Magnesium (Mg) alloys, which are recognized as among the lightest structural metals, are extensively utilized in the automotive, aerospace, and sports industries [

1,

2,

3,

4,

5,

6,

7]. AZ91 Mg alloy is recognized for its good vibration-damping capabilities and high strength-to-weight ratio, establishing it as the most prevalent and extensively utilized series of Mg alloys [

8,

9,

10,

11]. However, the mechanical strength and wear resistance of AZ91 Mg alloy are insufficient to meet the growing demands of the aerospace and lightweight equipment industries, creating a pressing need to develop advanced Mg-based composites with enhanced performance [

12]. The mechanical properties of Mg-based composites are significantly influenced by the type, quantity, intrinsic characteristics, and alignment of the reinforcements. Among the reinforcements, carbon fibers are particularly prominent due to their substantial impact on the directional strength and structural stability of the composites. Furthermore, the processing method and its control parameters play a pivotal role in determining the overall performance of the fabricated composites [

13,

14]. Among the different production methods, squeeze-casting techniques are widely used worldwide to manufacture Mg metal matrix composites (Mg-MMCs). This method is favored, as it combines the benefits of both forging and casting processes, enabling high-quality mass production at a low cost. Additionally, squeeze-casting allows for the production of complex structural parts with minimal casting defects, a short process time, and overall cost efficiency [

15,

16,

17,

18]. However, several attempts have been made to incorporate carbon reinforcements into the AZ91 matrix alloy to produce composite materials using alternative production methods [

19,

20,

21]. Gu et al. [

19] fabricated AZ91-based composites using a pressurized liquid metal infiltration process that incorporated both coated and uncoated carbon fiber fabric as reinforcement. Their results showed that the coated carbon fiber/AZ91 composite exhibited superior damping capacity at low temperatures compared to the uncoated version. In fact, this study focused on interface design through carbon coating to enhance damping properties but was limited to low-temperature applications (≤170 °C) and did not explore the mechanical–tribological performance. Also, Kandemir et al. [

20] investigated how the length (100 and 500 μm) and content (2.5 and 5.0 wt.%) of recycled short carbon fibers (RSCFs) affected the microstructure and mechanical properties of RSCFs/AZ91 composites produced using stir-casting and hot extrusion. They found that aligned RSCFs refined the alloy’s grains and intermetallic phases. Composites with 2.5 wt.% RSCFs showed increased hardness (16–20%) and yield strength (5–15%) but decreased ductility. Increasing the RSCF content to 5.0 wt.% negatively impacted the strength and further reduced the ductility due to fiber clustering and micro-cracks. Additionally, RSCF reinforcement did not improve creep resistance. The shortcoming of this work is that it examined extruded composites with low fiber content (≤5 wt.%), but their processing led to fiber breakage and offered no control over fiber orientation. Chen et al. [

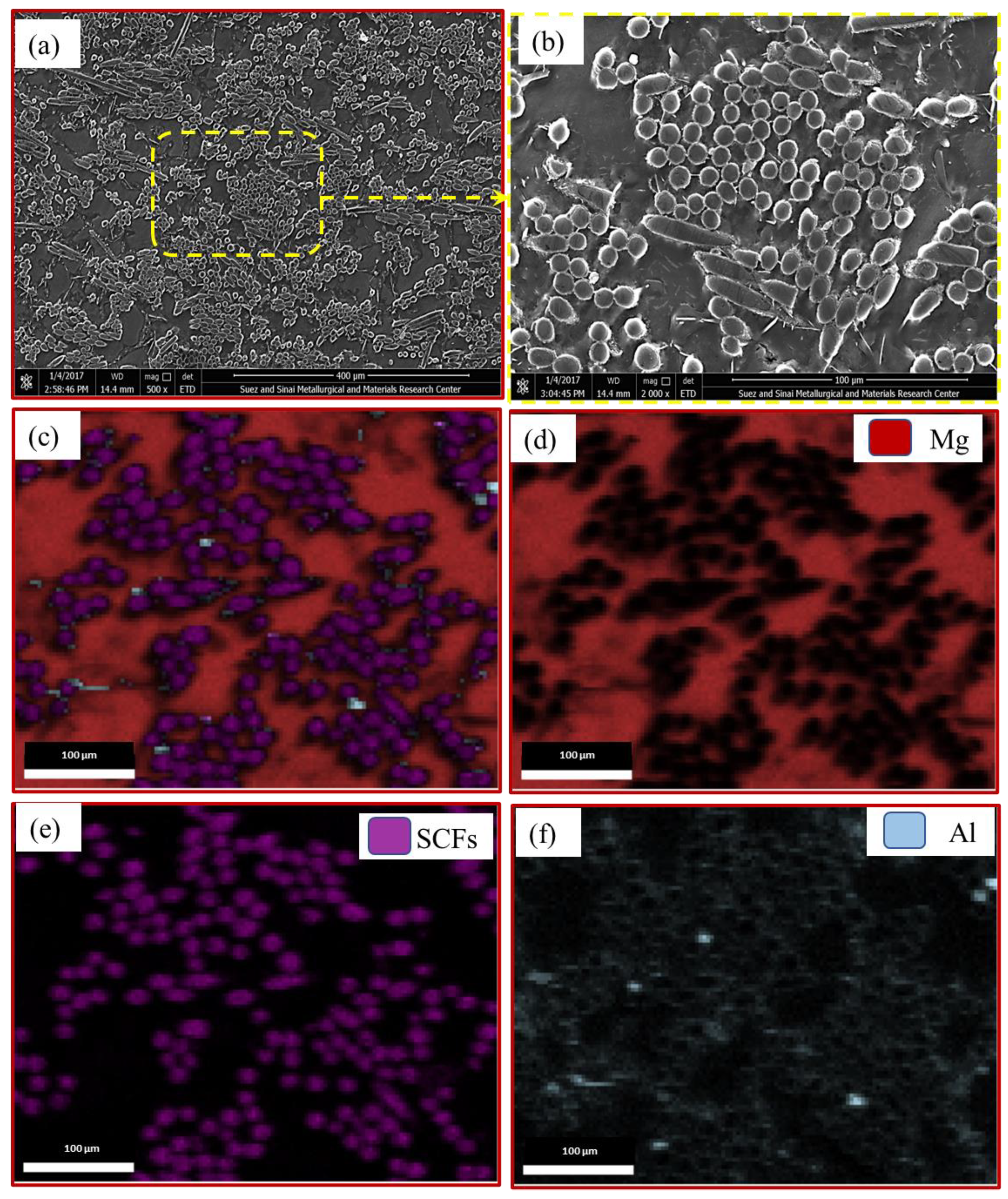

21] developed a liquid–solid extrusion using a vacuum pressure infiltration process to fabricate SCF-reinforced AZ91D parts with complex shapes for automotive applications. The produced composite exhibited a compressive strength of 487 MPa, representing a 40% increase over the AZ91D alloy (335 MPa), although with reduced compressive strain (half that of AZ91D). The fiber orientation significantly influenced the load-bearing capacity, with fibers parallel to the shear direction outperforming perpendicular ones. Peng et al. [

11] used molecular dynamics (MD) simulations to explore the effect of monolayer graphene (1LG) orientation on the mechanical properties of AZ91/1LG Mg composites under uniaxial tension. The results revealed that both Young’s modulus and tensile strength decrease as the 1LG orientation angle increases. Specifically, orientation angles of 0–10° improve these properties, with a 21.7% increase in Young’s modulus and a 19.7% increase in tensile strength at 0°. In contrast, angles of 20–90° reduce these properties. While the authors conducted MD simulations to demonstrate graphene orientation effects, their work remained theoretical, lacking experimental validation of the predicted bulk composite properties. Alrasheedi et al. [

22] investigated the low-cycle and high-cycle fatigue behavior of AZ91 alloy reinforced with a high-volume fraction of SCFs at 20 °C and 250 °C, targeting truck piston applications. Their S–N curves revealed that the AZ91/SCF composite exhibited a significantly higher fatigue strength of 55 MPa under high-cycle fatigue conditions at 250 °C, compared to the 37 MPa observed for the unreinforced AZ91 matrix alloy. Beniyel et al. [

23], using response surface methodology (RSM) with a Box–Behnken design and genetic algorithm optimization, investigated how load, sliding distance, and velocity affect the wear behavior of an AZ91D-Mg alloy. They found that the wear rate increased proportionally with increasing load, sliding distance, and velocity. Based on the abovementioned literature, the performance of AZ91-based composites is significantly influenced by key factors such as the fiber–matrix interface design, fiber orientation, volume fraction, and manufacturing techniques. These parameters govern the homogeneity of reinforcement distribution and the optimization of mechanical properties in both normal and parallel directions relative to the reinforcement plane. Given the growing applications of these composites in aerospace and transportation industries, these processing parameters remain a focal point of ongoing research. RSM and other theoretical optimization approaches have been widely employed to refine processing parameters for diverse materials [

24,

25,

26,

27,

28,

29]. For instance, Der et al. [

28] demonstrated the critical role of precision laser cutting in optimizing the manufacturing of thermoplastic-based thermal management systems, highlighting how parameter selection (e.g., power and speed) significantly influences material performance. Their multi-criteria decision-making (MCDM) approach, which combined experimental analysis with SWARA-weighted optimization, established that polypropylene cut at 90 W and 15 mm/s delivered superior results. This methodology underscores the broader applicability of systematic parameter optimization in material processing. Huang et al. [

29] used a 3 kW fiber laser to apply CoCrCuFeNi high-entropy alloy coatings to 45 steel. The research systematically examined how laser power, scanning speed, and powder feed rate affect the coating’s shape, dilution, hardness, and RSM. The goal was to find the optimal processing conditions for coating with a high shape ratio, high maximum hardness, and a dilution rate between 10% and 20%. The study determined that a laser power of 773.65 W, a scanning speed of 5 mm/s, and a powder feed rate of 15 g/min yielded the desired coating properties, specifically, a shape ratio of 5.07, a dilution rate of 14.29%, and a microhardness of 186.8 HV. The accuracy of the predicted values was confirmed through validation experiments, with errors remaining below 10%.

