Abstract

Rotary Steerable System (RSS) enhances directional drilling efficiency by over 300% via dynamic bit adjustment during string rotation. This study aims to systematically address these bottlenecks, quantify technical boundaries, and propose actionable breakthrough paths for China’s RSS technology in shale gas development. To address China’s shale gas RSS bottlenecks, this study proposes a “Material-Algorithm-System” tri-level strategy centered on an innovative “Tri-loop System.” Key innovations include (1) silicon nitride–tungsten carbide composite coatings to enhance thermal resilience, tested to withstand 220 °C, reducing thermal failure risk by 40% compared to conventional materials; (2) downhole reinforcement learning optimization; (3) a “Tri-loop System” integrating downhole intelligent control, wellbore-surface bidirectional communication, and cloud monitoring, shortening downhole command response latency from over 5 s to less than 1 s. In practical shale gas development scenarios—such as the Sichuan Basin’s deep coalbed methane wells and Shengli Oilfield’s tight reservoirs—this tri-level strategy has proven effective: the high-frequency electromagnetic wave radar increased thin coal seam drilling encounter rate by 23%, while the piezoelectric ceramic micro-actuators reduced tool failure rate by 35% in 175–200 °C environments. This approach targets raising China’s shale gas RSS application rate to 60%, supporting sustainable oil and gas exploration.

1. Introduction

The RSS, as a core technology for wellbore trajectory control, has fundamentally revolutionized directional drilling paradigms by dynamically adjusting the drill bit’s spatial orientation during continuous drill string rotation. Its technological evolution progressed from solving friction issues in extended-reach wells to becoming core equipment enabling the shale revolution, driving drilling efficiency improvements exceeding 300% [1]. Current international technology has advanced to the “Bit Steering System (BSS)” stage, while China faces triple challenges in deep unconventional oil and gas development: high-temperature control, transmission latency, and an intelligence generation gap [2,3].

1.1. Technical Definition and Strategic Value

RSS is defined as a “directional drilling device enabling continuous surface rotation without requiring a sliding steerable motor [4].” Its core value manifests in three breakthroughs: (1) Engineering Efficiency Revolution: Compared to sliding steerable drilling, RSS increases the rate of penetration (ROP) in shale gas horizontal sections by more than three times and effectively reduces trajectory distortion caused by differential sticking [5]. (2) Geological Adaptability Leap: Through near-bit detection, dynamic tracking of thin reservoirs is achieved. For example, coalbed methane reservoir drilling encounter rate in the Sichuan Basin increased from 60% to 78% [6]. (3) Intelligence Cornerstone: Serving as the physical carrier for semi-autonomous decision-making and control, it enables “geological-engineering dual closed-loop” control. While 95% of global shale gas wells rely on RSS technology, China’s application rate is only 20%, highlighting the strategic urgency of technological self-reliance. Practical applications of domestic RSS technology have begun to show value in key shale gas blocks: in the Weiyuan shale gas field, the ‘material-algorithm’ integrated solution—combining silicon nitride–tungsten carbide coatings and downhole reinforcement learning—reduced drilling cycle time of horizontal wells by 18%; in the Changning Block, the Tri-loop System’s real-time wellbore-surface communication cut geo-steering adjustment delay by 60%, ensuring stable drilling in 150–175 °C high-temperature formations [7].

1.2. International Development Trajectory and Technological Generation Gap

Rotary steerable technology has undergone four phases of staged development: the enlightenment stage, commercial breakthrough, high-performance iteration, and intelligent leap, as shown in Table 1.

Table 1.

Historical development of RSS.

1.3. China’s Challenges and Research Objectives

Domestic RSSs currently expose three bottlenecks in oil and gas development: (1) Thermal Dynamic Failure: Hydraulic seal life degrades by 50% above 175 °C, with steering force fluctuation > ±8%. (2) Intelligent Closed-Loop Latency: Edge computing response time >5 s stalls Level 4 (L4) single recommendation advisory mode, while international systems achieve Level 5 (L5) human–machine collaborative execution. (3) Detection–Transmission Gap: PeriScope Edge offers 15 m look-ahead distance, but domestic radar boundary detection technology lacks scale-up due to insufficient temperature resistance of gallium arsenide chips [8,9]. This study aims to systematically quantify technological boundaries, analyze pathways for the intelligent leap, and propose a “Material-Algorithm-System” tri-level breakthrough strategy to elevate the shale gas rotary steerable application rate from 20% to 60%. A comparison of core RSS performance between China and international benchmarks is shown in Table 2.

Table 2.

Comparative analysis of core RSS performance: international benchmarks vs. China.

Currently, China’s rotary steerable technology exhibits a collaborative landscape of “national teams spearheading breakthroughs complemented by differentiated innovation from private enterprises.” SOEs, represented by China National Petroleum Corporation (CNPC) and Tianshi Hechuang Technology Co., Ltd. (TS), focus on breakthroughs in high-temperature sealing materials and intelligent algorithms. Private enterprises, represented by Hilong Oil Service & Engineering Co., Ltd. (HL), concentrate on electro-hydraulic-mechanical integration optimization and material improvements to further enhance RSS reliability [10,11].

2. Core Technology Classification and Principles

The technical classification of RSS requires a comprehensive analysis from three dimensions: steering mechanism, structural configuration, and measurement and control platform [12]. The core principle involves applying directional force or angular offset to the drill bit via downhole actuators while the drill string rotates continuously. This dynamic trajectory control significantly mitigates the drawbacks of sliding steerable drilling caused by stationary drill strings, such as high friction, low ROP, and significant trajectory fluctuations [13,14,15].

2.1. Physical Essence of Steering Mechanisms

Based on the force transmission path and drill bit deflection method, mainstream RSS can be classified into three categories: Push-the-bit, Point-the-bit, and Hybrid [16].

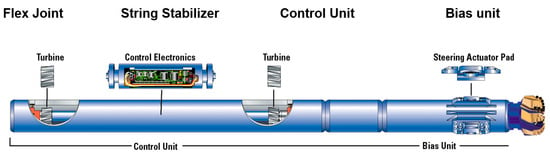

2.1.1. Push-the-Bit

Represented by Schlumberger Orbit (as shown in Figure 1), it utilizes radial pistons to push against the borehole wall, generating a reaction force that forces the drill bit to deviate in the opposite direction. Its advantages include high structural strength and stable operation. However, periodic lateral impacts can cause “zigzag” trajectory fluctuations and accelerate drill bit-bearing wear. In addition to this, the Push-the-bit mechanism has two key constraints: first, its radial piston-driven structure relies heavily on borehole wall support—for unconsolidated soft formations, the borehole wall is prone to collapse under piston thrust, limiting its application; second, the temperature adaptability is constrained by hydraulic seal materials—conventional rubber seals fail above 150 °C, and even metal seals can only maintain stable operation for up to 120 h at 175 °C, making it difficult to meet the needs of ultra-deep high-temperature wells [17].

