1. Introduction

The global electricity demand is projected to exhibit the fastest growth rate during the triennium of 2025–2027. This increase is primarily driven by industrial expansion, increased air-conditioning usage, ongoing electrification, the large-scale integration of electric vehicles (EVs) into modern power systems, and the worldwide proliferation of data centers. The annual growth rate is expected to reach approximately

until 2027, corresponding to 3500 TWh [

1]. By 2027, solar photovoltaic (PV) systems are expected to contribute nearly

to global electricity demand [

1].

In 2024, Brazil’s electricity demand increased by

[

1]. According to the national energy balance, hydropower remains the dominant source in the country’s electricity mix. Renewable sources account for

of the domestic electricity supply, with the residential sector representing

of the final consumption [

2].

The penetration of renewable energy sources, including PV, wind energy conversion systems, and hydropower, has expanded substantially in recent years [

3,

4]. Such expansion of distributed generation poses significant challenges to the conventional centralized grid paradigm.

The incorporation of photovoltaic technology into buildings is generally termed building-integrated photovoltaic (BIPV) systems [

5,

6]. A cost-effective BIPV solution was proposed [

7], employing a high step-up PV dc-building module combined with an inverter.

A power distribution system (PEDF) comprising three main components—PV generation, energy storage, and dc distribution—was presented in [

8]. Similarly, in [

9], two

kWp PV systems, operating within a 190–370 V range, supplied power to a 48 V LED lighting dc bus at the CleanTech-One Level Five laboratory.

Moreover, an IoT-based multifunctional system was deployed in a

kW PV dc residential building in Tamil Nadu, India [

10]. The proposed strategy reduced total losses by

through load prioritization and demand-side management. Furthermore, the integration of IoT into building automation improved energy management and enhanced occupant comfort [

11].

DC microgrids are generally organized into two configurations: unipolar and bipolar bus structures. The unipolar topology comprises positive and negative poles, while the bipolar topology includes three poles: positive, negative, and a central neutral point.

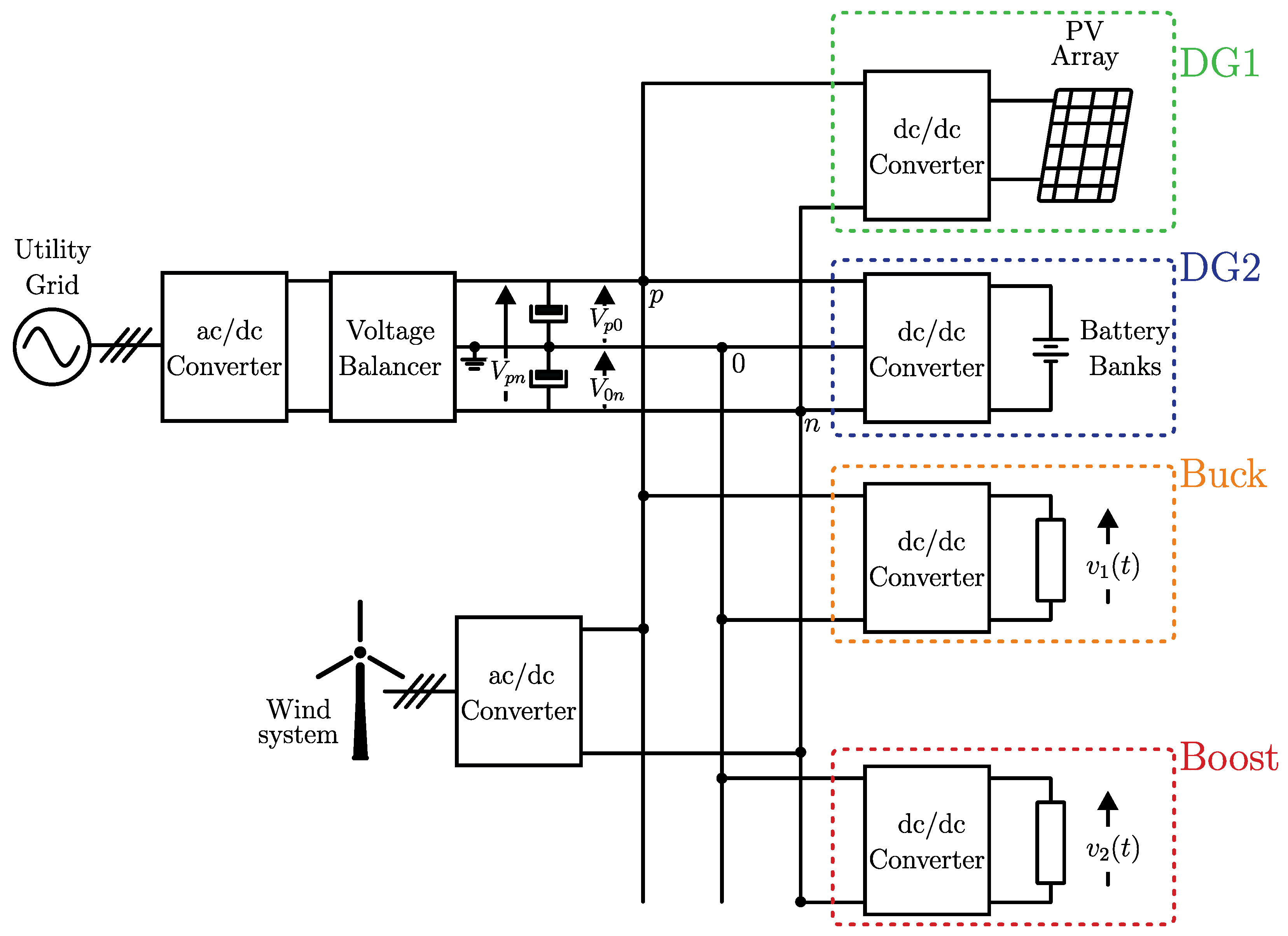

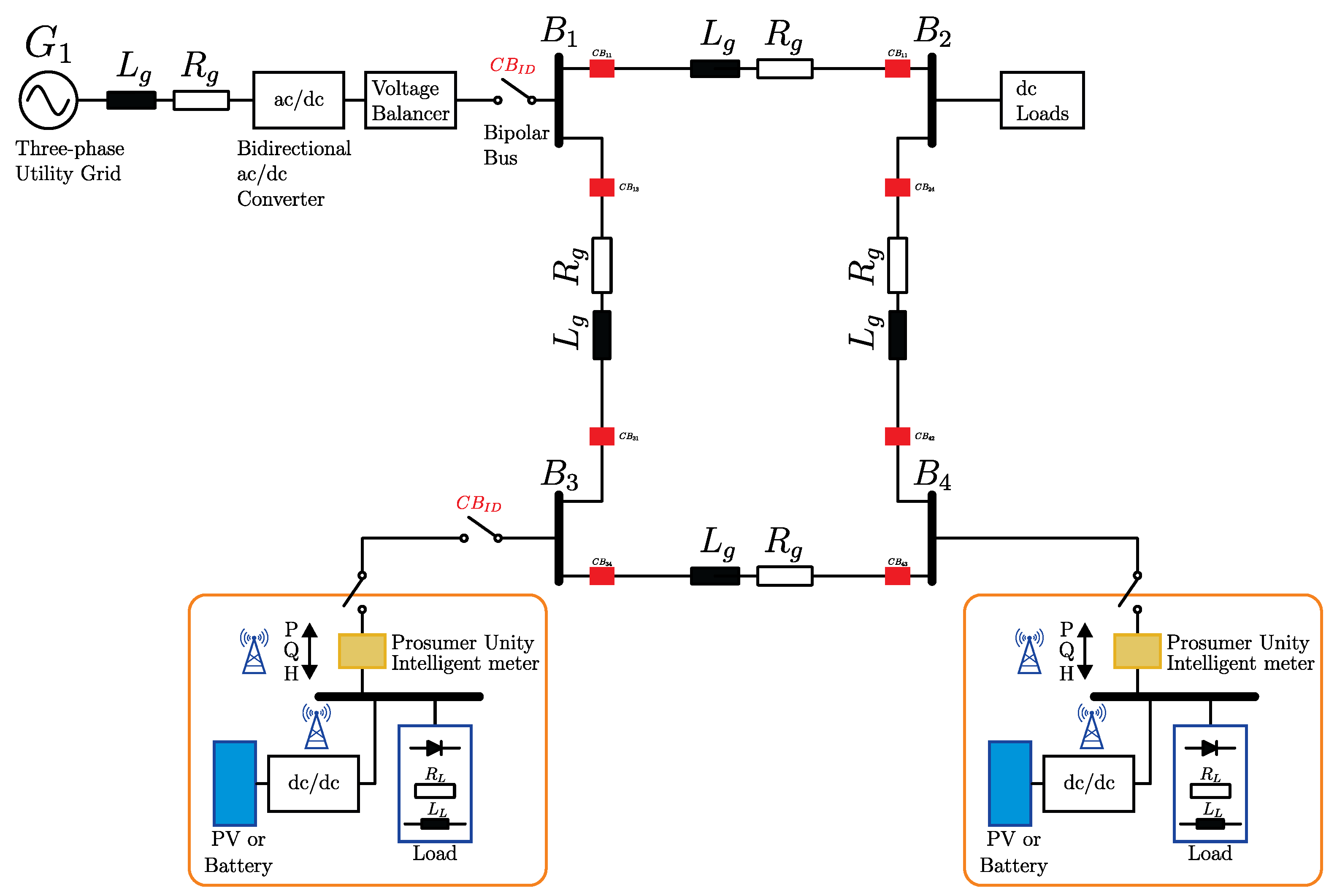

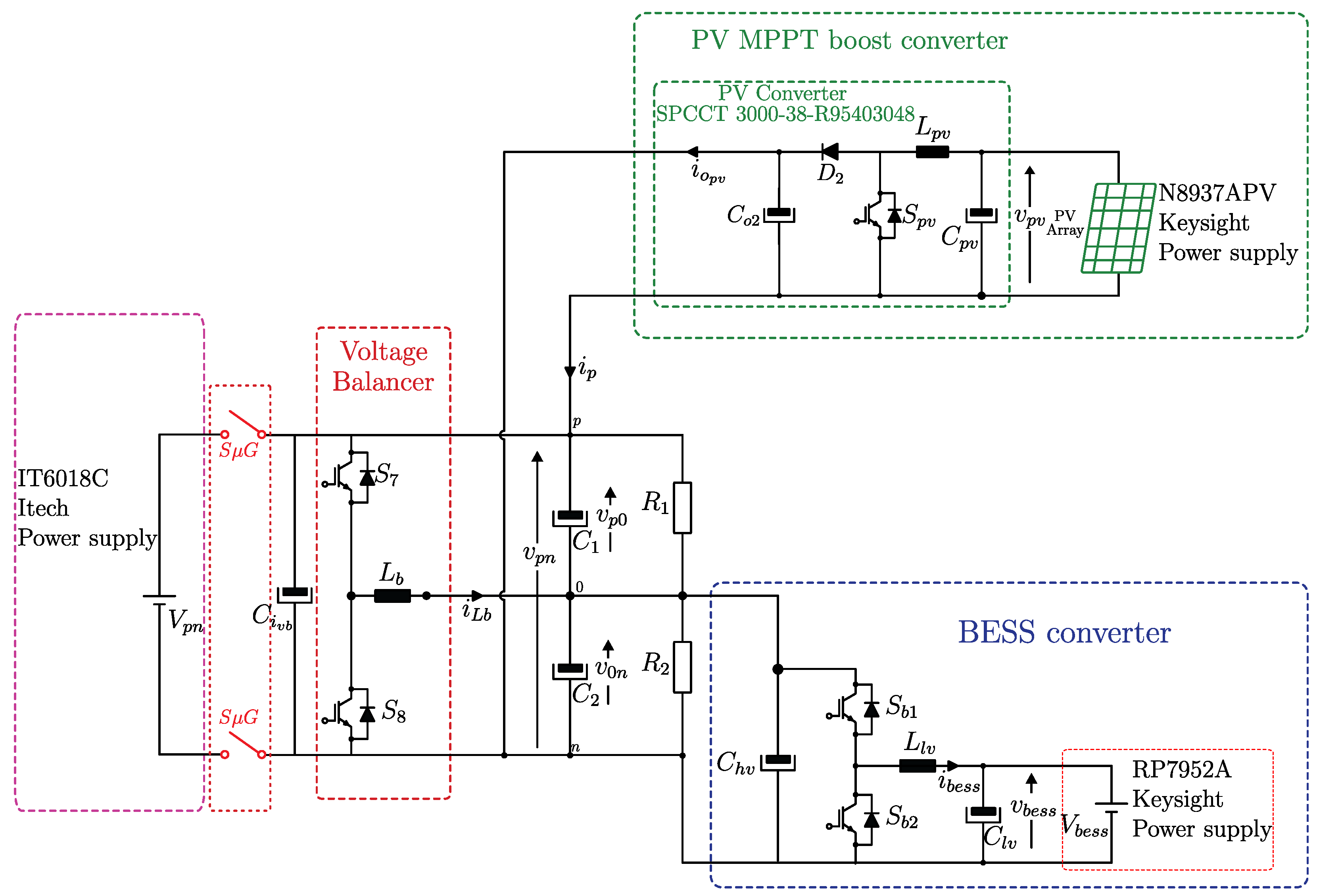

Figure 1 illustrates a bipolar dc microgrid based on a

p–0–

n bus structure, which integrates several distributed generators (DGs), such as an energy storage system (ESS), a wind energy conversion system (WECS), a PV array with an embedded dc–dc converter, and electronic dc loads such as buck and boost converters.

In a bipolar dc microgrid, the presence of three electrical poles allows renewable energy sources and dc loads to be connected either between the positive pole and the neutral point (p–0), between the neutral point and the negative pole (0–n), or directly between the positive and negative poles (p–n).

