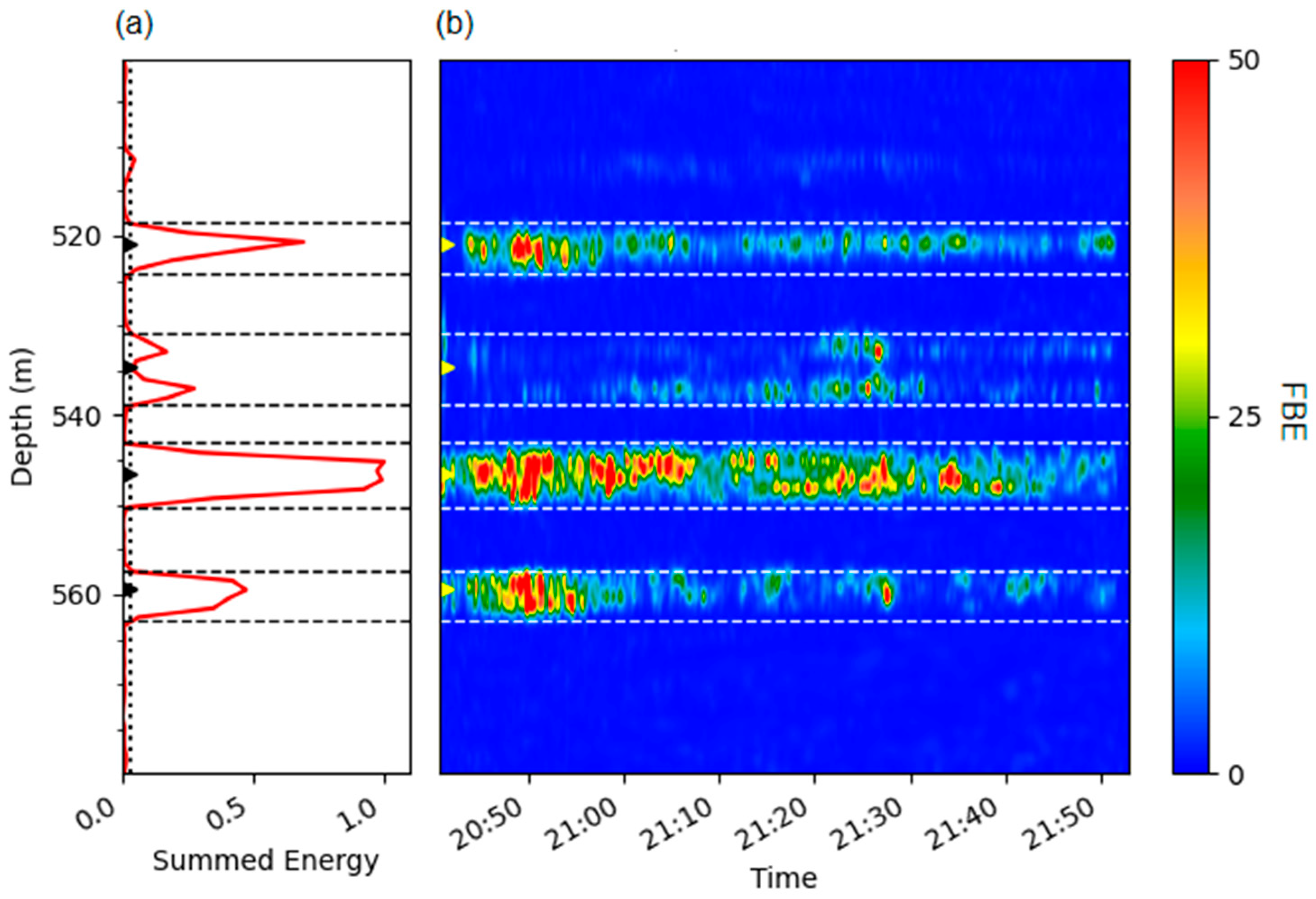

2.3. Uncertainty II: Perforation Cluster Depth Interval Determination

2.4. Uncertainty III: Fluid and Proppant Volume Calculation Algorithms