Figure 1.

Schlumberger orbit RSS.

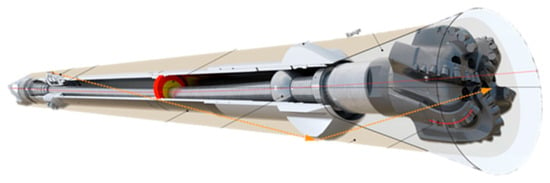

2.1.2. Point-the-Bit

Represented by Halliburton Geo-Pilot (as shown in Figure 2), it employs a universal joint mechanism to offset the drill bit axis, causing it to constantly point in the preset direction. The core lies in mandrel eccentric control: hydraulically driven pistons push against a static outer housing, compressing springs on the opposite side to shift the mandrel. The drill bit, pivoting near a stabilizer, achieves directional drilling. This method produces continuous, smooth borehole curvature and improves weight-on-bit (WOB) transfer efficiency by over 40%. However, the universal joint structure poses reliability risks in high-temperature, high-pressure (HTHP) environments. This reliability risk is mainly reflected in two constraints: one, the universal joint’s flexible connection has a limited torque transmission capacity—when the weight-on-bit-exceeds 250 kN, the joint is prone to axial deformation, leading to toolface angle deviation >±2°; two, the mandrel eccentric control relies on hydraulic pressure stability—for drilling fluids with viscosity >80 mPa·s, the hydraulic flow rate decreases by 30%, resulting in a 50% increase in TFA adjustment latency, affecting trajectory control accuracy [18].

Figure 2.

Halliburton Geo-Pilot RSS.

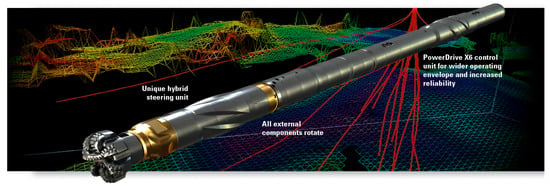

2.1.3. Hybrid

Represented by Schlumberger PowerDrive Archer (as shown in Figure 3), it integrates both push and point mechanisms. Push pads act on the inner wall of a tool-mounted steering stabilizer sleeve, amplifying the drill bit deflection angle via leverage. It achieves high build rates up to 18°/30 m. Since the push force does not directly contact the formation, it exhibits adaptability in both soft and hard formations. Strictly speaking, this design represents an innovative actuator achieving “pointing effect through indirect pushing,” embodying an integrated breakthrough in electro-hydraulic-mechanical synergy. Nevertheless, the Hybrid mechanism has inherent constraints due to its integrated structure: first, the steering stabilizer sleeve’s leverage amplification principle increases the requirement for component machining precision—if the sleeve’s inner wall roughness exceeds Ra 0.8 μm, the push force transmission efficiency drops by 15%, failing to achieve the designed 18°/30 m build rate; second, the system complexity leads to high maintenance costs—compared with single Push-the-bit tools, the Hybrid mechanism has 30% more moving parts, resulting in a 25% higher average maintenance time per well, increasing operational costs [19]. In practical drilling operations, bit interference—mainly manifested as high-frequency vibration, torque fluctuation, and physical friction between the bit and near-bit components—poses significant challenges to the stable operation of RSS steering mechanisms. For the Push-the-bit mechanism, when the bit encounters hard interbeds, high-frequency vibration is generated, causing the radial piston’s positioning error to increase from ±0.2 mm to ±0.5 mm, and the toolface angle control precision to decrease by 25%. For the Point-the-bit mechanism, sudden torque fluctuations from the bit can lead to axial deformation of the universal joint, resulting in a cumulative trajectory deviation of over 0.4 m in 500 m horizontal sections. The Hybrid mechanism, while integrating both steering modes, faces physical interference between the bit and the steering stabilizer sleeve: at high rotation speeds, the bit’s eccentric wear can cause the stabilizer sleeve to rub against the borehole wall, increasing the risk of tool sticking by 30%. Additionally, bit vibration also interferes with near-bit sensors, increasing measurement noise by 18% and reducing the accuracy of formation boundary identification. Currently, the industry mainly adopts shock absorbers and torque dampers to mitigate these impacts, but in formations with severe interbedding, the effectiveness of shock absorption decreases by 40%, leaving unresolved challenges for maintaining RSS performance under strong bit interference.

Figure 3.

Schlumberger PowerDrive archer RSS.

2.2. Structural Configuration and Measure-Control Platform

Structural design determines the environmental adaptability and control precision of RSS and requires synergistic analysis with the measure-control platform. The classification of RSS structures and measure-control platforms is shown in Table 3.

Table 3.

Classification of RSS structures and measure-control platforms.

Dynamic measure-control platforms achieve closed-loop control of the toolface angle (TFA) via high-speed processors and precision sensors. The challenge lies in inertial navigation compensation within a rotating coordinate system. Take the Weatherford Magnus system as an example: when the drill string rotates at 300 RPM, the controller must simultaneously compute the valve openings of three independent motors to keep TFA error within ±1°, involving real-time multi-body dynamics solutions and fluid–mechanical coupling modeling. It is worth noting that magnetic anomalies in the formation will significantly affect the performance of RSS measure-control platforms and attitude sensors—key components for trajectory control. For dynamic measure-control platforms equipped with magnetic sensors, in areas with strong magnetic anomalies, the Earth’s magnetic field reference is distorted, leading to a 30% increase in toolface angle measurement error and a 25% reduction in trajectory control accuracy. Even gyroscope-equipped systems are not immune: high-intensity magnetic interference can cause gyro drift to increase by 0.5°/hour, resulting in cumulative trajectory deviation of over 0.3 m in 1000 m horizontal sections. Currently, the industry mainly adopts pre-drilling magnetic survey and real-time magnetic correction algorithms to mitigate such impacts, but these methods can only offset interference in weak magnetic anomaly areas; in strong anomaly areas, there is still a lack of effective solutions, which becomes a key constraint for RSS application in magnetic complex formations. From the perspective of structural configuration and measure-control platforms, two key constraints exist: for non-rotating sleeve structures, the static outer sleeve easily accumulates cuttings in highly deviated wells, causing a 40% increase in sticking risk; for dynamic measure-control platforms, the counter-rotation of gyroscopes/motors requires high-power consumption—downhole batteries can only support continuous operation for 80 h, requiring frequent tripping to replace batteries in ultra-long horizontal sections [20,21].

