1. Introduction

Solar gasification aims to convert carbonaceous feedstocks into a value-added syngas via an endothermic reaction using an oxidizing agent (H

2O or CO

2), where process heat is provided by concentrated sunlight. The use of concentrated solar energy to drive endothermal reactions results in reduced CO

2 emissions and biomass resource savings, with potential for more syngas produced per unit of feedstock and no contamination caused by combustion by-products, in comparison with conventional autothermal processes requiring partial feedstock combustion [

1,

2]. However, solar thermochemical processes require the handling of solar power fluctuations for continuous day and night processing. Several methods have been proposed to mitigate the effects of fluctuating solar power availability on solar gasification. The benefit of heat storage in maintaining a sufficiently high temperature throughout day–night operations can be considered. The thermal inertia of reactors can be improved to buffer solar power variations. Internal heat storage can be achieved in molten-salt reactor designs [

3]. Several small-scale molten salt reactors have been developed [

4,

5]; however, they revealed technical obstacles such as the reactivity of salts with other species. Such molten-salt gasifiers have shown promising experimental performance and thermal efficiency [

6,

7]. Regarding external heat storage, solutions have been considered to integrate heat storage devices in solar thermochemical plants [

8], featuring the cycling of heat transfer fluids at the expense of moderate storage temperatures (around 700 °C) [

9]. Only particle-based storage has been reported to be feasible up to 900 °C. In this context, relevant dual-fluidized bed processes have been proposed [

10,

11,

12,

13,

14] due to favorable heat transfer characteristics. Solar-driven steam gasification of biomass was also recently proposed with indirect heat transfer to solid particles used as solar heat carrier media [

15,

16].

Regarding the gasification reaction, the solar–autothermal hybridization concept is another option for round-the-clock operation [

17]. Continuous syngas production can thus be achieved, while gradually replacing solar heating through in situ partial feedstock combustion whenever the incoming solar power is not sufficient. Autothermal–solar reactor heating reduces the requirements for heat storage capacity [

18] and, thereby, the oversizing of solar collectors. Conventional autothermal processes can be solarized via the integration of a concentrated solar energy source in the gasification plant [

19,

20], which can lead to competitive H

2 production costs while saving feedstock resources. The economic assessment of hybridized gasification was considered in [

21,

22]. A detailed techno-economic analysis of the hybridized gasification process was previously carried out, and a comparison with autothermal and solar gasification was also proposed. H

2 production costs from solar-only, hybrid, and conventional autothermal biomass gasification were assessed under different economic scenarios. Considering a biomass reference cost of EUR 0.1/kg and a land cost of EUR 12.9/m

2, the H

2 minimum cost was estimated to be EUR 2.99/kg

H2 and EUR 2.48/kg

H2 for solar–allothermal and hybrid processes, respectively, and EUR 2.25/kg

H2 for the conventional process. Potential cost savings for solar processes can arise from a decrease in solar tower and heliostat costs, combined with a lower land cost. The analysis also showed that a slight increase in the feedstock price penalized the autothermal process, thereby favoring solar-only and solar hybrid gasification. This is because solar processes favor better utilization of the biomass feedstock, thus reducing fuel production costs. In the case of waste gasification (such as agricultural and crop waste, food waste, and Solid Recovered Fuels), solar processes reduce CO

2 emissions, thus enabling lower environmental impacts for non-renewable feedstocks (for instance, plastic waste). The direct CO

2 emissions of solar-driven processes remain negligible or significantly lower than those of conventional autothermal processes. Thus, solar-driven gasification processes have promising long-term potential since they avoid or alleviate the costs associated with pollutants abatement and CO

2 mitigation.

Different studies have investigated the hybridization of existing solar reactors (vortex flow [

23]; dual fluidized bed [

24]) with the injection of oxygen. Alternatively, different studies have considered solar power integration for steam heating [

25,

26], thus limiting the impacts of solarization on the whole process. These studies considered hybridization at the process scale. Another approach consists of considering the gasifier alone to characterize its responses to varying solar conditions. A hybridized molten-salt reactor with high heat storage capacity was proposed in [

18]. The control of a hybridized reactor was also studied in [

27] by adding biomass feedstock and oxygen to maintain a temperature above 1100 K. During day periods, the consumption of the feedstock and oxygen was reduced, thus enhancing the energy upgrade factor from 0.88 to 1.20 and reducing CO

2 production and feedstock consumption when compared to the autothermal process. A stable H

2 + CO molar flow rate can be obtained, while the H

2:CO molar ratio can be tuned downstream. Other simulations have studied the effect of H

2O and O

2 injection rates on a hybrid 300 kW

th solar reactor [

17], but feedstock injection regulation has not been addressed, which would enable control of the total H

2 + CO production rate.

The implementation and development of dynamic control methods have been considered to evaluate the practical applicability of solar-only and hybridized control strategies. In the field of solar reactors, dynamic control aims at stabilizing thermal and chemical reactor performance, despite the fluctuating availability of solar power [

27,

28,

29,

30]. For example, models of solar-packed bed [

31] and vortex flow reactors [

32] were proposed using a feedback-based controller to stabilize the produced gas composition and optimize the control parameters and the reactor’s efficiency, thanks to the improved management of solar transients [

33]. In a different work, Boujjat et al. [

29] carried out yearly simulations (hourly time steps) to compare the hybridized and solar-only production of an upscaled process (at 10 MW

th scale) and to determine the total syngas production rate using real DNI data (Direct Normal Irradiation). The decrease in solar heat was directly balanced by an appropriate addition of biomass feedstock and O

2. Cloudy periods were thus managed by switching between solar, hybridized, and autothermal operation, without diminishing temperature control capabilities. Annual simulations were finally carried out to determine H

2 production costs [

21]. This methodology and research effort should be continued by utilizing a shorter sampling time and suitable control strategies, including control of syngas quantity or quality. Additional implementation was carried out in a solar electrical gasification reactor in [

30]. The obtained experimental results demonstrated the feasibility of on-site dynamic control. Suitable feedback was given, highlighting the benefits of short sampling times for the control of temperature. Longer sampling times may be suited for integrating weather forecasting in order to anticipate long-term variations in DNI.

