Utilization of Date Powder as a Natural Sweetener in Milk Chocolate: Impacts on Production Process and Quality Attributes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

- a.

- Non-marketable dry Sukkari dates: Non-marketable dry dates were obtained from a date factory in Buraydah, Qassim.

- b.

- Raw materials used in chocolate production: The raw materials for chocolate production (cocoa powder, skimmed milk powder, powdered sugar, lecithin, vanilla, and packaging materials) were purchased from the local market in Qassim, Saudi Arabia. Turkish cocoa butter was imported from Sade Koy Company and stored under refrigeration until manufacturing.

- c.

- Chemicals: All chemicals used in the research for chemical analyses were of high purity and were obtained from Sigma, Jeddah, Saudi Arabia.

2.2. Methods

2.2.1. Preparation of Dry Sukkari Date Powder

2.2.2. Preparation of Chocolate Mixes

2.2.3. Chemical Composition and Caloric Content for Date Powder and Chocolate Samples Produced

2.2.4. Estimation of Acid Number and Peroxide Value for Chocolate

2.2.5. Quantitative Estimation of Sugars

2.2.6. Viscosity Measurement

2.2.7. Sensory Evaluation of the Resulting Chocolate

2.2.8. Statistical Analysis

3. Results

3.1. Physical Properties of the Resulting Chocolate (Viscosity)

3.2. Chemical Analysis of Chocolate

3.2.1. Ash Content

3.2.2. Fat Content

3.2.3. Moisture Content

3.2.4. Protein Content

3.2.5. Total Carbohydrates

3.2.6. Total Energy

3.2.7. Quantification of Reducing and Non-Reducing Sugars in Date Powder and Resulting Chocolate

3.3. Preservation Quality of Molding and Coating Chocolate During Storage

3.3.1. Moisture Content of Molding and Coating Chocolate During Refrigerated Storage

3.3.2. Peroxide Value of Molding and Coating Chocolate After Production and During Refrigerated Storage

3.3.3. Acid Value of Molding and Coating Chocolate After Production and During Refrigerated Storage

3.4. Sensory Evaluation of the Produced Chocolate After Manufacturing and During Refrigerated Storage

3.4.1. Sensory Evaluation of Molding Chocolate

Color

Surface Appearance

Texture

Snap

Taste and Aroma