Several pilot projects have already implemented bipolar dc microgrids. For example, a hybrid ac-dc distribution system with a

V dc bipolar grid and a 380 V dc bus has been deployed in Finland [

12].

A representative medium- and low-voltage dc distribution system has been deployed by State Grid Jiangsu Electric Power in Wujiang, China. The installation comprises three bipolar dc levels, namely

,

, and

. This infrastructure supplies a wide assortment of dc-based applications, including industrial facilities, data centers, residential consumers, and rooftop photovoltaic units located in the Hongyi area [

13].

A key advantage of the bipolar configuration is the flexibility of voltage-level operation [

14]. The reliability of the system is improved because operation can continue with a single pole in the event of a pole fault. In such cases, either the

p–0 or 0–

n bus ensures continuous supply to dc loads, thereby improving the power transmission capability [

14,

15].

Although dc microgrids offer numerous advantages, they still face two major challenges: lack of standardization and unresolved protection issues [

16]. Furthermore, grounding methods, voltage level definitions, and islanding detection techniques are still under investigation [

17,

18,

19].

A voltage balancer is employed to maintain the balance between

and

even in the presence of unbalanced load conditions. Furthermore, it prevents dc current injection when the ac–dc converter is interfaced with a three-phase four-wire system [

20,

21,

22,

23].

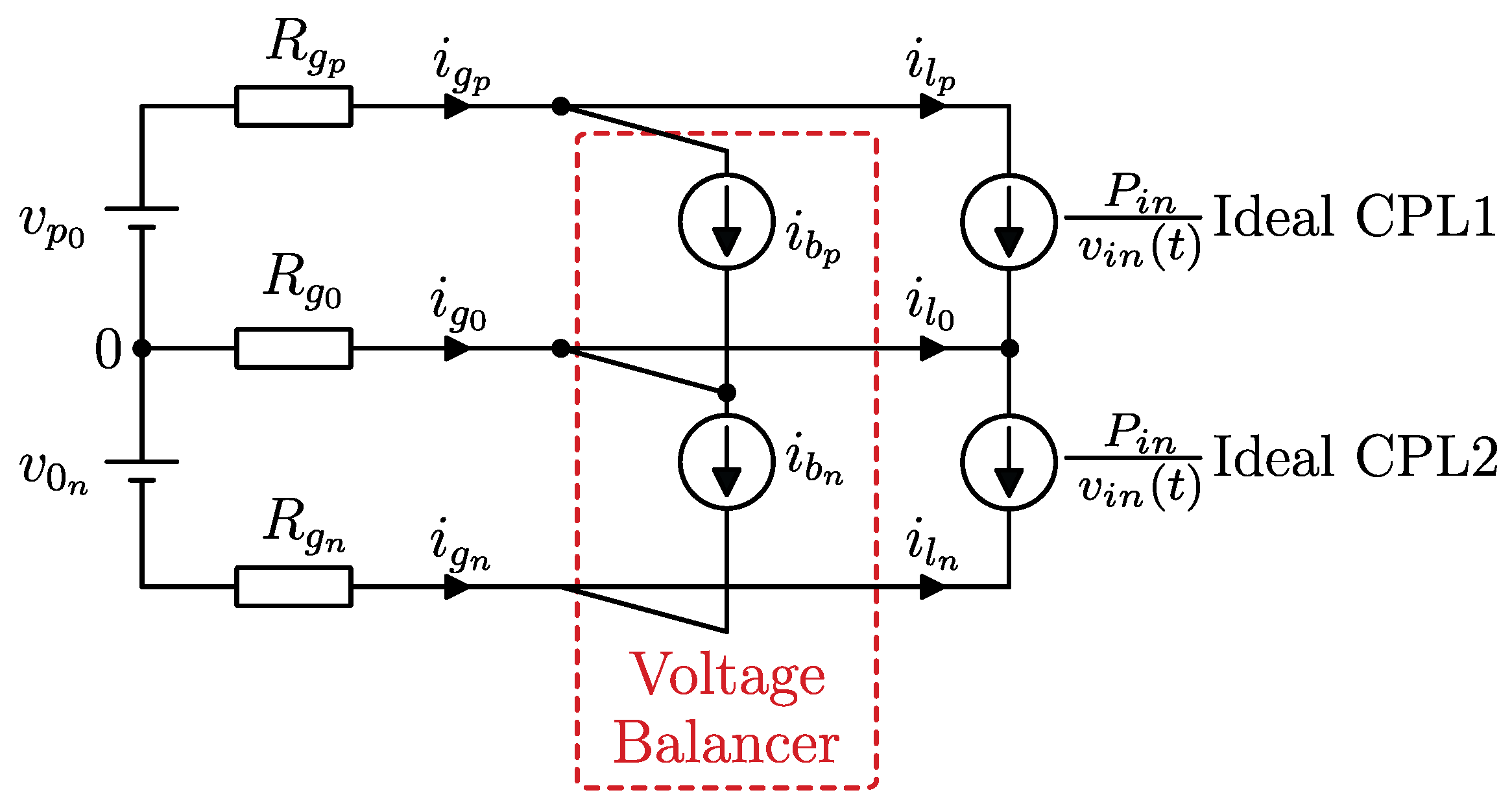

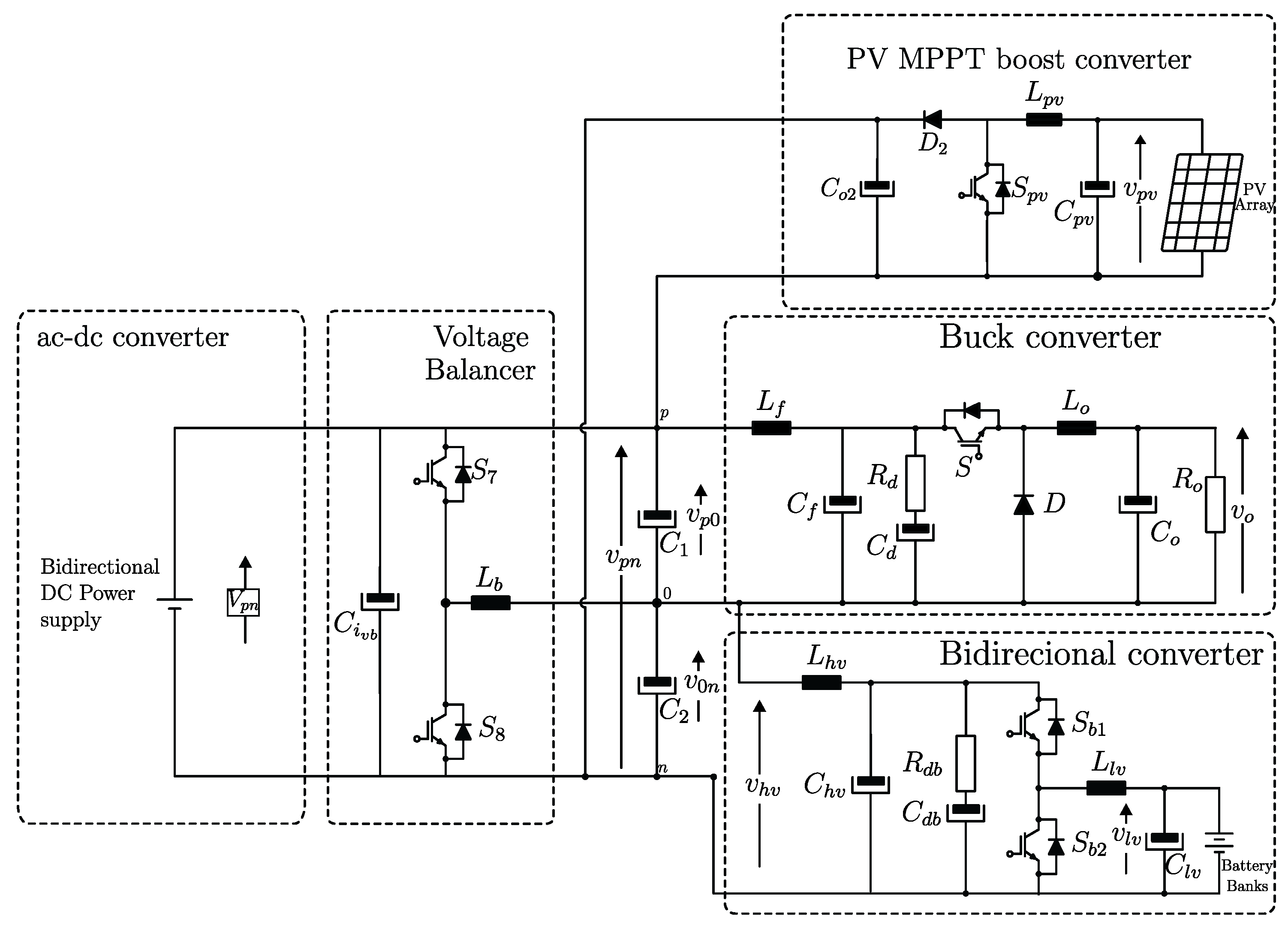

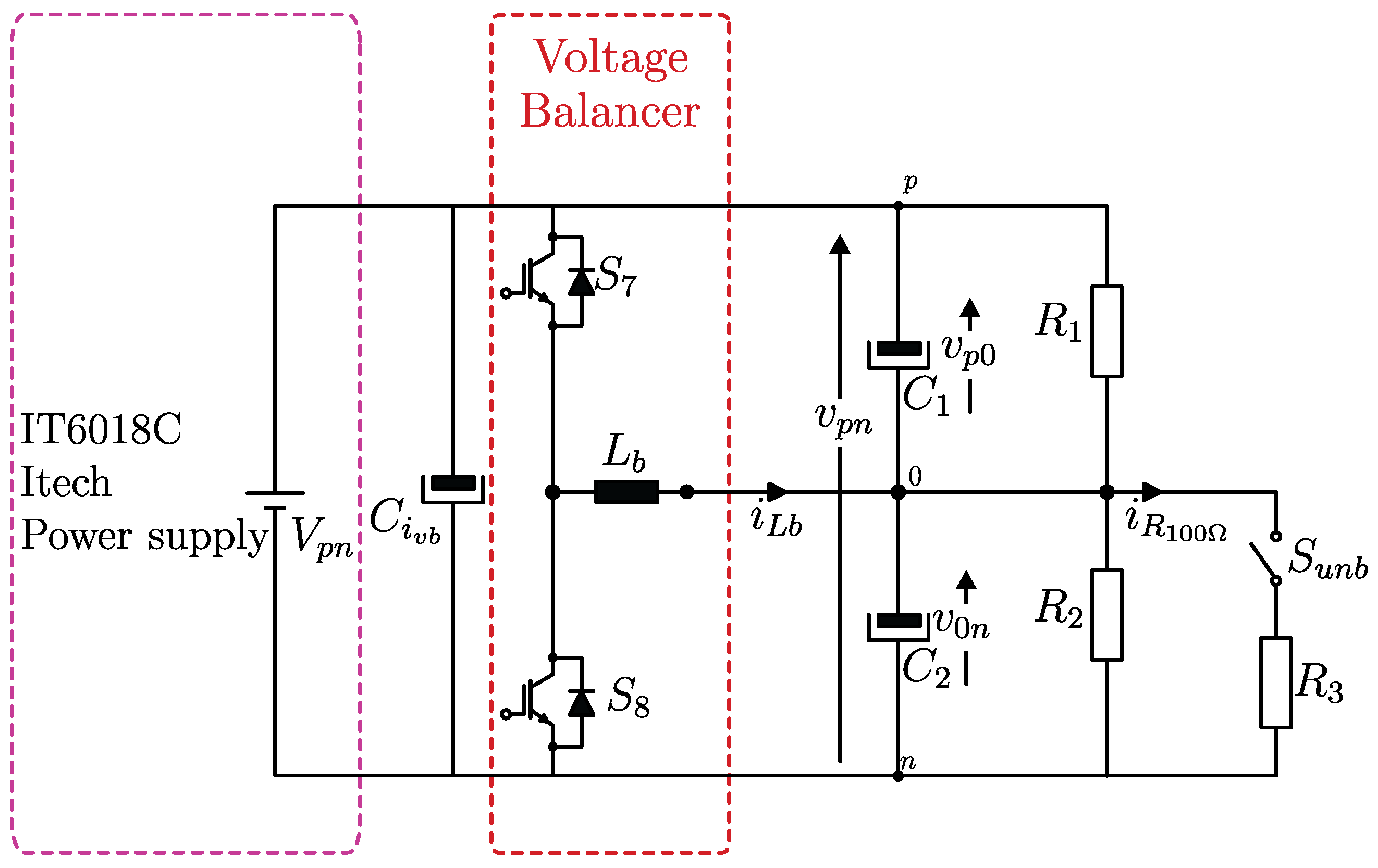

Figure 2 shows the equivalent circuit of a bipolar dc microgrid with a voltage balancer converter and two constant power loads (CPLs). The voltage balancer ensures that the neutral current

becomes zero when the branch currents

and

are equal.

