Designs of Bayesian EWMA Variability Control Charts in the Presence of Measurement Error

Abstract

1. Introduction

2. Preliminary Settings

3. Error-Embedded Bayesian EWMA Variability Control Charts

3.1. Construction

- 1.

- Given n, ,, ,, λ, and ARL0, can be expressed as the function of k3 by Equation (26), and can be expressed as the function of k4 by Equation (28).

- 2.

- Let as in Equation (27).

- 3.

- Simulate random numbers, , from ; compute with Equation (17); simulate random numbers, , from ; and compute with Equation (23) until ; then, record the run length, t.

- 4.

- Repeat step 3 10,000 times, and obtain the average run length, ARL(k3).

- 5.

- Determine the k3 value to make sure ARL(k3) is within 2 × ARL0 ± 2.

- 6.

- After k3 is obtained, simulate random numbers, , from ; compute with Equation (17); simulate random numbers, , from ; and compute with Equation (23) until or ; then, record the run length, t.

- 7.

- Repeat step 6 10,000 times, and obtain the average run length, ARL(k4).

- 8.

- Determine the k4 value to make sure ARL(k4) is within ARL0 ± 1.

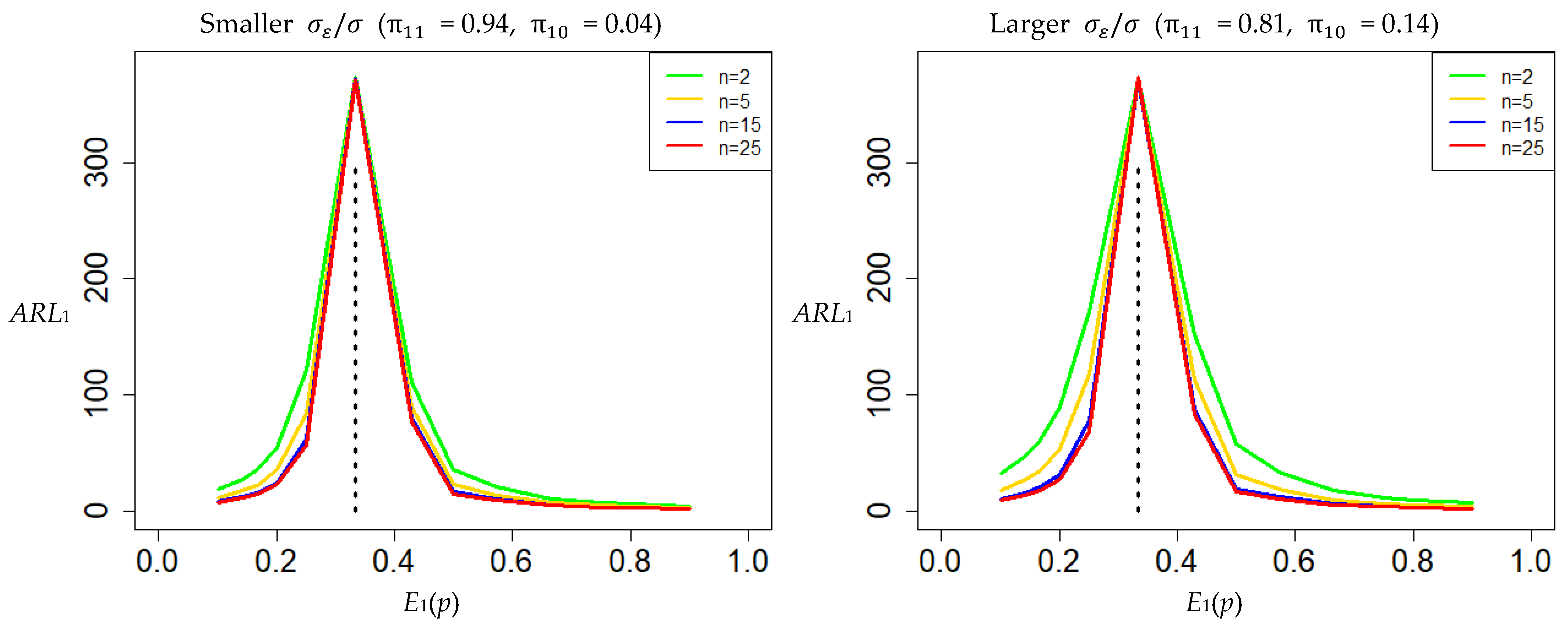

3.2. Detection Performance

- 1.

- Given n, ,, ,, λ, and ARL0, (k3, k4) can be obtained, and and can be calculated by Equations (26) and (28).

- 2.

- Let as in Equation (27).

- 3.

- Given and .

- 4.

- Simulate random numbers, , from , compute with Equation (17); simulate random numbers, , from ; and compute with Equation (23) until or ; then, record the run length, t.

- 5.

- Repeat step 4 10,000 times, and obtain the out-of-control average run length, ARL1.

4. Error-Corrected Bayesian EWMA Variability Control Charts

4.1. Construction

- 1.

- Given n, ,, ,, λ, and ARL0, can be expressed as the function of k5 by Equation (37), and can be expressed as the function of k6 by Equation (39).

- 2.

- Let as in Equation (38).

- 3.

- Simulate random numbers, , from ; compute with Equation (17); simulate random numbers, , from ; compute with Equation (31); and compute with Equation (34) until ; then, record the run length, t.

- 4.

- Repeat step 3 10,000 times, and obtain the average run length, ARL(k5).

- 5.

- Determine the k5 value to make sure ARL(k5) is within 2 × ARL0 ± 2.

- 6.

- After k5 is obtained, simulate random numbers, , from ; compute with Equation (17); simulate random numbers, , from ; compute with Equation (31); and compute with Equation (34) until or ; then, record the run length, t.

- 7.

- Repeat step 6 10,000 times, and obtain the average run length, ARL(k6).

- 8.

- Determine k6 value to make sure the ARL(k6) is within ARL0 ± 1.

4.2. Detection Performance

- 1.

- Given n, ,, ,, λ, and ARL0, (k5, k6) can be obtained, and and can be calculated by Equations (37) and (39).

- 2.

- Let as in Equation (38).

- 3.

- Given and .

- 4.

- Simulate random numbers, , from ; compute with Equation (17); simulate random numbers, , from ; compute with Equation (31); and compute with Equation (34) until or ; then, record the run length, t.

- 5.

- Repeat step 4 10,000 times, and obtain ARL1.

