Abstract

Nowadays, most of the heavy oil fields around the world have entered difficult exploiting stages, with problems regarding high viscosity and poor fluidity. However, there has been little previous research on the accurate identification and distribution of remaining oil with different levels of steam dryness. Therefore, this paper proposes a new nuclear magnetic resonance (NMR) interpretation method, as well as a new samples analysis method for remaining oil in the core. We conducted core displacement experiments using different methods. The nuclear magnetic resonance (NMR) tests and analysis of core thin sections after steam flooding were used to study the effect of different steam dryness levels on the migration and sedimentation mechanisms of heavy oil components. The results showed that the viscosity of crude oil and the permeability of rock cores are both sensitive to steam dryness; therefore, the improvement of steam dryness is beneficial for improving oil recovery. Heavy oil is mainly distributed in the medium pores of 10–50 μm and the small pores of 1–10 μm. However, with the decrease in steam dryness, the dynamic amount of crude oil in both medium and small pores decreases, and the bitumen in crude oil stays in the pores in the form of stars, patches, and envelopes, which leads to a decline in oil displacement efficiency. Thus, our study provides a micro-level understanding of remaining oil which lays the foundation for the further enhancement of oil recovery in heavy oilfields.

1. Introduction

As tertiary oil recovery continues, production from conventional oil fields has gradually become unable to meet the country’s growing energy demand. Against this backdrop, the efficient development and utilization of unconventional oil and gas resources—such as heavy oil, shale oil and gas, and natural gas hydrates—will serve as a critical means to alleviate China’s energy supply shortfall and ensure its energy security [1,2]. Steam flooding is an oil recovery method characterized by continuous steam injection through injection wells and continuous oil production from production wells, operating on a well-group basis. It is widely recognized as an effective technique for heavy oil reservoir development [3]. Numerous studies have demonstrated that steam injection can significantly reduce the viscosity of heavy crude oil through thermal conduction and convection, primarily due to the unique rheological properties of heavy oil—its viscosity exhibits highly temperature-sensitive behavior. This thermal viscosity reduction effect serves as the fundamental mechanism of thermal recovery techniques for heavy oil, including steam flooding, cyclic steam stimulation (CSS), and steam-assisted gravity drainage (SAGD). From a microscopic perspective, the injection of high-temperature steam disrupts the associative network of resin–asphaltene macromolecular structures in heavy oil, thereby reducing intermolecular interactions [4]. Simultaneously, it enhances crude oil fluidity by promoting wax crystal dissolution and resin desorption. On a macroscopic scale, this thermal-viscosity-reduction effect leads to comprehensive improvement in reservoir seepage characteristics: it significantly increases the oil mobility ratio while enhancing displacement front stability through a reduced oil–water viscosity ratio. Notably, the dominant mechanisms of thermal viscosity reduction vary across different thermal recovery processes. In steam flooding, it primarily induces reservoir-wide viscosity field reconstruction; in cyclic steam stimulation, it manifests as stepwise improvement in near-wellbore crude rheology; and in SAGD, it sustains optimal viscosity-reduction conditions at the steam chamber front through continuous thermal convection. This temperature-dependent rheology modification mechanism, coupled with ancillary effects such as thermal fluid expansion and steam distillation, constitutes the most fundamental characteristic distinguishing thermal recovery from conventional production methods [5,6,7,8]. When high-temperature steam is injected into the reservoir, it not only induces an exponential decline in crude oil viscosity through direct heat exchange (typically, a 10 °C temperature increase can reduce heavy oil viscosity by more than 50%) but also reduces oil–water interfacial tension, promotes asphaltene disaggregation, and enhances crude oil mobility [9,10,11,12]. Furthermore, thermal fluid expansion significantly increases formation energy, while steam distillation extracts light hydrocarbon components. These synergistic effects collectively constitute the multi-physical/chemical mechanisms by which thermal recovery enhances heavy oil recovery, ensuring its dominant role in heavy oil development. Additionally, high-temperature steam induces the expansion of both oil and water while causing rock matrix expansion, which decreases pore volume and increases oil production. A systematic investigation into the effects of steam dryness on remaining oil distribution holds significant scientific and engineering implications [13,14,15].

