1. Introduction

Many countries have successively announced net-zero carbon emission targets to address the escalating dual challenges of global climate change and energy insecurity. Power generation from low-grade heat sources offers a practical pathway toward achieving these goals [

1]. Such heat sources are widely distributed in industrial waste heat, geothermal energy, solar thermal utilization, biomass energy, and ocean thermal gradients. Among various thermal energy conversion approaches, the Organic Rankine Cycle (ORC) has been extensively recognized as a leading technology for harnessing low-grade heat and transforming it into electricity, offering both high applicability and significant potential for energy recovery [

2]. Maximizing the conversion efficiency from available thermal energy to electricity is a critical objective for ORC systems. However, in many thermal power generation scenarios, both sink and heat source temperatures vary with time, leading to off-design operation [

3]. Consequently, Maximum Power Point Tracking (MPPT) control is required to adapt operating conditions and sustain optimal power output [

4].

Maximum Power Point Tracking (MPPT) technology enables ORC systems to deliver maximum power output under varying sink and heat source conditions [

5]. Quoilin et al. [

6] proposed three MPPT control strategies. The first maintains a constant evaporation temperature by regulating pump flow rate and expander speed to control evaporation temperature and superheat degree. The second strategy determines the optimal evaporation temperature through a fitted correlation. The third utilizes a fitted relationship among heat source temperature, condenser temperature, and expander speed to identify the optimal working fluid flow rate under current operating conditions. Simulation results demonstrated that the optimal evaporation temperature strategy achieved the highest efficiency, providing theoretical guidance for subsequent studies.

Subsequent research has primarily focused on superheat temperature and evaporation pressure control. For MPPT strategies based on evaporation pressure, Hu et al. [

7] simulated two approaches—fixed-pressure and sliding-pressure operation—adapted from steam turbine control. The results showed that at low geothermal mass flow rates, fixed-pressure operation achieved higher efficiency, whereas under fixed geothermal temperature with variable mass flow rates, sliding-pressure operation was superior. Peralez et al. [

8] developed a reduced-order evaporator model and proposed a dynamic optimization algorithm to compute evaporation pressure for real-time control, demonstrating improved power generation efficiency. Hernandez et al. [

9] introduced a perturbation-based extremum-seeking approach for real-time determination of the optimal evaporation temperature. To ensure system stability, they combined extended predictive adaptive control with model predictive control, achieving better performance than PID control. Li et al. [

10] integrated reinforcement learning with model predictive control for evaporation pressure regulation, enhancing both response speed and control accuracy. Wang [

11] compared fixed- and sliding-pressure operations, finding that sliding-pressure operation could increase net power output by up to 43.9%. Overall, these studies demonstrate that effective evaporation pressure control enables ORC systems to achieve maximum power output across diverse operating conditions.

In addition to evaporating pressure control, which enables the system to achieve maximum power output, regulating the superheat degree can also allow the ORC system to deliver maximum output under varying sink and heat source conditions [

12]. Vaupel et al. [

13] compared different maximum power output strategies for ORC systems and concluded that maintaining the minimum superheat degree is the most effective approach. Hernandez et al. [

14] designed multiple model predictive control (MPC) strategies, adopting linear MPC when the superheat degree is relatively high and nonlinear MPC (NMPC) when it is low, in order to prevent the system from exceeding safe operating boundaries. This hybrid strategy not only increases net power output but also ensures safe operation. Zhou et al. [

15] developed a 4 kW ORC experimental platform to compare and validate five MPPT strategies, finding that maintaining a constant superheat degree allows the system to operate safely. Fatigati et al. [

16] proposed a model-based feedforward proportional–integral–derivative (PID) algorithm for superheat degree control, with experimental results demonstrating that this method enables the ORC system to achieve its designed output.

The two most widely adopted control strategies are the Minimal Superheat Temperature (MST) strategy [

13] and the Optimal Evaporating Temperature (OET) strategy [

6]. The OET strategy is theoretically derived and depends on heat source temperature, cold source temperature, and working fluid flow rate. In practice, the optimal evaporating temperature is calculated under given operating conditions and used as the setpoint. By contrast, the MST strategy regulates the evaporator outlet to maintain a small degree of superheating.

The OET strategy is best suited to scenarios with relatively stable operating conditions or cases where the heat source temperature or flow rate exceeds the rated value, as it allows the system to sustain optimal thermal efficiency and achieve high power output. However, under operating conditions where the heat source temperature or flow rate is below the rated level, OET control may drive the system beyond safe operating boundaries, potentially leading to equipment damage. In contrast, the MST strategy is more effective under severe heat source fluctuations or scenarios where the heat source temperature or flow rate declines below the specified operating point, ensuring safe and stable operation. Nevertheless, under conditions where the heat source temperature or flow rate exceeds the rated value, the MST strategy cannot enable the system to reach maximum power output.

A review of the existing literature indicates that relatively few MPPT strategies are able to simultaneously guarantee the safe operation of the ORC system and enhance power output to its maximum potential [

5]. To address this gap, this study proposes an MPPT strategy based on the joint optimization of evaporating pressure and superheat degree. The strategy compiles the optimal evaporating pressure and superheat degree under various sink and heat source conditions into a system characteristic map. During operation, the controller references this map to obtain the optimal values corresponding to the current operating conditions. To further ensure that the system remains within safe operating limits, a Nonlinear Model Predictive Control (NMPC) algorithm is employed.

The rest of this manuscript is arranged as follows.

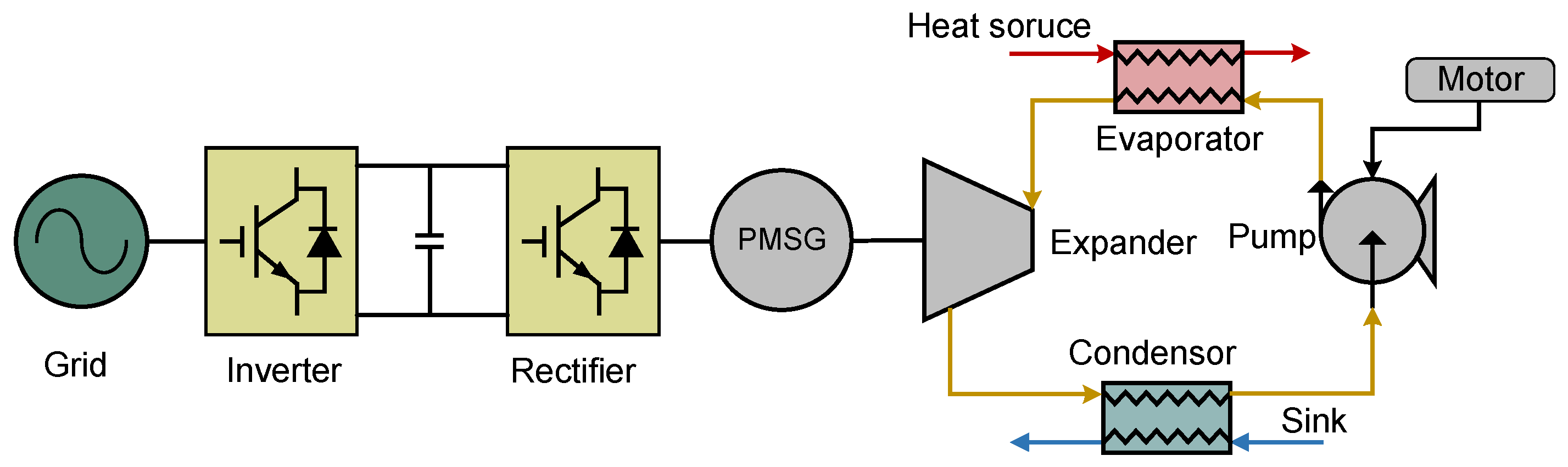

Section 2 introduces the configuration of the ORC system and its control architecture, as well as the dynamic model of the ORC.

Section 3 analyzes the relationship among output power, evaporating pressure, and superheat degree under different sink and heat source conditions, and it presents the proposed MPPT strategy.

Section 4 details the design of the NMPC system. Finally,

Section 5 discusses and evaluates the simulation results.

3. An Mppt Strategy Based on Optimal Evaporation Pressure and Superheat Degree

To maximize the power output of an ORC system when sink and heat source temperatures change, this study proposes a MPPT strategy based on optimal evaporation pressure and superheat degree.

3.1. The Effect of Heat Source on the ORC System

First, the power output, evaporation pressure, and superheat are analyzed under different expander rotational speeds with a sink temperature of .