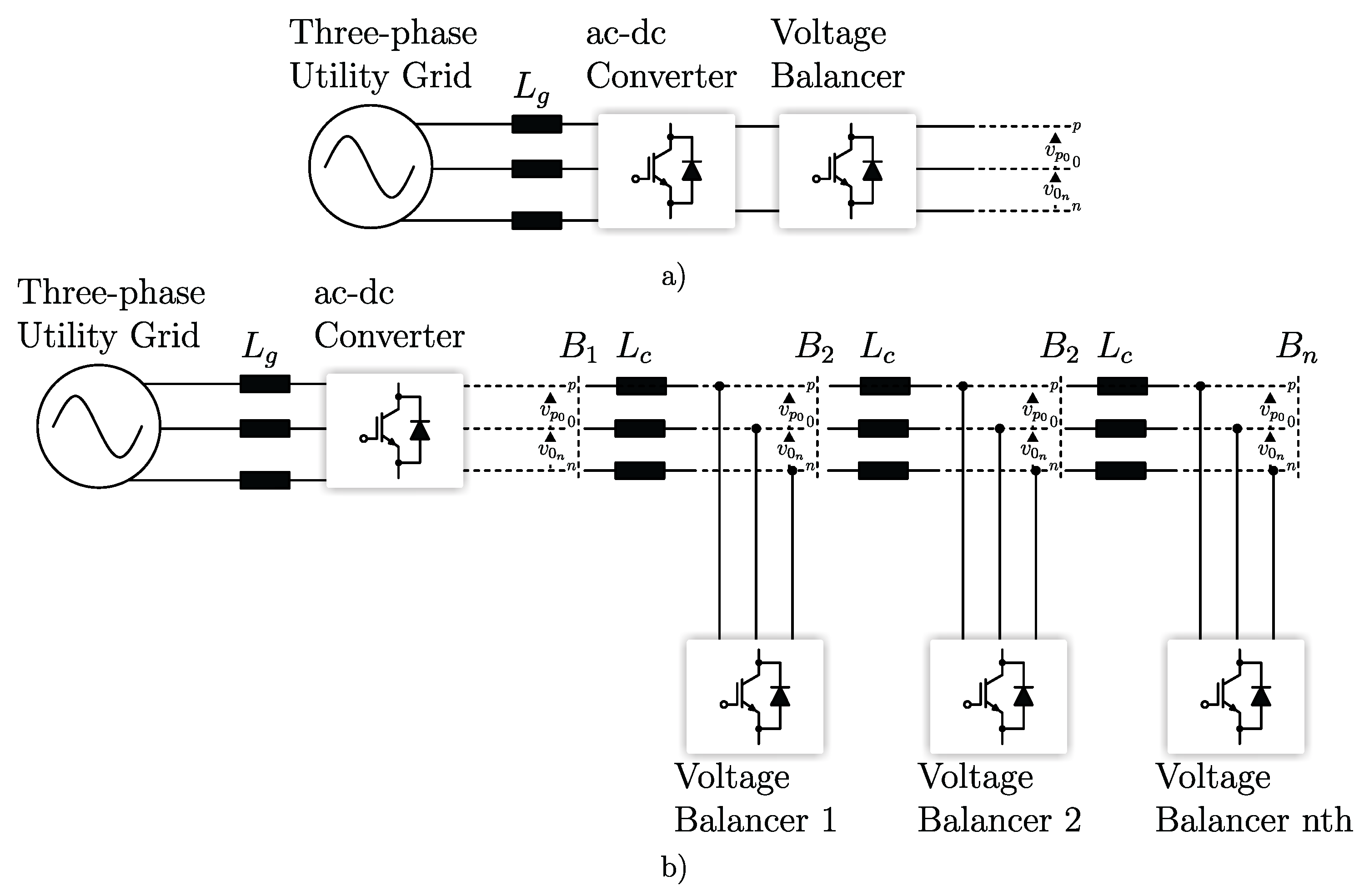

Figure 3 illustrates two voltage balancer configurations applied in bipolar dc microgrids. In

Figure 3a, the centralized configuration is depicted, where a sufficiently large voltage balancer ensures bus voltage balancing. This approach is typically adopted in small-scale bipolar dc microgrids. Among the available topologies, the buck–boost converter is the most widely employed voltage balancer in centralized LVDC microgrids, owing to its simple structure and ease of control [

20].

Figure 3b represents a bipolar dc microgrid with decentralized voltage balancers. In multi-mesh bipolar dc microgrids, the centralized approach may not be suitable, since long line connections can still result in asymmetric load voltages. In such cases, the decentralized strategy becomes more appropriate, with multiple voltage balancer converters distributed across the bipolar dc grid [

24,

25]. Various voltage balancer converters suitable for mitigating voltage unbalance issues in bipolar dc microgrids are presented in [

26,

27,

28].

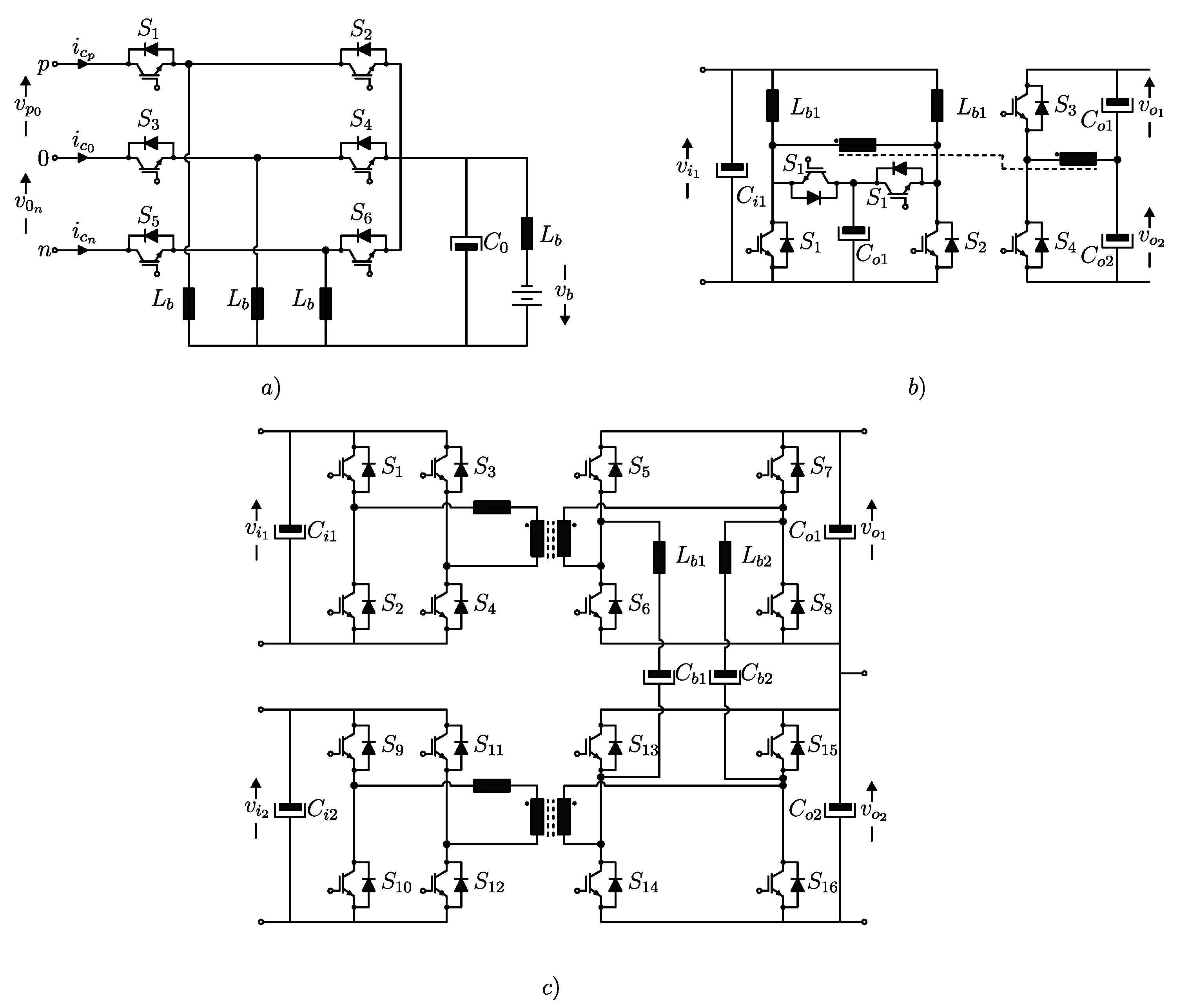

Figure 4 presents three representative configurations of voltage balancers suitable for bipolar dc microgrids. In

Figure 4a, a solution employing a three-phase bidirectional buck–boost converter is illustrated, as reported in [

29].

Whenever galvanic isolation is mandatory, isolated conversion stages can be incorporated into the voltage balancing architecture. In this context, the configuration depicted in

Figure 4b utilizes a dual active bridge arrangement that establishes isolated and balanced dc outputs. Alternatively,

Figure 4c displays an interleaved dual-boost-based voltage balancer, in which the design strategically exploits leakage and coupled inductances to support balancing functionality.

Furthermore, ref. [

30] investigates voltage imbalance mitigation through coordinated operation and control of multiple dc zero-carbon buildings (DC-ZCBs) integrated into the microgrid infrastructure.

Bipolar dc architectures can have multi-bus and reconfigurable topologies [

14]. An example of the latter is illustrated in

Figure 5, where a ring-based dc microgrid configuration is presented. Such an arrangement enhances system reliability and operational redundancy, since multiple DER converters remain interconnected through the dc network. Additionally, the ring structure offers improved flexibility during fault events and scheduled maintenance, enabling sustained service continuity [

14].

Unlike ac systems, dc microgrids do not present natural current zero-crossings, making them more vulnerable to severe pole-to-ground and pole-to-pole faults. These disturbances may result in excessive fault currents, potentially damaging power semiconductor devices if not promptly cleared. In [

31], a rapid fault diagnosis strategy requiring a reduced number of sensors is introduced, relying on analytical fault modeling and frequency-response inspection of the system. Complementarily, ref. [

32] proposes a coordinated control method aimed at mitigating voltage regulation issues inherent to dc ring microgrids.

In dc microgrids, droop control is utilized to regulate the dc bus voltage, enable current and power sharing among converters, and ensure proper operation under islanded conditions. Its main advantage is the facilitation of parallel operation among voltage-source converters.

Alternatively, master–follower strategies are also employed for bus regulation, where the master converter provides a large dispatchable capacity, while the follower converter operates as a complementary resource to enhance system reliability [

33].

This paper proposes a bipolar dc microgrid composed of bidirectional dc power supply, a buck–boost voltage balancer, a low-voltage BESS connected to the 0–n node, a PV converter, and unbalanced electronic and resistive loads. The control architecture must ensure reliable operation in both grid-connected and islanded modes. The BESS converter employs the V–I droop control method.

In the grid-connected mode, the BESS converter exchanges the required power with the main grid to recharge or discharge the battery bank, while the voltage balancer guarantees bus voltage balance. In the islanded mode, the BESS converter regulates the dc bus voltage within a specified range, complying with the droop curve, and the voltage balancer operates as a voltage doubler to guarantee the balance of the intermediate and bus voltages.

For the droop controller of the BESS converter, unplanned islanding is seen as a load transient, enabling a seamless transition from grid-connected to islanded operation. However, voltage deviation is inherent to droop control.

This work addresses a comprehensive analysis of voltage balancing demonstrated in a bipolar dc microgrid under both grid-connected and islanded operating modes. The experimental results demonstrate effective voltage symmetry across the intermediate dc bus levels. By employing droop-based control in conjunction with the proposed voltage balancer strategy, the microgrid maintains reliable and stable operation even during islanded conditions.

This paper is organized as follows.

Section 2 details bipolar dc microgrid architecture,

Section 3 presents the control strategy of the microgrid.