Based on the introduction above and in light of the existing literature, it is evident that AZ91 Mg alloy and its composites demonstrate significant potential for lightweight applications in aerospace and transportation industries. However, critical challenges remain in optimizing their performance under combined mechanical and tribological loading conditions across operational temperature ranges. Previous research has predominantly examined isolated factors, such as processing techniques, reinforcement types, fiber–matrix interface characteristics, and volume fraction, often without developing a framework to integrate these parameters for composite performance. Furthermore, determining how controlled fiber orientation affects surface roughness and wear behavior, especially at high SCF volume fractions (23%), remains an area of interest that needs to be explored. Thus, this study directly addresses these critical knowledge gaps by implementing an integrated optimization methodology that systematically examines the interdependent relationships among processing parameters, temperature-dependent mechanical behavior, and wear performance characteristics.

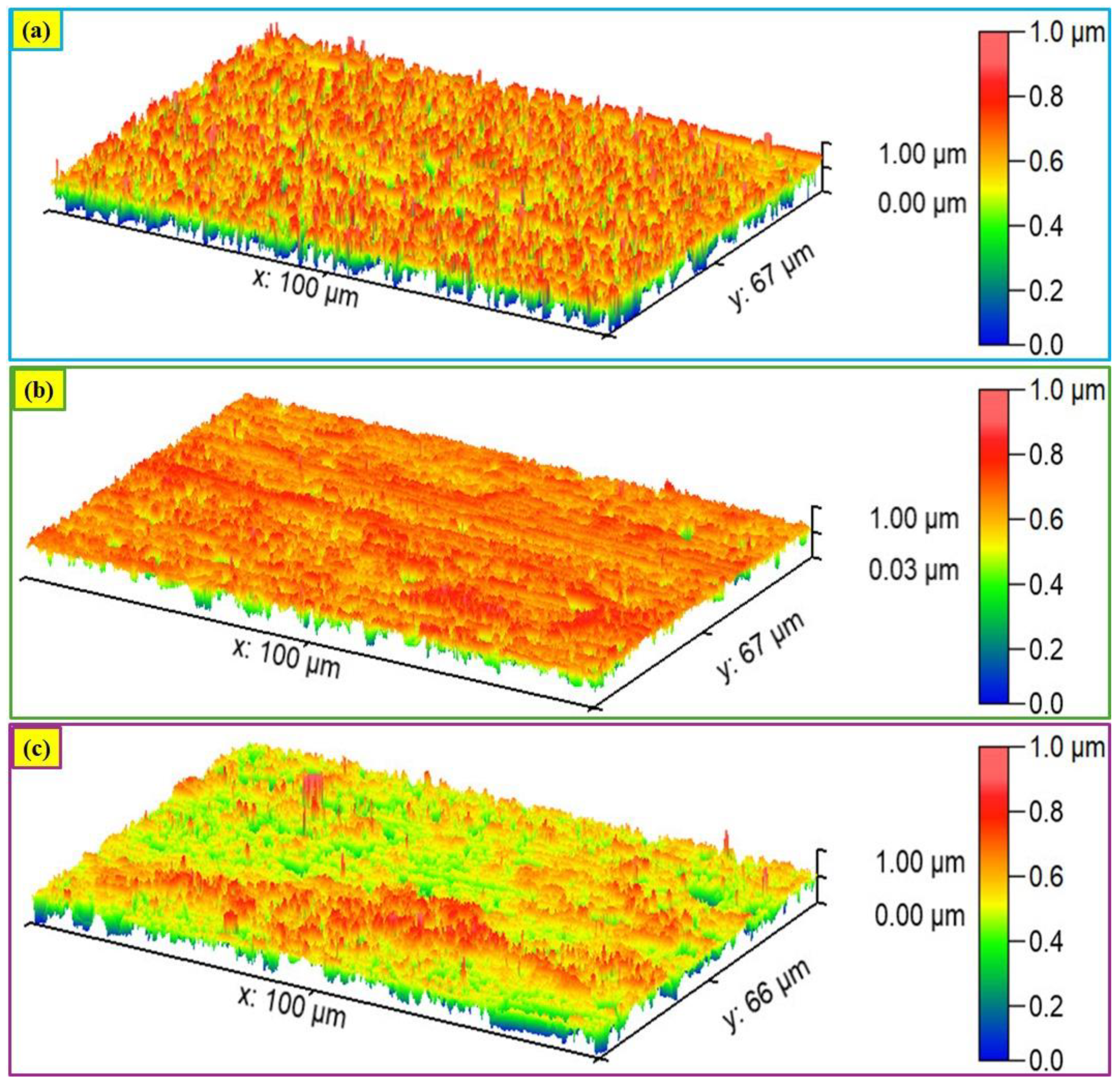

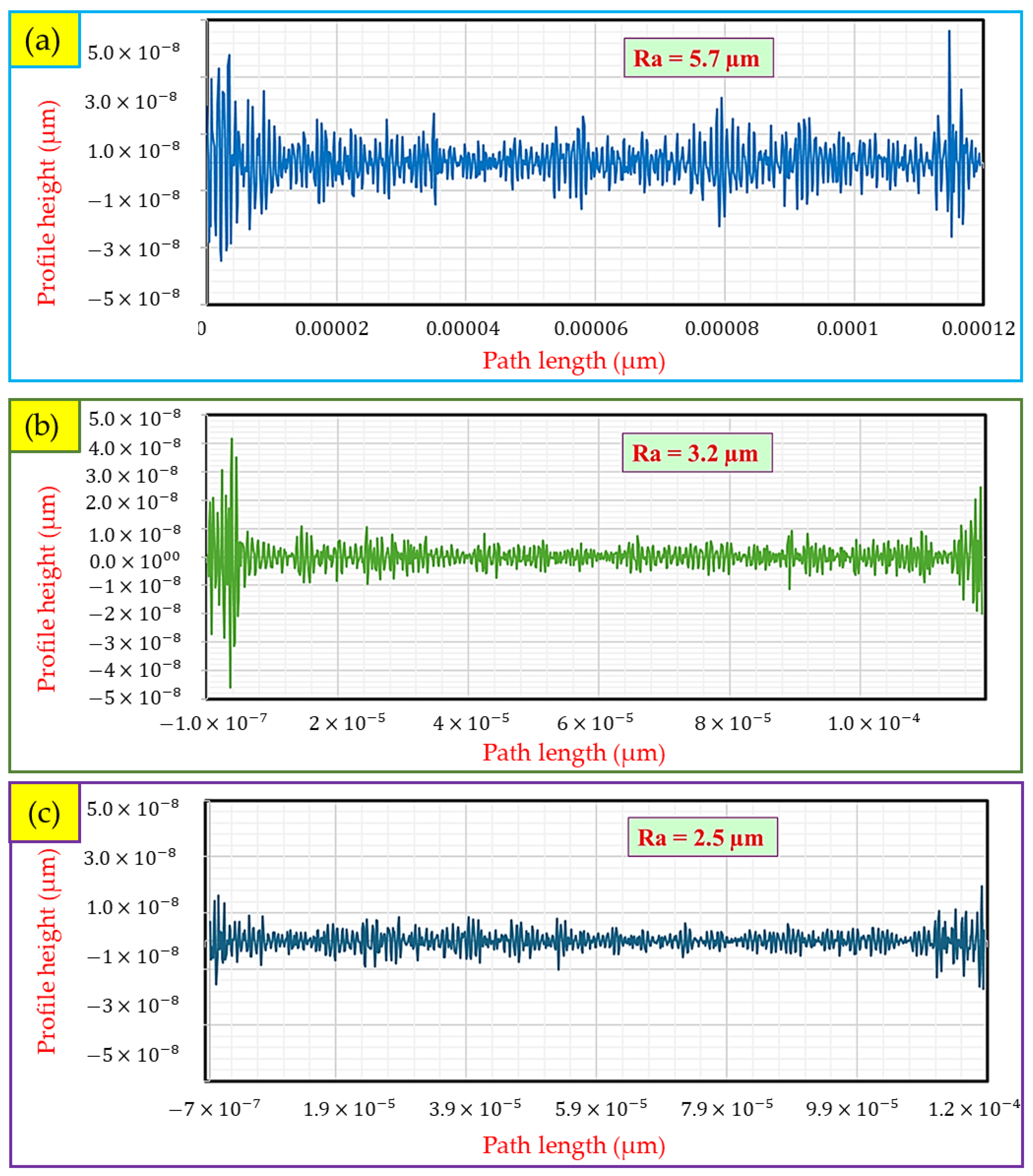

The novelty of the current study is derived from three key advancements in the field of magnesium matrix composites: (1) the development of a squeeze-casting technique that enables the precise control of short carbon fiber (SCF) orientation (parallel/normal) at an industrially viable 23 vol.%, overcoming the fiber breakage and porosity limitations of conventional extrusion/stir-casting methods; (2) a systematic investigation, for the first time, of the combined mechanical–wear performance of AZ91/SCF composites across a broad temperature range (20–300 °C), addressing a critical knowledge gap for high-temperature applications in the aerospace and automotive industries; and (3) the integration of RSM with 3D surface topography analysis to establish quantitative relationships among SCF alignment, surface roughness, and wear resistance, yielding a predictive framework for composite design.

