Bi-Level Optimization Method for Frequency Regulation Performance of Industrial Extraction Heating Units Under Deep Peak Shaving Conditions

Abstract

1. Introduction

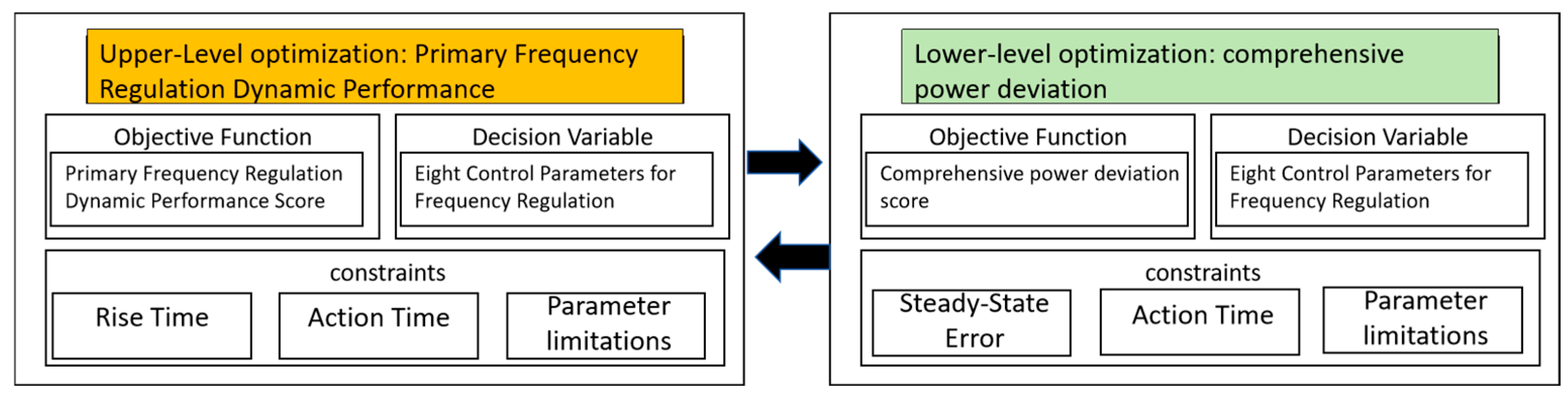

2. Bi-Level Optimization Architecture for Frequency Regulation Performance Under Deep Peak Shaving Condition of Heating Units

2.1. Bi-Level Optimization Framework for Deep Peak Shaving and Frequency Regulation Performance of Heating Units [15]

- (1)

- Initialize and analyze the sensitivity of the unit model, and construct a set of control parameters.

- (2)

- In the optimization of primary frequency regulation dynamic performance in the upper layer, an evaluation score system is defined to characterize the performance of the unit’s primary frequency regulation dynamic performance (with decision variables of overshoot and regulation time), as shown in Equation (1).

- (3)

- In the optimization of comprehensive power deviation at the lower level, an evaluation score system is defined to characterize the magnitude of power deviation of the unit under stable operating conditions (the decision variables are frequency modulation power deviation and heating power deviation), as shown in Equation (2).

- (4)

- For the overall unit, an evaluation score system is defined to characterize the performance of frequency regulation (the decision variables are the current primary frequency regulation dynamic performance score and the comprehensive power deviation score), as shown in Equation (3)

- (5)

- In the case of output , let the maximum loop parameter set feedback back to the upper layer for further optimization. All the involved weights (, ; , ; , ) are constructed based on power grid experts’ opinions and engineering requirements. The upper-layer dynamic performance weights, i.e., (overshoot weight) and (settling time weight), can be set to 0.55 and 0.45, respectively. For the lower-layer comprehensive power deviation weights, (heating power deviation weight) can be increased to 0.65, while (frequency modulation power deviation weight) is set to 0.35. As for the overall performance weights and , they need to balance “dynamic response” and “steady-state accuracy”. In the example, (upper-layer dynamic performance weight) is set to 0.4 and (lower-layer power deviation weight) to 0.6, which is in line with the engineering requirement of “steady-state power accuracy taking precedence over short-term dynamic fluctuations” under deep peak shaving.

2.2. Comprehensive Quantification Method for Deep Peak Shaving and Frequency Regulation Performance of Heating Units

- (1)

- Normalized standard deviation measure

- (2)

- Basic rating function

- (3)

- Out-of-bounds penalty function

- (4)

- Comprehensive rating function

- (1)

- Determine the optimal value for the variable to be evaluated, and define the evaluation interval range based on the characteristics of the variable;

- (2)

- Solve the comprehensive scoring function based on the optimal value and evaluation interval;

- (3)

- Find the score value corresponding to the current variable to be scored based on the obtained function, and comprehensively compare the scores of various parameters.

