Workplace Exposure to Dust Emissions in Additive Manufacturing with an FFF Method

Abstract

1. Introduction

- Volatile organic compounds (VOCs).

- Dust (particulate matter).

2. Objective and Research Methodology

2.1. The Objective of the Research

- Dyes added by manufacturers to the polymer from which the filament is made;

- Printing process parameters.

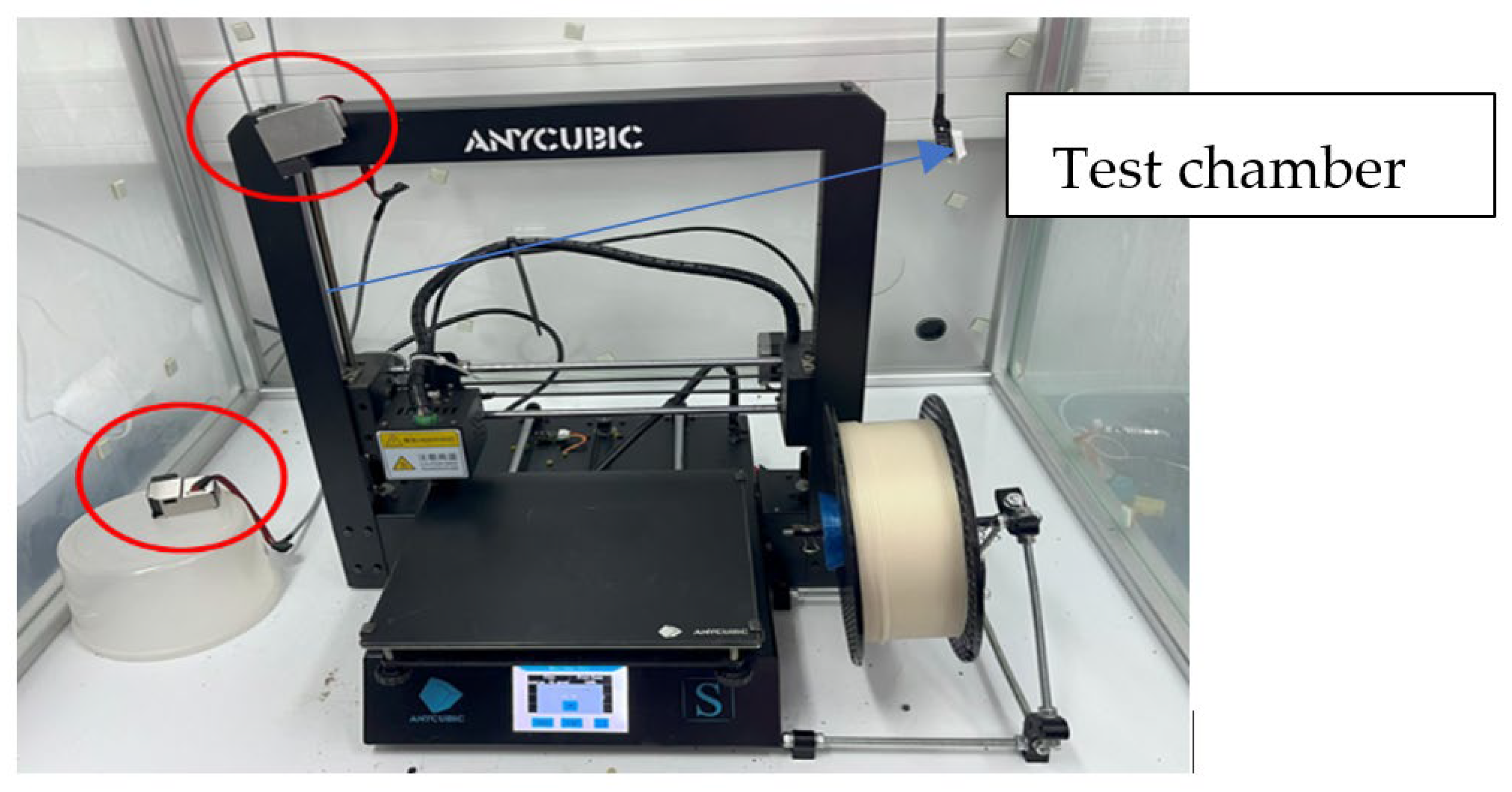

2.2. Methodology

- Extruder temperature [factor A];

- Bed temperature [factor B];

- Layer thickness [factor C];

- Head movement speed/printing speed [factor D];

- Nozzle diameter [factor E];

- Cooling fan speed [factor F].

