Numerical Simulation Study on Volume Fracturing of Shale Oil Reservoirs in Y Block of Ordos Basin, China

Abstract

1. Introduction

2. Cohesive Bonding Unit Simulation Method

2.1. Linear Elastic Traction Separation Behavior

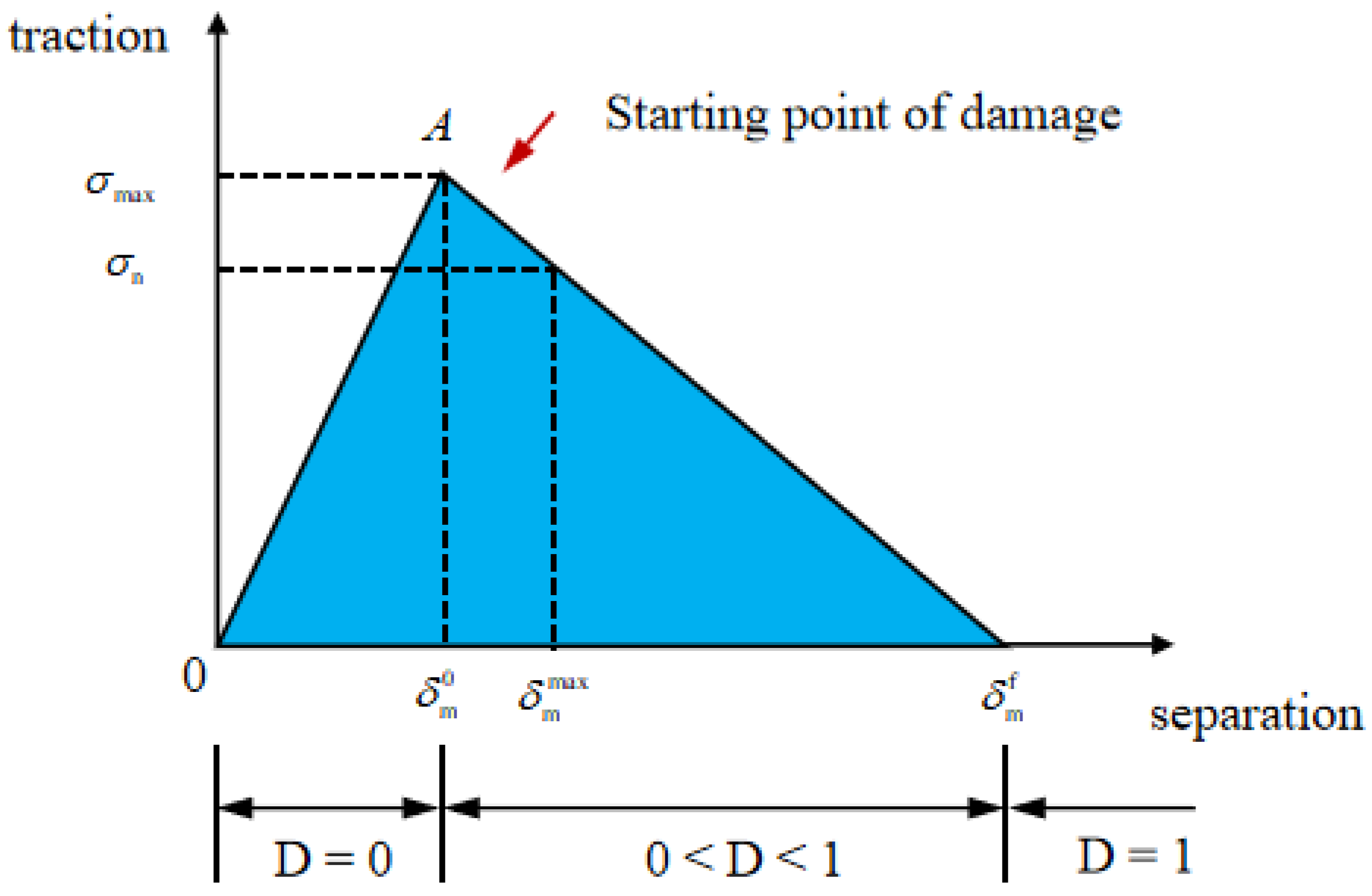

2.2. Damage Model of Cohesive Bonding Unit

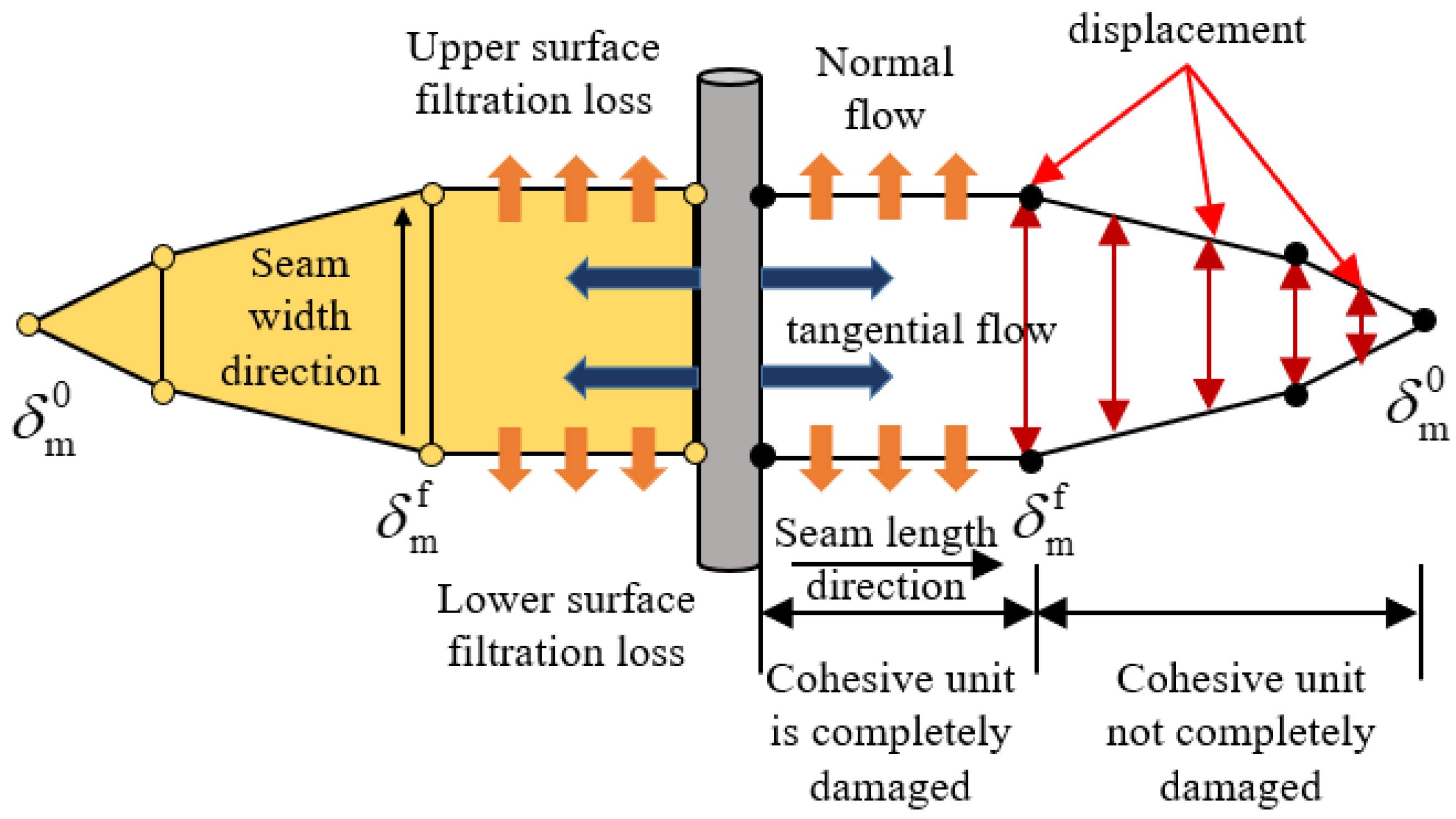

2.3. The Constitutive Response of Fluid Within the Gaps of Cohesive Bonding Units

