Rotary Steerable Drilling Technology: Bottlenecks Breakthroughs and Intelligent Trends in China Shale Gas Development

Abstract

1. Introduction

1.1. Technical Definition and Strategic Value

1.2. International Development Trajectory and Technological Generation Gap

1.3. China’s Challenges and Research Objectives

2. Core Technology Classification and Principles

2.1. Physical Essence of Steering Mechanisms

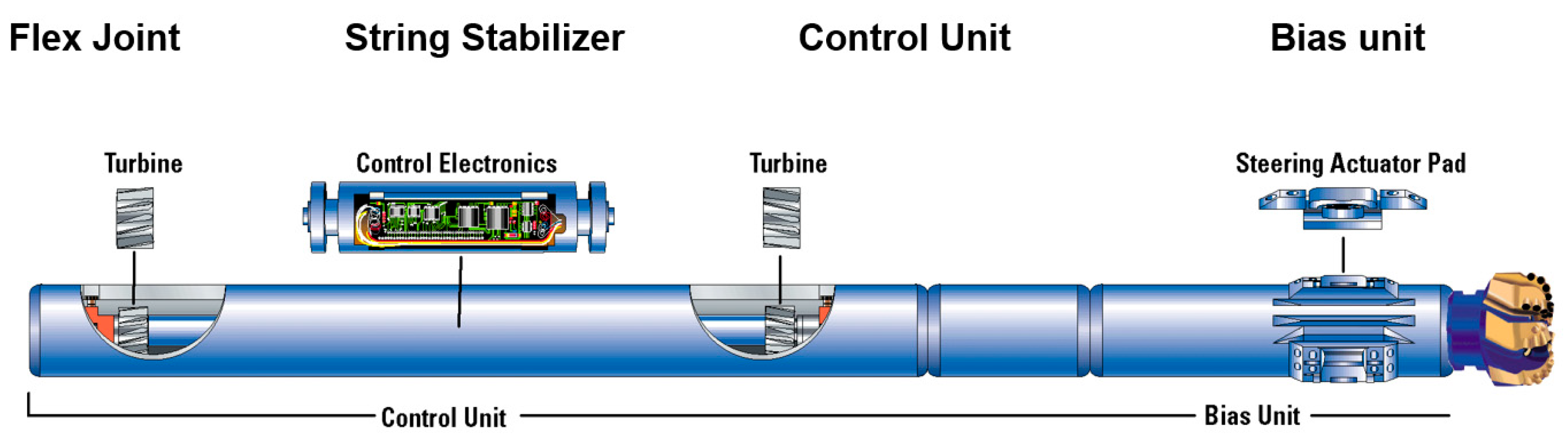

2.1.1. Push-the-Bit

2.1.2. Point-the-Bit

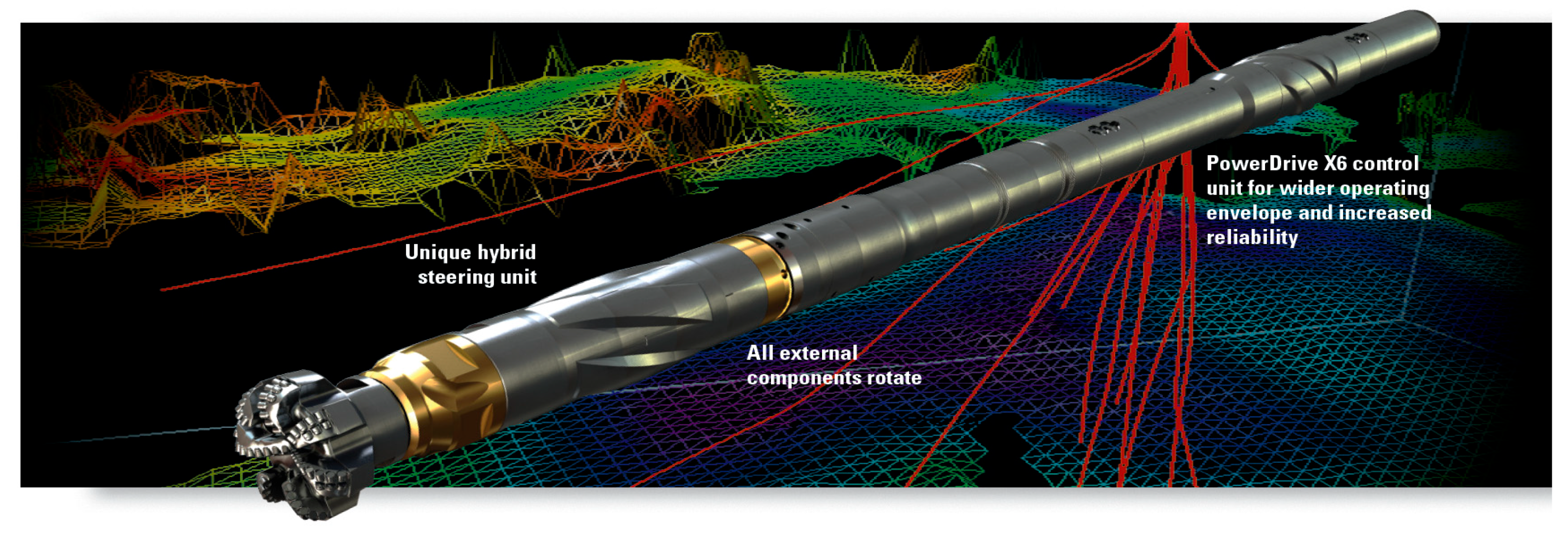

2.1.3. Hybrid

2.2. Structural Configuration and Measure-Control Platform

2.3. Power Drive and Actuator Evolution

2.4. China’s Technological Breakthrough Points

3. Technological Progress and Performance Boundaries

3.1. Extreme Environment Adaptability Breakthroughs

3.2. Detection and Control Precision Leap

3.3. Intelligent Performance Leap

4. Intelligent Transformation Trends

4.1. Leap in Intelligent Decision Hierarchy

4.2. Neural Center of Data Transmission

4.3. Breakthroughs in Downhole Intelligent Closed-Loop

5. Unsolved Challenges and Countermeasures

5.1. High-Temperature High-Pressure Dynamic Control Bottleneck

5.2. Downhole Intelligent Closed-Loop Latency

5.3. Ultra-Deep Well Detection and Transmission Limits

6. Conclusions

6.1. Performance Breakthroughs Coexist with Technological Gaps

6.2. Core Contradictions of Intelligent Transformation

6.3. China’s Strategic Breakout Path

