Accumulation and Exploration Potential of Coalbed Methane Collected from Longtan Formation of Santang Syncline in Zhijin, Guizhou Province

Abstract

1. Introduction

2. Study Area and Data Used

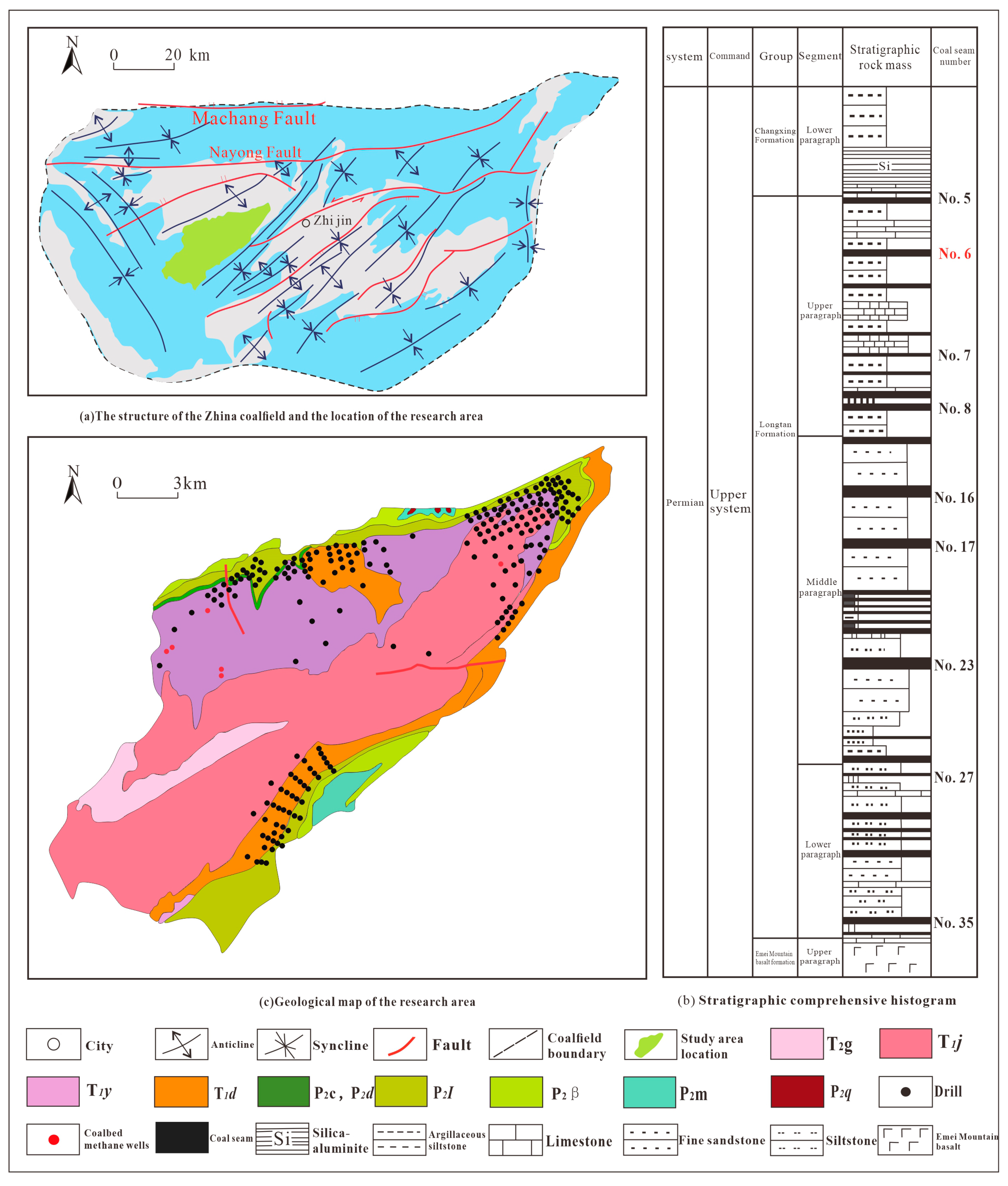

2.1. Geological Background

2.2. Sample Collection and Experimental Testing

3. Results and Discussion

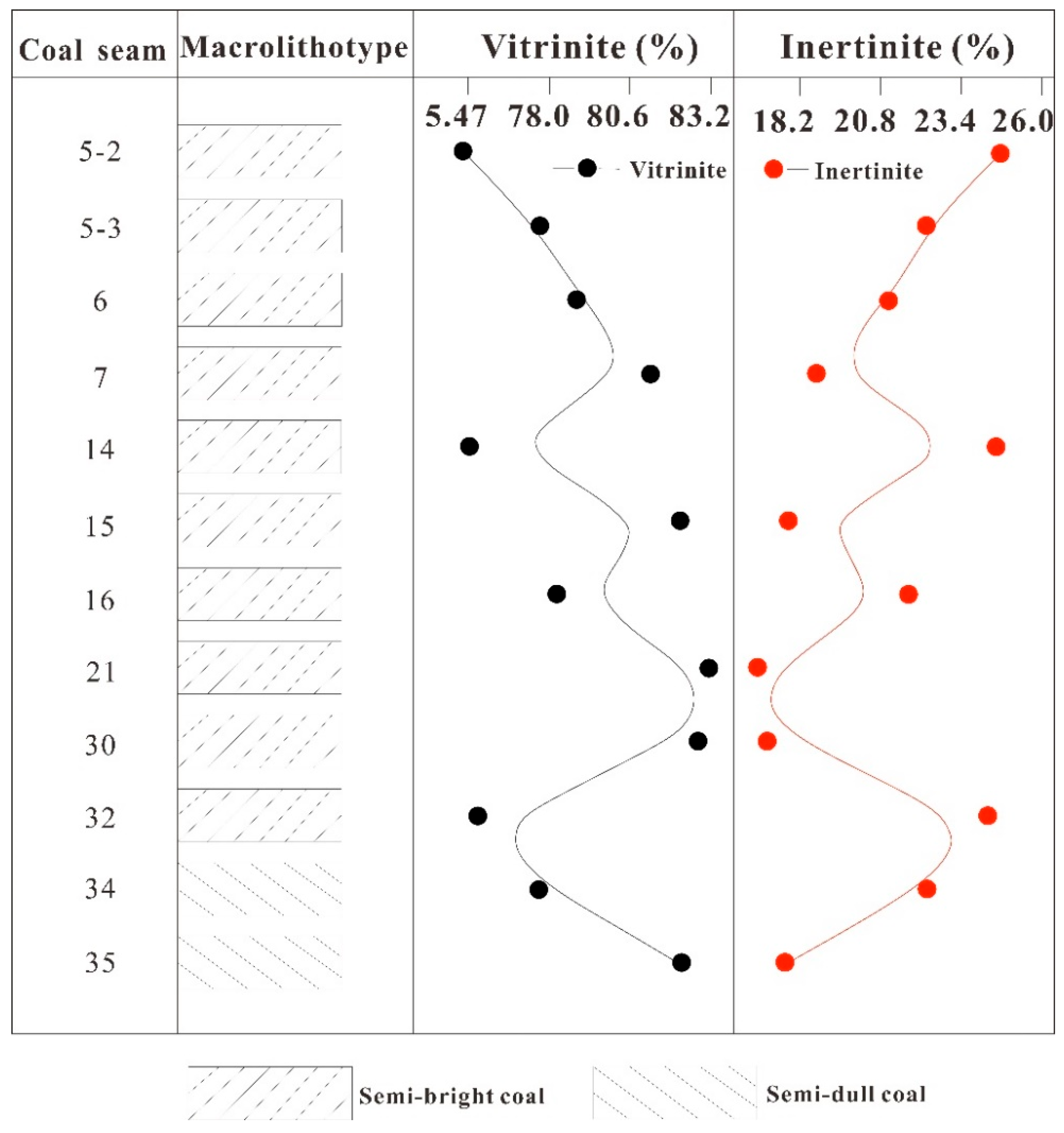

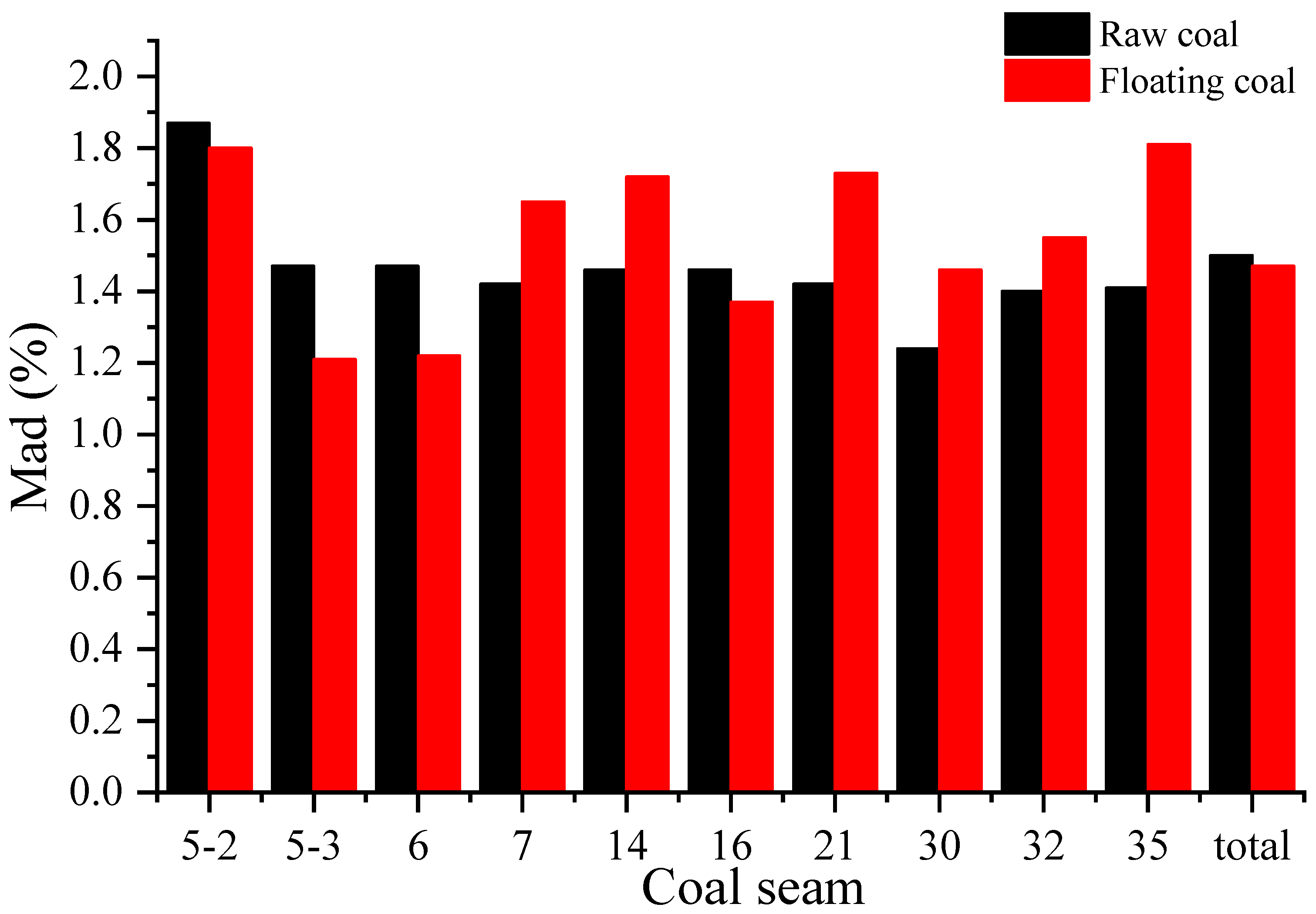