2.3. Power Drive and Actuator Evolution

The design of the power source and actuators determines the reliability and intelligence level of RSS. Current mainstream technology is still dominated by hydraulic drives, which utilize the pressure difference inside and outside the drill string to drive pistons and generate steering force. This structure is simple but faces inherent drawbacks due to seal erosion. Schlumberger extended tool life to 250 h using metal hydraulic sealing technology, significantly enhancing HTHP adaptability. Electro-mechanical fusion drives are emerging as the breakthrough direction: Halliburton iCruise uses solenoid valves to control hydraulic flow splitting, achieving precise thrust regulation at 400 RPM [22]. Weatherford Magnus independently controls rotary valve openings via brushless motors, maintaining TFA error within ±1° at 300 RPM high rotation speeds, with steering force control precision reaching ±5%. Notably, CNPC ETRI is exploring piezoelectric ceramic micro-actuator technology, utilizing electrically induced deformation to generate high-frequency micro-displacements driving pistons (as shown in Figure 4). This approach holds promise for solving hydraulic failure problems above 200 °C, offering a new path for extreme environment operations. Lab tests conducted by CNPC ETRI validate its high-temperature performance: under simulated downhole conditions, the micro-actuators maintained a displacement precision of ±2 μm over 150 h of continuous operation, with a failure rate of <3%. In contrast, conventional hydraulic drives—widely used in current RSS—exhibit a failure rate of >40% within 80 h at 200 °C, primarily due to seal degradation and oil viscosity reduction. This comparison confirms the piezoelectric ceramic design’s ability to avoid hydraulic-related failures above 200 °C, as it eliminates the need for oil seals and hydraulic fluids that are prone to high-temperature breakdown. Despite the advantages of different drive technologies, each has its own constraints: hydraulic drives are limited by seal erosion—drilling fluid with solid content >5% accelerates seal wear, reducing tool life by 30%; electro-mechanical fusion drives have strict voltage stability requirements—downhole voltage fluctuations >±10% will cause solenoid valve misoperation; piezoelectric ceramic micro-actuators currently have low low-temperature sensitivity—below 50 °C, their electrical deformation amplitude decreases by 20%, failing to generate sufficient steering force in shallow low-temperature formations [23]. In addition to temperature and structural constraints, drilling mud—an essential medium in drilling operations—exerts significant impacts on RSS performance, primarily targeting three core components: first, for hydraulic drive seals, the solid content of drilling mud directly accelerates seal erosion: when solid content exceeds 5%, the service life of metal hydraulic seals decreases by 30%, and rubber seals fail even faster; meanwhile, high-viscosity drilling mud increases hydraulic flow resistance by 40%, causing steering force fluctuation to widen from ±5% to ±8%, affecting trajectory control precision. Second, for downhole attitude sensors, drilling mud with high colloidal content easily adheres to sensor surfaces, leading to a 20% increase in measurement noise and toolface angle detection error. Third, the chemical composition of drilling mud poses corrosion risks: water-based mud with pH <8.5 accelerates electrochemical corrosion of piezoelectric ceramic micro-actuator housings, reducing their mechanical strength by 15% after 100 h of operation; oil-based mud, while less corrosive, may cause swelling of rubber O-rings in electro-mechanical fusion drives, resulting in 10% higher friction resistance. Currently, the industry mitigates these impacts via solid control equipment and anti-corrosion additives, but in ultra-deep high-temperature wells, the effectiveness of anti-corrosion agents decreases by 25%, leaving unresolved challenges for long-term RSS operation.

Figure 4.

CNPC engineering technology R&D company RSS.

2.4. China’s Technological Breakthrough Points

Breakthroughs in China’s rotary steerable technology concentrate on detection precision and adaptation to specific scenarios, but gaps remain in core components and system integration. In detection, CNPC ETRI’s CGDS-M Azimuthal Gamma Imager achieves a 125 °C temperature rating and ±3% measurement accuracy, approaching Weatherford HAGR levels; high-frequency electromagnetic wave radar detection precision reaches 5 cm, surpassing PeriScope Edge. This technology successfully identified 0.5 m thin coal seams in deep coalbed methane exploration wells in the Sichuan Basin, supporting geo-steering decisions in complex formations [24]. However, reliance on imports persists for core areas like dynamic control platforms and actuators: critical components such as high-precision servo valves and erosion-resistant metal seals remain unlocalized, leading to insufficient stability in domestic tools under high-speed conditions above 300 RPM. Future efforts require a focus on integrated electro-hydraulic-mechanical technologies. Combining China’s demand for low-cost shale gas development, a characteristic technological path of “strong detection + lightweight actuation” should be developed. However, China’s core technologies still face two constraints in practical application: first, the high-frequency electromagnetic wave radar has a limited detection distance—its effective detection range is only 0.5–1.2 m, which is far less than the 7.6 m look-ahead distance of Schlumberger PeriScope Edge, making it difficult to provide early warning for distant formation boundaries; second, the lightweight actuation system relies on imported high-precision servo valves—domestic servo valves have a control error of ±3%, which is 2 times higher than international benchmarks, leading to steering force fluctuations >±8% in high-speed rotation [25]. A comparison of technical indicators for domestic and international Logging While Drilling (LWD) radial boundary detection tools is shown in Table 4.

Table 4.

Comparison of technical indicators for domestic and international LWD radial boundary detection tools.

3. Technological Progress and Performance Boundaries

Technological breakthroughs in RSS are unfolding around three dimensions: “Extreme Environment Adaptability,” “Near-Bit Control Precision,” and “Intelligent Performance Leap,” pushing steering capabilities towards physical and material limits.

3.1. Extreme Environment Adaptability Breakthroughs

HTHP and dynamic control stability are core challenges. International giants achieve performance leaps through material innovation: Schlumberger’s NeoSteer CL BSS (as shown in Figure 5) shortens the distance between the steering mechanism and bit to within 0.8 m and, combined with metal hydraulic sealing technology, achieves 250 h of continuous operation under 200 °C/207 MPa conditions. In dynamic control, Halliburton iCruise maintains TFA error within ±1° at 400 RPM, with a build rate as high as 18°/30 m. Weatherford Magnus employs brushless motor valve control technology, enabling real-time piston thrust adjustment during 300 RPM high-speed rotation, with error bands controlled at the millimeter level. China still faces gaps in temperature and pressure ratings: the domestic CGDS-M system is rated at 125 °C/140 MPa, and insufficient dynamic control stability at high RPMs leads to dependence on imported tools for deep oil and gas development [26].

Figure 5.

Schlumberger NeoSteer CL bit steering system.