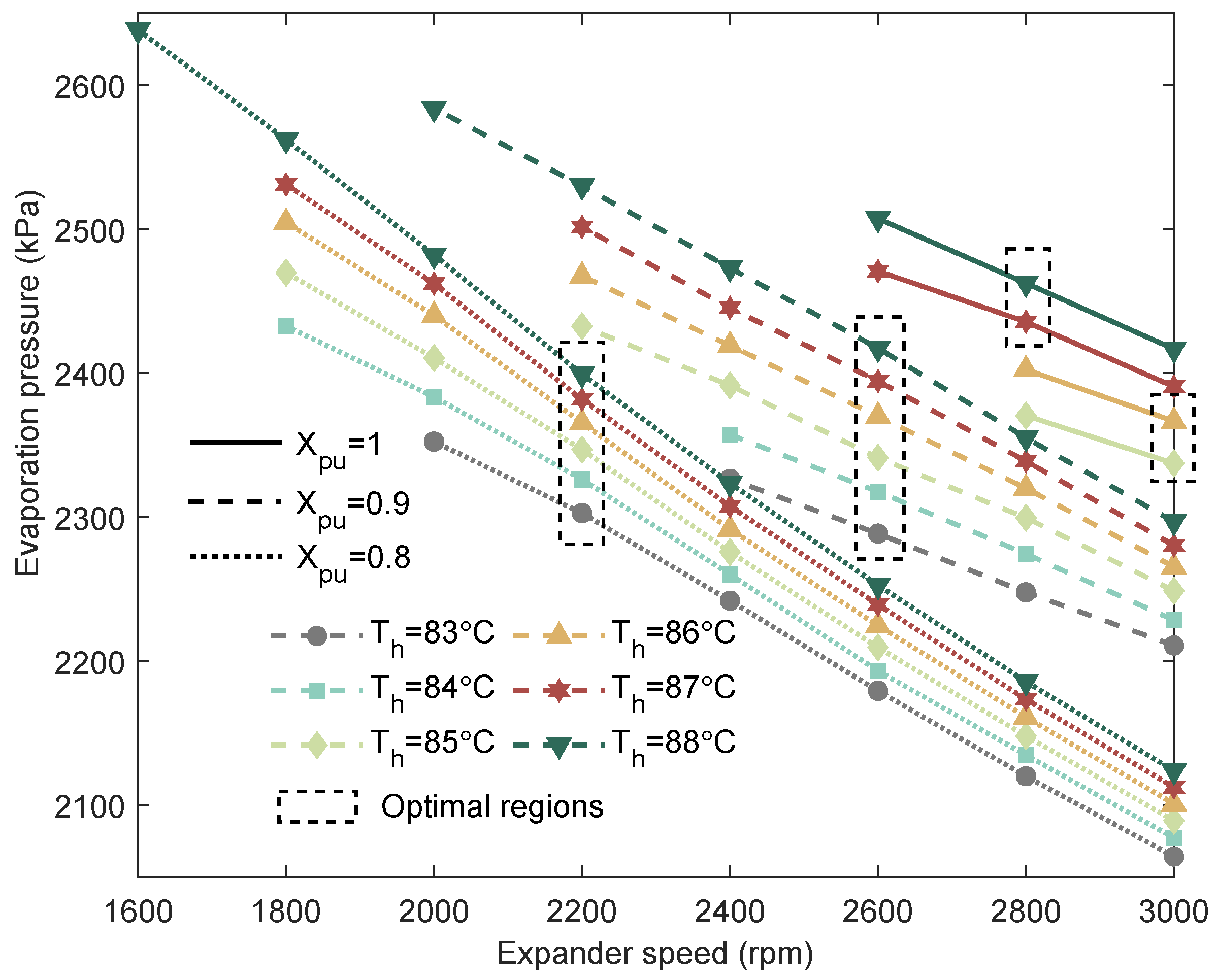

As shown in

Figure 5, the output power of the ORC system exhibits distinct variations with changes in the working fluid flow rate and expander rotational speeds when the heat source temperature is below the rated operating condition. It can be observed that the ORC system exhibits a maximum power output for each combination of working fluid flow rate and expander speed. This maximum output can be achieved by appropriately adjusting the pump and the expander rotational speed. Moreover, The findings demonstrate that lowering the heat source temperature imposes constraints on system operation, making it necessary to decrease the working fluid flow rate. This measure ensures that the ORC system continues to operate safely and avoids potential instabilities associated with inadequate thermal input.

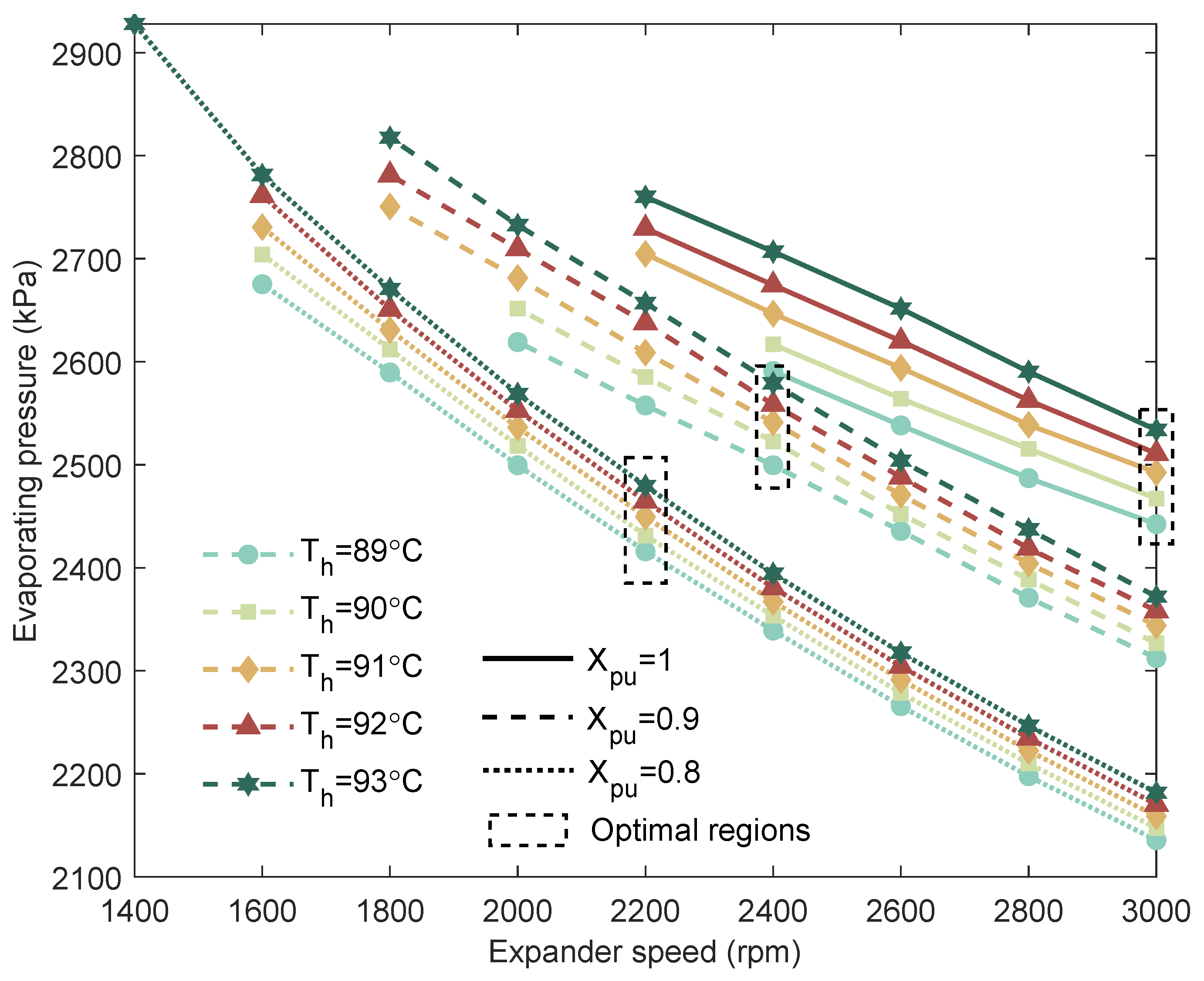

As illustrated in

Figure 6, a decrease in expander rotational speed results in an increase in evaporation pressure. Similarly, a higher working fluid flow rate also leads to a rise in evaporation pressure. In the ORC power generation system, the evaporation pressure is influenced not only by the flow rate but also by the heat source temperature and expander rotational speed. Among these factors, the working fluid flow rate exerts a greater influence than the heat source temperature. When combined with the power output characteristics shown in

Figure 5, it becomes evident that an optimal evaporation pressure exists across different heat source temperatures. This optimal condition can be achieved through coordinated adjustments of the pump and expander rotational speeds.