3. Field Dataset

3.1. Well Completion and Fracture Treatment Design

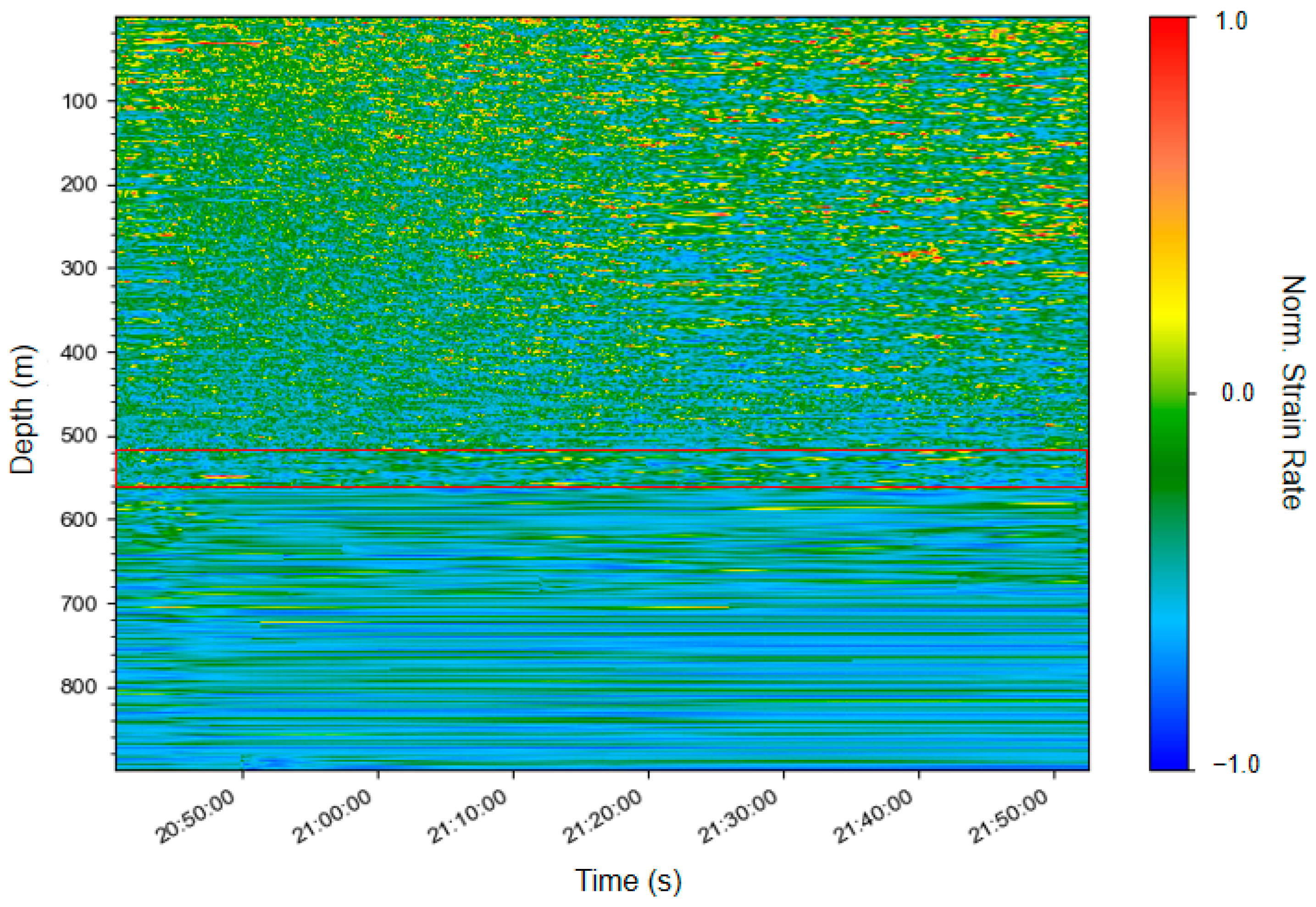

3.2. DAS Data Acquisition

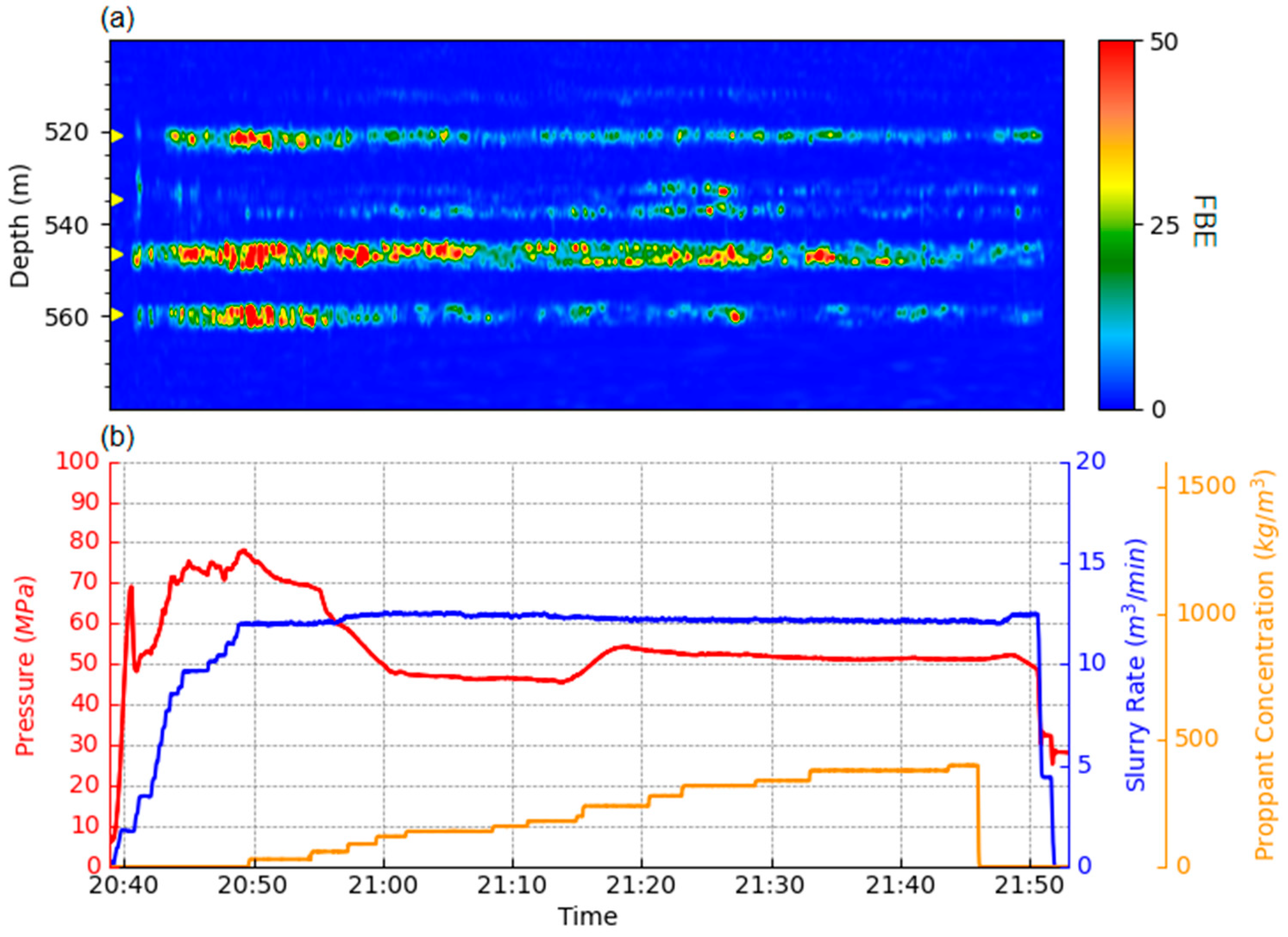

