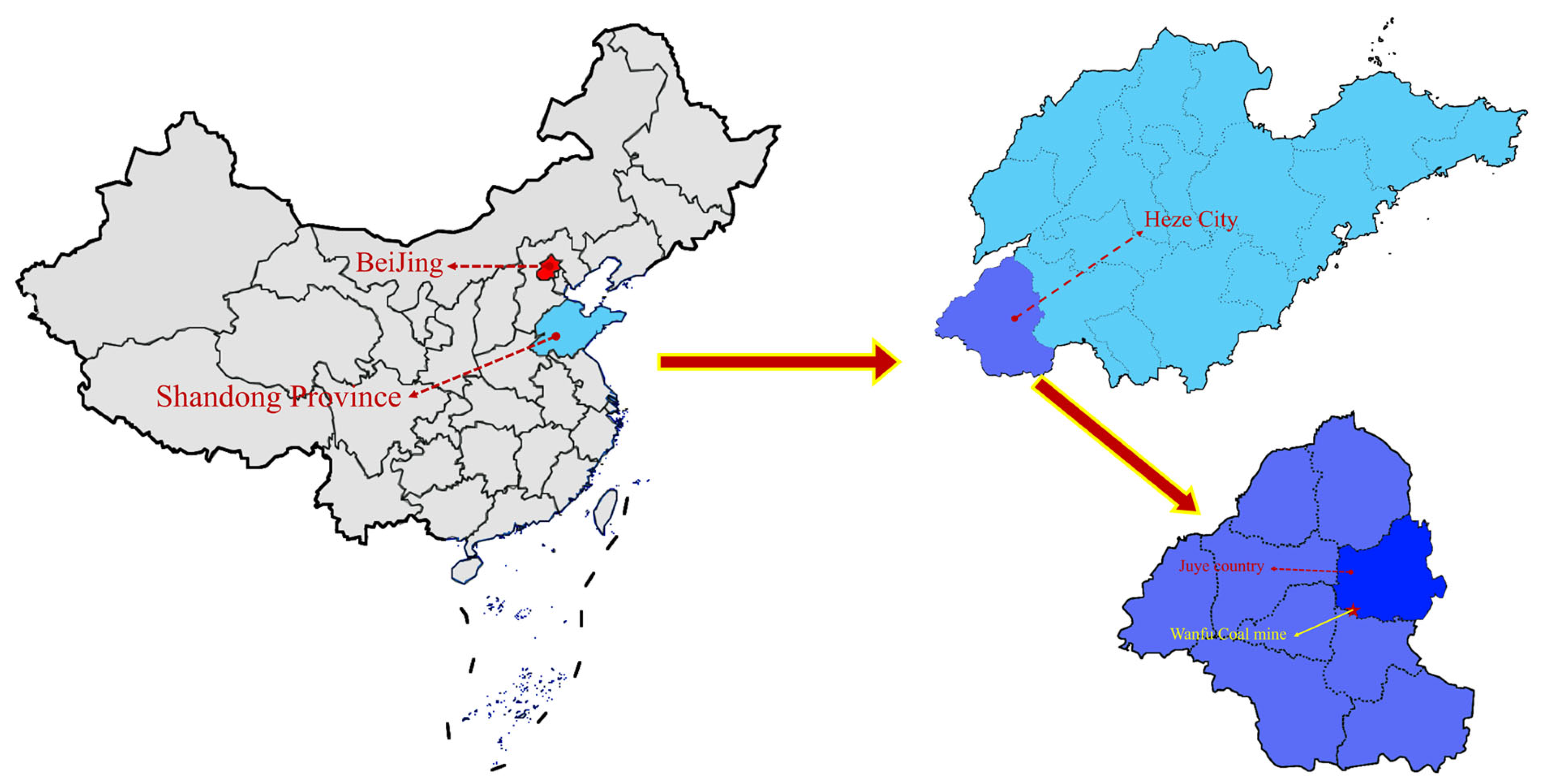

An Investigation of Water–Heat–Force Coupling During the Early Stage of Shaft Wall Pouring in Thick Topsoil Utilizing the Freezing Method

Abstract

1. Introduction

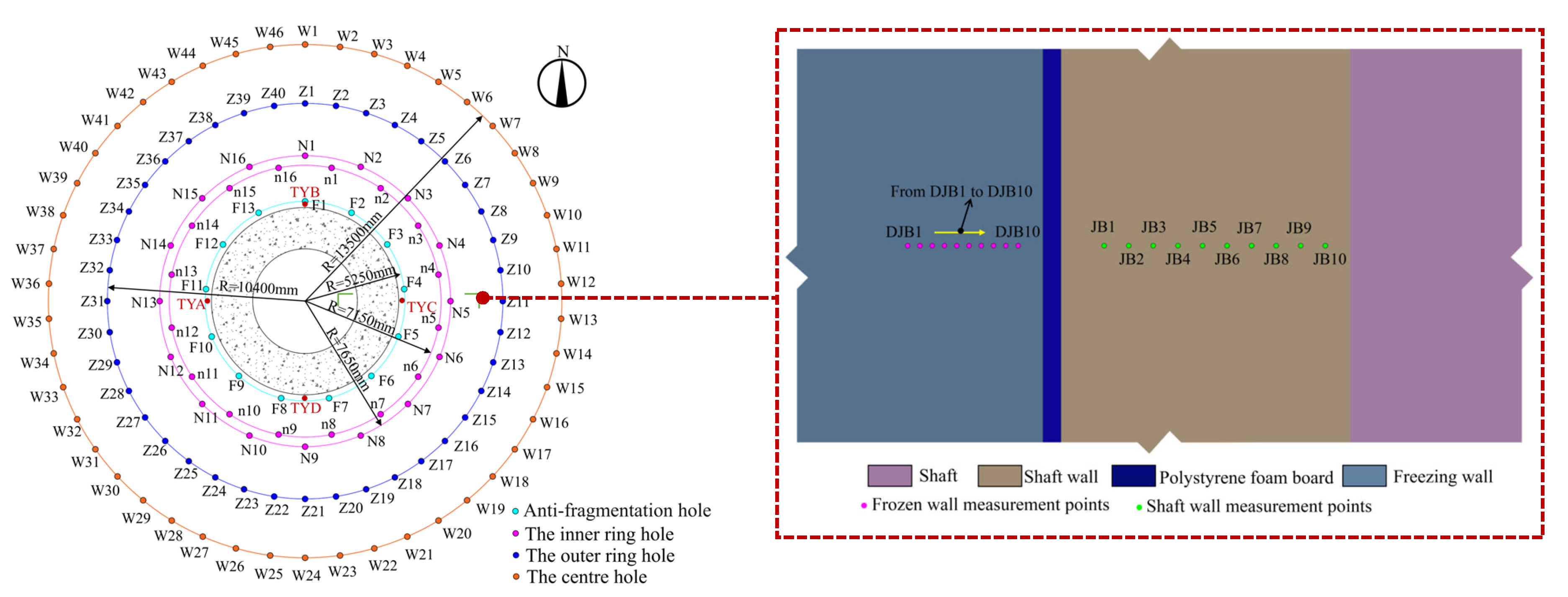

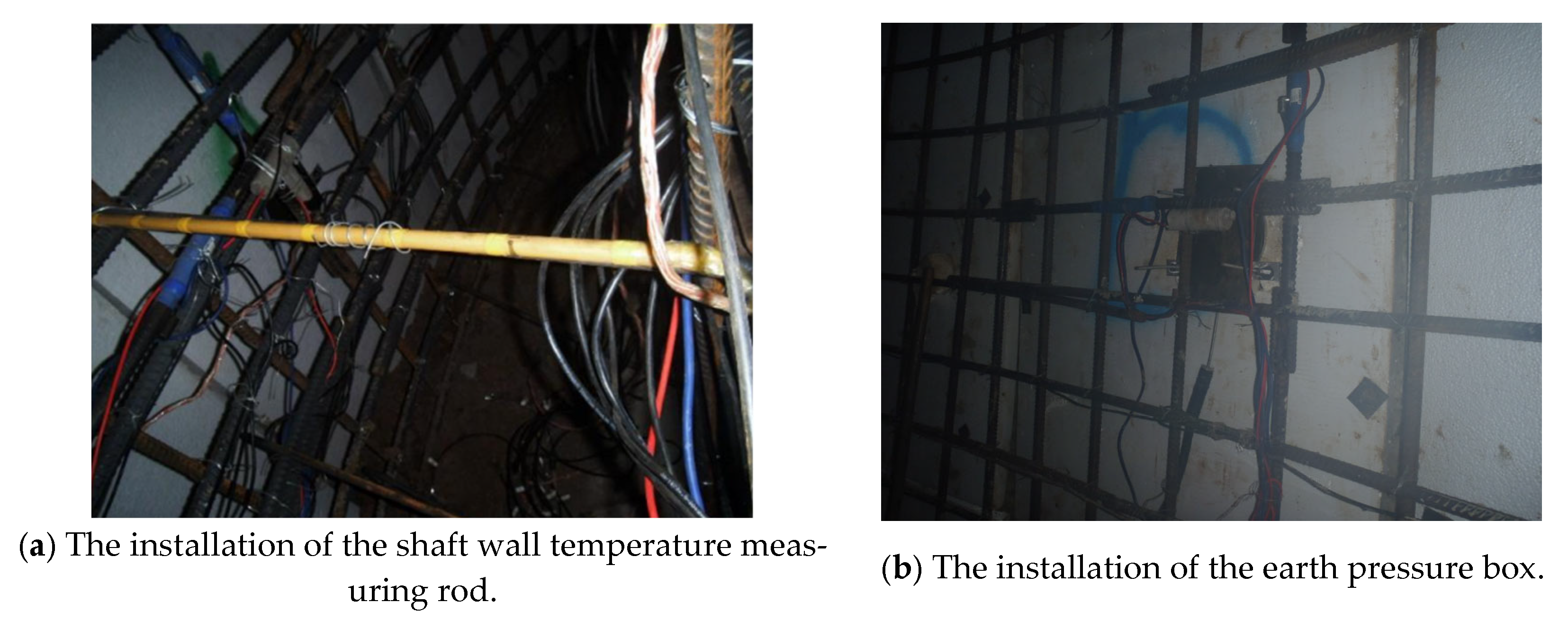

2. Data Analysis of Field Measurements

- (1)

- The thickness of the loose layer of the Quaternary (Q) and Neoproterozoic (N) deposits is large, reaching 780 m, and the proportion of clay is high and expansive, especially the thick clay layer in the lower part of the Neoproterozoic (N), which is semiconsolidated and has a low water content, which is unfavorable for the freezing construction of the shaft.