Different experimental studies of hybridized reactors have also been performed. Varying O

2:C and H

2O:C molar ratios have been considered, and oxygen addition increases reactor temperatures at the expense of reduced H

2 production [

5]. Similarly, the gasification of beechwood particles in a hybridized solar spouted-bed reactor [

34] showed that a decrease in the reactor temperature due to decreasing solar power input could be counteracted by additional feedstock and oxygen injection. Similar results were obtained regarding solid recovered fuel particle gasification [

34]. Finally, in a molten-salt reactor, injecting oxygen maintained the medium temperature at about 1210 K while decreasing the solar power input [

35]. Again, the production of H

2 decreased significantly (by 25%), whereas the production of CO

2 increased 2-fold. The role of steam addition was considered in particular, as it can enhance H

2:CO molar ratios at the expense of higher solar heat consumption for steam generation. Hence, the H

2:CO mole ratio should not be a controlled parameter to be considered during process hybridization, whereas downstream water–gas shift reaction (WGS) should be encouraged for such applications [

27].

Dynamic control of solar hybrid gasification is proposed for continuous day and night operation. The hybridization strategy applied in previous studies involved constant H

2 + CO production [

36,

37]. However, it has only been validated for steady-state operations in a lab-scale gasifier model, which does not imply its feasibility during transients. This is why a dynamic control study appears interesting in discussing the practical application of hybridization under real solar power input conditions. Controlling H

2 + CO production seems essential to integrating hybridized gasifiers in a continuous process. However, the practical application of solar heating requires demonstrating the feasibility of continuous control to cope with fluctuating solar power inputs. A continuous control code is thus developed and applied in this study. In particular, an application to an upscaled gasification plant is proposed, yielding daily to yearly performance results. The goal is to promote solar energy integration with thermochemical conversion processes. The objective of this study is to provide dynamic control validations and to assess the management of transient regimes between autothermal (night) and allothermal (day) operations. This represents a major innovation in the design of biomass gasification reactors at a large scale using dynamic control strategies based on high-resolution model predictive control, industrial-scale validation, and exploration of alternative hybridization strategies. A continuous optimization problem is formulated comprising two inputs and two constraints for the simultaneous control of both H

2 + CO production and reactor’s content temperature (at 1.5 kW scale). Upscaling to the industrial scale (10 MW

th) is then performed to identify the potential yearly performance results of hybridized gasification and to highlight the impact of design choices on these results. In particular, the role of potential sunlight defocusing during clear days is addressed to maintain a constant syngas production rate while avoiding reactor overheating. The dynamic model uses high time resolutions (1 s for direct solar irradiance data) and chemical dynamics integration to yield yearly results. To date, such a dynamic control tool applied to solar thermochemical fuel production processes under various operation strategies has never been developed. The control tool can be used to simulate solar–autothermal hybridized gasification, enabling a controlled H

2 + CO production rate under a stabilized reactor content temperature. Finally, alternative control strategies are assessed: (i) solar-only gasification and (ii) hybridization thanks to another external heat source. Even though the goal is not to yield complete performance results, these cases might provide further insights into the design and controllability of solar-heated processes.