3.1. Coal Seam Burial Depth and Coal Rock Quality

3.2. Petrophysical Characteristics of Coal Reservoirs

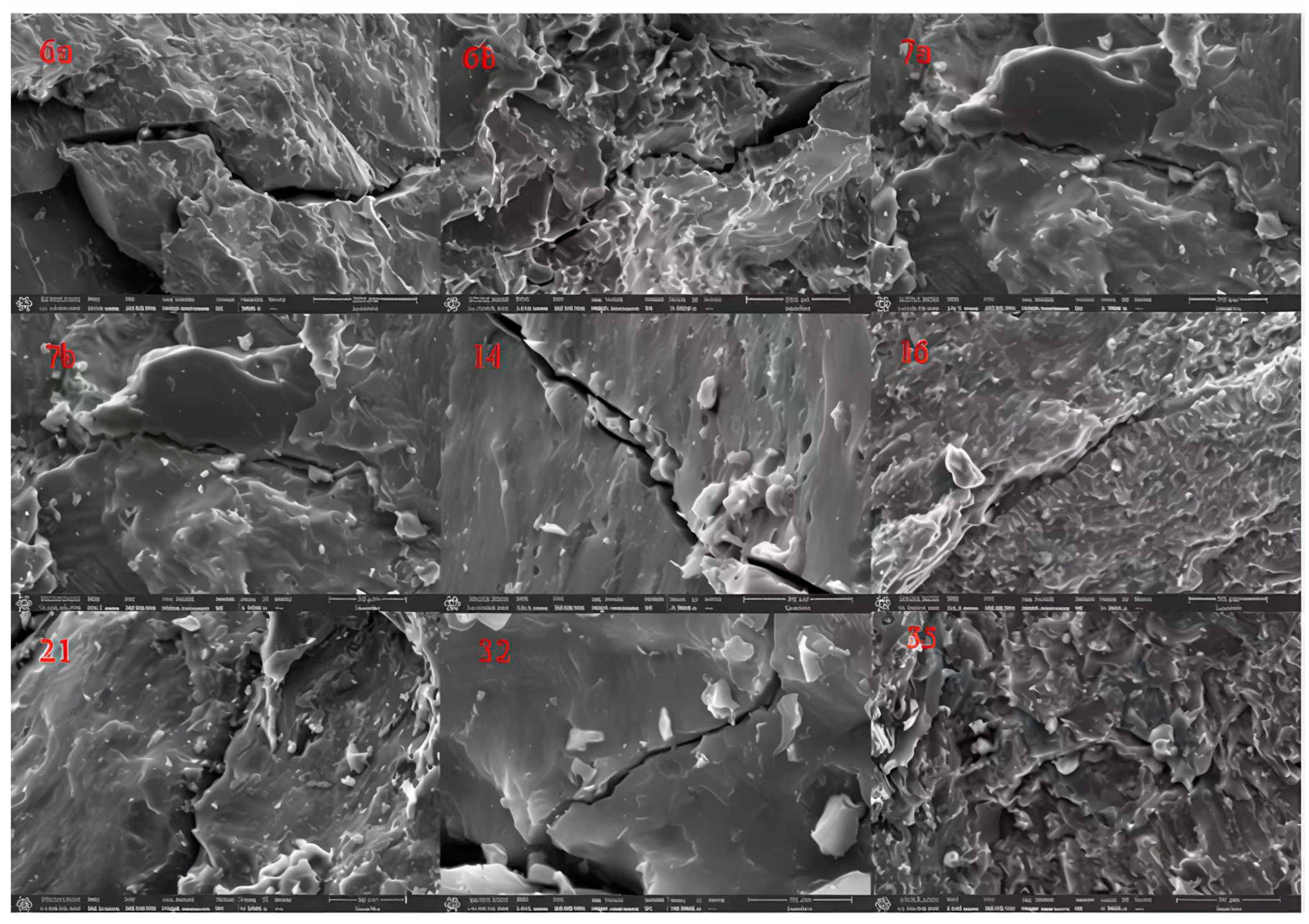

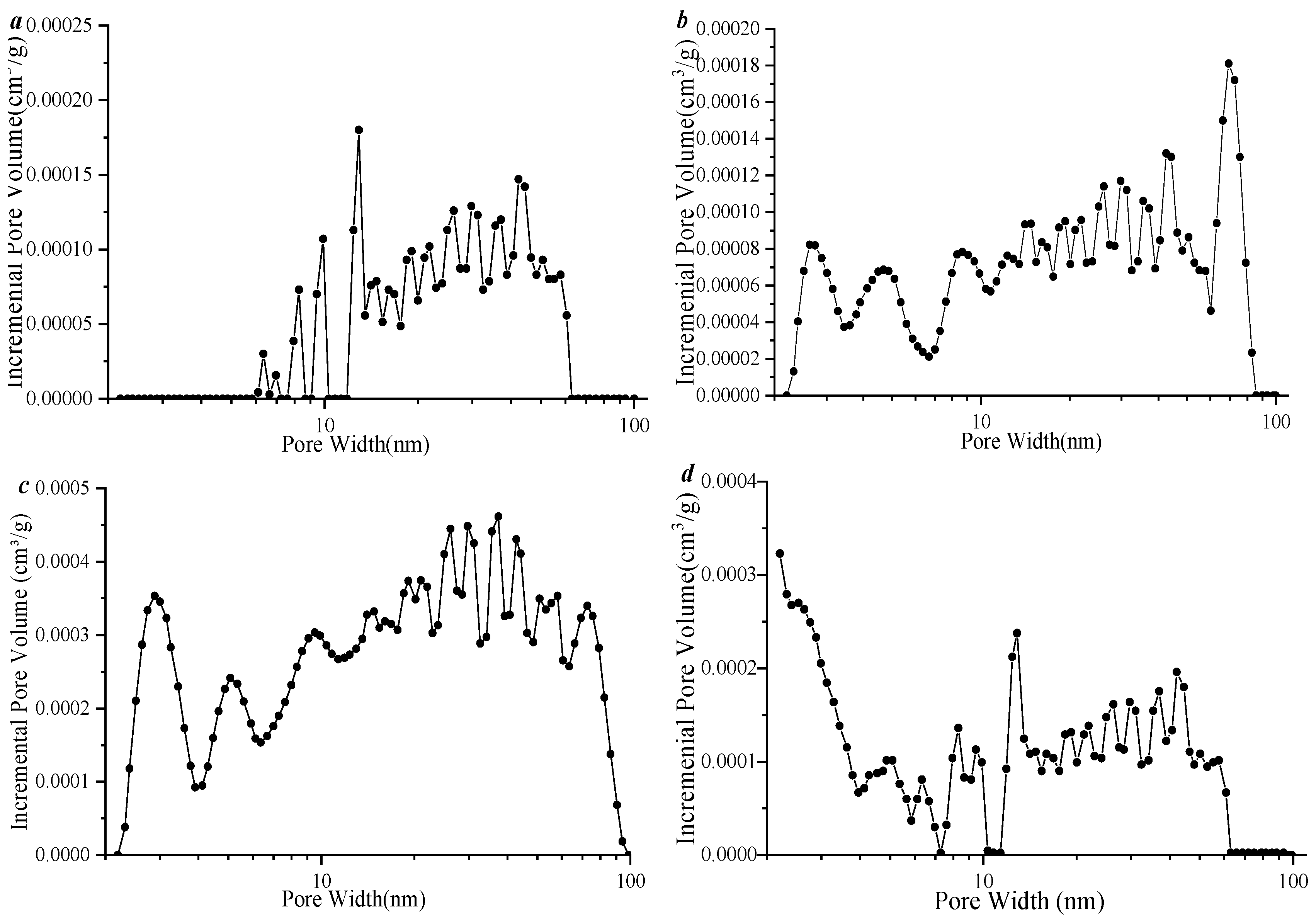

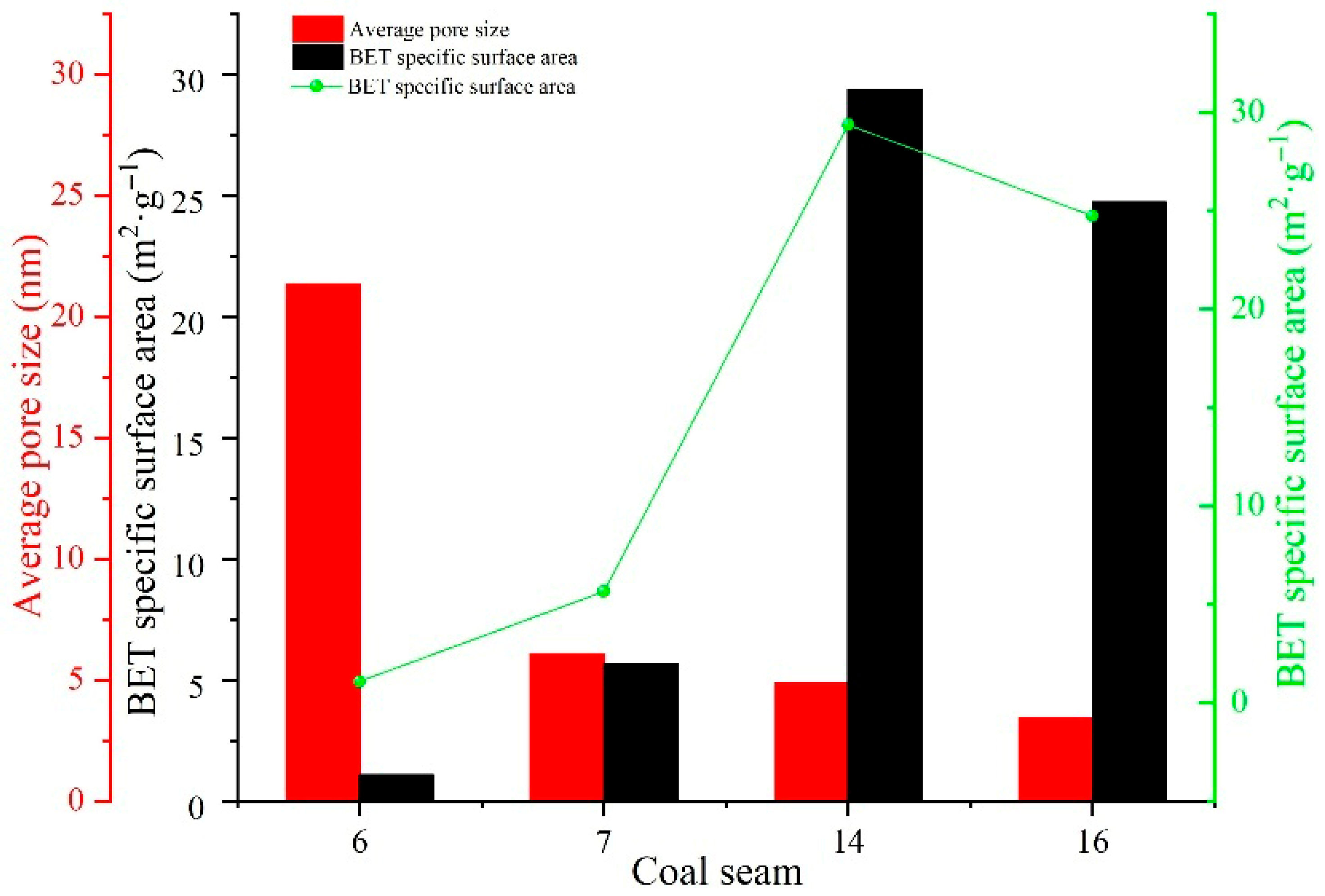

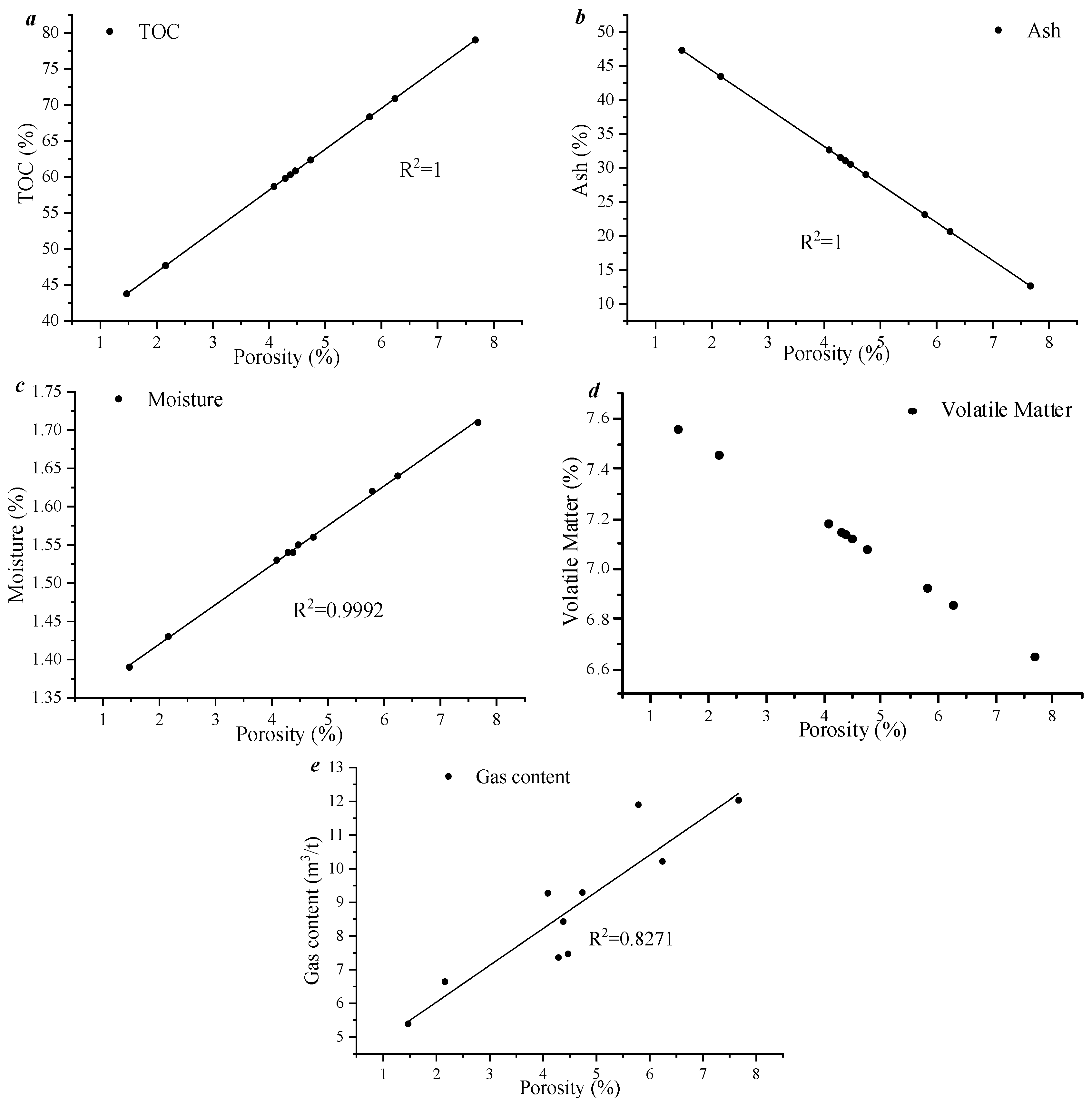

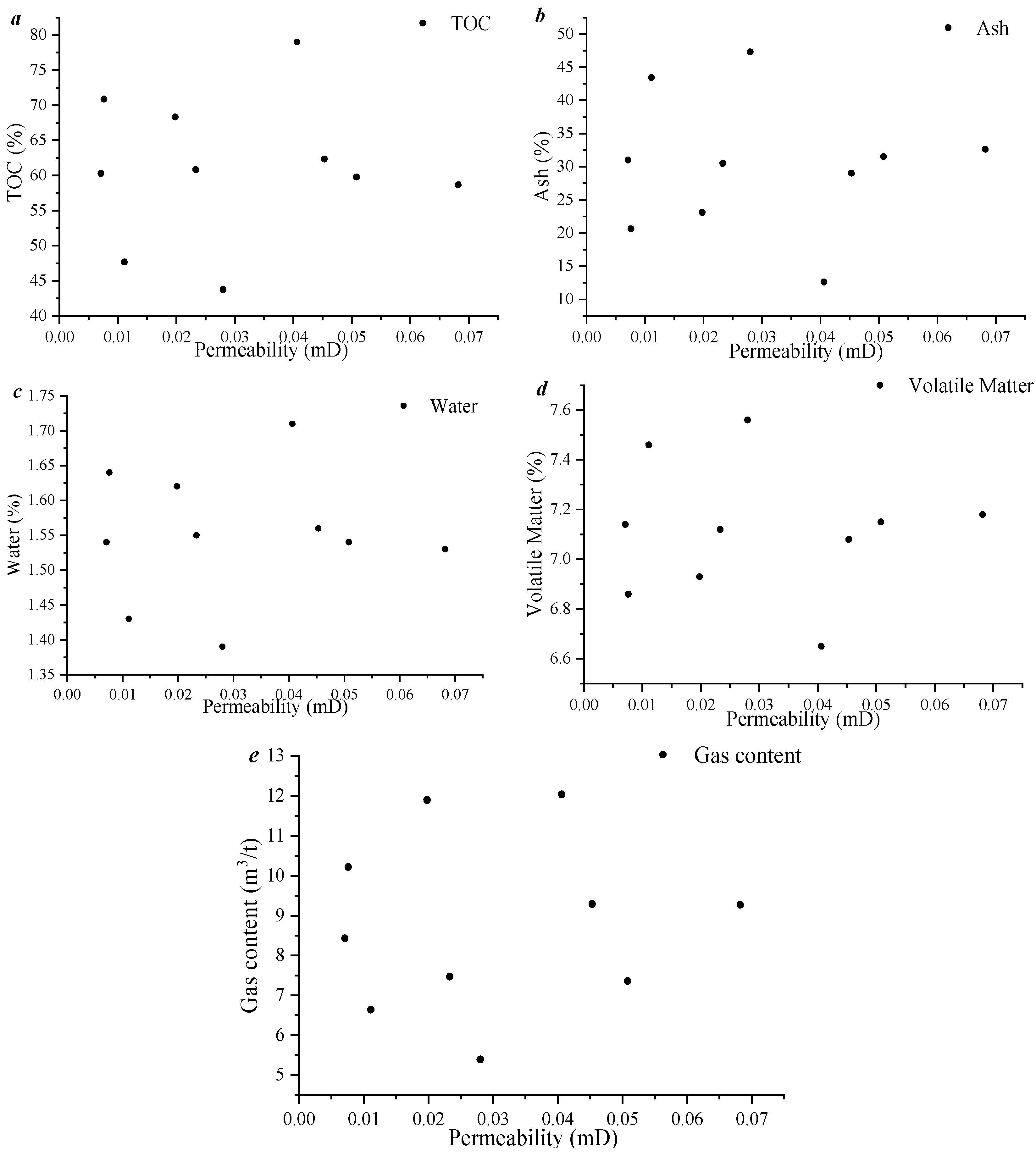

3.2.1. Pore–Fracture Structure

3.2.2. Coal Seam Adsorption Characteristics

3.3. Potential Evaluation of Coalbed Methane Resources in Well Areas