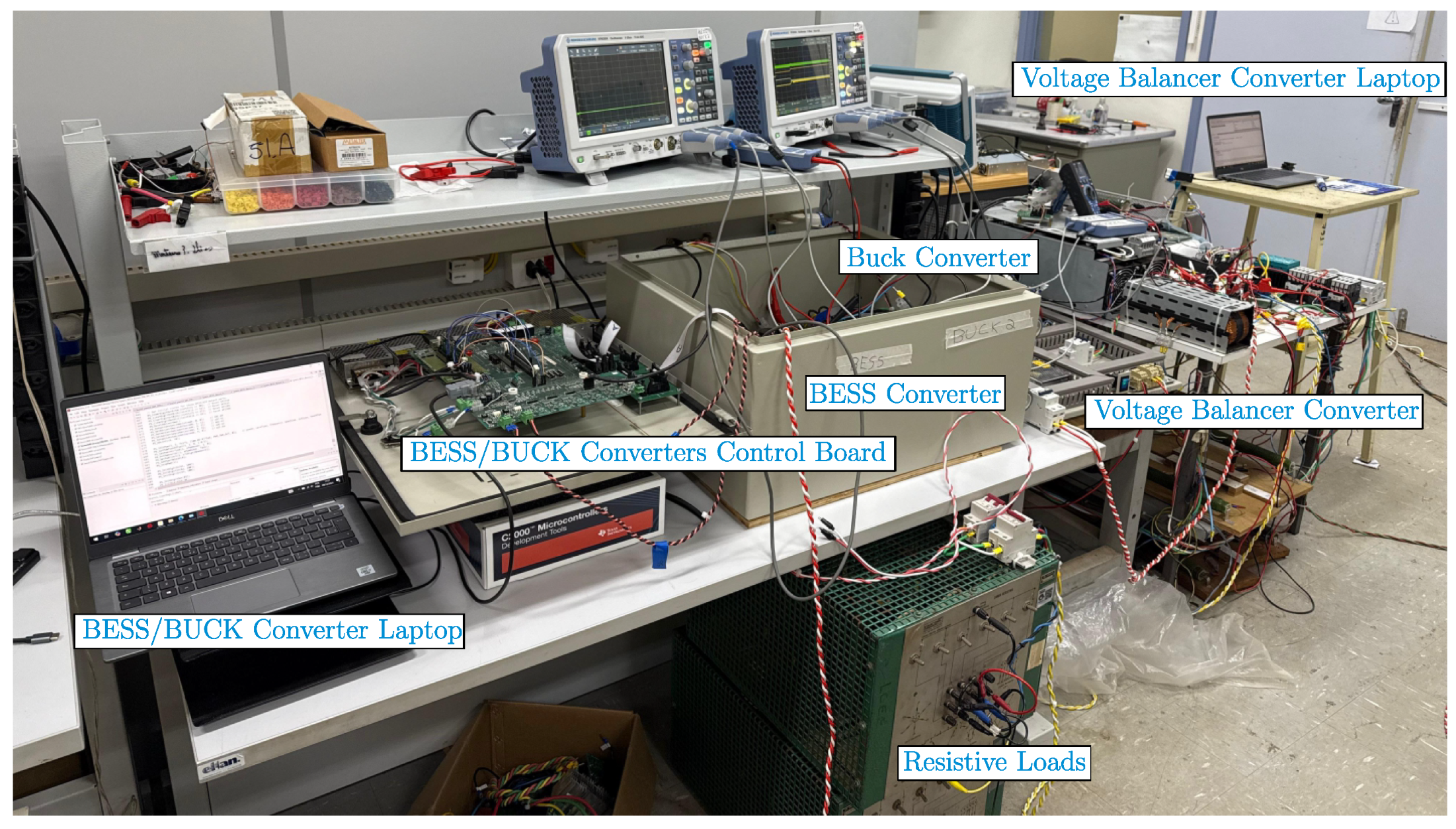

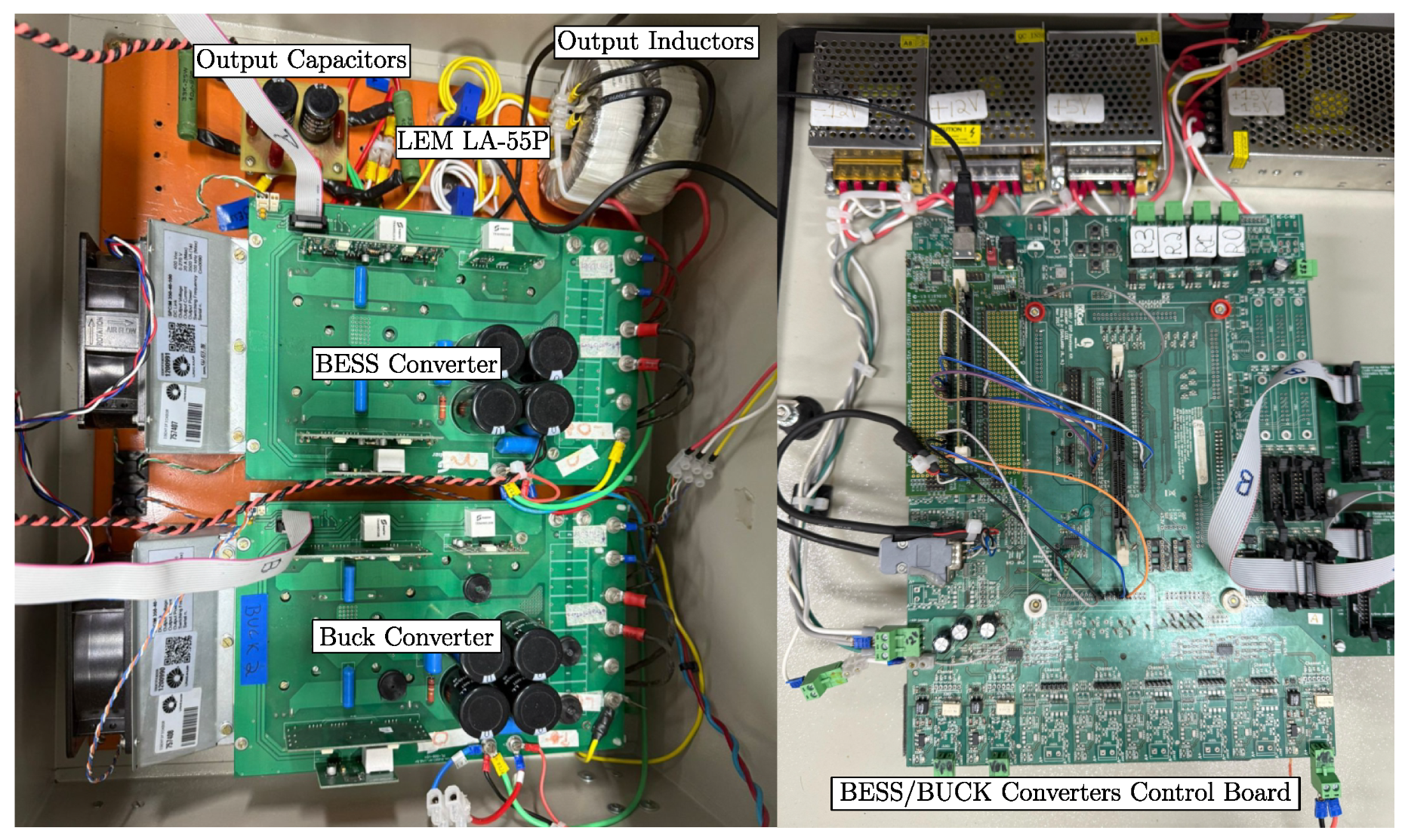

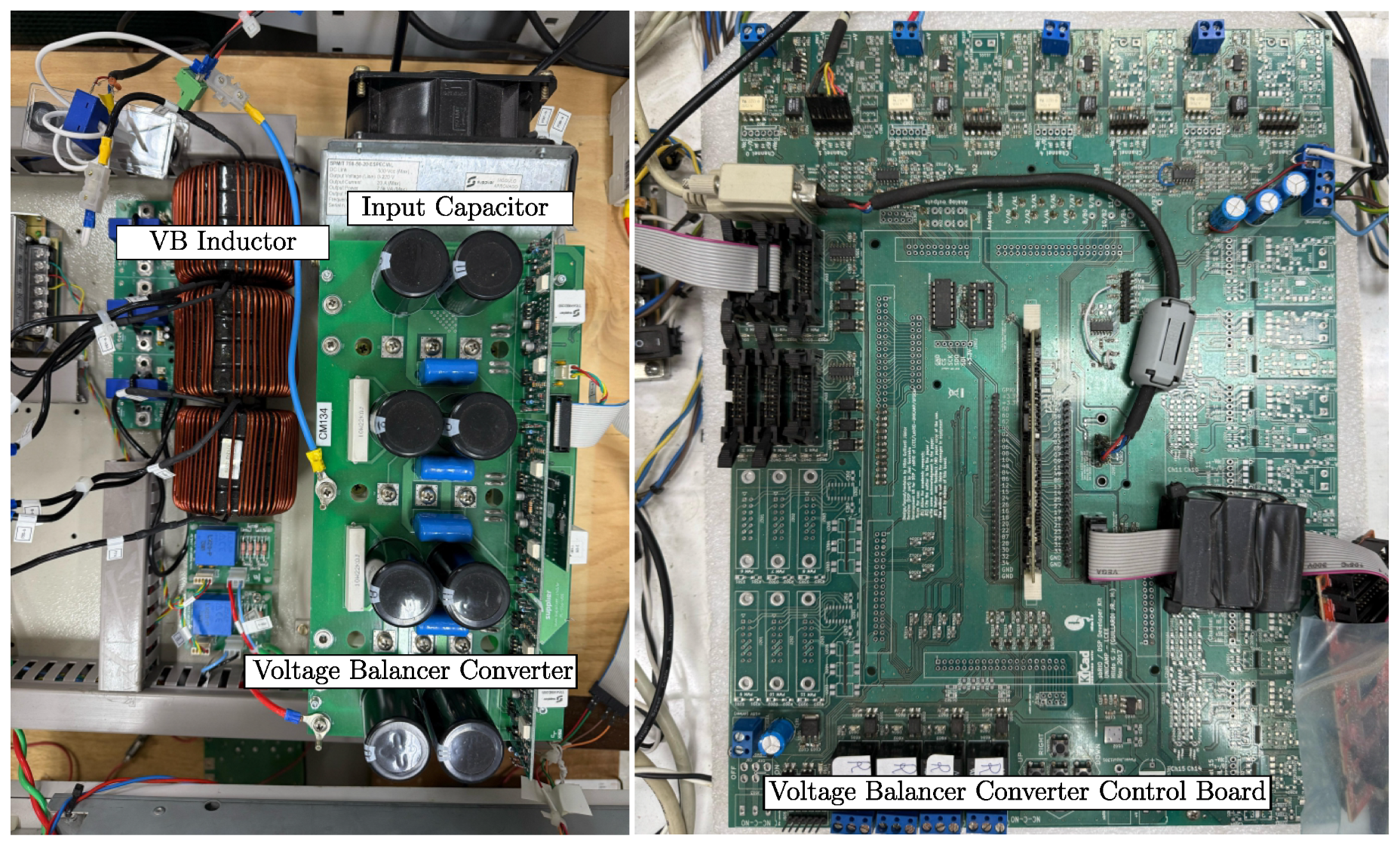

Section 4 shows the hardware setup,

Section 5 shows operation modes of the microgrid and

Section 6 details the experimental verification of the proposed bipolar dc microgrid approach.

Section 7 concludes this paper.

3. Control Strategy of the Microgrid

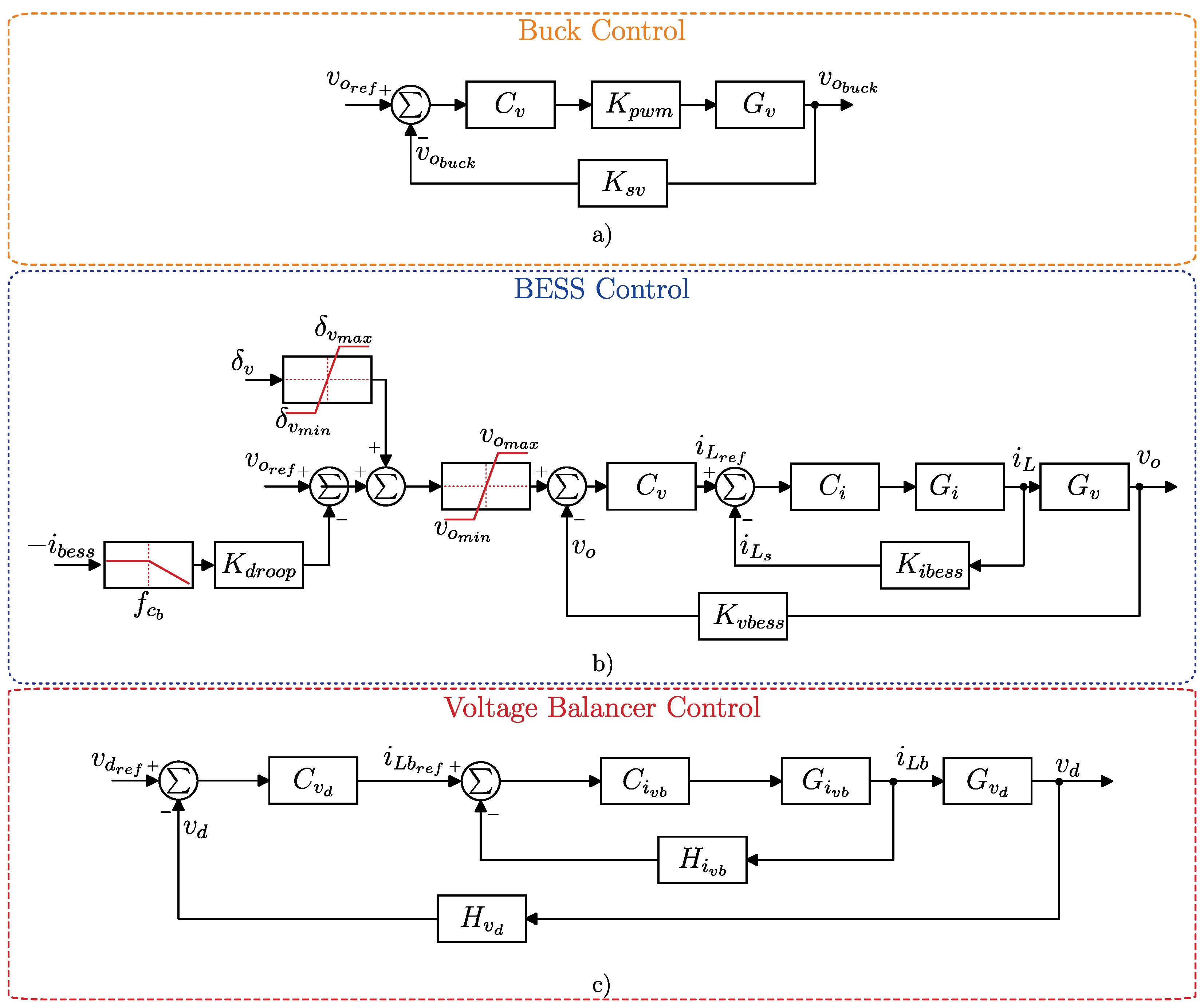

Figure 7 shows the complete control system of the bipolar dc microgrid.

Figure 7a displays the control block diagram of the buck converter, where

denotes the modulator gain and

the voltage sensor gain.

The design of the lead–lag compensator follows [

34,

35]. Equation (

1) presents the transfer function relating the output voltage

and the duty cycle

.

,

and

denote the output inductance, output capacitance, and equivalent load resistance of the converter, respectively.

Equation (

2) describes the lead–lag PID controller, including a high-frequency filter to avoid saturation of the derivative gain. This PID controller is designed to achieve a crossover frequency of 535 Hz and a phase margin of 75.5°. The lead-lag poles and zeros are described in

Table 1.

Figure 7b displays the control block diagram of the droop-controlled BESS converter considered in this work. The small-signal model of a generic droop-controlled boost converter is described in [

36]. In this work, a single low-voltage (95 V) BESS converter under droop control is proposed and connected to one of the intermediate buses (

p–0 or 0–

n). This configuration enables reliable and seamless operation of the bipolar DC microgrid in both grid-connected and islanded modes, leveraging the plug-and-play capability of droop control.