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, G.; Huang, W.; Gao, D. Real-time control algorithm of well trajectory for push-the-bit rotary steering drilling system. SPE J. 2023, 28, 2148–2164. [Google Scholar] [CrossRef]

- Gomaa, M.A.K. Online Control and Optimization of Directional Drilling. Master’s Thesis, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia, 2016. [Google Scholar]

- Li, Y.; Niu, W.; Li, H.; Luo, Z.; Wang, L. Study on a new steering mechanism for point-the-bit rotary steerable system. Adv. Mech. Eng. 2014, 6, 923178. [Google Scholar] [CrossRef]

- Majeed, G.A.M. Directional Drilling Optimization with Mud Motor and Rotary Steerable System. Ph.D. Thesis, Politecnico di Torino, Torino, Italy, 2020. [Google Scholar]

- Jebur, A.A.M. Directional Drilling Tools Assessment and the Impact of Bottom Hole Assembly Configuration on the Well Trajectory and Operation Optimization. Ph.D. Thesis, Politecnico di Torino, Torino, Italy, 2020. [Google Scholar]

- Ma, T.; Liu, Y.; Cai, J.; Chen, P. Deep and horizontal drilling technologies for natural gas. In Sustainable Natural Gas Drilling; Elsevier: Amsterdam, The Netherlands, 2024; pp. 35–78. [Google Scholar]

- Dong, Z.; Tian, S.; Xue, H.; Lu, S.; Liu, B.; Erastova, V.; Wu, M.; Wu, R. Analysis of pore types in lower cretaceous Qingshankou shale influenced by electric heating. Energy Fuels 2024, 38, 20577–20590. [Google Scholar] [CrossRef]