3. Results

Dust Emission Intensity Index

- forecasting dust concentration in a room of a given volume,

- the impact of printing parameters on emission intensity,

- the relationship between emission intensity and filament type,

4. Analysis and Discussion of the Experimental Results

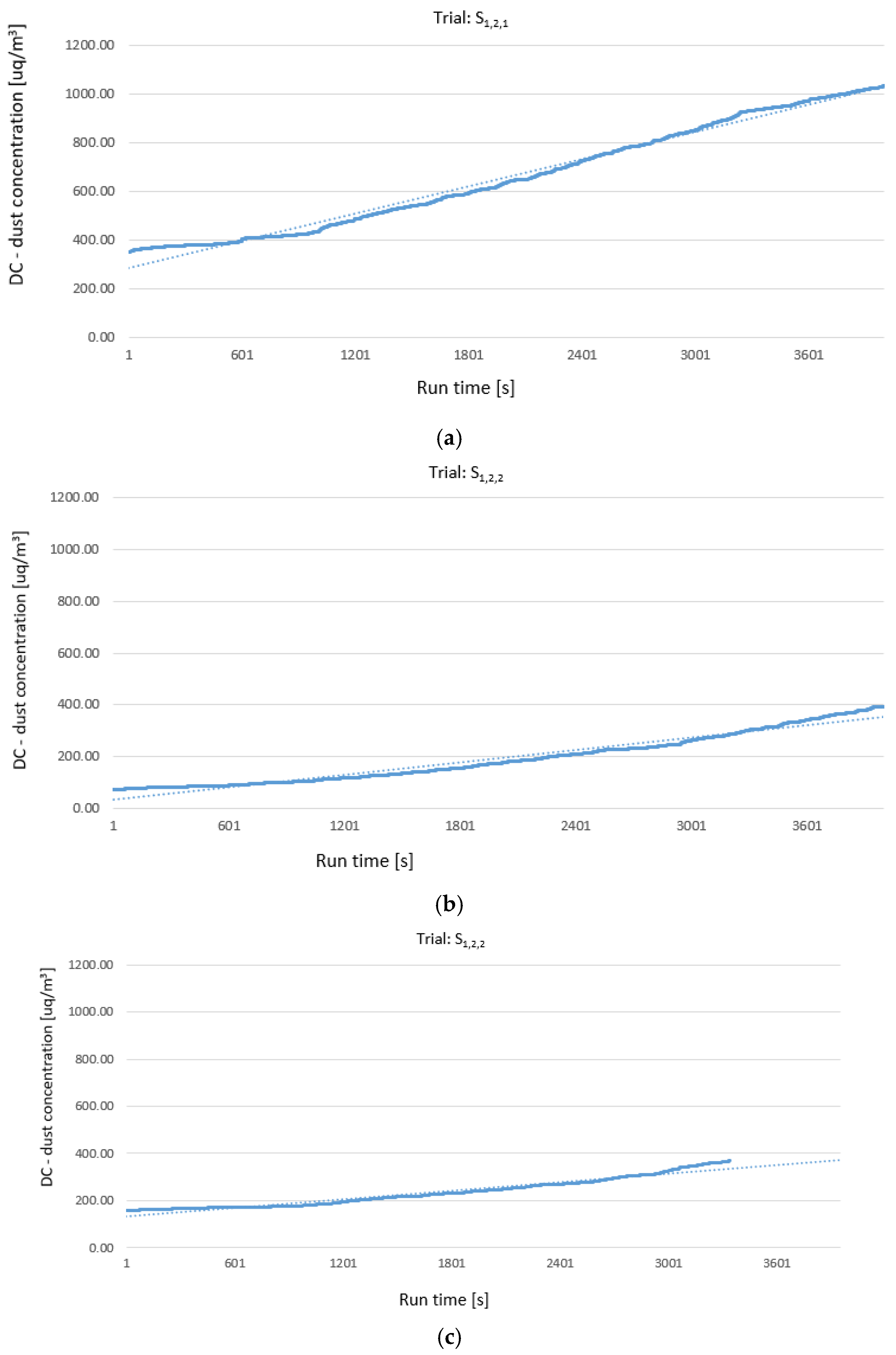

4.1. Forecasting of Dust Concentration in a Room

- DC—dust concentration in a room of a volume Vr

- tp—process time

- DEII—Dust Emission Intensity Index

- Vr—room volume [m3]