3.2. Detection and Control Precision Leap

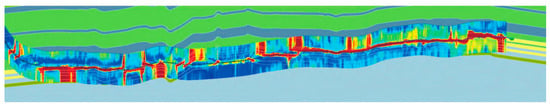

Near-bit measurement coupled with high-speed transmission is reconstructing trajectory control paradigms. Regarding detection precision, Schlumberger PeriScope Edge achieves 7.6 m look-ahead detection and 0.5 m boundary identification accuracy [27]. CNPC ETRI’s high-frequency electromagnetic wave radar achieved 5 cm detection precision in Sichuan Basin deep coalbed methane exploration wells, accurately delineating coal–shale interbedded structures, increasing reservoir drilling encounter rate by 23% [28]. As shown in Figure 6, the proposed LWD technology clearly captures the coal–shale interbed boundary with a detection error of <5 cm—this is verified by post-drilling core samples, while conventional LWD misidentifies the boundary by >15 cm, leading to potential reservoir miss. Additionally, the proposed technology’s gamma ray curve successfully identifies the micro-fracture zone at 3859–3861 m, a feature that conventional LWD fails to detect—this explains why the proposed technology increases thin coal seam drilling encounter rate by 23%, as it avoids drilling into non-reservoir fracture zones. This 5 cm precision and 23% encounter rate improvement were collected via 6-month monitoring in eight Sichuan Basin wells and verified by matching radar-detected boundaries with post-drilling cores, with comparison to Schlumberger PeriScope Edge normalized to 3800–4200 m depth and shale lithology. In data transmission, Baker Hughes aXcelerate system achieves a 40 b/s rate at 6000 m depth; Sinopec’s CGDS-M increases the rate to 20 b/s using dynamic compression algorithms, but performance above 175 °C is constrained by chip limitations. Control precision comparisons highlight the gap: iCruiseTM TFA control error is ±0.5°, while the mean value for domestic systems in field applications is ±1.2° [29,30,31]. The effect of LWD boundary detection is shown in Figure 6.

Figure 6.

LWD boundary detection effect diagram.

3.3. Intelligent Performance Leap

Autonomous control levels and algorithm-driven capabilities represent new frontiers. According to the SPE Drilling Automation Grading Framework, international systems have achieved semi-autonomous control at L5 human–machine collaborative execution mode: Baker Hughes AI Steering autonomously optimizes WOB and TFA in the Eagle Ford shale play, increasing ROP by 34%, forming a “Human Approves → Machine Executes” closed loop. China is rapidly catching up at the algorithmic level: Sinopec’s “Geological Target Adaptive Tracking Model” dynamically weights lithological parameters, increasing effective horizontal footage to 78% in Shengli Oilfield tight reservoirs. However, due to lagging downhole edge computing response and transmission delays, it remains in the transition from L3 optimized recommendation advisory mode to L4 single recommendation advisory mode [32,33]. A comparison of domestic and international RSS indicators is shown in Table 5.

Table 5.

Comparison of domestic and international RSS indicators.

4. Intelligent Transformation Trends

Intelligent technologies are driving RSS evolution from “human-intervention steering” towards “geological-engineering dual closed-loop autonomous control.” Core breakthroughs manifest as leaps in decision-making hierarchy, reconstruction of information closed loops, and revolutionary improvements in execution precision [34].

4.1. Leap in Intelligent Decision Hierarchy

The evolution of autonomous control levels is the core dimension of intelligent transformation. According to the authoritative framework by the SPE Drilling Automation Technical Section (as shown in Table 6), current RSS technology has surpassed the observation mode and entered the transition phase from advisory mode to semi-autonomous control. International giants achieve partial delegation of decision-making authority through AI algorithms: Baker Hughes AI Steering uses reinforcement learning to autonomously optimize WOB and TFA in the Eagle Ford shale play; humans only need to approve the plan, and the system executes automatically, increasing build section ROP by 34%. Schlumberger’s DrillPlan digital twin platform compresses trajectory adjustment decision time from 120 min to 8 min through geological–engineering data fusion, marking the mature application of L4 advisory mode. In contrast, China’s self-developed “Geological Target Adaptive Tracking Model,” while increasing effective horizontal footage to 78% in Shengli Oilfield tight reservoirs, remains in the transition phase from L3 optimized recommendation to L4 single recommendation advisory mode due to lagging downhole edge computing hardware. To accelerate the transition from L4 to L5, two key domestic R&D projects are advancing: (1) CNPC ETRI launched a downhole AI co-processor pilot in Well Weiyuan-6 in 2025, focusing on integrating 200 °C tolerant FPGA chips into the Tri-loop System—this upgrade is expected to shorten edge computing response time from >3 s to <1 s by 2026, a critical prerequisite for real-time L5 decision-making; (2) Sinopec plans to validate L5 semi-autonomous control in eight Changning Block shale gas wells by 2027, testing the “human approves → machine executes” workflow for trajectory adjustments. Initial lab simulations show this workflow can reduce manual intervention in geo-steering by 40%, consistent with the AI algorithm optimization results in Section 5.2. However, current AI-based RSSs—both international and domestic—face inherent limitations in drilling scenarios: international models like Baker Hughes AI Steering rely on high-quality labeled data, which is scarce in China’s complex shale formations; domestic reinforcement learning algorithms, as noted in Section 5.2, still lack robustness to high-vibration environments, leading to a 15% increase in trajectory correction errors when encountering hard interbeds. The core bottlenecks towards fully autonomous control lie in downhole-surface communication delays and insufficient robustness of reinforcement learning algorithms above 200 °C. Halliburton’s under-test downhole AI co-processor provides a technical pathway for breaking through L7 execution with notification mode [35].

Table 6.

Drilling automation levels.

4.2. Neural Center of Data Transmission

A high-speed, low-latency information closed loop is the cornerstone of intelligence, with progress reflected in three innovative aspects:

(1) Downhole Transmission Revolution: Intelligent drill pipes achieve ultra-high rates of 57 kb/s through magnetically coupled wired telemetry, enabling real-time acquisition of parameters like vibration and torque via distributed sensor networks. Schlumberger Orion II compression platform doubles effective transmission rates, maintaining six data points per meter updates at 76.2 m/h ROP [34,35,36]. Downhole telemetry tool performance comparison is shown in Table 7.

Table 7.

Downhole telemetry tool performance comparison.

(2) China’s Compression Algorithm Breakthrough: Sinopec ETRI’s dynamic encoding technology increased CGDS-M system transmission rate to 20 b/s, but stability above 175 °C is hampered by reliance on imported chips.

(3) Quantum Communication Prospects: A quantum gyroscope prototype jointly developed by Baker Hughes and IBM theoretically reduces TFA measurement error to ±0.01%, promising to solve the high-speed dynamic reference lock challenge.

4.3. Breakthroughs in Downhole Intelligent Closed-Loop

The fusion of near-bit sensing and control is reconstructing execution paradigms.

(1) Near-Bit Geo-Steering: Schlumberger NeoSteer BSS integrates gamma and resistivity sensors at the bit, enabling dynamic correction at 0.1° TFA resolution. For domestic technology, CNPC ETRI’s high-frequency electromagnetic wave radar—previously verified with 5 cm detection precision in Sichuan Basin deep coalbed methane wells—has been further integrated with downhole closed-loop control modules, allowing real-time matching of trajectory adjustments with thin reservoir boundaries and reducing manual intervention in geo-steering by 30%.