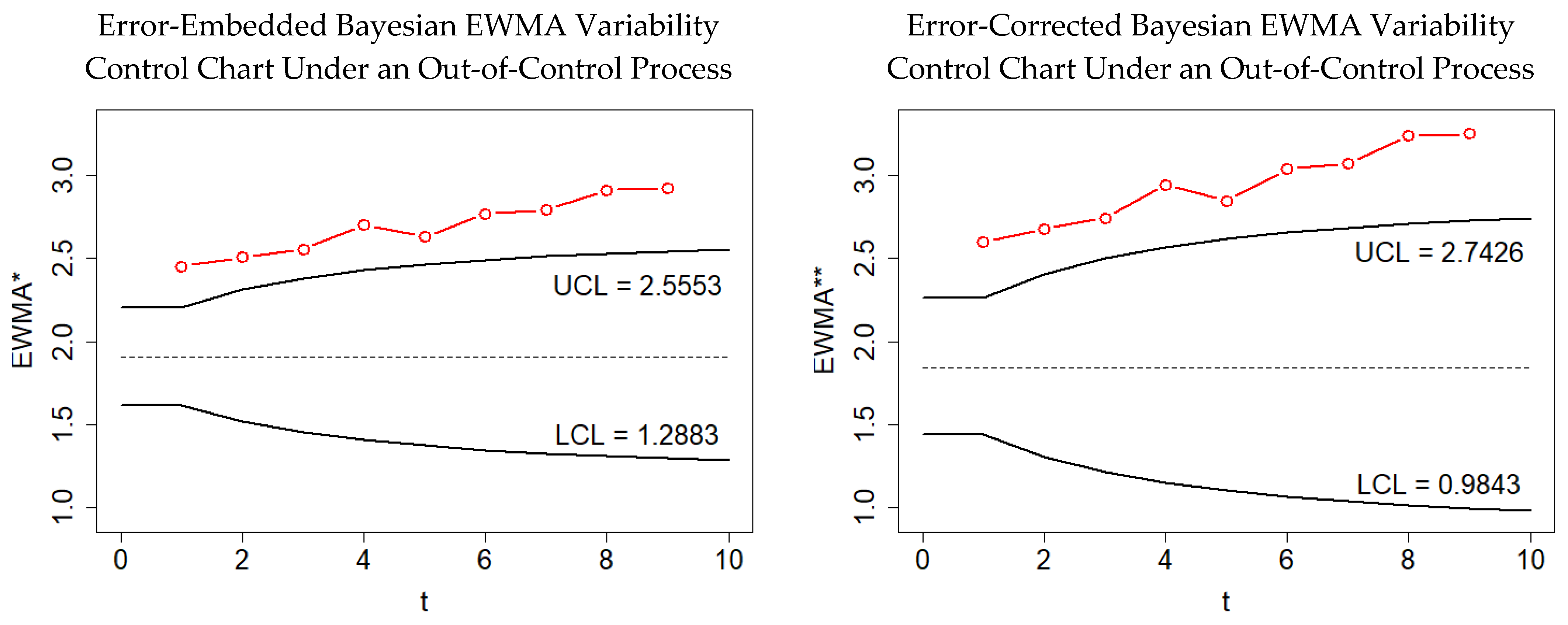

5. Comparisons

5.1. The Impact of Misusing Control Charts

5.2. Widely Applicable Control Charts

- Case 1:

- Using the existing control chart in Lin et al. [5] to monitor a process without measurement errors;

- Case 2:

- Using the proposed control charts to monitor a process without measurement errors;

- Case 3:

- Using the proposed control charts to monitor a process with measurement errors, where the variance of measurement error is small relative to the in-control process variance;

- Case 4:

- Using the proposed control charts to monitor a process with measurement errors, where the variance of measurement error is large relative to the in-control process variance.