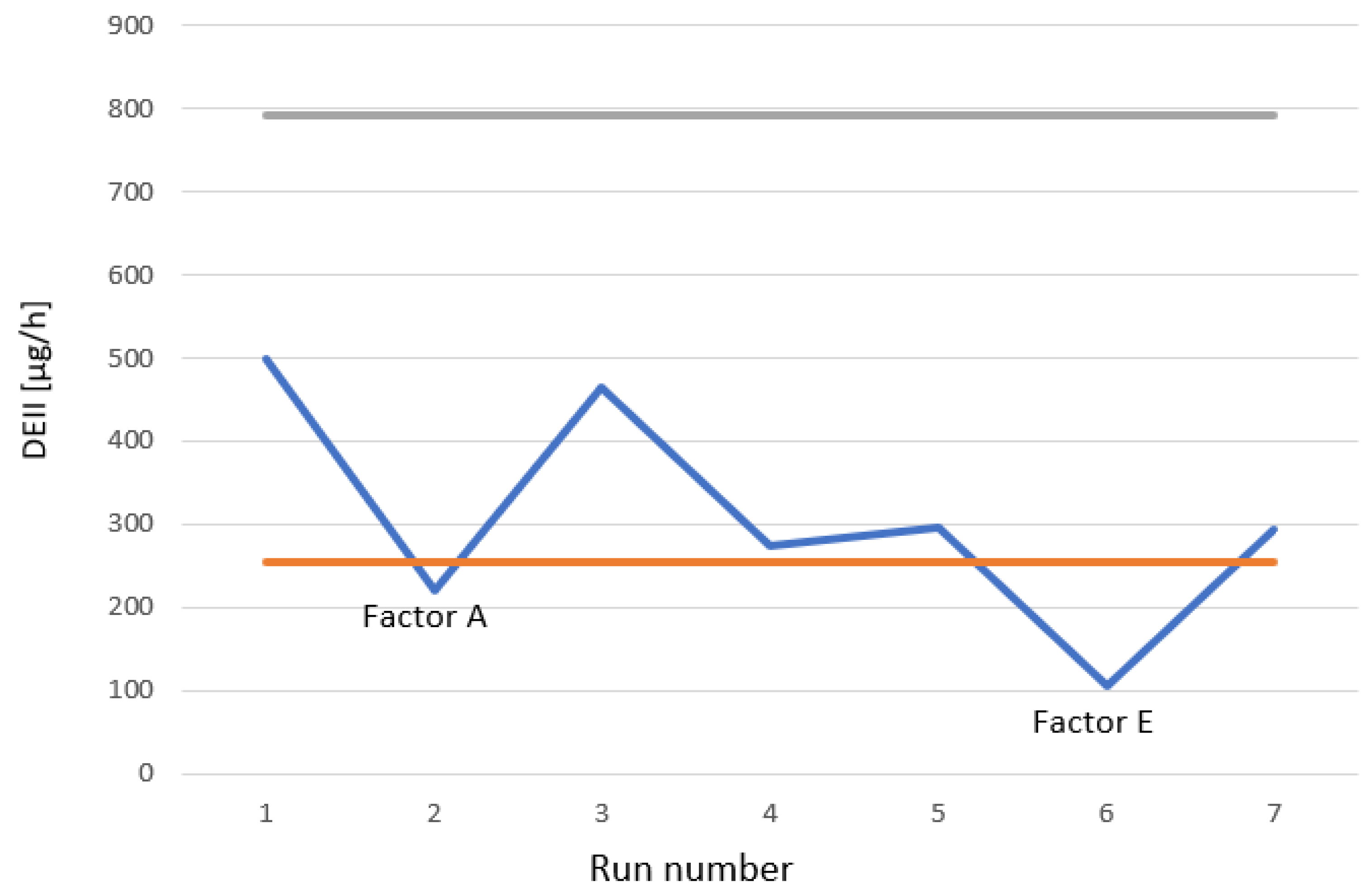

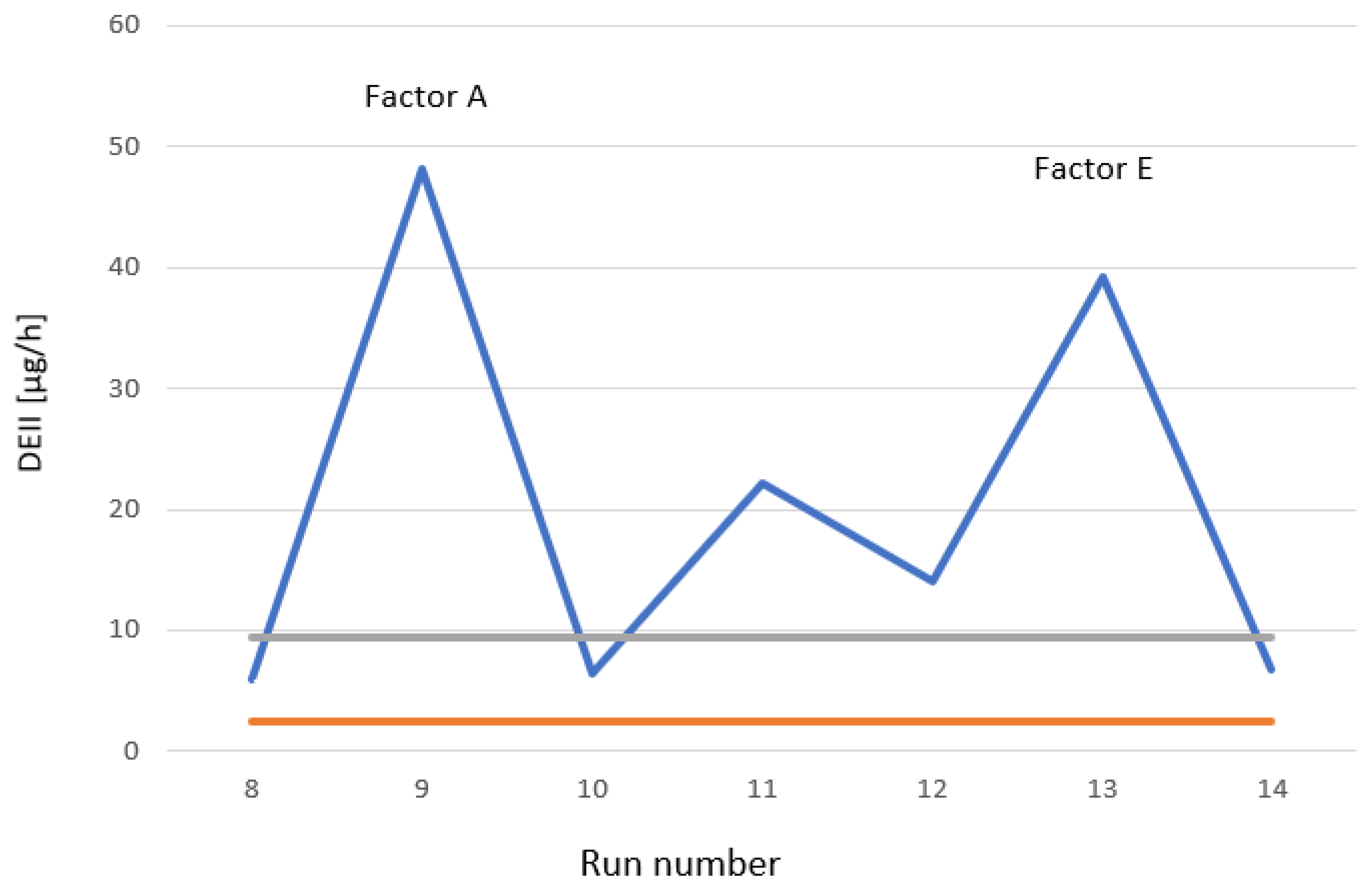

4.2. The Impact of Process Factors on the Dust Emission Intensity Index

- In runs 1–7 marked as a blue line (in run 1, all parameters are set at the (+) level; in runs 2–7, one of the factors is set at the (−) level, while the others remain at the (+) level).