4. Results

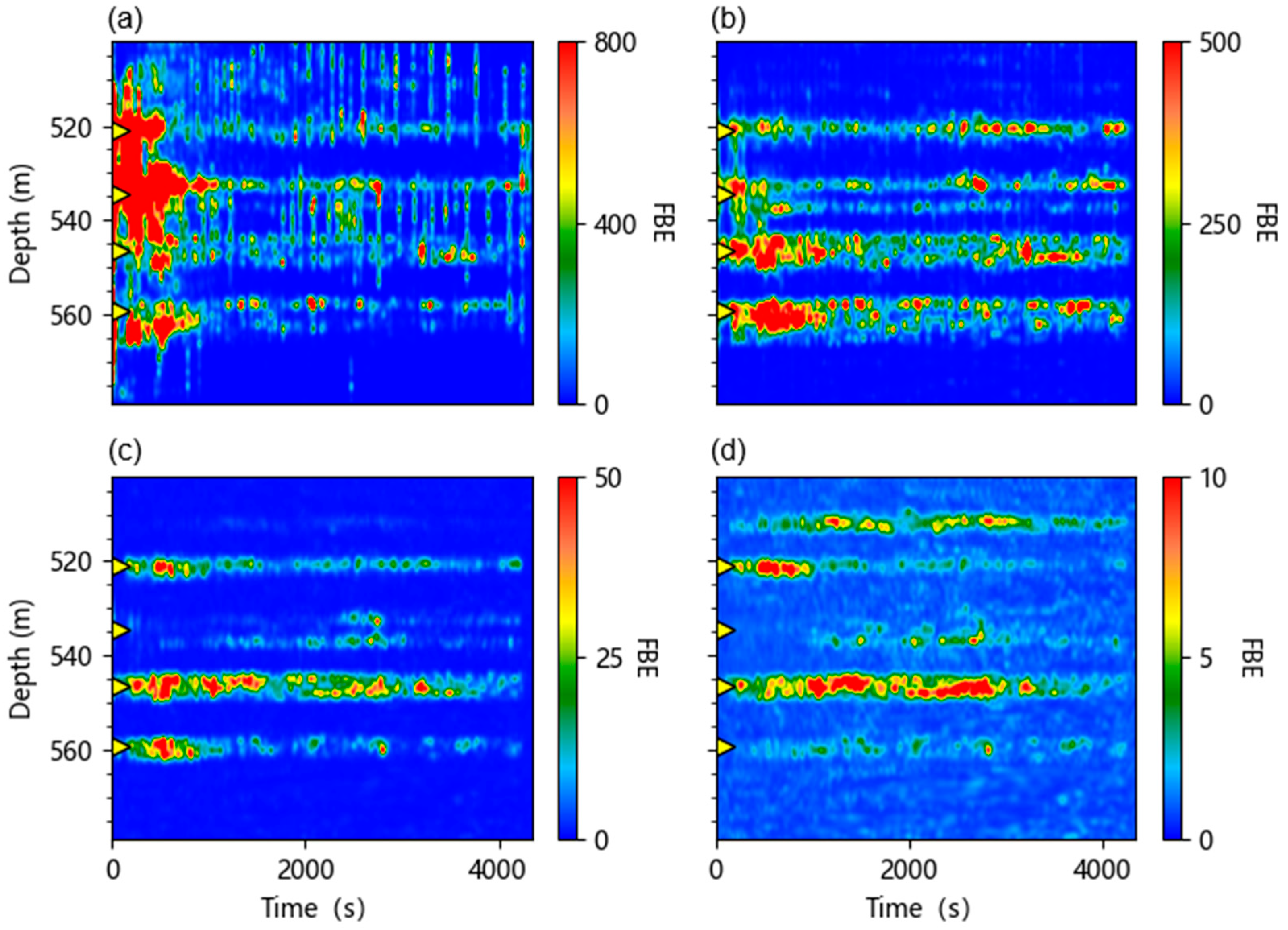

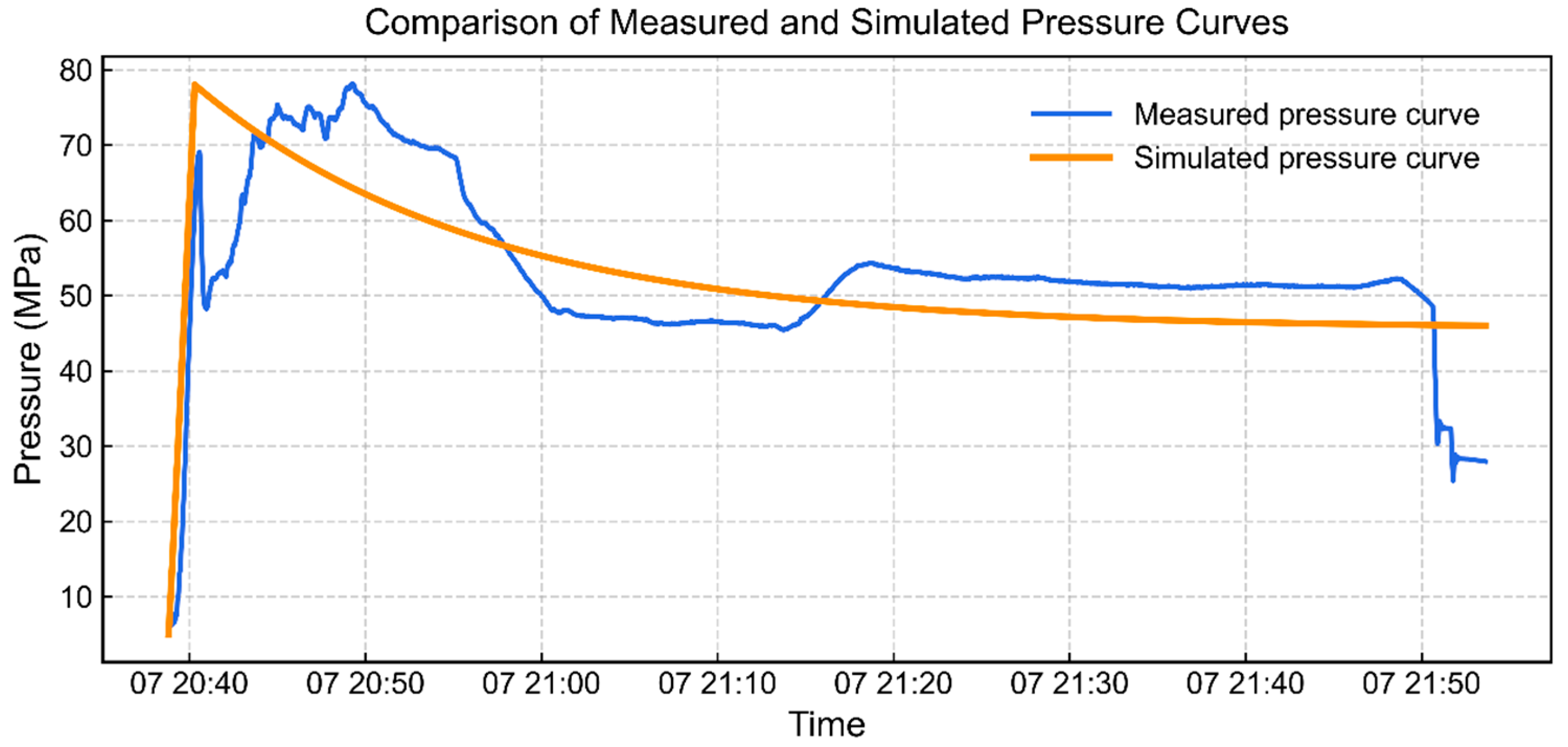

4.1. FBE Dataset Selection

4.2. Perforation Cluster Depth Interval Determination