Mohammad Ashrafi et al. [16] conducted experimental and numerical simulations of steam flooding in heavy oil reservoirs, demonstrating the existence of an optimal steam temperature and dryness for maximizing recovery efficiency. Azad et al. [17] employed a stochastic optimization algorithm with net present value as the objective function to study the influence of steam dryness on recovery rates. Luo et al. [18] performed sensitivity analyses on steam injection and production parameters and optimized steam dryness using a dual-level Plackett–Burman experimental design. Eickmeier et al. [19] calculated wellbore heat losses and steam property variations with time and depth by adjusting steam dryness and pressure, demonstrating the significant impact of steam dryness on heat transfer. Farouq et al. [20] incorporated gas slippage effects in their models of wellbore pressure drop and steam dryness, calculating the variations in steam dryness during pressure drop and its effects on recovery efficiency. In recent years, nuclear magnetic resonance (NMR) has emerged as a prominent method for studying remaining oil. Webber et al. [21] investigated the NMR responses of organic carbon at different temperatures, observing a reduction in Free Induction Decay (FID) signal amplitude with increasing temperature. Singer et al. [22] conducted NMR tests on core samples at varying reduction temperatures, establishing optimization functions between NMR logging porosity and core NMR porosity, as well as between gas-measured porosity and mercury intrusion porosity, thereby deriving T2 (Transverse Relaxation Time) cutoff values for movable fluids and effective pore sizes for organic-rich tight cores. Li et al. [23] utilized NMR technology to study oil and gas distribution characteristics during fracturing in low-permeability reservoirs. Zhou et al. [24] examined the influence of pore connectivity on aqueous phase occurrence and proposed an NMR-based permeability prediction method.

In summary, while numerous experimental studies have been conducted to elucidate the effects of steam dryness on steam flooding recovery efficiency, research on the micro-distribution of remaining oil during steam flooding remains in its preliminary stages [25,26,27,28,29]. Mercury intrusion porosimetry can identify the impact of steam–rock–water reactions on pore structure in heavy oil reservoirs, while NMR technology can elucidate the differential retention phenomena of various heavy oil components in porous media under varying steam dryness conditions. These approaches are essential for investigating the formation mechanisms and occurrence states of micro-scale remaining oil in heavy oil steam flooding. This study introduces an innovative nuclear magnetic resonance (NMR) interpretation methodology coupled with residual oil analysis of thin-section core samples, aiming to systematically investigate the impact of steam dryness on the microscopic distribution of residual heavy oil. The research elucidates how variations in steam dryness markedly alter oil displacement efficiency by modifying pore-scale architecture and the morphology of asphaltene deposition. Furthermore, it delineates the distinct mobilization behaviors of crude oil in mesopores (intermediate-sized pores) versus micropores, which have previously been poorly understood. These findings establish a microscopic theoretical framework for optimizing steam flooding strategies, offering critical insights into enhancing heavy oil recovery at the fundamental level.

2. Materials and Methods

2.1. Experiment Materials

The simulated formation brine was provided by Northeast Petroleum University. The simulated oil, with a viscosity of 1055 mPa·s at 65 °C, was prepared by mixing crude oil and aviation kerosene at a ratio of 1:3.5 at room temperature. The crude oil was supplied by Shengli Oilfield, Dongying, China.

Measurement accuracy: The measurement accuracy for liquids was 0.001 g. Calibration method: Dual calibration using volume and density. The experimental setup and conditions replicated those found in the field: 65 °C (reservoir temperature), 250 °C (steam injection temperature), and back pressure: 28 MPa.

Columnar core samples with different permeabilities were selected from the oilfield, which were used for the seepage experiment. The micropore structure parameters of the core were measured by a conventional mercury injection instrument. The core oil displacement test equipment includes a constant speed and constant pressure injection pump device, a high-pressure steam generator (0~350 ± 2 °C), a high-pressure piston container, a high-pressure valve seat, and pipe valve parts. After steam flooding, the remaining oil content of crude oil in the pores of the core test T2 using a nuclear magnetic resonance instrument (Manufacturer: MR Cores Corporation of the United States; The equipment was purchased in Beijing, China) and the retention of asphaltene in the thin section of the core casting after steam flooding was tested using a polarizing microscope. (Manufacturer: Zeiss Far East LTD, Germany; The equipment was purchased in Harbin, China).