3. Hydraulic Fracturing Simulation of Fractured Formations Based on Cohesive Unit Method

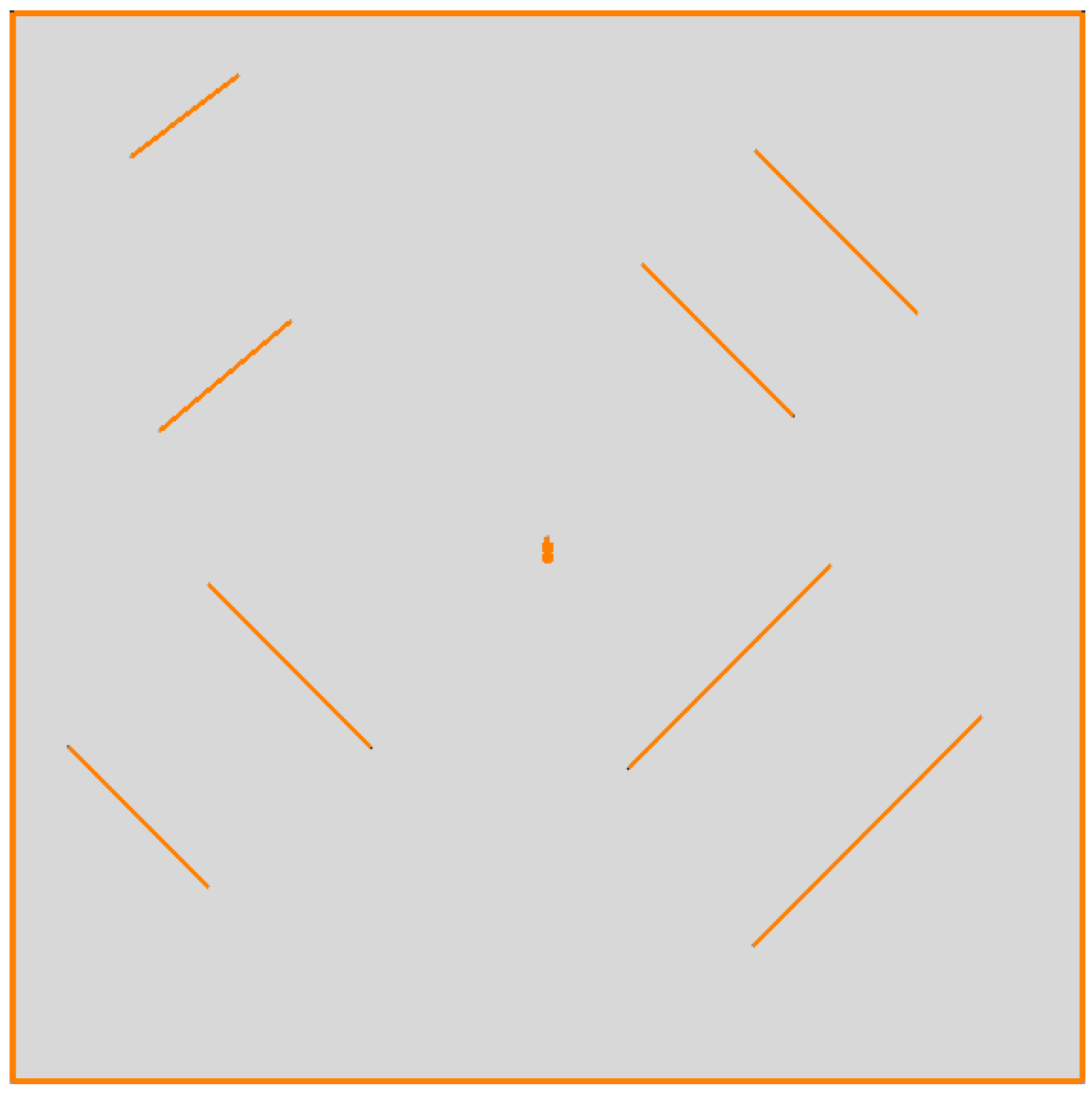

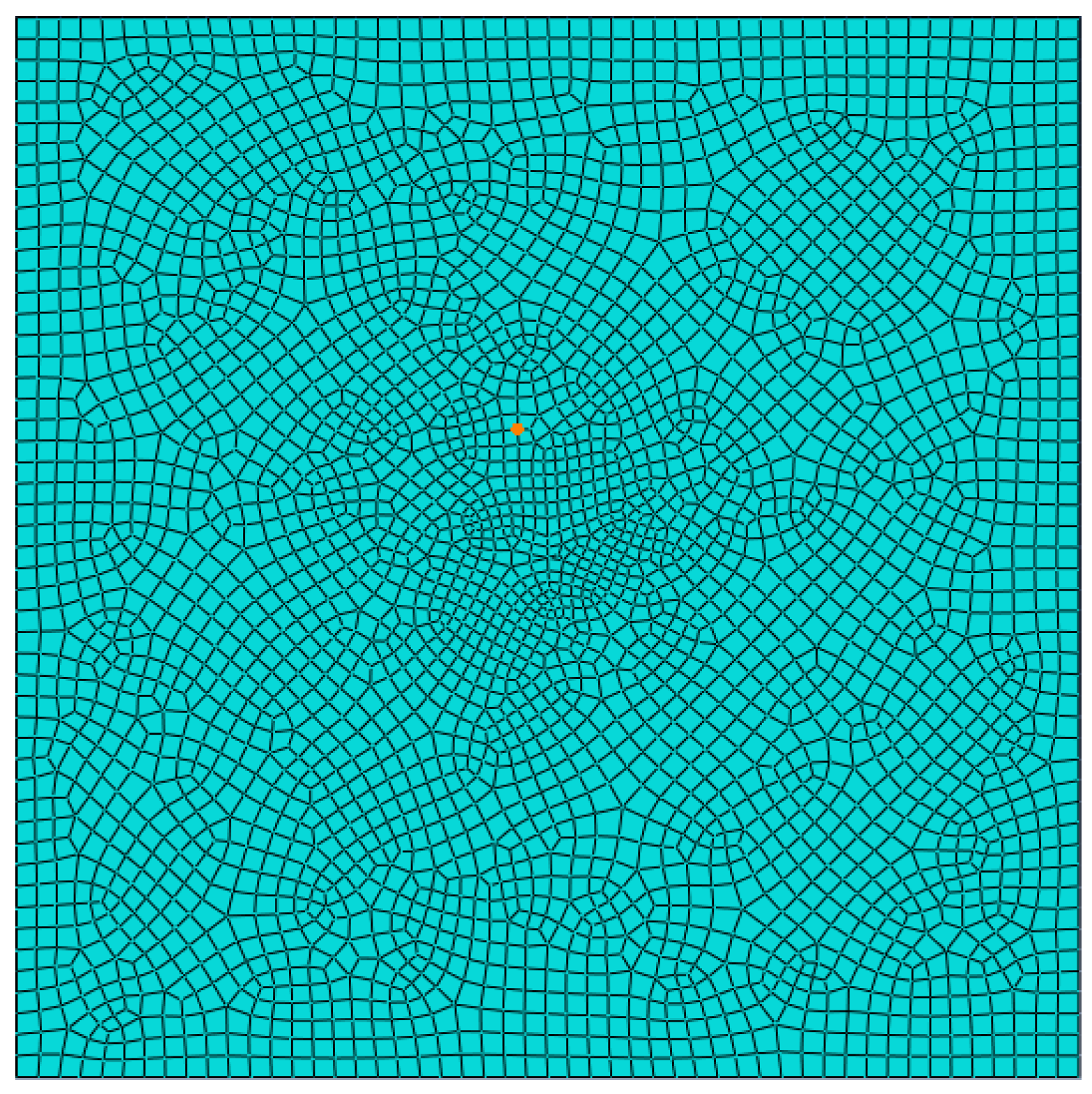

3.1. Establishment of a Model for the Formation Law of Volume Fracturing Crack Network

3.2. The Influence of Different Geostress Differences on the Initiation and Propagation of Cracks

- (1)