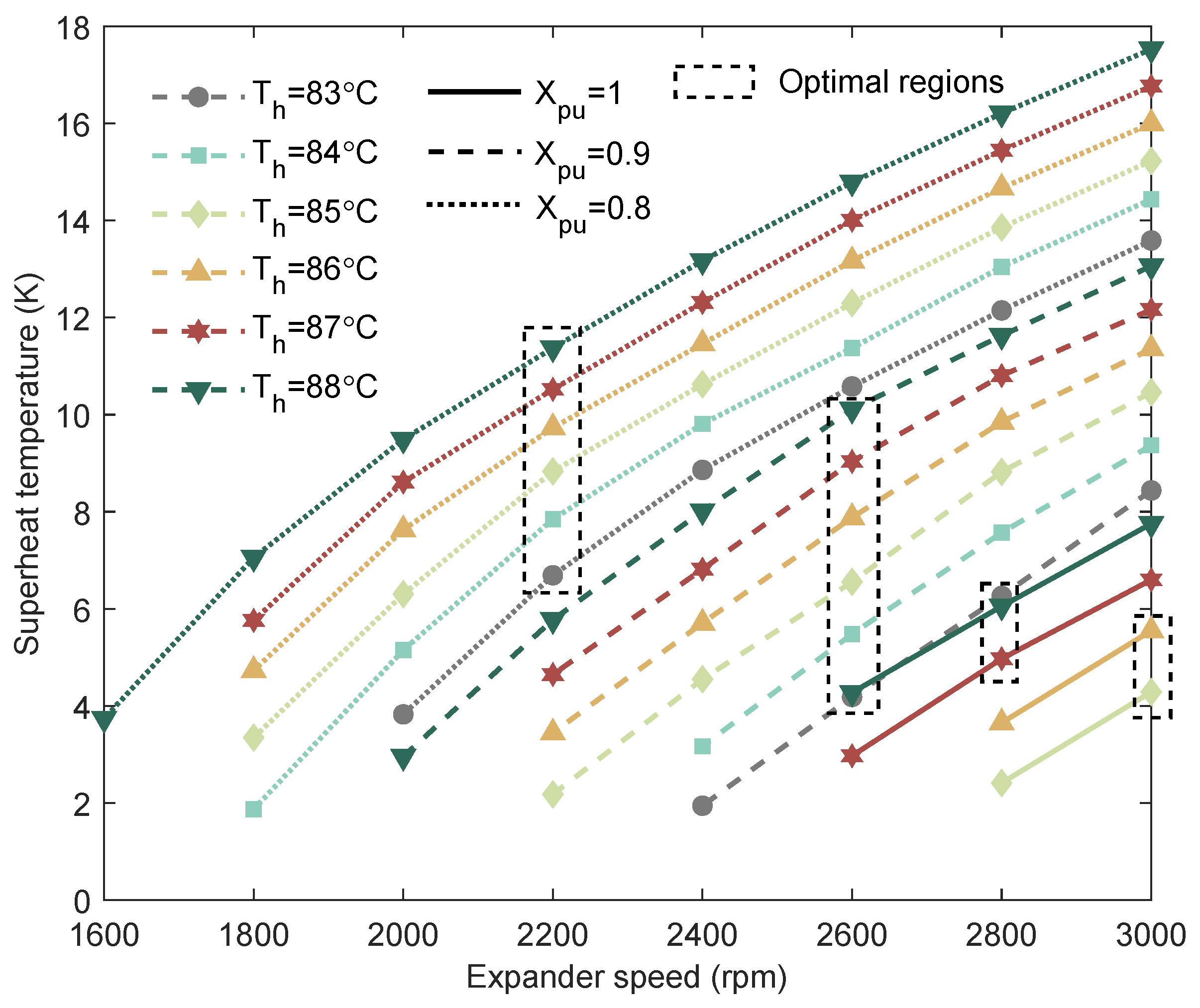

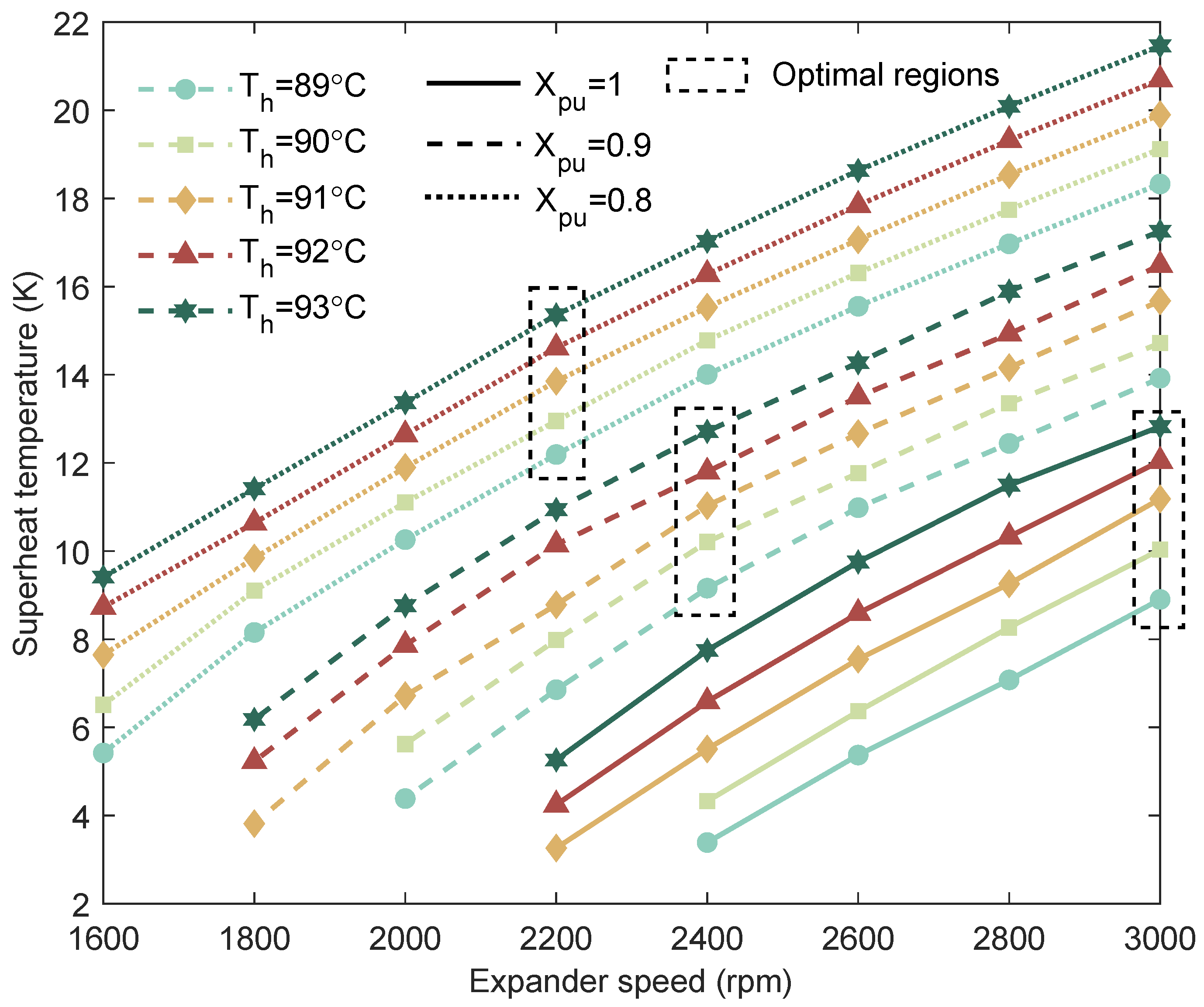

From

Figure 7, it can be observed that the degree of superheat is strongly influenced by various parameters. As the rotational speed decreases, the superheat degree also declines. This occurs because a lower rotational speed reduces the

at the expander inlet, which elevates the evaporation pressure and consequently diminishes the superheat. Similarly, increasing

also reduces the superheat degree, whereas higher heat source temperatures enhance it. Integrating these observations with the results in

Figure 5, it is evident that an optimal superheat degree exists that maximizes the system power output. Notably, while the minimum superheat temperature (MST) control strategy ensures safe operation, it yields suboptimal power output and fails to achieve the global optimum across different heat source temperatures.

Next, the system characteristics are analyzed under conditions where the heat source temperature exceeds the rated operating value.

As can be observed in

Figure 8,

Figure 9 and

Figure 10 below, the relevant characteristics are highly similar to both the system characteristics of the ORC system and those under the condition where the heat source temperature is below the rated operating point.

By integrating these observations with the power output characteristics in

Figure 5, it becomes clear that an optimal superheat degree exists that maximizes the system’s power output. Notably, although the minimum superheat temperature (MST) control strategy ensures reliable and safe operation, it delivers only suboptimal power performance and fails to achieve the global optimum across different heat source temperature conditions.