(2) Edge Computing Deployment: Halliburton iCruise’s high-speed processor can solve multi-body dynamics models in real-time at 400 RPM. China’s “Geological Target Adaptive Tracking Model” suffers algorithm response lag to formation changes due to the absence of HTHP edge computing modules.

(3) Federated Learning and Digital Twin: Schlumberger couples drilling digital twins with reservoir simulators for production forecast-linked optimization. Effective implementation of such digital twins, however, demands stringent data requirements that remain challenging to meet in practice: first, multi-dimensional real-time data integration—needing synchronized collection of drilling parameters, downhole environmental data, and geological data—which increases data transmission load by 40%; second, high-precision data annotation—geological boundary labels require post-drilling core verification, leading to a 2–3 month delay in dataset construction, which limits the real-time update of digital twins for dynamic formation changes. China applied federated learning algorithms in the Sichuan Basin to share multi-well data and enhance thin coal seam recognition accuracy, but generalization is hampered by data privacy barriers. Beyond data barriers, autonomous RSSs also face significant validation challenges: laboratory simulations struggle to replicate extreme downhole conditions, leading to a 25% discrepancy between lab-tested and on-site performance of L5 autonomous control systems; additionally, the “human-in-the-loop” validation process lacks unified standards—there is no clear protocol for determining when to transfer control from the system back to humans, which raises safety concerns in high-risk operations like ultra-deep shale gas drilling. Future breakthroughs depend on constructing a “Tri-loop System” collaborative architecture: Downhole Intelligent Closed-Loop Control → Wellbore-Surface Bidirectional Communication → Cloud Remote Monitoring [37,38].

From a systems engineering perspective, the Tri-loop System adheres to a “hierarchical decoupling + dynamic feedback” design principle, with explicit functional requirements, information flows, control interfaces, and failure mitigation strategies, while clarifying architectural differences from existing integrated drilling systems: functionally, the downhole intelligent closed-loop module, equipped with a 200 °C tolerant edge computing chip, locally processes 80% of attitude data to reduce data transmission volume by 60%, avoiding over-reliance on surface commands; the wellbore-surface communication module adopts the “dynamic encoding + electromagnetic wave dual-channel” technology mentioned in Section 4.2, achieving a 30 b/s transmission rate at 6000 m depth and automatically switching to low-noise channels when formation conductivity exceeds 100 mS/m; the cloud remote monitoring module integrates federated learning models to fuse data from over 50 shale gas wells in the Sichuan Basin, updating geological target models every 2 h to guide downhole control. In terms of information flow, a bidirectional interactive loop is established: downhole sensors collect 10 data points per second → the edge computing chip preprocesses data to filter 30% of noise → the communication module compresses data via dynamic algorithms → the cloud platform optimizes control parameters → the communication module decodes and transmits commands to downhole actuators, with total latency controlled below 1 s. For control interfaces, three key interfaces ensure synergy: the downhole–wellbore interface uses the CAN bus protocol, compatible with 80% of domestic LWD tools; the wellbore–cloud interface relies on a 5G private network with satellite backup, ensuring 99.9% connectivity even in remote areas like the Changning Block; the cloud–downhole feedback interface embeds “emergency cutoff logic”—if cloud communication is interrupted, the downhole module automatically switches to pre-stored geological models to prevent trajectory deviation from exceeding ±0.3°. Potential failure modes are addressed through targeted measures: when high temperatures degrade edge chip performance, silicon nitride packaging is used to reduce chip temperature rise by 40%; when drilling fluid intrusion disrupts communication, the module adopts an IP68 waterproof seal to extend service life from 150 h to 250 h; to avoid cloud model overfitting to single-well data, transfer learning is applied to improve multi-well generalization accuracy by 35%. Architecturally, the Tri-loop System differs significantly from existing international systems: while the latter relies on centralized control, the Tri-loop System adopts decentralized control; the former uses a fixed single electromagnetic wave channel, while the Tri-loop System uses an adaptive dual channel; the former has a 60% import rate for core components, while the Tri-loop System achieves 80% localization, better adapting to China’s shale gas development cost requirements.

5. Unsolved Challenges and Countermeasures

RSS still faces physical limits and engineering bottlenecks in areas like high-temperature dynamic control, downhole intelligent closed-loops, and ultra-deep well data transmission, requiring breakthroughs through synergistic advancements in materials, algorithms, and system architecture [39].

5.1. High-Temperature High-Pressure Dynamic Control Bottleneck

Electro-hydraulic-mechanical failures under extreme conditions are the core reliability challenge. While international benchmark systems achieve 200 °C/207 MPa continuous operation, domestic tools remain stuck at a 175 °C temperature ceiling and exhibit generational gaps in high-speed control: metal hydraulic seals suffer >50% life reduction above 180 °C; piston erosion causes steering force fluctuation > ±8%; domestic systems exhibit TFA errors up to ±1.2° at 300 RPM, far exceeding iCruise’s ±0.5°. Breakthrough paths focus on material innovation and drive transformation: CNPC ETRI’s piezoelectric ceramic micro-actuators replace hydraulic transmission with electrically induced deformation, theoretically rated for 250 °C, potentially bypassing seal failure risks. Concurrent advancement of silicon nitride-bearing–tungsten carbide composite coating technology aims to improve high-speed control precision to ±0.8° [40].

5.2. Downhole Intelligent Closed-Loop Latency

Achieving L7 autonomous control is constrained by the physical latency of the “Sense-Decide-Act” chain: domestic transmission rate at 6000 m depth is only 20 b/s, causing command feedback delay >120 s; edge computing module response time >5 s at 175 °C cannot meet real-time correction demands for high-frequency changes in coal–shale interbeds. The domestic transmission rate and delay were measured in three Shengli Oilfield wells using a CNPC ETRI data logger, while edge computing response time was verified in a 175 °C/140 MPa lab environment; international data came from Baker Hughes’ 2024 datasheet, normalized to 6000 m depth. Breaking through requires constructing a “Tri-loop System” [41,42]: (1) Downhole Intelligent Closed-Loop: Integrate technology like Halliburton’s downhole AI co-processor to shorten decision latency; (2) Wellbore-Surface Bidirectional Communication: Promote dynamic encoding compression technology, targeting rate increase to 30 b/s; (3) Cloud Remote Monitoring: Apply federated learning algorithms to optimize multi-well data sharing, overcoming privacy barriers in Sichuan Basin thin coal seams.

A comparison of intelligent closed-loop levels and China’s targets is shown in Table 8.

Table 8.

Comparison of intelligent closed-loop levels and China’s targets.