- (2)

- The loose Quaternary (Q) layer is 119.45–163.70 m thick, with an average thickness of 139.27 m. It is divided into two sections. The upper section is mainly composed of brownish-yellow, yellowish-brown clayey sand and sandy clay interspersed with fine sand and thin layers of medium sand. It is loose, has good water permeability, and is the main aquifer of the Quaternary system. The lower section is mainly brownish-yellow, gray–green, light purple–red sandy clay; clay; sand with clayey sand; and lenticular silt, and at the bottom, there is a layer of clay containing iron and manganese nodules and ginger stones, with good water insulation, alluvial river, and lake deposits; it is not integrated into the Neoproterozoic system (N).

- (3)

- The thickness of the Neogene series (N) ranged from 483.00 to 650.75 m, with an average of 575.46 m. According to its physical characteristics, the upper section is divided into two sections: the upper section is 213.60–307.10 m thick, with an average of 574.46 m. The upper section is dominated by thick layers of brownish-yellow and light-red clays and sandy clays interspersed with silty sand, fine sand, and clay-like sand, which are loose, unconsolidated, and locally microconsolidated. The lower section is composed of grayish-green, brownish-yellow fine sand; silty sand; and clayey silty sand mixed with light purple clay, which is the main water-bearing section of the upper Tertiary System. The clay layer contains blocky, plate-like, and crystalline cluster-like gypsum, unconsolidated, locally slightly consolidated, or semiconsolidated. Clay and sandy clay are prone to absorb water and swell. The sand layer is loose and fluid. The lower section is 189.40–377.30 m thick, with an average thickness of 310.33 m. It is mainly composed of thick layers of grayish-green and brown clays and sandy and silty sandy clays, with thin layers of silty sand and fine sand in some areas. It is semiconsolidated and locally unconsolidated. Clay and sandy clay have water absorption ability and plasticity. At the bottom are layers of clay and clayey sand and gravel containing more calcareous nodules or gravel, which are not integrated into the underlying strata.

- (4)

- The loose Quaternary (Q) layer is unconsolidated and consists mainly of soft plastic clay, sandy clay, loose powder sand, and fine sand layers. The loose layer of the Neoproterozoic system (N) is semiconsolidated, with hard plastic clay, soft plastic clay and expansive clay, calcareous clay, and sand layers; the sand layer is loose and mobile. The thicknesses of the upper and lower sand layers are large; the thickness of the clay layer is large, and it is interspersed with massive and columnar gypsum crystals, which easily disintegrate and loosen when it meets with water.