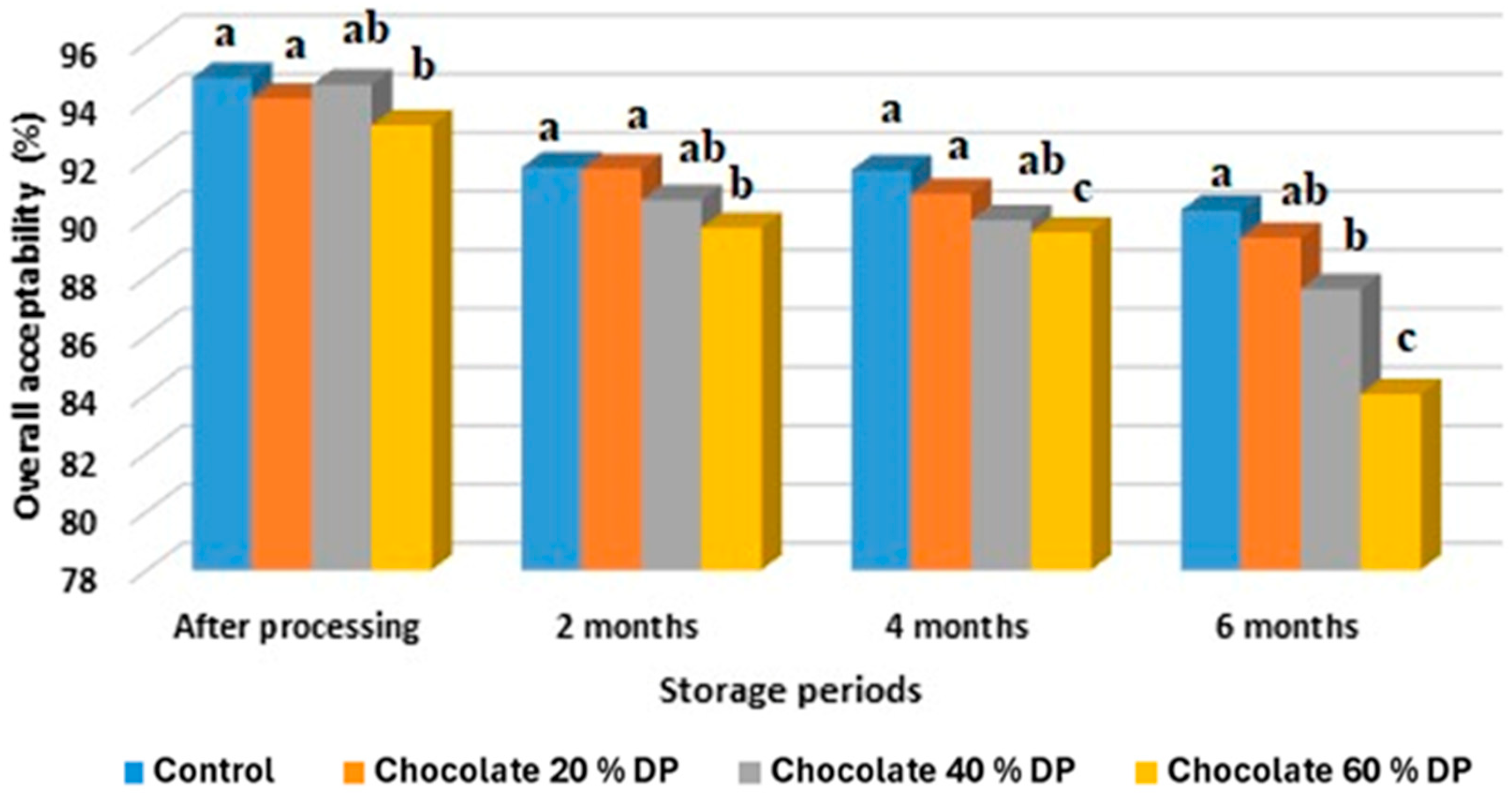

3.4.2. Sensory Evaluation of Wafer Biscuits Coated with Chocolate

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Almuzaini, H.A.; Faqih, E.H.; Alhumaid, N.A.; Shabib, Z.A.; El-Hady, E.-S.A.A.; Gadallah, M.G.E. Advantages of Khalas date products (Phoenix dactylifera L.) as a natural substitute for sugar and sweeteners in food processing. Alex. Sci. Exch. J. 2024, 45, 661–674. [Google Scholar] [CrossRef]

- Yusuf, N.; Kooli, C.; Khoj, H.; Bajnaid, N.O. Strategizing sustainable food security in Saudi Arabia: A policy and scenario approach to agricultural resilience. Outlook Agric. 2025, 54, 77–90. [Google Scholar] [CrossRef]

- Yousif, A.K.; Alghamdi, A.S. Suitability of nine Saudi date cultivars for candy making. In Proceedings of the First International Conference on Date Palms, United Arab Emirates University, Al-Ain, United Arab Emirates, 8–10 March 1998; pp. 100–110. [Google Scholar]

- Assirey, E.A.R. Nutritional composition of fruit of 10 date palm (Phoenix dactylifera L.) cultivars grown in Saudi Arabia. J. Taibah Univ. Sci. 2015, 9, 75–79. [Google Scholar] [CrossRef]

- Miller, C.J.; Dunn, E.V.; Hashim, I.B. The glycaemic index of dates and date/yoghurt mixed meals. Are dates ‘the candy that grows on trees’? Eur. J. Clin. Nutr. 2003, 57, 427–430. [Google Scholar] [CrossRef] [PubMed]

- Jagirdar, S.A. Modern development in fruit production. J. Agric. Res. 1998, 29, 442–447. [Google Scholar]

- Manickavasagan, A.; Thangavel, K.; Dev, S.R.S.; Delfiya, D.S.A.; Nambi, E.; Orsat, V.; Raghavan, G.S.V. Physicochemical characteristics of date powder produced in a pilot-scale spray dryer. Dry. Technol. 2015, 33, 1114–1123. [Google Scholar] [CrossRef]

- Al Madhi, N.A.M.; abd El, E.-S.A.A.; Hady, Z.A.S. Evaluation of Date Kernels Oil as a Substitute for Cocoa Butter in Milk Chocolate Production. J. Agric. Vet. Sci. 2017, 10. [Google Scholar]

- Alsaleem, K.A.; Musa, K.H.; Hamouda, M.E.A.; Hamad, E.M. Assessing Quality Attributes and Antioxidant Effects in Chocolate Milk Formulated with Gum Arabic and Desert Truffle. Processes 2024, 12, 1714. [Google Scholar] [CrossRef]