4. Conclusions

- (1)

- Ro,max of the coal seams ranges from 3.20 to 3.60%. Metamorphic grade generally increases with burial depth. Coal lithotypes are predominantly semi-bright coal, with subordinate semi-bright to semi-dull coal, and minor semi-dull coal. Roofs of coal seam are composed of gray-black mudstone and calcareous mudstone, with some areas developing limestone, and the floors are composed of bauxitic mudstone.

- (2)

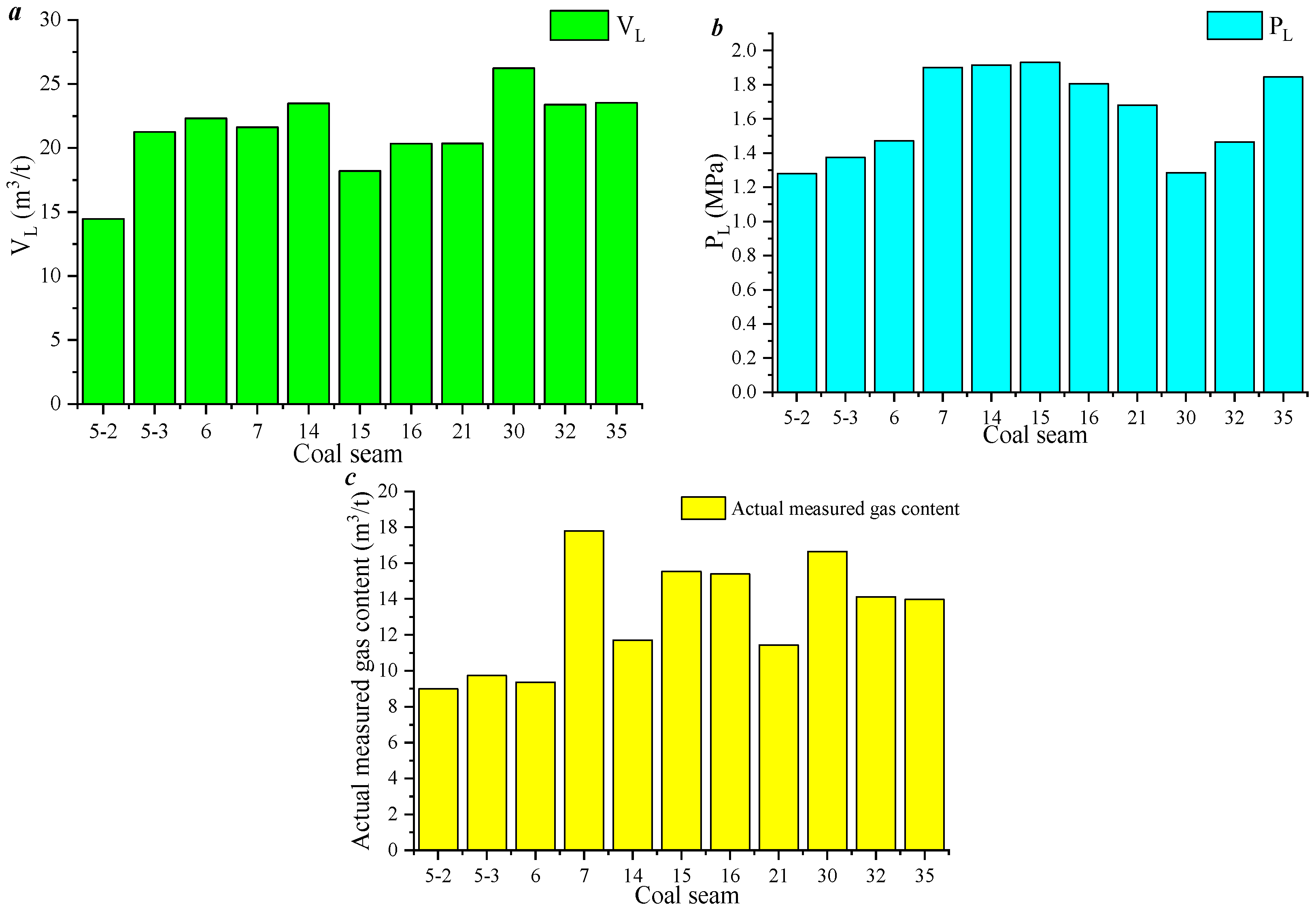

- Pore structure of coal seams 6 and 14 are more complex, while those of coal seams 7 and 16 tend to be simpler. Coal seams 5-3 and 6 exhibit the weakest adsorption capacity and the lowest theoretical gas saturation. Gas saturation of other seams exceeds 55%. VL increases with burial depth (maximum in coal seam 30), while PL exhibits a low–high–low trend (lower at both ends, higher in the middle). Measured gas content is highest in the middle, followed by the lower part, and lowest in the upper part. Favorable reservoir conditions in coal seams 14, 16, and 21; relatively favorable reservoir conditions in coal seam 7; and unfavorable reservoir conditions in coal seams 6, 30, 32, and 35. Among coal groups penetrated by this well, the middle coal group exhibits the most favorable reservoir conditions, followed by the upper and lower coal groups.