2.2. Procedures

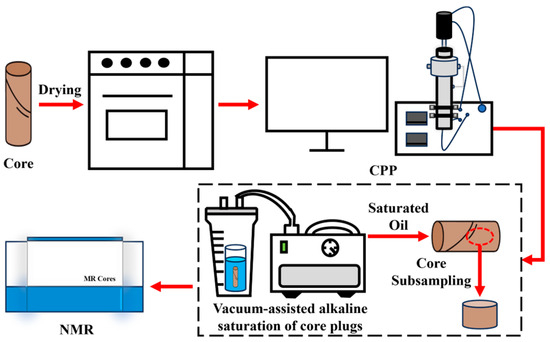

Before steam flooding, the core sample is sliced for mercury injection capillary pressure (MICP) testing, followed by an evaluation of the oil displacement efficiency via steam flooding. During the displacement process, nuclear magnetic resonance (NMR) testing is conducted on the core. After the oil displacement experiment, the core slices are examined for residual oil distribution. The experimental procedure is illustrated in Figure 1:

Figure 1.

Experimental flowchart.

- (1)

- Core Characterization

The core samples used in the experiment were all taken from the oilfield site and were consistent with the physical properties of the reservoir on site. The dried core samples were weighed, and their porosity/permeability was measured using an Automated Permeameter Porosimeter.

- (2)

- Water Saturation

After drying and weighing, core samples were vacuum-saturated with formation water for 24 h.

- (3)

- Oil Saturation

Experimental oil was injected at a constant rate of 0.1 mL/min until no water production was observed at the outlet. The injection rate and incubator temperature were subsequently increased to determine the initial oil saturation.

The prepared core was placed in the magnet probe, and the resonance frequency was adjusted. T2 imaging pulse sequences were selected, and the system parameters were optimized to acquire T2 spectra at different echo times.

- (4)

- Steam Flooding

Steam was injected at 0.05 mL/min while monitoring the inlet pressure and oil production to calculate recovery efficiency.

The NMR test was conducted again (using the same method as in Step 3) to observe the changes in fluid distribution. All samples had to remain fully saturated, as the rock matrix does not generate NMR signals. Core samples, cuttings, and wellbore wall materials should be maintained under saturated conditions prior to NMR analysis.

- (5)

- The calibration methodology between NMR relaxation time and mercury intrusion porosimetry for pore structure characterization.

Under conditions of rapid fluid diffusion, the fluid relaxation time in core pores can be approximately expressed as follows:

T2 is the transverse relaxation time;

T2B is the intrinsic relaxation time of the fluid (ms);

ρ2 is the surface relaxivity of the fluid in the pore (μm/ms);

S/V is the surface-to-volume ratio of the pore, which is inversely proportional to pore size.

T2B is typically greater than 3000 ms. When the core pore size is small, T2B is much larger than T2, allowing the first term on the right side of Equation (1) to be neglected, thus yielding the following:

The S/V ratio in Equation (2) represents the specific surface area of the pore. From Equation (2), it can be seen that for rocks with intergranular pores, the magnitude of T2 is primarily determined by lithology and the pore’s specific surface area S/V ratio. If pores are assumed to be ideal spheres, then S/V = 3/r; if pore throats are assumed to be ideal cylinders, then S/V = 2/r. Further assuming the pore radius is proportional to the throat radius, Equation (2) can be rewritten as follows:

C is the transverse conversion coefficient and FS is the pore shape factor (FS = 3 for spherical pores; FS = 2 for cylindrical throats).

For a given core sample, the surface relaxivity ρ2 can be approximately treated as constant. Therefore, Equation (3) shows that pore radius is proportional to the T2 value. The T2 spectrum can reflect the distribution of rock pore radii, where larger pores correspond to longer T2 relaxation times, while smaller pores correspond to shorter T2 relaxation times.

- (6)

- Steam dryness control and quantification

In this study, steam dryness was precisely controlled through the automated regulation of steam generator operating parameters, including feedwater flow rate, combustion intensity, and system pressure, to maintain the target vapor phase fraction. The dryness fraction (defined as the mass ratio of dry steam to total wet steam) was quantified using an integrated approach combining separator calorimetry for direct measurement and thermodynamic modeling based on real-time pressure-enthalpy monitoring. Downstream of the generator, in-line phase fraction meters with ±2% accuracy provided continuous dryness verification, while distributed temperature sensing along the injection wellbore enabled spatial tracking of dryness variations. This multi-method quantification system ensured maintained steam dryness within ±0.05 of the target value (typically 0.7–0.9) throughout all experimental runs, as validated by periodic separator tests conducted in accordance with ASME PTC 6-2004 (R2022). Steam Turbines. American Society of Mechanical Engineers: New York, NY, USA, 2004 standards. The controlled dryness levels were subsequently correlated with thermal efficiency metrics and production response characteristics.