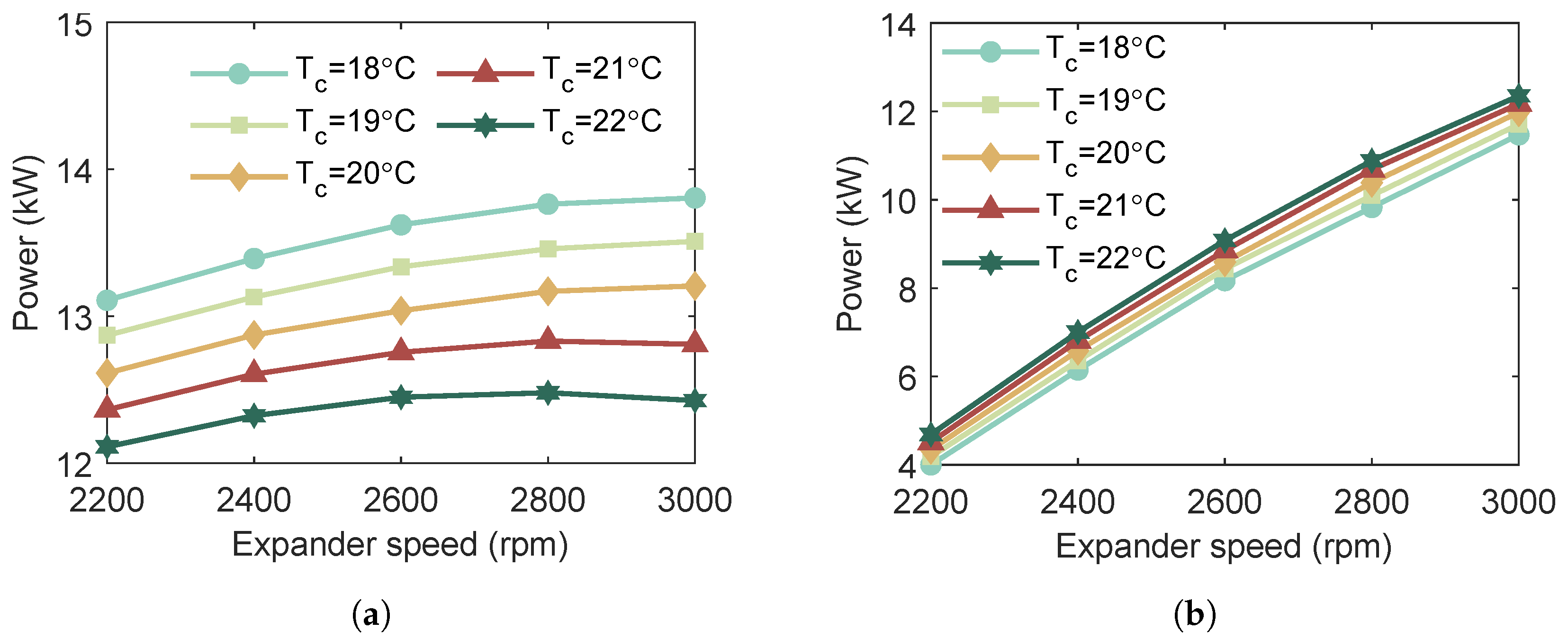

3.2. The Effect of Heat Sink Temperature on the ORC System

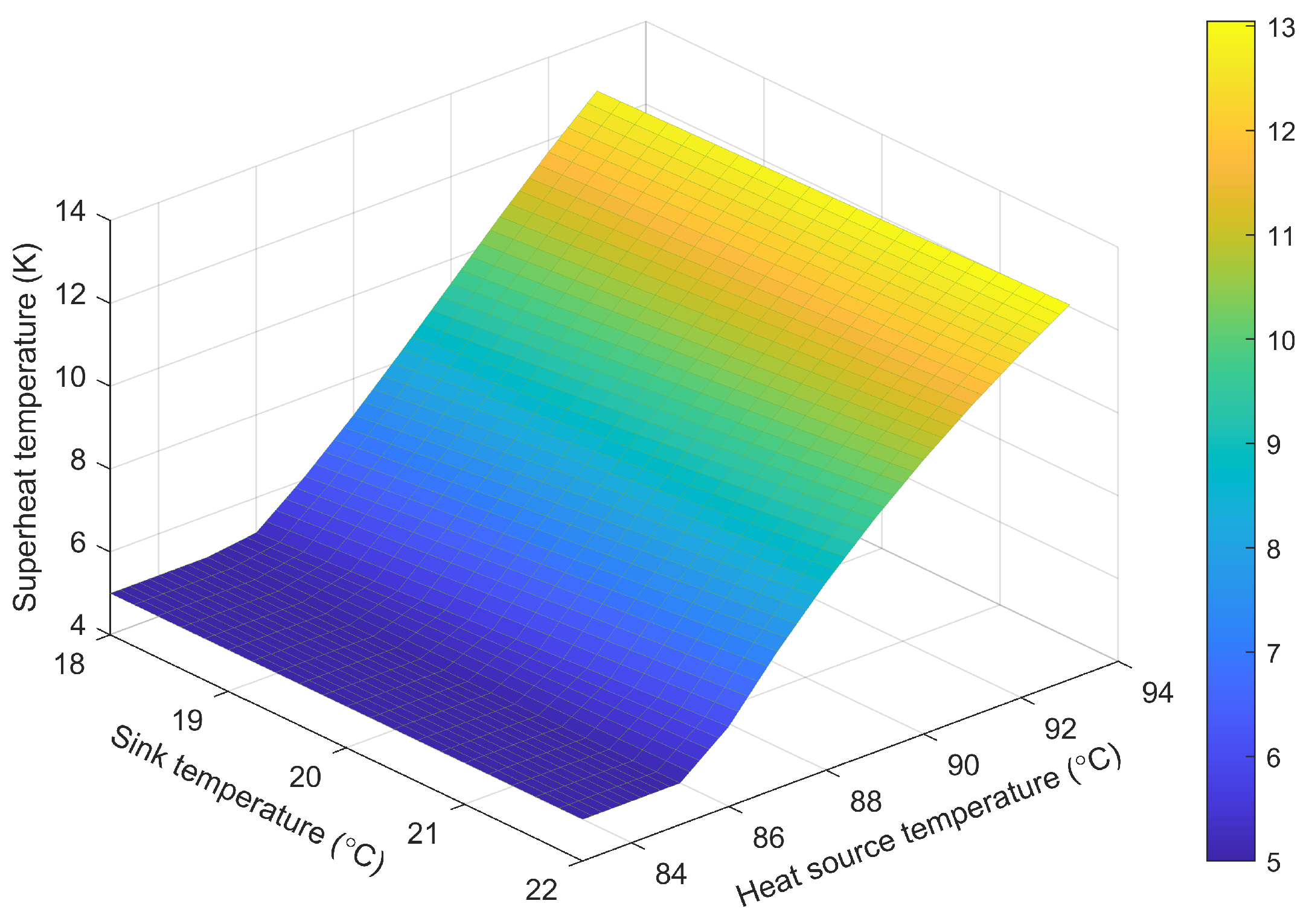

The heat sink temperature exerts a non-negligible influence on the thermodynamic performance of the ORC system. Therefore, its effect must be considered in the design of the MPPT strategy. Owing to the relatively narrow operating range of the heat sink, the optimal evaporation pressure and superheat degree are investigated within a temperature range of 18 ∼ . Simulation results show that variations in heat sink temperature have only a marginal effect on evaporation pressure. Accordingly, the effect of expander rotational speed on evaporation pressure is not analyzed in this study.

Figure 11 illustrates the influence of expander rotational speed on the system’s output power and superheat degree under different cooling water inlet temperatures. As shown, an increase in cooling water inlet temperature results in reduced output power and an elevated superheat degree. This finding indicates that, under conditions of fixed expander rotational speed, a near-linear relationship exists between the superheat degree and output power. Accordingly, the ORC system exhibits an optimal superheat degree at which maximum power output can be achieved.

By comparing

Figure 11 with

Figure 12, it is observed that an increase in heat source temperature causes the optimal expander rotational speed to shift downward, while the optimal superheat degree remains essentially constant.

A comparative analysis of

Figure 12 and

Figure 13 reveals that an increase in heat source temperature leads to an overall rise in the superheat degree. This occurs because higher heat source temperatures elevate the evaporating pressure, which in turn inevitably increases the superheat degree. In addition, this phenomenon is closely associated with expander efficiency. Both the pressure level and the thermodynamic state of the working fluid influence expander performance. A higher superheat degree allows the fluid to deliver more energy to the expander, thereby enabling greater mechanical energy output during the expansion process.

By comparing

Figure 13 and

Figure 14, it is observed that the optimal superheat degree decreases slightly. Moreover, when both the heat source and sink temperatures increase, the expander rotational speed corresponding to the optimal superheat degree varies within a certain range. This behavior arises from a fundamental characteristic of expanders: peak isentropic efficiency is achieved only within a specific range of rotational speeds.