- In runs 8–14 marked as an orange line (in run 8, all parameters are set at the (−) level; in runs 9–14, one of the factors is set at the (+) level, while the others remain at the (−) level).

- Intensification of chemical processes—high extruder temperature promotes the acceleration of chemical reactions and physical processes within the filament, leading to the disintegration of the material structure into finer particles. As a result, a greater amount of potentially harmful substances is released into the surrounding environment, affecting air quality.

- Increase in the intensity of thermodynamic processes—high extruder temperature triggers more intense thermodynamic transformations, including the expansion of gases trapped in the micro-pores of the filament. As the material is heated, gases are released more rapidly, which can generate additional emissions of fine particles. The solid particles expelled in this way are carried by the expanding gases, facilitating their migration into the surrounding environment, thereby increasing dust emissions.

- A larger nozzle diameter allows for the extrusion of a thicker material stream, which reduces the amount of heat delivered per unit mass of filament, as well as the pressure under which the filament is extruded. The lower amount of heat delivered to the material also reduces its thermal degradation, resulting in lower emissions of ultrafine particles. The reduction in pressure leads to less swelling of the filament after it exits the nozzle.

- The use of a larger nozzle reduces the number of layers required to form the object, thereby shortening the process time. This, in turn, limits the number of extruder movements and the surface area of the filament exposed to heat and air. As a result, the number of particles emitted into the surrounding environment decreases.

- With a larger nozzle, the extruded material has a relatively small surface area compared to its volume, which limits the exposure of the material to factors that promote its oxidation and degradation. A smaller contact surface means that the filament is less susceptible to processes that lead to the emission of ultrafine particles. For example, for a printed object with a volume of 1 cm3 (in the form of a cube), the surface area of the material exposed to air is 157 cm2 when using a 0.4 mm diameter nozzle. With a 0.8 mm diameter nozzle, the surface area exposed to air decreases to just under 105.5 cm2.

- Since the thicker filament has a relatively smaller surface area compared to its volume, it allows for faster heat dissipation. Faster solidification reduces the time during which the material remains in a semi-liquid state, thus decreasing the risk of thermal degradation and dust emissions.