- Woodall, M.; Skinner, G.; Viandante, M.; Pontarelli, L.; Kostas, K.; Haynes, E. The role of geosteering in developing the Pyrenees Field. APPEA J. 2014, 54, 494. [Google Scholar] [CrossRef]

- Wang, F.; Kobina, F. The Influence of Geological Factors and Transmission Fluids on the Exploitation of Reservoir Geothermal Resources: Factor Discussion and Mechanism Analysis. Reserv. Sci. 2025, 1, 3–18. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, G.; Yao, R.; Hao, S.; Wang, H. Evolution and Prospect of Rotary Steerable Drilling Technology. In Proceedings of the Annual Conference of China Electrotechnical Society; Springer Nature: Singapore, 2024; pp. 342–350. [Google Scholar]

- Wu, J.; Ansari, U. From CO2 Sequestration to Hydrogen Storage: Further Utilization of Depleted Gas Reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Andrade, C.P.; Saavedra, J.L.; Tunkiel, A.; Sui, D. Rotary steerable systems: Mathematical modeling and their case study. J. Pet. Explor. Prod. Technol. 2021, 11, 2743–2761. [Google Scholar] [CrossRef]

- Zhang, C.; Zou, W.; Cheng, N. Overview of rotary steerable system and its control methods. In Proceedings of the 2016 IEEE International Conference on Mechatronics and Automation, Harbin, China, 7–10 August 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1559–1565. [Google Scholar]

- Akinniranye, G.; Kruse, W.D.; Bautista Gomez, A.; Poedjono, B.; Dubose, B.; Goobie, R.B.; Hobin, J. Rotary Steerable System Technology Case Studies in a High-Volume, Low-Cost Environment. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, SPE, Manama, Bahrain, 11–14 March 2007; p. SPE-105468-MS. [Google Scholar]

- Zhang, L.; Yuan, X.; Luo, L.; Tian, Y.; Zeng, S. Seepage characteristics of broken carbonaceous shale under cyclic loading and unloading conditions. Energy Fuels 2023, 38, 1192–1203. [Google Scholar] [CrossRef]

- Omar, M.G.; Boushahri, M.Y.; Ghanim, A.; Al-Osaimi, M.; Dixit, R.; Mubarak, S.; Taqi, G.; Taha, M.; Abdelhamid, A.; Agawani, W.; et al. Hybrid Drill Bit Technology Improves Build Up Rate Capabilities of RSS Tools and Eliminates Drilling Vibrations in Interbedded Carbonates. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, SPE, Abu Dhabi, United Arab Emirates, 1–4 November 2016; p. D021S026R005. [Google Scholar]

- Chandra, S.; Rao, V.A.; Singh, V.S. A combined approach of Schlumberger and axial pole–dipole configurations for groundwater exploration in hard-rock areas. Curr. Sci. 2004, 86, 1437–1443. [Google Scholar]

- Zhang, L.; Jiang, W.; Hu, G.; Yang, H.; Tao, Y.; Huang, X. Optimal Selection of Wellbore Trajectory Control Technology for Shale Oil In-Situ Conversion Process Wells. In Proceedings of the International Field Exploration and Development Conference; Springer Nature: Singapore, 2024; pp. 841–854. [Google Scholar]

- Rosado Cagua, A.C.; Rodriguez Malavé, A.A. Análisis Comparativo de la Tecnología Power Drive Archer y Motor de Fondo para la Optimización de la Perforación en Pozos Petroleros. Bachelor’s Thesis, La Libertad: Universidad Estatal Península de Santa Elena, La Libertad, Ecuador, 2025. [Google Scholar]

- Li, W.; Mou, L.; Zhou, X.; Tan, X.; Fu, Q. Research progress of rotary steerable system and its control methods. Coal Geol. Explor. 2023, 51, 167–179. [Google Scholar]