- (3)

- Coal seams 7 and 16 exhibit moderate thickness and are dominated by blocky coal, demonstrating favorable gas content and high gas saturation. Gas content measurements from nine coal seams in this study indicate consistently favorable results, all exceeding 8 m3/t. Geological CBM resource abundance is highest in coal seam 6 (0.56 × 108 m3/km2) and lowest in coal seam 5-2 (0.15 × 108 m3/km2).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, F.Y.; Hou, W.; Xiong, X.Y.; Xu, B.R.; Wu, P.; Wang, H.Y.; Feng, K.; Yun, J.; Li, S.G.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Tao, S.; Chen, S.D.; Pan, Z.J. Current status, challenges, and policy suggestions for coalbed methane industry development in China: A review. Energy Sci. Eng. 2019, 7, 1059–1074. [Google Scholar] [CrossRef]

- Song, Y.; Zhao, M.J.; Hong, F.; Liu, S.B.; Qin, S.F.; Wang, H.Y. Pool-forming stages and enrichment models of medium- to high-rank coalbed methane. Acta Geol. Sin.-Engl. Ed. 2010, 84, 1539–1546. [Google Scholar] [CrossRef]

- Mastalerz, M.; Hampton, L.; Drobniak, A.; Loope, H. Significance of analytical particle size in low-pressure N2 and CO2 adsorption of coal and shale. Int. J. Coal Geol. 2017, 178, 122–131. [Google Scholar] [CrossRef]

- Chen, Z.L.; Tang, D.Z.; Xu, H.; Tao, S.; Zhang, B.; Cai, J.L.; Meng, C.Z. The pore system properties of coalbed methane reservoirs and recovery in western Guizhou and eastern Yunnan. J. China Coal Soc. 2010, 35 (Suppl. S1), 158–163. [Google Scholar] [CrossRef]

- Tian, Z.B.; Ma, Y.L.; Li, X.; Ji, Y.J.; Li, D.S. A method for detecting coalbed methane gas storage structure in coal goaf—A case in Qinshui coal field in Shanxi province. Chin. J. Geophys. -Chin. Ed. 2022, 65, 4495–4503. [Google Scholar] [CrossRef]

- Guo, C.; Xia, Y.C.; Ma, D.M.; Sun, X.Y.; Dai, G.L.; Shen, J.; Chen, Y.; Lu, L.L. Geological conditions of coalbed methane accumulation in the Hancheng area, southeastern Ordos Basin, China: Implications for coalbed methane high-yield potential. Energy Explor. Exploit. 2019, 37, 922–944. [Google Scholar] [CrossRef]

- Mosher, K.; He, J.; Liu, Y.; Rupp, E.; Wilcox, J. Molecular simulation of methane adsorption in micro- and mesoporous carbons with applications to coal and gas shale systems. Int. J. Coal Geol. 2013, 109, 36–44. [Google Scholar] [CrossRef]

- Küster, F.; Nikrityuk, P.; Junghanns, M.; Nolte, S.; Tünnermann, A.; Ackermann, R.; Richter, A.; Guhl, S.; Meyer, B. In-situ investigation of single particle gasification in a defined gas flow applying TGA with optical measurements. Fuel 2017, 194, 544–556. [Google Scholar] [CrossRef]

- Li, C.G.; Jiang, B.; Ju, W.; Cheng, G.X.; Song, Y. Characteristics of tectonic deformation in the Daning-Jixian region, eastern Ordos Basin: Implications for the exploration and development of coalbed methane. Energy Explor. Exploit. 2019, 37, 907–921. [Google Scholar] [CrossRef]

- Wu, C.F.; Liu, X.L.; Zhang, S.S. Construction of index system of “Hierarchical progressive” geological selection of coalbed methane in multiple seam area of eastern Yunnan and western Guizhou. J. China Coal Soc. 2018, 43, 1647–1653. [Google Scholar]

- Mahamud, M.; Menéndez, J.; Sarquís, P. CO2 activation of chars: Effect of burn-off on texture and fractal properties. Fuel Process. Technol. 2014, 119, 41–51. [Google Scholar] [CrossRef]

- Cao, X.H.; Xiao, Z.H.; Cao, Y.J.; Sun, B.; Jiang, W.; Cao, Y.Z.; Chen, J.M. Coal reservoir geological features comparative analysis between eastern Yunnan, western Guizhou area and Qinshui Basin. China Coal Geol. 2020, 32, 55–60. [Google Scholar]

- Guo, C.; Qin, Y.; Yi, T.S.; Ma, D.M.; Wang, S.Q.; Shi, Q.M.; Bao, Y.; Chen, Y.; Qiao, J.W.; Lu, L.L. Review of the progress of geological research on coalbed methane co-production. Coalf. Geol. Explor. 2022, 50, 42–57. [Google Scholar]

- Li, S.; Tang, D.Z.; Pan, Z.J.; Xu, H.; Guo, L.L. Evaluation of coalbed methane potential of different reservoirs in western Guizhou and eastern Yunnan, China. J. Fuel 2015, 139, 257–267. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, A.; Zhao, C.; Wang, W.; Jiang, Y.; Vandeginste, V.; Xue, Z.; Guo, Y.; Miao, H. A new parameter for characterizing pore-fracture structure heterogeneity: Fractal dimension based on the mercury extrusion curve. Front. Earth Sci. 2024, 18, 782–796. [Google Scholar] [CrossRef]

- He, L.W.; Yan, Z.H.; Chen, J.; Hu, H.Y.; Li, M.L. Research on fine drainage control technology of coalbed methane wells in Liu panshui area. Petrochem. Technol. 2025, 32, 295–297. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, C.; Zhao, C.; Zhang, T.; Lu, G.; Zou, M. Effects of nano-pore and macromolecule structure of coal samples on energy parameters variation during methane adsorption under different temperature and pressure. Fuel 2021, 289, 119804. [Google Scholar] [CrossRef]

- Liu, Y.H.; Liu, S.Q.; Wang, W.K.; Tian, Y.C.; Du, R.B.; Chen, S.H.; Sang, S.X. Application of PCA-FCE model in CBM development evaluation: A case study for Liupanshui coalmine area in Guizhou Province. China Coal Geol. 2025, 37, 69–74. [Google Scholar]

- Li, J.X.; Qu, X.Y.; Pei, Y.J.; He, C.H. Development effect and productivity evaluation of multi-thin coal seam horizontal well in Zhijin block, Guizhou Province. Coal Sci. Technol. 2025, 1–13. Available online: https://link.Cnki.net/urlid/11.2402.td.20250117.1511.002 (accessed on 24 September 2025).

- Zhang, J.; Wei, C.; Ju, W.; Yan, G.; Lu, G.; Hou, X.; Kai, Z. Stress sensitivity characterization and heterogeneous variation of the pore-fracture system in middle-high rank coals reservoir based on NMR experiments. Fuel 2019, 238, 331–344. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, C.; Ju, W.; Qin, Z.; Ji, Y.; Quan, F.; Hu, Y. Microscopic distribution and dynamic variation of water under stress in middle and high rank coal samples. J. Nat. Gas Sci. Eng. 2020, 79, 103369. [Google Scholar] [CrossRef]

- Sun, Z.; Wei, Y.L.; Zhao, L.Y.; Long, C.Y.; Liu, J.T.; Zhou, X.Z. Development opportunities and risk countermeasures of coalbed methane industry in Guizhou Province. China Coalbed Methane 2022, 19, 40–43. [Google Scholar]

- Zeng, J.Y.; Gao, W.; Yan, Z.H.; Nie, J. CBM industrial development status in Bijie area and strategical thinking on the 14th Five-Year Plan. Nat. Gas Technol. Econ. 2022, 16, 23–29. [Google Scholar]

- Chen, X.X.; Deng, Y. Geological characteristics and exploration and development countermeasures of coalbed methane in Guizhou. Chem. Des. Commun. 2021, 47, 12–13. [Google Scholar]

- Chen, C.R.; Zhou, X.Z.; Zhao, F.P.; Meng, H.T.; Zhu, S.L.; Zhao, Y.Z.; Wei, Y.L. Geological and engineering collaborative control technology for high production of CBM wells in thin-medium-thick coal seam clusters: A case study of Wenjiaba block in the Zhina Coalfield, Guizhou. Nat. Gas Ind. 2023, 43, 55–64. [Google Scholar]