Therefore, based on the above analysis of the system characteristics, the following conclusions can be drawn:

Adjusting a single parameter—either the evaporating pressure or the superheat degree—cannot enable the ORC system to achieve maximum power output;

The MST strategy primarily ensures safe system operation and facilitates control rather than improving power output;

The optimal evaporating pressure lies within a specific range, and further increases in pressure do not necessarily yield higher power output;

The optimal superheat degree also falls within a defined range, and further reductions in superheat do not lead to increased power output.

3.3. An Mppt Strategy Based on Optimal Evaporation Pressure and Superheat Degree

At present, Maximum Power Point Tracking (MPPT) strategies applied to Organic Rankine Cycle (ORC) systems are primarily classified into two types: the Minimal Superheat Temperature (MST) strategy and the Optimal Evaporation Temperature (OET) strategy. The MST strategy maintains the superheat at the outlet of the evaporator in the ORC system at a minimum value. However, as analyzed in

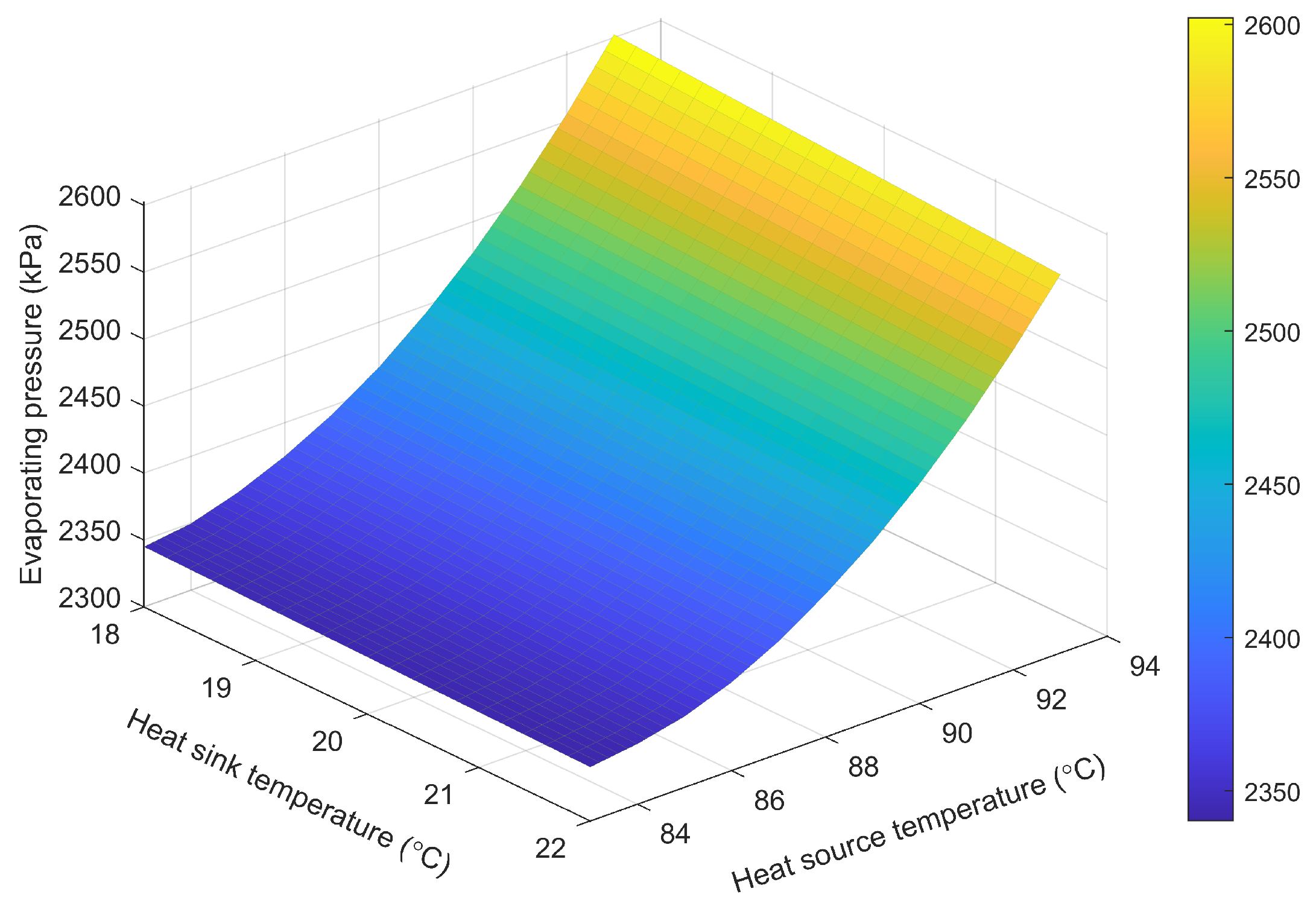

Section 3.1, under high heat-source temperatures, adjusting only the superheat degree is insufficient for the system to achieve maximum output power. In contrast, the OET strategy ensures that the ORC system operates at the optimal evaporation temperature. Nevertheless, the analysis also reveals that when the heat-source temperature is relatively low, this strategy fails to maintain the system at the optimal evaporation temperature. Based on the preceding analysis, it is evident that the ORC system achieves maximum power output at optimal values of evaporation pressure and superheat degree, which vary with the sink and heat source temperatures. Accordingly, this study proposes a novel Maximum Power Point Tracking (MPPT) strategy that leverages both optimal evaporation pressure and superheat degree. The proposed methodology constructs characteristic maps that correlate the optimal evaporation pressure and superheat degree with different combinations of heat source and sink temperatures, as illustrated in

Figure 15 and

Figure 16.

Figure 15 and

Figure 16 illustrate the optimal evaporation pressure and superheat degree under different heat-source and heat-sink temperatures. The data corresponding to the rated operating condition were obtained from experimental measurements, while those for off-design conditions were derived from simulations.