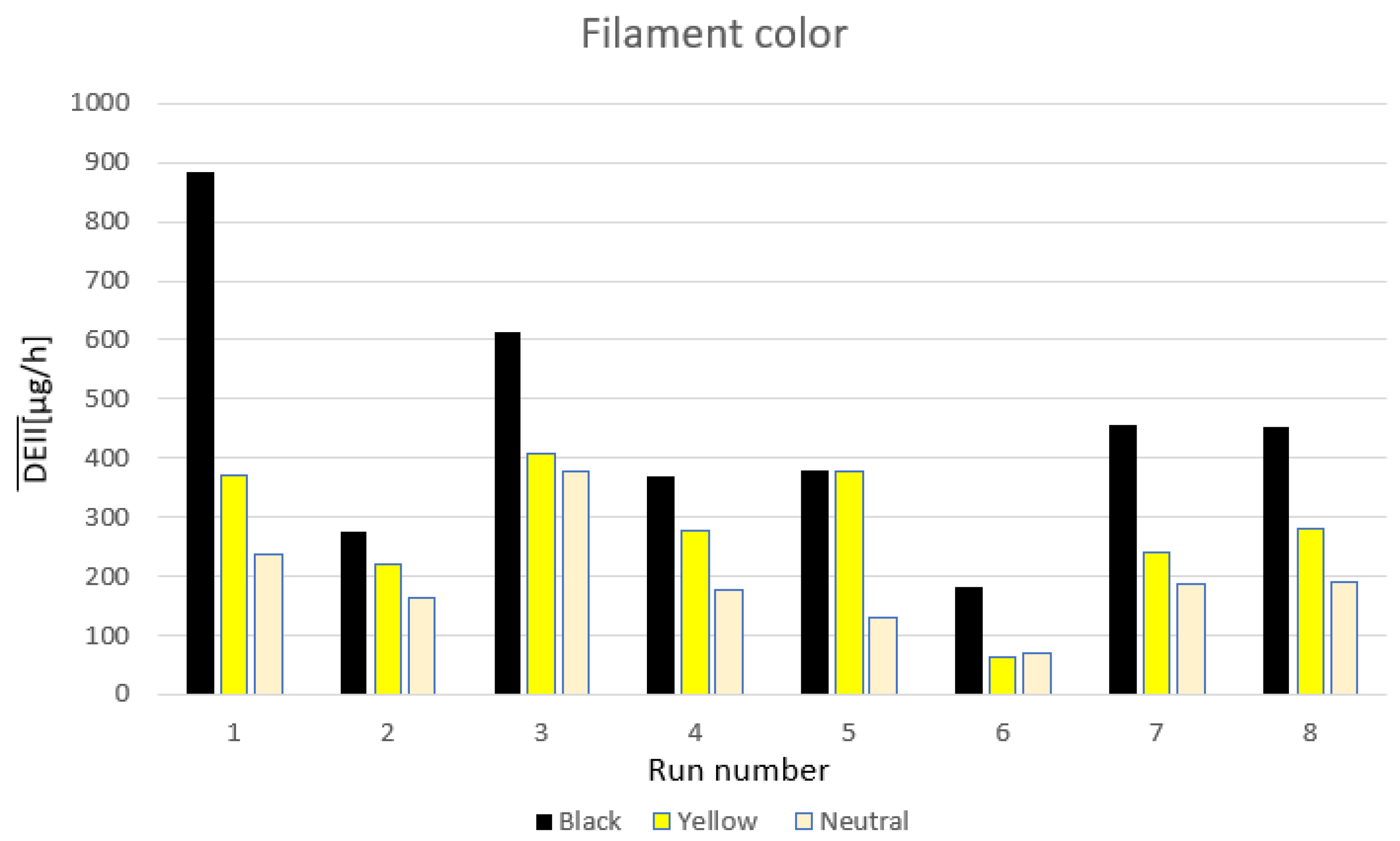

4.3. The Dust Emission Intensity Index Depending on the Filament Type and Supplier

5. Conclusions

- Dust emissions generated during the additive manufacturing process using an FFF method can pose a threat to individuals operating the printers or present in rooms where they are used, especially with prolonged exposure to the emitted pollutants. It has been shown that under specific conditions (small room, high extruder temperature, wide print path), negative health effects may occur after approximately 40 min of exposure.

- Among FFF process parameters, the nozzle diameter and extruder temperature have the greatest impact on dust emission levels. A lower extruder temperature results in less thermal degradation of the material. Increasing the nozzle diameter allows for the extrusion of a thicker filament stream, which reduces the amount of heat applied per unit mass of filament and the pressure during extrusion. Additionally, a filament with a larger diameter has a smaller surface area in contact with air relative to its volume, which limits its exposure to factors that lead to degradation and particle emission.

- An impact of the filament composition, especially the dyes, on dust emissions was also observed. However, no effect of the manufacturer was found. This means that efforts to reduce emissions should primarily focus on the color composition of the filament, rather than its source.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Campbell, I.; Bourell, D.; Gibson, I. Additive Manufacturing: Rapid Prototyping Comes of Age. Rapid Prototyp. J. 2012, 18, 255–258. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Karayannis, P.; Petrakli, F.; Gkika, A.; Koumoulos, E. 3D-Printed Lab-on-a-Chip Diagnostic Systems—Developing a Safe-by-Design Manufacturing Approach. Micromachines 2019, 10, 825. [Google Scholar] [CrossRef] [PubMed]

- Siemiński, P.; Budzik, G. Additive Manufacturing Techniques: 3D Printing, 3D Printers; Warsaw University of Technology Press: Warsaw, Poland, 2015; pp. 11–145. (In Polish) [Google Scholar]

- Bravia, L.; Murmura, F.; Santos, G. Additive Manufacturing: Possible Problems with Indoor Air Quality. Procedia Manuf. 2019, 41, 952–959. [Google Scholar] [CrossRef]

- Khaki, S.; Rio, M.; Marin, P. Monitoring Indoor Air Quality in Additive Manufacturing Environments. Procedia CIRP 2020, 90, 455–460. [Google Scholar] [CrossRef]

- Stefaniak, A.B.; LeBouf, R.F.; Yi, J.; Ham, J.; Nurkewicz, T.; Schwegler-Berry, D.E.; Chen, B.T.; Wells, J.R.; Duling, M.G.; Lawrence, R.B.; et al. Characterization of Chemical Contaminants Generated by a Desktop Fused Deposition Modeling 3-Dimensional Printer. J. Occup. Environ. Hyg. 2017, 14, 540–550. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Wolff, S.; Wang, S. Eco-Friendly Additive Manufacturing of Metals: Energy Efficiency and Life Cycle Analysis. J. Manuf. Syst. 2021, 60, 459–472. [Google Scholar] [CrossRef]

- Liao, J.; Cooper, D.R. The Environmental Impacts of Metal Powder Bed Additive Manufacturing. J. Manuf. Sci. Eng. 2021, 143, 030801. [Google Scholar] [CrossRef]

- Maines, E.M.; Porwal, M.K.; Ellison, C.J.; Reineke, T.M. Sustainable Advances in SLA/DLP 3D Printing Materials and Processes. Green Chem. 2021, 23, 6863–6897. [Google Scholar] [CrossRef]

- Mele, M.; Campana, G.; D’Avino, G. Life Cycle Impact Assessment of Desktop Stereolithography. J. Clean. Prod. 2020, 244, 118743. [Google Scholar] [CrossRef]

- Stabile, L.; Scungio, M.; Buonanno, G.; Arpino, F.; Ficco, G. Airborne Particle Emission of a Commercial 3D Printer: The Effect of Filament Material and Printing Temperature. Indoor Air 2017, 27, 452–459. [Google Scholar] [CrossRef]

- Azimi, P.; Zhao, D.; Pouzet, C.; Crain, N.E.; Stephens, B. Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments. Environ. Sci. Technol. 2016, 50, 1260–1268. [Google Scholar] [CrossRef]