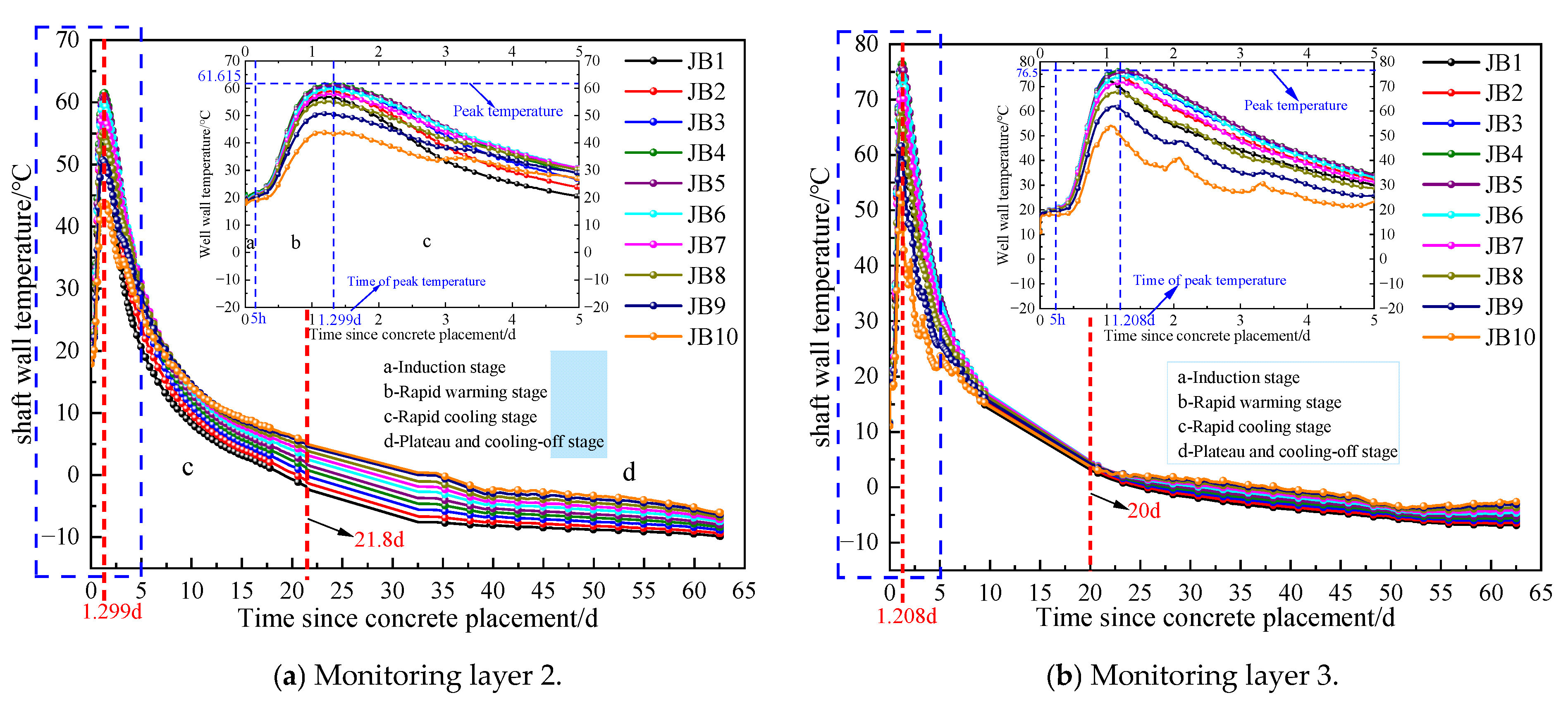

Temperature Field Evolution Law of Shaft Wall Concrete

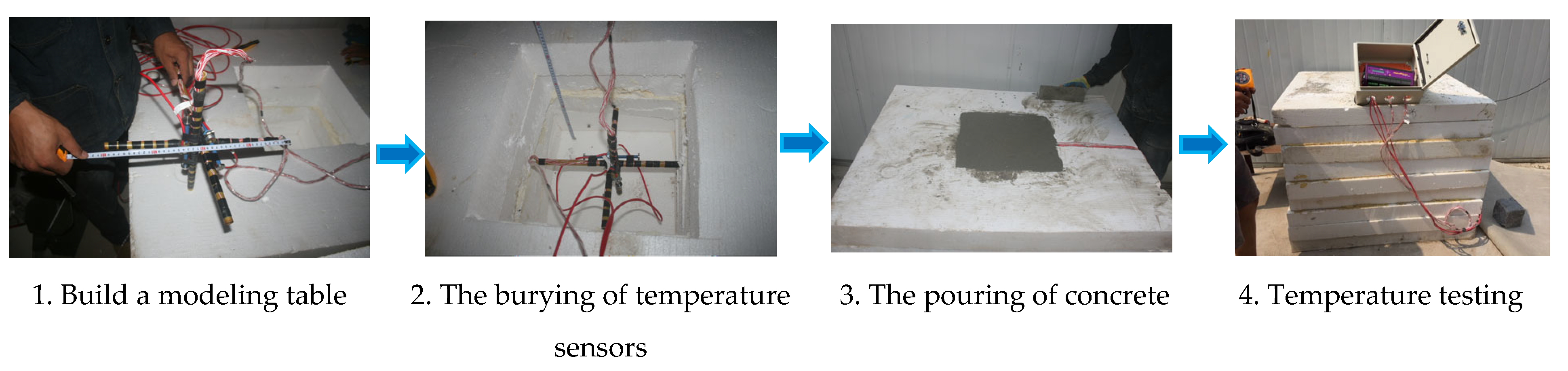

3. High-Strength Concrete CF80 Thermal Insulation Temperature Rise Test

3.1. Experimental Steps

3.2. Analysis of Experimental Data

3.3. Determination of Parameters

4. Modeling of Coupled Hydrothermal Analysis via the Freezing Method

4.1. Control Equations for the Permafrost Temperature Field

4.2. Controlling Equations for the Permafrost Moisture Field

4.3. Temperature Field Control Equations for the Shaft Wall Concrete and Foam Plate

4.4. Coupled Hydrothermal Control Equations

4.5. Secondary Development of Coupled Models Based on PDE Modules

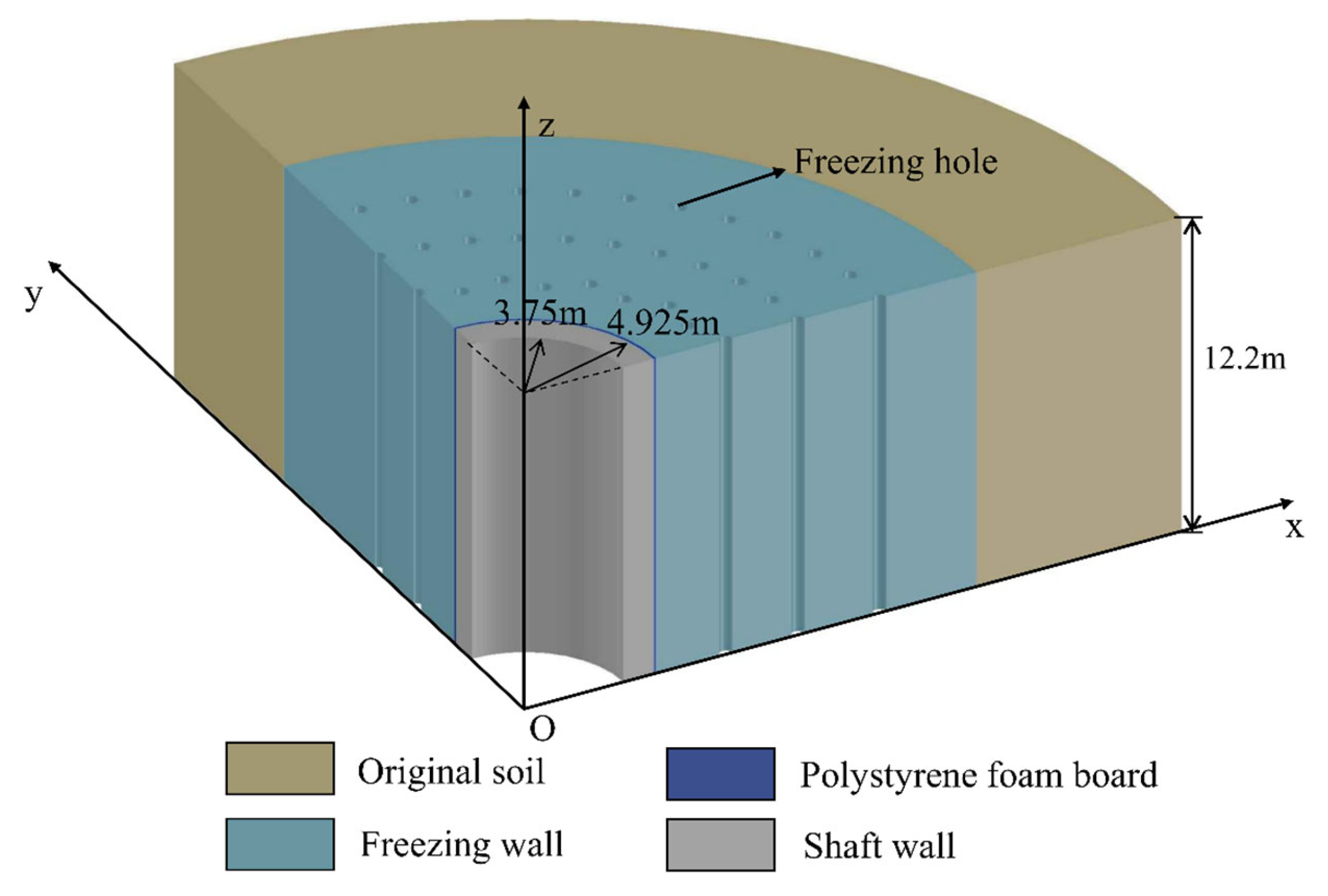

5. Numerical Calculation Model Determination

5.1. Model Physical Parameters

5.2. Boundary Condition Setting

6. Comparison and Analysis of Numerical Calculation Results

7. Conclusions

- (1)

- A coupled thermal–hydraulic three-field analysis model was established based on heat transfer in porous media, seepage in unsaturated soil, and frost heave theory, with temperature and soil relative saturation as unknown variables (see Equations (14), (15) and (22)); the study determines reasonable values and settings for parameters such as the expansion deformation coefficient, equivalent thermal conductivity, and specific heat capacity of the three-phase medium; an adiabatic temperature rise model; a VG stagnant water model; and a Gardner permeability model, providing a theoretical basis for modeling and analyzing water–heat–force coupling under the influence of hydration heat during the initial pouring of the lining in frozen construction methods.

- (2)