Equation (

3) presents the transfer function relating the bess inductor current

and the duty cycle

d.

,

, and

represent the output inductance, output capacitance, and static duty cycle of the converter, respectively.

and

are the output voltage and the output current, respectively.

Equation (

4) presents the transfer function relating the output voltage and the BESS inductor current.

and

represent the battery voltage and the inductor current.

The V-I droop control technique may be implemented using only the inductor current feedback. In this technique, the inductor BESS current is filtered by a low-pass filter (crossover frequency of ), then multiplied by the droop resistance , and subsequently injected into the voltage control loop.

Equation (

5) details the transfer function that relates the inductor current and the output current. Considering the low-pass filtering of the BESS inductor current

, the transfer function between inductor current and output current can be approximated.

Therefore, the droop resistance

is described in Equation (

6).

Equation (

7) shows the voltage reference of the droop control. In this system,

is the no-load voltage reference. The voltage droop is achieved by multiplying the droop coefficient

by the BESS inductor current

. The voltage term

is utilized depending on the microgrid operation mode. In grid-connected mode,

is used to recharge/discharge the battery bank. In the islanding scenario,

can be utilized to the dc bus restoration at the nominal voltage.

Figure 7c shows the control block diagram of the voltage balancer [

23], where

denotes the voltage sensor gain and

current sensor gain.

denotes the internal PI current controller, while

regulates the differential voltage.

The voltage balancer maintains the balance between the voltages

and

by providing a current path between the positive and negative poles. The control system must ensure that the differential voltage is zero (

). The voltage deviation percentage in the bipolar dc microgrid is defined by (

8). Since no standardized limit exists for bipolar dc microgrids, a maximum value of 5% is adopted in this work.

Equation (

9) details the transfer function relating the inductor current

to the duty cycle

[

23], where a PI controller is tuned to achieve a 90° phase margin and a crossover frequency of 1200 Hz.

,

, and

represent the output voltage, inductance, and inductor parasitic resistance, respectively.

Equation (

10) shows the transfer function between the differential voltage and the inductor current of the voltage balancer [

23], with control parameters set for a 90° phase margin and a 120 Hz crossover frequency.

Table 1 shows the experimental control parameters.

and

C represent the output resistance and capacitance of the bus, respectively.

5. Operation Modes of the Bipolar DC Microgrid

A dc microgrid must ensure reliable operation both when connected to the dc grid-forming source and during islanded mode with smooth transitions between them. The details of the operation of the proposed system in these two operation modes are described in this section, along with the adopted strategy to ensure smooth transition in front of an unintentional islanding event in the microgrid.

During grid-connected operation, the dc grid former converter functions as a voltage source, regulating the 380-V bipolar dc bus. The voltage balancer actively maintains the voltage symmetry between the intermediate buses, and . Meanwhile, the BESS converter provides bidirectional power exchange to support battery charging and discharging, operating as a current-controlled source under this condition.

The charging and discharging actions are governed by the parameter . Positive values of correspond to battery charging, whereas negative values indicate discharging. Variations in the BESS voltage reference introduce dynamic voltage deviations into the system.

The voltage balancing performance of the microgrid is analyzed in the next section. Initially, an unbalanced resistive load is applied to the microgrid, and the voltage balancer is required to ensure overall bus voltage balance. Furthermore, an electronic load is subsequently introduced into the microgrid, and its impact on voltage unbalance is evaluated. The behavioral differences between these two loading conditions are presented and discussed.

During islanded operation, the dc grid former converter is electrically isolated from the bipolar dc microgrid by opening the switch . In this condition, the BESS converter assumes the primary responsibility for regulating the lower bus voltage, , within the specified operational limits. Simultaneously, the voltage balancer operates as a voltage-doubling stage, thereby maintaining proper voltage symmetry between the intermediate buses and .

Through coordinated control, the BESS converter and the voltage balancer collectively ensure adequate load supply capability, reliable standalone operation of the microgrid, and sustained voltage balance across the bipolar dc network.

When the dc grid former is disconnected from the microgrid, the droop-controlled BESS seamlessly assumes the voltage regulation role, enabling a smooth transition from grid-connected to islanded operation, inherently supporting plug-and-play functionality. From the droop controller’s perspective, this unintentional disconnection works as a sudden load variation. By adapting its operating point accordingly, the droop control mechanism maintains stable voltage regulation, thus preserving the reliable operation of the bipolar dc microgrid.

In the next section, the experimental results demonstrate the seamless transition from mode A (grid-connected) to mode B (islanded operation). The voltage balancing performance of the microgrid, as well as the effectiveness of the droop control, are evaluated. Moreover, the presented results confirm the complete and reliable operation of the bipolar dc microgrid.

6. Bipolar DC Microgrid Experimental Results

In this work, the dc bus voltages and range between V to V, resulting in maximum and minimum voltages of 420 V and 360 V between the dc bus poles. These maximum and minimum values limit the range of the droop curve used in the BESS converter. Initially, the voltage balancing of the bipolar microgrid is tested under unbalanced resistive and electronic loads.

The following subsections bring the following content:

Section 6.1 shows the voltage balancer entering operation in open-loop.

Section 6.2 illustrates the resistive loads vary, perturbing the balance of the bipolar dc bus.

Section 6.3 brings the results of the voltage balancer operating in closed-loop.

Section 6.4 introduces electronic loads, known for affecting the stability of electrical systems.

In

Section 6.5, the balancer operates in closed-loop, with electronic loads in the system, keeping its stability.

Section 6.6 presents the results of the balancer within and islanded operation.

Finally,

Section 6.7 qualitatively summarizes the experimental results.

The following experimental results are based on the measurement of the voltage imbalance between the intermediate voltages

and

. Regardless of the imbalance condition, the system must continue operating within the voltage limits. Therefore, the first experiments demonstrate the necessity of the balancer operating in closed-loop.The results presented in

Section 6.1,

Section 6.2,

Section 6.3,

Section 6.4 and

Section 6.5 correspond to the grid-connected operating condition (Mode A). In

Section 6.6, the microgrid seamlessly transitions from the grid-connected to the islanded condition and continues operating under Mode B (islanded mode).

6.1. Voltage Balancer Entering Operation

In mode A (grid-connected operation), the ITECH dc power supply regulates the 380 V bipolar dc bus voltage . The voltage balancer ensures the balance of the intermediate bus voltages and . The BESS converter uses the V–I droop control method, recharging and discharging the battery bank to exchange the required power.

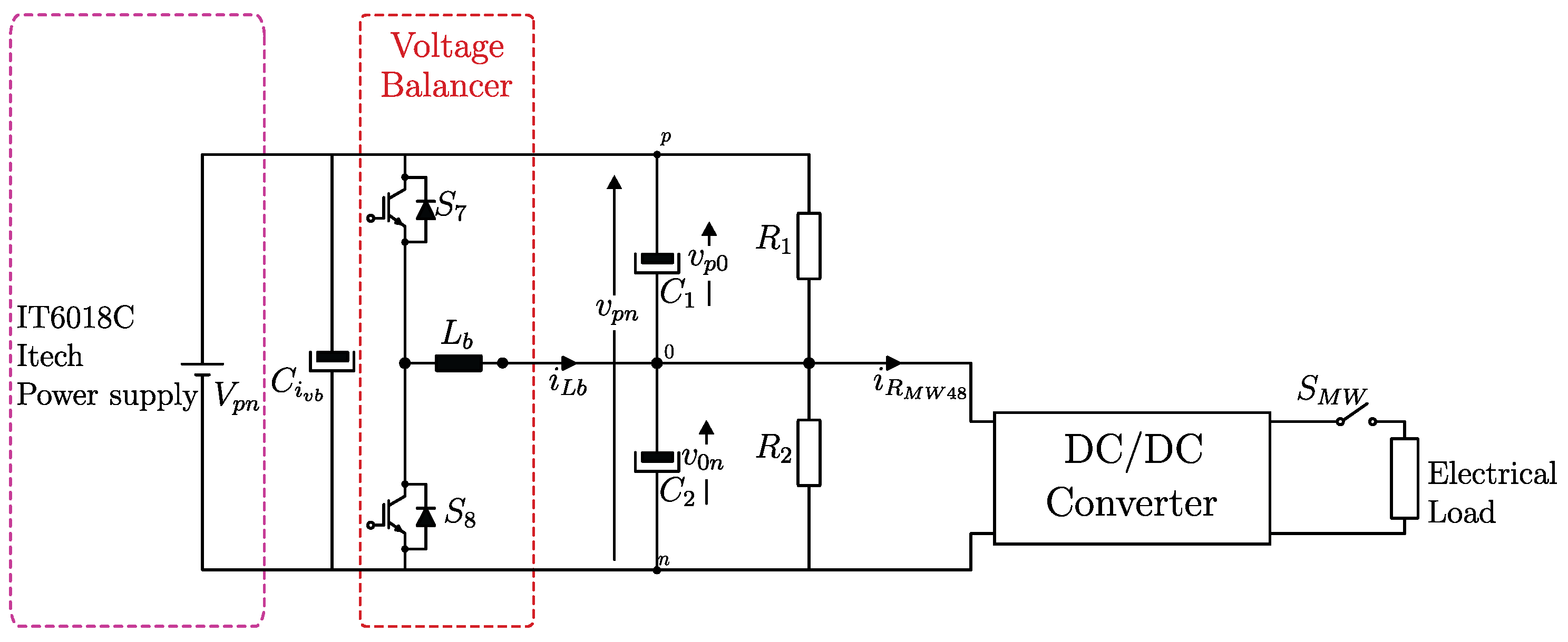

Figure 12 illustrates the equivalent circuit of the scenario analyzed. The resistances are given as

,

, and

. When the switch

is closed, the equivalent resistance at the 0–

n node is calculated as

.

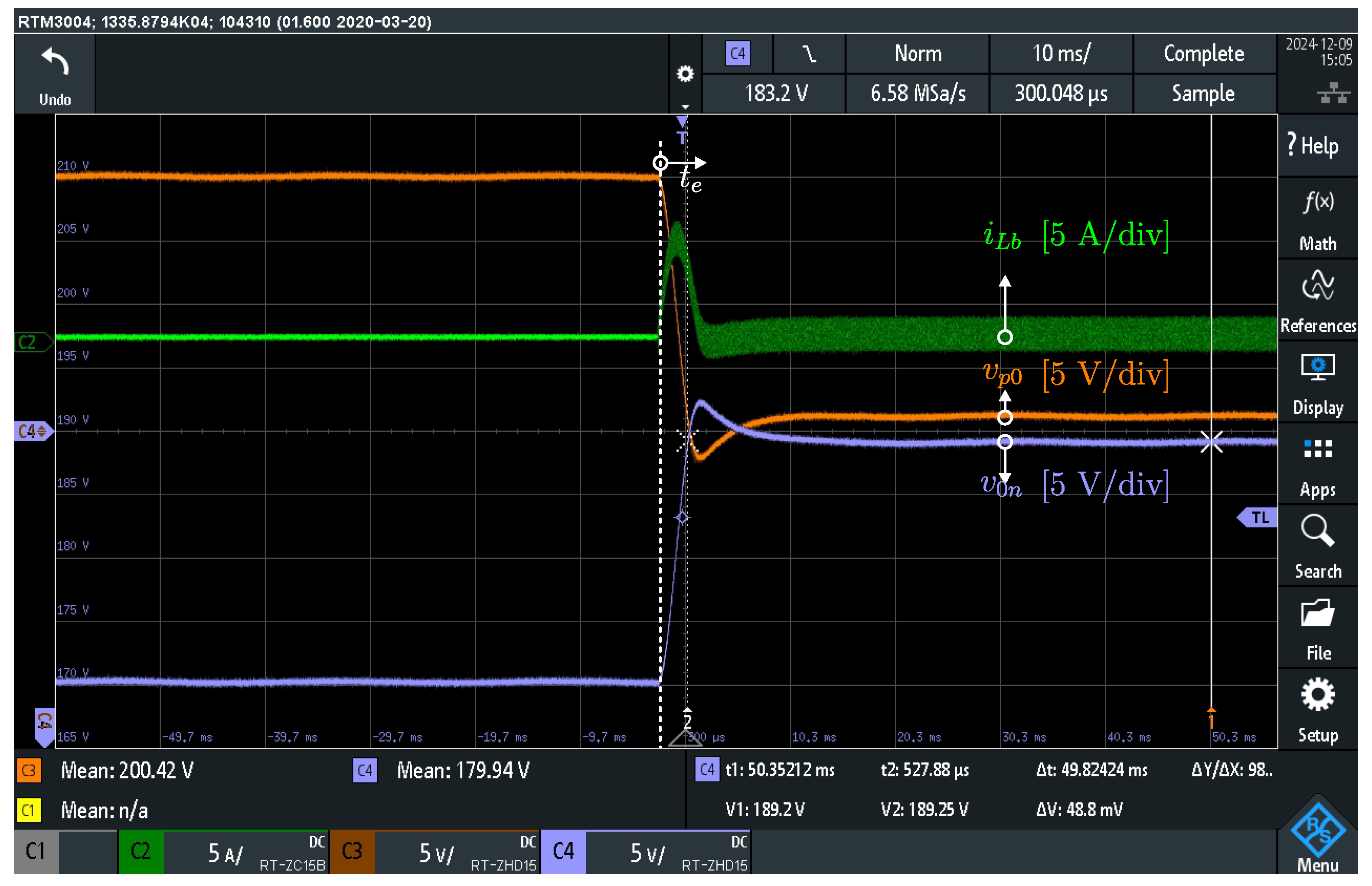

Figure 13 illustrates the transient response of the bipolar dc microgrid when the voltage balancer is activated under an unbalanced load condition. Channel 2 presents the voltage balancer current

(green trace, 5 A/div), Channel 3 presents the 190 V node voltage

(orange trace, 5 V/div, offset: 190 V), and Channel 4 presents the 190 V node voltage

(light blue trace, 5 V/div, offset: 190 V).