- Gu, J.; Wensing, M.; Uhde, E.; Salthammer, T. Characterization of Particulate and Gaseous Pollutants Emitted During Operation of a Desktop 3D Printer. Environ. Int. 2019, 123, 476–485. [Google Scholar] [CrossRef]

- Davis, A.Y.; Zhang, Q.; Wong, J.P.S.; Weber, R.J.; Black, M.S. Characterization of Volatile Organic Compound Emissions from Consumer-Level Material Extrusion 3D Printers. Build. Environ. 2019, 160, 106209. [Google Scholar] [CrossRef]

- Min, K.; Li, Y.; Wang, D.; Chen, B.; Ma, M.; Hu, L.; Liu, Q.; Jiang, G. 3D Printing-Induced Fine Particle and Volatile Organic Compound Emission: An Emerging Health Risk. Environ. Sci. Technol. Lett. 2021, 8, 616–625. [Google Scholar] [CrossRef]

- Environmental Protection Agency (EPA). Particulate Matter (PM) Basics; EPA Website. 2022. Available online: https://www.epa.gov (accessed on 4 September 2025).

- World Health Organization (WHO). Air Quality Guidelines; WHO Website: Geneva, Switzerland, 2021; Available online: https://www.who.int (accessed on 20 August 2025).

- Viitanen, A.; Kallonen, K.; Kukko, K.; Kanerva, T.; Saukko, E.; Hussein, T.; Hämeri, K.; Saamanen, A. Technical Control of Nanoparticle Emissions from Desktop 3D Printing. Indoor Air 2021, 31, 1061–1071. [Google Scholar] [CrossRef] [PubMed]

- Warlimont, H.; Martienssen, W. Springer Handbook of Condensed Matter and Materials Data; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar] [CrossRef]

- Zhang, Q.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Weber, R.J. Characterization of Particle Emissions from Consumer Fused Deposition Modeling 3D Printers. Aerosol Sci. Technol. 2017, 51, 1275–1286. [Google Scholar] [CrossRef]

- Zhang, Q.; Pardo, M.; Rudich, Y.; Kaplan-Ashiri, I.; Wong, J.P.S.; Davis, A.Y.; Black, M.S.; Weber, R.J. Chemical Composition and Toxicity of Particles Emitted from a Consumer-Level 3D Printer Using Various Materials. Environ. Sci. Technol. 2019, 53, 12054–12061. [Google Scholar] [CrossRef]

- Stephens, B.; Azimi, P.; Orch, Z.E.; Ramos, T. Ultrafine Particle Emissions from Desktop 3D Printers. Atmos. Environ. 2013, 79, 334–339. [Google Scholar] [CrossRef]

- Ordinance of the Minister of Family, Labour and Social Policy. Ordinance of the Minister of Family, Labour and Social Policy of 12 June 2018 on the Highest Permissible Concentrations and Intensities of Harmful Factors for Health in the Work Environment. J. Laws 2018. Item 1286. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20180001286 (accessed on 3 September 2025).

- Regulation of the Minister of Environment. Regulation of the Minister of Environment of 26 January 2010 on Reference Values for Certain Substances in the Air. J. Laws 2010. Item 87. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20100160087 (accessed on 3 September 2025).

- U.S. Department of Labor, Occupational Safety and Health Administration (OSHA). 1926.55—Gases, Vapors, Fumes, Dusts, and Mists; U.S. Department of Labor: Washington, DC, USA, 2020. [Google Scholar]

- Health and Safety Executive (HSE). EH40/2005 Workplace Exposure Limits, 4th ed.; HSE: London, UK, 2020. [Google Scholar]

- Tang, C.-L.; Seeger, S. Measurement of Sub-4 nm Particle Emission from FFF 3D Printing with the TSI Nano Enhancer and the Airmodus Particle Size Magnifier. Aerosol Sci. Technol. 2024, 58, 644–656. [Google Scholar] [CrossRef]

- Tang, C.-L.; Chan, K.-H.; Lee, S.-Y. Development of a Standard Emission Test Method for the Determination of Particle Emission from 3D Printing with Fused Filament Fabrication Filaments. Preprint, ResearchGate. 2023. Available online: https://www.researchgate.net/publication/390493160 (accessed on 4 September 2025).

- Durai, M.A.; Ashok, D. Multi-Objective Optimization of Surface Finish and VOC Emissions in FFF 3D Printing Using ANN–NSGA-II Approach. Sci. Rep. 2025, 15, 34394. [Google Scholar] [CrossRef]

- Kim, B.; Shin, J.H.; Kim, H.P.; Jo, M.S.; Kim, H.S.; Lee, J.S.; Yu, I.J. Assessment and Mitigation of Exposure of 3-D Printer Emissions. Front. Toxicol. 2022, 3, 817454. [Google Scholar] [CrossRef]

- Secondo, L.E.; Adawi, H.I.; Cuddehe, J.; Hopson, K.; Schumacher, A.; Mendoza, L.; Lewinski, N.A. Comparative Analysis of Ventilation Efficiency on Ultrafine Particle Removal in University MakerSpaces. Atmos. Environ. 2020, 224, 117321. [Google Scholar] [CrossRef] [PubMed]