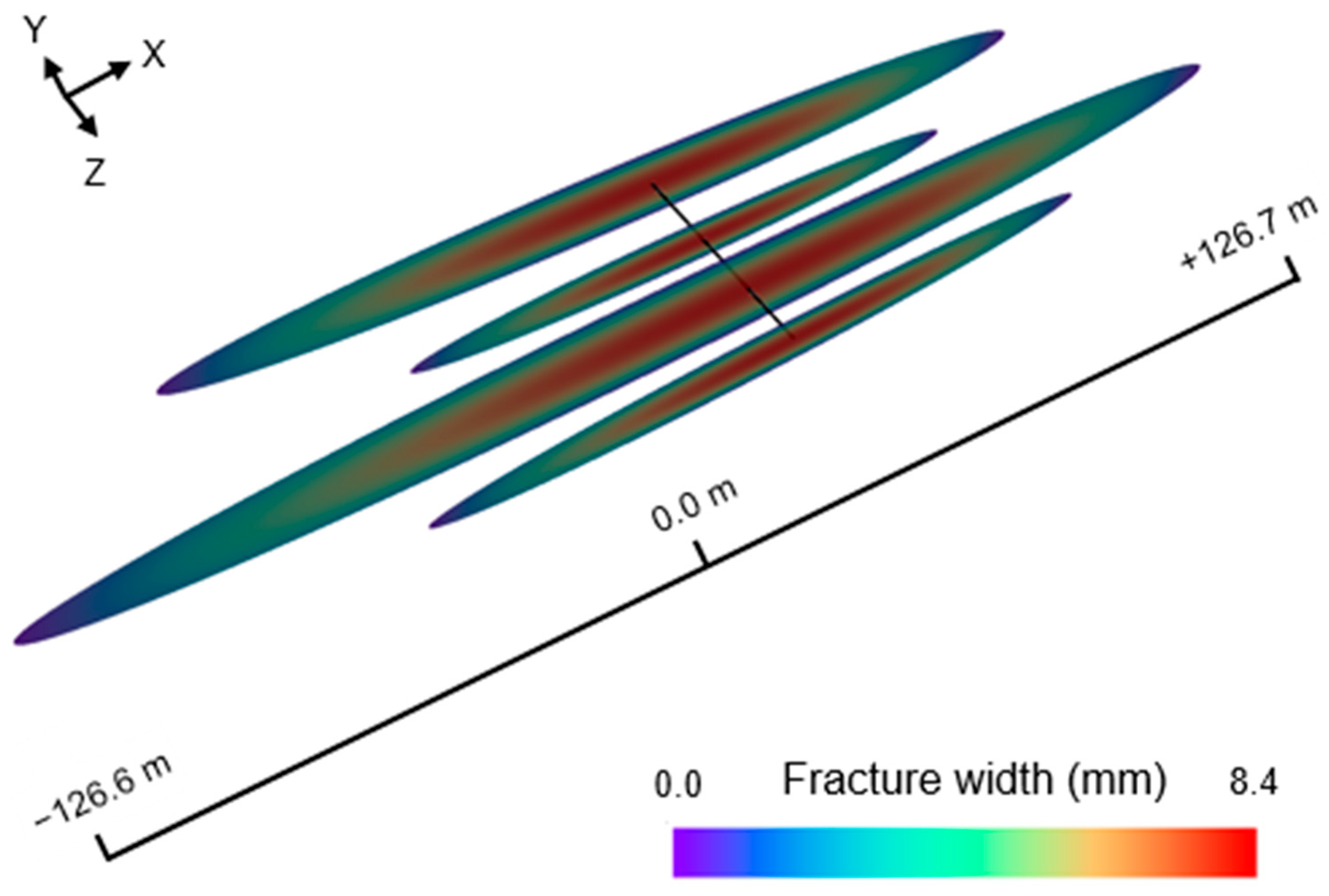

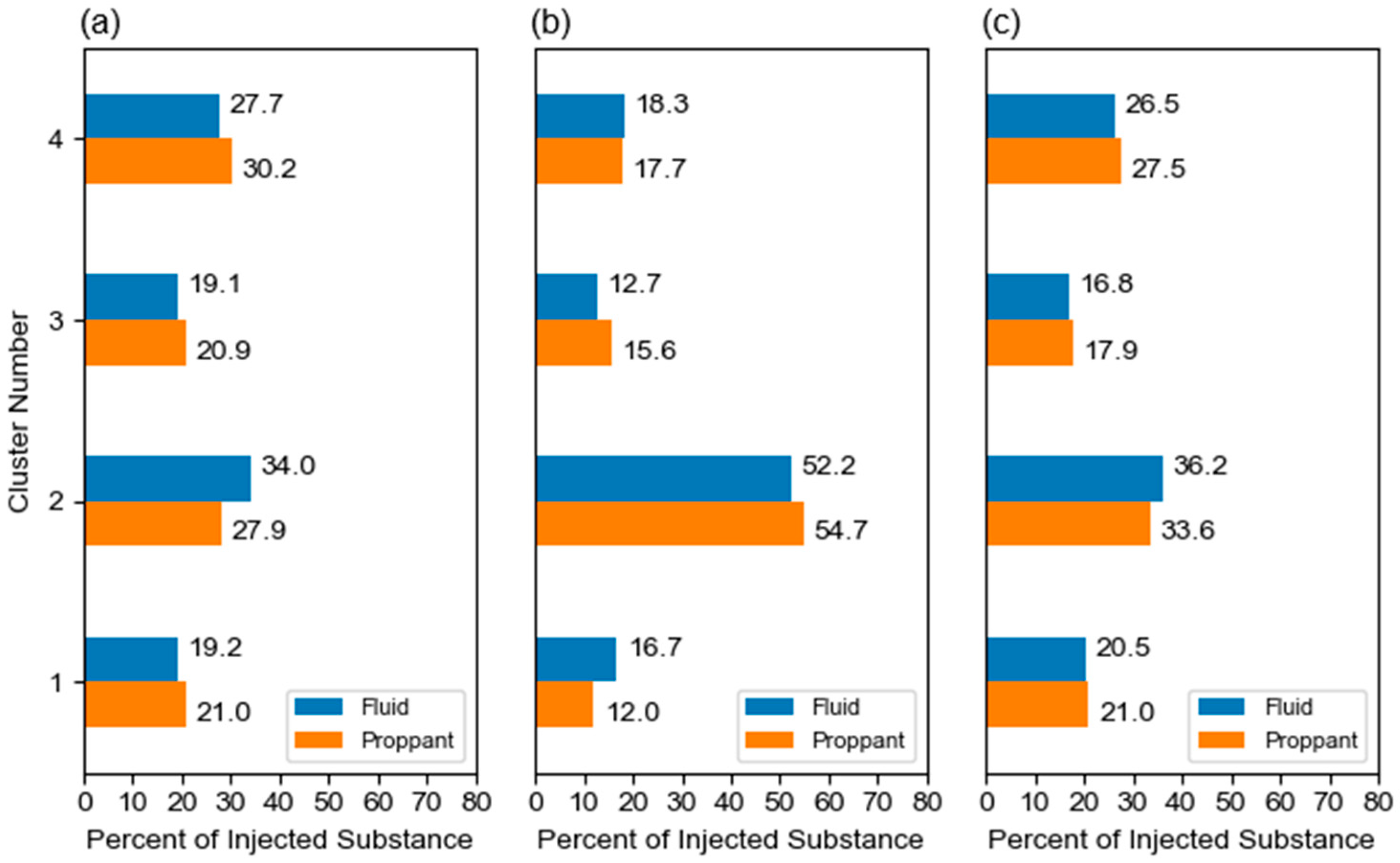

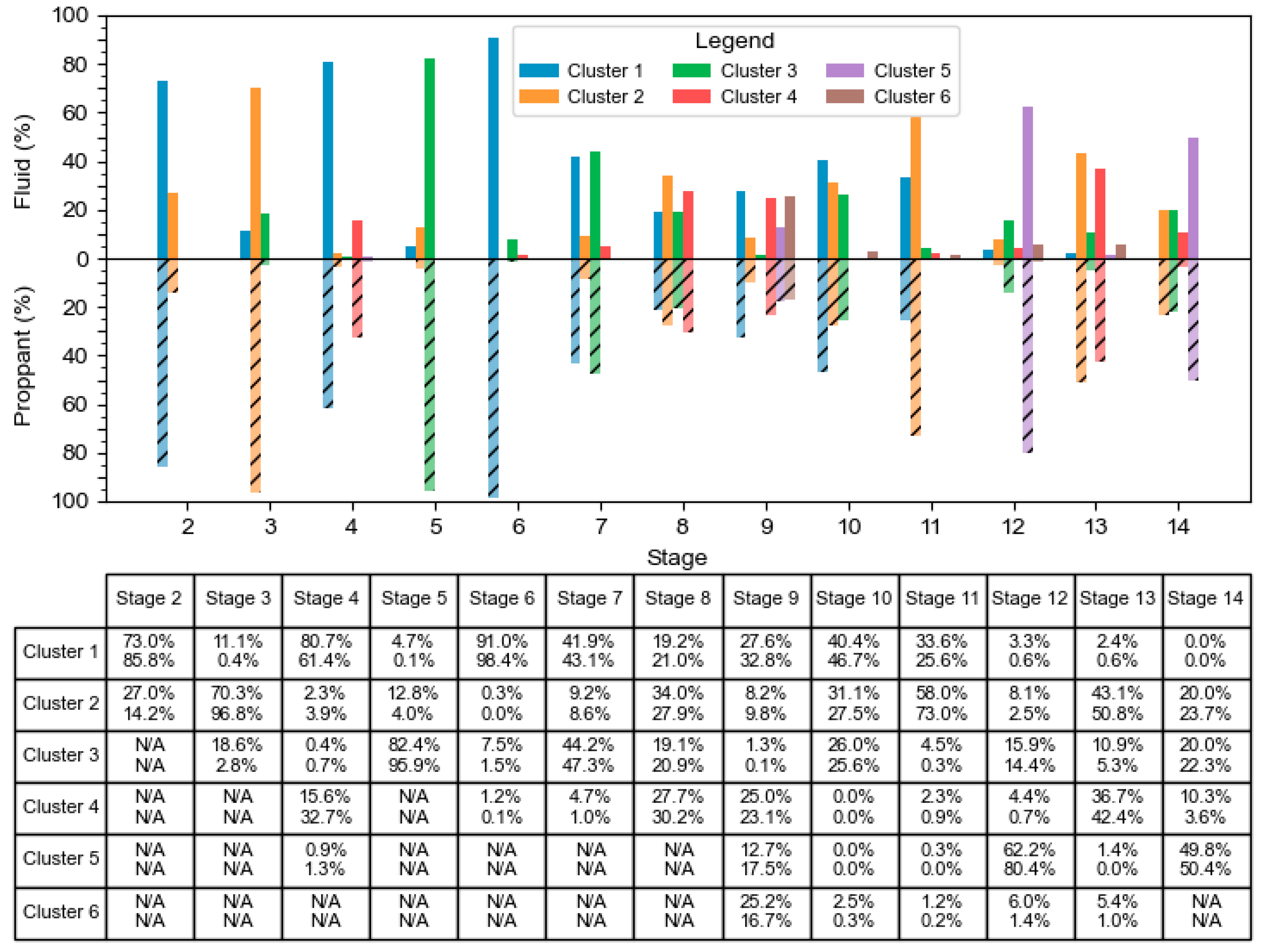

4.3. Quantitative Calculation of Fluid and Proppant Volumes

5. Discussion

5.1. Reasons for the Discrepancies Between Equations (1) and (5)

5.2. Limitations of Equation (1)

6. Conclusions

- (1)