The experimental results are organized before and after the connection of the voltage balancer in .

Before , the dc power supply ensures the 380 V pole-to-pole bipolar dc bus, the voltage balancer is detached, and the intermediary voltages are unbalanced. The voltage is 170 V and the is 210 V, resulting in a voltage deviation of approximately 40 V (). This voltage deviation depends on the respective bus loading conditions.

The voltage balancer is activated with a fixed duty cycle of at . After 15 ms, the balancer regulates the voltages and reducing and the voltage deviation to approximately 3 V (). The experimental results demonstrate that the voltage balancer maintains the voltage balance under unbalanced loading conditions. Because of this feature, this converter is essential for a bipolar dc microgrid.

6.2. Voltage Balancer Responding to Load Variations

To evaluate the dynamic response of the system to load variations, a resistive load step of

perturbs the 0–

n dc bus.

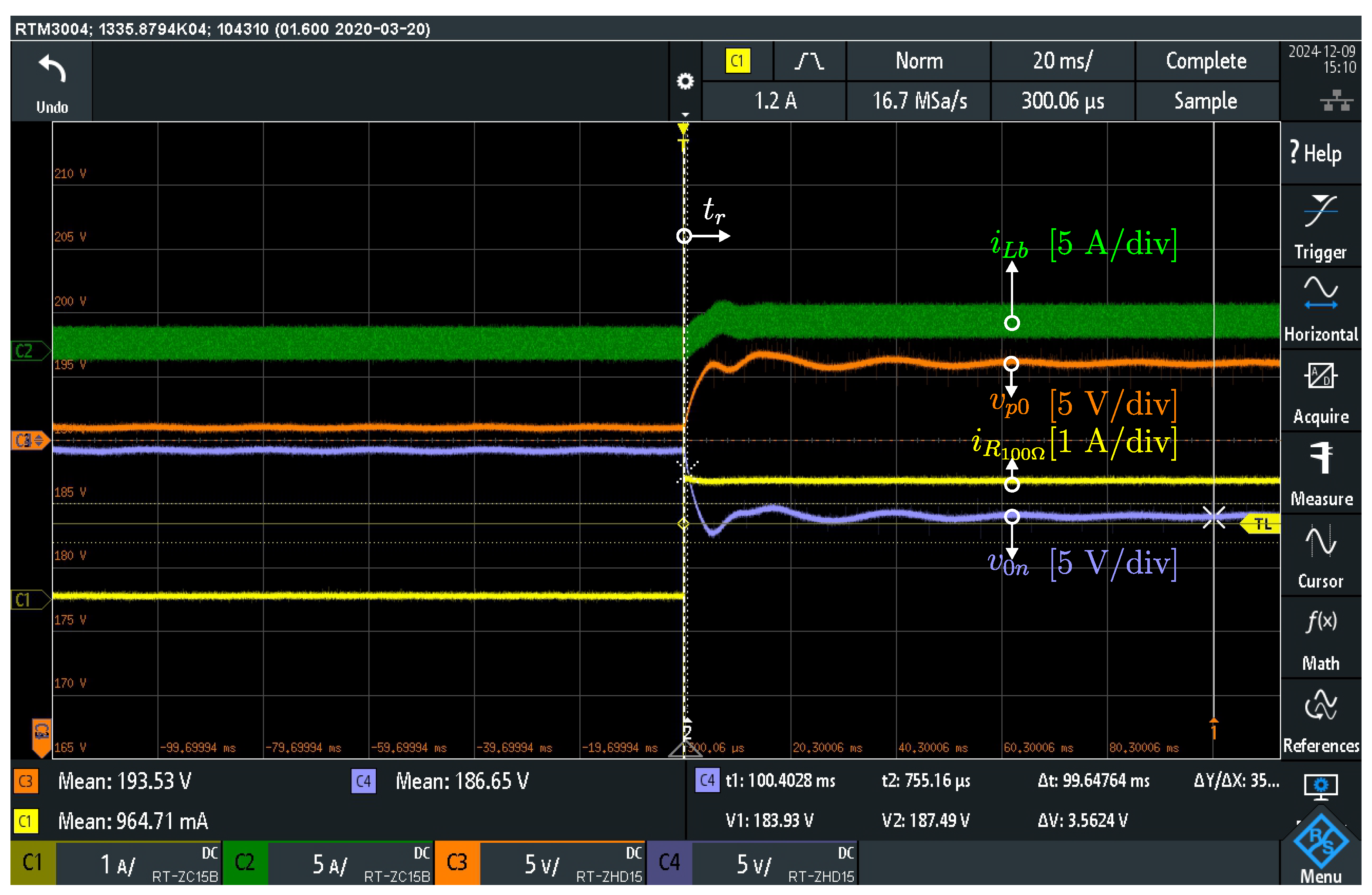

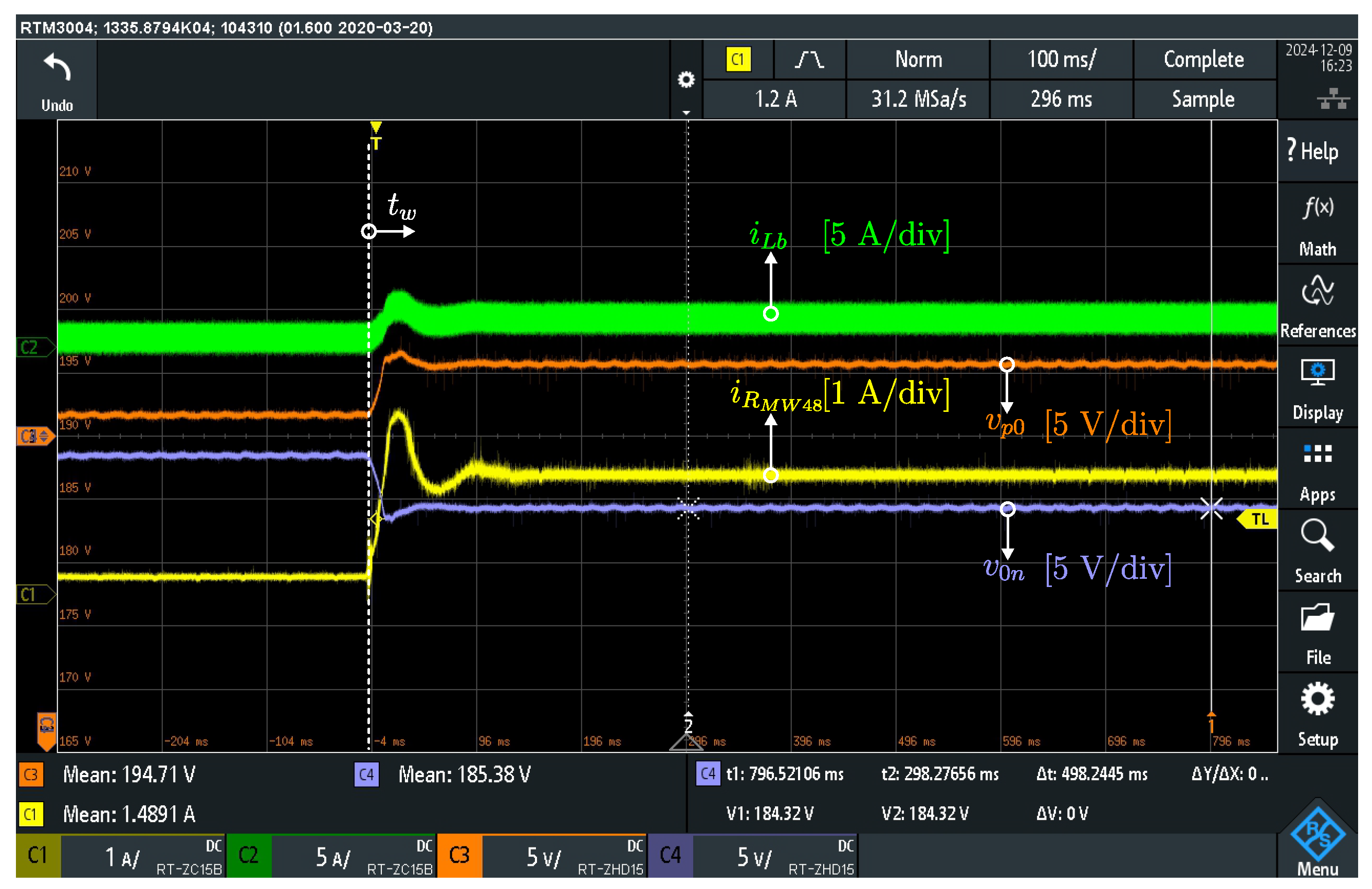

Figure 14 illustrates the transient response of the bipolar dc microgrid to this event.

Channel 1 presents the load current (yellow trace, 1 A/div), Channel 2 presents the voltage balancer current (green trace, 5 A/div), Channel 3 presents the 190 V node voltage (orange trace, 5 V/div, offset: 190 V), and Channel 4 presents the 190 V node voltage (light blue trace, 5 V/div, offset: 190 V).

Before , the voltage balancer maintains the balance of the bipolar dc bus voltages, with a deviation of approximately 3 V (). At , a resistive load is connected to the 0–n dc bus in parallel with the . After 40 ms, the voltages and stabilizes, exhibiting a deviation of approximately 12 V (). This increased deviation results from the open-loop operation of the voltage balancer with a fixed duty cycle of . Since exceeds the maximum unbalance adopted, closed-loop control of the voltage balancer is required.

6.3. Closed-Loop Voltage Balancer

In open-loop mode, the voltage balancer cannot compensate for the increased voltage deviation that happens due to load imbalance. To mitigate the voltage deviation, the voltage balancer operates in closed-loop mode to ensure the balance between and . The resistances are defined as and .