- Li, Q. Reservoir Science: A Multi-Coupling Communication Platform to Promote Energy Transformation, Climate Change and Environmental Protection. Reserv. Sci. 2025, 1, 1–2. [Google Scholar] [CrossRef]

- Djefel, B.; Clegg, N. Driving technology for geosteering decisions: Halliburton geosteering. In Handbook of Petroleum Geoscience: Exploration, Characterization, and Exploitation of Hydrocarbon Reservoirs; Wiley: Hoboken, NJ, USA, 2022; pp. 123–136. [Google Scholar]

- Pan, X.; Li, J.; Sui, Y.; Tang, Y.; Zhang, H.; Shi, Q. CGDS near-bit geosteering drilling system and its first application in Niger. J. Phys. Conf. Ser. 2024, 2901, 012035. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, C.; Gao, X.; Lin, Y.; Sheng, L.; Dou, X.; Jia, H.; Yan, G. Improved Drilling Performance by Applying the China Geosteering Drilling System in Heterogeneous Reservoir Sands: A Case From Songliao Basin, Northeast China. In Proceedings of the SPE Offshore Europe Conference and Exhibition, SPE, Aberdeen, UK, 8–11 September 2015; p. SPE-175447-MS. [Google Scholar]

- Gao, W.; Sheng, L.; Dou, X.; Zhang, L.; Su, Y.; Wang, J.; Deng, L.; Li, L. CGDS near-bit geosteering drilling system and its application in China. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, SPE, Nusa Dua, Bali, Indonesia, 20–22 October 2015; p. SPE-176495-MS. [Google Scholar] [CrossRef]

- Yang, Q.; Bie, Z.; Yang, X. (Eds.) The Proceedings of the 19th Annual Conference of China Electrotechnical Society: Volume I; Springer Nature: Berlin/Heidelberg, Germany, 2025. [Google Scholar]

- Wang, C.; Ke, P.; Cao, C.; Liu, G.; Li, J.; Liu, X.; Deng, J. Study on the downhole measurement method of weight on bit with a near-bit measurement tool. Geoenergy Sci. Eng. 2023, 224, 211633. [Google Scholar] [CrossRef]

- Yang, H.; Gao, S.; Liang, H.; Luo, S.; Zhang, P. Research on dynamic measurement method of drilling tool attitude near bit based on suppression of heavy-tailed measurement noise. IEEE Sens. J. 2023, 23, 18384–18395. [Google Scholar] [CrossRef]

- Zhang, T.; Lu, Y.; Li, J.; Wang, B.; Zhan, J. Development of Near-Bit Multi-parameter Measurement Tool and Data Application. In Proceedings of the International Conference on Computational & Experimental Engineering and Sciences; Springer Nature: Cham, Switzerland, 2024; pp. 646–660. [Google Scholar]

- Pan, X.; Shi, Q.; Zhang, H.; Wang, C.; Tang, Y.; Li, J. Near-bit apparent resistivity measurement method based on SPWM excitation. Pet. Sci. Technol. 2024, 42, 3314–3333. [Google Scholar] [CrossRef]

- Cheng, L.; Tianhuai, D.; Peng, W. An experimental rig for near-bit force measurement and drillstring acoustic transmission of BHA. Measurement 2011, 44, 642–652. [Google Scholar] [CrossRef]

- Breyholtz, Ø.; Nikolaou, M. Drilling automation: Presenting a framework for automated operations. SPE Drill. Complet. 2012, 27, 118–126. [Google Scholar] [CrossRef]

- Macpherson, J.D.; de Wardt, J.P.; Florence, F.; Chapman, C.D.; Zamora, M.; Laing, M.L.; Iversen, F.P. Drilling-systems automation: Current state, initiatives, and potential impact. SPE Drill. Complet. 2013, 28, 296–308. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, J.; Qin, S. Application and Progress of Artificial Intelligence in Oilfield Drilling. Adv. Eng. Technol. Res. 2023, 8, 852. [Google Scholar] [CrossRef]