- Tao, J.J.; Wang, L.X.; Huang, J.Y. Geology and development potential of CBM in three major coalfields, Guizhou Province. Nat. Gas Technol. Econ. 2019, 13, 29–34. [Google Scholar]

- Li, Y.; Hao, H.Y.; Chang, L.M.; Huang, M.Y.; Cai, L.; Ban, J.P. Analysis of challenges in CBM well cementing of Zhina Coalfield in Guizhou Province. China Coalbed Methane 2018, 15, 3–7. [Google Scholar]

- Jiang, W. Study on the CBM Single Well’s Fracturing/Drainage Model of Multi-Coalbeds Area in Zhina Coal Field. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2015. [Google Scholar]

- Chen, R.; Zhang, Z.Y. Sedimentary environment and palaeogeographical pattern of the Early Carboniferous Late Yangguan—Early Datang stage in eastern Yunnan—Western Guizhou area—Enlightenment for shale gas exploration. Geol. Bull. China 2023, 42, 307–316. [Google Scholar]

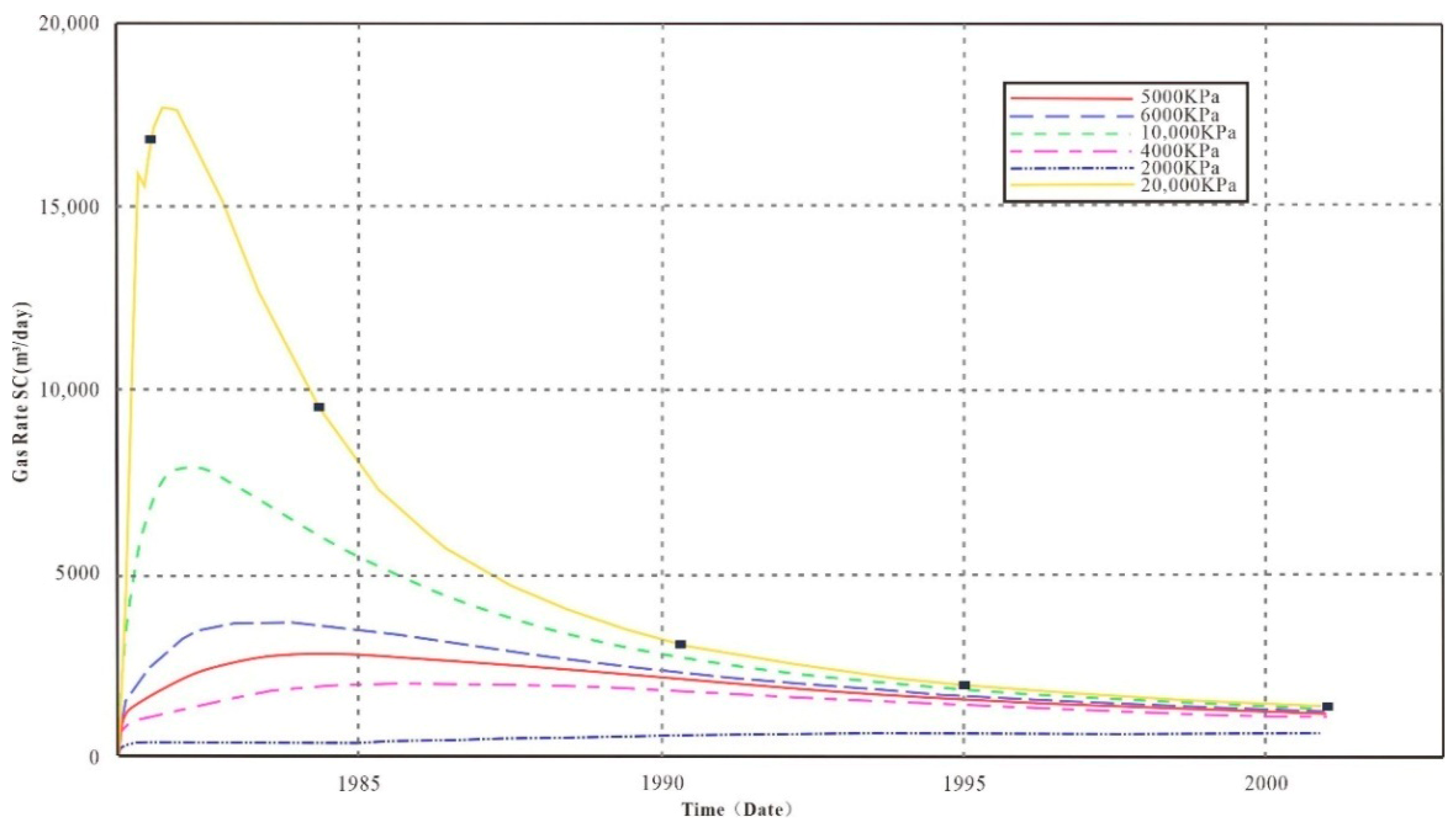

- Miao, H.Y.; Veerle, V.; Zhang, J.J.; Chen, S.B.; Chang, X.C.; Du, Y.; Wang, Y.; Wei, C.T.; Luo, J.H.; Quan, F.K.; et al. Control mechanism of pressure drop rate on coalbed methane productivity by using production data and physical simulation technology. Fuel, accepted.

- Tang, S.L.; Tang, D.Z.; Xu, H.; Tao, S.; Li, S.; Geng, Y.G. Geng Geological mechanisms of the accumulation of coalbed methane induced by hydrothermal fluids in the western Guizhou and eastern Yunnan regions. J. Natural Gas Sci. Eng. 2016, 33, 644–656. [Google Scholar] [CrossRef]

- Guo, L.L.; Tang, D.Z.; Xu, H.; Li, S.; Gao, L.J. Analysis on physical property features of different coal rank coal reservoirs in western Guizhou and eastern Yunnan area. Coal Sci. Technol. 2014, 42, 99–103. [Google Scholar]

- Yao, P.; Zhang, J.; Lv, D.; Vandeginste, V.; Chang, X.; Zhang, X.; Wang, D.; Han, S.; Liu, Y. Effect of water occurrence in coal reservoirs on the production capacity of coalbed methane by using NMR simulation technology and production capacity simulation. Geoenergy Sci. Eng. 2024, 243, 213353. [Google Scholar] [CrossRef]

- GB/T 18023-2000; Classification of Macrolithotype for Bituminouscoal. State Administration for Market Regulation: Beijing, China, 2000.