- Awad, T.S.; Marangoni, A.G. Ingredient Interactions Affecting Texture and Microstructure of Confectionery Chocolate; Marcel Dekker: New York, NY, USA, 2006. [Google Scholar]

- Toker, O.S.; Ozonuk, S.; Gunes, R.; Icyer, N.C.; Rasouli, H.P.; Konar, N.; Palabiyik, I.; Altop, C. Importance of emulsifiers in chocolate industry: Effect on structure, machinability, and quality of intermediate and final products. J. Am. Oil Chem. Soc. 2024, 101, 721–733. [Google Scholar] [CrossRef]

- Servais, C.; Ranc, H.; Roberts, I.D. Determination of chocolate viscosity. J. Texture Stud. 2003, 34, 467–497. [Google Scholar] [CrossRef]

- Wood, E.J. The Science of Chocolate; Taylor & Francis: Abingdon, UK, 2008. [Google Scholar]

- Machalkova, L.; Hrivna, L.; Nedomova, S.; Juzl, M. The effect of storage temperature and production method of chocolate confectionery on changes in its quality. In Proceedings of the MendelNet2014 Conference, Brno, Czech Republic, 19–20 November 2014; pp. 417–422. [Google Scholar]

- AOAC. Official Methods of Analysis, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2000. [Google Scholar]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists; AOAC International: Rockville, MD, USA, 2000; Volume 11. [Google Scholar]

- Iwe, M.O. Handbook of Sensory Methods and Analysis; Rojoint Communication Services Ltd.: Enugu, Nigeria, 2010; pp. 75–78. [Google Scholar]

- SAS Institute. Statistical Analysis System; SAS Institute Inc.: Cary, NC, USA, 2003. [Google Scholar]

- Siddeeg, A.; Zeng, X.-A.; Ammar, A.-F.; Han, Z. Sugar profile, volatile compounds, composition and antioxidant activity of Sukkari date palm fruit. J. Food Sci. Technol. 2019, 56, 754–762. [Google Scholar] [CrossRef] [PubMed]

- Afoakwa, E.O. Chocolate Science and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Yadav, P.; Pandey, J.P.; Garc, S.K. Biochemical changes during storage of chocolate. Int. Res. J. Biochem. Bioinform. 2011, 1, 242–247. [Google Scholar]

- Derouich, M.; Meziani, R.; Bourkhis, B.; Filali-Zegzouti, Y.; Alem, C. Nutritional, mineral and organic acid composition of syrups produced from six Moroccan date fruit (Phoenix dactylifera L.) varieties. J. Food Compos. Anal. 2020, 93, 103591. [Google Scholar] [CrossRef]

- Rațu, R.N.; Veleșcu, I.D.; Stoica, F.; Usturoi, A.; Arsenoaia, V.N.; Crivei, I.C.; Postolache, A.N.; Lipșa, F.D.; Filipov, F.; Florea, A.M.; et al. Application of agri-food by-products in the food industry. Agriculture 2023, 13, 1559. [Google Scholar] [CrossRef]

- Al-Farsi, M.A.; Lee, C.Y. Nutritional and functional properties of dates: A review. Crit. Rev. Food Sci. Nutr. 2008, 48, 877–887. [Google Scholar] [CrossRef]

- Mahato, D.K.; Keast, R.; Liem, D.G.; Russell, C.G.; Cicerale, S.; Gamlath, S. Optimisation of natural sweeteners for sugar reduction in chocolate flavoured milk and their impact on sensory attributes. Int. Dairy J. 2021, 115, 104922. [Google Scholar] [CrossRef]

- Joseph, C.; Batra, R.; Selvasekaran, P.; Chidambaram, R. Low calorie cocoa-based products: A short review. J. Food Sci. Technol. 2022, 59, 2931–2939. [Google Scholar] [CrossRef] [PubMed]

- da Cruz, R.M.S. Food Packaging: Innovations and Shelf-Life; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Petcu, C.D.; Tăpăloagă, D.; Mihai, O.D.; Gheorghe-Irimia, R.-A.; Negoiță, C.; Georgescu, I.M.; Tăpăloagă, P.R.; Borda, C.; Ghimpețeanu, O.M. Harnessing natural antioxidants for enhancing food shelf life: Exploring sources and applications in the food industry. Foods 2023, 12, 3176. [Google Scholar] [CrossRef]