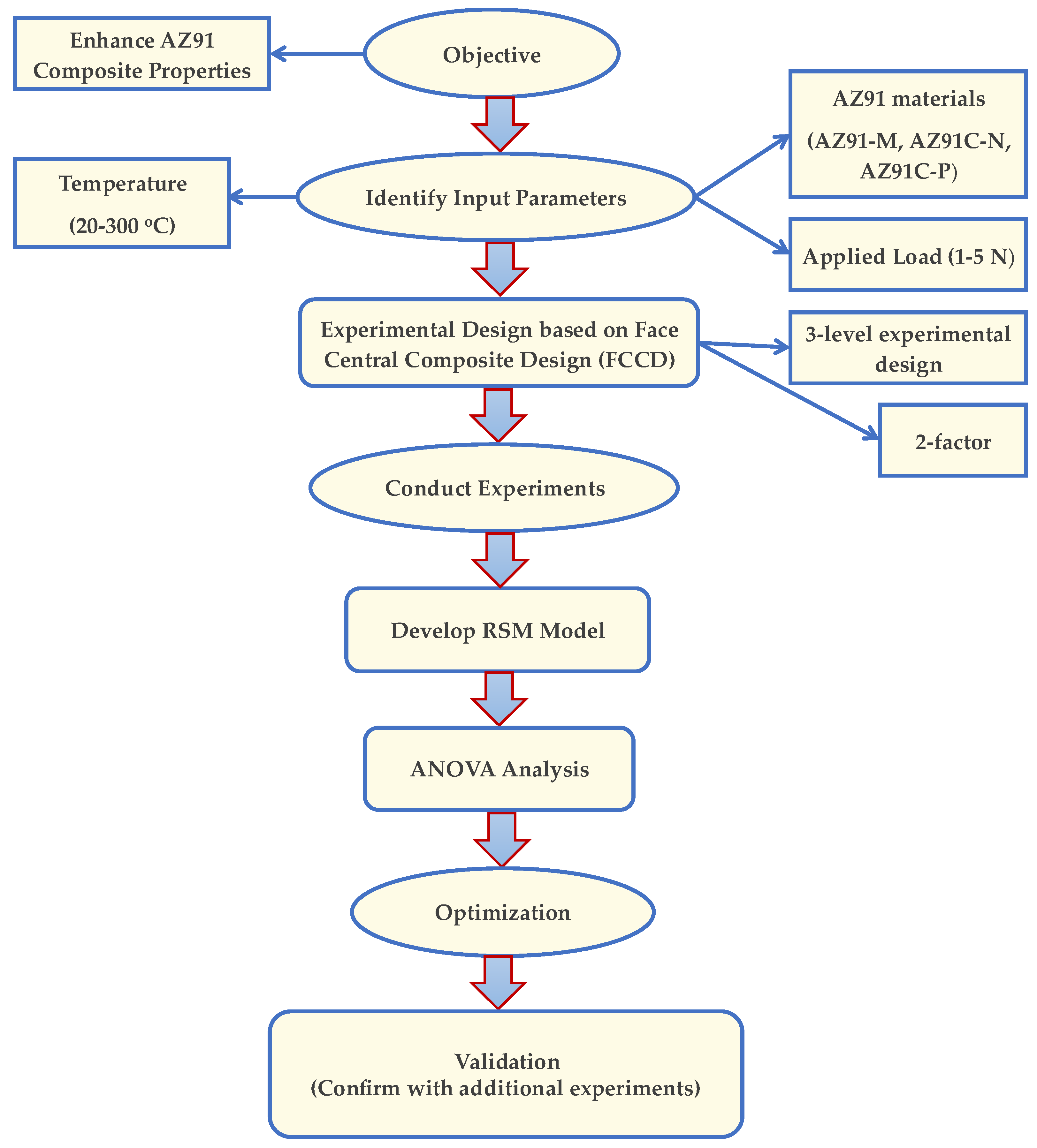

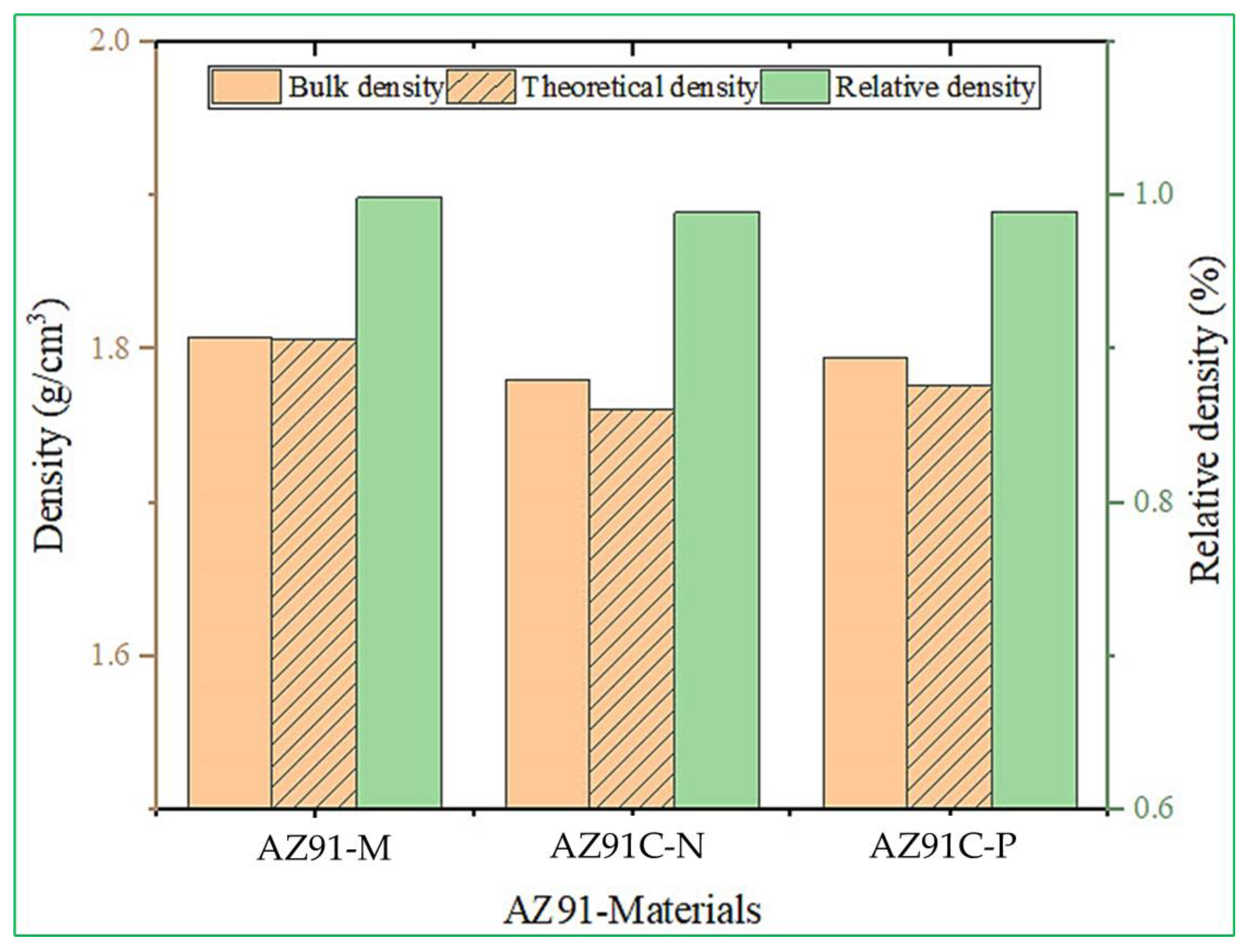

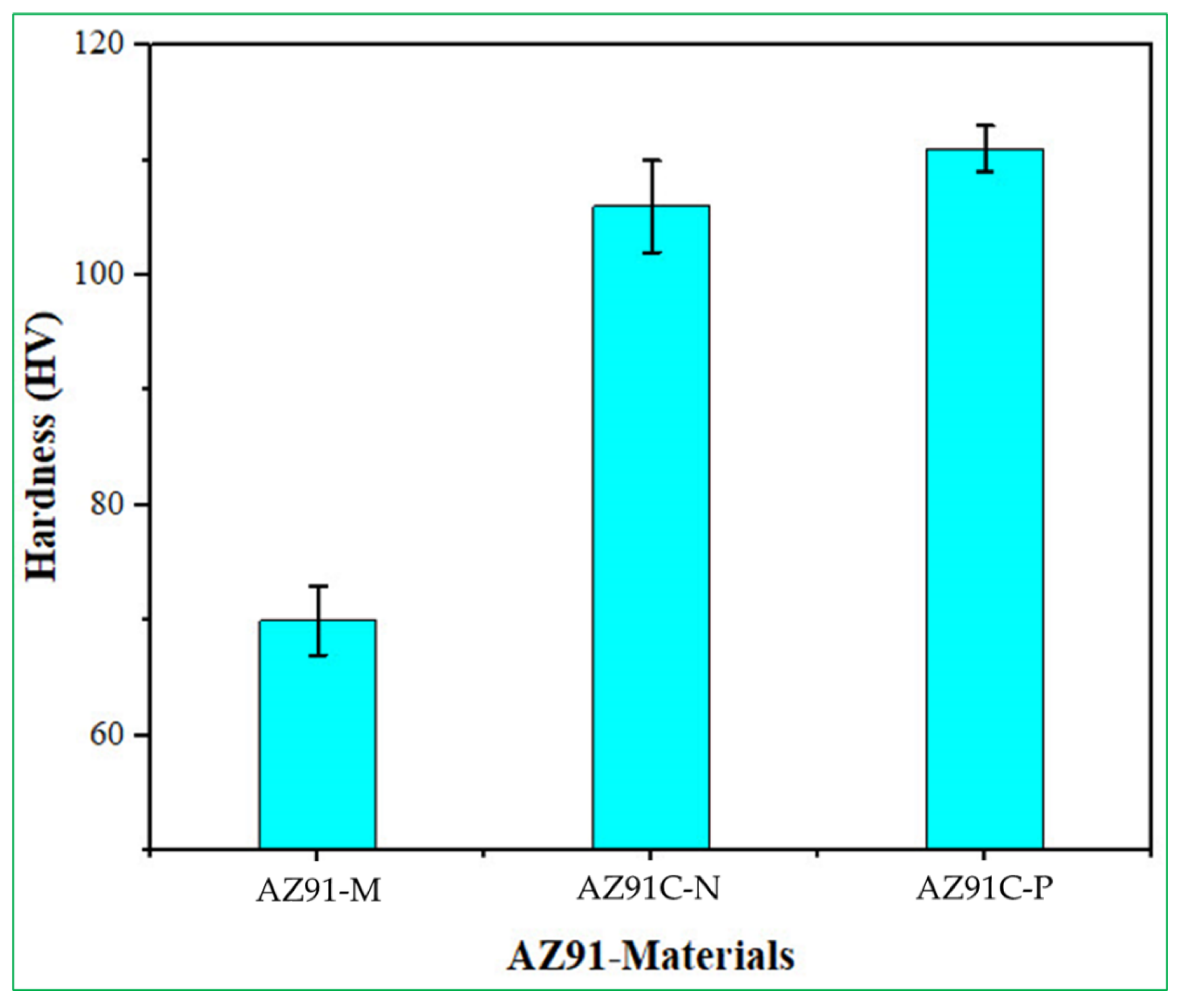

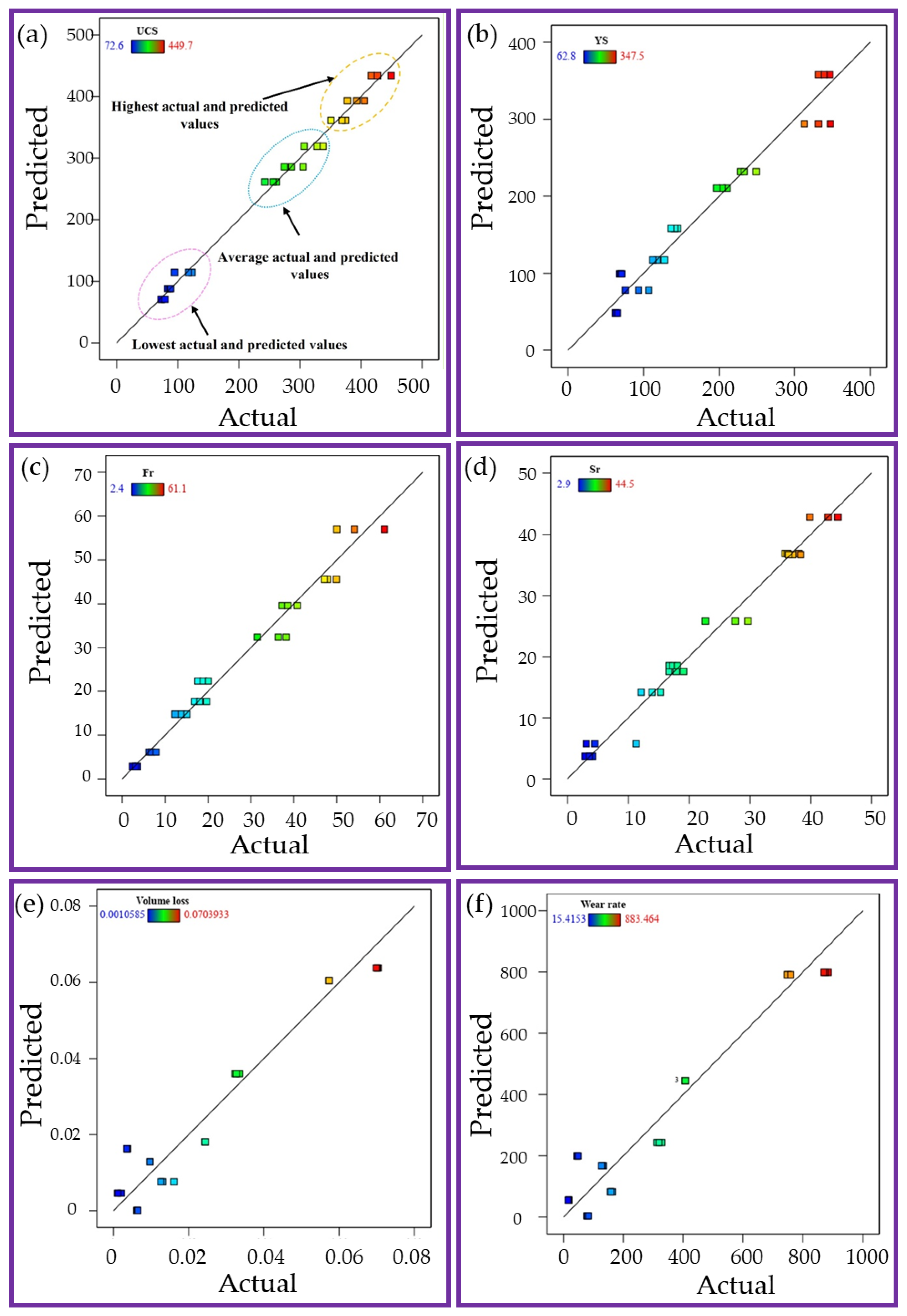

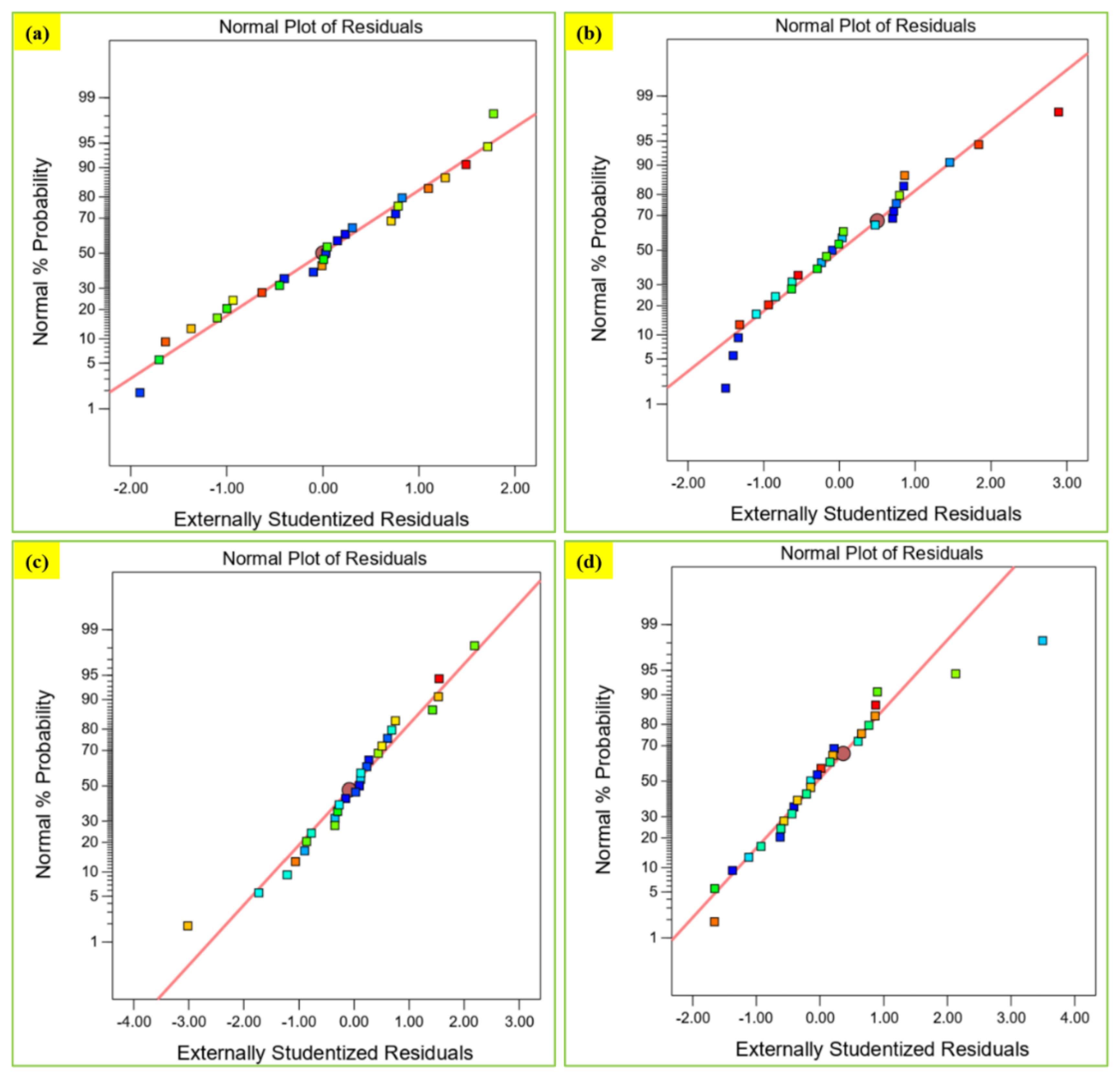

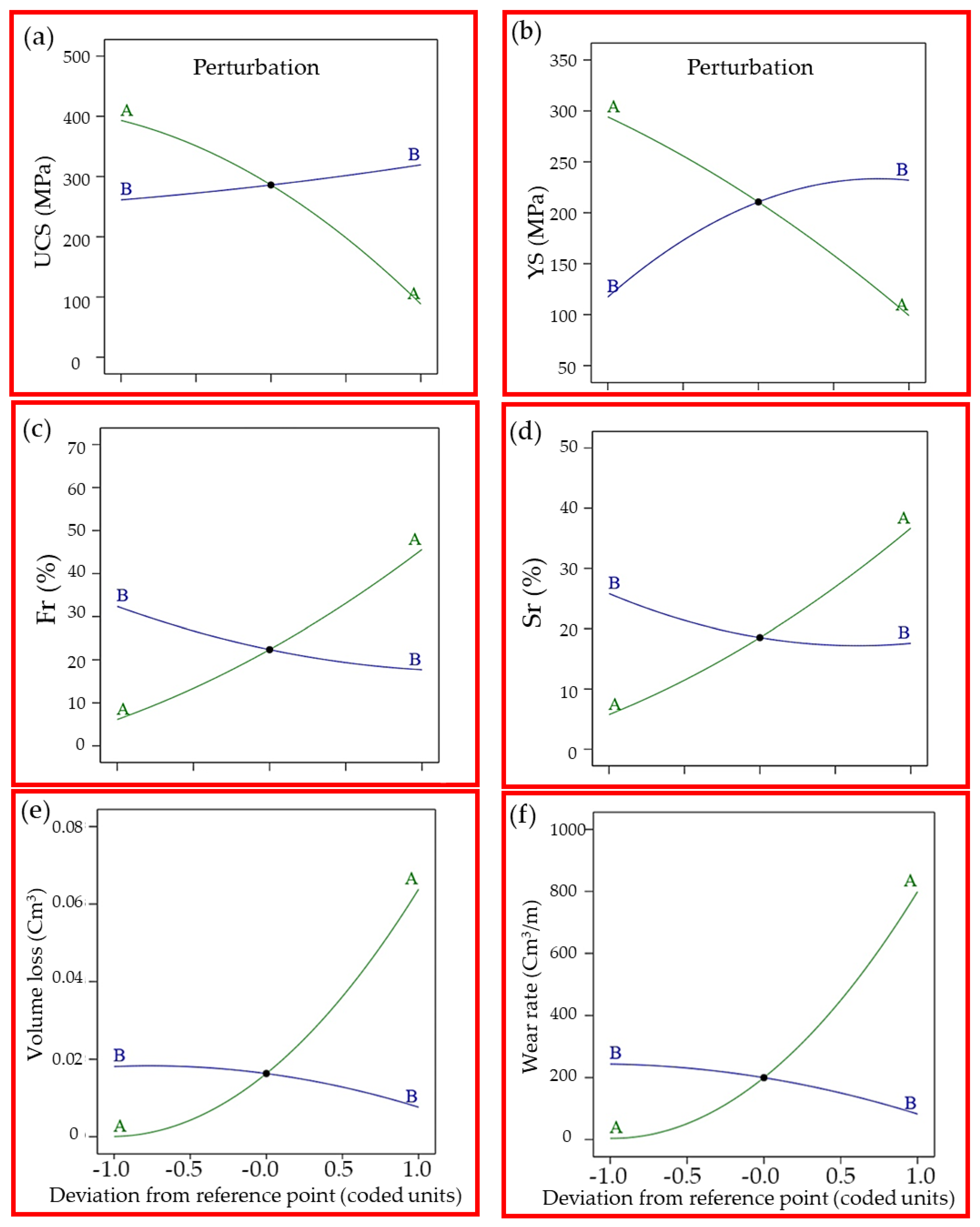