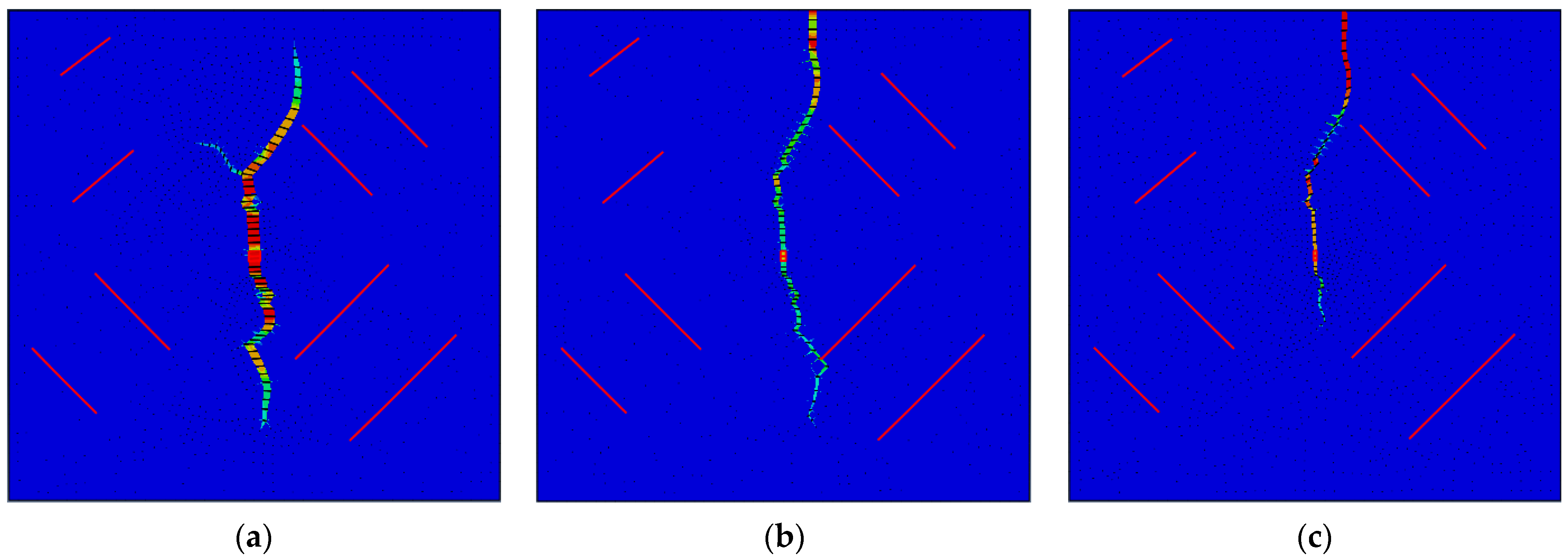

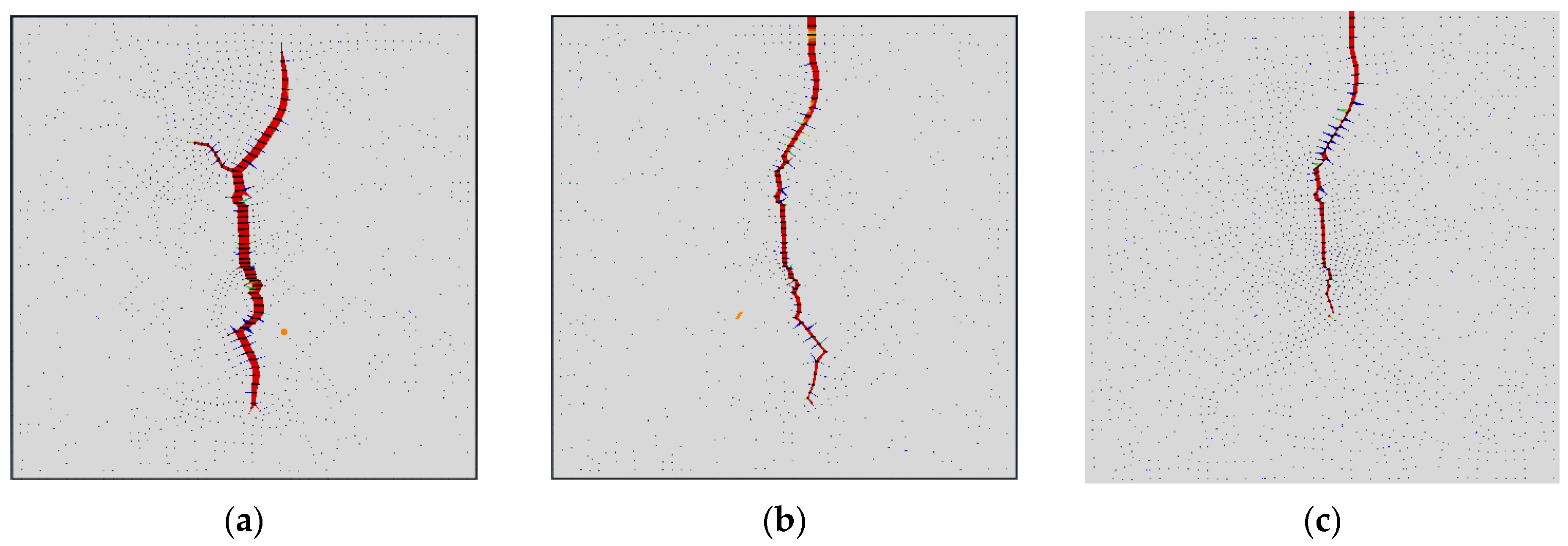

- The influence of natural crack location on crack direction

- (2)

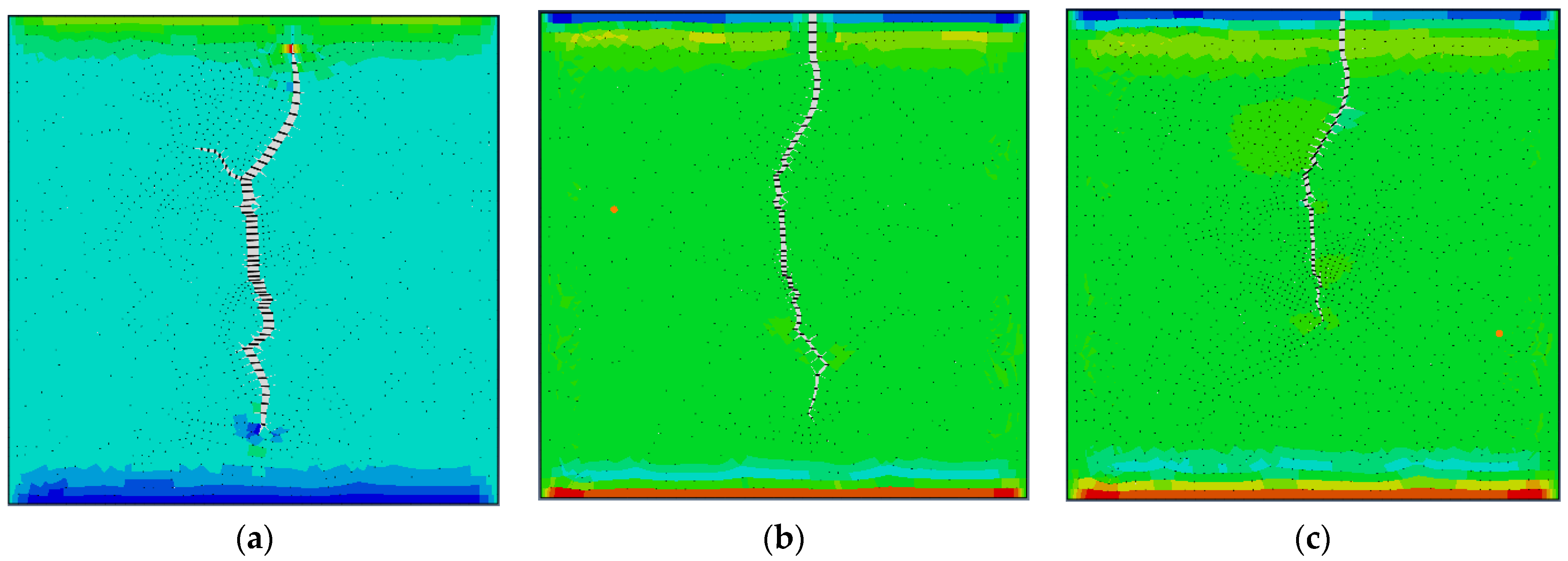

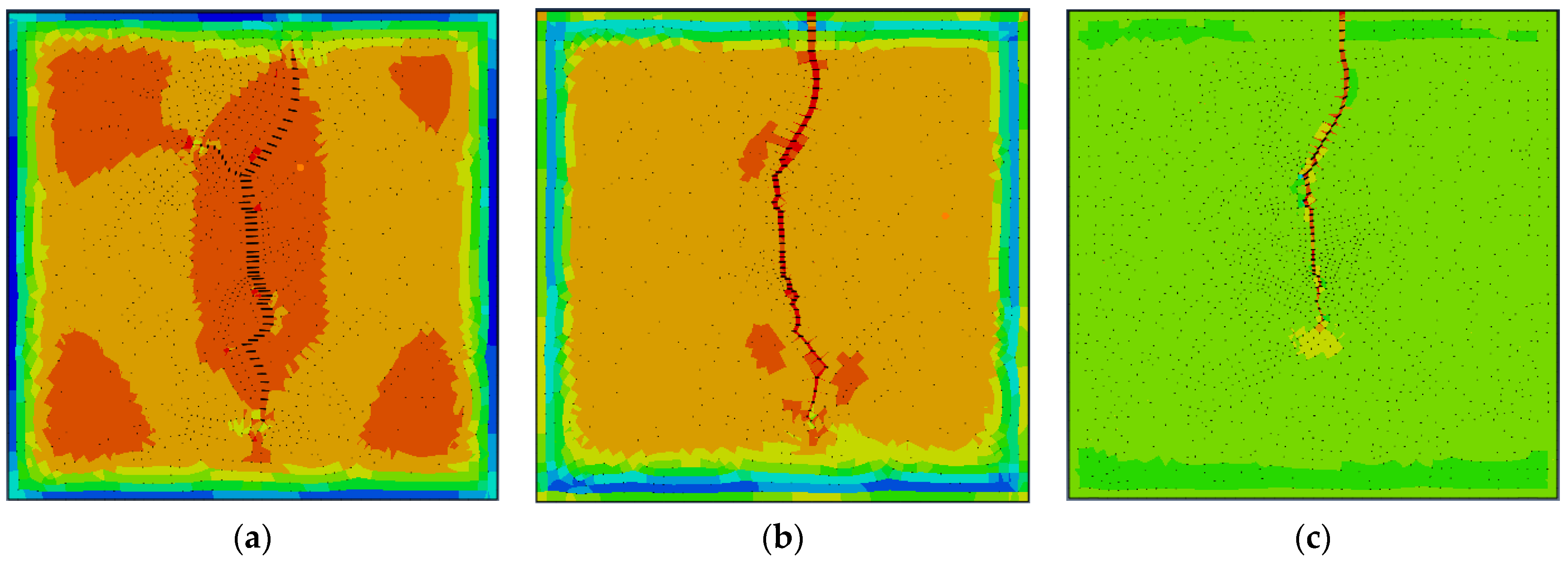

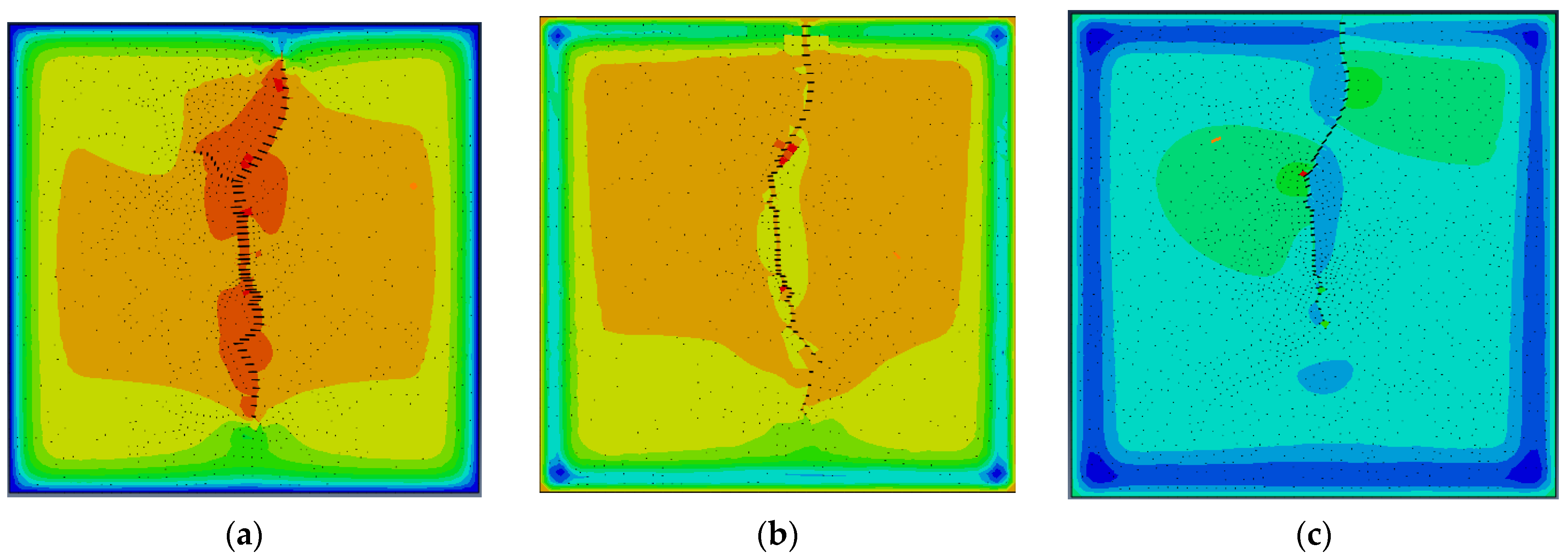

- Effective velocity of pore fluid under different geostress differences (FLVEL)