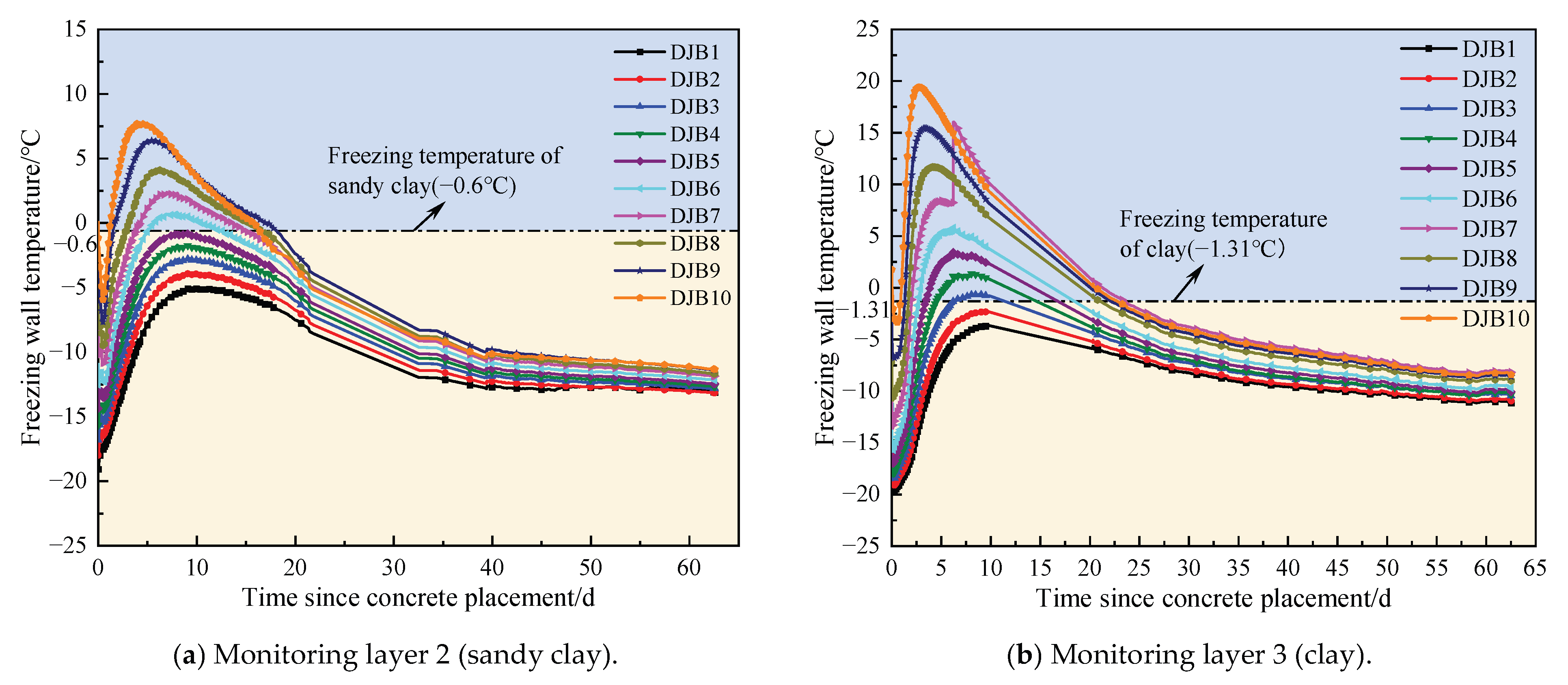

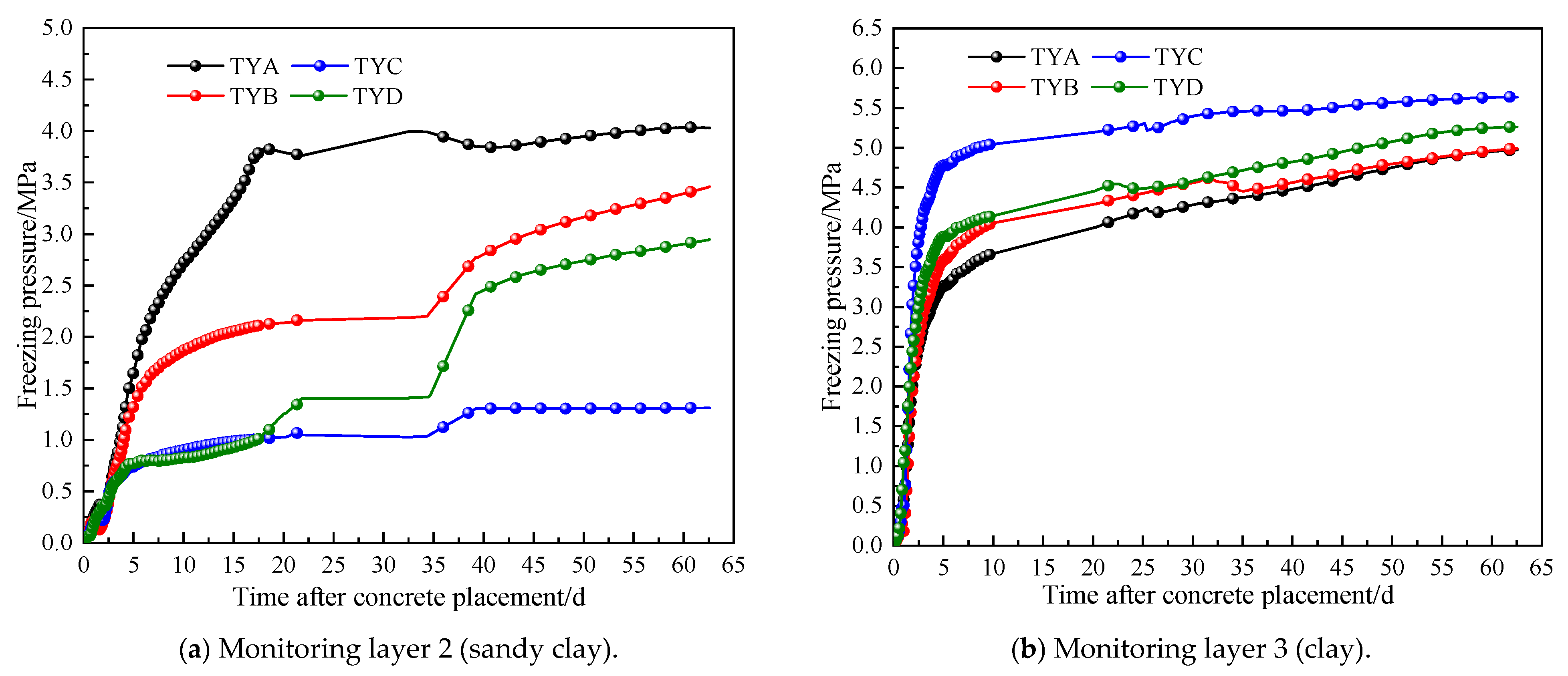

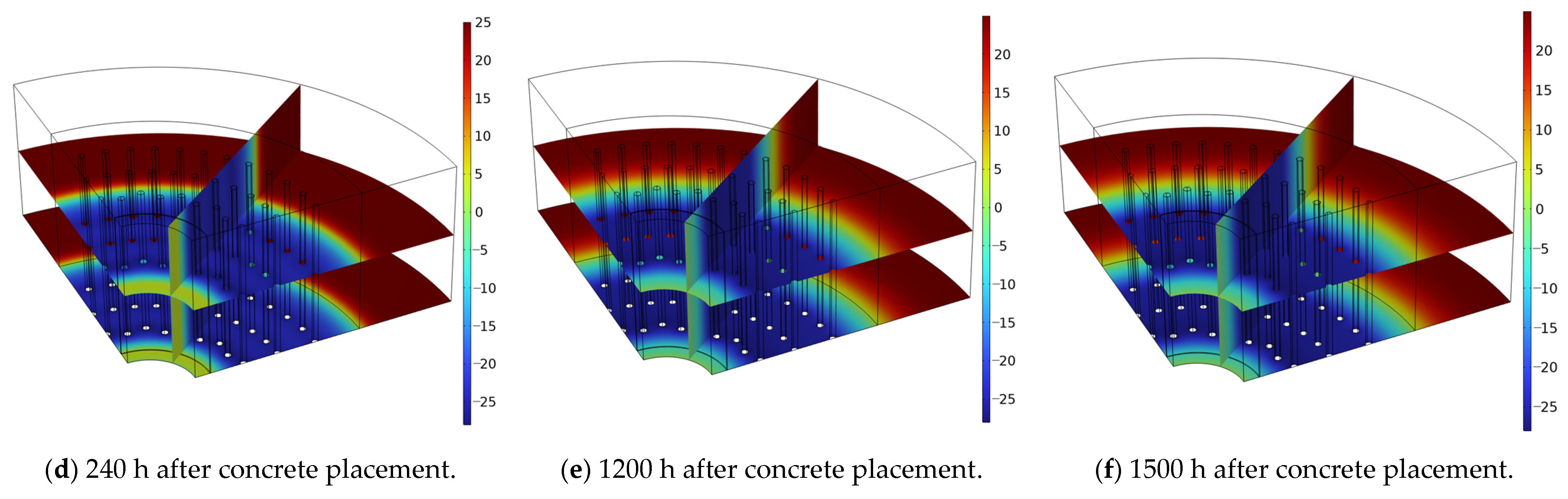

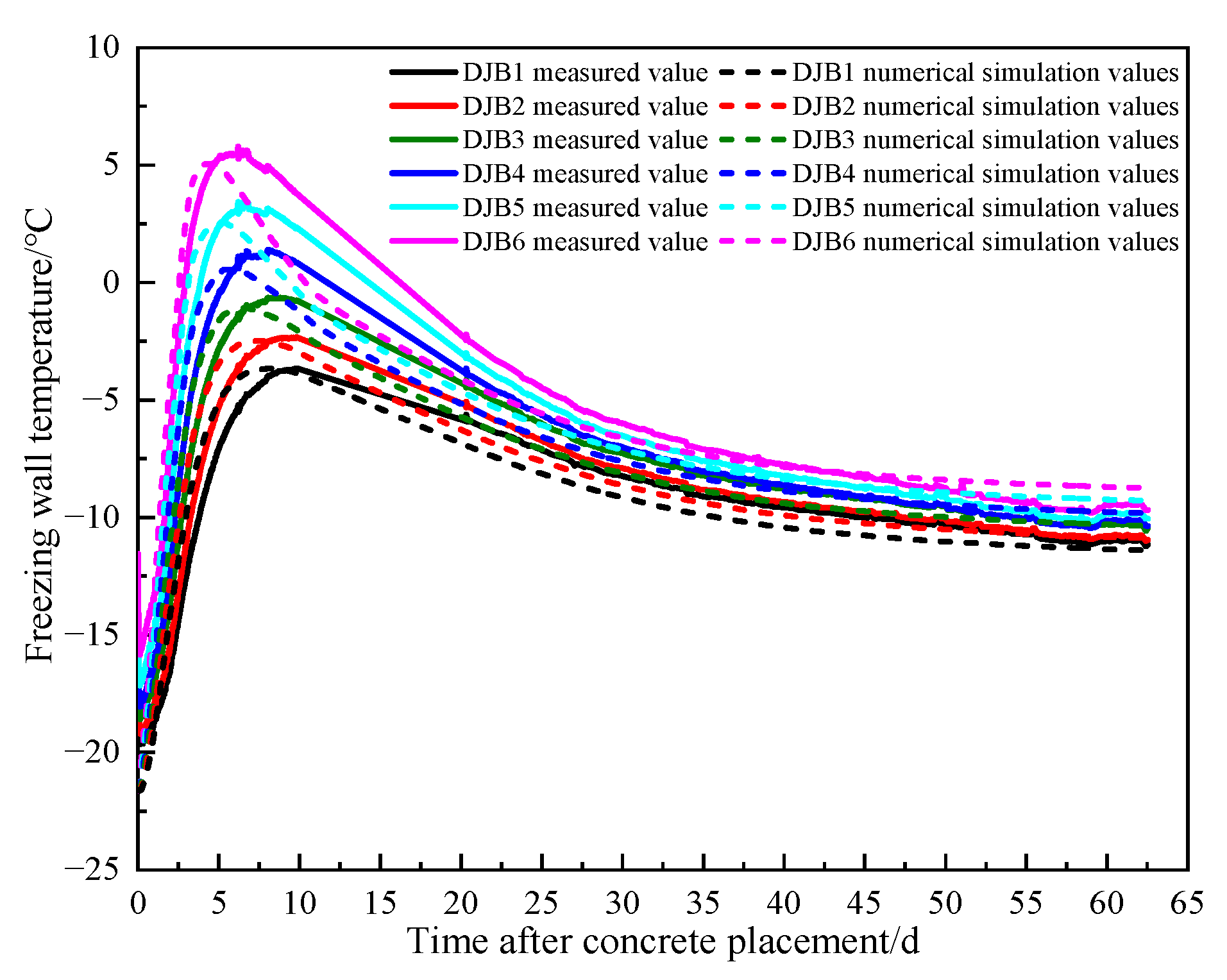

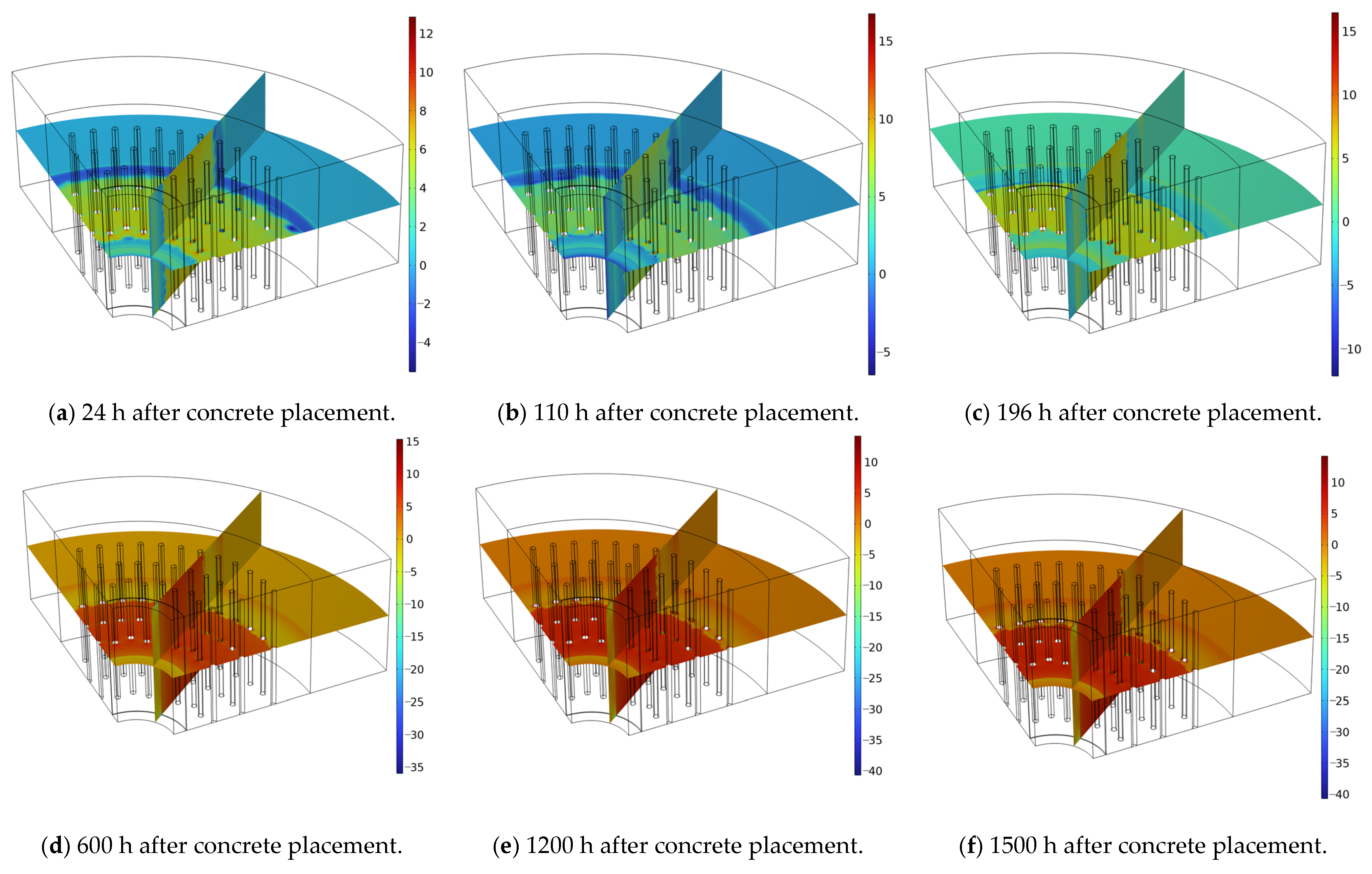

- An analysis of multi-layer field measurement data shows that the thickness of the shaft well lining and the initial temperature are positively correlated with the peak temperature of the shaft well wall, while the initial temperature is negatively correlated with the age of the peak temperature. After the steel fiber concrete is poured, the temperature rise changes in four stages: induction, rapid heating, rapid cooling, and steady cooling. The time taken for measurement points DJB1 to DJB10 to reach peak temperature showed a decreasing trend; the maximum thawing depth times for the second and third layers were approximately 8 d and 7 d, respectively, and the thawing range of the clay layer in the third layer was greater than that of the sandy clay layer in the second layer. The peak freezing pressures for the second and third layers were 0.5 and 0.6 times the design bearing capacity, respectively, to ensure the structural safety of the shaft wall; there were high requirements for the early-age strength of the outer concrete during construction.

- (3)