3. Results and Discussion

3.1. Core Pore Size Variation Analysis

The changes in reservoir pore structure caused by water–rock reactions during steam injection in heavy oil reservoirs under high temperature and pressure conditions can cause damage to the reservoir.

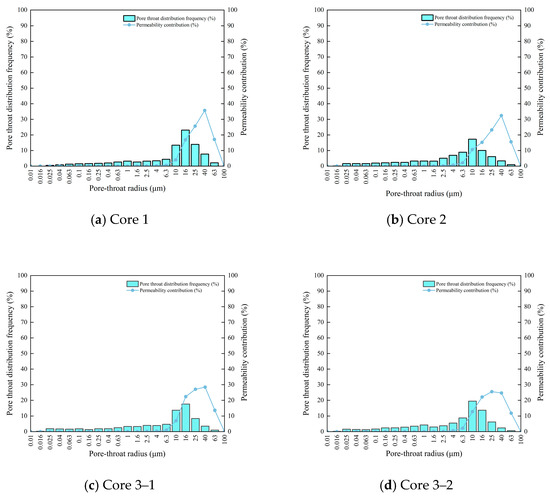

Therefore, in order to further explore the changes in core pore size after steam flooding, mercury intrusion experiments were conducted on the core before and after the experiment, and the experimental results are shown in Figure 2. The characteristic parameters of the pore structure are presented in Table 1.

Figure 2.

(a,b) Mercury injection test results under different permeability conditions. (c,d) Mercury injection test results before and after steam flooding at constant permeability.

Table 1.

Parameters of the core pore structure.

The experimental results presented in Figure 2 and Table 1 demonstrate the pore structure modifications under steam injection conditions, demonstrating three fundamental correlations:

- (1)

- a direct relationship between permeability and pore dimensions (3123, 2205, and 1147 × 10−3 μm2 permeabilities corresponding to 10.52, 8.25, and 7.05 μm mean pore radii);

- (2)

- an inverse permeability-sorting coefficient correlation (7.09, 6.23, and 6.05);

- (3)

- increasing structural coefficients (1.09, 1.15, 1.65) with decreasing permeability. Steam injection (50% steam dryness) significantly altered pore architecture, reducing mean pore radius (8.25–7.10 μm) and dominant throat size (16.0–10.0 μm) while decreasing sorting coefficient (6.23–5.71) and increasing structural coefficient (1.15–1.41).

These observations reflect three key pore-scale mechanisms: First, the permeability–pore size relationship results from throat-selective mineral dissolution–precipitation cycles, where steam-induced dissolution of cementing materials is followed by secondary mineral deposition in critical flow constrictions [30]. Second, the sorting coefficient reduction indicates particle mobilization and redistribution processes that preferentially affect smaller pore throats, creating heterogeneous pore networks. Third, increasing structural coefficients demonstrate thermal stress-induced pore network reorganization through differential grain expansion, cement weakening, and framework compaction. The observed permeability reduction, despite the maintained porosity, confirms that steam flooding primarily impacts pore connectivity through throat-plugging mechanisms rather than bulk porosity alteration, explaining the disproportionate flow response relative to pore size change.

3.2. Core Oil Displacement Experiment

To compare and analyze the oil displacement effects of steam with different dryness levels, we re-obtained core samples with similar physical properties and conducted three different dryness steam oil displacement tests. The results are shown in Table 2 and Figure 3.

Table 2.

Steam flooding oil displacement efficiency under different steam injection dryness.

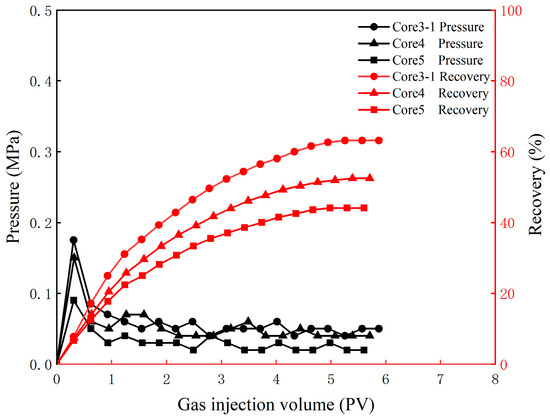

Figure 3.

Experimental results of steam flooding effect with different dryness levels.