- Stefaniak, A.B.; Du Preez, S.; Du Plessis, J.L. Additive Manufacturing for Occupational Hygiene: A Comprehensive Review of Processes, Emissions, and Exposures. J. Toxicol. Environ. Health Part B 2021, 24, 173–222. [Google Scholar] [CrossRef] [PubMed]

- Hamrol, A. Quality Management and Engineering; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2022; ISBN 978-83-01-19863-3. (In Polish) [Google Scholar]

- Raffo, M.; Appolloni, L.; D’Alessandro, D. Housing Spaces in Europe: A Comparative Analysis of Standards in Nine European Countries. Eur. J. Public Health 2020, 30 (Suppl. 5), ckaa166-126. [Google Scholar] [CrossRef]

- Benabderazag, K.; Rouchon, D.; Boulanger, A.; Dupont, P.; Martin, L. Characterization of Thermomechanical Properties and Emission Behaviour in 3D-Printed Biocomposite Fabricated Using Fused Deposition Modelling. Compos. Part B Eng. 2024, 299, 110541. [Google Scholar] [CrossRef]

- Hejna, A.; Marć, M.; Szymański, P.; Mizera, K.; Barczewski, M. Analysis of Emission of Volatile Organic Compounds and Thermal Degradation in Investment Casting Using Fused Deposition Modelling (FDM) and Three-Dimensional Printing (3DP) Made of Various Thermoplastic Polymers. Environ. Sci. Pollut. Res. 2024, 31, 60371–60388. [Google Scholar] [CrossRef] [PubMed]

| 3D Printing Method | Occupational Health and Safety Hazards | Environmental Hazards |

|---|---|---|

| Fused Deposition Modeling (FDM) | Emission of fine particles and volatile organic compounds (VOCs). Potential burns from hot printer components (extruder, heated bed). Improper handling of chemicals used for adhesion or post-processing. | Consumption of difficult-to-recycle polymer (ABS, PLA) waste in the form of used filaments. |

| Stereolithography (SLA) | Exposure to chemicals in the form of liquid; toxic and irritating resins. Emission of UV radiation during the curing process. Skin and respiratory irritation due to inadequate ventilation. | Difficulties in recycling resins, which are challenging to manage and can contaminate the environment. High energy consumption. Emission of volatile organic compounds (VOCs) during resin curing. |

| Selective Laser Sintering (SLS) | Exposure to dust harmful to the respiratory system. Burn risk. Exposure to laser radiation. | High energy consumption. Use of large quantities of powders that are difficult to recycle. Potential for dust emissions into the atmosphere. |

| Digital Light Processing (DLP) | Exposure to toxic resins, similar to SLA. UV light emission, which can be harmful to the skin and eyes. Potential hazards associated with chemical waste after printing. | Problems with the disposal of used materials, such as resins. High energy consumption. Potential environmental contamination from chemicals used in printing. |

| Binder Jetting | Exposure to dust that may irritate the respiratory system. Risk of contamination from chemicals used for material bonding. Potential hazards related to contact with solvents. | Difficulties in disposing of unused powders. High energy and material consumption. Emission of volatile organic compounds (VOCs) during drying and curing of prints. |

| Electron Beam Melting (EBM) | Exposure to electromagnetic radiation. High temperatures causing burn risks. Explosion risk when mishandling metallic powders. | Very high energy consumption. Waste in the form of used metallic powders, which are difficult to recycle. Potential environmental contamination from metallic dust. |

| Acceptable Levels of Dust Concentration [mg/m3] | |||

|---|---|---|---|

| Poland | USA | WHO | |

| Total dust organic and inorganic | 10 mg/m3 | 15 mg/m3 | - |

| Max concentration of PM10 in the environment | 40 µg/m3 | 40 µg/m3 | 50 µg/m3 |

| Max concentration of PM2.5 in the environment | 20 µg/m3 | 10 µg/m3 | 20 µg/m3 |

| Author | Color | Head Temperature [°C] | Emission Rates | Print Time |

|---|---|---|---|---|

| [Particles/min] | ||||

| [31] | Brown | 210–220 | 4.89 × 108 | 2 h 30 min |

| Not described | 210–220 | 4.27 × 108 | 1 h 55 min | |

| [7] | Blue | 215 | 1.1 ± 0.7 × 1010 | 20 min |

| Blue | 215 | 1.6 ± 0.2 × 1010 | 21 min | |

| Red | 215 | 1.3 ± 0.5 × 1010 | 22 min | |

| Green | 215 | 1.3 ± 0.2 × 1010 | 23 min |

| Designation | Head Temperature | Bed Temperature | Layer | Printing Speed | Nozzle Diameter | Cooling |

|---|---|---|---|---|---|---|

| Ht [°C] | Bt [°C] | L [mm] | Ps [mm/s] | Nd [mm] | Yes/No | |

| A | B | C | D | E | F | |

| + | 225 | 60 | 0.2 | 50 | 0.4 | yes |

| − | 190 | 21 | 0.3 | 30 | 0.8 | no |

| Run [r] | Run Code | The Examined Factor | |||||

|---|---|---|---|---|---|---|---|

| Head Temperature [A] | Bed Temperature [B] | Layer [C] | Printing Speed [D] | Nozzle Diameter [E] | Cooling [F] | ||