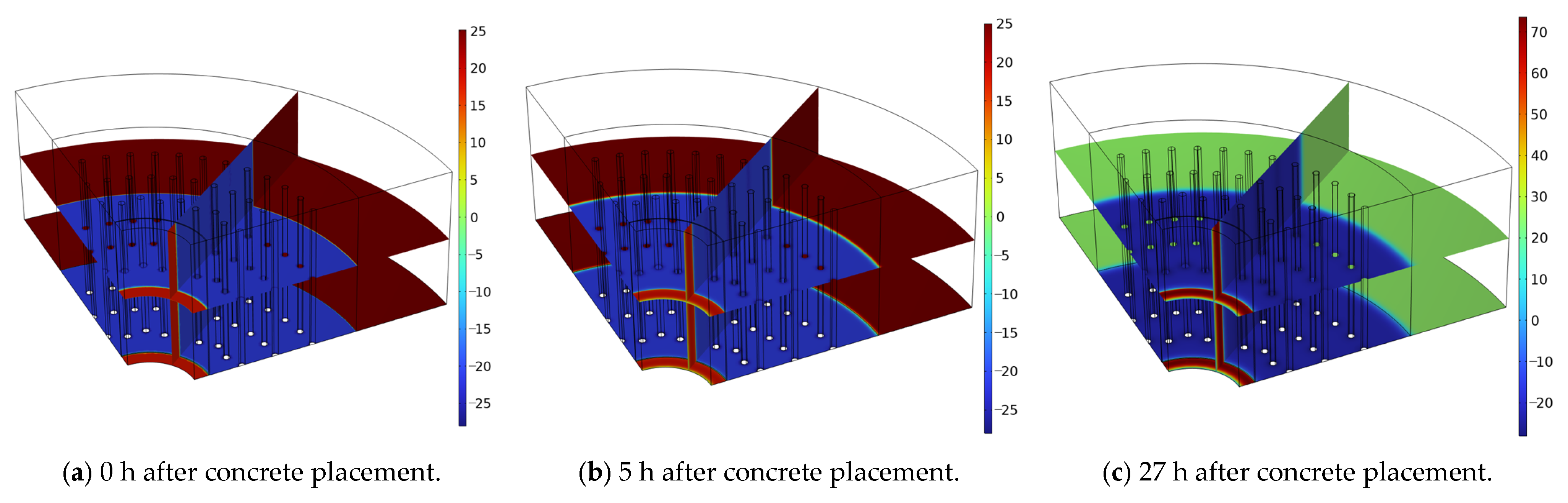

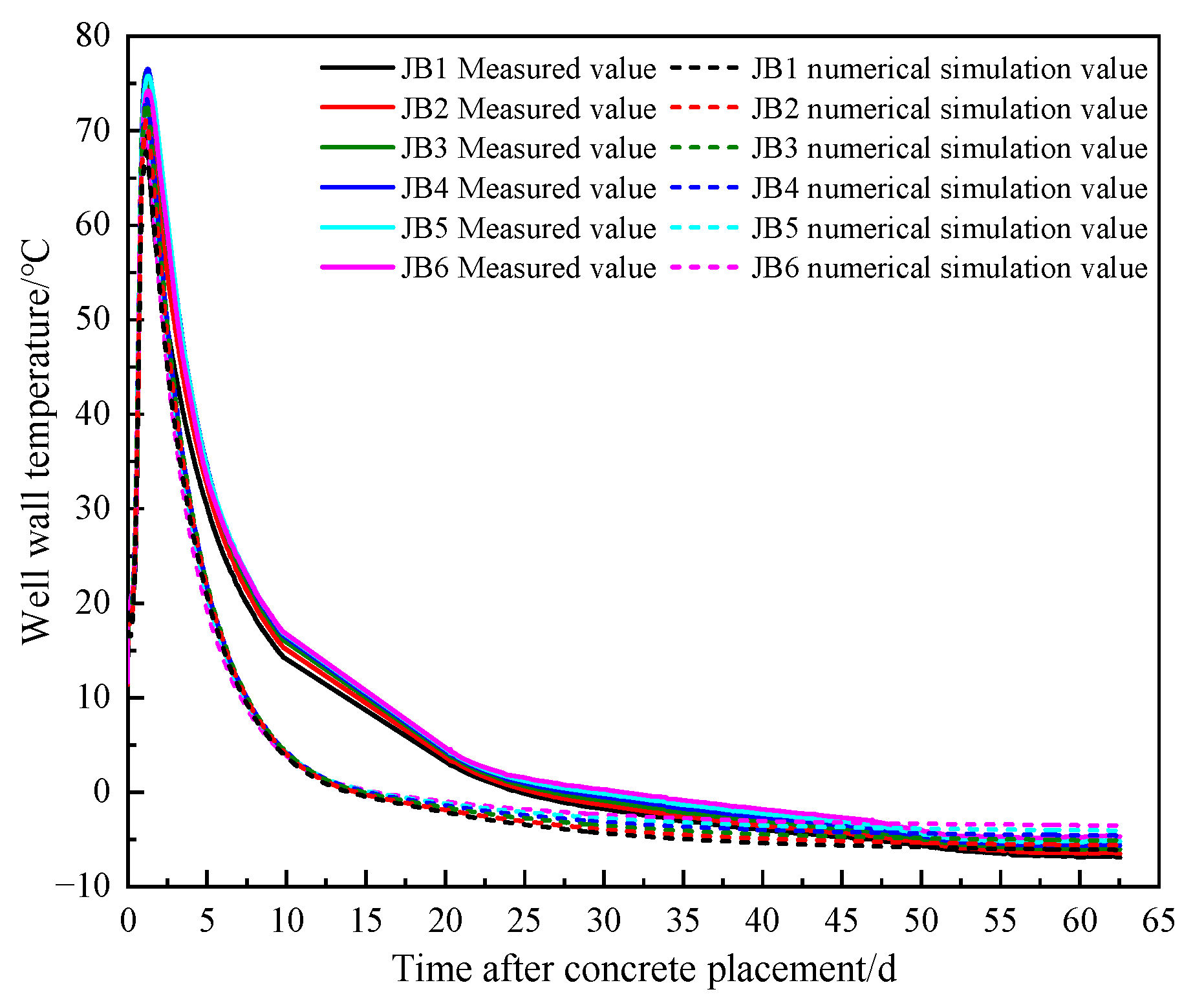

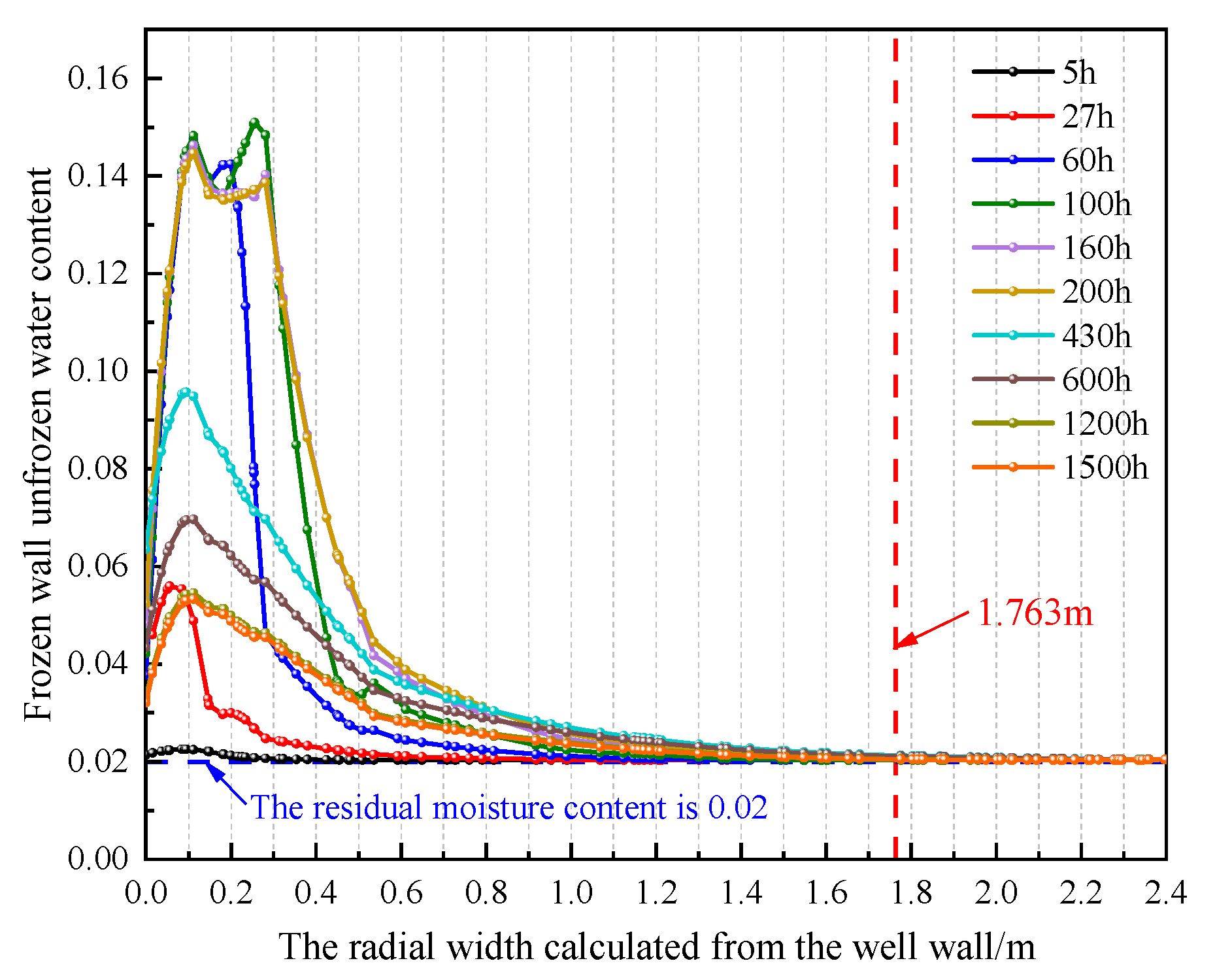

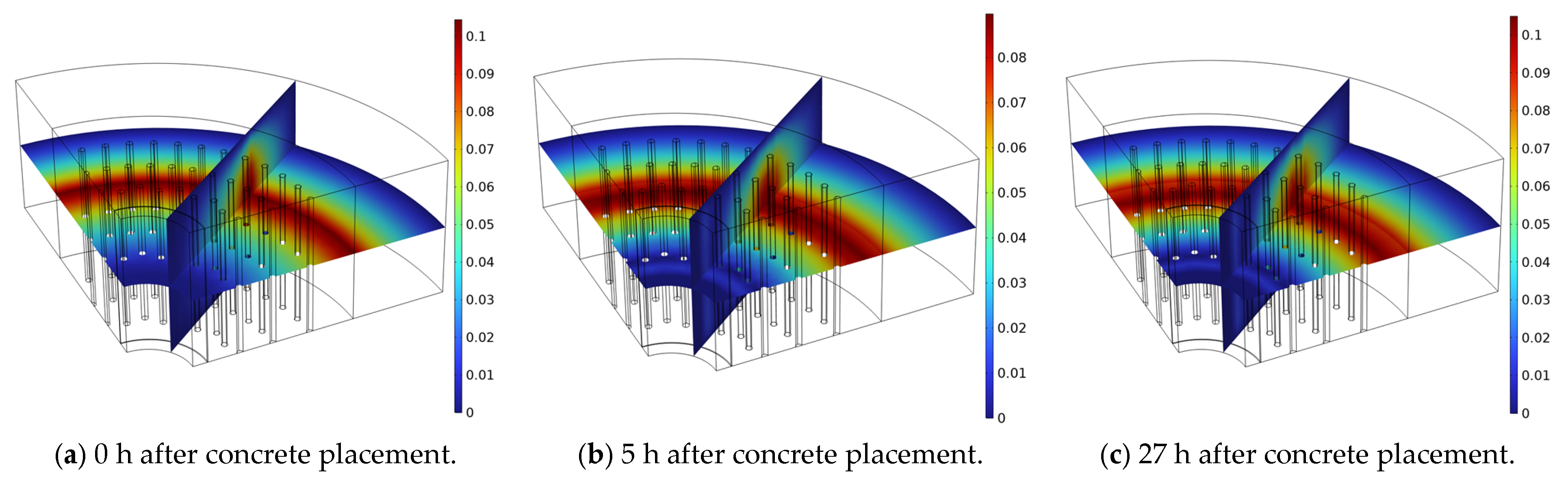

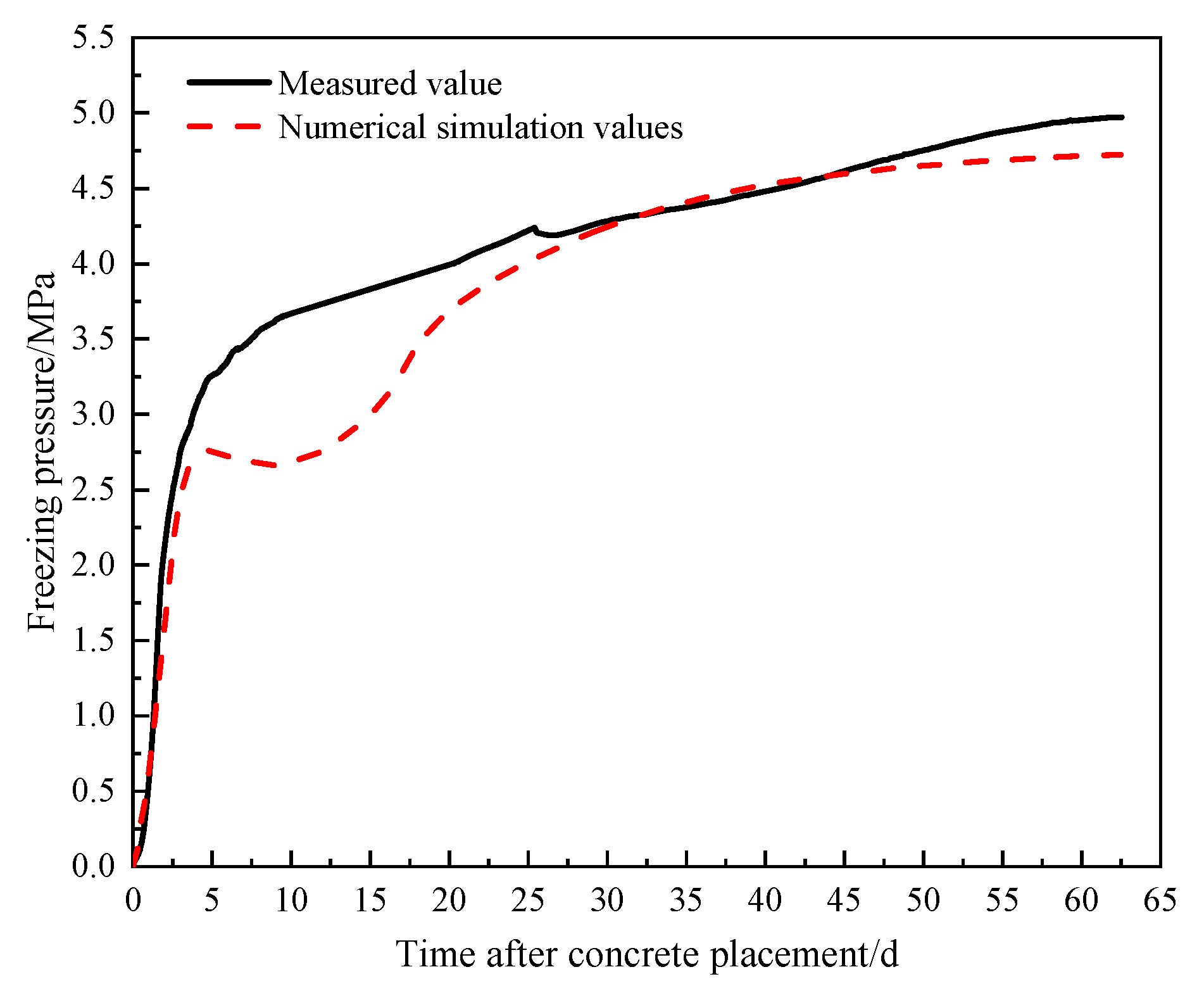

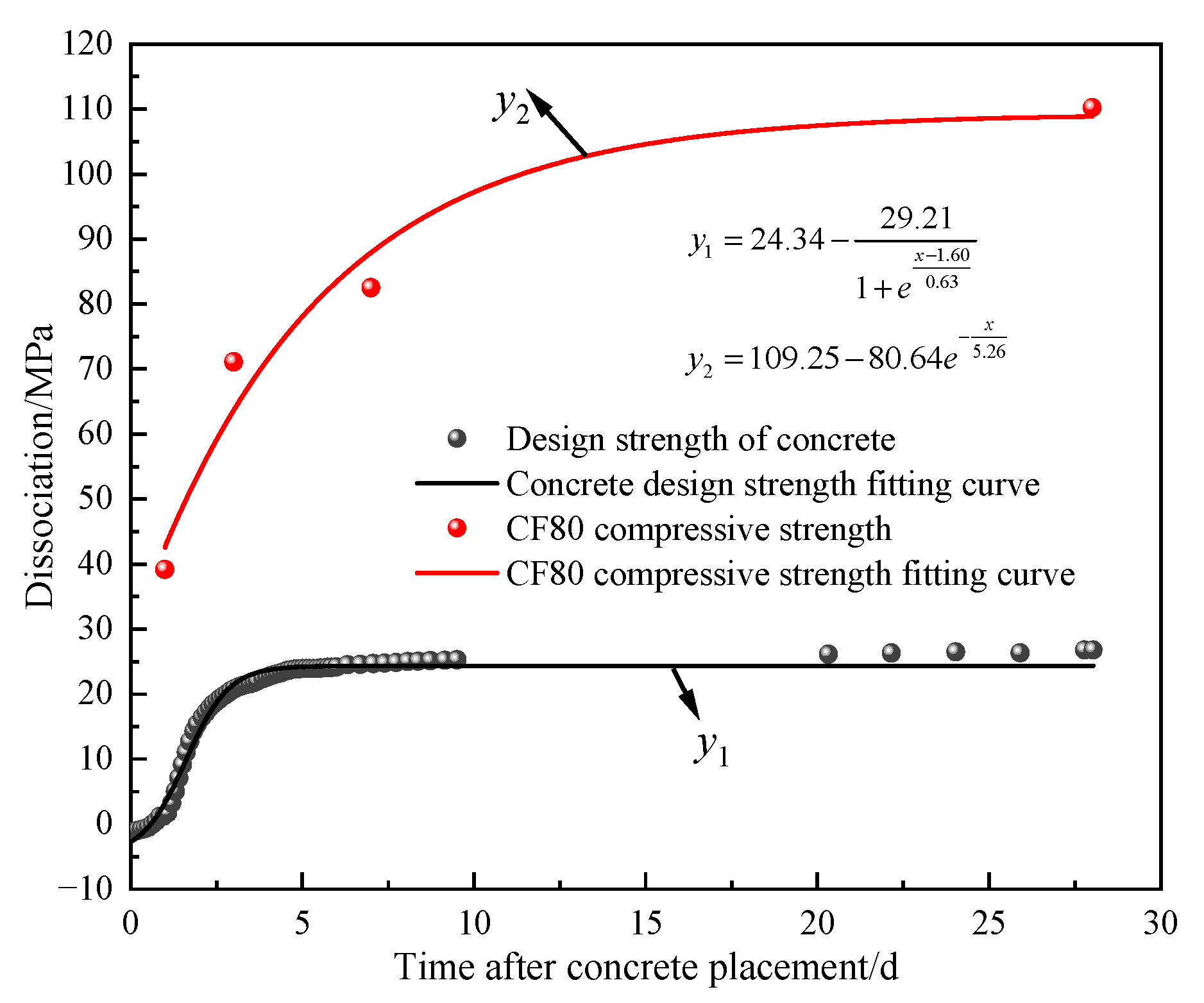

- Taking the third layer as the model example, the unfrozen water content was determined to reach a maximum thaw depth of 0.3576 m after 160 h of pouring, and the error rate between the model and the measured data was 4.64%; the peak temperature of the shaft wall caused by hydration heat reached 73.62 °C at around 27 h, with an error rate of 3.76% between the model and the measured results. The freezing pressure reached a peak of 4.72 MPa around 61.7d, with an error rate of 5.03% between the model and measured data, validating the reliability of the numerical model; additionally, the compressive strength growth of the shaft wall lining met the load-bearing requirements for freezing pressure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pilecki, Z.; Krawiec, K.; Pilecka, E.; Nagy, S.; Łątka, T. Temperature anomaly as an indicator of groundwater flow prior to the shaft sinking with the use of artificial ground freezing. Eng. Geol. 2025, 347, 107916. [Google Scholar] [CrossRef]

- Semin, M.; Golovatyi, I.; Levin, L.; Pugin, A. Enhancing efficiency in the control of artificial ground freezing for shaft construction: A case study of the Darasinsky potash mine. Clean. Eng. Technol. 2023, 18, 100710. [Google Scholar] [CrossRef]

- Zhang, S.; Yue, Z.; Lu, X.; Zhang, Q.; Sun, T.; Qi, Y. Model test and numerical simulation of foundation pit constructions using the combined artificial ground freezing method. Cold Reg. Sci. Technol. 2022, 205, 103700. [Google Scholar] [CrossRef]

- Fu, Y.; Hu, J.; Wu, Y. Finite element study on temperature field of subway connection aisle construction via artificial ground freezing method. Cold Reg. Sci. Technol. 2021, 189, 103327. [Google Scholar] [CrossRef]