6. Examples for Demonstration

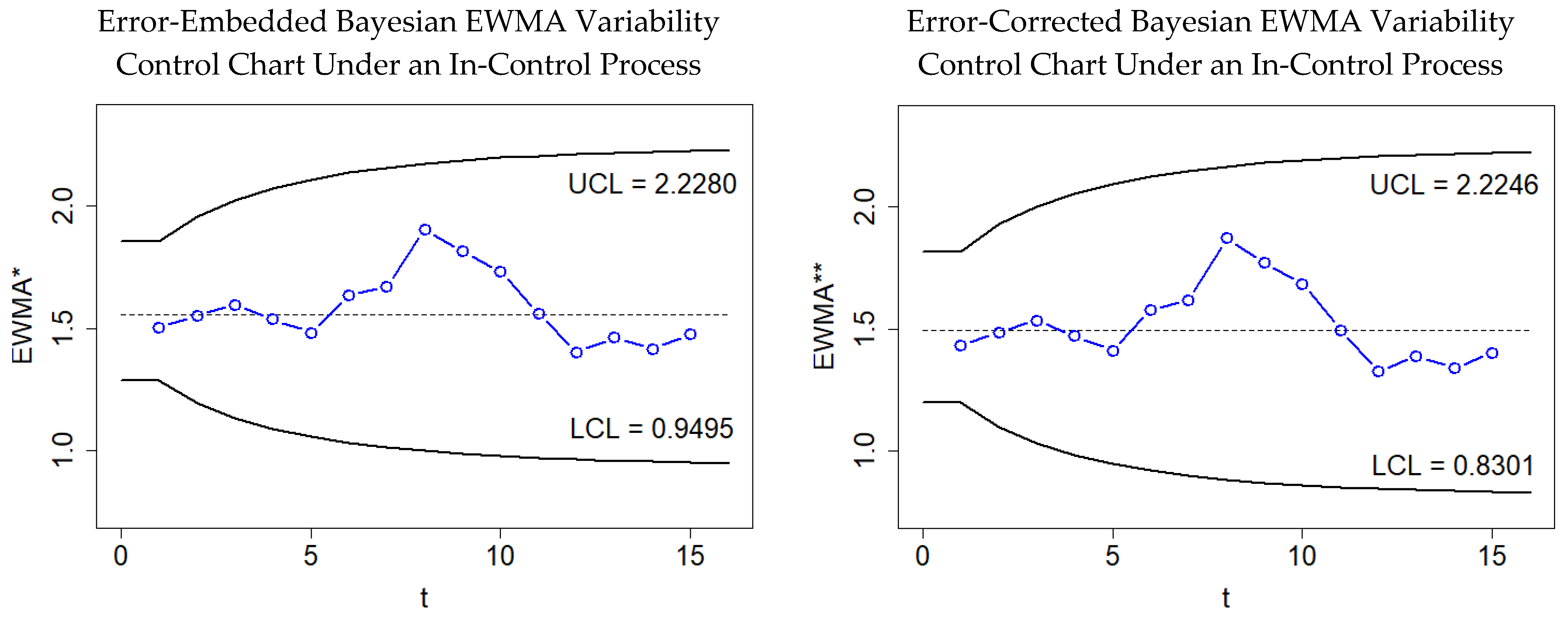

6.1. A Banking Example

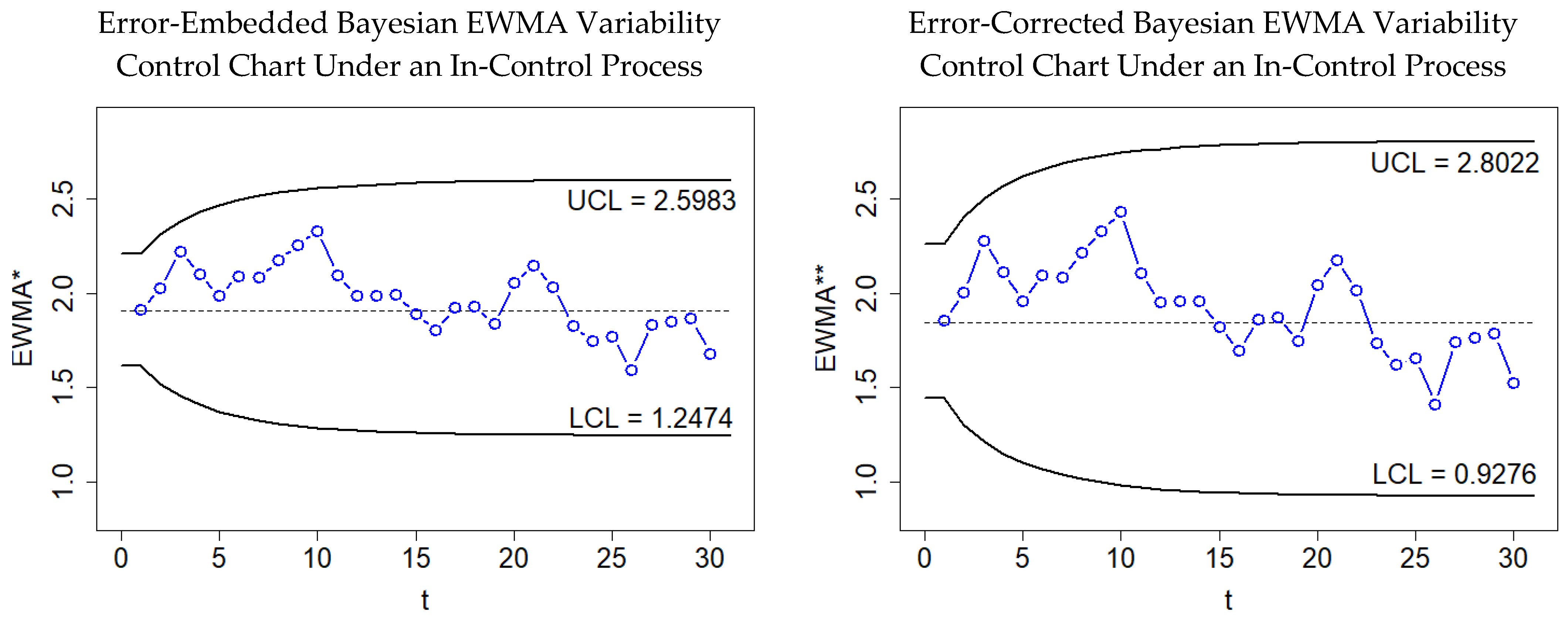

6.2. A Semiconductor Example

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ARL | Average Run Length |

| EWMA | Exponentially Weighted Moving Average |

| ME | Measurement Error |

Appendix A

| t | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2564.00 | 2465.14 | 2479.90 | 2502.87 | 2432.84 | 2529.27 | 2489.70 | 2524.18 | 2475.53 | 2484.31 | 1.9157 | 1.8551 |

| 2 | 2565.80 | 2492.29 | 2500.81 | 2459.87 | 2547.43 | 2447.89 | 2545.34 | 2560.99 | 2436.17 | 2512.49 | 2.0241 | 2.0056 |

| 3 | 2416.73 | 2531.34 | 2432.85 | 2576.84 | 2406.22 | 2546.75 | 2493.32 | 2486.59 | 2501.93 | 2436.12 | 2.2217 | 2.2798 |

| 4 | 2496.56 | 2538.75 | 2540.95 | 2506.27 | 2526.22 | 2491.55 | 2480.54 | 2491.60 | 2549.73 | 2460.94 | 2.0995 | 2.1102 |

| 5 | 2554.29 | 2488.50 | 2513.05 | 2533.49 | 2467.11 | 2505.03 | 2486.48 | 2477.46 | 2540.19 | 2512.51 | 1.9896 | 1.9577 |

| 6 | 2413.92 | 2393.78 | 2405.53 | 2484.62 | 2412.41 | 2531.63 | 2517.54 | 2460.91 | 2456.65 | 2475.50 | 2.0906 | 2.0979 |

| 7 | 2570.93 | 2533.52 | 2441.22 | 2501.88 | 2467.94 | 2434.32 | 2436.69 | 2541.21 | 2526.73 | 2516.11 | 2.0816 | 2.0853 |

| 8 | 2556.22 | 2485.50 | 2550.52 | 2484.78 | 2506.32 | 2526.16 | 2598.02 | 2523.36 | 2492.81 | 2516.33 | 2.1734 | 2.2128 |

| 9 | 2502.25 | 2511.92 | 2568.35 | 2413.65 | 2545.77 | 2458.12 | 2576.19 | 2560.92 | 2573.36 | 2497.49 | 2.2561 | 2.3275 |

| 10 | 2440.82 | 2527.77 | 2484.78 | 2568.93 | 2573.09 | 2564.29 | 2498.91 | 2468.65 | 2473.55 | 2565.47 | 2.3305 | 2.4307 |

| 11 | 2497.13 | 2541.12 | 2467.40 | 2482.88 | 2515.32 | 2545.48 | 2505.70 | 2491.13 | 2464.33 | 2502.48 | 2.0974 | 2.1073 |

| 12 | 2516.95 | 2512.65 | 2510.76 | 2539.59 | 2448.07 | 2540.35 | 2557.58 | 2590.45 | 2542.64 | 2560.61 | 1.9877 | 1.9550 |

| 13 | 2415.75 | 2452.28 | 2435.47 | 2508.80 | 2453.53 | 2472.23 | 2595.82 | 2461.82 | 2502.89 | 2504.01 | 1.9889 | 1.9567 |

| 14 | 2435.34 | 2460.05 | 2445.20 | 2440.93 | 2420.32 | 2474.88 | 2499.75 | 2515.91 | 2464.40 | 2535.14 | 1.9900 | 1.9583 |

| 15 | 2473.10 | 2507.22 | 2454.80 | 2483.71 | 2494.75 | 2572.62 | 2572.78 | 2526.44 | 2461.58 | 2484.90 | 1.8910 | 1.8209 |

| 16 | 2440.94 | 2475.50 | 2461.17 | 2438.56 | 2447.43 | 2456.68 | 2462.75 | 2469.59 | 2403.24 | 2473.67 | 1.8019 | 1.6972 |

| 17 | 2467.40 | 2498.67 | 2569.45 | 2453.25 | 2435.14 | 2495.16 | 2434.60 | 2449.84 | 2494.57 | 2553.90 | 1.9217 | 1.8635 |

| 18 | 2548.91 | 2554.21 | 2488.15 | 2561.21 | 2497.58 | 2570.46 | 2481.64 | 2522.35 | 2515.83 | 2481.32 | 1.9295 | 1.8743 |

| 19 | 2501.13 | 2490.26 | 2493.13 | 2483.29 | 2463.23 | 2524.62 | 2438.58 | 2448.68 | 2458.09 | 2493.20 | 1.8366 | 1.7453 |

| 20 | 2533.39 | 2475.59 | 2496.49 | 2512.10 | 2577.58 | 2517.21 | 2476.10 | 2532.40 | 2427.20 | 2552.96 | 2.0529 | 2.0456 |

| 21 | 2552.65 | 2456.06 | 2522.77 | 2512.14 | 2528.73 | 2412.64 | 2508.94 | 2585.92 | 2464.45 | 2503.52 | 2.1476 | 2.1770 |

| 22 | 2496.32 | 2479.17 | 2472.60 | 2490.63 | 2514.52 | 2491.01 | 2501.26 | 2462.85 | 2454.38 | 2548.76 | 2.0329 | 2.0177 |

| 23 | 2565.73 | 2521.93 | 2574.34 | 2572.48 | 2544.85 | 2563.75 | 2489.86 | 2523.78 | 2522.40 | 2506.21 | 1.8296 | 1.7356 |

| 24 | 2514.38 | 2405.19 | 2510.19 | 2485.82 | 2548.79 | 2500.38 | 2484.43 | 2517.11 | 2524.88 | 2488.94 | 1.7466 | 1.6205 |

| 25 | 2464.86 | 2497.33 | 2538.76 | 2504.01 | 2520.88 | 2414.63 | 2503.48 | 2414.43 | 2474.55 | 2512.63 | 1.7720 | 1.6557 |