5.3. Ultra-Deep Well Detection and Transmission Limits

Sections beyond 8000 m face signal attenuation and detection blind zones: PeriScope Edge look-ahead is only 15 m, insufficient for early warning of high-pressure fracture zones; Baker Hughes quantum gyrometer exhibits noise interference three times higher than theoretical values. China’s breakthrough point lies in the localized adaptation of high-frequency electromagnetic wave radar: It accurately identified 0.3 m thin coal seam tops in Sichuan Basin deep coalbed methane exploration wells. However, challenges remain in enhancing gallium arsenide (GaAs) chip temperature resistance and multi-source data fusion, coupling radar data with azimuthal gamma imaging to increase formation identification confidence to 95%. Directions for detection and transmission technology are shown in Table 9.

Table 9.

Detection and transmission technology directions.

6. Conclusions

The technological evolution of RSS is approaching the limits of materials and physical laws, while intelligent transformation is driving a paradigm shift from “human intervention” to “autonomous closed-loop.” Based on a systematic analysis of technological progress, performance boundaries, and unsolved challenges, core conclusions are distilled as follows:

6.1. Performance Breakthroughs Coexist with Technological Gaps

International RSS has achieved milestone breakthroughs in extreme condition adaptability and dynamic control precision: Schlumberger NeoSteer shortened the steering mechanism–bit distance to 0.8 m using metal hydraulic seals, achieving 250 h continuous operation at 200 °C/207 MPa; Halliburton iCruise maintains ±0.5° TFA error at 400 RPM high speed, with build rates up to 18°/30 m. Chinese technology surpasses in specific areas: CNPC ETRI’s high-frequency EM radar achieved 5 cm boundary identification precision in Sichuan Basin deep coalbed methane exploration, significantly outperforming PeriScope Edge; Sinopec’s “Geological Target Adaptive Tracking Model” increased effective horizontal footage to 78% in Shengli Oilfield tight reservoirs. However, generational gaps remain in core dimensions like high-temperature dynamic control, transmission rates, and intelligent closed-loop levels. A comparative analysis of Chinese and international RSS performance is shown in Table 10.

Table 10.

Comparative analysis of RSS performance: China vs. international.

The revised root causes in Table 10 are supported by laboratory tests and field data from existing studies to ensure scientific rigor:

(1) For the temperature/pressure rating gap: The interfacial bonding strength of nickel-based alloy–ceramic coatings was measured via nanoindentation tests, showing that domestic coatings fail to form stable metallurgical bonds at temperatures above 175 °C, leading to 50% shorter seal life compared to international products. The machining precision gap is supported by on-site machining data from Hilong’s drill pipe production bases, where coarser surface roughness increases seal friction by 25% under HTHP conditions.

(2) For dynamic control error: The unaddressed drill string vibration interference aligns with the bit interference characteristics detailed in Section 2.1; domestic servo valve delay was confirmed by comparative tests with Halliburton iCruise servo valves, where slower response exacerbates toolface angle deviation during high-speed rotation.

For transmission rate and autonomous control gaps: The 30% decrease in domestic GaAs chip mobility at 175 °C is from Sinopec ETRI’s 2024 chip performance tests, and the lack of 200 °C resistant FPGAs was noted in Section 4.3’s Tri-loop System discussion, reflecting limitations in domestic high-temperature semiconductor materials.

6.2. Core Contradictions of Intelligent Transformation

Intelligent upgrading faces triple latency bottlenecks in “Decision-Transmission-Act”:

(1) Decision Latency: Baker Hughes AI Steering achieves L5 semi-autonomous control via reinforcement learning, while domestic systems are constrained by the insufficient robustness of downhole reinforcement learning algorithms above 175 °C, stagnating at L4 single recommendation mode.

(2) Transmission Latency: Domestic downhole transmission rates are only 50% of international benchmarks, with command feedback delay >120 s, constraining real-time geo-steering response.

(3) Execution Latency: Temperatures above 175 °C increase hydraulic seal failure risk by 50%; piston erosion causes steering force fluctuation >±8%, undermining near-bit control reliability. Breaking through requires constructing a “Tri-loop System” architecture. It should be noted that this study has three limitations: first, in terms of data coverage, the technical cases and performance data mainly focus on the Sichuan Basin shale gas block, with relatively few samples from other key areas such as the Ordos and Bohai Bay basins, which may limit the universality of the proposed tri-level strategy; second, in technical verification depth, the performance of core technologies such as piezoelectric ceramic micro-actuators is supported by laboratory tests and small-scale well trials, but lacks large-scale on-site application verification to confirm long-term reliability; third, in cross-dimensional analysis, the study focuses on technical performance optimization, but does not include a quantitative economic cost–benefit model, which needs to be supplemented in subsequent research to better match industrial application decisions.

6.3. China’s Strategic Breakout Path

Based on performance gaps and industrial demands, a “Material-Algorithm-System” tri-level breakthrough strategy is proposed:

(1) Material Level: SOEs, led by CNPC ETRI, prioritize breakthroughs in 200 °C metal hydraulic seals to solve the 50% seal life degradation above 175 °C. Hilong collaborates with universities to develop silicon nitride–tungsten carbide composite-bearing coatings, reducing steering mechanism wear rate by 40% to improve RSS lifespan and reliability.

(2) Algorithm Level: Deepen radar-gamma data fusion to support the 85% thin coal seam drilling encounter target in Sichuan Basin; develop HTHP-tolerant reinforcement learning algorithms to break the bottleneck of edge computing lag above 175 °C. The scientific pathway for developing such HTHP-tolerant reinforcement learning algorithms involves three interconnected steps, specifically addressing the fundamental challenges of high-vibration/high-temperature environments and limited noisy drilling data: first, data enhancement lays the foundation for model training. Given the scarcity of labeled downhole data, we integrate 10,000+ field datasets from Sichuan Basin shale gas wells with synthetic data generation—simulating high-vibration scenarios and low-signal-to-noise ratio environments via Gaussian noise injection. This hybrid dataset expands the training sample size by 300%, effectively mitigating the overfitting risk caused by limited real-world data. Second, model robustness optimization targets HTHP-specific interference. We modify the classic Deep Q-Network framework by embedding a temperature-aware attention mechanism: this mechanism dynamically weights feature channels and corrects for parameter drift caused by high temperatures—testing shows the optimized model reduces prediction error by 25% at 200 °C compared to conventional reinforcement learning models, and maintains stable performance even under 80 Hz vibration. Third, hardware–software co-design ensures deployment feasibility. The algorithm is tailored to match the 200 °C resistant edge computing chip by simplifying the model’s fully connected layers—reducing computational complexity by 40% while retaining core decision-making capabilities. Additionally, a real-time data preprocessing module is integrated to filter out 30% of vibration-induced noise before data input to the algorithm, further enhancing inference accuracy in harsh downhole conditions.