3. Multi-Objective Optimization of Frequency Regulation Performance of Heating Units Based on HO Algorithm

3.1. Multi-Objective Optimization of Frequency Regulation Dynamic Performance

- (1)

- Objective function

- (2)

- Constraint conditions

- (1)

- Frequency modulation rise time constraint

- (2)

- Frequency modulation action time constraint

- (3)

- Upper and lower limit constraints on frequency modulation control parameters

3.2. Multi-Objective Optimization of Comprehensive Power Deviation

- (1)

- Objective function

- (2)

- Constraint conditions

- (1)

- Steady-state error constraint

- (2)

- Frequency deviation power constraint

- (3)

- Unit power constraint

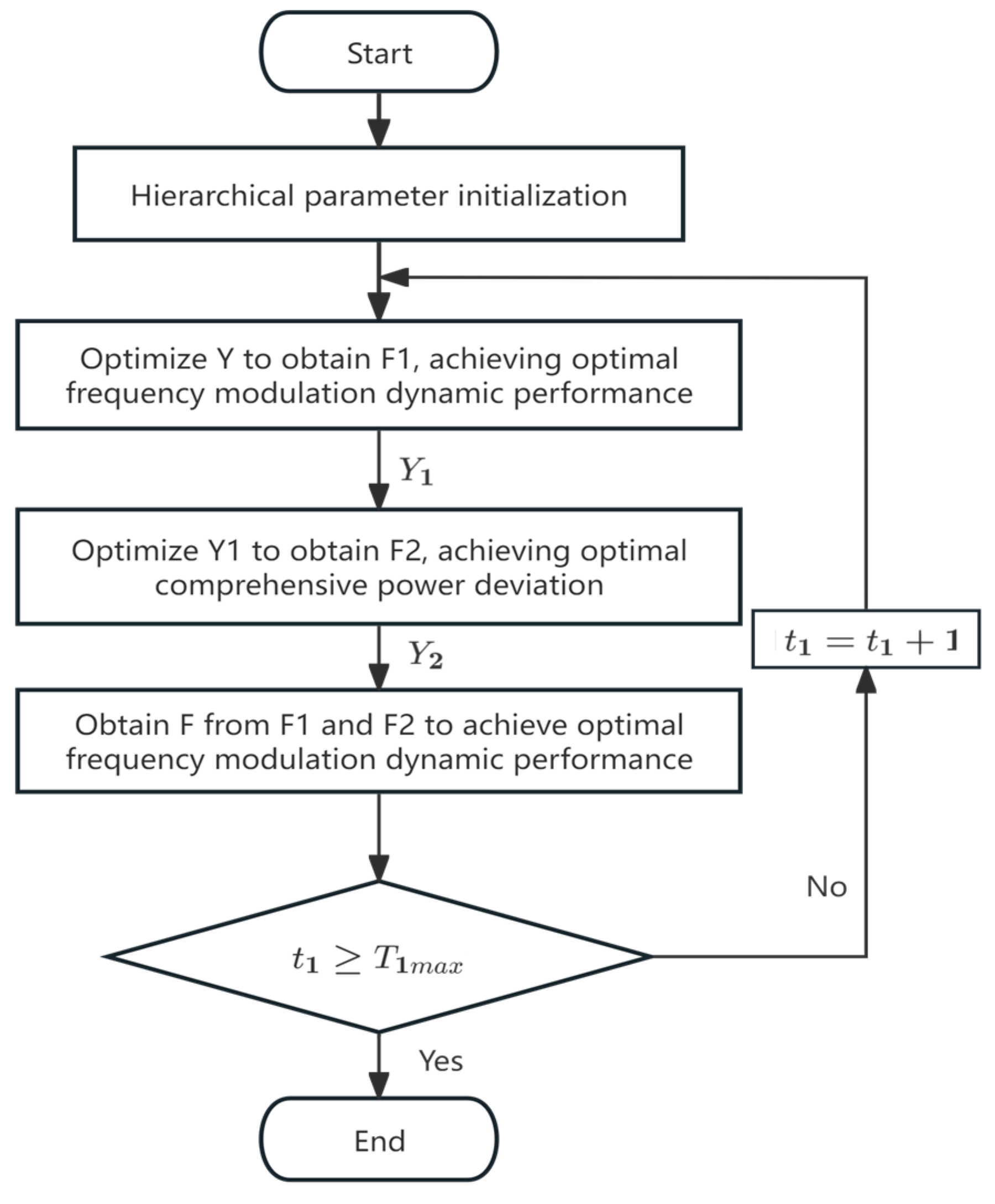

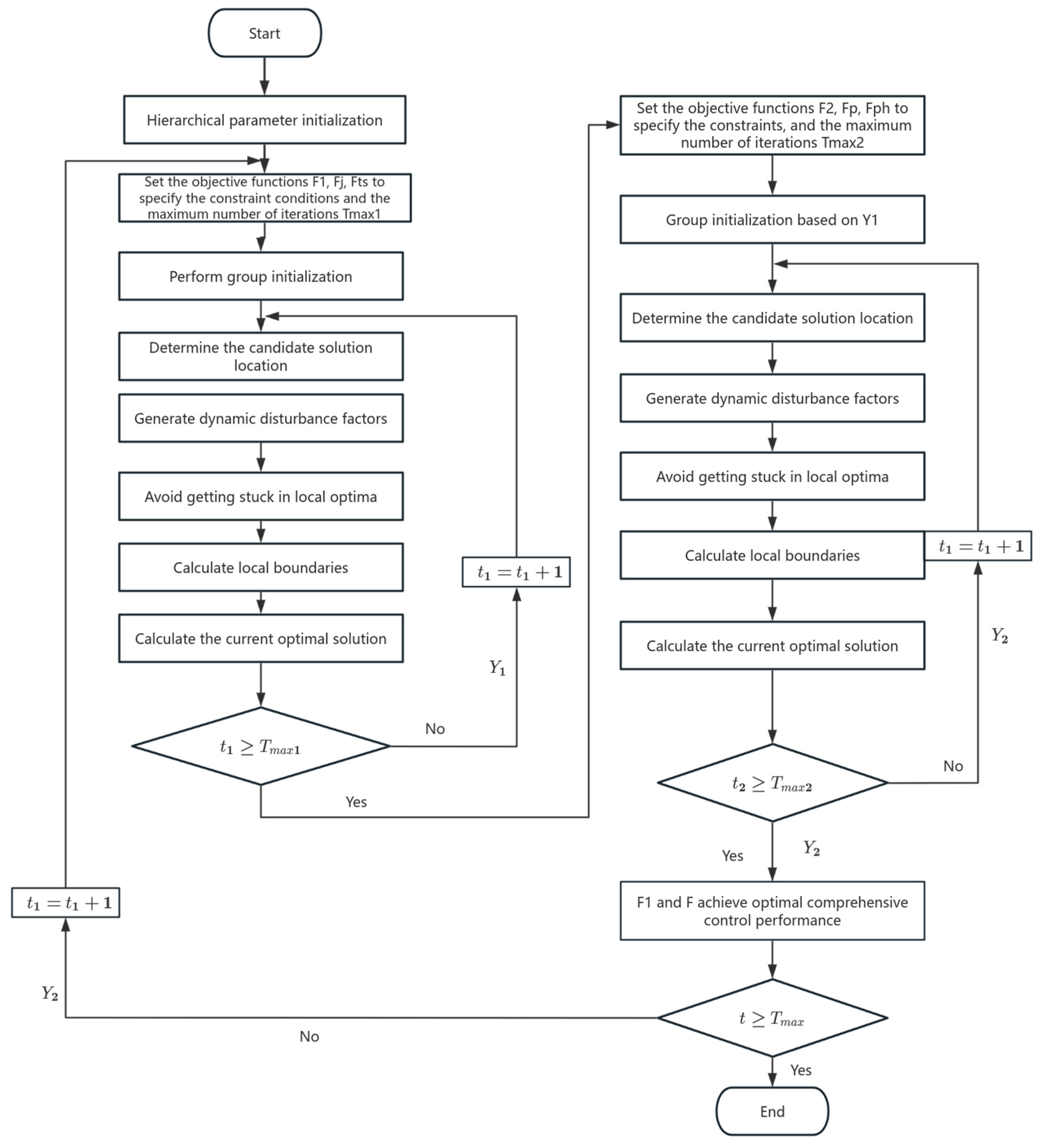

3.3. Dual Layer Optimization Solution for Frequency Modulation Performance

- (1)

- Upper-level optimization processOn the basis of determining the optimization objectives of the overshoot evaluation score and the adjustment time evaluation score in the frequency modulation process, the dynamic performance optimization process of the unit frequency modulation is as follows:

- (1)

- Set objective functions , , and , specify constraints and maximum iteration times;

- (2)

- Perform group initialization and determine candidate solution positions;

- (3)

- Generate disturbance factors to avoid getting stuck in local optima;

- (4)

- Calculate the local boundary to obtain the current optimal solution, output the optimal control parameter set , and return to continue optimization when the number of solving iterations is less than the maximum number of iterations.