5. Conclusions

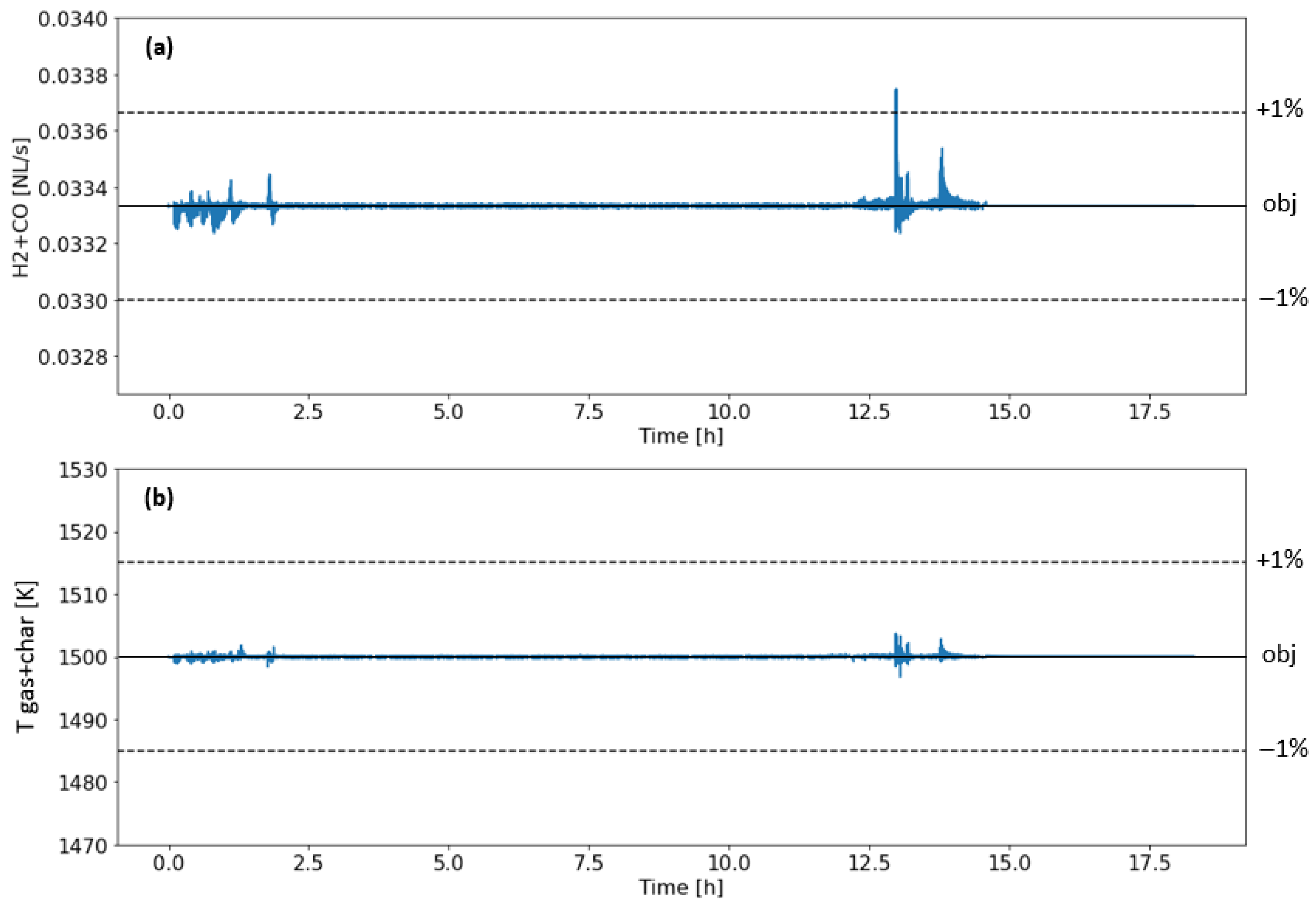

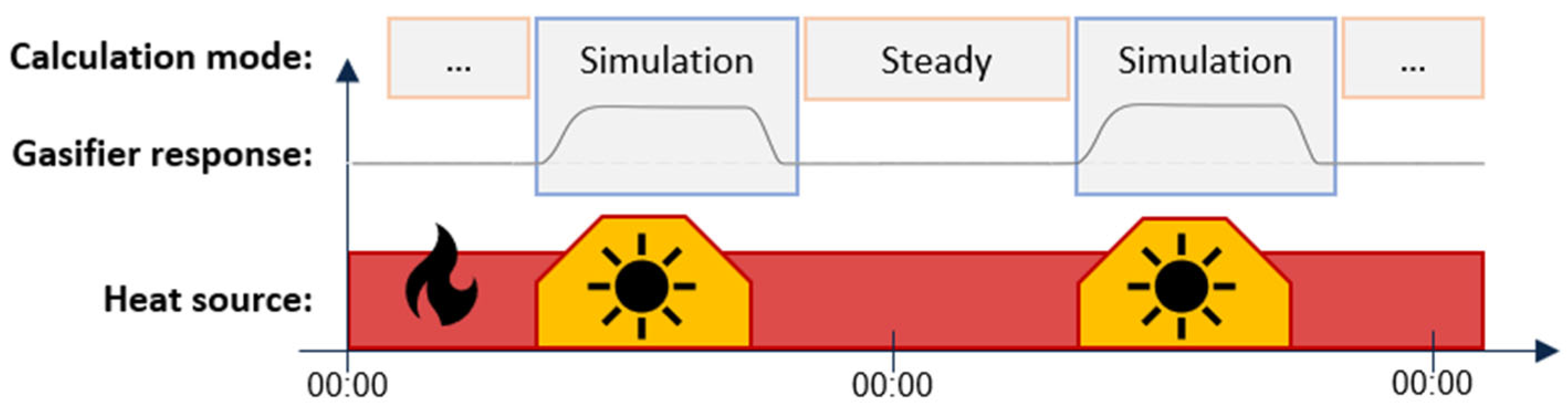

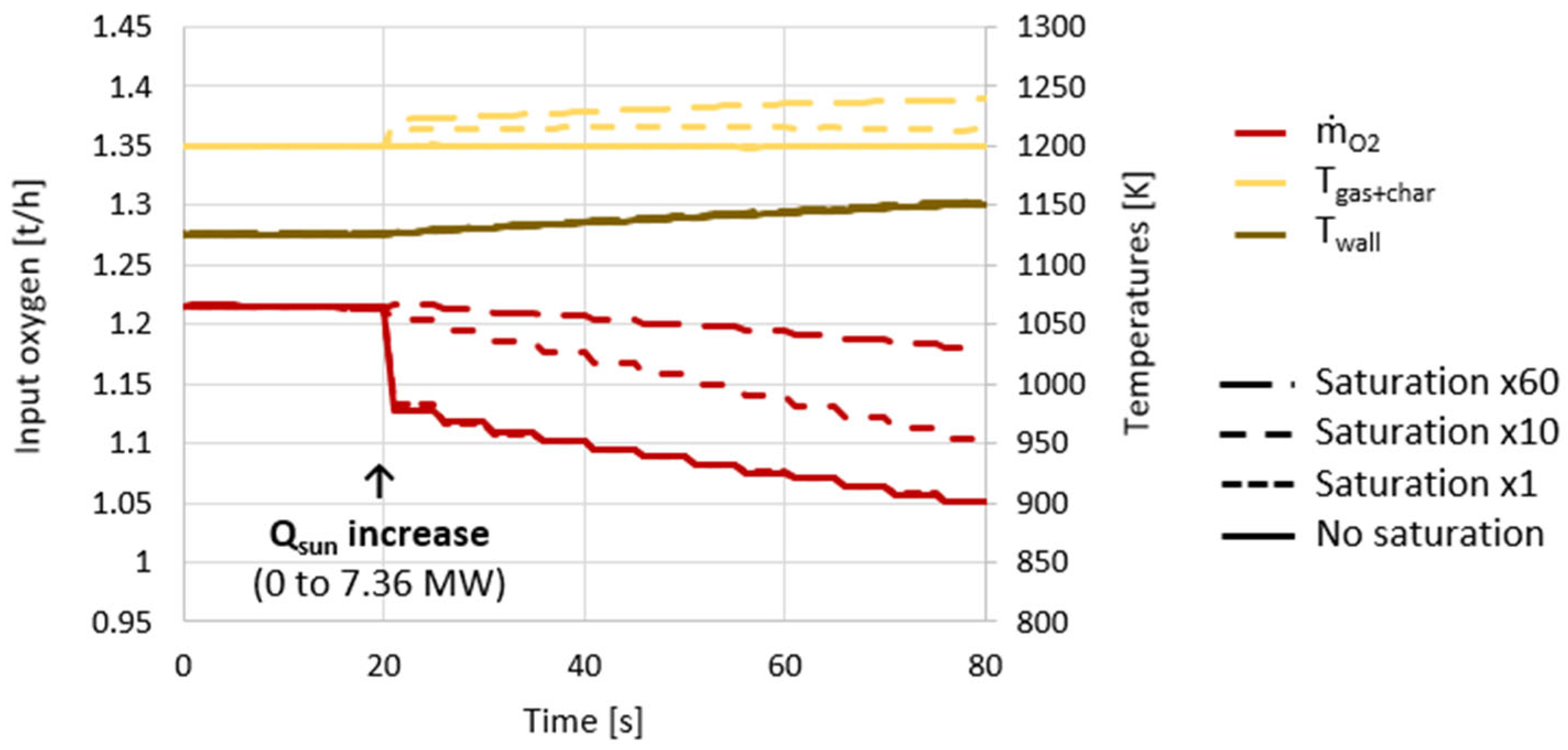

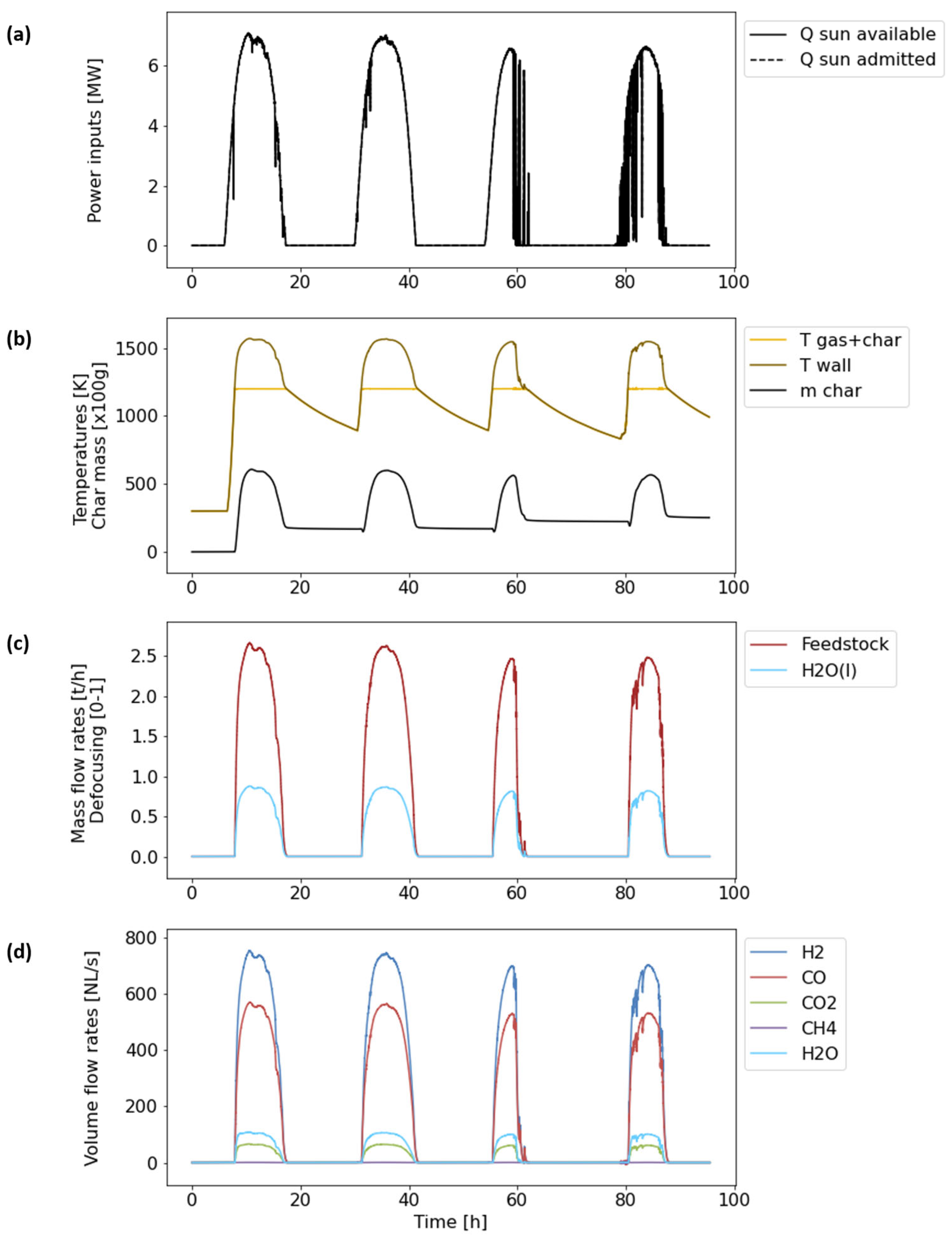

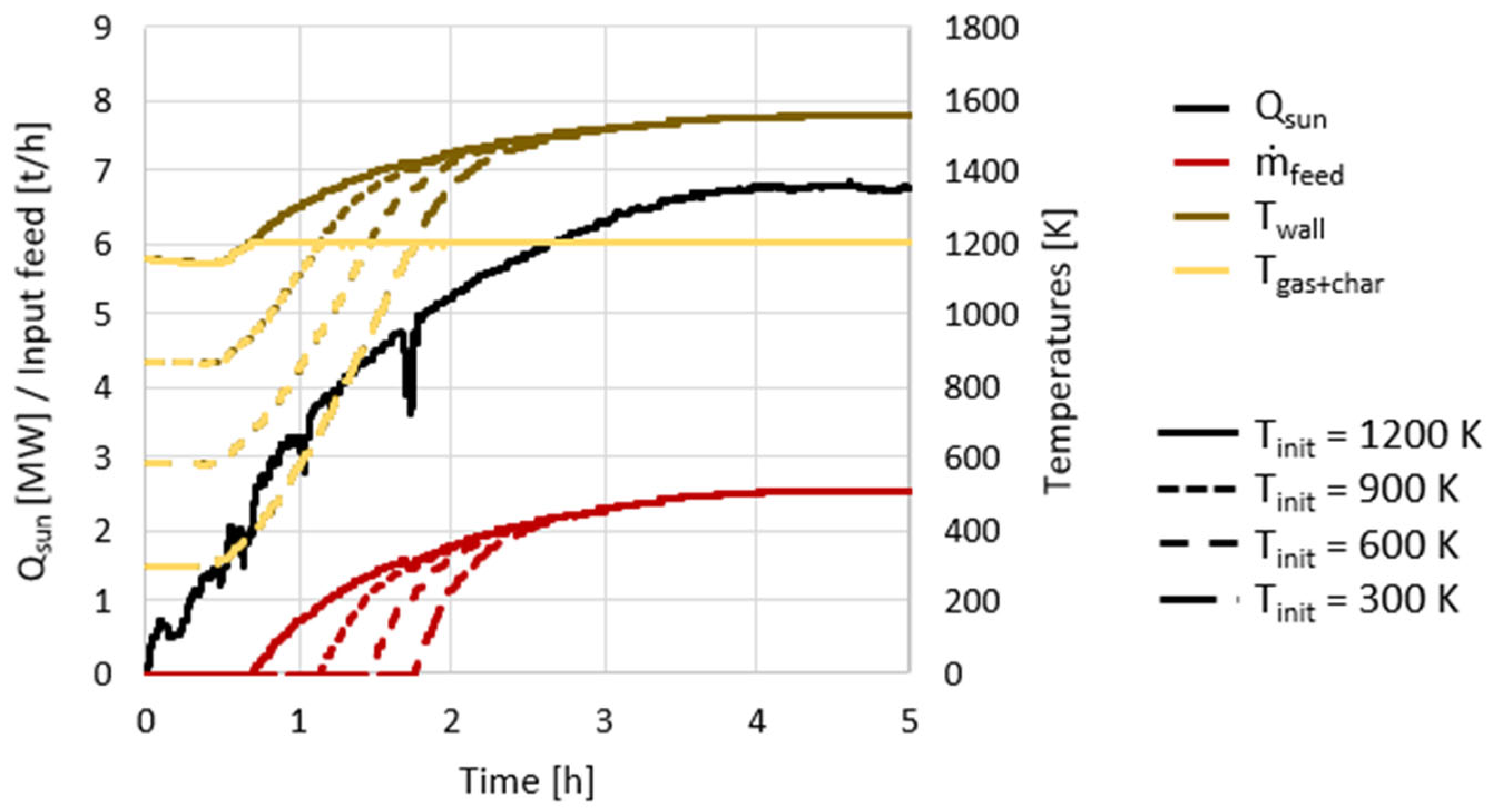

Dynamic control of a solar gasification reactor was proposed to maintain a stable reactor temperature and syngas production rate during continuous day and night operations. The dynamic model proposed, with char gasification kinetics and detailed unsteady heat transfer equations, was well suited to assessing the dynamic controllability of a hybridized gasifier. A model predictive control algorithm was implemented, based on reactor state forecasting over multiple time steps. However, it quickly appeared that a simple step-by-step control algorithm was sufficient, provided that small-enough sampling times were considered. A continuous optimization problem was formulated to maintain a constant H2 + CO production rate and the gasifier’s content temperature around the clock. This yielded satisfying control precisions with a 5 s sampling time, despite some severe solar power input evolution. Good robustness was also achieved, always with the same reactor state reached at night (autothermal operation), regardless of its history during the day. This allowed us to decorrelate daily production cases, thus enabling the parallelization of yearly performance calculations.