- FBE dataset selection critically influences quantitative accuracy. Field analysis shows that the 50–200 Hz frequency band provides optimal sensitivity to injection-related acoustic signals while effectively suppressing background noise, yielding strong correlations with the injection rate.

- (2)

- Cluster depth intervals can be reliably identified using local minima in summed FBE profiles. This method is practical for real-time applications, although ambiguous boundaries or signal overlap may require refinement through multi-stage comparison, operational context integration, and manual quality control.

- (3)

- Volume estimation is highly sensitive to algorithm selection. Equation (1), based on laboratory-calibrated power-law relationships, aligns closely with field behavior, whereas the linear approximation (Equation (5)) introduces larger discrepancies—highlighting the importance of model calibration.

- (4)

- Sensitivity analysis of the correlation parameter A in Equation (1) indicates that it exerts a strong, nonlinear influence on estimated flow rates and hence fluid volumes. The flow rate estimations can vary by up to 300% within A ∈ [0.08, 0.1]. Field applications should employ the site-specific calibration of A.

- (5)

- Systematic uncertainty analysis enhances the robustness of DAS interpretation. The proposed workflow offers a practical and reproducible framework suitable for real-time fracture diagnostics in complex completions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DAS | Distributed Acoustic Sensing |

| FBE | Frequency Band Energy |

| FFT | Fast Fourier Transform |

| N/A | Not Applicable |

| OTDR | Optical Time-Domain Reflectometry |

| ϕ-OTDR | Phase-sensitive Optical Time-Domain Reflectometry |

| PSD | Power Spectral Density |

| RMS | Root Mean Squared |

| SPL | Sound Pressure Level |

| SRV | Stimulated Reservoir Volume |

| STFT | Short-Time Fourier Transform |

References

- Weijers, L.; Wright, C.; Mayerhofer, M.; Pearson, M.; Griffin, L.; Weddle, P. Trends in the North American Frac Industry: Invention through the Shale Revolution. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5–7 February 2019; SPE: Richardson, TX, USA, 2019; p. D011S001R001. [Google Scholar] [CrossRef]

- Cipolla, C.; Singh, A.; McClure, M.; McKimmy, M.; Lassek, J. The Perfect Frac Stage—What’s the Value? In Proceedings of the Unconventional Resources Technology Conference (URTeC), Houston, TX, USA, 17–19 June 2024; pp. 923–942. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, J.; Zhang, J.; Meng, S.; Li, J. Modeling of Scale-Dependent Perforation Geometrical Fracture Growth in Naturally Layered Media. Eng. Geol. 2024, 336, 107499. [Google Scholar] [CrossRef]

- Molenaar, M.M.; Fidan, E.; Hill, D.J. Real-Time Downhole Monitoring of Hydraulic Fracturing Treatments Using Fibre Optic Distributed Temperature and Acoustic Sensing. In Proceedings of the SPE/EAGE European Unconventional Resources Conference and Exhibition, Vienna, Austria, 20–22 March 2012; SPE: Richardson, TX, USA, 2012; p. SPE-152981. [Google Scholar] [CrossRef]

- Molenaar, M.M.; Hill, D.J.; Webster, P.; Fidan, E.; Birch, B. First Downhole Application of Distributed Acoustic Sensing for Hydraulic-Fracturing Monitoring and Diagnostics. SPE Drill. Complet. 2012, 27, 32–38. [Google Scholar] [CrossRef]

- Molenaar, M.M.; Cox, B.E. Field Cases of Hydraulic Fracture Stimulation Diagnostics Using Fiber Optic Distributed Acoustic Sensing (DAS) Measurements and Analyses. In Proceedings of the SPE Middle East Unconventional Resources Conference and Exhibition, Muscat, Oman, 28–30 January 2013; SPE: Richardson, TX, USA, 2013; p. SPE-164030. [Google Scholar] [CrossRef]

- Ugueto, G.A.; Ehiwario, M.; Grae, A.; Molenaar, M.; McCoy, K.; Huckabee, P.; Barree, B. Application of Integrated Advanced Diagnostics and Modeling to Improve Hydraulic Fracture Stimulation Analysis and Optimization. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2014; SPE: Richardson, TX, USA, 2014; p. SPE-168603. [Google Scholar] [CrossRef]

- Sui, W.; Liu, R.; Cui, K. Application and Research Progress of Distributed Optical Fiber Acoustic Sensing Monitoring for Hydraulic Fracturing. Sci. Sin. Technol. 2021, 51, 371–387. [Google Scholar] [CrossRef]

- Rashid, A.; Tackie-Otoo, B.N.; Abdul Latiff, A.H.; Otchere, D.A.; Jamaludin, S.N.F.; Asfha, D.T. Research Advances on Distributed Acoustic Sensing Technology for Seismology. Photonics 2025, 12, 196. [Google Scholar] [CrossRef]

- Rasool, M.H.; Ridha, S.; Latif, A.H.A.; Krishna, S. Industrial Adoption of Distributed Acoustic Sensing (DAS) in Petroleum Engineering and Geosciences: Real-World Evidence. J. Petro Chem. Eng. 2025, 51, 22–29. [Google Scholar]

- Boone, K.; Crickmore, R.; Werdeg, Z.; Laing, C.; Molenaar, M. Monitoring Hydraulic Fracturing Operations Using Fiber-Optic Distributed Acoustic Sensing. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference (URTeC), San Antonio, TX, USA, 20–22 July 2015; URTEC: Richardson, TX, USA, 2015; p. URTeC-2158449. [Google Scholar] [CrossRef]