| 26 | 2516.34 | 2555.88 | 2474.97 | 2442.51 | 2449.85 | 2446.55 | 2529.90 | 2525.74 | 2499.15 | 2538.38 | 1.5948 | 1.4097 |

| 27 | 2504.20 | 2403.89 | 2516.06 | 2419.25 | 2493.21 | 2448.34 | 2458.90 | 2585.72 | 2458.88 | 2521.87 | 1.8353 | 1.7435 |

| 28 | 2534.66 | 2574.43 | 2507.66 | 2504.81 | 2536.87 | 2451.53 | 2547.65 | 2548.46 | 2507.01 | 2444.67 | 1.8518 | 1.7664 |

| 29 | 2549.85 | 2498.02 | 2543.10 | 2451.31 | 2506.00 | 2512.02 | 2447.26 | 2575.41 | 2481.99 | 2437.76 | 1.8666 | 1.7870 |

| 30 | 2558.56 | 2532.71 | 2499.79 | 2487.91 | 2488.18 | 2489.06 | 2521.98 | 2528.55 | 2503.30 | 2466.84 | 1.6799 | 1.5279 |

| t | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2548.21 | 2479.40 | 2629.48 | 2514.54 | 2542.24 | 2446.25 | 2345.95 | 2533.91 | 2446.74 | 2586.05 | 2.4531 | 2.6009 |

| 2 | 2388.74 | 2483.66 | 2628.76 | 2502.62 | 2502.05 | 2359.01 | 2491.19 | 2524.44 | 2529.16 | 2508.56 | 2.5078 | 2.6768 |

| 3 | 2504.38 | 2497.03 | 2509.65 | 2391.71 | 2521.84 | 2463.11 | 2458.15 | 2483.06 | 2467.49 | 2593.63 | 2.5570 | 2.7451 |

| 4 | 2470.81 | 2575.68 | 2408.46 | 2522.90 | 2509.24 | 2526.22 | 2499.72 | 2559.27 | 2551.17 | 2439.82 | 2.7013 | 2.9453 |

| 5 | 2517.34 | 2574.32 | 2478.88 | 2488.76 | 2518.96 | 2514.95 | 2523.71 | 2536.48 | 2527.25 | 2384.19 | 2.6312 | 2.8480 |

| 6 | 2425.46 | 2497.56 | 2369.95 | 2436.65 | 2449.25 | 2485.81 | 2448.37 | 2512.61 | 2443.10 | 2506.43 | 2.7680 | 3.0380 |

| 7 | 2522.41 | 2471.50 | 2391.56 | 2477.01 | 2465.11 | 2584.79 | 2422.00 | 2518.89 | 2539.50 | 2500.85 | 2.7912 | 3.0702 |

| 8 | 2534.16 | 2524.13 | 2457.42 | 2571.41 | 2512.77 | 2598.77 | 2473.14 | 2588.74 | 2410.53 | 2587.86 | 2.9121 | 3.2379 |

| 9 | 2565.93 | 2425.30 | 2467.73 | 2559.42 | 2470.60 | 2493.72 | 2515.51 | 2477.13 | 2428.64 | 2585.48 | 2.9209 | 3.2501 |

References

- Shewhart, W.A. Some applications of statistical methods to the analysis of physical and engineering data. Bell Syst. Tech. J. 1924, 3, 43–87. [Google Scholar] [CrossRef]

- MacCarthy, B.L.; Wasusri, T. A review of non-standard applications of statistical process control (SPC) charts. Int. J. Qual. Reliab. Manag. 2002, 19, 295–320. [Google Scholar] [CrossRef]

- Tsung, F.; Li, Y.; Jin, M. Statistical process control for multistage manufacturing and service operations: A review and some extensions. Int. J. Serv. Oper. Inform. 2008, 3, 191–204. [Google Scholar] [CrossRef]

- Ning, X.; Shang, Y.; Tsung, F. Statistical process control techniques for service processes: A review. In Proceedings of the 6th International Conference on Service Systems and Service Management, Xiamen, China, 8−10 June 2009. [Google Scholar]

- Lin, C.H.; Lu, M.C.; Yang, S.F.; Lee, M.Y. A Bayesian control chart for monitoring process variance. Appl. Sci. 2021, 11, 2729. [Google Scholar] [CrossRef]

- Ferrell, E.B. Control charts using midranges and medians. Ind. Qual. Control 1953, 9, 30–34. [Google Scholar]

- Bakir, S.T.; Reynolds, M.R.J. A nonparametric procedure for process control based on within-group ranking. Technometrics 1979, 21, 175–183. [Google Scholar] [CrossRef]

- Amin, R.W.; Reynolds, M.R.J.; Bakir, S.T. Nonparametric quality control charts based on the sign statistic. Commun. Stat. Theory Methods 1995, 24, 1597–1624. [Google Scholar] [CrossRef]

- Chakraborti, S.; Laan, P.V.D.; Bakir, S.T. Nonparametric control charts: An overview and some results. J. Qual. Technol. 2001, 33, 304–315. [Google Scholar] [CrossRef]

- Altukife, F.S. Nonparametric control charts based on sum of ranks. Pakistan J. Stat. 2003, 19, 291–300. [Google Scholar]

- Altukife, F.S. A new nonparametric control charts based on the observations exceeding the grand median. Pakistan J. Stat. 2003, 19, 343–351. [Google Scholar]

- Bakir, S.T. A distribution-free Shewhart quality control chart based on signed-ranks. Qual. Eng. 2004, 16, 613–623. [Google Scholar] [CrossRef]

- Bakir, S.T. Distribution free quality control charts based in sign rank like statistics. Commun. Stat. Theory Methods 2006, 35, 743–757. [Google Scholar] [CrossRef]

- Chakraborti, S.; Eryilmaz, S. A non-parametric Shewhart type sign rank control chart based on runs. Commun. Stat. Simul. Comput. 2007, 36, 335–356. [Google Scholar] [CrossRef]

- Chakraborti, S.; Graham, M. Nonparametric Control Charts. Encyclopedia of Quality and Reliability; John Wiley & Sons: New York, NY, USA, 2007. [Google Scholar]

- Li, S.; Tang, L.; Ng, S. Nonparametric CUSUM and EWMA control charts for detecting mean shifts. J. Qual. Technol. 2010, 42, 209–226. [Google Scholar] [CrossRef]

- Graham, M.A.; Chakraborti, S.; Human, S.W. A nonparametric EWMA sign chart for location based on individual measurements. Qual. Eng. 2011, 23, 227–241. [Google Scholar] [CrossRef]

- Graham, M.A.; Chakraborti, S.; Human, S.W. A nonparametric exponentially weighted moving average signed-rank chart for monitoring location. Comput. Stat. Data Anal. 2011, 55, 2490–2503. [Google Scholar] [CrossRef]

- Zou, C.; Tsung, F. Likelihood ratio-based distribution-free EWMA control charts. J. Qual. Technol. 2010, 42, 174–196. [Google Scholar] [CrossRef]

- Jones-Farmer, L.; Champ, C. Distribution-free phase I control chart for subgroup scale. J. Qual. Technol. 2010, 42, 373–387. [Google Scholar] [CrossRef]

- Zombade, D.M.; Ghute, V.B. Nonparametric control chart for variability using runs rules. Experiment 2014, 24, 1683–1691. [Google Scholar]