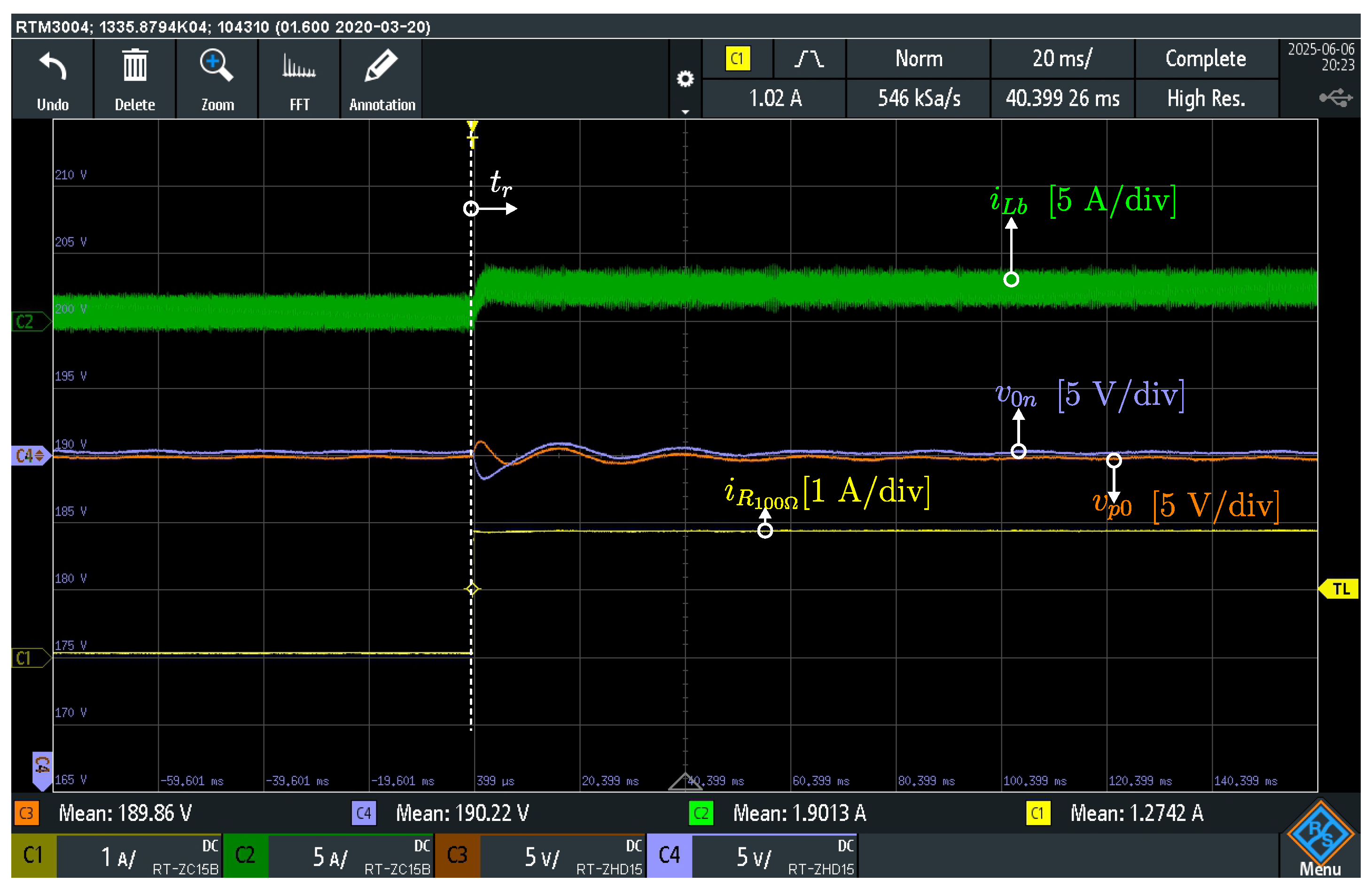

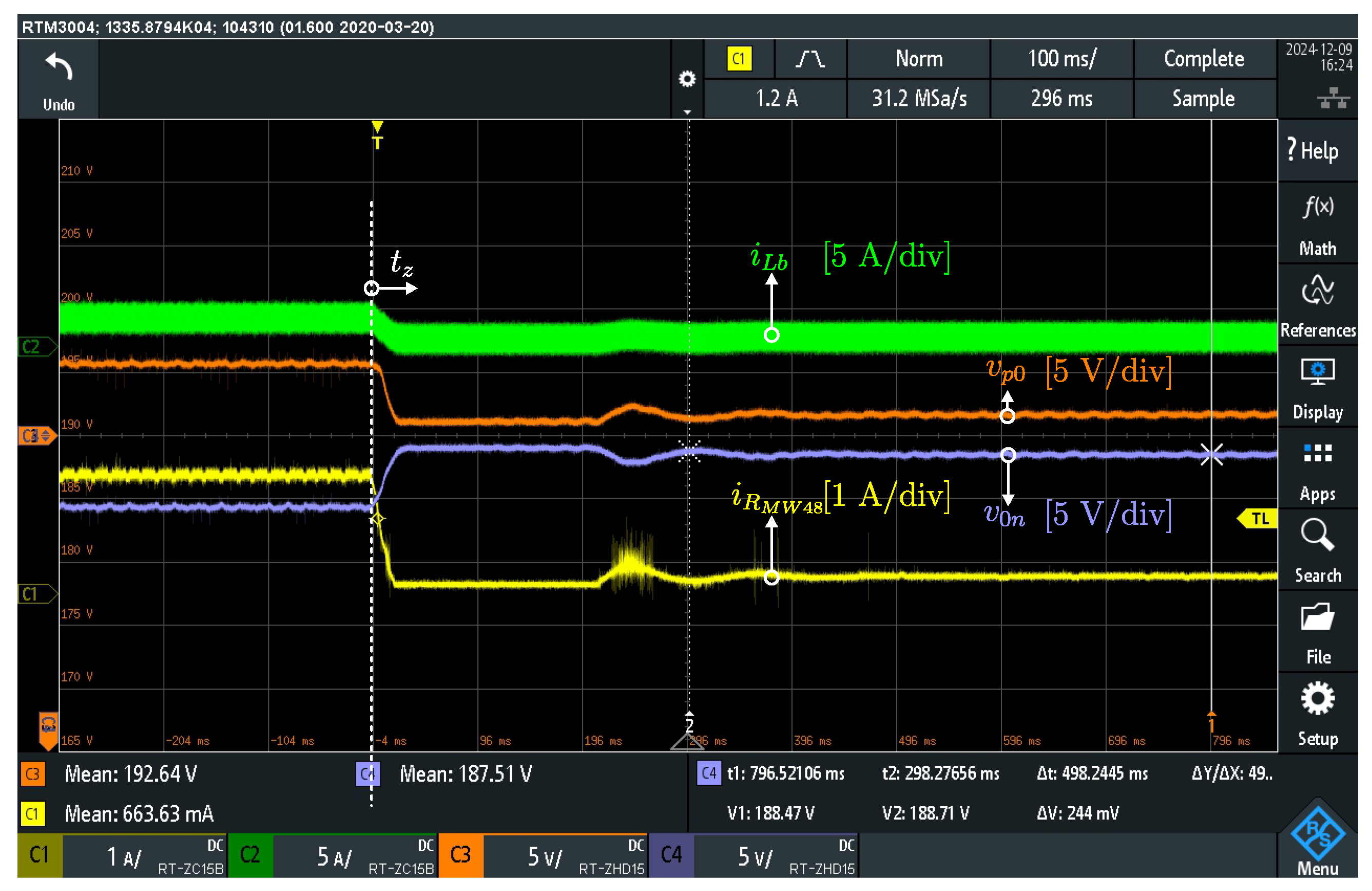

Figure 15 illustrates the transient response of the bipolar dc microgrid under a resistive load step of

applied at the 0–

n dc bus.

Channel 1 presents the load current (yellow trace, 1 A/div), Channel 2 presents the voltage balancer current (green trace, 5 A/div), Channel 3 presents the 190 V node voltage (orange trace, 5 V/div, offset: 190 V), and Channel 4 presents the 190 V node voltage (light blue trace, 5 V/div, offset: 190 V).

Before , the voltage balancer regulates the bipolar dc bus voltages, reducing the deviation to approximately V (). At , a resistive load is connected to the 0–n dc bus in parallel. After 40 ms, the voltage balancer equalizes again the voltages and . Therefore, the closed-loop operation of the voltage balancer effectively guarantees the stability and minimizes the voltage deviation of the intermediate bus voltages.

The importance of employing a closed-loop technique for the balancer control in a microgrid is emphasized based on

Table 7. The comparison between

Section 6.1,

Section 6.2 and

Section 6.3 is carried out considering the imbalance level of each test. In the case of open-loop operation, depending on the load step, the system may operate outside the limits defined by the droop curve. Such a condition can be highly detrimental to the equipment connected to the microgrid, potentially leading to failures or even complete system malfunction.

Assuming a maximum imbalance condition in the system and with the balancer operating in open-loop, an electronic load whose rated operation depends on the defined voltage limits may fail to operate properly.

6.4. Load Converter Experimental Setup: Voltage Balancer in Open-Loop and the Transient Response Due to Load Step

The load converter is implemented using the RSP-1000-48 module (Mean Well®). The load converter operates with an input voltage of 190 V, an output voltage of 48 V, and a rated power of 1 kW.

Figure 16 presents the equivalent circuit including the load converter, where

and

.

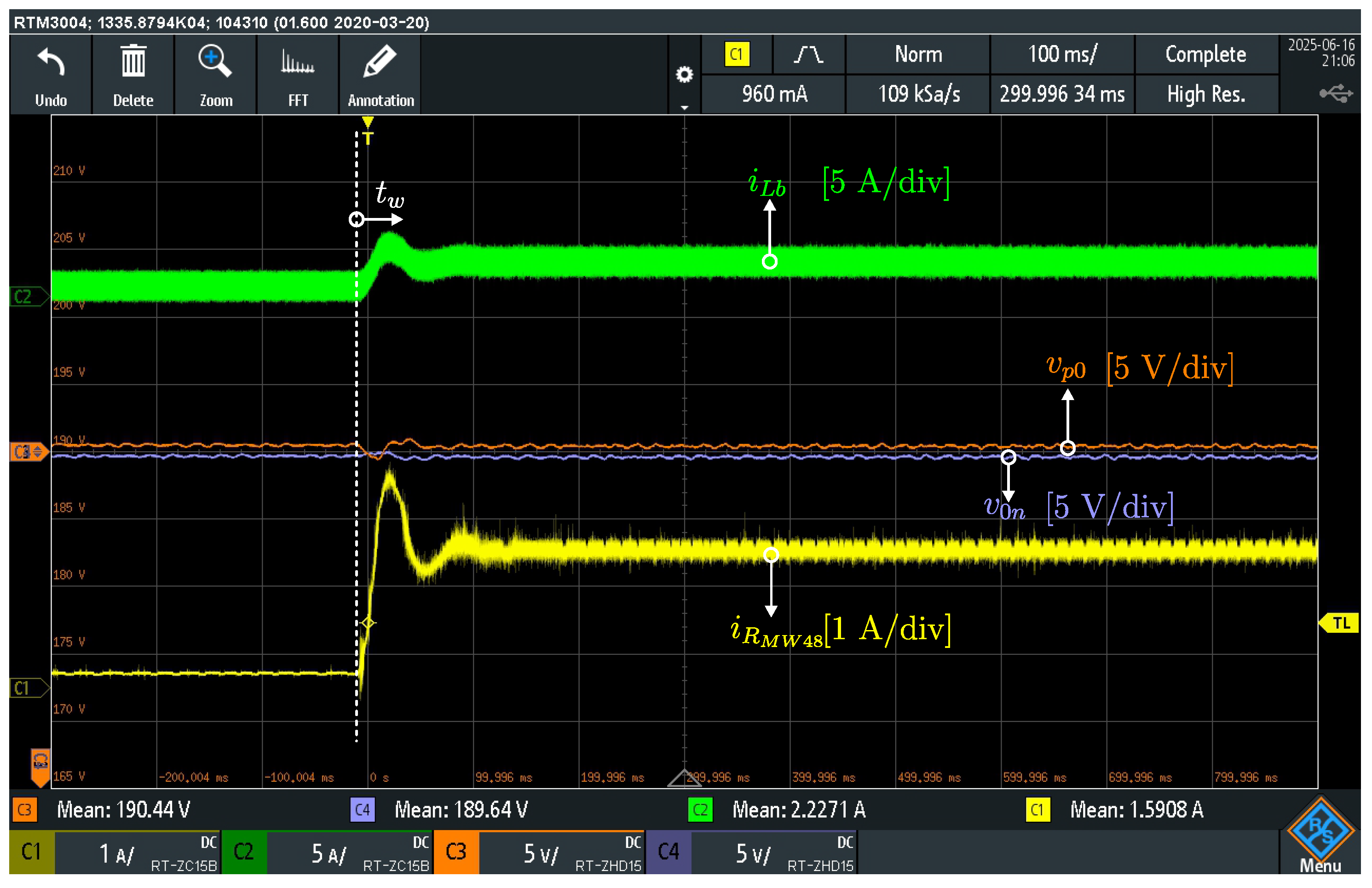

Figure 17 illustrates the dynamic behavior of the microgrid when the load converter is connected to the 0–

n dc bus.

Channel 1 presents the load converter current (yellow trace, 1 A/div), Channel 2 presents the voltage balancer current (green trace, 5 A/div), Channel 3 presents the voltage (orange trace, 5 V/div, offset: 190 V), Channel 4 presents the voltage (light blue trace, 5 V/div, offset: 190 V).

At , the switch closes and the load converter is connected to the 0–n dc bus. After approximately 100 ms, the intermediary bus voltages and reach balance, with a voltage deviation of about 12 V (). In this condition, the input current of the load converter, , is approximately 2 A.

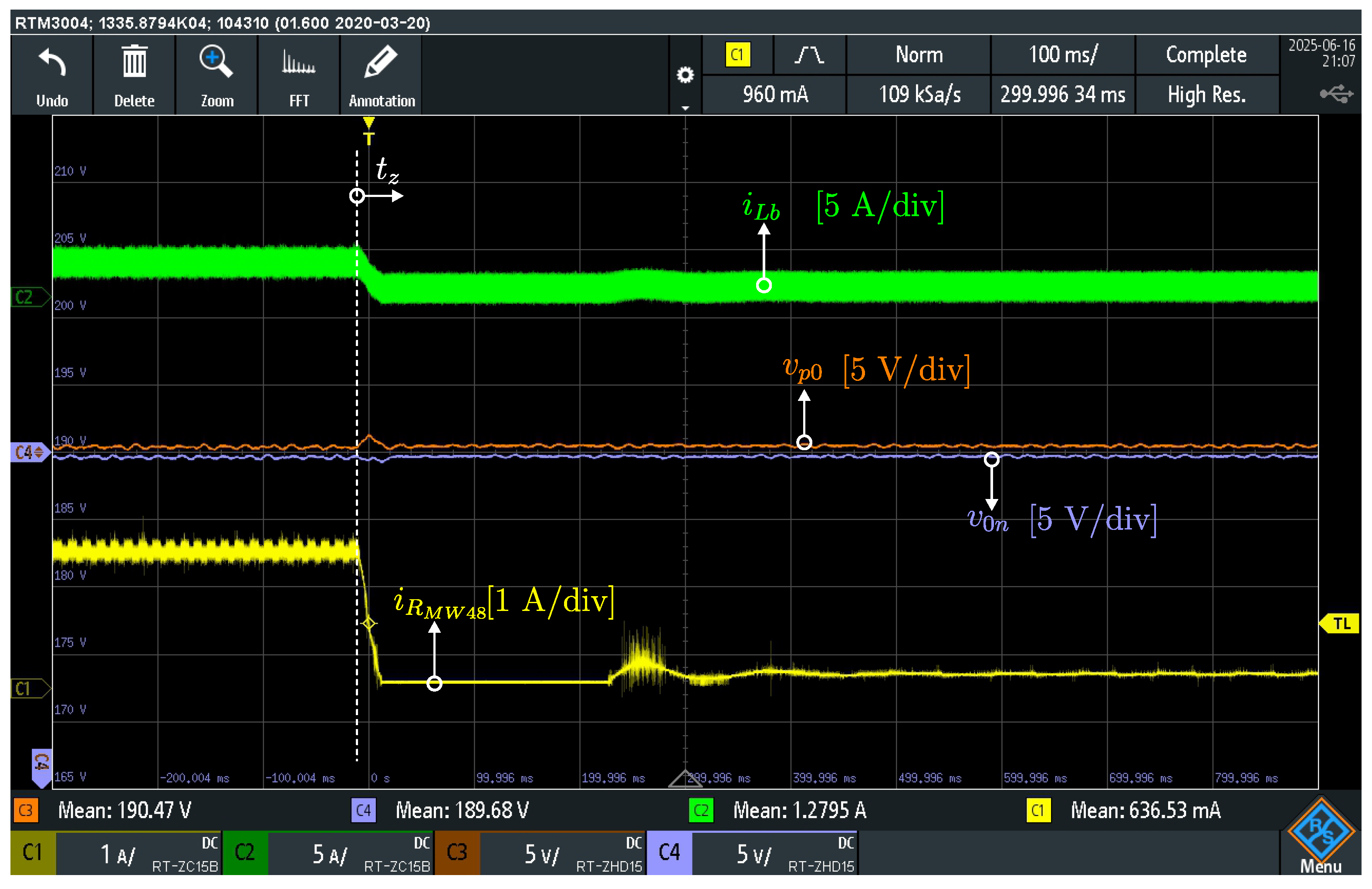

Figure 18 illustrates the transient response corresponding to the disconnection of the load converter from the 0–

n dc bus. At instant

, the switch

opens. Therefore, after 100 ms, the voltage deviation decreases to approximately 3 V (

).