- (2)

- On the basis of the optimal control parameter set outputted by the upper layer, the optimization process of the lower layer is as follows:

- (1)

- Set objective functions , and , specify constraints and maximum iteration times;

- (2)

- Perform group initialization based on and determine candidate solution positions;

- (3)

- Generate disturbance factors to avoid getting stuck in local optima;

4. Example Analysis

4.1. Example Introduction

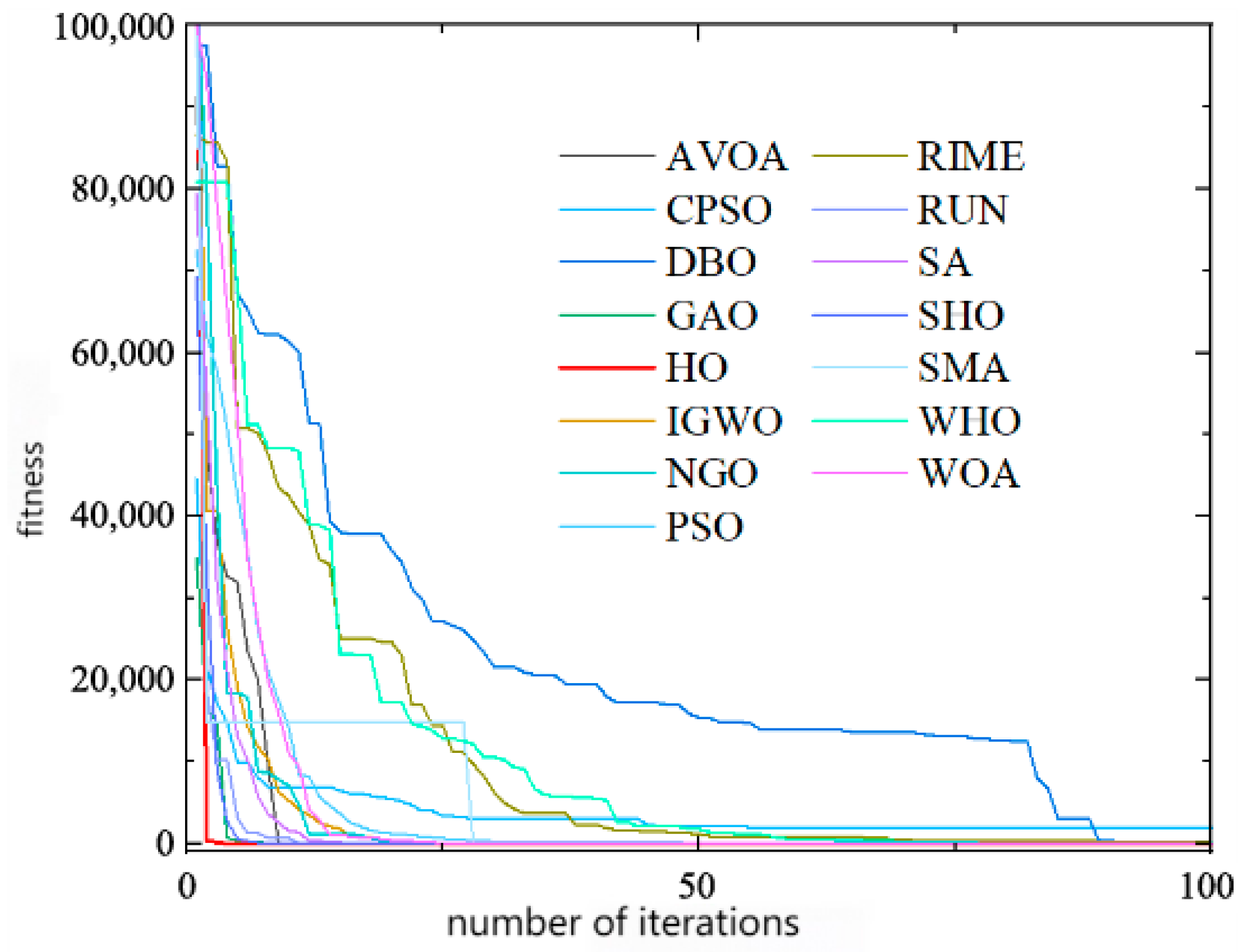

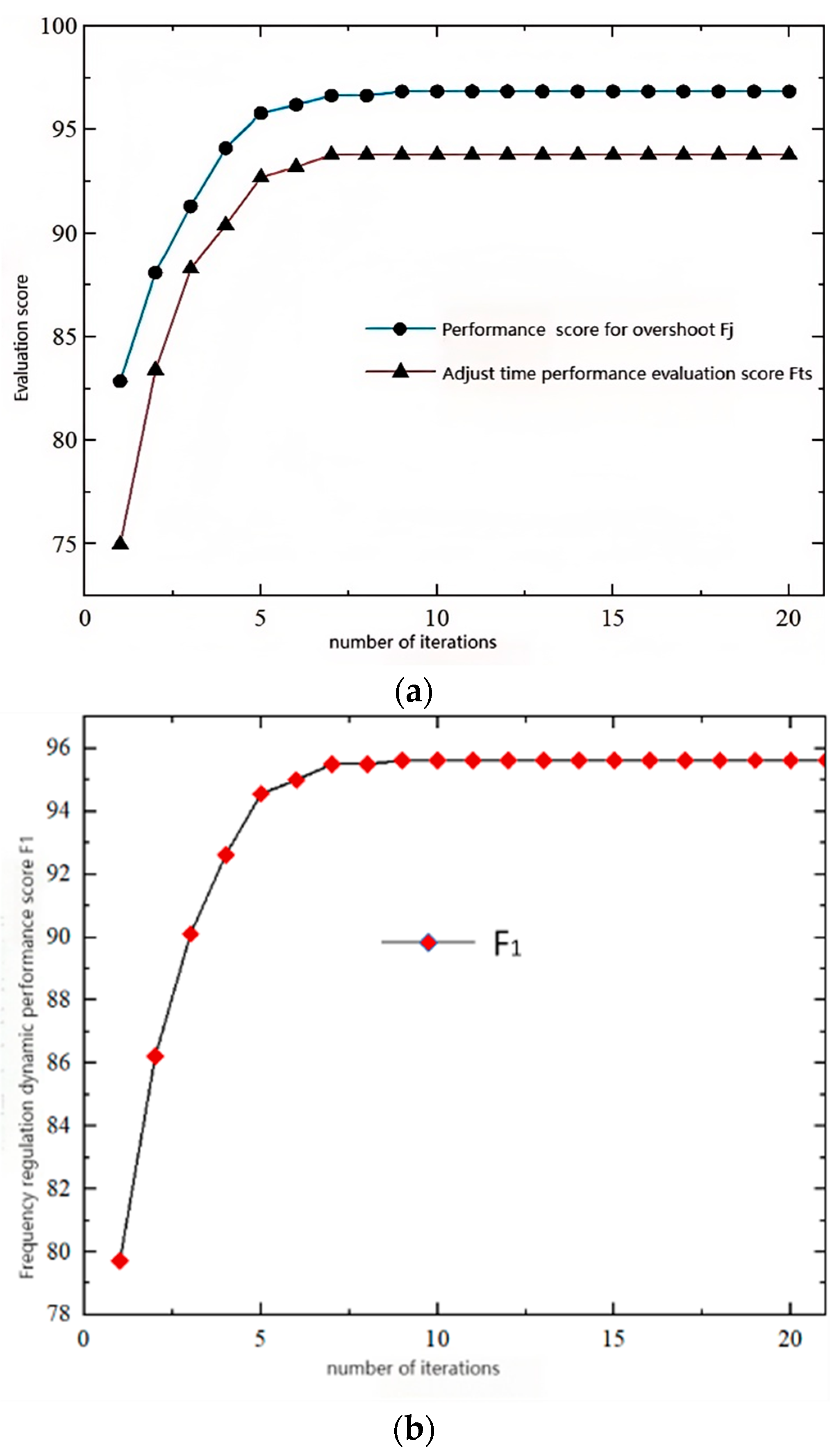

4.2. Upper-Level Optimization Analysis

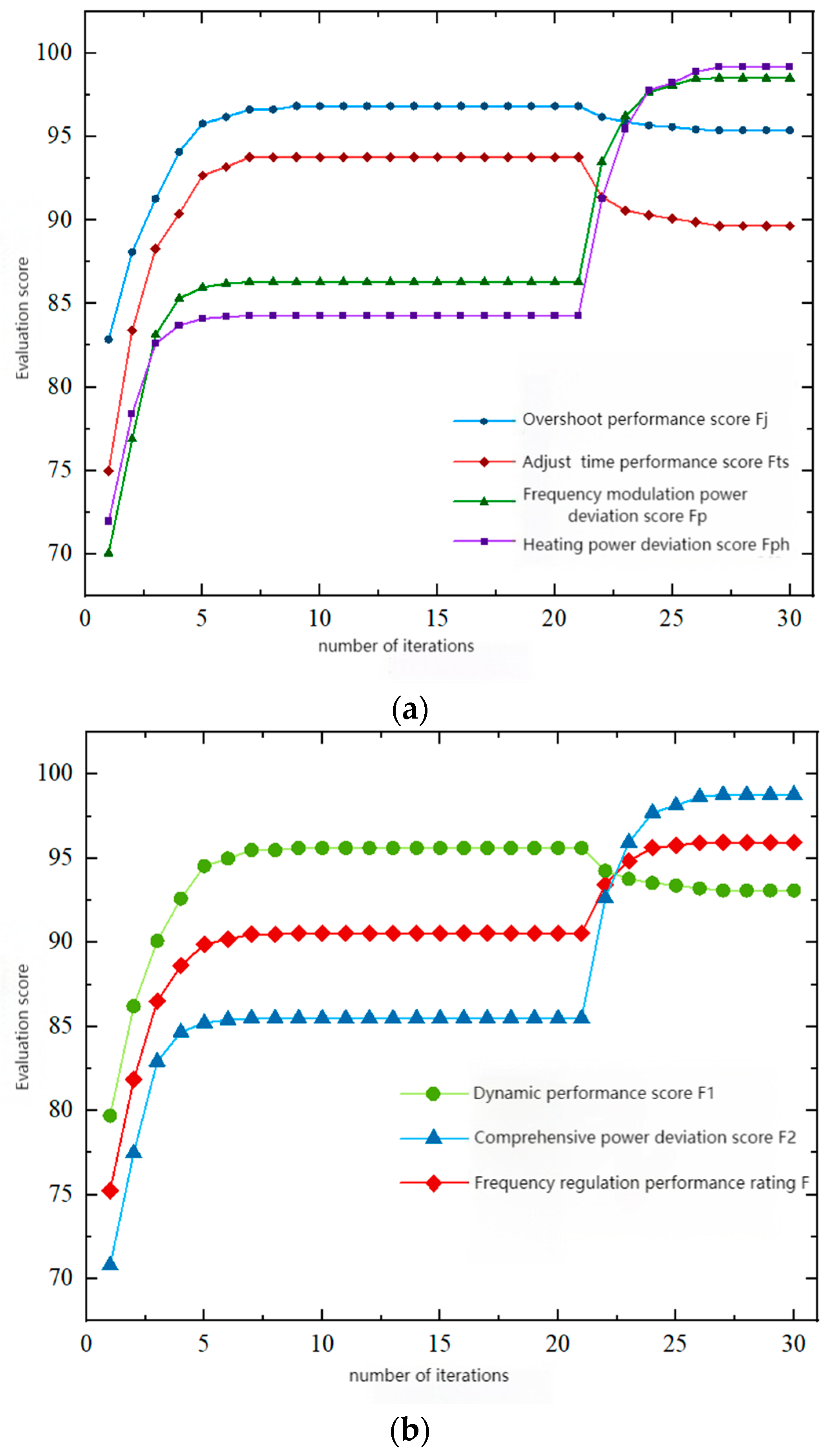

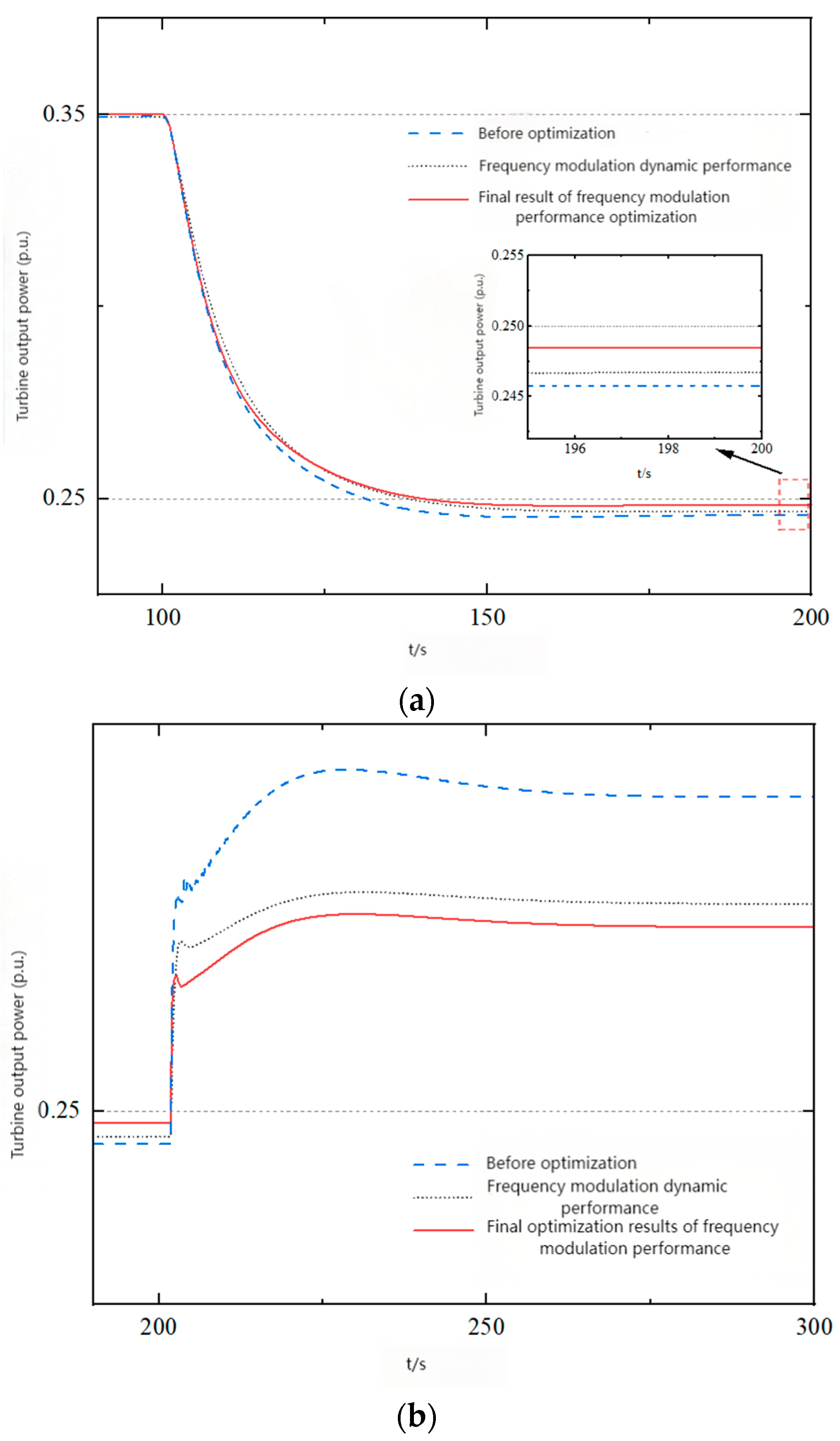

4.3. Analysis of Multi-Objective Optimization Results for Comprehensive Power Deviation and Frequency Modulation Performance

5. Conclusions

- (1)