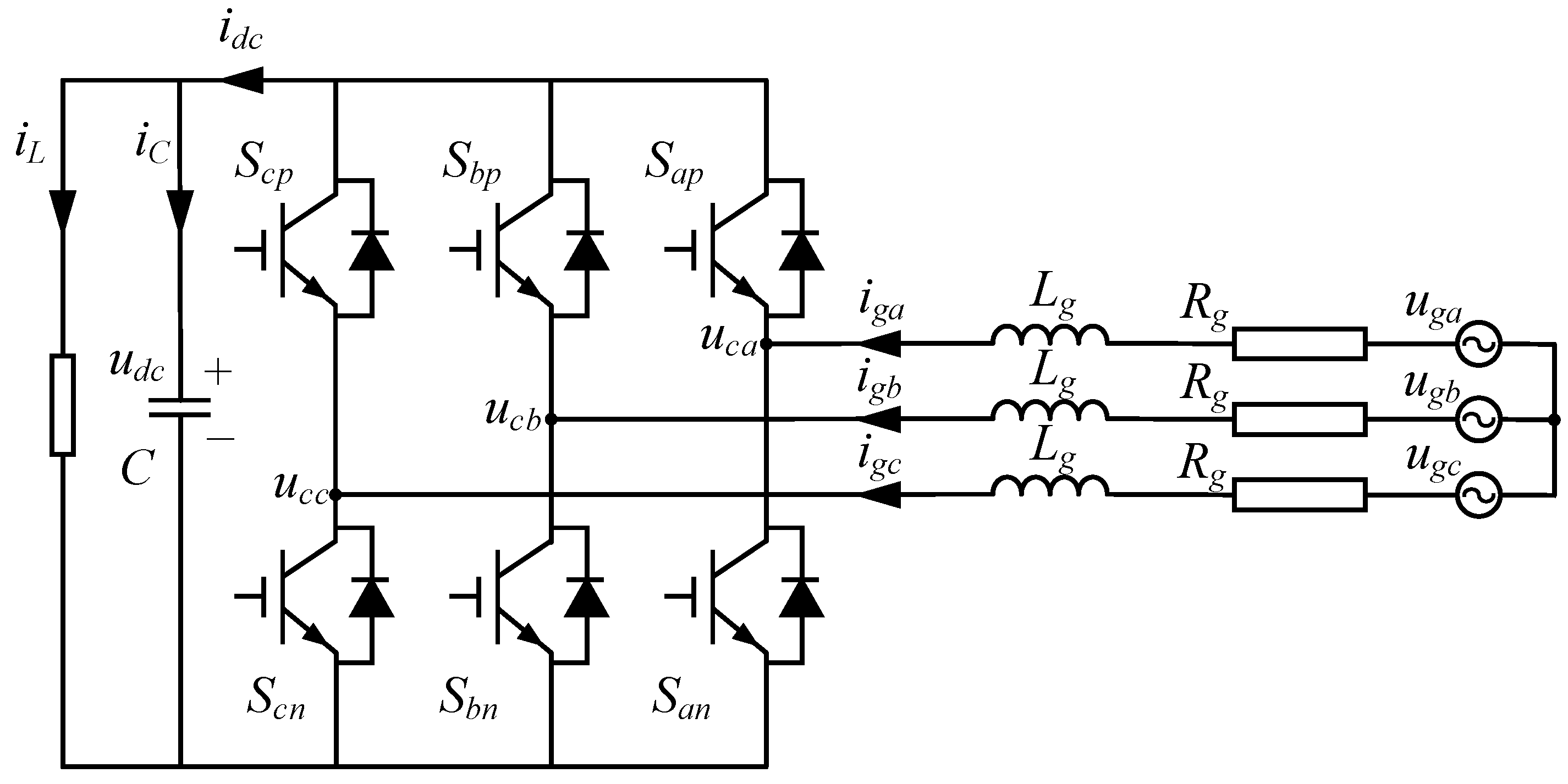

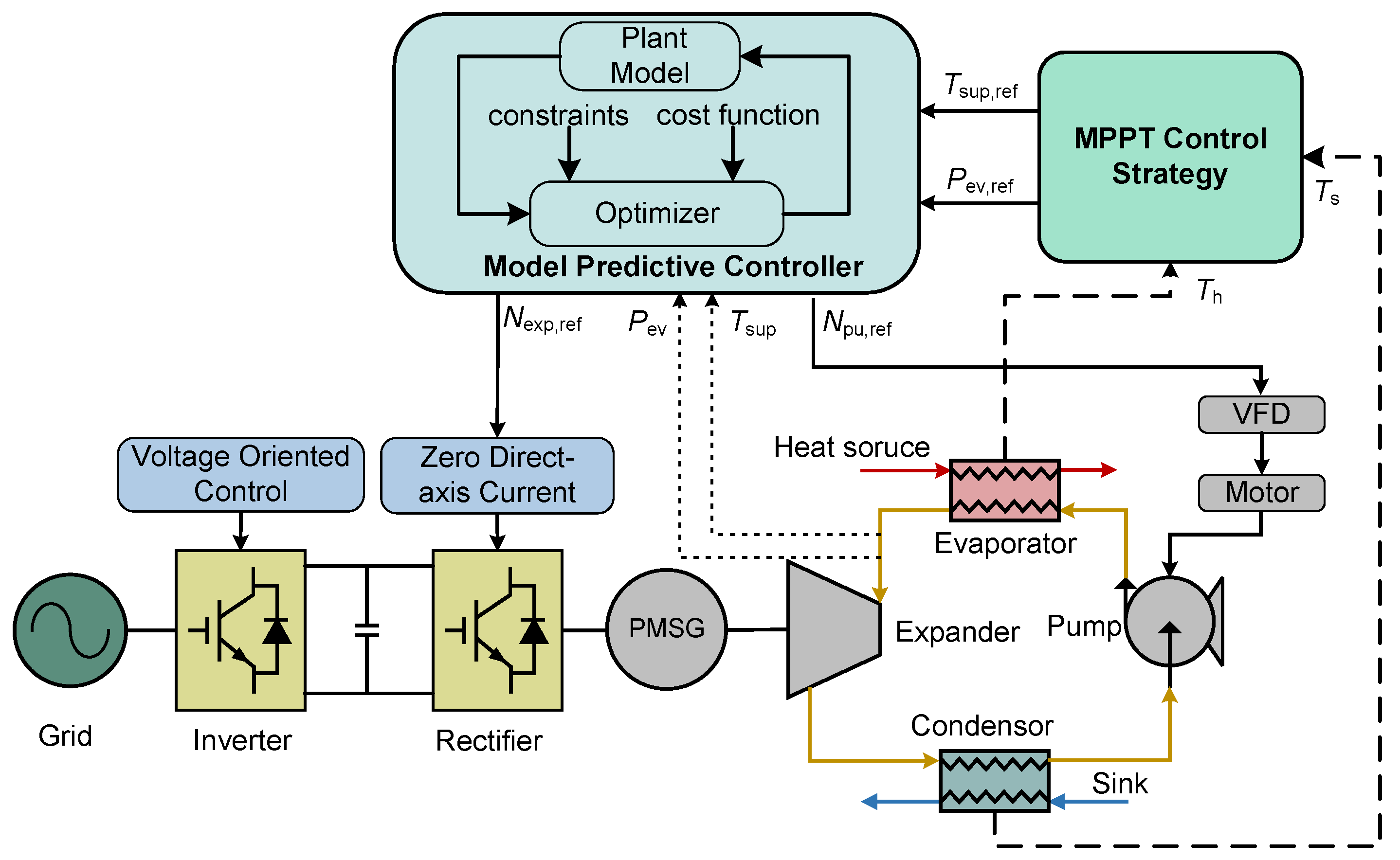

The ORC control system consists of an MPPT control strategy module and an MPC controller. Specifically, the MPPT strategy acquires the temperatures of the heat source and sink and outputs the optimal evaporation pressure and superheat degree as reference values for the MPC controller. Based on these reference values, the MPC controller regulates the rotational speeds of the expander and working fluid pump to control the evaporation pressure and superheat degree of the ORC system. When the MPC controller increases the speed of the working fluid pump, the mass flow rate of the working fluid rises, which elevates the system’s evaporation pressure but reduces the degree of superheat. Conversely, when the pump speed is reduced, the opposite effect occurs. Similarly, when the MPC controller increases the expander speed, the expander ingests a greater mass flow of the working fluid, leading to a decrease in both the evaporation pressure and the degree of superheat. Conversely, reducing the expander speed produces the opposite effect. The expander speed is adjusted via the rectifier, while the pump speed is governed by a motor driven through a variable frequency drive (VFD).

The proposed MPPT strategy operates in two sequential stages, as illustrated in

Figure 17. First, characteristic maps of the optimal evaporation pressure and superheat degree are established, with the corresponding values at different operating conditions obtained through dynamic simulations. During real-time control, the MPPT strategy provides the optimal evaporation pressure and superheat degree as reference signals for the MPC controller. These values are retrieved from the characteristic maps via parameter look-up based on real-time operating conditions.