- Yang, S.F.; Arnold, B.C. A new approach for monitoring process variance. J. Stat. Comput. Simul. 2016, 86, 2749–2765. [Google Scholar] [CrossRef]

- Maravelakis, P.; Panaretos, J.; Psarakis, S. EWMA chart and measurement error. J. Appl. Stat. 2004, 31, 445–455. [Google Scholar] [CrossRef]

- Tran, K.D.; Nguyen, H.D.; Nguyen, T.H.; Tran, K.P. Design of a variable sampling interval exponentially weighted moving ave age median control chart in presence of measurement error. Qual. Reliab. Eng. Int. 2021, 37, 374–390. [Google Scholar] [CrossRef]

- Noor-ul-Amin, M.; Riaz, A.; Safeer, A. Exponentially weighted moving average control chart using auxiliary variable with measurement error. Commun. Stat. Simul. Comput. 2020, 51, 1002–1014. [Google Scholar] [CrossRef]

- Chen, L.P.; Yang, S.F. A new p-control chart with measurement error correction. Qual. Reliab. Eng. Int. 2023, 39, 81–98. [Google Scholar] [CrossRef]

- Yang, S.F.; Chen, L.P.; Lin, C.K. Adjustment of measurement error effects on dispersion control chart with distribution-free quality variable. Sustainability 2023, 15, 4337. [Google Scholar] [CrossRef]

- McCann, M.; Johnston, A. UCI Machine Learning Repository. Available online: https://archive.ics.uci.edu/ml/datasets/SECOM (accessed on 1 December 2021).

| (α0, β0) | E0(p) | E0(p*) | n = 2 | n = 5 | n = 15 | n = 25 |

|---|---|---|---|---|---|---|

| (1, 1) | 0.5000 | 0.4900 | (2.6409, 2.6347) | (2.6452, 2.6544) | (2.6378, 2.6519) | (2.6327, 2.6633) |

| (1, 2) | 0.3333 | 0.3400 | (2.8344, 2.4322) | (2.8389, 2.4727) | (2.8441, 2.4716) | (2.8467, 2.4712) |

| (1, 3) | 0.2500 | 0.2650 | (2.9211, 2.3265) | (2.9274, 2.3981) | (2.9371, 2.4091) | (2.9481, 2.3925) |

| (1, 4) | 0.2000 | 0.2200 | (3.0066, 2.2305) | (2.9964, 2.3466) | (2.9985, 2.3632) | (3.0096, 2.3516) |

| (1, 5) | 0.1667 | 0.1900 | (3.0730, 2.1540) | (3.0345, 2.3173) | (3.0383, 2.3391) | (3.0493, 2.3301) |

| (1, 6) | 0.1429 | 0.1686 | (3.1232, 2.0949) | (3.0715, 2.2929) | (3.0630, 2.3224) | (3.0736, 2.3211) |

| (1, 7) | 0.1250 | 0.1525 | (3.1722, 2.0531) | (3.0904, 2.2673) | (3.0783, 2.3170) | (3.0978, 2.3047) |

| (1, 8) | 0.1111 | 0.1400 | (3.2013, 2.0041) | (3.1117, 2.2476) | (3.0961, 2.2987) | (3.1092, 2.2997) |

| (1, 9) | 0.1000 | 0.1300 | (3.2305, 1.9608) | (3.1202, 2.2306) | (3.1034, 2.2993) | (3.1148, 2.3010) |

| (α0, β0) | E0(p) | E0(p*) | n = 2 | n = 5 | n = 15 | n = 25 |

|---|---|---|---|---|---|---|

| (1, 1) | 0.5000 | 0.4750 | (2.6725, 2.6295) | (2.6776, 2.6542) | (2.6637, 2.6557) | (2.6581, 2.6630) |

| (1, 2) | 0.3333 | 0.3633 | (2.8017, 2.4913) | (2.8013, 2.5323) | (2.8188, 2.5356) | (2.8277, 2.5129) |

| (1, 3) | 0.2500 | 0.3075 | (2.8355, 2.4257) | (2.8611, 2.4983) | (2.8825, 2.4956) | (2.9026, 2.4670) |

| (1, 4) | 0.2000 | 0.2740 | (2.8868, 2.3664) | (2.8818, 2.4784) | (2.9103, 2.4855) | (2.9365, 2.4583) |

| (1, 5) | 0.1667 | 0.2517 | (2.9229, 2.3364) | (2.8960, 2.4711) | (2.9218, 2.4845) | (2.9482, 2.4607) |

| (1, 6) | 0.1429 | 0.2357 | (2.9495, 2.3062) | (2.9126, 2.4600) | (2.9241, 2.4904) | (2.9522, 2.4664) |

| (1, 7) | 0.1250 | 0.2238 | (2.9712, 2.2825) | (2.9193, 2.4520) | (2.9252, 2.4908) | (2.9490, 2.4772) |

| (1, 8) | 0.1111 | 0.2144 | (2.9867, 2.2617) | (2.9310, 2.4551) | (2.9162, 2.4917) | (2.9431, 2.4796) |

| (1, 9) | 0.1000 | 0.2070 | (2.9992, 2.2460) | (2.9348, 2.4401) | (2.9164, 2.4994) | (2.9315, 2.5042) |