- The comprehensive quantification method for frequency regulation performance developed eliminates the influence of dimensionality in the system, and combines the dynamic characteristics of heating units under deep peak shaving conditions to develop a layered optimization strategy, achieving coordinated optimization of dynamic response and steady-state accuracy.

- (2)

- The optimization of the upper-level frequency modulation dynamic performance has improved the overshoot score and adjustment time score; The comprehensive power deviation optimization at the lower level has improved the frequency modulation power deviation score and heating power deviation score.

- (3)

- The frequency regulation performance score of the example heating unit has been improved by 27.5%, which has good engineering application value. Before the power deviation optimization, the frequency modulation power deviation is 8.5 MW, after the optimization, it is 7.65 MW, reducing 0.85 MW, meeting the grid regulation of “frequency modulation power deviation ≤ 8 MW”; The deviation of heating power before optimization is 0.99 MW, and after optimization it is 0.45 MW, a decrease of 0.54 MW, which meets the demand of industrial users with a heating deviation of ≤1 MW, which has good engineering application value.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shu, Y.B. Creating a first-class academic journal, forging new quality productive forces and building a new-type energy system. Energy Internet 2024, 1, 1–2. [Google Scholar] [CrossRef]

- Li, D.D.; Sun, Y.R.; Xu, B.; Zhang, J.L.; Liu, Q. Minimum inertia and primary frequency capacity assessment for a new energy high permeability power system considering frequency stability. Power Syst. Prot. Control 2021, 49, 54–61. [Google Scholar] [CrossRef]

- Yang, L.; Cao, X.; Zhou, Y.; Lin, Z.; Zhou, J.; Guan, X.; Wu, Q. Frequency-Constrained Coordinated Scheduling for Asynchronous AC Systems under Uncertainty via Distributional Robustness. IEEE Trans. Netw. Sci. Eng. 2025. [Google Scholar] [CrossRef]

- Zhang, X.K.; Wang, Z.J.; Xia, D.W.; Wang, J.G.; Hu, H.Z. New Modeling for Primary Frequency Regulation Capability of Thermal Power Units Under Deep Peak Regulation. Power Syst. Technol. 2022, 46, 4947–4954. [Google Scholar] [CrossRef]

- Sheng, K. Refined modeling of primary frequency regulation power response characteristics for thermal power units. Electr. Power 2021, 54, 111–118. [Google Scholar] [CrossRef]

- Deng, T.Y.; Tian, L.; Liu, J.Z. Control method for improving frequency and peak regulation capabilities of heating units using heat network energy storage. Proc. CSEE (Chin. Soc. Electr. Eng.) 2015, 35, 3626–3633. [Google Scholar] [CrossRef]

- Wang, R.Y. Modeling and Performance Improvement of Primary Frequency Regulation System for Thermal Power Units Based on Particle Swarm Optimization Identification. Master’s Thesis, Shandong University, Jinan, China, 2020. [Google Scholar] [CrossRef]