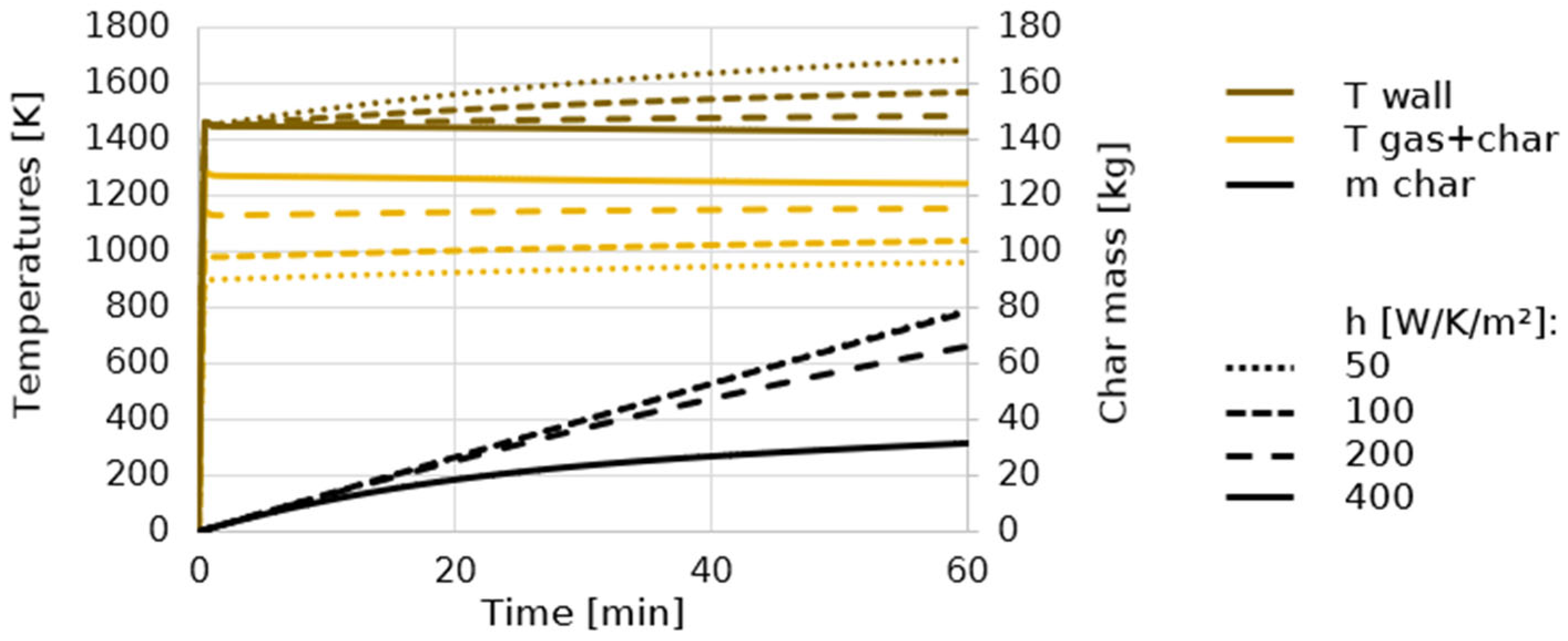

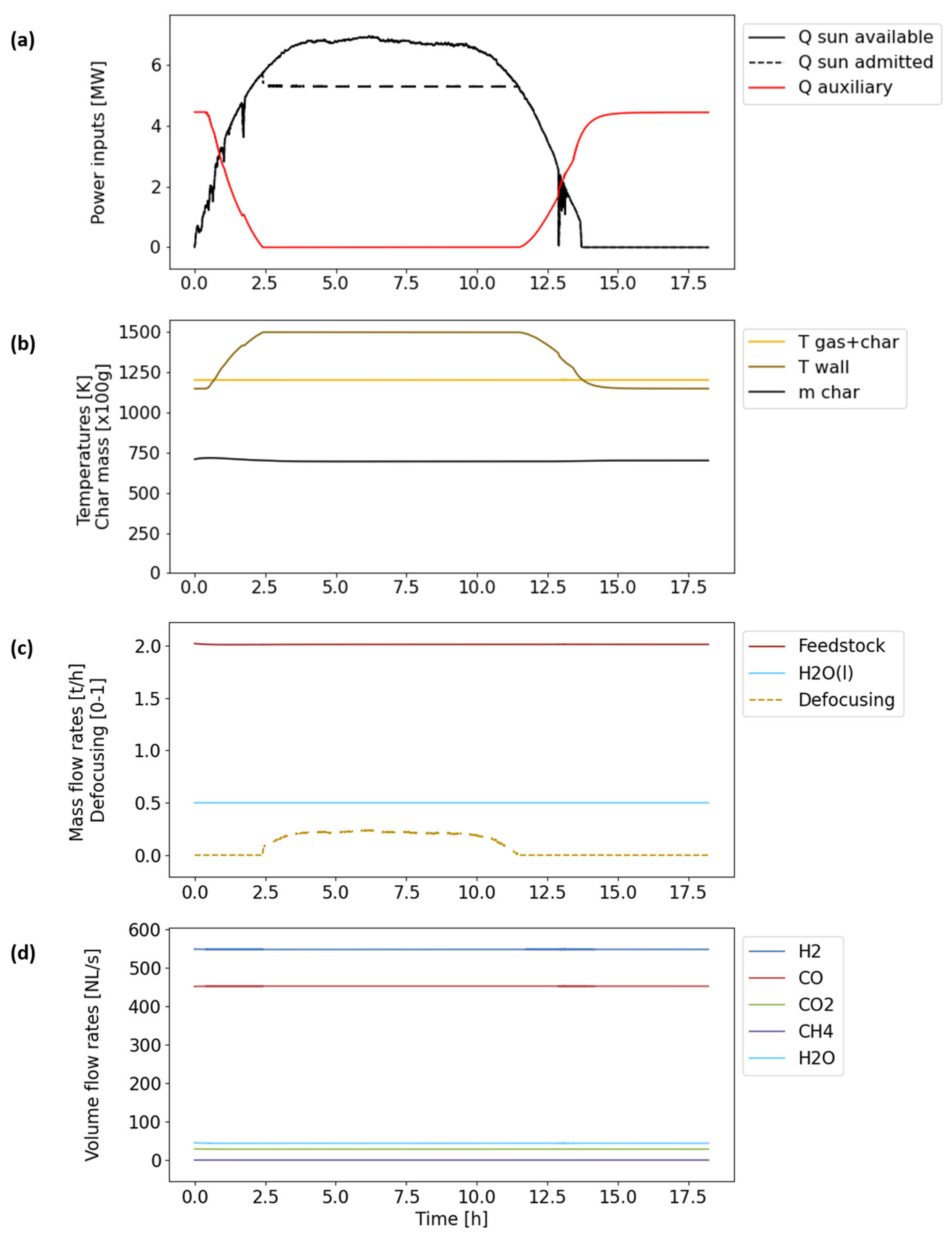

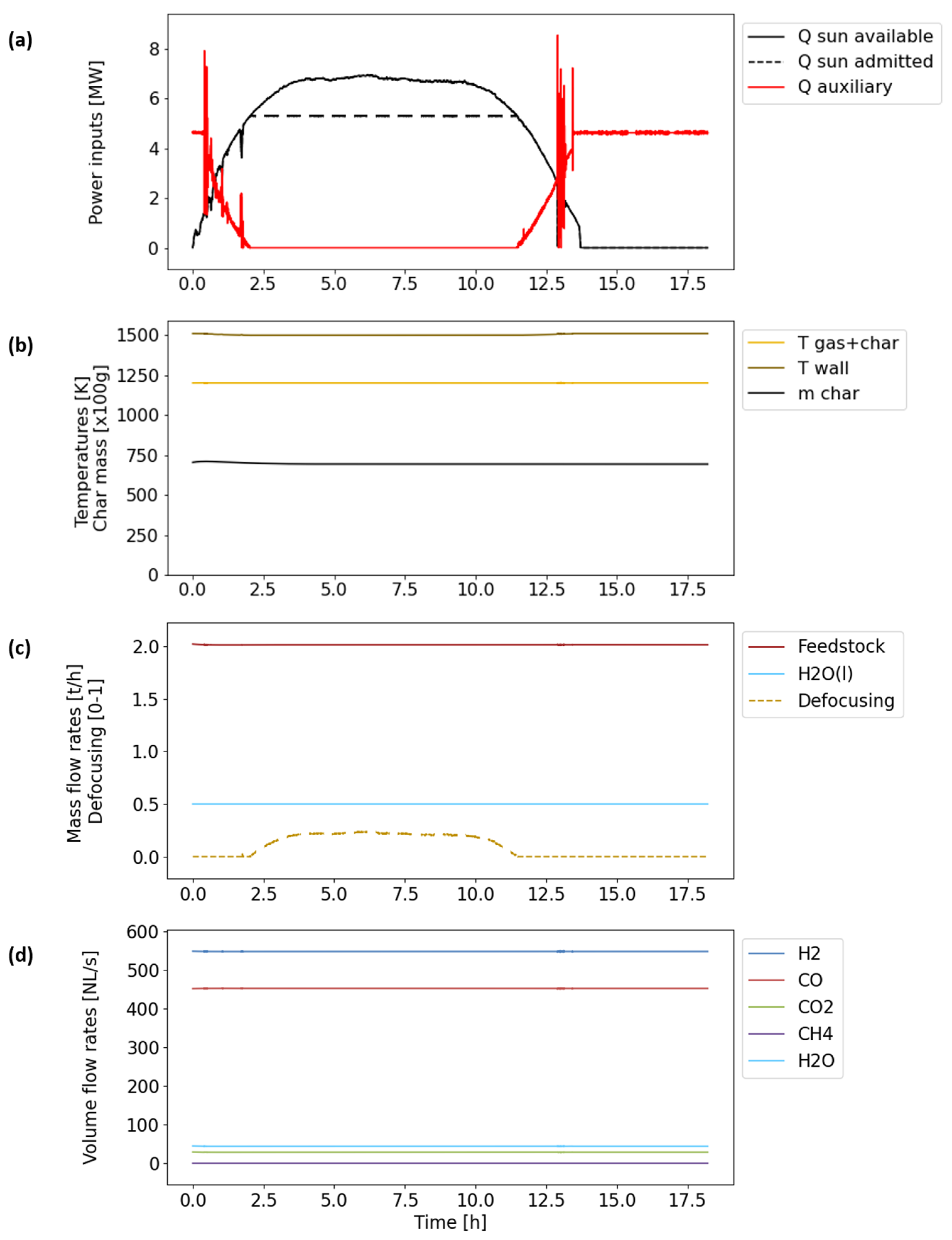

An upscaled 10 MWth gasifier design was proposed for further investigations. Among other things, reactor upscaling presented a difficulty regarding insufficient wall-to-content heat transfer, which might be handled by implementing technological upgrades (reactant pre-heating, wall fins, inert particles addition, etc.). The resulting yearly performance assessment was performed with solar irradiation data from Targasonne (France). In comparison with autothermal-only gasification, hybridization allowed us to save between 6.2% and 7.6% of the wood resources and between 17.7% and 19.5% of the O2 