| (α1, β1) | E1(p) | E1(p*) | n = 2 | n = 5 | n = 15 | n = 25 |

|---|---|---|---|---|---|---|

| (9, 1) | 0.9000 | 0.8500 | 4.57 | 3.27 | 2.37 | 2.21 |

| (4, 1) | 0.8000 | 0.7600 | 6.40 | 4.44 | 3.24 | 3.00 |

| (3, 1) | 0.7500 | 0.7150 | 7.73 | 5.24 | 3.85 | 3.57 |

| (2, 1) | 0.6666 | 0.6399 | 11.21 | 7.56 | 5.56 | 5.16 |

| (4, 3) | 0.5714 | 0.5543 | 20.94 | 13.99 | 10.38 | 9.65 |

| (1, 1) | 0.5000 | 0.4900 | 35.91 | 23.13 | 16.78 | 15.39 |

| (3, 4) | 0.4286 | 0.4257 | 111.21 | 90.28 | 80.03 | 77.55 |

| (1, 2) IC | 0.3333 IC | 0.3400 IC | 373.60 | 372.26 | 371.85 | 371.61 |

| (1, 3) | 0.2500 | 0.2650 | 121.47 | 84.86 | 62.27 | 57.34 |

| (1, 4) | 0.2000 | 0.2200 | 55.38 | 35.53 | 24.93 | 23.03 |

| (1, 5) | 0.1667 | 0.1900 | 35.68 | 22.79 | 16.33 | 15.02 |

| (1, 6) | 0.1429 | 0.1686 | 28.08 | 17.80 | 12.70 | 11.70 |

| (1, 9) | 0.1000 | 0.1300 | 19.07 | 12.07 | 8.66 | 7.95 |

| (α1, β1) | E1(p) | E1(p*) | n = 2 | n = 5 | n = 15 | n = 25 |

|---|---|---|---|---|---|---|

| (9, 1) | 0.9000 | 0.7430 | 7.14 | 4.14 | 2.67 | 2.37 |

| (4, 1) | 0.8000 | 0.6760 | 9.96 | 5.80 | 3.71 | 3.30 |

| (3, 1) | 0.7500 | 0.6425 | 12.14 | 7.01 | 4.42 | 3.95 |

| (2, 1) | 0.6666 | 0.5866 | 17.69 | 10.03 | 6.45 | 5.67 |

| (4, 3) | 0.5714 | 0.5228 | 33.50 | 19.21 | 12.31 | 10.83 |

| (1, 1) | 0.5000 | 0.4750 | 57.69 | 31.62 | 19.53 | 17.13 |

| (3, 4) | 0.4286 | 0.4272 | 152.04 | 112.50 | 87.94 | 83.05 |

| (1, 2) IC | 0.3333 IC | 0.3633 IC | 371.38 | 371.23 | 370.99 | 373.48 |

| (1, 3) | 0.2500 | 0.3075 | 171.99 | 117.98 | 78.29 | 68.91 |

| (1, 4) | 0.2000 | 0.2740 | 89.69 | 54.11 | 32.20 | 27.60 |

| (1, 5) | 0.1667 | 0.2517 | 61.27 | 34.81 | 20.83 | 17.80 |

| (1, 6) | 0.1429 | 0.2357 | 47.73 | 27.13 | 16.18 | 13.79 |

| (1, 9) | 0.1000 | 0.2070 | 32.81 | 18.29 | 10.97 | 9.44 |

| (α0, β0) | E0(p)/E0(p**) | E0(p*) | n = 2 | n = 5 | n = 15 | n = 25 |

|---|---|---|---|---|---|---|

| (1, 1) | 0.5000 | 0.4900 | (2.6409, 2.6347) | (2.6452, 2.6544) | (2.6378, 2.6519) | (2.6327, 2.6633) |

| (1, 2) | 0.3333 | 0.3400 | (2.8344, 2.4322) | (2.8389, 2.4727) | (2.8441, 2.4716) | (2.8467, 2.4712) |

| (1, 3) | 0.2500 | 0.2650 | (2.9211, 2.3265) | (2.9274, 2.3981) | (2.9371, 2.4091) | (2.9481, 2.3925) |

| (1, 4) | 0.2000 | 0.2200 | (3.0066, 2.2305) | (2.9964, 2.3466) | (2.9985, 2.3632) | (3.0096, 2.3516) |

| (1, 5) | 0.1667 | 0.1900 | (3.0730, 2.1540) | (3.0345, 2.3173) | (3.0383, 2.3391) | (3.0493, 2.3301) |

| (1, 6) | 0.1429 | 0.1686 | (3.1232, 2.0949) | (3.0715, 2.2929) | (3.0630, 2.3224) | (3.0736, 2.3211) |

| (1, 7) | 0.1250 | 0.1525 | (3.1722, 2.0531) | (3.0904, 2.2673) | (3.0783, 2.3170) | (3.0978, 2.3047) |

| (1, 8) | 0.1111 | 0.1400 | (3.2013, 2.0041) | (3.1117, 2.2476) | (3.0961, 2.2987) | (3.1092, 2.2997) |

| (1, 9) | 0.1000 | 0.1300 | (3.2305, 1.9608) | (3.1202, 2.2306) | (3.1034, 2.2993) | (3.1148, 2.3010) |

| (α0, β0) | E0(p)/E0(p**) | E0(p*) | n = 2 | n = 5 | n = 15 | n = 25 |

|---|---|---|---|---|---|---|

| (1, 1) | 0.5000 | 0.4750 | (2.6725, 2.6295) | (2.6776, 2.6542) | (2.6637, 2.6557) | (2.6581, 2.6630) |

| (1, 2) | 0.3333 | 0.3633 | (2.8017, 2.4913) | (2.8013, 2.5323) | (2.8188, 2.5356) | (2.8277, 2.5129) |

| (1, 3) | 0.2500 | 0.3075 | (2.8355, 2.4257) | (2.8611, 2.4983) | (2.8825, 2.4956) | (2.9026, 2.4670) |

| (1, 4) | 0.2000 | 0.2740 | (2.8868, 2.3664) | (2.8818, 2.4784) | (2.9103, 2.4855) | (2.9365, 2.4583) |

| (1, 5) | 0.1667 | 0.2517 | (2.9229, 2.3364) | (2.8960, 2.4711) | (2.9218, 2.4845) | (2.9482, 2.4607) |

| (1, 6) | 0.1429 | 0.2357 | (2.9495, 2.3062) | (2.9126, 2.4600) | (2.9241, 2.4904) | (2.9522, 2.4664) |

| (1, 7) | 0.1250 | 0.2238 | (2.9712, 2.2825) | (2.9193, 2.4520) | (2.9252, 2.4908) | (2.9490, 2.4772) |

| (1, 8) | 0.1111 | 0.2144 | (2.9867, 2.2617) | (2.9310, 2.4551) | (2.9162, 2.4917) | (2.9431, 2.4796) |

| (1, 9) | 0.1000 | 0.2070 | (2.9992, 2.2460) | (2.9348, 2.4401) | (2.9164, 2.4994) | (2.9315, 2.5042) |