- Liu, Z.Z. Performance Analysis and Improvement of Primary Frequency Regulation for Coal-Fired Power Units. Master’s Thesis, Shandong University, Jinan, China, 2024. [Google Scholar] [CrossRef]

- Shen, Y.Y. Primary frequency regulation strategy for thermal power units based on frequency division and adaptive dead zone control. Sci. Technol. Eng. 2023, 23, 15498–15505. [Google Scholar] [CrossRef]

- Chang, D.F.; Wang, W.; Jiang, H.; Wang, Q.; Fu, Y.W.; Gao, L.; Liu, H. Multi-variable coordinated optimization of primary frequency regulation for 1000MW units. Therm. Power Gener. 2018, 47, 123–128. [Google Scholar] [CrossRef]

- Deng, X.; Sun, W.; Xiao, H.W. Comprehensive control method for energy storage batteries participating in primary frequency regulation. High Volt. Eng. 2018, 44, 1157–1165. [Google Scholar] [CrossRef]

- Liu, B.L.; Xu, X.W. Optimal setting of generator excitation system droop coefficient based on power grid operation dataset. Power Syst. Technol. 2017, 41, 508–513. [Google Scholar] [CrossRef]

- Xia, Y.; Li, Z.; Xi, Y.; Wu, G.; Peng, W.; Mu, L. Accurate Fault Location Method for Multiple Faults in Transmission Networks Using Travelling Waves. IEEE Trans. Ind. Inform. 2024, 20, 8717–8728. [Google Scholar] [CrossRef]

- Fang, X. Energy equity-aware load shedding optimization methodology. Energy Internet 2025, 2, 45–54. [Google Scholar] [CrossRef]

- Shang, Y.P.; Ma, S.X. Simulation study on primary frequency regulation based on dynamic characteristics of combined heat and power units. J. Taiyuan Univ. Technol. 2010, 41, 83–86. [Google Scholar] [CrossRef]

- Qi, W. Study on dynamic characteristics of primary frequency regulation load response for heating steam turbines. Turbine Technol. 2018, 60, 303–306. [Google Scholar] [CrossRef]

- Amiri, M.H.; Mehrabian Hashing, N.; Montaner, M.; Mirjalili, S.; Khodadadi, N. Hippopotamus optimization algorithm: A novel nature-inspired optimization algorithm. Sci. Rep. 2024, 14, 5032. [Google Scholar] [CrossRef] [PubMed]

- Deb, K.; Pratap, A.; Agarwal, S.; Marivan, T. A fast and elitist multi objective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

| Module Name | Parameter | Value | Parameter | Value |

|---|---|---|---|---|

| Speed control system module | Amplification factor of speed deviation | 12.5 | Oil engine time constant | 4.294 |

| PID control proportional coefficient | 0.628 | |||

| Turbine module | Steam volume time constant | 0.34 | Proportional coefficient of high-pressure cylinder | 0.341 |

| Heating extraction module | Extraction volume time constant | 9.042 | Butterfly valve PID control parameters | 2.827 |

| Butterfly valve hydraulic motor time constant | 9.231 |

| Module Name | Parameter | Value | Parameter | Value |

|---|---|---|---|---|

| Speed control system module | Amplification factor of speed deviation | 11.1 | Oil engine time constant | 5.244 |

| PID control proportional coefficient | 0.45 | |||

| Turbine module | Steam volume time constant | 0.21 | Proportional coefficient of high-pressure cylinder | 0.312 |

| Heating extraction module | Extraction volume time constant | 6.782 | Butterfly valve PID control parameters | 4.5 |

| Butterfly valve hydraulic motor time constant | 6.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, L.; Hu, H.; Xi, J.; Xiong, L. Bi-Level Optimization Method for Frequency Regulation Performance of Industrial Extraction Heating Units Under Deep Peak Shaving Conditions. Processes 2025, 13, 3111. https://doi.org/10.3390/pr13103111

Wen L, Hu H, Xi J, Xiong L. Bi-Level Optimization Method for Frequency Regulation Performance of Industrial Extraction Heating Units Under Deep Peak Shaving Conditions. Processes. 2025; 13(10):3111. https://doi.org/10.3390/pr13103111

Chicago/Turabian StyleWen, Libin, Hong Hu, Jinji Xi, and Li Xiong. 2025. "Bi-Level Optimization Method for Frequency Regulation Performance of Industrial Extraction Heating Units Under Deep Peak Shaving Conditions" Processes 13, no. 10: 3111. https://doi.org/10.3390/pr13103111

APA StyleWen, L., Hu, H., Xi, J., & Xiong, L. (2025). Bi-Level Optimization Method for Frequency Regulation Performance of Industrial Extraction Heating Units Under Deep Peak Shaving Conditions. Processes, 13(10), 3111. https://doi.org/10.3390/pr13103111