The experimental results on oil displacement efficiency reveal a clear correlation between steam dryness and recovery performance. Specifically, oil recovery efficiency decreases proportionally with reduced steam dryness, declining from 63.1% at 50% steam dryness to 52.5% at 30%, and further to 44.1% at 10% steam dryness [31].

This trend can be attributed to the fundamental thermodynamics of steam flooding processes. Higher dryness steam contains a greater proportion of vapor phase, which possesses higher latent heat content. This enables more effective heat transfer throughout the reservoir matrix, as high-dryness steam releases significant latent heat at the condensation front, effectively establishing a high-temperature condensation zone that significantly reduces oil viscosity across a larger area. In contrast, lower-dryness steam is essentially high-temperature water mixed with a small amount of steam. Although it has substantial heat capacity, this heat is primarily sensible heat, which is more readily absorbed by the rock formation. This results in slower advancement of the thermal front, a smaller effective heating radius, and higher wellbore heat loss rates. The reduced heat-carrying capacity leads to narrower heating radii and steeper thermal gradients, which limit the extent of viscosity reduction. Additionally, lower dryness steam exhibits poorer heat retention, causing more rapid heat loss to adjacent formations and less efficient thermal utilization. Under low steam dryness conditions, discrete and localized heating zones form, creating uneven sweep patterns that leave significant portions of the reservoir inadequately heated and poorly drained.

The superior performance observed at 50% steam dryness stems from its ability to establish a sustained heating zone in the central region of the core sample, creating optimal conditions for viscosity reduction and oil mobilization across a larger reservoir volume.

3.3. Nuclear Magnetic Resonance Analysis of Residual Crude Oil After Steam Flooding

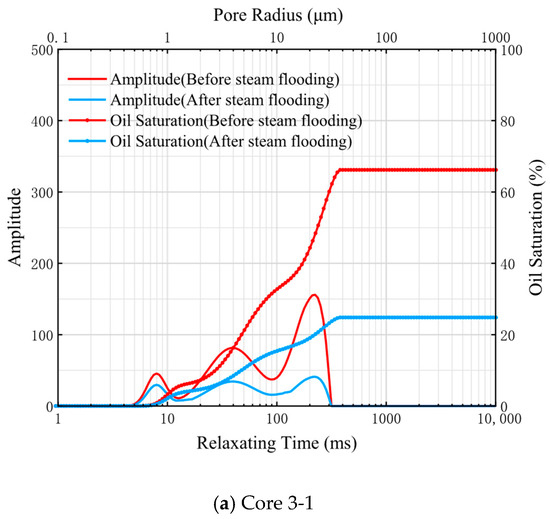

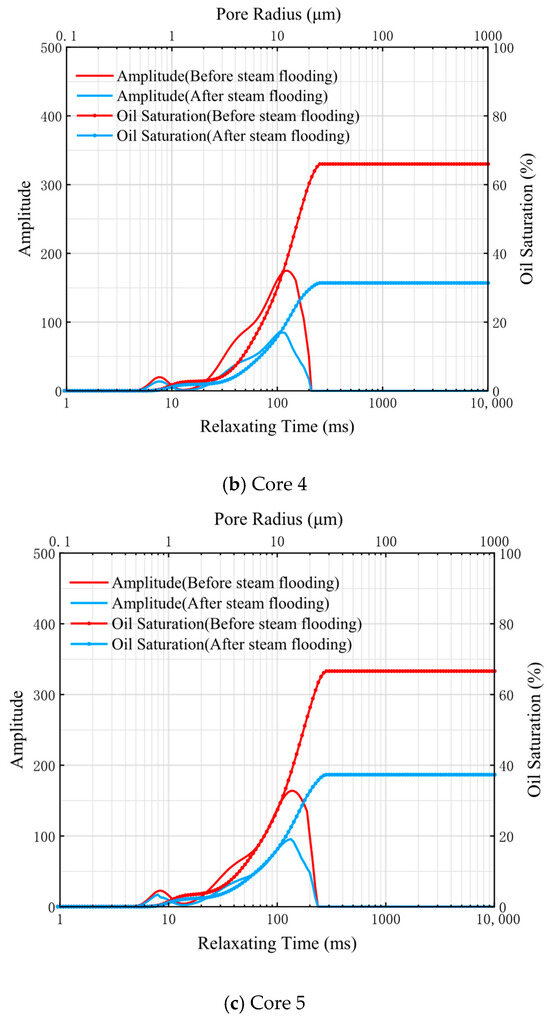

The NMR test results of movable fluid distribution in core samples before and after steam flooding under different steam dryness conditions are presented, with the variation curves of recovery factor and injection pressure versus steam injection volume during the oil displacement process shown in Figure 4. The relevant data are summarized in Table 3.