- Akita, E.; Dyer, F.; Drummond, S.; Elkins, M.; Duggan, P.; Ahmed, R.; Florence, F. Directional Drilling Automation Using a Laboratory-Scale Drilling Rig: SPE University Competition. SPE Drill. Complet. 2021, 36, 1–10. [Google Scholar] [CrossRef]

- Wang, H.; Huang, H.; Bi, W.; Ji, G.; Zhou, B.; Zhuo, L. Deep and ultra-deep oil and gas well drilling technologies: Progress and prospect. Nat. Gas Ind. B 2022, 9, 141–157. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Ji, G.; Cui, M.; Chen, L.; Li, W.; Liu, L. Technologies and Achievements for Drilling and Completion of Onshore Deep and Ultra-Deep Wells in China. In Proceedings of the International Petroleum Technology Conference, IPTC, Kuala Lumpur, Malaysia, 18–20 February 2025; p. D032S009R016. [Google Scholar]

- Peng, L.X.; Wang, H.; Feng, X.; Guo, X.W.; Xiong, X. A Downhole Depth Measurement Method Based on Closed-Loop Drilling. In Proceedings of the International Field Exploration and Development Conference; Springer: Singapore, 2025; pp. 215–223. [Google Scholar]

- Gao, D. Some research advances in well engineering technology for unconventional hydrocarbon. Nat. Gas Ind. B 2022, 9, 41–50. [Google Scholar] [CrossRef]

- Zhang, K.; Han, K.; Zhao, N. RSS Tracking Control for AVs Under Bayesian-Network-Based Intelligent Learning Scheme. Actuators 2025, 14, 37. [Google Scholar] [CrossRef]

- Ignova, M.; Mantle, K.; Brovko, K.; Abe, V.; Gorodnov, A.; Li, L. Downhole Trajectory Automation of RSS Tools: Autonomous Drilling Becomes Reality. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, SPE, Stavanger, Norway, 7–9 March 2023; p. D031S022R003. [Google Scholar]

- Tilley, J.; Nair, V.N.; Hamoudi, L. Case Study: Intelligent RSS Improving Drilling Performance on Three Mile Laterals in the Appalachian Basin. In Proceedings of the SPE Annual Technical Conference and Exhibition? SPE, Virtual, 26–29 October 2020; p. D022S061R007. [Google Scholar]

| Development Stage | Time Period | Technical Characteristics | Representative Achievements |

|---|---|---|---|

| Enlightenment stage | 1970s–1990s | Static Push-the-bit tools, solving friction in offshore extended-reach wells | Baker Hughes Navitrak (temperature rating: 125 °C) |

| Commercial breakthrough | 1997–2010 | Mature dynamic control technology, significantly improved build rates | Halliburton Geo-Pilot (build rate: 12°/30 m, temperature rating: 150 °C) |

| High-performance iteration | 2011–2020 | Hybrid steering tools enabling high build rates, breakthroughs in temperature and pressure ratings | Schlumberger PowerDrive Archer (build Rate: 18°/30 m, temperature rating: 200 °C/207 MPa) |