- (3)

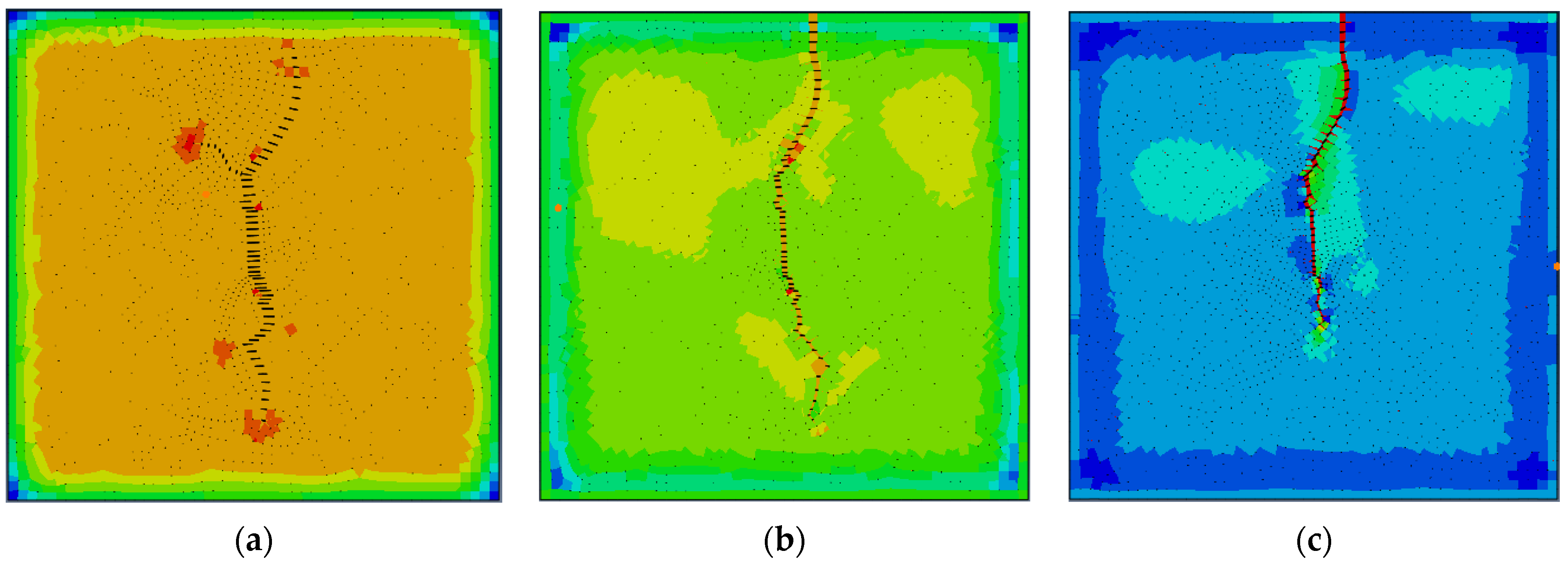

- Distribution of maximum and minimum principal stresses under different geostress differences

- (4)

- Distribution of Fracture Openness (PFOPEN) Under Different Ground Stress Differences

- (5)

- Distribution of Pore Pressure (POR) Results Under Different Ground Stress Differences

- (6)