| (α1, β1) | E1(p)/E1(p**) | E1(p*) | n = 2 | n = 5 | n = 15 | n = 25 |

|---|---|---|---|---|---|---|

| (9, 1) | 0.9000 | 0.8500 | 4.57 | 3.27 | 2.37 | 2.21 |

| (4, 1) | 0.8000 | 0.7600 | 6.40 | 4.44 | 3.24 | 3.00 |

| (3, 1) | 0.7500 | 0.7150 | 7.73 | 5.24 | 3.85 | 3.57 |

| (2, 1) | 0.6666 | 0.6399 | 11.21 | 7.56 | 5.56 | 5.16 |

| (4, 3) | 0.5714 | 0.5543 | 20.94 | 13.99 | 10.38 | 9.65 |

| (1, 1) | 0.5000 | 0.4900 | 35.91 | 23.13 | 16.78 | 15.39 |

| (3, 4) | 0.4286 | 0.4257 | 111.21 | 90.28 | 80.03 | 77.55 |

| (1, 2) IC | 0.3333 IC | 0.3400 IC | 373.60 | 372.26 | 371.85 | 371.61 |

| (1, 3) | 0.2500 | 0.2650 | 121.47 | 84.86 | 62.27 | 57.34 |

| (1, 4) | 0.2000 | 0.2200 | 55.38 | 35.53 | 24.93 | 23.03 |

| (1, 5) | 0.1667 | 0.1900 | 35.68 | 22.79 | 16.33 | 15.02 |

| (1, 6) | 0.1429 | 0.1686 | 28.08 | 17.80 | 12.70 | 11.70 |

| (1, 9) | 0.1000 | 0.1300 | 19.07 | 12.07 | 8.66 | 7.95 |

| (α1, β1) | E1(p)/E1(p**) | E1(p*) | n = 2 | n = 5 | n = 15 | n = 25 |

|---|---|---|---|---|---|---|

| (9, 1) | 0.9000 | 0.7430 | 7.14 | 4.14 | 2.67 | 2.37 |

| (4, 1) | 0.8000 | 0.6760 | 9.96 | 5.80 | 3.71 | 3.30 |

| (3, 1) | 0.7500 | 0.6425 | 12.14 | 7.01 | 4.42 | 3.95 |

| (2, 1) | 0.6666 | 0.5866 | 17.69 | 10.03 | 6.45 | 5.67 |

| (4, 3) | 0.5714 | 0.5228 | 33.50 | 19.21 | 12.31 | 10.83 |

| (1, 1) | 0.5000 | 0.4750 | 57.69 | 31.62 | 19.53 | 17.13 |

| (3, 4) | 0.4286 | 0.4272 | 152.04 | 112.50 | 87.94 | 83.05 |

| (1, 2) IC | 0.3333 IC | 0.3633 IC | 371.38 | 371.23 | 370.99 | 373.48 |

| (1, 3) | 0.2500 | 0.3075 | 171.99 | 117.98 | 78.29 | 68.91 |

| (1, 4) | 0.2000 | 0.2740 | 89.69 | 54.11 | 32.20 | 27.60 |

| (1, 5) | 0.1667 | 0.2517 | 61.27 | 34.81 | 20.83 | 17.80 |

| (1, 6) | 0.1429 | 0.2357 | 47.73 | 27.13 | 16.18 | 13.79 |

| (1, 9) | 0.1000 | 0.2070 | 32.81 | 18.29 | 10.97 | 9.44 |

| Panel A. | (α0, β0) = (1, 3), E0(p) = 0.2500, and E0(p*) = 0.2650 | |||||

|---|---|---|---|---|---|---|

| n = 2 | n = 15 | |||||

| (α1, β1) | E1(p) | E1(p*) | The Existing Chart in Lin et al. [5] | The Error-Embedded/ Error-Corrected Charts | The Existing Chart in Lin et al. [5] | The Error-Embedded/ Error-Corrected Charts |

| (9, 1) | 0.9000 | 0.8500 | 2.84 | 2.92 | 1.67 | 1.41 |

| (3, 1) | 0.7500 | 0.7150 | 4.52 | 4.64 | 2.52 | 2.24 |

| (1, 1) | 0.5000 | 0.4900 | 14.26 | 15.45 | 7.03 | 6.66 |

| (1, 2) | 0.3333 | 0.3400 | 78.04 | 96.36 | 39.42 | 40.82 |

| (1, 3) IC | 0.2500 IC | 0.2650 IC | 376.48 | 370.81 | 536.30 | 370.69 |

| (1, 4) | 0.2000 | 0.2200 | 313.92 | 211.46 | 407.28 | 116.32 |

| (1, 5) | 0.1666 | 0.1899 | 155.05 | 106.38 | 111.64 | 45.82 |

| (1, 9) | 0.1000 | 0.1300 | 45.91 | 35.98 | 21.61 | 14.40 |

| Panel B. | (α0, β0) = (1, 4), E0(p) = 0.2000, and E0(p*) = 0.2200 | |||||

| n = 2 | n = 15 | |||||

| (α1, β1) | E1(p) | E1(p*) | The Existing Chart in Lin et al. [5] | The Error-Embedded/ Error-Corrected Charts | The Existing Chart in Lin et al. [5] | The Error-Embedded/ Error-Corrected Charts |

| (3, 1) | 0.7500 | 0.7150 | 4.13 | 4.27 | 1.79 | 1.77 |

| (1, 1) | 0.5000 | 0.4900 | 9.94 | 10.99 | 4.33 | 4.27 |

| (1, 2) | 0.3333 | 0.3400 | 33.03 | 41.77 | 14.01 | 15.42 |

| (1, 3) | 0.2500 | 0.2650 | 113.86 | 164.84 | 58.49 | 77.21 |

| (1, 4) IC | 0.2000 IC | 0.2200 IC | 335.12 | 370.88 | 407.68 | 370.45 |

| (1, 5) | 0.1666 | 0.1899 | 426.53 | 269.61 | 1040.31 | 170.40 |

| (1, 9) | 0.1000 | 0.1300 | 99.15 | 66.11 | 54.79 | 23.80 |

| (1, 19) | 0.0500 | 0.0850 | 38.45 | 30.01 | 16.68 | 10.63 |

| Panel A. | (α0, β0) = (1, 3), E0(p) = 0.2500, and E0(p*) = 0.3075 | |||||

|---|---|---|---|---|---|---|

| n = 2 | n = 15 | |||||

| (α1, β1) | E1(p) | E1(p*) | The Existing Chart in Lin et al. [5] | The Error-Embedded/ Error-Corrected Charts | The Existing Chart in Lin et al. [5] | The Error-Embedded/ Error-Corrected Charts |

| (9, 1) | 0.9000 | 0.7430 | 4.03 | 5.36 | 2.32 | 1.93 |

| (3, 1) | 0.7500 | 0.6425 | 6.22 | 8.27 | 3.34 | 2.84 |

| (1, 1) | 0.5000 | 0.4750 | 16.47 | 26.39 | 8.39 | 8.30 |

| (1, 2) | 0.3333 | 0.3633 | 59.37 | 143.42 | 32.87 | 50.85 |

| (1, 3) IC | 0.2500 IC | 0.3075 IC | 184.84 | 370.61 | 223.60 | 370.67 |

| (1, 4) | 0.2000 | 0.2740 | 449.28 | 269.21 | 2862.30 | 146.99 |

| (1, 5) | 0.1666 | 0.2516 | 615.74 | 162.35 | 14995.95 | 63.28 |

| (1, 9) | 0.1000 | 0.2070 | 273.29 | 67.23 | 1769.88 | 19.84 |

| Panel B. | (α0, β0) = (1, 4), E0(p) = 0.2000, and E0(p*) = 0.2740 | |||||

| n = 2 | n = 15 | |||||

| (α1, β1) | E1(p) | E1(p*) | The Existing Chart in Lin et al. [5] | The Error-Embedded/ Error-Corrected Charts | The Existing Chart in Lin et al. [5] | The Error-Embedded/ Error-Corrected Charts |

| (3, 1) | 0.7500 | 0.6425 | 5.30 | 6.19 | 2.26 | 2.02 |

| (1, 1) | 0.5000 | 0.4750 | 10.98 | 17.73 | 4.84 | 5.12 |

| (1, 2) | 0.3333 | 0.3633 | 26.68 | 69.44 | 12.02 | 19.33 |

| (1, 3) | 0.2500 | 0.3075 | 56.31 | 222.62 | 29.07 | 94.84 |

| (1, 4) IC | 0.2000 IC | 0.2740 IC | 111.09 | 370.35 | 81.91 | 370.67 |

| (1, 5) | 0.1666 | 0.2516 | 193.40 | 309.54 | 267.60 | 216.23 |

| (1, 9) | 0.1000 | 0.2070 | 581.26 | 117.85 | 16623.06 | 35.94 |

| (1, 19) | 0.0500 | 0.1735 | 388.81 | 58.65 | 6526.48 | 15.87 |

| Panel A. | n = 2 | ||||

|---|---|---|---|---|---|

| Case 1 | Case 2 | Case 3 | Case 4 | ||

| (α1, β1) | E1(p) | Data Without ME: Using Existing Chart in Lin et al. [5] | Data Without ME: Using Error-Corrected Chart π11 = 1, π10 = 0 | Data with ME: Using Error-Corrected Chart π11 = 0.94, π10 = 0.04 | Data with ME: Using Error-Corrected Chart π11 = 0.81, π10 = 0.14 |