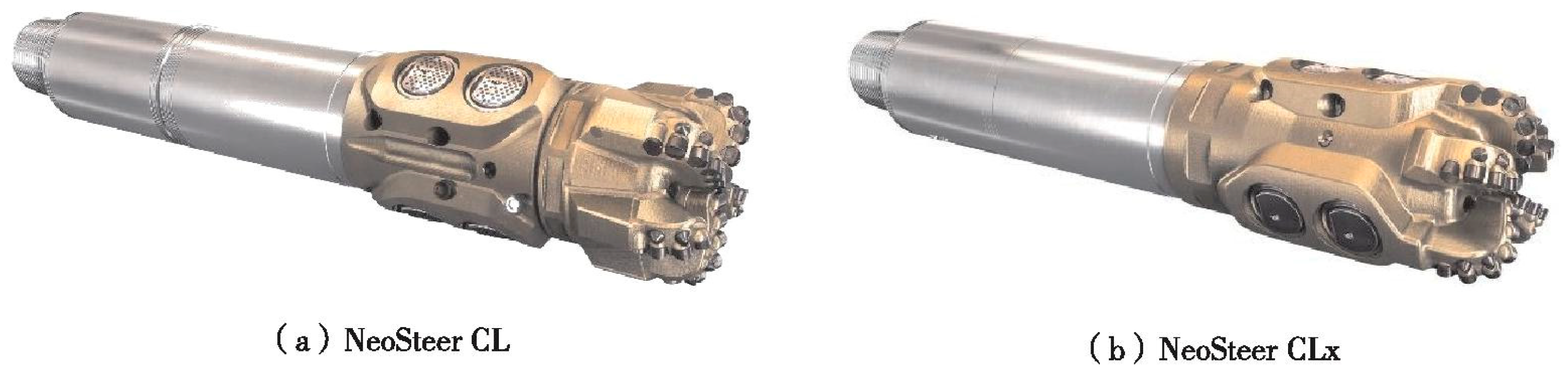

| Intelligent leap | 2020–Present | BSS integrated with downhole AI co-processors enabling semi-autonomous control | NeoSteer CL BSS (near-bit spacing: 0.8 m) |

| Performance Parameter | International Benchmark | China Level |

|---|---|---|

| Temperature/pressure rating | 200 °C/207 MPa | 175 °C/140 MPa |

| Dynamic control precision | ±0.5° | ±1.2° |

| Transmission rate (6000 m) | 40 b/s | 20 b/s |

| Near-bit spacing | 0.8 m | 1.5 m |

| Look-ahead detection precision | 0.5 m | 0.05 m (Short-range boundary) |

| Build rate | 18°/30 m | 12°/30 m |

| Intelligent control level | L5 (Human–Machine collab.) | L4 (Single recommendation) |

| Shale gas application rate | 95% | 20% |

| Classification Dimension | Type | Technical Characteristics | Representative System |

|---|---|---|---|

| Structural form | Non-rotating sleeve | Static outer sleeve protects internal sensors; simple control algorithm; prone to sticking; weak hole cleaning | Baker Hughes Autotrak |

| Fully rotating | Entire tool rotates with drill string; adaptable to enlarged boreholes; requires dynamic compensation to maintain measurement reference | Schlumberger PowerDrive | |

| Measure-control platform | Static platform | Sensors fixed relative to borehole; stable data acquisition; suitable for low RPM conditions | Weatherford revolution |

| Dynamic platform | Gyroscopes/motors counter-rotate to cancel drill string rotation, locking onto Earth’s coordinate system; extremely high demands on control real-time performance | Halliburton iCruise |

| Company | Product | Detection Distance (m) | Detection Precision (m) | Temperature Rating (°C) |

|---|---|---|---|---|

| Schlumberger | PeriScope edge | 7.6 | 0.5 | 200 |

| Baker Hughes | AziTrak | 5.2 | - | 180- |

| Halliburton | ADR | 5.5 | - | 190 |

| CNPC | High-Freq. EM wave radar | - | 0.05 | 175 |

| Performance Dimension | International Benchmark | China Level |

|---|---|---|

| Build rate (°/30 m) | 18 | ≤15 |

| Temperature/pressure rating | 200 °C/207 MPa | 125 °C/140 MPa |

| Near-bit spacing (m) | 0.8 | 1.2 |

| Detection precision (m) | 0.50 (Look-Ahead) | 0.05 (Boundary) |

| Transmission rate (b/s) | 40 | 20 |

| Dynamic control speed (RPM) | 400 | 150 |

| Level | Definition | Mode |

|---|---|---|

| L1 | Full manual operation: machine provides no assistance; human responsible for all decisions and execution. | Observation mode |

| L2 | Multi-option assisted decision: machine provides multiple options; human selects and executes. | Observation mode |

| L3 | Optimized recommendation advisory: machine provides optimized recommendation; human selects and executes. | Advisory mode |

| L4 | Single recommendation advisory: machine proposes a single recommended plan; human decides and executes. | Advisory mode |

| L5 | Human–machine collaborative execution: machine proposes plan; human approves; machine executes automatically. | Semi-autonomous control |