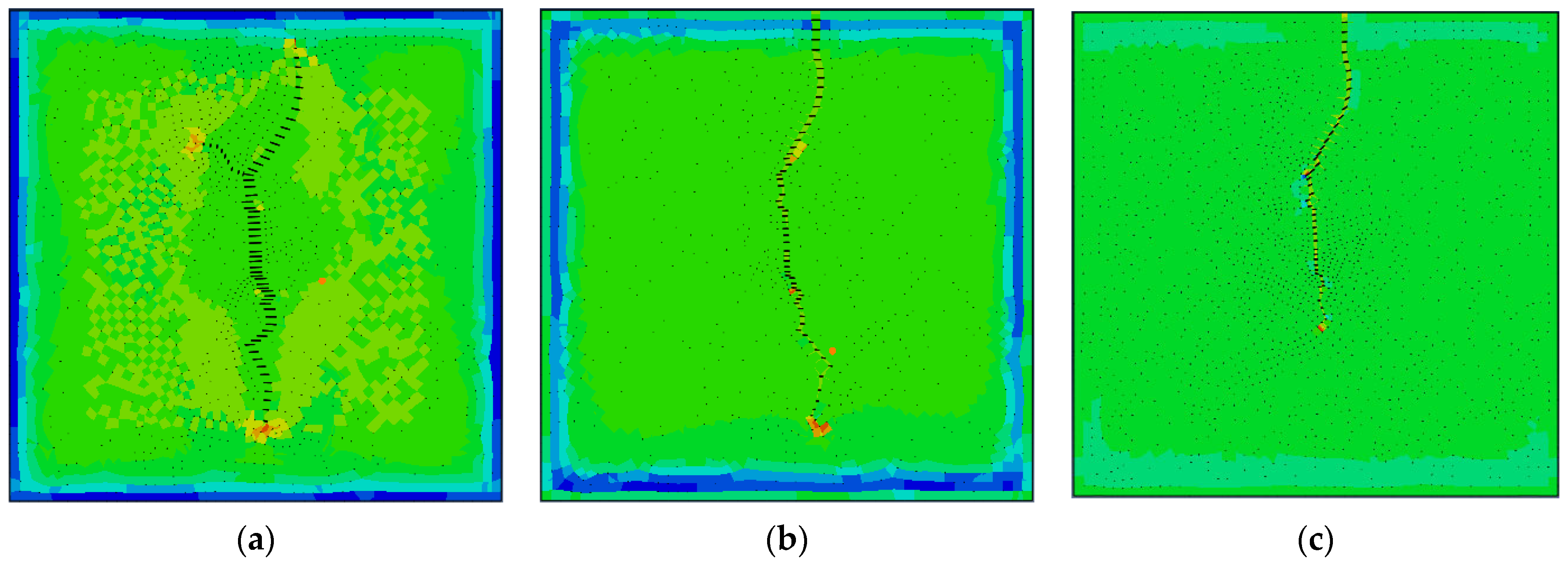

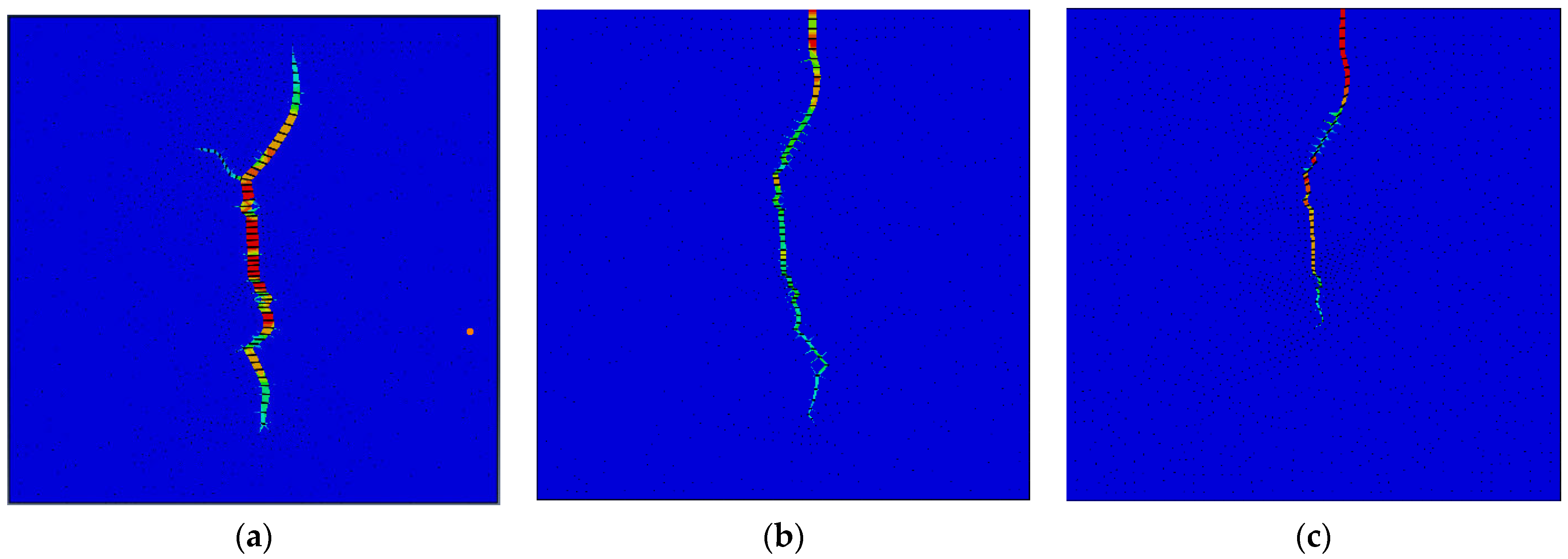

- Stiffness Reduction Rate (SDEG) Under Different Ground Stress Differences

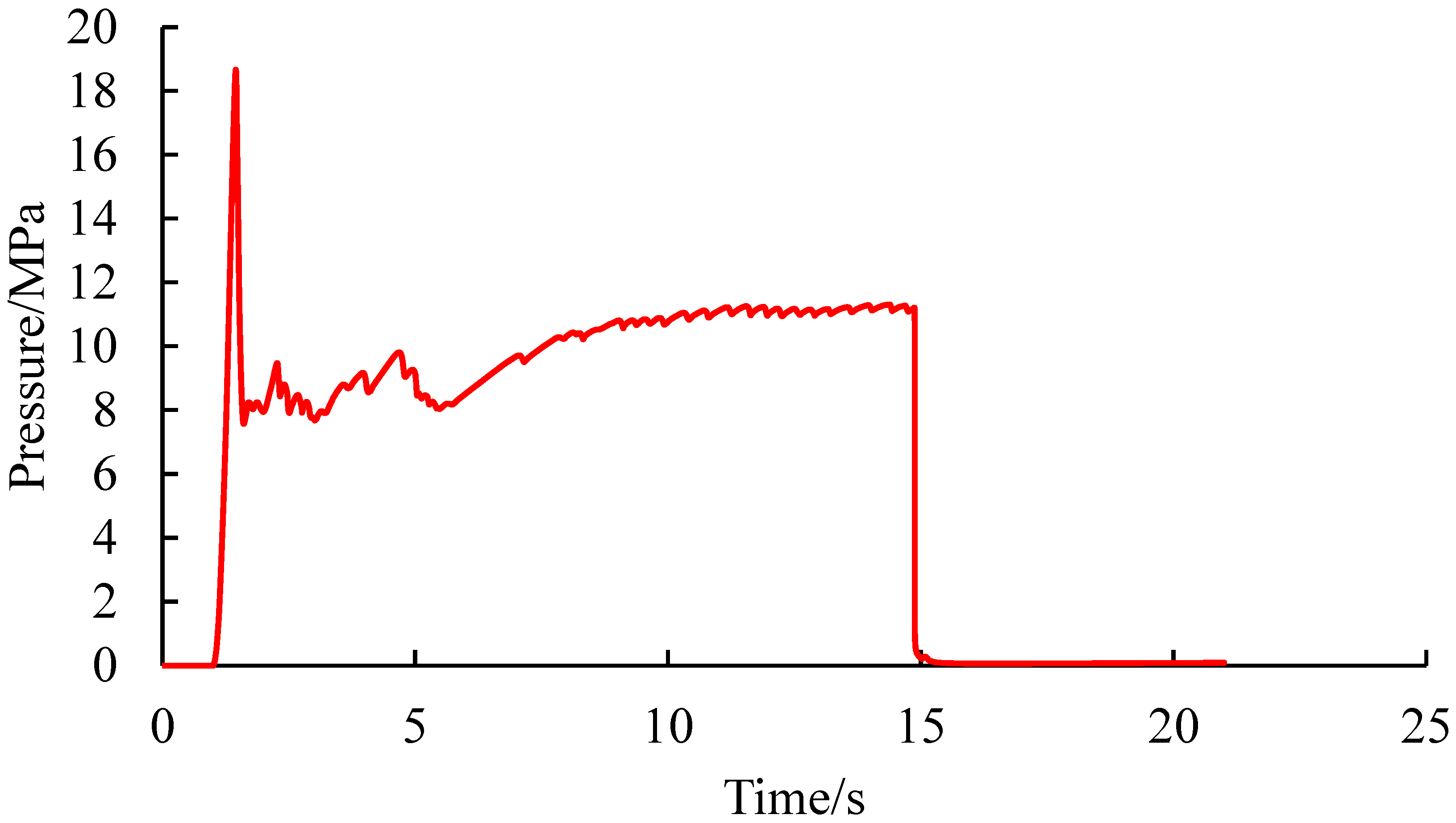

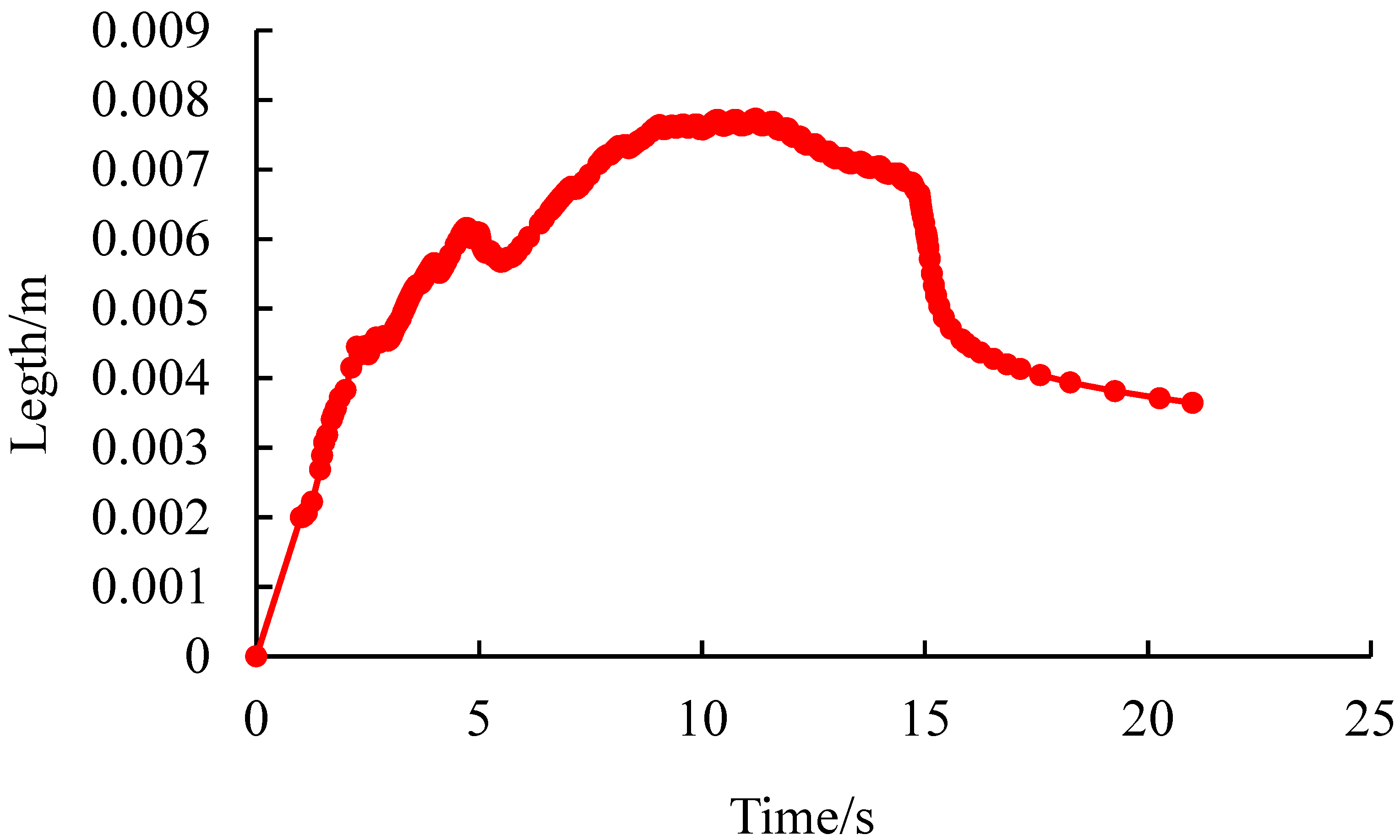

3.3. Quantitative Characterization of Pore Pressure Changes and Crack Width at Injection Points Under Different Geostress Differences