| 1 | All+ | + | + | + | + | + | + |

| 2 | A (−−) All (+) | −− | + | + | + | + | + |

| 3 | B (−−) All (+) | + | −− | + | + | + | + |

| 4 | C (−−) All (+) | + | + | −− | + | + | + |

| 5 | D (−−) All (+) | + | + | + | −− | + | + |

| 6 | E (−−) All (+) | + | + | + | + | −− | + |

| 7 | F (−−) All (+) | + | + | + | + | + | −− |

| 8 | All (−−) | −− | −− | −− | −− | −− | −− |

| 9 | A (+) All (−−) | + | −− | −− | −− | −− | −− |

| 10 | B (+) All (−−) | −− | + | −− | −− | −− | −− |

| 11 | C (+) All (−−) | −− | −− | + | −− | −− | −− |

| 12 | D (+) All (−−) | −− | −− | −− | + | −− | −− |

| 13 | E (+) All (−−) | −− | −− | −− | −− | + | −− |

| 14 | F (+) All (−−) | −− | −− | −− | −− | + | + |

| Run [r] | Code of the Run | Manufacturer [m] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||||||

| Color [c] | ||||||||||

| Black | Yellow | Transparent | Black | Yellow | Transparent | Black | Yellow | Transparent | ||

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | ||

| 1 | All+ | T1,2,1 | ||||||||

| 2 | A (−) All (+) | |||||||||

| 3 | B (−) All (+) | |||||||||

| 4 | C (−) All (+) | |||||||||

| 5 | D (−) All (+) | |||||||||

| 6 | E (−) All (+) | |||||||||

| 7 | F (−) All (+) | |||||||||

| 8 | All (−) | T8,2,1 | ||||||||

| 9 | A (+) All (−) | |||||||||

| 10 | B (+) All (−) | |||||||||

| 11 | C (+) All (−) | |||||||||

| 12 | D (+) All (−) | |||||||||

| 13 | E (+) All (−) | |||||||||

| 14 | F (+) All (−) | |||||||||

| Run r | Code | Manufacturer m | Mean | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | |||||||||

| Color c | |||||||||||

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |||

| DEII | |||||||||||

| 1 | All+ | 906 | 500 | 268 | 691 | 283 | 211 | 1058 | 328 | 235 | 498 |

| 2 | A (−) All (+) | 289 | 238 | 141 | 173 | 211 | 71 | 365 | 211 | 276 | 220 |

| 3 | B (−) All (+) | 503 | 464 | 428 | 519 | 341 | 315 | 817 | 420 | 384 | 466 |

| 4 | C (−) All (+) | 362 | 265 | 184 | 347 | 213 | 71 | 403 | 350 | 276 | 275 |

| 5 | D (−) All (+) | 283 | 309 | 157 | 541 | 569 | 68 | 311 | 259 | 160 | 295 |

| 6 | E (−) All (+) | 129 | 55 | 45 | 89 | 33 | 38 | 325 | 102 | 131 | 105 |

| 7 | F (−) All (+) | 436 | 242 | 297 | 239 | 206 | 69 | 690 | 273 | 194 | 294 |

| 8 | All (−) | 7 | 3 | 3 | 10 | 5 | 4 | 9 | 8 | 5 | 6 |

| 9 | A (+) All (−) | 156 | 14 | 50 | 44 | 7 | 4 | 113 | 29 | 15 | 48 |

| 10 | B (+) All (−) | 6 | 4 | 4 | 8 | 6 | 4 | 10 | 8 | 7 | 6 |

| 11 | C (+) All (−) | 53 | 18 | 22 | 7 | 4 | 2 | 54 | 28 | 12 | 22 |

| 12 | D (+) All (−) | 25 | 18 | 6 | 7 | 4 | 15 | 24 | 21 | 6 | 14 |

| 13 | E (+) All (−) | 98 | 28 | 3 | 10 | 3 | 4 | 135 | 61 | 9 | 39 |

| 14 | F (+) All (−) | 9 | 6 | 6 | 8 | 4 | 4 | 13 | 7 | 4 | 7 |

| Color | Run Number | Average Emission Rate [µg/h] | Concentration After 1 h [µg/m3] | Time After Which WHO Standards Were Exceeded |

|---|---|---|---|---|

| Black | 1 | 885 | 30.52 | 98 min |

| Black | 8 | 9 | 0.31 | - |

| Yellow | 1 | 370 | 12.76 | 235 min |

| Yellow | 8 | 5 | 0.17 | - |

| Neutral | 1 | 238 | 8.20 | 365 min |

| Neutral | 8 | 4 | 0.14 | - |

| F-Value | p-Value | |

|---|---|---|

| Manufacturer | 1.48 | 0.232 |

| Color | 3.24 | 0.042 |

| Lack of fit | 0.19 | 0.944 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamrol, A.; Osiński, F. Workplace Exposure to Dust Emissions in Additive Manufacturing with an FFF Method. Processes 2025, 13, 3470. https://doi.org/10.3390/pr13113470

Hamrol A, Osiński F. Workplace Exposure to Dust Emissions in Additive Manufacturing with an FFF Method. Processes. 2025; 13(11):3470. https://doi.org/10.3390/pr13113470

Chicago/Turabian StyleHamrol, Adam, and Filip Osiński. 2025. "Workplace Exposure to Dust Emissions in Additive Manufacturing with an FFF Method" Processes 13, no. 11: 3470. https://doi.org/10.3390/pr13113470

APA StyleHamrol, A., & Osiński, F. (2025). Workplace Exposure to Dust Emissions in Additive Manufacturing with an FFF Method. Processes, 13(11), 3470. https://doi.org/10.3390/pr13113470