5. Results and Discussion

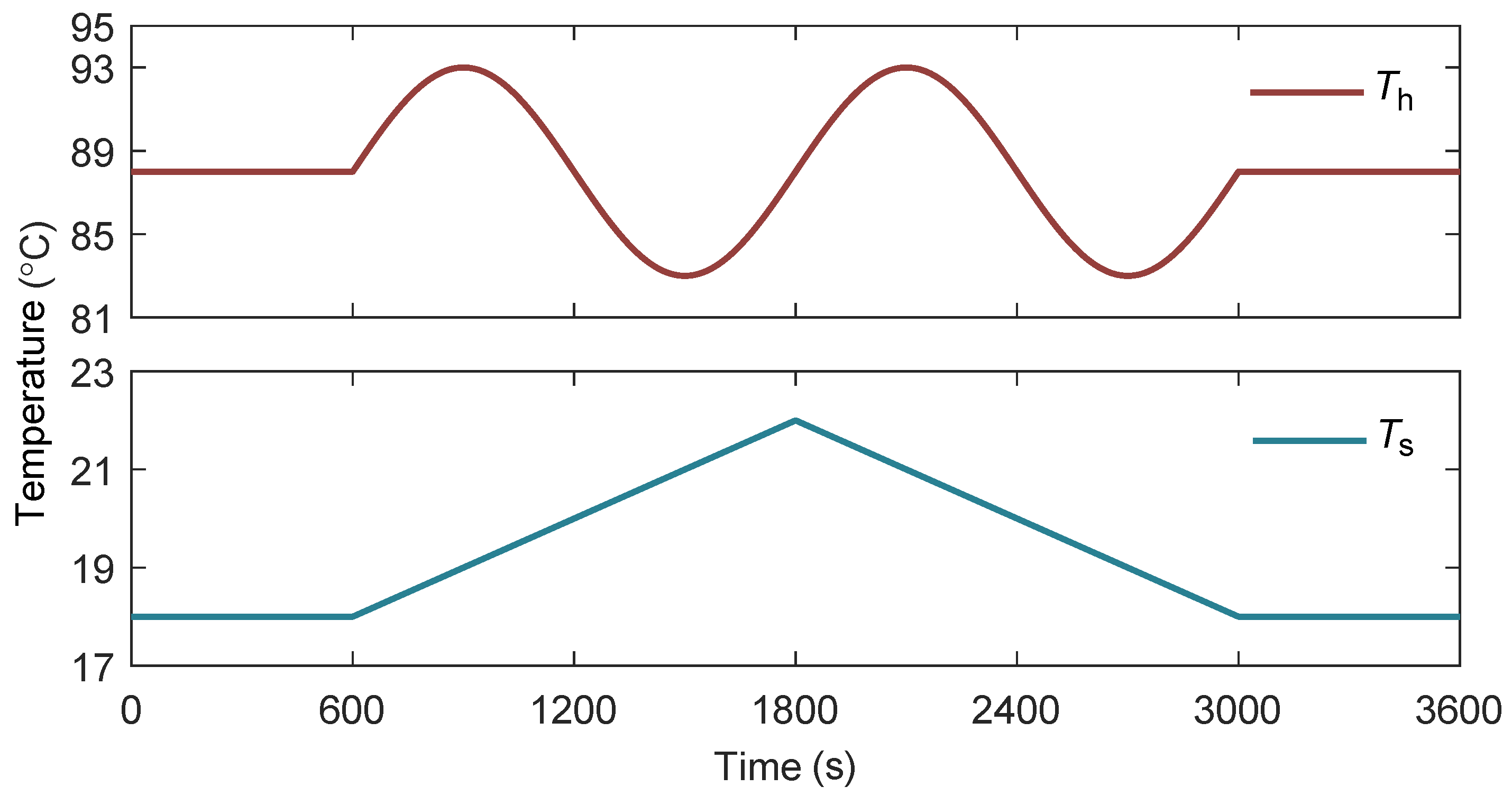

To validate the proposed MPPT strategy, dynamic models of the ORC system were established, and the MPC controller was implemented in MATLAB/Simulink. Furthermore, a test scenario was designed that combined a sinusoidally varying heat source with a linearly varying sink, as illustrated in

Figure 18.

The sinusoidal and linear heat-source variations designed in this study were chosen to represent two fundamental categories of transient behavior: periodic fluctuations, such as those arising from diurnal solar irradiance or cyclic feedstock supply in biomass combustion. The linear variation of the heat sink considered in this study primarily reflects the temperature changes of seawater when it is used as the cooling medium during ship navigation.

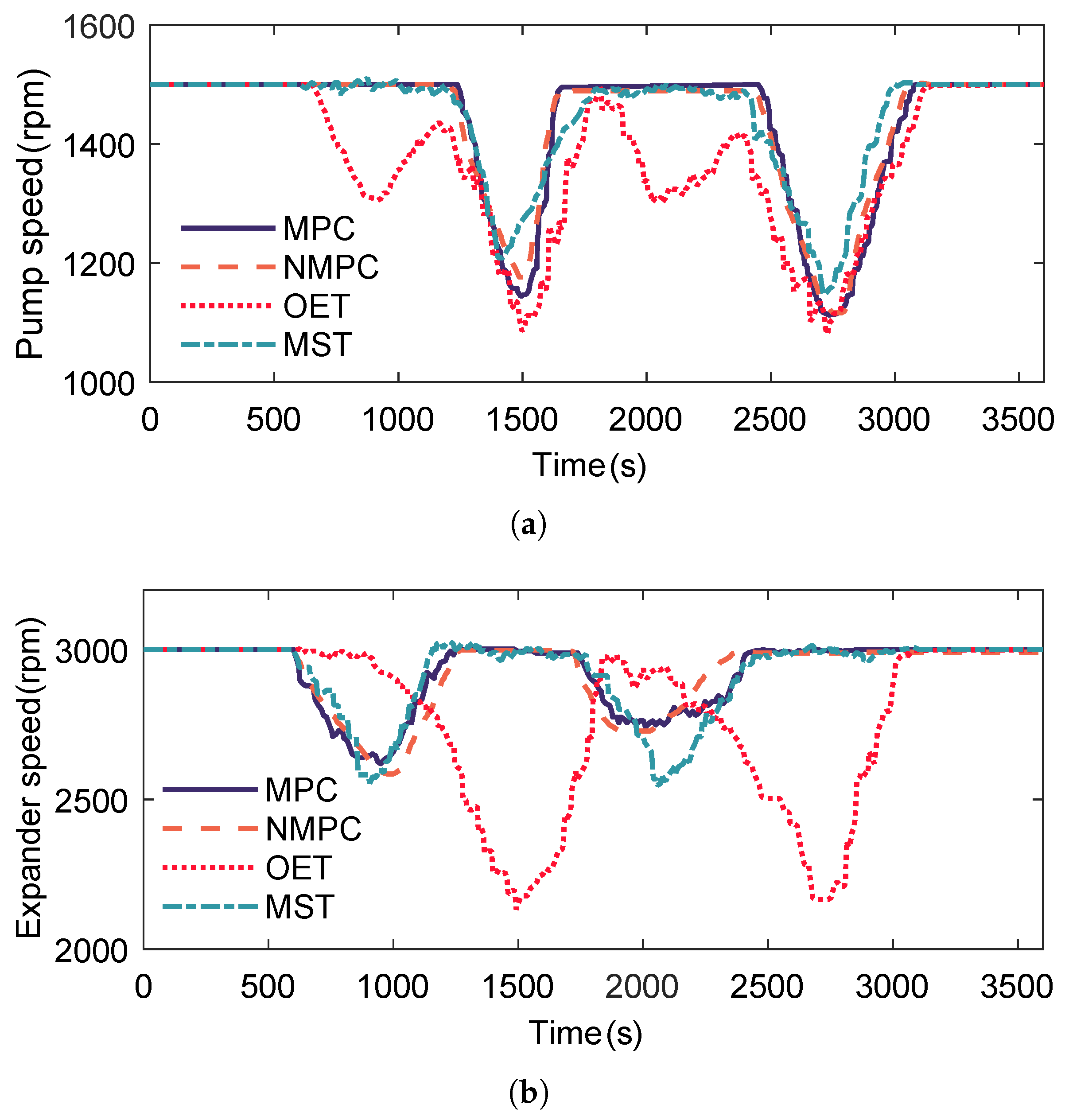

Figure 19 illustrates the variation in pump and expander rotational speeds during the control process. As shown, the MPC, NMPC, and MST strategies exhibit similar trends. Under the OET strategy, however, the pump speed is frequently adjusted to maintain constant pressure. When the heat source temperature is relatively high, the MPC and NMPC strategies keep the pump speed nearly constant, achieving the optimal evaporation pressure and superheat degree primarily by adjusting the expander speed. In contrast, the OET strategy simultaneously adjusts both pump and expander speeds to maintain constant pressure. When the heat source temperature is low, the MPC, NMPC, and MST strategies maintain safe system operation mainly by regulating the pump speed. By comparison, the OET strategy imposes excessive adjustments on the expander speed to enforce constant pressure, ultimately leading to reduced efficiency.