6.5. Load Converter Experimental Setup: Closed-Loop Voltage Balancer and the Transient Response Due to Load Step

To guarantee the voltage balancing of the intermediary voltages even with unbalanced load steps, the voltage balancer is operating in closed-loop. The resistances connected to the bipolar bus are and .

Figure 19 illustrates the transient response observed during the connection of the load converter to the 0–

n dc bus.

Channel 1 presents the load converter current (yellow trace, 1 A/div), Channel 2 presents the voltage balancer current (green trace, 5 A/div), Channel 3 presents the bus voltage (orange trace, 5 V/div, offset: 190 V), and Channel 4 presents the bus voltage (light blue trace, 5 V/div, offset: 190 V).

At , the switch closes, and the load converter is connected to the 0–n dc bus. After approximately 100 ms, the intermediary bus voltages and reach balance, with a voltage deviation of about V (). In this condition, the input current is approximately 2 A.

Figure 20 illustrates the transient response corresponding to the disconnection of the 48 V converter from the 0–

n dc bus. At instant

, after 100 ms, the dc bus voltage deviation is again approximately

V (

).

In closed-loop mode, the voltage balancer ensures the balance of the intermediary voltages. This converter maintains a voltage unbalance below during transients and keeps the dc microgrid compliant with the droop voltage range.

The dynamic performance of the load converter contrasts with that of the resistive load. Specifically, the input current of the load converter has an oscillatory dynamic behavior, whereas the resistive load displays a damped response. In practical applications of dc microgrids, considering that all loads are inherently electronic and have input dynamic characteristics that are more similar to those of the load converter. Therefore, the dc bus must ensure adequate reliability to guarantee that the frequent connection and disconnection of such loads does not affect the system.

Furthermore,

Table 8 presents a comparison of a load step applied to the load converter when the balancer operates in open-loop and its corresponding response under closed-loop operation. The comparison between

Section 6.1,

Section 6.2 and

Section 6.3 is carried out considering the imbalance level of each test.

To provide a clearer understanding of this relationship between the systems, the responses presented in

Table 7 and

Table 8 can be compared. The microgrid must be able to withstand the oscillatory behavior induced by the load step at the load converter input. Thus, it is observed that the proposed control for the voltage balancer ensures reliable operation during the tests performed under microgrid operating mode A.

6.6. Unplanned Island Scenario

In this section, the dynamic behavior of the microgrid is evaluated under an unplanned islanding event of the dc grid-forming converter when the

, shown in

Figure 9, opens. The load resistances are set to

and

.

The droop control of the BESS converter guarantees a smooth transition from grid-connected to islanded operation. The following results present the unplanned islanding scenario triggered when switch is opened.

When opens, the dc power supply is disconnected from the bipolar dc bus, and the microgrid becomes islanded. The BESS converter perceives this event as a load step, and regulates the bus voltage within the specified operating range of the droop curve. In this scenario, the voltage balancer acts as a voltage doubler, maintaining the balance between the intermediate bus voltages and .

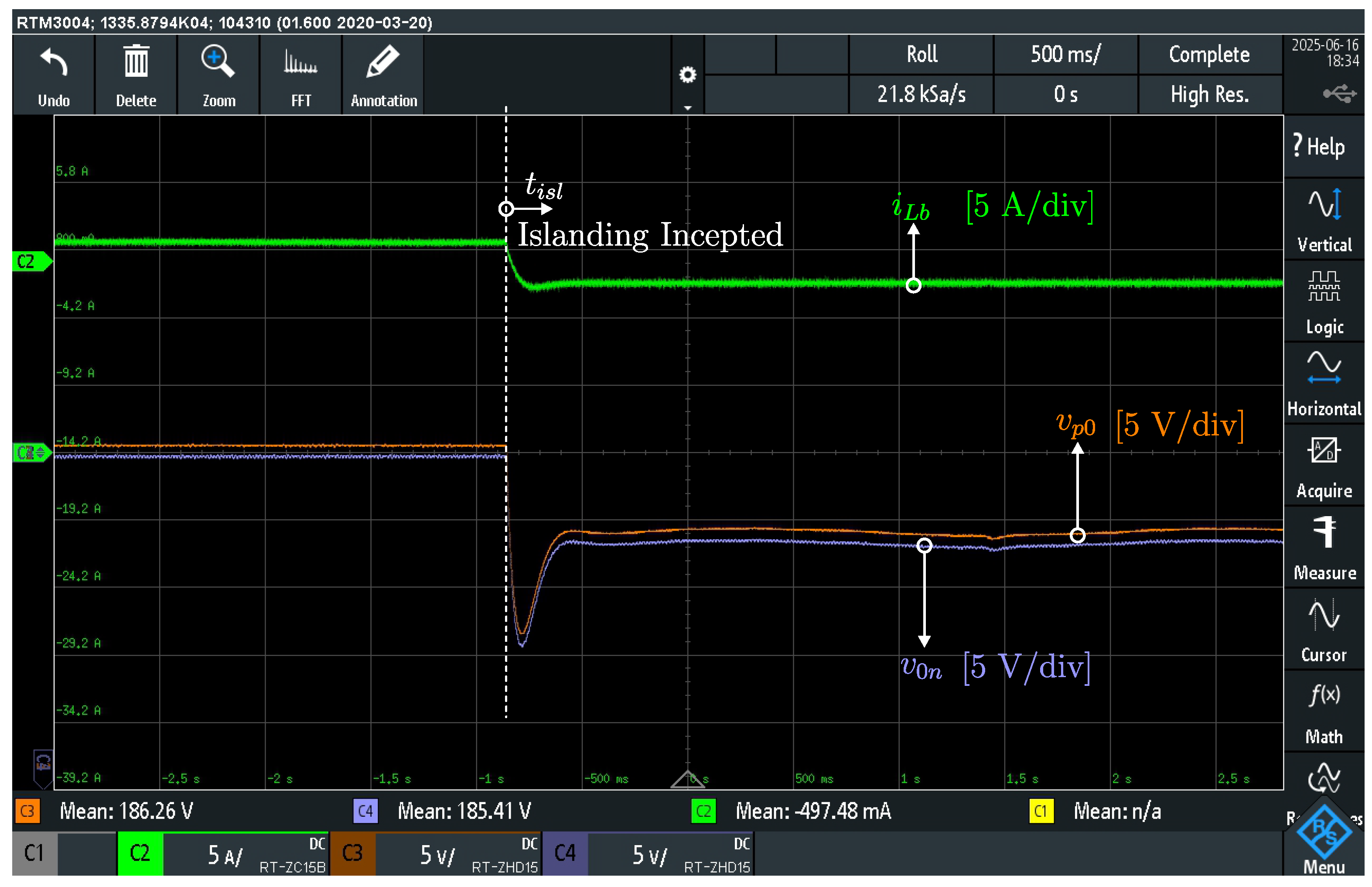

Figure 21 illustrates the transient response of the bipolar dc microgrid at the instant

, when the unplanned islanding occurs. Channel 2 presents the voltage balancer current

(green trace, 2 A/div), Channel 3 presents the bus voltage

(orange trace, 5 V/div, offset: 190 V), and Channel 4 presents the bus voltage

(light blue trace, 5 V/div, offset: 190 V).

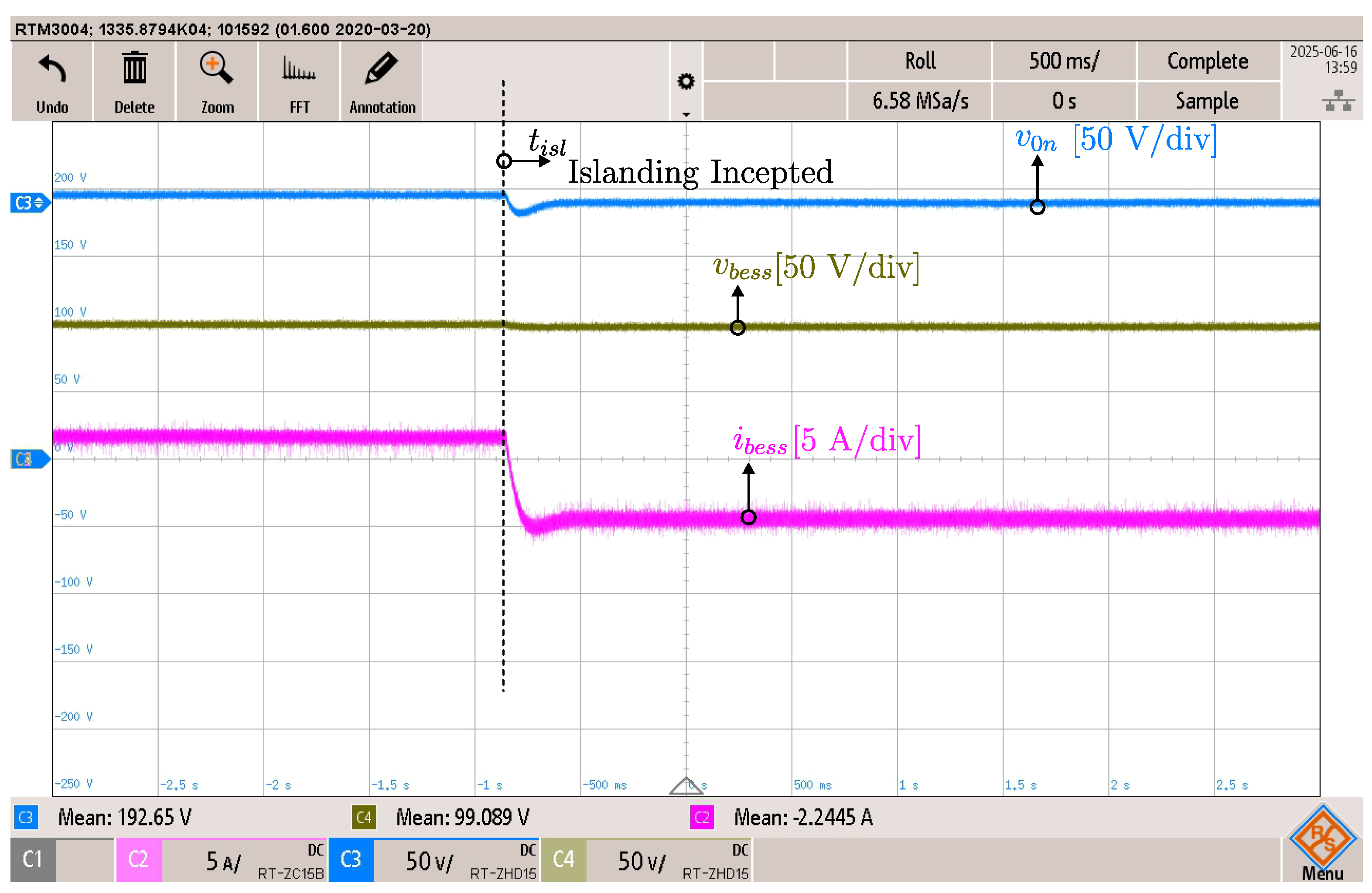

Figure 22 illustrates the transient response of the BESS converter during the unplanned islanding event at

. Channel 2 presents the inductor current

(pink trace, 5 A/div), Channel 3 presents the bus voltage

(light blue trace, 2 V/div, offset: 190 V), and Channel 4 presents the output voltage

(green trace, 2 V/div, offset: 95 V).

Before , the bidirectional dc power supply regulates the total dc bus at 380 V. The voltage balancer operates in closed-loop, ensuring the balance of the intermediary voltage of the bipolar bus, and the BESS converter is connected to the 0–n dc bus, recharging the battery with approximately A. The voltage deviation of the system is V ().

At , the unplanned islanded scenario occurs when the switch opens. The bidirectional power supply is detached from the microgrid, and the BESS converter acts as the dc grid-forming converter. At this moment, the loads from the two unipolar buses are fed the BESS connected in the negative bus. The BESS provides 5 A resulting in a voltage drop of 5 V due to V/A. The resulting voltage is 185 V.

In the islanded scenario, the BESS feeds directly only the negative pole, but the voltage balancer doubles the voltage sourced, redirecting power from the negative pole to the positive pole, and keeping at 184 V. This voltage deviates approximately 0.8 V from the voltage sourced in the negative pole, corresponding to . The total dc voltage remains near 369 V.

The BESS current increases steadily from 0 A to 5 A, supplying the load power requirement of the microgrid. For the BESS converter, this islanding scenario is perceived as a load step. These results confirm the seamless and well-controlled transition from grid-connected operation to the islanded scenario.

Furthermore,

Table 9 presents a comparison of voltages and the unbalance deviation before the islanding and after the transition to mode B.

6.7. Overview of Qualitative Experimental Tests

In

Section 6.1, the voltage balancer enters in operation in open-loop. It improves the microgrid’s voltage regulation in the connected scenario. However, in

Section 6.2, when subjected to more unbalanced loads, the voltage balancer becomes less effective, requiring closed-loop regulation.

In a closed-loop, it can accurately regulate the voltage on the bipolar bus, as shown in

Section 6.3. The voltage balancer and the microgrid remain stable when operating with electronic loads in open-loop or in closed-loop, as in

Section 6.4 and

Section 6.5. In all of these cases, the voltage balancer accuracy increases when operating in closed-loop.

Finally,

Section 6.6 shows the microgrid operating with the BESS, which sources power to one of the poles, and the voltage balancer, which redistributes the power to the other pole, and keeps the voltages equalized. Thus, the voltage balancer allows the bipolar microgrid to operate with a unipolar power source while balancing the unipolar voltages.