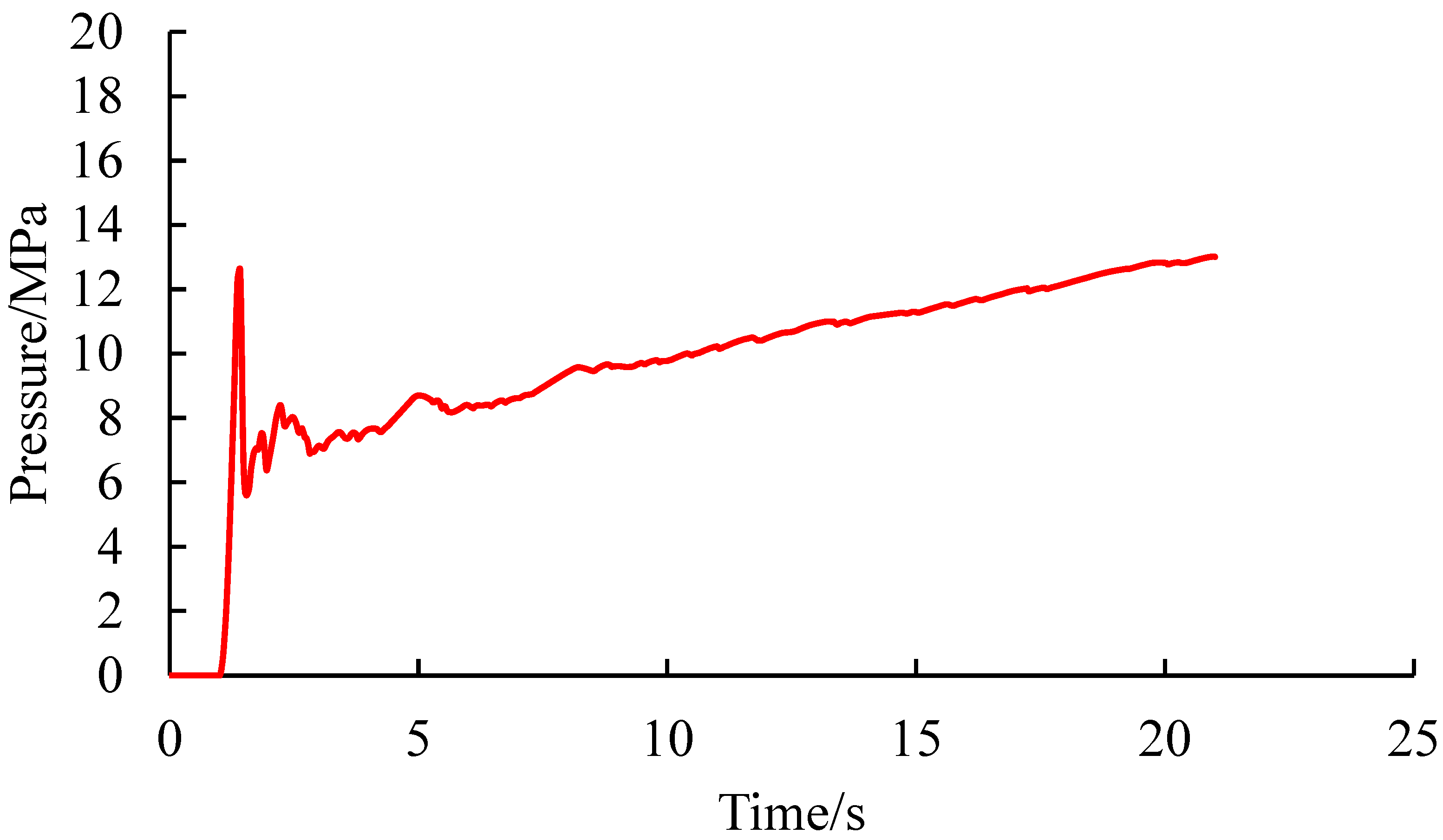

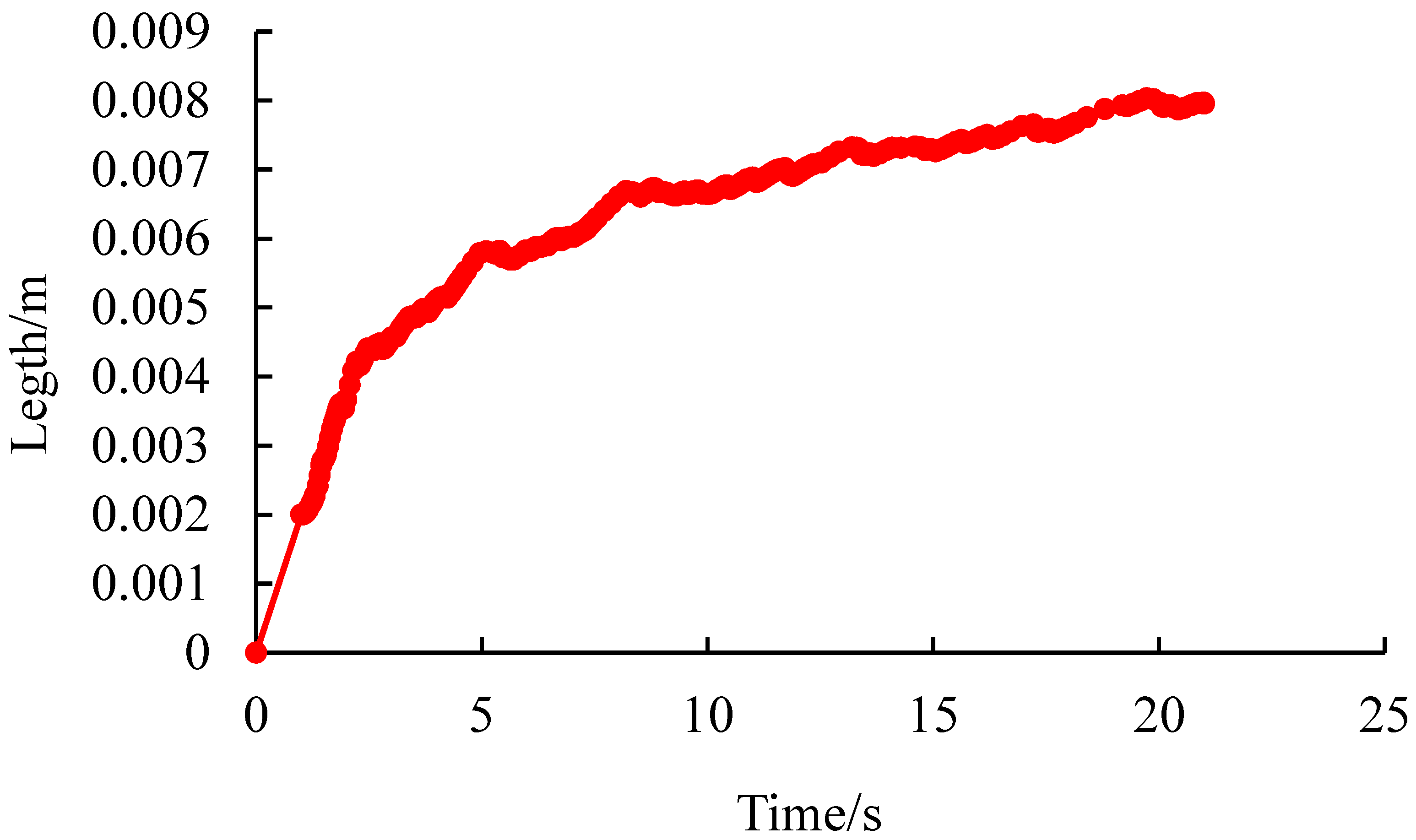

- (1)

- Quantitative characterization of pore pressure changes and crack width at the injection point when the ground stress difference is 0 MPa

- (2)