Figure 4.

NMR results of crude oil distribution frequency before and after steam flooding with different steam dryness levels.

Table 3.

The proportion of crude oil distribution in pores of different sizes of the core (permeability 2205 × 10−3 μm2).

The experimental results demonstrate a clear pore-size-dependent response to steam flooding, revealing fundamental insights into the microscopic mechanisms of thermal enhanced oil recovery. The data show that medium pores (10–50 μm) and small pores (1–10 μm) collectively account for over 95% of initial oil saturation across all cores, establishing these pore classes as the primary storage spaces and production targets. After steam flooding, the differential depletion patterns between pore sizes become particularly noteworthy—while all pore classes showed reduced oil saturation, medium pores exhibited significantly higher recovery rates (58.07–62.01% contribution to total displacement) compared to small pores (36.86–39.56%), suggesting that viscous forces dominate in larger pores while capillary forces retain more oil in smaller pores.

The progressive increase in medium pore contribution (from 58.1% to 62.0%) with decreasing steam dryness indicates that lower-dryness steam preferentially accesses and mobilizes oil from larger pores, likely due to more rapid heat loss in smaller pore throats, which restricts effective viscosity reduction. This phenomenon becomes more pronounced as steam dryness declines, with the 10% dryness steam showing 62.01% contribution from medium pores compared to 58.07% at 50% dryness. The relative stability of small pore contribution (39.1–36.9%) across steam qualities suggests a threshold effect where steam dryness below 30% fails to significantly improve recovery from smaller pores, possibly due to insufficient heat penetration or increased capillary trapping.

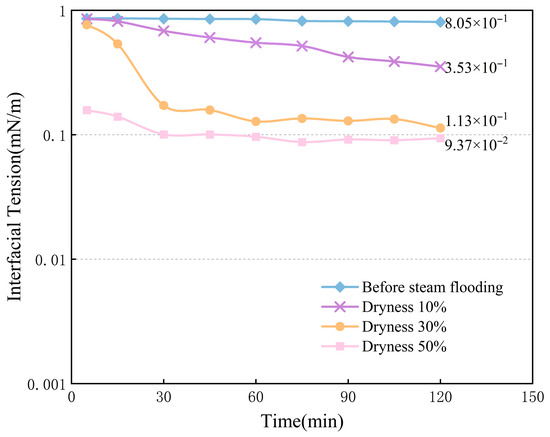

These findings have important implications for reservoir management, particularly in heterogeneous formations where pore size distribution varies significantly. The demonstrated relationship between steam dryness and pore-scale recovery efficiency suggests that optimal steam flooding strategies should consider not just bulk reservoir properties but also the pore size distribution characteristics. Higher steam qualities appear necessary to effectively recover oil from smaller pores, while medium pores respond well across a wider dryness range. This understanding could guide the development of graded steam injection protocols or targeted stimulation methods to improve recovery from different pore classes, potentially through cyclic steam dryness variation or complementary chemical treatments to modify interfacial forces in smaller pores. As can be seen from Figure 5, a higher steam dryness can effectively reduce the interfacial tension.

Figure 5.

The variation in interfacial tension under different steam dryness conditions.

3.4. Core Casting Thin Sections After Steam Flooding

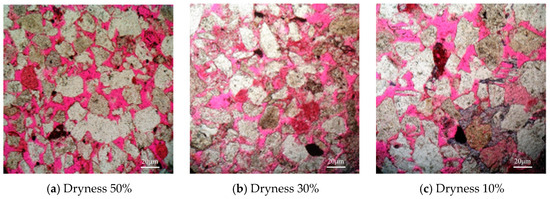

Three rock samples with permeabilities around 2000 × 10−3 μm2 were selected for steam flooding experiments at different steam dryness levels of 50%, 30%, and 10%, respectively. Following the steam flooding process, thin-section analysis was conducted on epoxy-impregnated core slices. The experimental results are presented in Figure 6, with detailed data shown in Table 4.

Figure 6.

Observation results of thin sections of cast after steam flooding of core with different permeability.

Table 4.

Changes in the composition of the produced liquid group after steam flooding under different steam injection dryness conditions.