resources (air combustion was not considered, but might alleviate overall costs). The yearly solar heat share was limited to 17.4% in order to use all the solar power available (ṅH2+CO = 1300 NL/s). Higher solar heat shares could only be achieved at lower H2 + CO production objectives (22.0% at ṅH2+CO = 1000 NL/s), at the cost of substantial sunlight defocusing during the days (7.2% solar heat loss), to avoid reactor overheating.

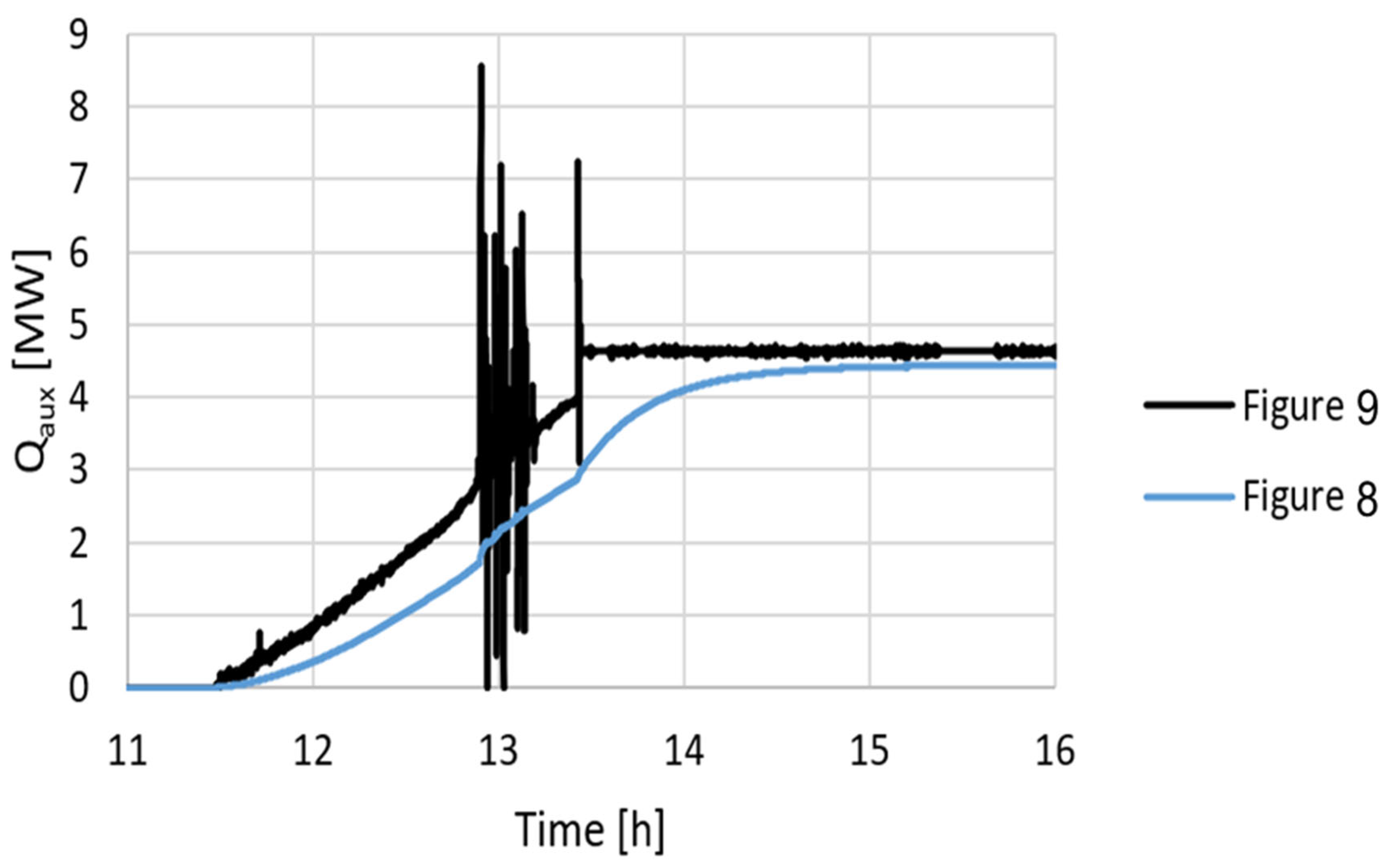

Other control strategies were also assessed, such as solar-only gasification and hybridization with external auxiliary heating sources. The state-of-the-art already shows that a solar-only gasifier cannot produce a constant flow of syngas throughout the year. However, complex flow sheets have been hypothesized with external combustion chambers, hot inert or reactive particle storage, and separated solar receivers. Separating these chambers seems to be more convenient regarding the process design, but might fail due to thermal efficiency issues. In the present study, even though auxiliary heating seemed to require a similar heat flux to in situ combustion, the efficiency of the corresponding heat source and heat transfer circuits was not considered. Given the various possible sources of external heating (electrical, external combustion, and heat storage), this alternative also appears to be a suitable option for process hybridization with controlled syngas production.