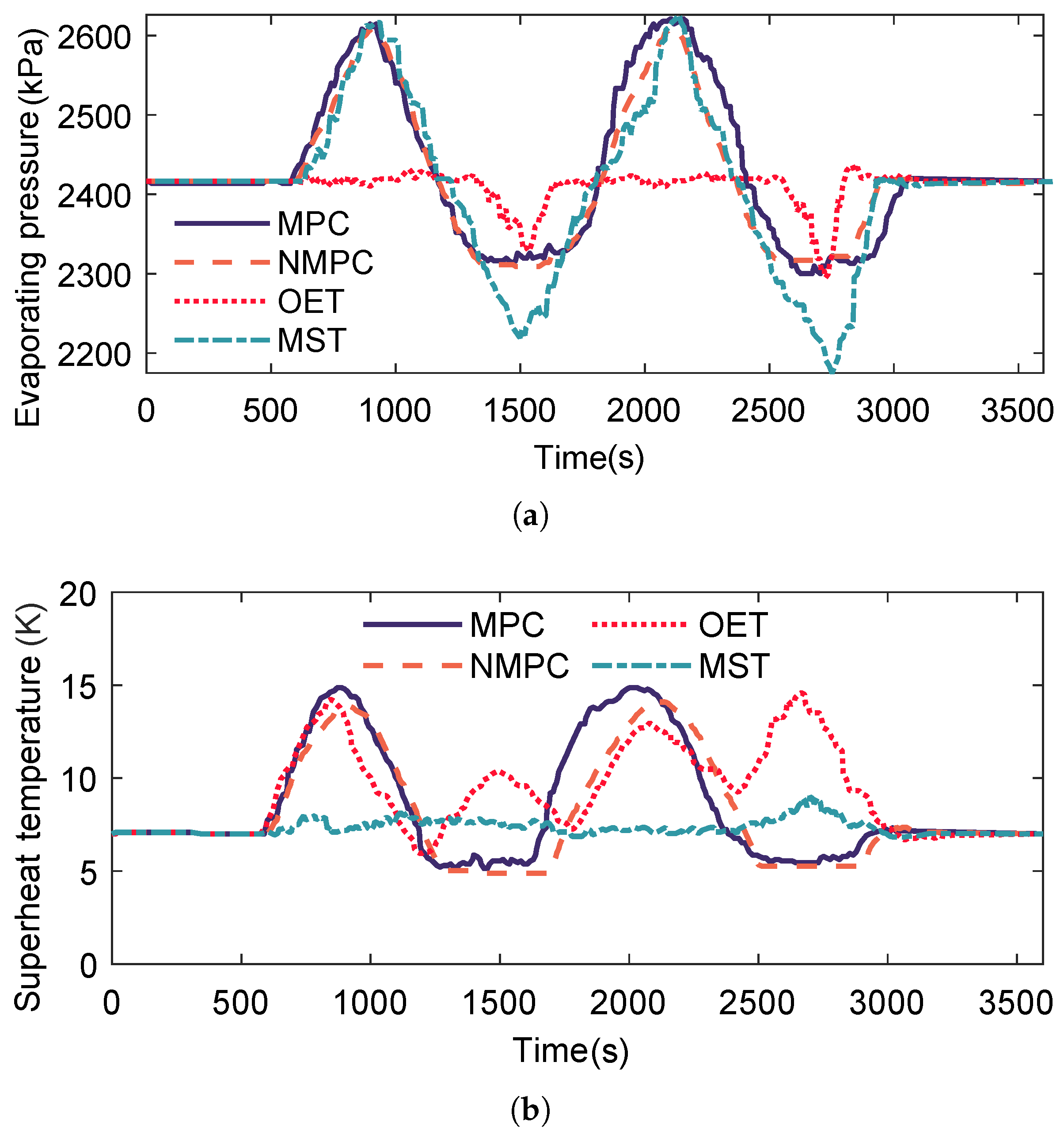

Figure 20 presents the variations in evaporating pressure and superheat degree. The trends of both parameters are highly similar under the MPC, NMPC, and MST control strategies. During operation, the OET strategy is generally able to maintain a constant pressure, but it fails to do so when the heat source temperature is low. Likewise, the MST strategy struggles to maintain the superheat degree at its setpoint when the heat source temperature is high. In contrast, both MPC and NMPC accurately track the optimal evaporating pressure, although the NMPC strategy exhibits larger tracking errors when operating far from the nominal point.

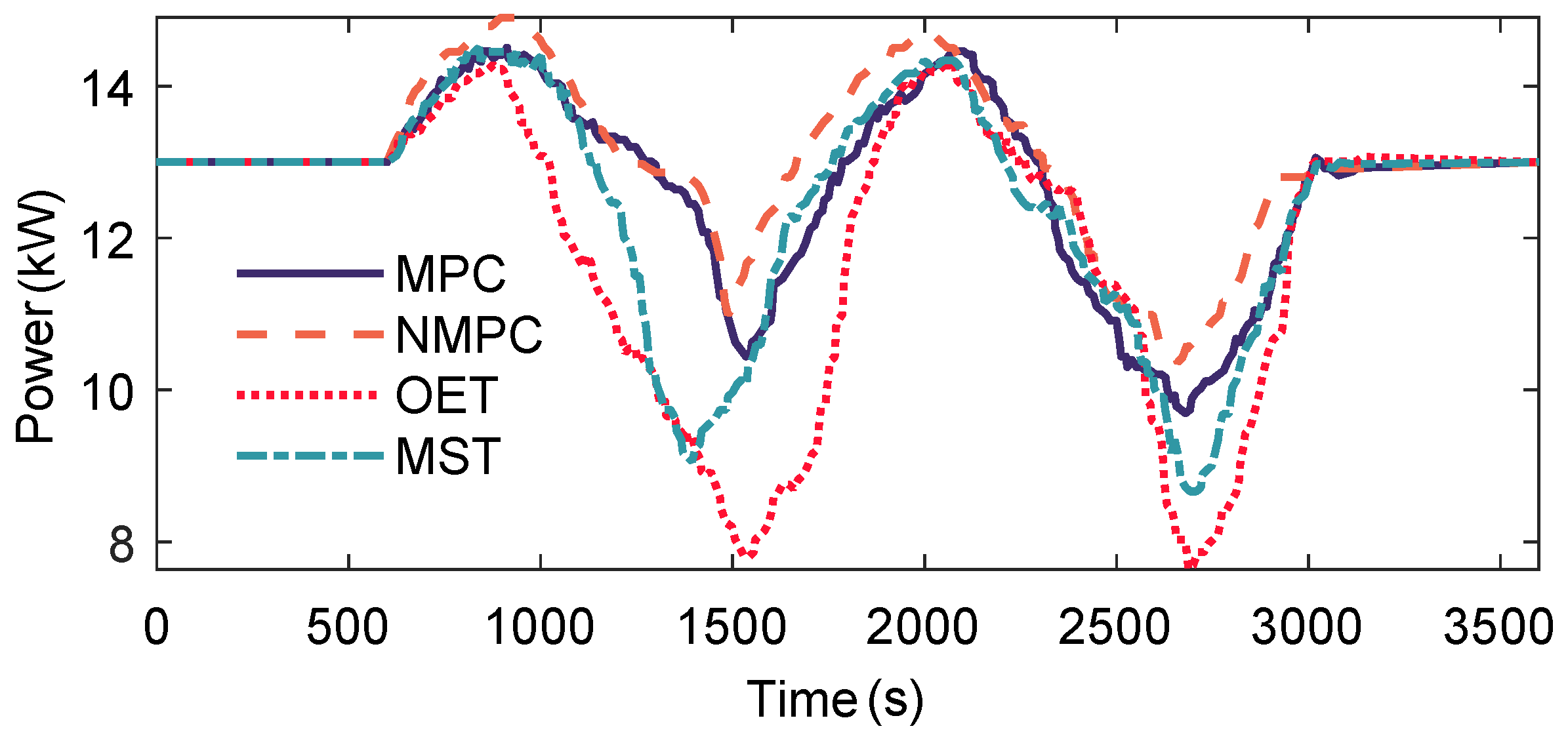

Figure 21 illustrates the variation in power output during the control process. As shown, the OET strategy incurs significant power loss in order to maintain constant pressure and thereby preserve expander efficiency. Under low heat source temperatures, the MST strategy also excessively adjusts the expander speed to achieve the tracking target, which results in reduced expander efficiency and power loss. The strategy proposed in this study represents a trade-off between the OET and MST approaches: it adopts the OET strategy when the heat source temperature is relatively high and the MST strategy when the temperature is relatively low. Consequently, the proposed MPPT strategy achieves relatively smooth power output under both MPC and NMPC control.

Integrating the power output over time yields the total electricity generation for the considered period, thereby providing a more intuitive comparison of the performance of the different strategies under fluctuating heat and sink temperatures, as summarized in

Table 1.

Using the electricity generation of the OET strategy as the baseline, the MST strategy achieves a 6.16% increase. In comparison, the strategy proposed in this study yields a 9.70% improvement with the basic MPC method and a 14.15% improvement with the NMPC method. The improvement in power generation achieved by the MPPT strategy proposed in this study under simultaneous fluctuations of heat-source and heat-sink temperatures can be attributed to two key factors. First, by jointly regulating the expander speed and the working-fluid pump speed, the system is able to track the optimal operating point more rapidly. Second, the proposed strategy maintains minimal superheat at low heat-source temperatures to ensure safe operation, while under high heat-source temperatures, it enables the system to operate at both the optimal evaporation pressure and superheat degree, thereby achieving maximum power output.

6. Conclusions

In this paper, a dynamic model of the ORC system was established, and the variations in evaporating pressure, superheat degree, and output power under different expander and working fluid pump speeds were analyzed. Based on these results, a Maximum Power Point Tracking (MPPT) strategy was proposed, founded on the optimal evaporating pressure and superheat degree. In addition, the machine-side control strategy and an MPC controller for the ORC system were designed, and their performance was validated through simulations. The main conclusions are as follows:

Adjusting a single parameter, such as evaporating pressure or superheat degree, cannot enable the ORC power generation system to achieve maximum output power;

The proposed MPPT strategy achieves coordinated control of evaporation pressure and superheat degree, enabling the system to attain maximum power output under varying operating conditions;

By simultaneously regulating the expander speed and the working fluid pump speed, the system exhibits a shorter response time and reaches the set point more rapidly;

The proposed MPPT strategy maintains the optimal pressure when the heat source temperature is relatively high and the minimum superheat degree when the temperature is relatively low;

Compared with the OET strategy, the proposed MPPT strategy increases power generation by 14.15%, and it achieves a 7.53% improvement compared with the MST strategy.

Overall, the MPPT strategy developed in this study, based on the optimal evaporating pressure and superheat degree, enables the ORC system to achieve maximum power output under fluctuating sink and heat source temperatures. The proposed MPPT strategy for ORC systems can be applied to waste heat recovery in marine engines, as well as to power generation from geothermal energy and industrial waste heat. Future work will focus on extending this approach to ORC power generation systems with more complex configurations.