The experimental results on asphaltene deposition in heavy oil reservoirs under steam injection reveal three distinct morphological patterns of asphaltene occurrence, each exhibiting characteristic impacts on reservoir properties. The observed star-shaped distribution represents the least detrimental form, where isolated asphaltene particles maintain minimal contact with pore walls, preserving most flow channels while causing negligible alterations to rock wettability. In contrast, the patch-type deposition demonstrates more significant reservoir damage through partial blockage of critical pore throats, creating discontinuous but substantial flow barriers that reduce effective permeability without completely isolating pore networks. The most severe encapsulated or networked morphology fundamentally alters both pore structure and surface properties, where interconnected asphaltene deposits not only physically obstruct flow paths but also induce wettability reversal through surface coating, thereby compounding permeability damage through combined physical blockage and modified fluid–rock interactions.

The progressive morphological transition from star-shaped to encapsulated deposits with decreasing steam dryness suggests a steam-energy-dependent deposition mechanism, where lower-dryness steam fails to maintain sufficient thermal energy to keep asphaltenes dispersed, promoting their aggregation into larger, more continuous structures. This phenomenon correlates strongly with the observed deterioration in production performance at lower steam qualities, as the evolving deposit morphology increasingly impacts multiple damage mechanisms: pore throat blockage reduces absolute permeability, wettability alteration affects relative permeability, and networked deposits create preferential flow paths that exacerbate sweep efficiency challenges [32]. The identification of these distinct deposition patterns provides critical insights into developing targeted mitigation strategies, suggesting that early-stage star-shaped deposits might be addressed through solvent treatments, while more advanced networked formations may require combined thermal–chemical approaches. These findings underscore the importance of maintaining optimal steam dryness, not just for viscosity reduction but also for controlling the spatial organization of asphaltene deposits, which ultimately determines their impact on reservoir performance.

The compositional analysis of produced fluids reveals fundamental thermodynamic and kinetic processes governing component redistribution during steam flooding operations. The observed increase in saturated hydrocarbons (from 33.75% to 43.50%) and aromatic hydrocarbons (from 32.42% to 34.94%), accompanied by corresponding decreases in non-hydrocarbons (from 28.80% to 19.53%) and asphaltenes (from 5.03% to 2.03%), demonstrates selective mobilization driven by both volatility differences and molecular interactions under thermal conditions. This fractionation effect follows a clear steam dryness-dependent trend, where higher temperature gradients associated with increased steam dryness enhance the preferential extraction of lighter components through combined thermal distillation and viscosity reduction mechanisms. The progressive depletion of polar compounds (non-hydrocarbons and asphaltenes) in produced fluids indicates their increasing retention in the reservoir matrix, where they undergo thermal cracking, polymerization, and eventual deposition as the thermal front advances.

The compositional shift has significant implications for both production chemistry and reservoir management. The accumulating heavy fractions near wellbores and in pore throats create zones of progressively changing fluid composition and rock wettability, establishing conditions favorable for asphaltene and paraffin precipitation. This explains the frequently observed near-wellbore formation damage in thermal operations, where deposited heavy fractions not only reduce absolute permeability but also modify relative permeability characteristics through wettability alteration.

4. Conclusions

The purpose of this paper is to recognize the influence of water–rock reactions as a result of steam injection on the pore structure of heavy oil reservoirs, explore the differential retention phenomenon of different heavy oil components in porous media during steam flooding of heavy oil reservoirs, and identify the formation mechanism and occurrence state of micro-residual oil in heavy oil steam flooding. The results can be categorized into four classes.

- (1)

- Steam injection in heavy oil reservoirs induces pore structure alterations through water–rock reactions, reducing the average pore radius from 8.25 μm to 7.10 μm. While this causes reservoir damage, steam’s heat transfer effect simultaneously lowers oil viscosity due to temperature sensitivity. Higher steam dryness creates a central heating zone in the core, enhancing heat transfer to crude oil and further reducing viscosity, thereby improving injection pressure and recovery rates.

- (2)

- For reservoirs with permeability ranging from 1000 to 3000 × 10−3 μm2, the pore sizes for primary fluid storage are distributed between 1 and 50 μm. As core permeability decreases, the proportion of large pores (50–100 μm) reduces, while that of small pores (1–10 μm) increases, indicating deteriorating reservoir quality.

- (3)

- Increasing steam dryness from 10% to 50% boosts flooding efficiency by 19%. Pre-flooding, heavy oil mainly occupied 1–10 μm pores; post-flooding, it predominantly migrated to 10–50 μm pores, with minimal retention in sub-1 μm pores.