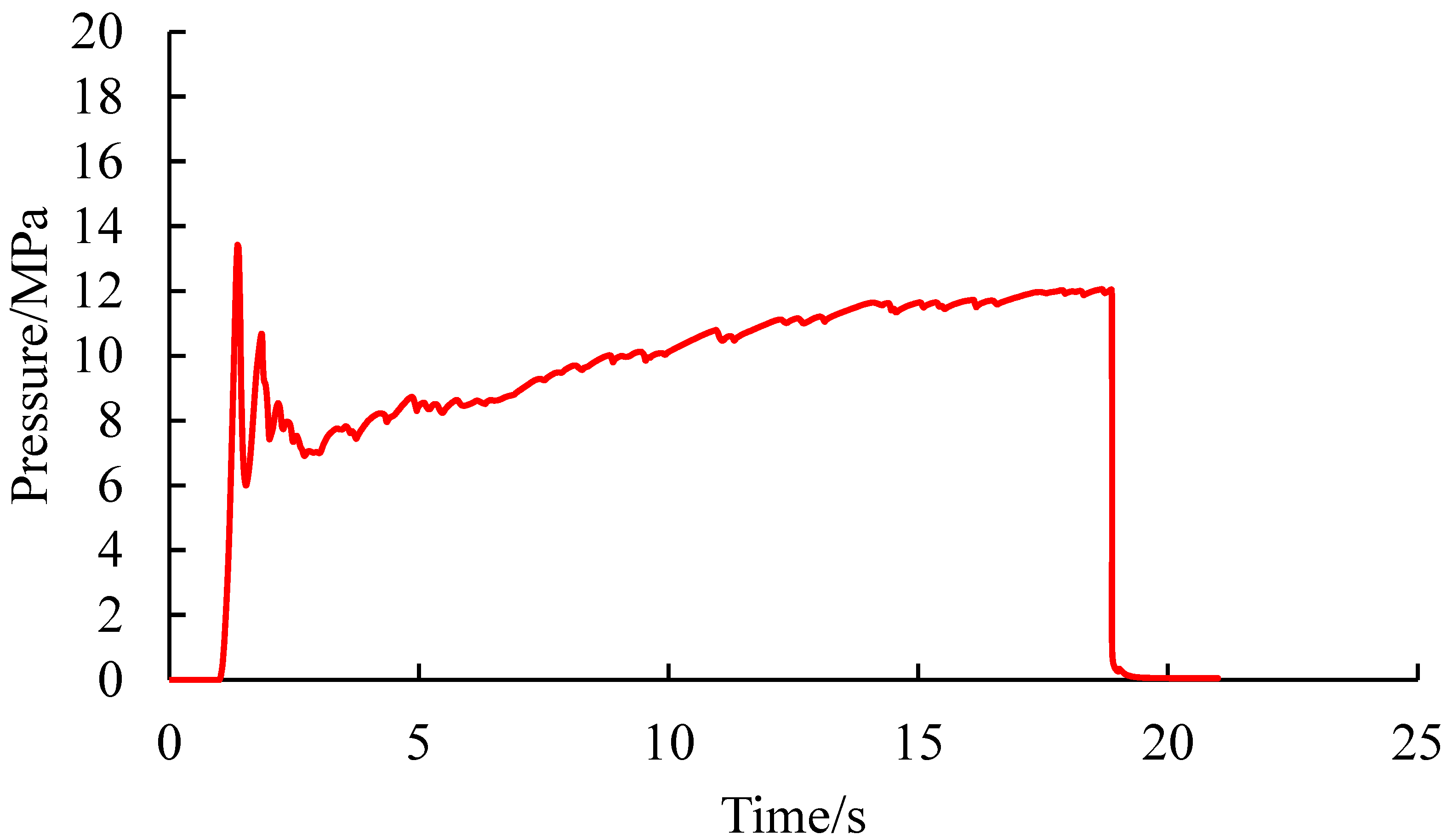

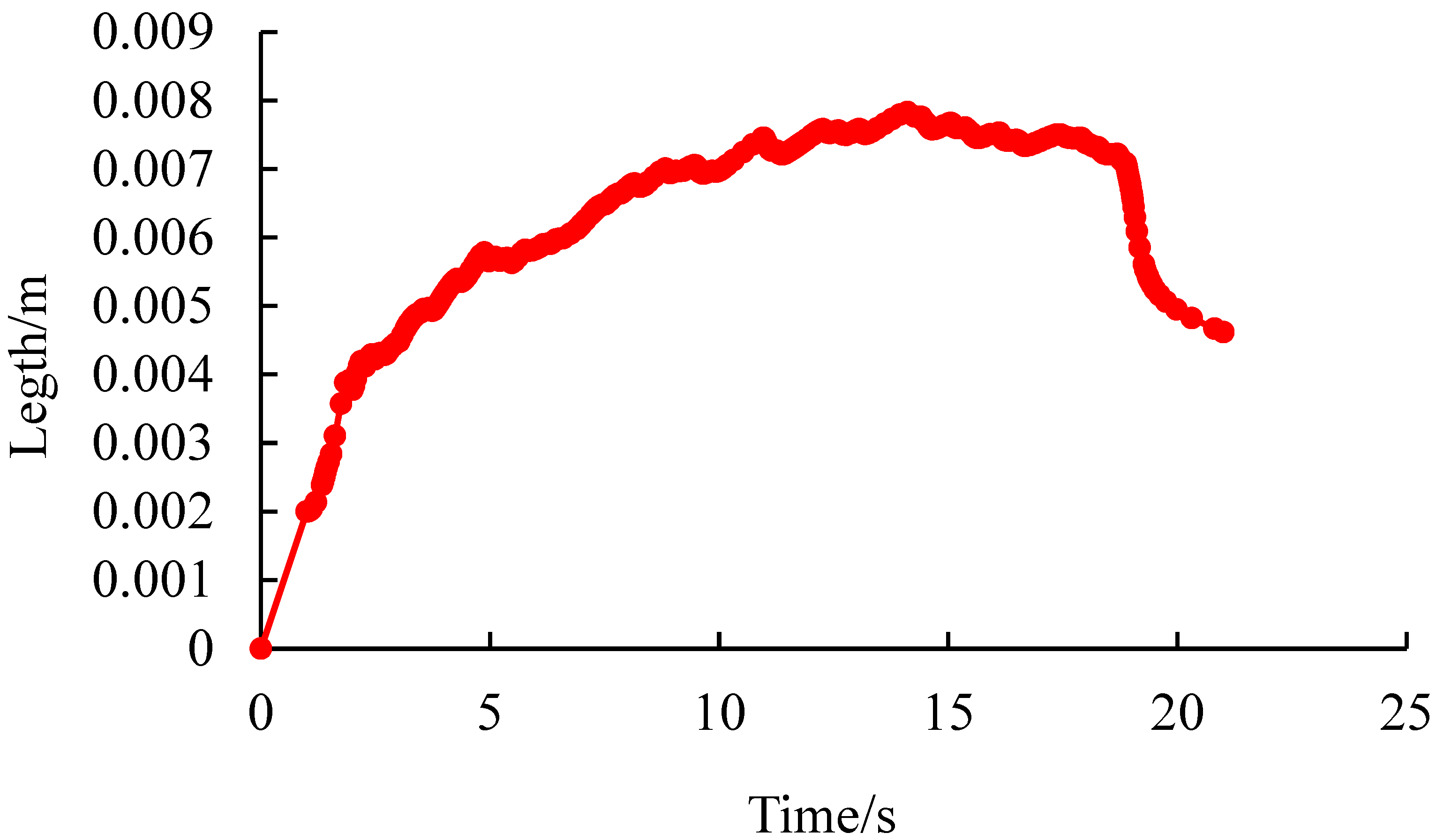

- Quantitative characterization of pore pressure changes and crack width at the injection point when the ground stress difference is 1 MPa

- (3)

- Quantitative characterization of pore pressure changes and crack width at the injection point when the ground stress difference is 5 MPa

4. Conclusions

- (1)

- During the fracturing process, as the fracturing fluid is continuously injected, the fracturing fractures continue to open and expand forward, generating double-wing cracks. At the same time, the fluid on the fracture wall leaks into the reservoir matrix, causing changes in pore pressure, displacement, and stress of the reservoir matrix, which in turn affects the size of the fracturing fractures. The existence of natural fractures has a significant impact on the direction of hydraulic fractures. The tip of hydraulic fractures will deflect towards natural fractures.

- (2)

- The difference in geostress has a significant impact on the complexity of cracks. The smaller the difference in geostress, the more complex the cracks, and the more branching cracks there are. When the stress difference in this model is 0 MPa, multiple branching cracks are generated. The larger the difference in geostress, the more likely it is to form a double-wing crack perpendicular to the minimum principal stress, with a simpler crack morphology.

- (3)

- When the geostress difference is 0 MPa, 1 MPa, and 5 MPa, the pore pressure at the injection point generally increases rapidly first and then decreases slightly, followed by a wave-like change. When the injection point pressure starts to increase rapidly, there is a pressure holding process. As the fluid gradually fills the pores, the water pressure rises rapidly, and the injection point pressure curve suddenly increases to the highest point, causing rupture. When rupture occurs, the pressure drops sharply, forming a peak. Subsequently, as the fracturing fluid continues to be injected, the cracks continue to expand, and wave-like pressure changes occur, indicating the continuous generation of microcracks. The crack width at the injection point shows an overall trend of increasing first and then decreasing. When the stress difference is 0 MPa, 1 MPa, and 5 MPa, the peak rupture pressures are 12.63 MPa, 13.42 MPa, and 18.33 MPa, respectively; the maximum crack opening degrees are 0.797 cm, 0.779 cm, and 0.771 cm, respectively. By simulating and analyzing the crack initiation and propagation laws under different stress differences, the optimal renovation plan and construction displacement can be determined. It has certain guiding significance for the design of hydraulic fracturing in mining sites.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Lei, W.; Huang, J. The Investigation on Initiation and Propagation of Hydraulic Fractures in Shale Reservoir. Geofluids 2021, 2021, 2366709. [Google Scholar] [CrossRef]

- Benouadah, N.; Djabelkhir, N.; Song, X.; Rasouli, V.; Damjanac, B. Simulation of Competition Between Transverse Notches Versus Axial Fractures in Open Hole Completion Hydraulic Fracturing. Rock Mech. Rock Eng. 2021, 54, 2249–2265. [Google Scholar] [CrossRef]

- Suo, Y.; Chen, Z.; Rahman, S.S.; Yan, H. Numerical simulation of mixed-mode hydraulic fracture propagation and interaction with different types of natural fractures in shale gas reservoirs. Environ. Earth Sci. 2020, 79, 279. [Google Scholar] [CrossRef]

- Xu, W.; Zhao, S.; Zhang, W.; Zhao, X. Numerical Simulation of Crack Propagation and Branching Behaviors in Heterogeneous Rock-like Materials. Buildings 2024, 14, 158. [Google Scholar] [CrossRef]

- Zhang, L.; Jin, Y.; Dong, Z.; Yuan, R. A Numerical Study of Hydraulic Fracture Propagation Geometry in a Layered Shale Reservoir. Geofluids 2022, 2022, 6966791. [Google Scholar] [CrossRef]

- Bi, J.; Zhou, X.P.; Qian, Q.H. The 3D Numerical Simulation for the Propagation Process of Multiple Pre-existing Flaws in Rock-Like Materials Subjected to Biaxial Compressive Loads. Rock Mech. Rock Eng. 2016, 49, 1611–1627. [Google Scholar] [CrossRef]

- Shen, Z. Study on the Initiation and Propagation of Hydraulic Fracturing Fractures and Nonlinear Seepage Laws in Shale Under the Influence of Bedding. Ph.D. Thesis, Chongqing University, Chongqing, China, 2021. [Google Scholar]

- Zhang, Y. Study on the Mechanism of Hydraulic Fracture Initiation, Propagation, and Intersection Network Formation in Shale Driven by Non-Uniform Pressure Fluid. Ph.D. Thesis, Chongqing University, Chongqing, China, 2022. [Google Scholar]

- Cheng, T. Study on the Initiation and Propagation Mechanism of Perforation Fracturing Near the Wellbore in Horizontal Wells with Thin and Poor Shale Layers. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2024. [Google Scholar]

- Liu, J. Study on the Mechanism of Crack Initiation and Propagation in Hydraulic Fracturing of Shale with Defects. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2019. [Google Scholar]

- Suo, Y.; Chen, Z.; Rahman, S.S.; Song, H. Experimental and Numerical Investigation of the Effect of Bedding Layer Orientation on Fracture Toughness of Shale Rocks. Rock Mech. Rock Eng. 2020, 53, 3625–3635. [Google Scholar] [CrossRef]

- Irwin, P.G. Analysis of stress and strains near the end of a crack extension force. J. Appl. Mech. 1957, 24, 361–364. [Google Scholar] [CrossRef]

- Dong, Z. Theoretical and Numerical Simulation Study on the Initiation and Propagation Characteristics of Hydraulic Fractures in Rocks. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2020. [Google Scholar]

- Chang, X. Research on the Mechanism of Complex Fracture Expansion and Geometric Shape Optimization Design in Shale Reservoirs. Ph.D. Thesis, China University of Petroleum (East China), Dongying, China, 2016. [Google Scholar]

- Taliercio, A.; Landriani, G.S. A failure conditionfor layered rock. Int. J. Rock Mech. Min. Sci. Geomech. 1988, 25, 299–305. [Google Scholar] [CrossRef]