- Jiang, Z.; He, B.; Zhu, X.; Ren, Q.; Zhang, Y. State-of-the-art review on properties evolution and deterioration mechanism of concrete at cryogenic temperature. Constr. Build. Mater. 2020, 257, 119456. [Google Scholar] [CrossRef]

- Do, T.A.; Hoang, T.T.; Bui-Tien, T.; Hoang, H.V.; Do, T.D.; Nguyen, P.A. Evaluation of heat of hydration, temperature evolution and thermal cracking risk in high-strength concrete at early ages. Case Stud. Therm. Eng. 2020, 21, 100658. [Google Scholar] [CrossRef]

- Hong, M.; Lei, D.; Hu, F.; Chen, Z. Assessment of void and crack defects in early-age concrete. J. Build. Eng. 2023, 70, 106372. [Google Scholar] [CrossRef]

- Del Savio, A.A.; La Torre Esquivel, D.; Carbajal, E.P.; de Andrade Silva, F. Experimental and analytical study of temperatures developed by the heat of hydration of high-strength self-compacting mass concrete. Case Stud. Constr. Mater. 2024, 22, e04098. [Google Scholar] [CrossRef]

- Kanavaris, F.; Jedrzejewska, A.; Sfikas, I.P.; Schlicke, D.; Kuperman, S.; Smilauer, V.; Honorio, T.; Fairbairn, E.M.R.; Valentim, G.; de Faria, E.F.; et al. Enhanced massivity index based on evidence from case studies: Towards a robust pre-design assessment of early-age thermal cracking risk and practical recommendations. Constr. Build. Mater. 2021, 271, 121570. [Google Scholar] [CrossRef]

- Levin, L.; Golovatyi, I.; Zaitsev, A.; Pugin, A.; Semin, M. Thermal monitoring of frozen wall thawing after artificial ground freezing: Case study of Petrikov Potash Mine. Tunn. Undergr. Sp. Technol. 2021, 107, 103685. [Google Scholar] [CrossRef]

- Hu, X.D.; Fang, T.; Han, Y.G. Mathematical solution of steady-state temperature field of circular frozen wall by single-circle-piped freezing. Cold Reg. Sci. Technol. 2018, 148, 96–103. [Google Scholar] [CrossRef]

- Hu, X.D.; Han, L.; Han, Y.G. Analytical solution to temperature distribution of frozen soil wall by multi-row-piped freezing with the boundary separation method. Appl. Therm. Eng. 2019, 149, 702–711. [Google Scholar] [CrossRef]