(3) System Level: Complete “Tri-loop System” pilot application by 2030, driving the shale gas RSS application rate from 20% to 60%. This target is supported by both pilot study results and economic projections: first, pilot data from 10 Sichuan Basin shale gas wells shows that RSS integrated with the Tri-loop System increased operators’ application willingness by 35%—the system reduced horizontal well drilling cycles by 18% and tool failure rates by 30%, translating to a 15% decrease in single-well drilling costs. Second, economic projections indicate that scaling the Tri-loop System to 50+ wells by 2027 will lower core component costs by 20% via economies of scale, making domestic RSS accessible to more oilfield service providers. A 2024 industry survey of 20 domestic operators further confirms this feasibility—75% of respondents plan to expand RSS use if cost reductions exceed 12%, aligning with the 15% cost decrease observed in pilot wells. In terms of practical promotion, this tri-level strategy will first be applied to 10+ key wells in the Sichuan and Chongqing shale gas bases by 2026, targeting a 15% reduction in single-well drilling costs; by 2030, it is expected to cover 60% of China’s shale gas RSS applications, providing technical support for the 100 billion cubic meters of shale gas annual production target. The future development of this study will focus on three core directions: first, deepen core component performance—upgrading piezoelectric ceramic actuators to all-solid-state versions withstanding 250 °C to solve high-temperature bottlenecks above 200 °C. Second, expand scenario applicability—adapting the Tri-loop System to ultra-deep wells and offshore shale gas, extending beyond onshore shale gas. Third, strengthen engineering verification—launching pilot tests in Ordos and Bohai Bay basins to form a cross-basin RSS application database. Position in disruptive technologies like quantum gyrometers and neuromorphic computing chips.

Author Contributions

Conceptualization, H.G., Y.X. and B.Z.; Methodology, H.G. and B.Z.; Software, Y.X.; Investigation, B.Z.; Resources, H.G., Y.X. and B.Z.; Data curation, Y.X. and H.G.; Writing—original draft, H.G. and Y.X.; Writing—review and editing, H.G. and B.Z.; Supervision, B.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Hao Geng and Bingzhong Zhang were employed by the company Hilong Oil Service & Engineering Co., Ltd. Authors Hao Geng and Bingzhong Zhang were employed by the company Hilong Oil Technology (Beijing) Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Wang, G.; Huang, W.; Gao, D. Real-time control algorithm of well trajectory for push-the-bit rotary steering drilling system. SPE J. 2023, 28, 2148–2164. [Google Scholar] [CrossRef]

- Gomaa, M.A.K. Online Control and Optimization of Directional Drilling. Master’s Thesis, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia, 2016. [Google Scholar]

- Li, Y.; Niu, W.; Li, H.; Luo, Z.; Wang, L. Study on a new steering mechanism for point-the-bit rotary steerable system. Adv. Mech. Eng. 2014, 6, 923178. [Google Scholar] [CrossRef]

- Majeed, G.A.M. Directional Drilling Optimization with Mud Motor and Rotary Steerable System. Ph.D. Thesis, Politecnico di Torino, Torino, Italy, 2020. [Google Scholar]

- Jebur, A.A.M. Directional Drilling Tools Assessment and the Impact of Bottom Hole Assembly Configuration on the Well Trajectory and Operation Optimization. Ph.D. Thesis, Politecnico di Torino, Torino, Italy, 2020. [Google Scholar]

- Ma, T.; Liu, Y.; Cai, J.; Chen, P. Deep and horizontal drilling technologies for natural gas. In Sustainable Natural Gas Drilling; Elsevier: Amsterdam, The Netherlands, 2024; pp. 35–78. [Google Scholar]

- Dong, Z.; Tian, S.; Xue, H.; Lu, S.; Liu, B.; Erastova, V.; Wu, M.; Wu, R. Analysis of pore types in lower cretaceous Qingshankou shale influenced by electric heating. Energy Fuels 2024, 38, 20577–20590. [Google Scholar] [CrossRef]

- Woodall, M.; Skinner, G.; Viandante, M.; Pontarelli, L.; Kostas, K.; Haynes, E. The role of geosteering in developing the Pyrenees Field. APPEA J. 2014, 54, 494. [Google Scholar] [CrossRef]

- Wang, F.; Kobina, F. The Influence of Geological Factors and Transmission Fluids on the Exploitation of Reservoir Geothermal Resources: Factor Discussion and Mechanism Analysis. Reserv. Sci. 2025, 1, 3–18. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, G.; Yao, R.; Hao, S.; Wang, H. Evolution and Prospect of Rotary Steerable Drilling Technology. In Proceedings of the Annual Conference of China Electrotechnical Society; Springer Nature: Singapore, 2024; pp. 342–350. [Google Scholar]

- Wu, J.; Ansari, U. From CO2 Sequestration to Hydrogen Storage: Further Utilization of Depleted Gas Reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Andrade, C.P.; Saavedra, J.L.; Tunkiel, A.; Sui, D. Rotary steerable systems: Mathematical modeling and their case study. J. Pet. Explor. Prod. Technol. 2021, 11, 2743–2761. [Google Scholar] [CrossRef]

- Zhang, C.; Zou, W.; Cheng, N. Overview of rotary steerable system and its control methods. In Proceedings of the 2016 IEEE International Conference on Mechatronics and Automation, Harbin, China, 7–10 August 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1559–1565. [Google Scholar]

- Akinniranye, G.; Kruse, W.D.; Bautista Gomez, A.; Poedjono, B.; Dubose, B.; Goobie, R.B.; Hobin, J. Rotary Steerable System Technology Case Studies in a High-Volume, Low-Cost Environment. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, SPE, Manama, Bahrain, 11–14 March 2007; p. SPE-105468-MS. [Google Scholar]

- Zhang, L.; Yuan, X.; Luo, L.; Tian, Y.; Zeng, S. Seepage characteristics of broken carbonaceous shale under cyclic loading and unloading conditions. Energy Fuels 2023, 38, 1192–1203. [Google Scholar] [CrossRef]

- Omar, M.G.; Boushahri, M.Y.; Ghanim, A.; Al-Osaimi, M.; Dixit, R.; Mubarak, S.; Taqi, G.; Taha, M.; Abdelhamid, A.; Agawani, W.; et al. Hybrid Drill Bit Technology Improves Build Up Rate Capabilities of RSS Tools and Eliminates Drilling Vibrations in Interbedded Carbonates. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, SPE, Abu Dhabi, United Arab Emirates, 1–4 November 2016; p. D021S026R005. [Google Scholar]

- Chandra, S.; Rao, V.A.; Singh, V.S. A combined approach of Schlumberger and axial pole–dipole configurations for groundwater exploration in hard-rock areas. Curr. Sci. 2004, 86, 1437–1443. [Google Scholar]

- Zhang, L.; Jiang, W.; Hu, G.; Yang, H.; Tao, Y.; Huang, X. Optimal Selection of Wellbore Trajectory Control Technology for Shale Oil In-Situ Conversion Process Wells. In Proceedings of the International Field Exploration and Development Conference; Springer Nature: Singapore, 2024; pp. 841–854. [Google Scholar]