- Tien, Y.M.; Ien, Y.M.; Kuo, M.C. A failure criterion for transversely anisotropic rocks. Int. J. Rock Mech. Min. Sci. 2001, 38, 399–412. [Google Scholar] [CrossRef]

- Jaeger, J.C. Shear failure of anisotropic rock. Geol. Mag. 1960, 97, 65–72. [Google Scholar] [CrossRef]

- Nasseri, M.H.B.; Rao, K.S.; Ramamurthy, T. Anisotropic strength and deformational behavior of Himalayan schists. Int. J. Rock Mech. Min. Sci. 2003, 40, 3–23. [Google Scholar] [CrossRef]

- Ramamurthy, T. Strength, modulus responses of anisotropic rocks. Compressive Rock Eng. 1993, 4, 313–329. [Google Scholar]

- Niandou, H.; Shao, J.F.; Henry, J.P.; Fourmaintraux, D. Laboratory investigation of the mechanical behaviour of Tournemire shale. Int. J. Rock Mech. Min. Sci. 1997, 34, 3–16. [Google Scholar] [CrossRef]

- Yew, C.H.; Li, Y. Fracturing of a deviated wells. SPE Prod. Eng. 1988, 3, 429–437. [Google Scholar] [CrossRef]

- Deeg, W.F.J. Hydraulic fracture initiation in deviated or horizontal openhole wellbore. In Proceedings of the SPE/ISRM Rock Mechanics in Petroleum Engineering, Trondheim, Norway, 8–10 July 1998. SPE-47386. [Google Scholar]

- Anderson, G.D. Effects of friction on hydraulic fractures growth near unboneder interfaces in rocks. Soc. Pet. Eng. J. 1981, 21, 21–29. [Google Scholar] [CrossRef]

- Blanton, T.L. An experimental study of interaction between hydraulically induced and PreExisting Fractures. In Proceedings of the SPE Unconventional Gas Recovery Symposium, Pittsburgh, PA, USA, 16–18 May 1982. SPE-10847. [Google Scholar]

- Blanton, T.L. Propagation of hydraulically and dynamically induced fractures in naturally fractured reservoirs. In Proceedings of the SPE Unconventional Gas Technology Symposium, Louisville, Kentucky, 18–21 May 1986. SPE-15261. [Google Scholar]

- Warpinski, N.R. Hydraulic fracturing in tight, fissured media. J. Pet. Technol. 1991, 42, 146–151. [Google Scholar] [CrossRef]

- Fisher, M.K.; Heinze, J.R.; Harris, C.D.; Davidson, B.M.; Wright, C.A.; Dunn, K.P. Optimizing horizontal completion techniques in the Barnett shele using Micro-seismic fracture mapping. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004. SPE-90051. [Google Scholar]

- Fisher, M.K.; Wright, C.A.; Davidson, B.M.; Steinsberger, N.P.; Buckler, W.S.; Goodwin, A.; Fielder, E.O. Integrating fracture mapping technologies to improve stimulations in the Barnett shale. SPE Prod. Facil. 2005, 20, 85–93. [Google Scholar] [CrossRef]

- Weijers, L.; Wright, C.A.; Sugiyama, H.; Sato, K.; Zhigang, L. Simulataneous propagarion of multiple hydraulic fractures evidence impact and modeling implications. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 7–10 November 2000. SPE-64772. [Google Scholar]

- Mayerhofer, M.; Lolon, E.; Warpinski, N.; Cipolla, C.; Walser, D.; Rightmire, C. What is stimulated reservoir volume. SPE Prod. Oper. 2010, 25, 89–98. [Google Scholar] [CrossRef]

- Soliman, M.Y.; East, L.; Augustine, J. Fracturing design amied at enhancing fracture complexity. In Proceedings of the SPE EUROPEC/EAGE Annual Conference and Exhibition, Barcelona, Spain, 14–17 June 2010. SPE-130043. [Google Scholar]

- Munjiza, A.; Andrews, K.R. Discrete element modeling of rock failure. Rock Mech. Rock Eng. 2017, 50, 553–575. [Google Scholar]

- Peng, Y.; Kondo, D. A numerical simulation of rock fracture using lattice Boltzmann method. Eng. Fract. Mech. 2011, 78, 2843–2852. [Google Scholar]

- Chen, M.; Li, M.; Wu, Y.; Kang, B. Simulation of Hydraulic Fracturing Using Different Mesh Types Based on Zero Thickness Cohesive Element. Processes 2020, 8, 189. [Google Scholar] [CrossRef]

- Liu, Z. Research on the Initiation and Propagation Law of Fracturing Fractures in Fractured Reservoirs Based on Finite Element Discrete Element Method. Ph.D. Thesis, Northeast Petroleum University, Daqing, China, 2022. [Google Scholar]

- Crouch, S.L. Solution of plane elasticity problems by displacement discontinuity method. Int. J. Num. Methods Eng. 1976, 10, 301–343. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O. A discrete numerical model for granular assemblies. Géotechnique 1979, 19, 47–65. [Google Scholar] [CrossRef]

- Lecampion, B.; Bunger, A.; Zhang, X. Numerical methods for hydraulic fracture propagation: A review of recent trends. J. Nat. Gas. Sci. Eng. 2018, 49, 66–83. [Google Scholar] [CrossRef]

- Paluszny, A.; Zimmerman, R.W. Numerical simulation of multiple 3D fracture propagation using arbitrary meshes. Comput. Methods Appl. Mech. Eng. 2011, 200, 953–966. [Google Scholar] [CrossRef]

- Tang, X.; Rutqvist, J.; Hu, M.; Rayudu, N.M. Modeling three-dimensional fluid-driven propagation of multiple fractures using TOUGH-FEMM. Rock Mech. Rock Eng. 2019, 52, 611–627. [Google Scholar] [CrossRef]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Methods Eng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- Gao, S. Research on the Mechanism of Fracture Initiation and Extension in Hydraulic Fracturing of Oil Shale Horizontal Wells. Ph.D. Thesis, Jilin University, Changchun, China, 2017. [Google Scholar]

- Barenblatt, G.I. The formation of equilibrium cracks during brittle fracture. General ideas and hypotheses. Axially-Symmetric cracks. J. Appl. Math. Mech. 1959, 23, 622–636. [Google Scholar]

- Dugdale, D.S. Yielding of steel sheets containing slits. J. Mech. Phys. Solids 1960, 8, 100–104. [Google Scholar] [CrossRef]

- Guo, J.; Luo, B.; Lu, C.; Lai, J.; Ren, J. Numerical investigation of hydraulic fracture propagation in a layered reservoir using the cohesive zone method. Eng. Fract. Mech. 2017, 195–207. [Google Scholar] [CrossRef]

- Gonzalez, M.; Taleghani, A.D.; Olson, J.E. A cohesive model for modeling hydraulic fractures in naturally fractured formations. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, The Woodlands, TX, USA, 3–5 February 2015; Society of Petroleum Engineers: Richardson, TX, USA, 2015. [Google Scholar]

- Dean, R.H.; Schmidt, J.H. Hydraulic-fracture predictions with a fully coupled geomechanical reservoir simulator. SPE J. 2009, 14, 707–714. [Google Scholar] [CrossRef]

- Zhang, G.M.; Liu, H.; Zhang, J.; Wu, H.A.; Wang, X.X. Three-dimensional finite element simulation and parametric study for horizontal well hydraulic fracture. J. Pet. Sci. Eng. 2010, 72, 310–317. [Google Scholar] [CrossRef]

- Liu, Q. Research on the Mechanism and Parameter Optimization of Hydraulic Jet Radial Horizontal Well Controlled Fracturing. Ph.D. Thesis, China University of Petroleum (Beijing), Beijing, China, 2019. [Google Scholar]

- Zhai, L. Research on the Mechanism of Fracture Initiation and Expansion in Hydraulic Fracturing of Perforated and Completed Oil Shale Horizontal Wells. Ph.D. Thesis, Jilin University, Changchun, China, 2021. [Google Scholar]

| Name | Parameter | Numerical Value | Unit |

|---|---|---|---|

| In situ stress field | Maximum horizontal principal stress | 10 × 106 | Pa |

| Minimum horizontal principal stress | 5 × 106 | Pa | |

| Matrix | Modulus of elasticity | 15 | GPa |

| Poisson’s ratio | 0.25 | / | |

| Initial void ratio | 0.1 | / | |

| Permeability coefficient | 1 × 10−7 | m/s | |

| Pump injection parameters | Fracturing fluid viscosity | 0.001 | Pa·s |

| Fracturing fluid displacement | 0.1 | m3/min | |

| injection time | 20 | s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Chen, J.; Sun, Z.; Xiong, J.; Wang, H.; Song, W.; Lei, J. Numerical Simulation Study on Volume Fracturing of Shale Oil Reservoirs in Y Block of Ordos Basin, China. Processes 2025, 13, 3356. https://doi.org/10.3390/pr13103356

Zhang J, Chen J, Sun Z, Xiong J, Wang H, Song W, Lei J. Numerical Simulation Study on Volume Fracturing of Shale Oil Reservoirs in Y Block of Ordos Basin, China. Processes. 2025; 13(10):3356. https://doi.org/10.3390/pr13103356

Chicago/Turabian StyleZhang, Jinyuan, Junbin Chen, Zhen Sun, Jiao Xiong, Haoyu Wang, Wenying Song, and Junjie Lei. 2025. "Numerical Simulation Study on Volume Fracturing of Shale Oil Reservoirs in Y Block of Ordos Basin, China" Processes 13, no. 10: 3356. https://doi.org/10.3390/pr13103356

APA StyleZhang, J., Chen, J., Sun, Z., Xiong, J., Wang, H., Song, W., & Lei, J. (2025). Numerical Simulation Study on Volume Fracturing of Shale Oil Reservoirs in Y Block of Ordos Basin, China. Processes, 13(10), 3356. https://doi.org/10.3390/pr13103356