- Sayas-Barberá, E.; Paredes, C.; Salgado-Ramos, M.; Pallarés, N.; Ferrer, E.; de Vera, C.N.-R.; Pérez-Álvarez, J.Á. Approaches to enhance sugar content in foods: Is the date palm fruit a natural alternative to sweeteners? Foods 2023, 13, 129. [Google Scholar] [CrossRef]

- Benucci, I.; Lombardelli, C.; Esti, M. A comprehensive review on natural sweeteners: Impact on sensory properties, food structure, and new frontiers for their application. Crit. Rev. Food Sci. Nutr. 2024, 65, 4615–4633. [Google Scholar] [CrossRef] [PubMed]

- Saedi, S.; Jafarian, S.; Ghaboos, S.H.H.; Nasiraei, L.R. Formulation optimization of a probiotic low-calorie chocolate milk and investigating its qualitative properties during storage. Heliyon 2024, 10, e36430. [Google Scholar] [CrossRef] [PubMed]

- Râpă, M.; Darie-Niță, R.N.; Coman, G. Valorization of fruit and vegetable waste into sustainable and value-added materials. Waste 2024, 2, 258–278. [Google Scholar] [CrossRef]

- Brito, T.B.N.; Ferreira, M.S.L.; Fai, A.E.C. Utilization of agricultural by-products: Bioactive properties and technological applications. Food Rev. Int. 2022, 38, 1305–1329. [Google Scholar] [CrossRef]

| The Components, % | Molding Milk Chocolate | |||

| Control Sample | Replacing Sugar with Sukkari Date Powder, % | |||

| 10% | 20% | 30% | ||

| Cocoa butter, 40 | 400 | 400 | 400 | 400 |

| Cocoa powder, 7 | 70 | 70 | 70 | 70 |

| Sugar powder, 40 | 400 | 360 | 320 | 280 |

| Sukkari date powder, | 0 | 40 | 80 | 120 |

| Skimmed milk powder, 12 | 120 | 120 | 120 | 120 |

| Lecithin, 0.7 | 7 | 7 | 7 | 7 |

| Vanilla powder, 0.3 | 3 | 3 | 3 | 3 |

| Total, 100 (g) | 1000 | 1000 | 1000 | 1000 |

| Coating milk chocolate | ||||

| Control Sample | Replacing sugar with Sukkari date powder, % | |||

| 60% | 20% | 40% | 60% | |

| Cocoa butter, 50 | 500 | 500 | 500 | 500 |

| Cocoa powder, 6 | 60 | 60 | 60 | 60 |

| Sugar powder, 34 | 340 | 272 | 204 | 136 |

| Sukkari date powder, | 0 | 68 | 136 | 204 |

| Skimmed milk powder, 9 | 90 | 90 | 90 | 90 |

| Lecithin, 0.7 | 7 | 7 | 7 | 7 |

| Vanilla powder, 0.3 | 3 | 3 | 3 | 3 |

| Total, 100 (g) | 1000 | 1000 | 1000 | 1000 |

| Molding Milk Chocolate | |

|---|---|

| Characteristics | Maximum score |

| Color | 10 |

| Surface appearance | 10 |

| Texture | 15 |

| Break (Snab) | 15 |

| Taste | 30 |

| Aroma | 20 |

| Overall Acceptability | 100 |

| Coating milk chocolate | |

| Characteristics | Maximum score |

| Color | 10 |

| Surface appearance | 40 |

| Taste | 40 |

| Aroma | 10 |

| Overall Acceptability | 100 |

| Molding Milk Chocolate | Viscosity (Pa./s) | Coating Milk Chocolate | Viscosity (Pa./s) |

|---|---|---|---|

| CS | 2545 ± 7.61 a | CS | 606 ± 3.71 b |

| C10%dp | 1228 ± 4.51 d | C20%dp | 380 ± 2.71 d |

| C20%dp | 1650 ± 4.02 c | C40%dp | 540 ± 3.01 c |

| C30%dp | 1810 ± 4.02 b | C60%dp | 750± 3.92 a |

| Sample | Ash | Fat | Moisture | Protein | Carbohydrates | Total Energy (kcal/100 g) |