| L6 | Timed veto execution: machine executes plan; human can veto within a defined timeframe. | Semi-autonomous control |

| L7 | Execution with notification: machine automatically executes plan and then notifies human. | Semi-autonomous control |

| L8 | On-demand notification autonomous: machine automatically executes plan and notifies human only upon request. | Autonomous control |

| L9 | Conditional notification autonomous: machine autonomously executes and decides whether to notify human. | Autonomous control |

| L10 | Fully autonomous control: machine fully autonomous in decision and execution. | Autonomous control |

| Technology Type | Transmission Rate | Temperature/Pressure Rating | Representative System |

|---|---|---|---|

| Intelligent drill pipe | 57 kb/s | 150 °C/103 MPa | IntelliPipe |

| Continuous wave compressive | 40 b/s | 200 °C/207 MPa | Orion II (SLB) |

| EM wave-pulse dual channel | 16 b/s + 4 b/s | 165 °C/137 MPa | xBolt (SLB) |

| Level | International Status | China Target | Core Supporting Technologies |

|---|---|---|---|

| L5 | AI Steering (34% ROP Increase) | Downhole response <1 s | Reinforcement learning algorithm optimization |

| L7 | iCruise (400 RPM control) | “Tri-loop System” Pilot Deployment | HTHP edge computing chips |

| L10 | Lab verification | Fully autonomous drilling | Quantum sensing + neuromorphic computing |

| Direction | Short-Term (2025) | Mid-Term (2030) | Long-Term (2035) |

|---|---|---|---|

| High-temp control | Piezo-Ceramic prototype (200 °C) | Silicon nitride bearings mass prod. (220 °C) | All-solid-state actuators (250 °C) |

| Intelligent loop | Edge response <3 s | “Tri-loop system” application | Fully autonomous drilling |

| Ultra-deep breakth. | Dual-Channel transmission 30 b/s | Quantum sensing downhole verification | Ground-well photonics network |

| Localized applic. | 5 cm radar scaled deployment | Thin res. encounter rate >85% | Deep O&G Dev. cost reduction 40% |

| Performance Parameter | International Benchmark | China Level | Root Cause of Gap |

|---|---|---|---|

| Temperature/Pressure rating | 200 °C/207 MPa | 175 °C/140 MPa | For metal seals: Insufficient interfacial bonding strength between nickel-based alloys and ceramic coatings; machining precision reaches Ra 1.6 μm |

| Dynamic control error (TFA) | ±0.5° | ±1.2° | For electro-hydraulic coupling: Control algorithms do not integrate dynamic drill string vibration interference; servo valve response delay >10 ms |

| Transmission rate | 40 b/s | 20 b/s | For high-temperature chips: Domestic GaAs chip electron mobility decreases by 30% at 175 °C; compression algorithms lack optimization for unstructured data |

| Autonomous control level | L5 (AI Steering) | L4 (Geo-target model) | For edge computing: Lack of 200 °C resistant FPGA chips; algorithms not adapted to shale gas well data noise |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, H.; Zhang, B.; Xie, Y. Rotary Steerable Drilling Technology: Bottlenecks Breakthroughs and Intelligent Trends in China Shale Gas Development. Processes 2025, 13, 3471. https://doi.org/10.3390/pr13113471

Geng H, Zhang B, Xie Y. Rotary Steerable Drilling Technology: Bottlenecks Breakthroughs and Intelligent Trends in China Shale Gas Development. Processes. 2025; 13(11):3471. https://doi.org/10.3390/pr13113471

Chicago/Turabian StyleGeng, Hao, Bingzhong Zhang, and Yingjian Xie. 2025. "Rotary Steerable Drilling Technology: Bottlenecks Breakthroughs and Intelligent Trends in China Shale Gas Development" Processes 13, no. 11: 3471. https://doi.org/10.3390/pr13113471

APA StyleGeng, H., Zhang, B., & Xie, Y. (2025). Rotary Steerable Drilling Technology: Bottlenecks Breakthroughs and Intelligent Trends in China Shale Gas Development. Processes, 13(11), 3471. https://doi.org/10.3390/pr13113471