| (9, 1) | 0.9000 | 2.50 | 2.50 | 2.92 | 5.36 |

| (3, 1) | 0.7500 | 3.92 | 3.92 | 4.64 | 8.27 |

| (1, 1) | 0.5000 | 13.01 | 13.00 | 15.45 | 26.39 |

| (1, 2) | 0.3333 | 81.76 | 81.65 | 96.36 | 143.42 |

| (1, 3) IC | 0.2500 IC | 370.24 | 370.90 | 370.81 | 370.61 |

| (1, 4) | 0.2000 | 177.71 | 178.22 | 211.46 | 269.21 |

| (1, 5) | 0.1666 | 86.05 | 86.23 | 106.38 | 162.35 |

| (1, 9) | 0.1000 | 28.69 | 28.73 | 35.98 | 67.23 |

| Panel B. | n = 15 | ||||

| Case 1 | Case 2 | Case 3 | Case 4 | ||

| (α1, β1) | E1(p) | Data Without ME: Using Existing Chart in Lin et al. [5] | Data Without ME: Using Error-Corrected Chart π11 = 1, π10 = 0 | Data with ME: Using Error-Corrected Chart π11 = 0.94, π10 = 0.04 | Data with ME: Using Error-Corrected Chart π11 = 0.81, π10 = 0.14 |

| (9, 1) | 0.9000 | 1.42 | 1.40 | 1.41 | 1.93 |

| (3, 1) | 0.7500 | 2.20 | 2.21 | 2.24 | 2.84 |

| (1, 1) | 0.5000 | 6.43 | 6.45 | 6.66 | 8.30 |

| (1, 2) | 0.3333 | 39.48 | 38.57 | 40.82 | 50.85 |

| (1, 3) IC | 0.2500 IC | 370.81 | 370.47 | 370.69 | 370.67 |

| (1, 4) | 0.2000 | 102.12 | 104.61 | 116.32 | 146.99 |

| (1, 5) | 0.1666 | 40.95 | 40.90 | 45.82 | 63.28 |

| (1, 9) | 0.1000 | 12.69 | 12.82 | 14.40 | 19.84 |

| t | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.36 | 0.81 | 4.91 | 5.60 | 2.97 | 6.10 | 11.52 | 1.42 | 1.05 | 3.32 | 1.5020 | 1.4327 |

| 2 | 3.66 | 13.59 | 5.26 | 3.21 | 32.18 | 3.30 | 2.91 | 1.52 | 2.54 | 7.54 | 1.5518 | 1.4870 |

| 3 | 1.79 | 3.87 | 10.68 | 30.40 | 0.13 | 8.35 | 5.11 | 2.66 | 9.21 | 3.99 | 1.5966 | 1.5359 |

| 4 | 16.63 | 8.84 | 8.34 | 3.48 | 7.49 | 1.86 | 1.25 | 6.06 | 8.27 | 7.10 | 1.5369 | 1.4708 |

| 5 | 0.44 | 9.67 | 0.96 | 1.40 | 2.36 | 0.38 | 8.92 | 5.42 | 11.88 | 6.44 | 1.4832 | 1.4122 |

| 6 | 4.34 | 8.90 | 11.91 | 3.48 | 19.54 | 1.15 | 7.90 | 6.10 | 7.77 | 0.01 | 1.6349 | 1.5777 |

| 7 | 15.03 | 7.20 | 4.39 | 5.87 | 9.96 | 2.57 | 1.87 | 0.98 | 4.31 | 14.17 | 1.6714 | 1.6175 |

| 8 | 14.06 | 0.40 | 3.20 | 11.18 | 10.01 | 4.38 | 10.48 | 1.98 | 10.85 | 1.25 | 1.9043 | 1.8715 |

| 9 | 0.07 | 12.71 | 2.52 | 7.46 | 1.70 | 3.64 | 4.13 | 2.32 | 3.54 | 3.48 | 1.8139 | 1.7729 |

| 10 | 12.90 | 18.36 | 2.90 | 3.14 | 0.95 | 12.68 | 4.23 | 5.92 | 2.42 | 6.92 | 1.7325 | 1.6841 |

| 11 | 7.53 | 1.33 | 0.92 | 0.45 | 3.62 | 0.72 | 0.38 | 3.47 | 0.40 | 2.63 | 1.5592 | 1.4951 |

| 12 | 5.63 | 6.49 | 3.62 | 2.70 | 3.87 | 10.79 | 1.75 | 5.57 | 0.37 | 4.10 | 1.4033 | 1.3250 |

| 13 | 3.00 | 1.57 | 1.20 | 2.61 | 18.73 | 10.89 | 18.33 | 3.12 | 3.18 | 6.28 | 1.4630 | 1.3901 |

| 14 | 1.53 | 1.61 | 0.13 | 11.15 | 8.82 | 3.77 | 4.60 | 1.95 | 1.79 | 1.87 | 1.4167 | 1.3396 |

| 15 | 21.51 | 0.57 | 8.72 | 3.29 | 6.92 | 3.33 | 3.74 | 6.28 | 1.39 | 12.86 | 1.4750 | 1.4033 |

| t | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 3.74 | 0.10 | 1.15 | 6.89 | 5.47 | 0.31 | 1.66 | 1.01 | 2.63 | 0.70 | 0.9168 | 0.7944 |

| 2 | 0.73 | 1.56 | 1.22 | 0.82 | 0.46 | 3.24 | 4.14 | 0.13 | 2.43 | 0.13 | 0.8251 | 0.6944 |

| 3 | 1.32 | 0.21 | 3.92 | 0.22 | 0.05 | 0.88 | 0.67 | 0.88 | 3.62 | 2.93 | 0.7426 | 0.6044 |

| 4 | 1.12 | 0.16 | 1.55 | 1.31 | 0.65 | 6.01 | 4.70 | 1.57 | 3.84 | 4.75 | 0.6684 | 0.5234 |

| 5 | 2.68 | 2.46 | 0.06 | 1.92 | 3.16 | 2.00 | 2.27 | 1.45 | 2.14 | 0.23 | 0.6015 | 0.4505 |

| 6 | 1.24 | 3.80 | 0.39 | 0.60 | 1.69 | 2.05 | 0.58 | 0.99 | 6.93 | 0.72 | 0.5414 | 0.3849 |

| 7 | 4.93 | 2.04 | 2.94 | 0.85 | 0.01 | 0.91 | 2.61 | 2.90 | 1.48 | 2.30 | 0.4872 | 0.3258 |

| 8 | 4.98 | 0.59 | 1.51 | 4.14 | 4.16 | 1.56 | 1.41 | 0.76 | 0.67 | 0.25 | 0.4385 | 0.2727 |

| 9 | 1.12 | 0.76 | 0.79 | 0.92 | 2.17 | 2.74 | 1.75 | 2.98 | 1.76 | 0.46 | 0.3947 | 0.2249 |

| 10 | 4.62 | 0.10 | 5.46 | 2.79 | 1.91 | 2.35 | 0.44 | 1.87 | 7.06 | 2.22 | 0.3552 | 0.1818 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, M.-C.; Yang, S.-F. Designs of Bayesian EWMA Variability Control Charts in the Presence of Measurement Error. Processes 2025, 13, 3371. https://doi.org/10.3390/pr13103371

Lu M-C, Yang S-F. Designs of Bayesian EWMA Variability Control Charts in the Presence of Measurement Error. Processes. 2025; 13(10):3371. https://doi.org/10.3390/pr13103371

Chicago/Turabian StyleLu, Ming-Che, and Su-Fen Yang. 2025. "Designs of Bayesian EWMA Variability Control Charts in the Presence of Measurement Error" Processes 13, no. 10: 3371. https://doi.org/10.3390/pr13103371

APA StyleLu, M.-C., & Yang, S.-F. (2025). Designs of Bayesian EWMA Variability Control Charts in the Presence of Measurement Error. Processes, 13(10), 3371. https://doi.org/10.3390/pr13103371