|---|---|---|---|---|---|---|

| SDP | 3.72 | 0.20 | 9.37 | 3.02 | 83.69 | 351.44 |

| Molding milk chocolate | ||||||

| CS | 1.94 ± 0.14 b | 41.80 ± 1.21 a | 1.90 ± 0.36 a | 5.50 ± 0.28 a | 48.86 ± 163 a | 593.64 ± 2.83 a |

| C10%dp | 1.78 ± 0.13 b | 41.84 ± 1.42 a | 1.62 ± 0.16 ab | 6.06 ± 0.22 a | 48.70 ± 1.54 a | 595.24 ± 3.16 a |

| C20%dp | 2.42 ± 0.12 ab | 41.93 ± 1.23 a | 1.29 ± 0.15 ab | 6.64 ± 0.26 a | 47.82 ± 1.77 ab | 594.81 ± 3.41 a |

| C30%dp | 3.54 ± 0.18 a | 41.95 ± 1.32 a | 1.15 ± 0.15 b | 6.60 ± 0.27 a | 46.7 ± 1.536 b | 590.99 ± 2.64 b |

| Coating milk chocolate | ||||||

| CS | 1.30 ± 0.13 b | 50.31 ± 0.33 a | 3.42 ± 0.17 a | 4.99 ± 0.18 b | 39.98 ± 1.28 a | 6.36.67 ± 3.29 a |

| C20%dp | 2.96 ± 0.14 ab | 50.34 ± 0.32 a | 2.95 ± 0.12 ab | 5.08 ± 0.32 ab | 38.67 ± 1.13 a | 628.06 ± 2.81 c |

| C40%dp | 3.77 ± 0.18 a | 50.37 ± 0.37 a | 2.75 ± 0.13 ab | 5.15 ± 0.34 a | 37.96 ± 1.13 ab | 625.77 ± 2.54 c |

| C60%dp | 4.97 ± 0.22 a | 50.51 ± 0.37 a | 2.35 ± 0.13 b | 5.20 ± 0.36 a | 36.97 ± 1.13 b | 623.27 ± 3.73 b |

| Sample | Reducing Sugars | Non-Reducing Sugars | Total Sugars |

|---|---|---|---|

| SDP | 14.61 | 60.69 | 75.30 |

| Molding milk chocolate | |||

| CS | 5.19 ± 0.21 b | 44.29 ± 1.23 a | 49.44 ± 1.25 b |

| C10%dp | 5.45 ± 0.24 ab | 39.53 ± 1.02 b | 45.07 b ± 1.32 c |

| C20%dp | 5.58 ± 0.27 ab | 38.46 ± 1.72 b | 44.45 ± 1.62 c |

| C30%dp | 6.44 ± 0.41 a | 37.89 ± 1.62 b | 44.33 ± 1.62 c |

| Coating milk chocolate | |||

| CS | 3.69 ± 0.13 c | 28.23 ± 0.72 d | 38.92 ± 0.62 d |

| C20%dp | 5.74 ± 0.12 ab | 32.58 ± 1.01 c | 38.33 ± 1.62 d |

| C40%dp | 5.48 ± 0.15 ab | 31.66 ± 1.01 c | 37.15 ± 1.15 d |

| C60%dp | 5.33 ± 0.19 b | 31.58 ± 1.02 c | 36.91 ± 1.01 e |

| Sample | Storage Period (Month) | |||

|---|---|---|---|---|

| 0 | 2 | 4 | 6 | |

| Molding milk chocolate | ||||

| CS | 1.90 ± 0.36 a | 3.16 ± 0.15 a | 3.38 ± 0.13 a | 3.97 ± 0.14 a |

| C10%dp | 1.62 ± 0.16 ab | 2.24 ± 0.12 ab | 2.45 ± 0.12 ab | 3.40 ± 0.17 ab |

| C20%dp | 1.29 ± 0.15 ab | 1.90 ± 0.12 b | 2.28 ± 0.11 b | 3.10 ± 0.16 ab |

| C30%dp | 1.15 ± 0.15 b | 1.65 ± 0.11 c | 1.96 ± 0.13 c | 2.94 ± 0.12 b |

| Coating milk chocolate | ||||

| CS | 3.42 ± 0.17 a | 3.70 ± 0.14 a | 3.87 ± 0.15 a | 4.35 ± 0.15 a |

| C20%dp | 2.95 ± 0.12 ab | 3.26 ± 0.13 ab | 3.45 ± 0.13 ab | 3.85 ± 0.14 ab |

| C40%dp | 2.75 ± 0.13 ab | 3.10 ± 0.12 ab | 2.84 ± 0.12 b | 3.23 ± 0.13 b |

| C60%dp | 2.35 ± 0.13 b | 2.65 ± 0.10 b | 3.36 ± 0.14 ab | 3.52 ± 0.13 ab |

| Sample | Odor (20) | Taste (30) | Snap (15) | Texture (15) | Surface Appearance (10) | Color (10) |