- Saw, J.; Zhu, X.; Luo, L.; Correa, J.; Soga, K.; Ajo-Franklin, J. Distributed Fiber Optic Sensing for In-Well Hydraulic Fracture Monitoring. Geoenerg. Sci. Eng. 2025, 250, 213792. [Google Scholar] [CrossRef]

- Lorwongngam, A.O.; McKimmy, M.; Oughton, E.; Cipolla, C. One Shot Wonder XLE Design: A Continuous Improvement Case Study of Developing XLE Design in the Bakken. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 31 January–2 February 2023; SPE: Richardson, TX, USA, 2023; p. D021S006R002. [Google Scholar] [CrossRef]

- Ramurthy, M.; Richardson, J.; Brown, M.; Sahdev, N.; Wiener, J.; Garcia, M. Fiber-Optics Results from an Intra-Stage Diversion Design Completions Study in the Niobrara Formation of DJ Basin. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 9–11 February 2016; SPE: Richardson, TX, USA, 2016; p. D021S006R005. [Google Scholar] [CrossRef]

- Trumble, M.; Sinkey, M.; Meehleib, J. Got Diversion Real-Time Analysis to Identify Success or Failure. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5–7 February 2019; SPE: Richardson, TX, USA, 2019; p. D021S005R002. [Google Scholar] [CrossRef]

- Ugueto, G.A.; Huckabee, P.T.; Molenaar, M.M. Challenging Assumptions about Fracture Stimulation Placement Effectiveness Using Fiber Optic Distributed Sensing Diagnostics: Diversion, Stage Isolation and Overflushing. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 3–5 February 2015; SPE: Richardson, TX, USA, 2015; p. D011S002R001. [Google Scholar] [CrossRef]

- Ugueto, G.; Huckabee, P.; Nguyen, A.; Daredia, T.; Chavarria, J.; Wojtaszek, M.; Reynolds, A. A Cost-Effective Evaluation of Pods Diversion Effectiveness Using Fiber Optics DAS and DTS. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020; SPE: Richardson, TX, USA, 2020; p. D011S002R001. [Google Scholar] [CrossRef]

- Thiruvenkatanathan, P.; Langnes, T.; Beaumont, P.; White, D.; Webster, M. Downhole Sand Ingress Detection Using Fibre-Optic Distributed Acoustic Sensors. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 7–10 November 2016; SPE: Richardson, TX, USA, 2016; p. SPE-183329-MS. [Google Scholar] [CrossRef]

- Bohn, R.; Hull, R.; Trujillo, K.; Wygal, B.; Parsegov, S.G.; Carr, T.; Carney, B.J. Learnings from the Marcellus Shale Energy and Environmental Lab (MSEEL) Using Fiber Optic Tools and Geomechanical Modeling. In Proceedings of the Unconventional Resources Technology Conference (URTeC), Austin, TX, USA, 20–22 July 2020; pp. 1833–1851. [Google Scholar] [CrossRef]

- Hull, R.; Woerpel, C.; Trujillo, K.; Bohn, R.; Wygal, B.; Carney, B.J.; Carr, T. Hydraulic Fracture Characterization Using Fiber Optic DAS and DTS Data. In Proceedings of the SEG International Exposition and Annual Meeting, Virtual, 11–16 October 2020; SEG: Houston, TX, USA, 2020; p. D041S096R007. [Google Scholar] [CrossRef]

- James-Ravenell, M.; Jin, G. Characterizing In-Well DAS Signal before Fiber Breakage. In Proceedings of the SEG International Exposition and Annual Meeting, Houston, TX, USA, 26–29 August 2024; SEG: Houston, TX, USA, 2024; p. SEG-2024. [Google Scholar] [CrossRef]

- Wu, B.; Wang, J.; Zhang, J.; Wang, M.; Wang, F.; Yan, T. Field Test of Single-Cluster Fracture Extension Strength Monitoring by Optical Fiber Outside Casing. Drill. Prod. Technol. 2022, 45, 84–88. [Google Scholar] [CrossRef]

- Pakhotina, I. Using Distributed Acoustic Sensing for Multiple-Stage Fractured Well Diagnosis. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2020. [Google Scholar]

- Zhao, Z.; Wu, X.; Qiao, Y.; Zhang, Y.; Tang, J.; Tian, Y.; Wang, C. Uncertainty Analysis of Quantitative Hydraulic Fracturing Fluid and Sand Volumes Calculated from DAS Data. In Proceedings of the SEG Workshop on Fiber Optics Sensing for Energy Applications, Xi’an, China, 21–23 July 2024; Society of Exploration Geophysicists: Houston, TX, USA, 2024; pp. 35–38. [Google Scholar] [CrossRef]

- Sharma, J.; Cuny, T.; Ogunsanwo, O.; Santos, O. Low-frequency distributed acoustic sensing for early gas detection in a wellbore. IEEE Sens. J. 2020, 21, 6158–6169. [Google Scholar] [CrossRef]

- Gemeinhardt, H.; Sharma, J. Machine-learning-assisted leak detection using distributed temperature and acoustic sensors. IEEE Sens. J. 2023, 24, 1520–1531. [Google Scholar] [CrossRef]

- Pakhotina, I.; Sakaida, S.; Zhu, D.; Hill, A.D. Diagnosing Multistage Fracture Treatments with Distributed Fiber-Optic Sensors. SPE Prod. Oper. 2020, 35, 852–864. [Google Scholar] [CrossRef]

- Chen, K.; Zhu, D.; Hill, A.D. Acoustic Signature of Flow from a Fractured Wellbore. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015; SPE: Houston, TX, USA, 2015. [Google Scholar] [CrossRef]

- Santos, R.A. Experimental Study of the Effect of Permeability on the Generation of Noise. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2018. [Google Scholar]

- In’t Panhuis, P.; den Boer, H.; Van Der Horst, J.; Paleja, R.; Randell, D.; Joinson, D.; Bartlett, R. Flow Monitoring and Production Profiling Using DAS. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 27–29 October 2014; SPE: Richardson, TX, USA, 2014; p. SPE-170917. [Google Scholar] [CrossRef]