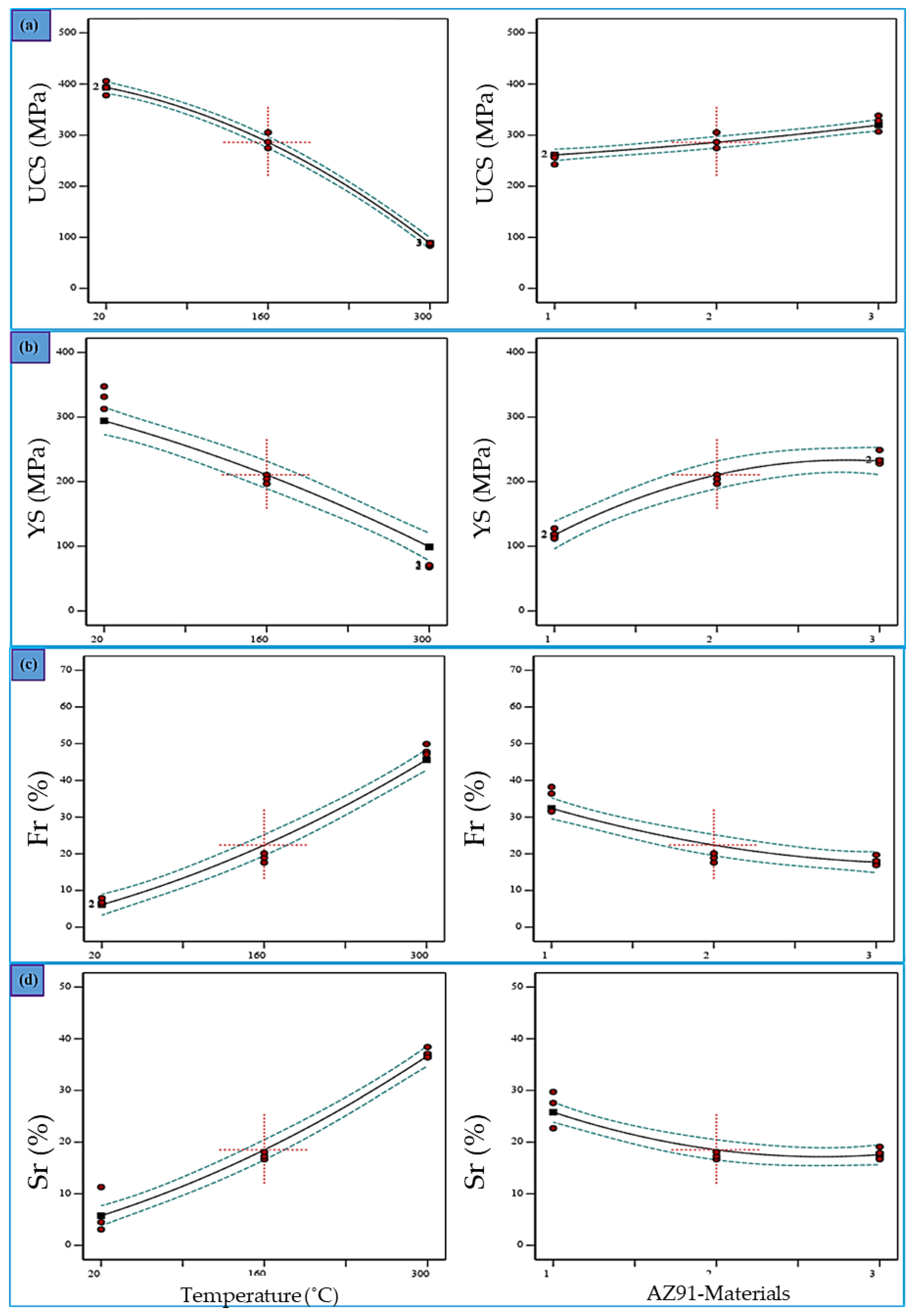

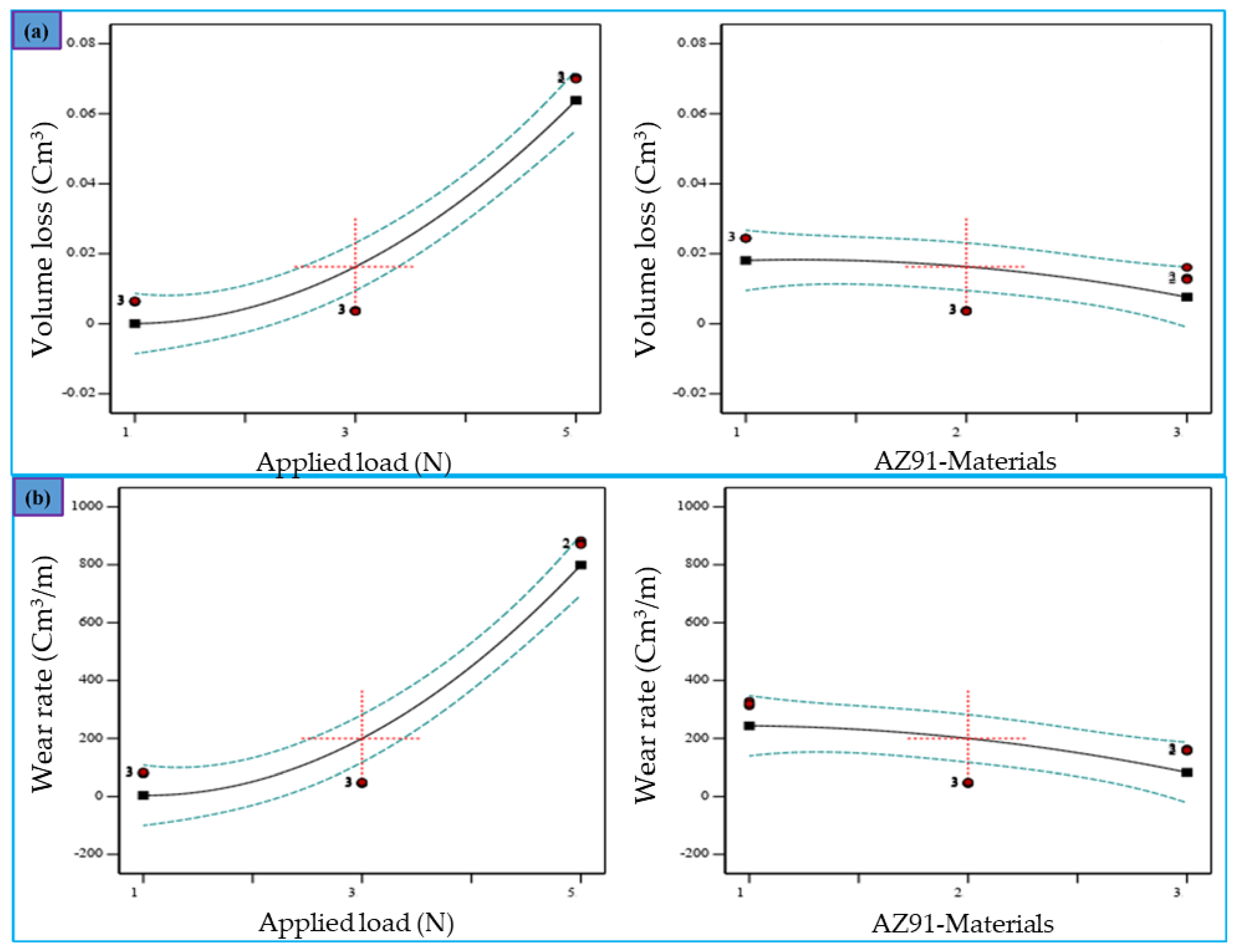

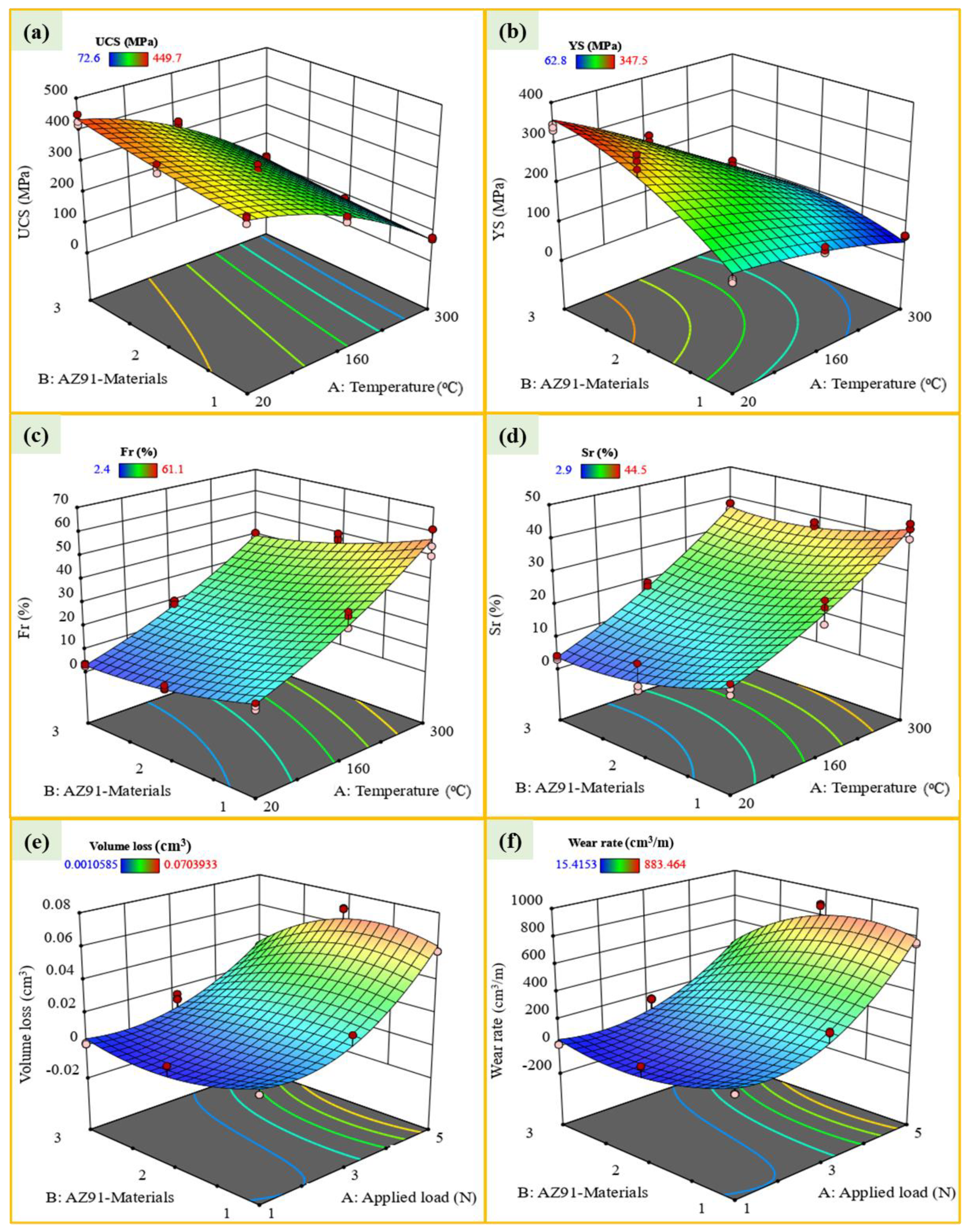

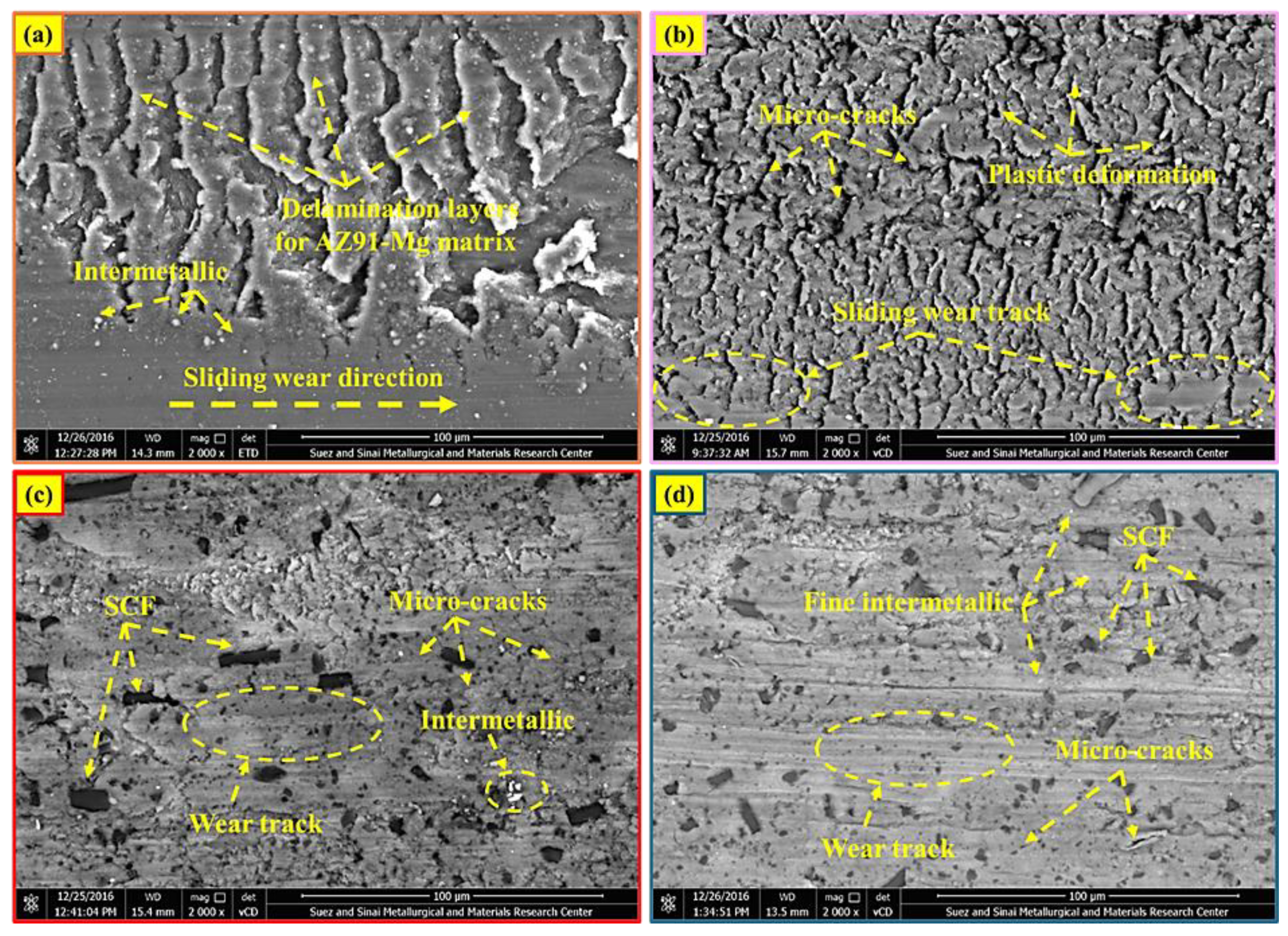

Finally, this study introduces a novel approach, utilizing RSM to optimize the ultimate compressive strength (UCS), yield strength (YS), reduction in height at fracture (Fr), and reduction in height at maximum stress (Sr) of squeeze-cast AZ91 Mg alloy and its 23 vol.% SCF-reinforced composites across a broad temperature range (20–300 °C). Additionally, the wear behavior in terms of volume loss, wear rate, worn surface morphology, and worn surface roughness is investigated under varying load conditions (1–5 N) for three distinct materials: the AZ91 matrix, Composite-N, and Composite-P.