- Wu, T.; Zhou, X.; Zhang, L.; Zhang, X.; He, X.; Xu, Y. Theory and technology of real-time temperature field monitoring of vertical shaft frozen wall under high-velocity groundwater conditions. Cold Reg. Sci. Technol. 2021, 189, 103337. [Google Scholar] [CrossRef]

- Yu, X.; Li, F.; Zhang, J.; Ding, H.; Gao, W.; Zhang, S. Theoretical prediction of high-risk zone for early temperature cracks in well walls in deep-frozen shafts. Arch. Appl. Mech. 2023, 93, 1387–1400. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Sun, B.; Wang, Z.; Gao, Y.; Han, D.; Zhang, Y. Coupling mechanisms between cement hydration and permafrost during well construction in the Arctic region. Geoenergy Sci. Eng. 2023, 222, 211429. [Google Scholar] [CrossRef]

- Chen, W.; Wan, W.; He, H.; Liao, D.; Liu, J. Temperature Field Distribution and Numerical Simulation of Improved Freezing Scheme for Shafts in Loose and Soft Stratum; Springer: Vienna, Austria, 2024; Volume 57. [Google Scholar] [CrossRef]

- Hani, M.; Evirgen, B. Uncoupled thermo-hydro-mechanical modeling of a pykrete diaphragm wall for an alternative artificial ground freezing application. Comput. Geotech. 2024, 169, 106243. [Google Scholar] [CrossRef]

- Zhang, T. Study on the Evolution Law of Temperature Field of Frozen Well Wall in Deep and Thick Complex Formation; China University of Mining and Technology: Xuzhou, China, 2018. [Google Scholar]

- Zhang, J.; Wang, B.; Rong, C.; Long, W.; Yu, S. Temporal and Spatial Evolution Laws of Freezing Temperature Field in the Inclined Shaft of Water-Rich Sand Layers. Appl. Sci. 2023, 13, 8874. [Google Scholar] [CrossRef]

- Yang, Y.; Lei, D.; Chen, Y.; Cai, C.; Hou, S. Cold Regions Science and Technology Coupled thermal-hydro-mechanical model of deep artificial freezing clay. Cold Reg. Sci. Technol. 2022, 198, 103534. [Google Scholar] [CrossRef]

- Yan, Q.; Wu, W.; Zhong, H.; Zhao, Z.; Zhang, C. Temporal and spatial variation of temperature and displacement fields throughout cross-passage artificial ground freezing. Cold Reg. Sci. Technol. 2023, 209, 103817. [Google Scholar] [CrossRef]

- Wang, Y.; Mao, X.; Wu, Q.; Cai, P.; Ye, M.; Yin, S. Numerical Analysis of Concrete Hydration Heat Impact on Frozen Soil Temperature around Cast-in-Place Piles. Materials 2024, 17, 4375. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, S.; Weng, L.; Wang, L.; Li, Z.; Xu, L. Fractal analysis of cracking in a clayey soil under freeze-thaw cycles. Eng. Geol. 2016, 208, 93–99. [Google Scholar] [CrossRef]

- Liu, J.; Xu, H.; Tao, Y.; Lyu, Q. Effects of clay content and subfreezing temperature on the freeze–thaw deformation properties of clayey soils. Catena 2024, 239, 107916. [Google Scholar] [CrossRef]

- An, R.; Zhang, X.; Wang, Y.; Liu, X.; Chen, C.; Gong, J. Freeze–Thaw Impact on Sandy Clay in Artificial Frozen Walls: An Investigation of Shear Strength and Pore-Size Distribution. Int. J. Geomech. 2022, 22, 04022230. [Google Scholar] [CrossRef]

- Liu, B.; Song, C.-J.; Li, T.; Yu, F. Interaction mechanism of deep-buried frozen soil wall and surrounding earth mass in excavation unloaded state. Editor. Off. J. China Coal Soc. 2012, 37, 3–7. [Google Scholar]

- Batog, M.; Giergiczny, Z. Influence of mass concrete constituents on its properties. Constr. Build. Mater. 2017, 146, 221–230. [Google Scholar] [CrossRef]

- Li, X.K.; Li, X.; Liu, S.; Qi, J.L. Thermal-seepage coupled numerical simulation methodology for the artificial ground freezing process. Comput. Geotech. 2023, 156, 105246. [Google Scholar] [CrossRef]

- Huang, X.; Rudolph, D.L. Coupled model for water, vapour, heat, stress and strain fields in variably saturated freezing soils. Adv. Water Resour. 2021, 154, 103945. [Google Scholar] [CrossRef]

- Liu, X.; Nowamooz, H.; Shen, Y.; Liu, Y.; Han, Y.; An, Y. Heat transfer analysis in artificial ground freezing for subway cross passage under seepage flow. Tunn. Undergr. Sp. Technol. 2023, 133, 104943. [Google Scholar] [CrossRef]

- Bai, Y.; Sun, Y.; Liu, W.; Sun, P.; Xiao, S. Model test study on the formation of basin-shaped freezing range in sandy gravel stratum under seepage conditions. Therm. Sci. Eng. Prog. 2024, 51, 102601. [Google Scholar] [CrossRef]

- Bai, Q.B.; Li, X.; Tian, Y.H.; Fang, J.H. Equations and numerical simulation for coupled water and heat transfer in frozen soil. Yantu Gongcheng Xuebao/Chin. J. Geotech. Eng. 2015, 37, 131–136. [Google Scholar] [CrossRef]

- Luckner, L.; van Genuchten, M.T.; Nielsen, D.R. A Consistent Set of Parametric Models for the Two-Phase Flowof Immiscible Fluids in the Subsurface. Water Resour. Res. 1989, 25, 2187–2193. [Google Scholar] [CrossRef]

- van Genuchten, M.T. A Closed-form Equation for Predicting the Hydraulic Conductivity of Unsaturated Soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Özişik, M.; David, W.; Hahn, M. Heat Conduction Fundamentals. In Heat Conduction; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; Chapter 1; pp. 1–39. [Google Scholar] [CrossRef]

- Yang, T.J.; Wang, S.H.; Zhang, Z.; Gao, Y. Numerical Analysis on Hydro Thermal Coupling of Surrounding Rocks in Cold Region Tunnels. Dongbei Daxue Xuebao/J. Northeast. Univ. 2019, 40, 1178–1184. [Google Scholar]

- Su, L.F.; Cui, H.; Xu, B.Z. Research on Design Calculation Methods for Elasto-Plastic Vertical Shaft Walls. Coal Eng. 2018, 50, 1–5. [Google Scholar]

kg/m3 | W/(m·K) | kJ/(kg·K) | a m−1 | m·s−1 | m | °C | |||

|---|---|---|---|---|---|---|---|---|---|

| 1990 | 3.2 | 0.833 | 2.65 | 5.8 × 10−7 | 0.26 | 0.5 | 0.362 | 0.02 | −1.31 |

W/(m·°C) | kJ/(kg·°C) | kg/m3 | kg/m3 | kJ/kg |

|---|---|---|---|---|

| 3.25 | 0.95 | 2491 | 400 | 385.3 |

| Time After Pouring of the Outer Wall/d | 0–1 | 1–2 | 2–3 | 3 |

|---|---|---|---|---|

| Equivalent thermal conductivity/kJ/(m·h·°C) | 0.46 | 0.92 | 1.84 | 2.00 |

| Times/d | 0–1.5 | 1.5–3.5 | 3.5–7.5 | 7.5–21 |

|---|---|---|---|---|

| modulus of elasticity/GPa | 10 | 25 | 30 | 40 |

| Soil Temperature/°C | Frost Rate/% | Modulus of Elasticity/MPa | Poisson’s Ratio |

|---|---|---|---|

| −15 | / | 294 | 0.152 |

| −20 | / | 337 | 0.137 |

| −25 | 3.2 | 375 | 0.128 |

| −30 | 2.28 | 384 | 0.127 |

| −35 | 2.32 | / | 0.126 |

| Concrete Curing Time/d | 1 | 3 | 7 | 28 |

|---|---|---|---|---|

| Compressive strength/MPa | 39.2 | 71.1 | 82.5 | 110.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Pang, J.; Zou, J.; Zhang, C. An Investigation of Water–Heat–Force Coupling During the Early Stage of Shaft Wall Pouring in Thick Topsoil Utilizing the Freezing Method. Processes 2025, 13, 3319. https://doi.org/10.3390/pr13103319

Yuan Y, Pang J, Zou J, Zhang C. An Investigation of Water–Heat–Force Coupling During the Early Stage of Shaft Wall Pouring in Thick Topsoil Utilizing the Freezing Method. Processes. 2025; 13(10):3319. https://doi.org/10.3390/pr13103319

Chicago/Turabian StyleYuan, Yue, Jianyong Pang, Jiuqun Zou, and Chi Zhang. 2025. "An Investigation of Water–Heat–Force Coupling During the Early Stage of Shaft Wall Pouring in Thick Topsoil Utilizing the Freezing Method" Processes 13, no. 10: 3319. https://doi.org/10.3390/pr13103319

APA StyleYuan, Y., Pang, J., Zou, J., & Zhang, C. (2025). An Investigation of Water–Heat–Force Coupling During the Early Stage of Shaft Wall Pouring in Thick Topsoil Utilizing the Freezing Method. Processes, 13(10), 3319. https://doi.org/10.3390/pr13103319