|---|---|---|---|---|---|---|

| After manufacturing (before cold storage) | ||||||

| CS | 19.13 ± 0.36 a | 28.20 ± 0.45 a | 14.20 ± 0.26 a | 14.13 ± 0.36 a | 9.53 ± 0.19 a | 9.60 ± 0.14 a |

| C10%dp | 19.20 ± 0.36 a | 27.27 ± 0.73 b | 14.27 ± 0.28 a | 14.27 ± 0.36 a | 9.60 ± 0.16 a | 9.47 ± 0.17 a |

| C20%dp | 19.13 ± 0.36 a | 28.40 ± 0.52 a | 14.13 ± 0.29 a | 14.13 ± 0.36 a | 9.47 ± 0.27 a | 9.30 ± 0.27 a |

| C30%dp | 19.17 ± 0.39 a | 27.27 ± 0.51 b | 13.90 ± 0.21 b | 13.47 ± 0.35 b | 9.53 ± 0.19 a | 9.33 ± 0.21 a |

| After 2 months of cold storage | ||||||

| CS | 18.47 ± 0.72 a | 26.60 ± 1.09 a | 13.53 ± 0.40 b | 14.07 ± 0.38 a | 9.67 ± 0.21 a | 9.40 ± 0.24 ab |

| C10%dp | 18.40 ± 0.72 a | 26.67 ± 1.65 a | 14.27 ± 0.48 a | 13.53 ± 0.54 b | 9.60 ± 0.16 a | 9.20 ± 0.24 b |

| C20%dp | 17.93 ± 0.90 ab | 25.80 ± 1.41 a | 13.93 ± 0.36 ab | 13.73 ± 0.45 ab | 9.06 ± 0.16 b | 9.63 ± 0.12 a |

| C30%dp | 18.47 ± 0.72 a | 24.53 ± 1.87 b | 14.00 ± 0.35 a | 13.80 ± 0.37 ab | 9.60 ± 0.16 a | 9.26 ± 0.21 ab |

| After 4 months of cold storage | ||||||

| CS | 18.00 ± 0.34 ab | 27.00 ± 0.45 ab | 13.80 ± 0.34 a | 14.10 ± 0.31 a | 9.27 ± 0.31 a | 9.43 ± 0.39 a |

| C10%dp | 18.53 ± 0.45 a | 27.73 ± 0.47 a | 13.43 ± 0.43 ab | 13.10 ± 0.54 ab | 8.83 ± 0.32 b | 9.20 ± 0.23 a |

| C20%dp | 17.93 ± 0.73 b | 27.40 ± 0.77 a | 12.97 ± 0.50 b | 13.13 ± 0.56 ab | 9.17 ± 0.19 a | 9.33 ± 0.24 a |

| C30%dp | 18.27 ± 0.50 a | 25.60 ± 0.42 b | 13.70 ± 0.37 ab | 13.30 ± 0.56 b | 8.87 ± 0.35 b | 9.70 ± 0.15 a |

| After 6 months of cold storage | ||||||

| CS | 18.07 ± 0.45 a | 27.50 ± 0.57 a | 13.00 ± 0.49 a | 13.13 ± 0.36 a | 9.27 ± 0.19 a | 9.33 ± 0.24 a |

| C10%dp | 18.00 ± 0.34 a | 27.07 ± 0.45 a | 13.07 ± 0.44 a | 13.00 ± 0.21 a | 9.19 ± 0.17 a | 9.00 ± 0.29 ab |

| C20%dp | 18.00 ± 0.20 a | 26.63 ± 0.46 b | 12.83 ± 0.34 ab | 12.60 ± 0.21 ab | 8.93 ± 0.14 b | 8.60 ± 0.22 b |

| C30%dp | 17.93 ± 0.43 b | 26.10 ± 0.47 c | 11.97 ± 0.50 b | 11.63 ± 0.36 b | 8.04 ± 0.19 c | 8.33 ± 0.34 c |