| Coal | Optical Characteristics | Mechanical Characteristics | Macrolithotype | Coal Structure |

|---|---|---|---|---|

| 5-2 | black, glassy luster | even fracture | Semi-bright | Massive with powdery intercalations |

| 5-3 | black, Like metallic luster | Stepped fracture | Semi-bright | Massive coal |

| 6 | black, glassy | Uneven and stepped fracture surfaces | Semi-bright | Powdery to massive |

| 7 | black, Like metallic luster | Stepped fracture | Semi-bright | Massive coal |

| 14 | black, glassy | Stepped fracture | Semi-dull to semi-bright | Massive coal |

| 16 | black, Like metallic luster | Uneven and stepped fracture surfaces | Semi-dull | Massive coal |

| 21 | black, glassy | Stepped fracture | Semi-bright | Massive coal |

| 30 | Black, Like metallic luster | Stepped fracture | Semi-dull | Massive coal |

| 32 | black, Like metallic luster | Stepped fracture | Semi-dull | Massive coal |

| 35 | black, glassy | Stepped fracture | Semi-dull | Massive coal |

| Coal Seam | Permeability/mD | Porosity/% |

|---|---|---|

| 5-3 | 0.0076 | 6.2066 |

| 6 | 0.0068 | 5.2495 |

| 7 | 0.01187 | 5.2410 |

| 14 | 0.0042 | 3.9372 |

| 16 | 0.004 | 4.3368 |

| 30 | 0.0295 | 7.2417 |

| 32 | 0.0017 | 6.8171 |

| 35 | 0.015 | 7.3798 |

| Coal | Average Pore Diameter/nm | BET Specific Surface Area/m2·g−1 | BJH Pore Volume/cm3·g−1 |

|---|---|---|---|

| 6 | 21.3116 | 1.0775 | 0.0056 |

| 7 | 6.0634 | 5.6578 | 0.0081 |

| 14 | 4.8568 | 29.3693 | 0.0315 |

| 16 | 3.4135 | 24.7256 | 0.0196 |

| Coal Seam | Thickness (m) | Depth (m) | Reservoir Pressure (MPa) | Porosity (%) | Permeability (mD) |

|---|---|---|---|---|---|

| 6 | 0.60 | 148.13 | 3.1306 | 7.67 | 0.029 |

| 7 | 1.45 | 245.68 | 2.3777 | 6.24 | 0.027 |

| 14 | 0.88 | 290.79 | 3.3929 | 2.39 | 0.215 |

| 21 | 0.58 | 366.64 | 4.2145 | 1.47 | 0.150 |

| 32 | 0.48 | 427.24 | 4.3633 | 4.09 | 0.190 |

| Coal Group | Coal Seam | Apparent Thickness (m) | Vitrinite (%) | Coal Structure | Total Gas Content (m3/t) | Gas Saturation (%) | Pressure Coefficient |

|---|---|---|---|---|---|---|---|

| Upper Coal Measure | 5-2 | 1.57 | 75.25 | Massive Structure with Silt Particles | 8.98 | 69.50 | |

| 6 | 2.35 | 78.90 | Massive | 9.36 | 42.00 | 1.2959 | |

| 7 | 2.58 | 81.25 | Massive | 17.80 | 82.50 | 0.9006 | |

| Middle Coal Measure | 14 | 0.88 | 75.45 | Massive | 11.70 | 50.00 | 1.0451 |

| 16 | 2.30 | 78.25 | Massive | 15.40 | 76.00 | 1.0429 | |

| 21 | 1.21 | 83.15 | Massive | 11.43 | 56.00 | ||

| Lower Coal Measure | 30 | 0.61 | 82.80 | Massive | 11.64 | 63.50 | |

| 32 | 2.72 | 75.75 | Massive | 14.12 | 60.50 | 0.9354 | |

| 35 | 1.28 | 82.25 | Massive | 13.97 | 59.00 |

| Coal Group | Coal Seam | Apparent Thickness (m) | Total Gas Content (m3/t) | Bulk Density (g/cm3) | CBM Resource Concentration (×108 m3/km2) | Coal Measure Methane Resource Abundance (×108 m3/km2) |

|---|---|---|---|---|---|---|

| Upper Coal Measure | 5-2 | 1.57 | 8.98 | 1.60 | 0.15 | 0.95 |

| 6 | 2.35 | 9.36 | 1.47 | 0.56 | ||

| 7 | 2.58 | 17.80 | 1.58 | 0.24 | ||

| Middle Coal Measure | 14 | 0.88 | 11.70 | 1.54 | 0.32 | 0.84 |

| 16 | 2.30 | 15.40 | 1.53 | 0.33 | ||

| 21 | 1.21 | 11.43 | 1.54 | 0.19 | ||

| Lower Coal Measure | 30 | 0.61 | 11.64 | 1.59 | 0.17 | 0.65 |

| 32 | 2.72 | 14.12 | 1.60 | 0.27 | ||

| 35 | 1.28 | 13.97 | 1.66 | 0.21 |

| Coal Group | Coal Seam | PL (MPa) | Ash Content (%) | Ro,max (%) | Porosity (%) | Permeability (mD) | Gas Saturation (%) | Evaluation |

|---|---|---|---|---|---|---|---|---|

| Upper Coal Measure | 5-2 | 1.28 | 31.53 | 3.045 | 4.29 | 69.50 | Poor | |

| 6 | 1.47 | 12.62 | 3.335 | 4.47 | 0.0294 | 42.00 | Poor | |

| 7 | 1.90 | 20.63 | 3.305 | 7.67 | 0.0271 | 82.50 | Favorable | |

| Middle Coal Measure | 14 | 1.915 | 31.03 | 3.32 | 6.24 | 0.215 | 50.00 | Moderately Favorable |

| 16 | 1.805 | 29.02 | 3.37 | 4.38 | 0.15 | 76.00 | Favorable | |

| 21 | 1.68 | 47.30 | 3.255 | 4.74 | 56.00 | Moderately Favorable | ||

| Lower Coal Measure | 30 | 1.285 | 23.11 | 3.615 | 1.47 | 63.50 | Poor | |

| 32 | 1.465 | 32.63 | 3.85 | 5.79 | 0.19 | 60.50 | Moderately Favorable | |

| 35 | 1.845 | 43.44 | 3.725 | 4.09 | 59.00 | Poor |

| Coal Seam | Reservoir Pressure MPa | Closure Pressure MPa | Fracture Pressure MPa | Unconfined Compressive Strength (MPa) | Elastic Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| 6 | 3.1306 | 7.33 | 7.41 | 6.70 | 2.021 | 0.35 |

| 7 | 2.3777 | 8.51 | 8.92 | 2.985 | 1.50 | 0.40 |

| 14 | 3.3929 | 7.88 | 8.12 | 26.30 | 3.80 | 0.36 |

| 21 | 4.2145 | 10.92 | 11.38 | |||

| 32 | 4.3633 | 8.11 | 10.91 | 21.51 | 2.88 | 0.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, S.; Liu, S.; Li, J.; Dai, X.; Lan, L.; Hou, J.; Liu, Z.; Zhang, J.; Hu, Y. Accumulation and Exploration Potential of Coalbed Methane Collected from Longtan Formation of Santang Syncline in Zhijin, Guizhou Province. Processes 2025, 13, 3106. https://doi.org/10.3390/pr13103106

Wen S, Liu S, Li J, Dai X, Lan L, Hou J, Liu Z, Zhang J, Hu Y. Accumulation and Exploration Potential of Coalbed Methane Collected from Longtan Formation of Santang Syncline in Zhijin, Guizhou Province. Processes. 2025; 13(10):3106. https://doi.org/10.3390/pr13103106

Chicago/Turabian StyleWen, Shupeng, Shuiqi Liu, Jian Li, Xinzhe Dai, Longbin Lan, Jianjun Hou, Zhu Liu, Junjian Zhang, and Yunbing Hu. 2025. "Accumulation and Exploration Potential of Coalbed Methane Collected from Longtan Formation of Santang Syncline in Zhijin, Guizhou Province" Processes 13, no. 10: 3106. https://doi.org/10.3390/pr13103106

APA StyleWen, S., Liu, S., Li, J., Dai, X., Lan, L., Hou, J., Liu, Z., Zhang, J., & Hu, Y. (2025). Accumulation and Exploration Potential of Coalbed Methane Collected from Longtan Formation of Santang Syncline in Zhijin, Guizhou Province. Processes, 13(10), 3106. https://doi.org/10.3390/pr13103106