- Langnes, T.; Thiruvenkatanathan, P. Detecting Downhole Sand Ingress Locations. Patent No. 11,053,791 B2, 6 July 2021. [Google Scholar]

- Sejdić, E.; Djurović, I.; Jiang, J. Time–Frequency Feature Representation Using Energy Concentration: An Overview of Recent Advances. Digit. Signal Process. 2009, 19, 153–183. [Google Scholar] [CrossRef]

- Welch, P. The Use of Fast Fourier Transform for the Estimation of Power Spectra: A Method Based on Time Averaging over Short, Modified Periodograms. IEEE Trans. Audio Electroacoust. 2003, 15, 70–73. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, M.; Guo, T.; Qu, Z.; Zhang, B.; Lv, M.; Wang, W. Proppant transport coupled with propagation of three-dimensional hydraulic-natural fractures. Rock Mech. Rock Eng. 2025, 58, 2435–2463. [Google Scholar] [CrossRef]

- Lakirouhani, A.; Jolfaei, S. Assessment of hydraulic fracture initiation pressure using fracture mechanics criterion and coupled criterion with emphasis on the size effect. Arab. J. Sci. Eng. 2024, 49, 5897–5908. [Google Scholar] [CrossRef]

- Cramer, D.D.; Zhang, J. Pressure-Based Diagnostics for Evaluating Treatment Confinement. SPE Prod. Oper. 2021, 36, 530–552. [Google Scholar] [CrossRef]

- Hamanaka, Y.; Zhu, D.; Hill, A.D. Investigation of the Reduction in Distributed Acoustic Sensing Signal Due to Perforation Erosion by Using CFD Acoustic Simulation and Lighthill’s Acoustic Power Law. Sensors 2024, 24, 5996. [Google Scholar] [CrossRef] [PubMed]

- Hamanaka, Y.; Zhu, D.; Hill, A.D.; Kerr, E. Evaluation of Perforation Erosion and Fluid Allocation with Distributed Acoustic Sensing in Multi-Stage Fracture Stimulation. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2025; SPE: Richardson, TX, USA, 2025; p. D021S006R005. [Google Scholar] [CrossRef]

- Somanchi, K.; Brewer, J.; Reynolds, A. Extreme Limited-Entry Design Improves Distribution Efficiency in Plug-and-Perforate Completions: Insights from Fiber-Optic Diagnostics. SPE Drill. Complet. 2018, 33, 298–306. [Google Scholar] [CrossRef]

- Katende, A.; Allen, C.; Rutqvist, J.; Nakagawa, S.; Radonjic, M. Experimental and numerical investigation of proppant embedment and conductivity reduction within a fracture in the Caney Shale, Southern Oklahoma, USA. Fuel 2023, 341, 127571. [Google Scholar] [CrossRef]

- Sun, X.; Mu, J.; Guo, X.; Cao, B.; Tang, T.; Zhang, T. Experimental Study on Effective Propping of Multi-Level Fractures Using Micro-Proppants. Processes 2025, 13, 2503. [Google Scholar] [CrossRef]

| Operation | Dominant Response Frequency Range | Remarks |

|---|---|---|

| Hydraulic fracturing and injection | 0–400 Hz | Energy concentrated in the mid-frequency band |

| Production (liquid/gas) | 0–500 Hz | Flow-induced signals; frequency may vary with production phase |

| Sand ingress | <50 Hz or >5 kHz | Low-frequency flow noise or high excitation frequency vibration |

| Wellbore leakage and noise sources | <300 Hz or Broadband | Leakage signals, background noise, and reflections; typically filtered or segmented during preprocessing |

| Mass | Cluster No. | Volume Percent of Equation (1) (%) | Volume Percent of Equation (5) (%) | Volume Percent of Benchmarked Simulation (%) | Errors of Equation (1) to Simulation (%) | Errors of Equation (5) to Simulation (%) |

|---|---|---|---|---|---|---|

| Fluid | 1 | 21.0 | 16.7 | 20.5 | 0.5 | 3.8 |

| 2 | 34.0 | 52.2 | 36.2 | 2.2 | 16.0 | |

| 3 | 19.1 | 12.7 | 16.8 | 2.3 | 4.1 | |

| 4 | 27.7 | 18.3 | 26.5 | 1.2 | 8.2 | |

| Proppant | 1 | 21.0 | 12.0 | 21.0 | 0.0 | 9.0 |

| 2 | 27.9 | 54.7 | 33.6 | 5.7 | 21.1 | |

| 3 | 20.9 | 15.6 | 17.9 | 3.0 | 2.3 | |

| 4 | 30.2 | 17.7 | 27.5 | 2.7 | 9.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.; Li, B.; Zhao, Z.; Wen, R.; Bai, Y.; Guo, H.; Tang, J.; Wang, C. An Enhanced Workflow for Quantitative Evaluation of Fluid and Proppant Distribution in Multistage Fracture Treatment with Distributed Acoustic Sensing. Processes 2025, 13, 3738. https://doi.org/10.3390/pr13113738

Liu W, Li B, Zhao Z, Wen R, Bai Y, Guo H, Tang J, Wang C. An Enhanced Workflow for Quantitative Evaluation of Fluid and Proppant Distribution in Multistage Fracture Treatment with Distributed Acoustic Sensing. Processes. 2025; 13(11):3738. https://doi.org/10.3390/pr13113738

Chicago/Turabian StyleLiu, Wenqiang, Bobo Li, Zhengguang Zhao, Rou Wen, Yu Bai, Haoran Guo, Jizhou Tang, and Chunlei Wang. 2025. "An Enhanced Workflow for Quantitative Evaluation of Fluid and Proppant Distribution in Multistage Fracture Treatment with Distributed Acoustic Sensing" Processes 13, no. 11: 3738. https://doi.org/10.3390/pr13113738

APA StyleLiu, W., Li, B., Zhao, Z., Wen, R., Bai, Y., Guo, H., Tang, J., & Wang, C. (2025). An Enhanced Workflow for Quantitative Evaluation of Fluid and Proppant Distribution in Multistage Fracture Treatment with Distributed Acoustic Sensing. Processes, 13(11), 3738. https://doi.org/10.3390/pr13113738