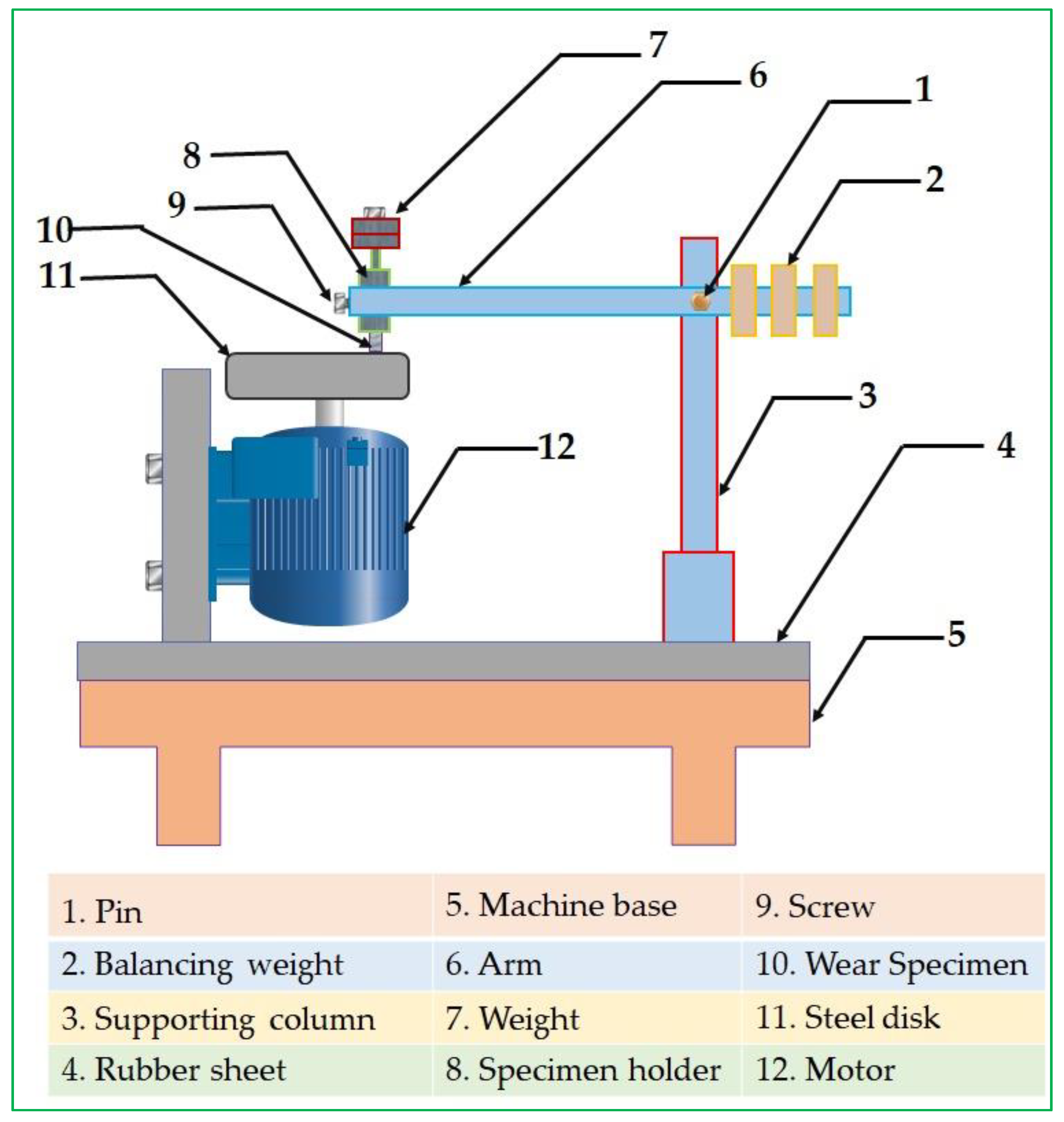

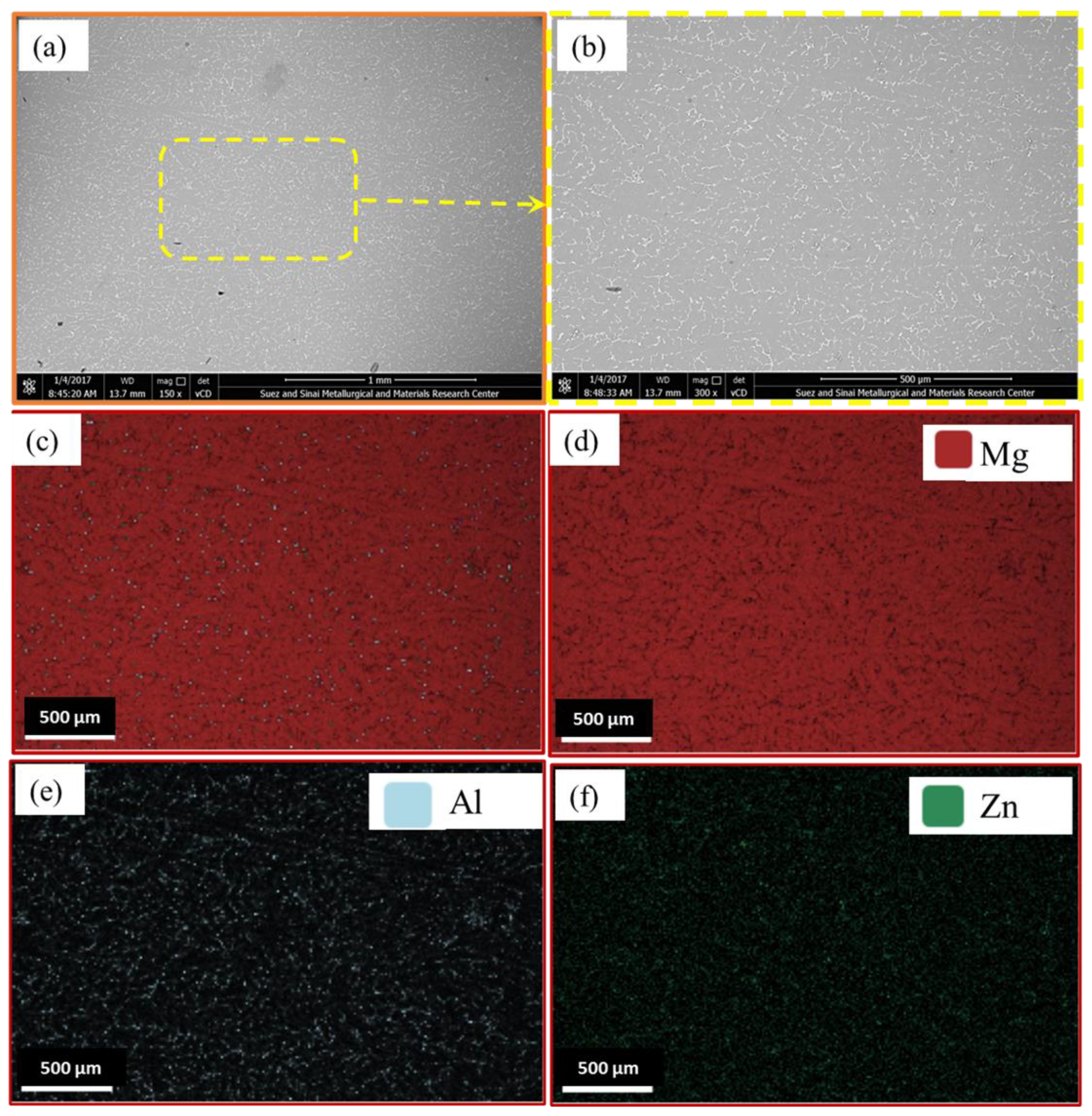

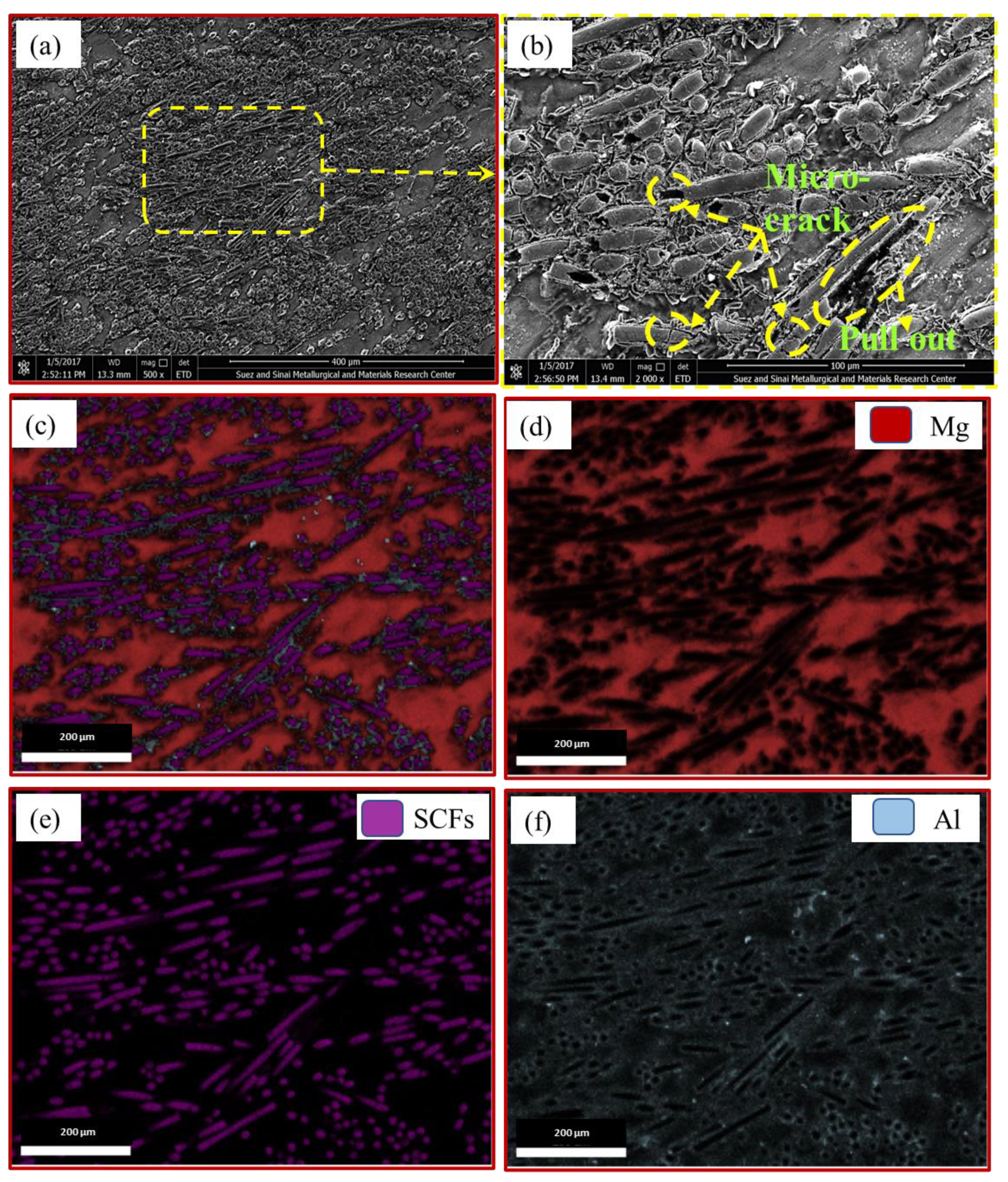

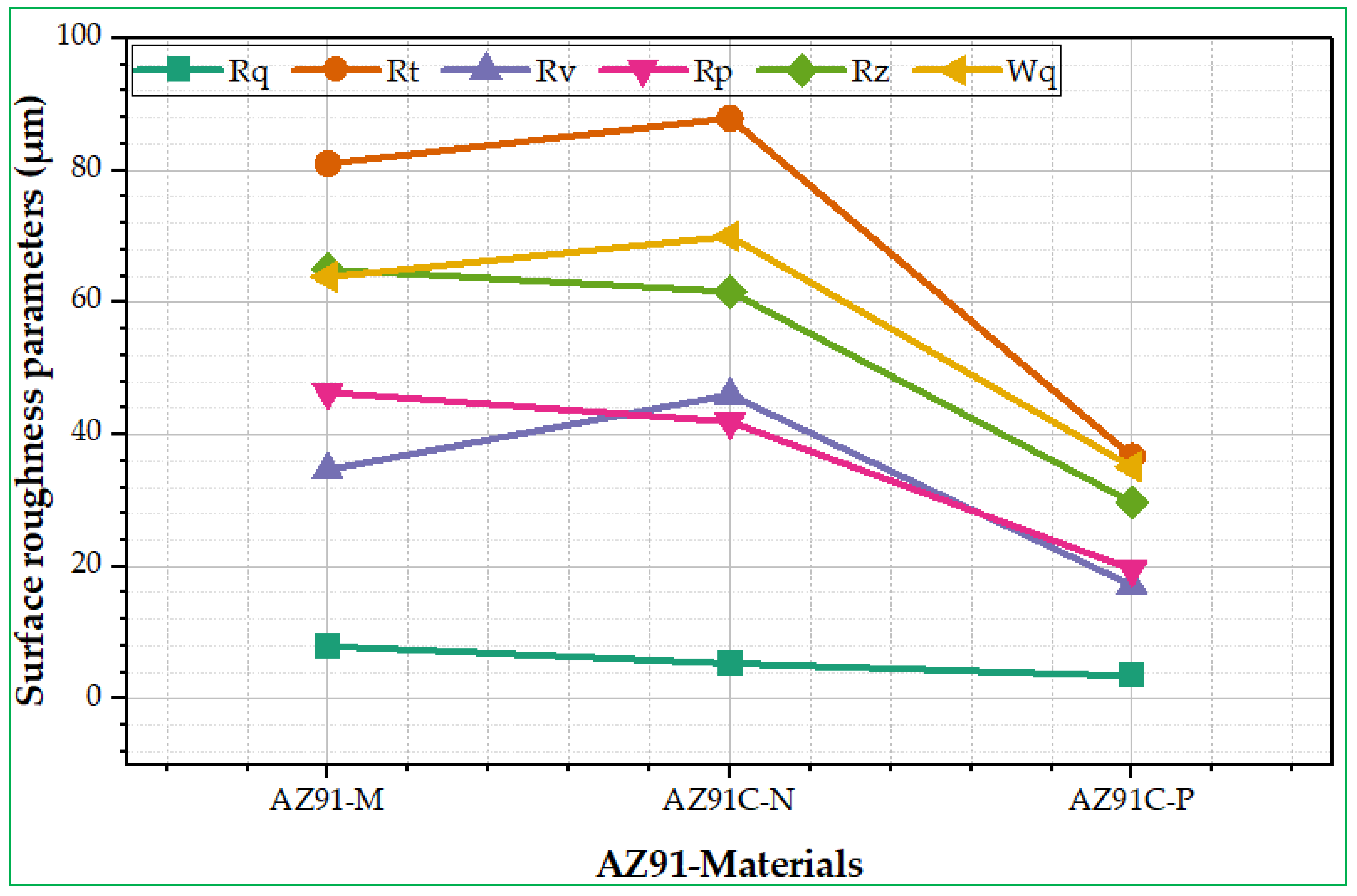

Optimization is performed using RSM-based Face-Centered Composite Design (FCCD) via Design-Expert software V10, targeting maximum mechanical performance and wear resistance. Furthermore, the influence of processing variables on metallographic characteristics, density, and hardness is examined. A key objective is to correlate SCF orientation with surface roughness parameters, providing critical insights into the surface quality of AZ91 and its high-fiber content composites. By integrating mechanical and wear behavior optimization with advanced statistical modeling, this work represents a significant advancement in magnesium-based composites, paving the way for their use in high-temperature and wear-resistant applications.