| Treatments | Odor (10) | Taste (40) | Surface Appearance (40) | Color (10) |

|---|---|---|---|---|

| After manufacturing (before cold storage) | ||||

| CS | 9.40 ± 0.19 a | 38.47 ± 0.52 ab | 38.40 ± 0.53 a | 9.47± 0.19 a |

| C20%dp | 9.33 ± 0.21 b | 38.93 ± 0.38 a | 37.98 ± 0.86 ab | 9.40 ± 0.24 ab |

| C40%dp | 9.30 ± 0.21 ab | 37.90 ± 0.484 b | 37.93 ± 0.86 b | 9.40 ± 0.24 ab |

| C60%dp | 8.53 ± 0.30 b | 35.33 ± 0.67 c | 37.27 ± 0.78 b | 9.47 ± 0.22 a |

| After 2 months of cold storage | ||||

| CS | 9.70 ± 0.12 a | 36.91 ± 1.17 a | 38.07 ± 0.91 a | 9.57 ± 0.18 a |

| C20%dp | 9.70 ± 0.12 a | 35.93 ± 1.17 ab | 38.07 ± 0.91 ab | 9.50 ± 0.18 a |

| C40%dp | 9.67 ± 0.12 a | 38.10 ± 1.01 a | 35.02 ± 1.27 b | 8.98 ± 0.33 a |

| C60%dp | 9.00 ± 0.17 a | 35.86 ± 1.39 b | 33.43 ± 1.28 c | 8.80 ± 0.38 b |

| After 4 months of cold storage | ||||

| CS | 9.67 ± 0.12 a | 38.10 ± 1.01 ab | 34.97 ± 1.27 ab | 8.98 ± 0.33 a |

| C20%dp | 8.87 ± 0.30 ab | 38.60 ± 1.76 a | 35.47 ± 1.15 a | 8.90 ± 0.26 a |

| C40%dp | 8.83 ± 0.57 b | 36.40 ± 1.98 b | 34.73 ± 1.65 b | 9.13 ± 0.95 ab |

| C60%dp | 7.80 ± 0.19 c | 34.07 ± 1.46 c | 32.43 ± 1.33 c | 8.60 ± 0.39 b |

| After 6 months of cold storage | ||||

| CS | 9.77 ± 0.15 a | 36.60 ± 1.76 ab | 35.47 ± 1.15 ab | 9.27 ± 0.28 a |

| C20%dp | 9.70 ± 0.66 a | 37.47 ± 1.67 a | 34.93 ± 1.80 a | 8.10 ± 0.38 b |

| C40%dp | 9.10 ± 0.36 ab | 37.33 ± 1.77 a | 32.07 ± 1.37 b | 7.87 ± 0.47 c |

| C60%dp | 6.57 ± 0.24 b | 32.83 ± 1.58 c | 31.30 ± 1.60 c | 8.57 ± 0.70 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Qafari, A.; Abd El-Hady, E.S.A.; Shabib, Z.; Almarzooq, A.F.; Alayouni, R.; Aljutaily, T.; Alsaleem, K.A. Utilization of Date Powder as a Natural Sweetener in Milk Chocolate: Impacts on Production Process and Quality Attributes. Processes 2025, 13, 3390. https://doi.org/10.3390/pr13113390

Al Qafari A, Abd El-Hady ESA, Shabib Z, Almarzooq AF, Alayouni R, Aljutaily T, Alsaleem KA. Utilization of Date Powder as a Natural Sweetener in Milk Chocolate: Impacts on Production Process and Quality Attributes. Processes. 2025; 13(11):3390. https://doi.org/10.3390/pr13113390

Chicago/Turabian StyleAl Qafari, Amal, El Sayed Attia Abd El-Hady, Zeinab Shabib, Ahmed F. Almarzooq, Raed Alayouni, Thamer Aljutaily, and Khalid A. Alsaleem. 2025. "Utilization of Date Powder as a Natural Sweetener in Milk Chocolate: Impacts on Production Process and Quality Attributes" Processes 13, no. 11: 3390. https://doi.org/10.3390/pr13113390

APA StyleAl Qafari, A., Abd El-Hady, E. S. A., Shabib, Z., Almarzooq, A. F., Alayouni, R., Aljutaily, T., & Alsaleem, K. A. (2025). Utilization of Date Powder as a Natural Sweetener in Milk Chocolate: Impacts on Production Process and Quality Attributes. Processes, 13(11), 3390. https://doi.org/10.3390/pr13113390