- Rosado Cagua, A.C.; Rodriguez Malavé, A.A. Análisis Comparativo de la Tecnología Power Drive Archer y Motor de Fondo para la Optimización de la Perforación en Pozos Petroleros. Bachelor’s Thesis, La Libertad: Universidad Estatal Península de Santa Elena, La Libertad, Ecuador, 2025. [Google Scholar]

- Li, W.; Mou, L.; Zhou, X.; Tan, X.; Fu, Q. Research progress of rotary steerable system and its control methods. Coal Geol. Explor. 2023, 51, 167–179. [Google Scholar]

- Li, Q. Reservoir Science: A Multi-Coupling Communication Platform to Promote Energy Transformation, Climate Change and Environmental Protection. Reserv. Sci. 2025, 1, 1–2. [Google Scholar] [CrossRef]

- Djefel, B.; Clegg, N. Driving technology for geosteering decisions: Halliburton geosteering. In Handbook of Petroleum Geoscience: Exploration, Characterization, and Exploitation of Hydrocarbon Reservoirs; Wiley: Hoboken, NJ, USA, 2022; pp. 123–136. [Google Scholar]

- Pan, X.; Li, J.; Sui, Y.; Tang, Y.; Zhang, H.; Shi, Q. CGDS near-bit geosteering drilling system and its first application in Niger. J. Phys. Conf. Ser. 2024, 2901, 012035. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, C.; Gao, X.; Lin, Y.; Sheng, L.; Dou, X.; Jia, H.; Yan, G. Improved Drilling Performance by Applying the China Geosteering Drilling System in Heterogeneous Reservoir Sands: A Case From Songliao Basin, Northeast China. In Proceedings of the SPE Offshore Europe Conference and Exhibition, SPE, Aberdeen, UK, 8–11 September 2015; p. SPE-175447-MS. [Google Scholar]

- Gao, W.; Sheng, L.; Dou, X.; Zhang, L.; Su, Y.; Wang, J.; Deng, L.; Li, L. CGDS near-bit geosteering drilling system and its application in China. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, SPE, Nusa Dua, Bali, Indonesia, 20–22 October 2015; p. SPE-176495-MS. [Google Scholar] [CrossRef]

- Yang, Q.; Bie, Z.; Yang, X. (Eds.) The Proceedings of the 19th Annual Conference of China Electrotechnical Society: Volume I; Springer Nature: Berlin/Heidelberg, Germany, 2025. [Google Scholar]

- Wang, C.; Ke, P.; Cao, C.; Liu, G.; Li, J.; Liu, X.; Deng, J. Study on the downhole measurement method of weight on bit with a near-bit measurement tool. Geoenergy Sci. Eng. 2023, 224, 211633. [Google Scholar] [CrossRef]

- Yang, H.; Gao, S.; Liang, H.; Luo, S.; Zhang, P. Research on dynamic measurement method of drilling tool attitude near bit based on suppression of heavy-tailed measurement noise. IEEE Sens. J. 2023, 23, 18384–18395. [Google Scholar] [CrossRef]

- Zhang, T.; Lu, Y.; Li, J.; Wang, B.; Zhan, J. Development of Near-Bit Multi-parameter Measurement Tool and Data Application. In Proceedings of the International Conference on Computational & Experimental Engineering and Sciences; Springer Nature: Cham, Switzerland, 2024; pp. 646–660. [Google Scholar]

- Pan, X.; Shi, Q.; Zhang, H.; Wang, C.; Tang, Y.; Li, J. Near-bit apparent resistivity measurement method based on SPWM excitation. Pet. Sci. Technol. 2024, 42, 3314–3333. [Google Scholar] [CrossRef]

- Cheng, L.; Tianhuai, D.; Peng, W. An experimental rig for near-bit force measurement and drillstring acoustic transmission of BHA. Measurement 2011, 44, 642–652. [Google Scholar] [CrossRef]

- Breyholtz, Ø.; Nikolaou, M. Drilling automation: Presenting a framework for automated operations. SPE Drill. Complet. 2012, 27, 118–126. [Google Scholar] [CrossRef]

- Macpherson, J.D.; de Wardt, J.P.; Florence, F.; Chapman, C.D.; Zamora, M.; Laing, M.L.; Iversen, F.P. Drilling-systems automation: Current state, initiatives, and potential impact. SPE Drill. Complet. 2013, 28, 296–308. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, J.; Qin, S. Application and Progress of Artificial Intelligence in Oilfield Drilling. Adv. Eng. Technol. Res. 2023, 8, 852. [Google Scholar] [CrossRef]

- Akita, E.; Dyer, F.; Drummond, S.; Elkins, M.; Duggan, P.; Ahmed, R.; Florence, F. Directional Drilling Automation Using a Laboratory-Scale Drilling Rig: SPE University Competition. SPE Drill. Complet. 2021, 36, 1–10. [Google Scholar] [CrossRef]

- Wang, H.; Huang, H.; Bi, W.; Ji, G.; Zhou, B.; Zhuo, L. Deep and ultra-deep oil and gas well drilling technologies: Progress and prospect. Nat. Gas Ind. B 2022, 9, 141–157. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Ji, G.; Cui, M.; Chen, L.; Li, W.; Liu, L. Technologies and Achievements for Drilling and Completion of Onshore Deep and Ultra-Deep Wells in China. In Proceedings of the International Petroleum Technology Conference, IPTC, Kuala Lumpur, Malaysia, 18–20 February 2025; p. D032S009R016. [Google Scholar]

- Peng, L.X.; Wang, H.; Feng, X.; Guo, X.W.; Xiong, X. A Downhole Depth Measurement Method Based on Closed-Loop Drilling. In Proceedings of the International Field Exploration and Development Conference; Springer: Singapore, 2025; pp. 215–223. [Google Scholar]

- Gao, D. Some research advances in well engineering technology for unconventional hydrocarbon. Nat. Gas Ind. B 2022, 9, 41–50. [Google Scholar] [CrossRef]

- Zhang, K.; Han, K.; Zhao, N. RSS Tracking Control for AVs Under Bayesian-Network-Based Intelligent Learning Scheme. Actuators 2025, 14, 37. [Google Scholar] [CrossRef]

- Ignova, M.; Mantle, K.; Brovko, K.; Abe, V.; Gorodnov, A.; Li, L. Downhole Trajectory Automation of RSS Tools: Autonomous Drilling Becomes Reality. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, SPE, Stavanger, Norway, 7–9 March 2023; p. D031S022R003. [Google Scholar]

- Tilley, J.; Nair, V.N.; Hamoudi, L. Case Study: Intelligent RSS Improving Drilling Performance on Three Mile Laterals in the Appalachian Basin. In Proceedings of the SPE Annual Technical Conference and Exhibition? SPE, Virtual, 26–29 October 2020; p. D022S061R007. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).