- (4)

- Reduced steam dryness diminishes oil utilization across all pore sizes, particularly affecting 1–10 μm pores. As dryness decreases from 50% to 10%, these pores’ recovery contribution drops from 39.1% to 36.9%, making recovery increasingly dependent on 10–50 μm pore oil content.

- (5)

- Steam flooding traps paraffin and asphalt in the core, evidenced by lower outlet asphalt content versus injection levels. This damage intensifies with decreasing dryness: the asphaltene mass fraction in the produced liquid declines from 3.19% to 2.03% when dryness reduces from 50% to 10%.

Author Contributions

Conceptualization, D.Z.; writing—original draft preparation, Y.W. and D.Z.; writing—review and editing, J.Z., P.S. and K.Z.; Resources, L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the State Key Laboratory of Shale Oil and Gas Enrichment Mechanisms and Effective Development (no. 33550000-22-ZC0613-0031).

Data Availability Statement

The data are available upon request.

Acknowledgments

The authors gratefully acknowledge Shengli Oilfield for supplying the crude oil samples used in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, Q.C.; Wu, J.J.; Li, Q.; Wang, F.L.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-bearing Sediment in Northern South China Sea by Horizontal Wellbore: Sensitivity Analysis. Nat. Resour. Res. 2025, 34, 1667–1699. [Google Scholar] [CrossRef]

- Li, Q. Reservoir Science: A Multi-Coupling Communication Platform to Promote Energy Transformation, Climate Change and Environmental Protection. Reserv. Sci. 2025, 1, 1–2. [Google Scholar]

- Najeh, A.; Mahmoud, R.P.; Hadi, J. A new semi-analytical modeling of steam-assisted gravity drainage in heavy oil reservoirs. J. Petrol. Sci. Eng. 2009, 69, 261–270. [Google Scholar] [CrossRef]

- Franco, C.A.; Medina, O.E.; Galeano-Caro, D.; Salinas, L.M.; Alzate, L.G.; Molina, D.; Rendón, G.J.; Obregón, C.C.; Lopera, S.H.; Cortes, F.B. Enhancing heavy crude oil mobility at reservoir conditions by nanofluid injection in wells with previous steam stimulation cycles: Experimental evaluation and field trial implementation. J. Mol. Liq. 2025, 424, 127024. [Google Scholar] [CrossRef]

- Santos, M.D.; Neto, A.D.; Mata, W.; Silva, J.P. New antenna modelling using wavelets for heavy oil thermal recovering methods. J. Petrol. Sci. Eng. 2011, 76, 63–75. [Google Scholar] [CrossRef]

- Bian, X.B.; Zhang, S.C.; Zhang, J.C.; Wang, F. A new method to optimize the fracture geometry of a frac-packed well in unconsolidated sandstone heavy oil reservoirs. Sci. China Technol. Sci. 2012, 55, 1725–1731. [Google Scholar] [CrossRef]

- Yousef, A.A.; Lake, L.W.; Jensen, J.L. Analysis and interpretation of interwell connectivity from production and injection rate fluctuations using a capacitance model. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 22–26 April 2006. SPE 99998. [Google Scholar] [CrossRef]

- Dinh, A.; Tiab, D. Inferring interwell connectivity from well bottomhole pressure fluctuations in waterfloods. SPE Reserv. Eval. Eng. 2008, 11, 874–881. [Google Scholar] [CrossRef]

- Lzgec, O.; Kabir, C.S. Establishing injector/producer connectivity before breakthrough during fluid injection. In Proceedings of the SPE Western Regional Meeting, San Jose, CA, USA, 24–26 March 2009. SPE 121203. [Google Scholar] [CrossRef]

- Cao, Y.B.; Liu, D.Q.; Tang, P.Z.; He, S.Q. Improving multiple steam stimulation effects with foam fluids in the Cao-20 Block. Pet. Drill. Technol. 2006, 34, 78–80. (In Chinese) [Google Scholar] [CrossRef]

- Niu, S.F. Research and application of channeling plugging technique by using foam with gasifying nitrogen-carbon by steam. Pet. Geol. Recover. Effic. 2005, 12, 78–80. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, H.L.; Liu, H.Q.; Wang, H.; Wang, S.L.; Bao, S.C. Optimization design of profile control parameters for steam stimulation wells. Acta Pet. Sin. 2007, 28, 105–108. (In Chinese) [Google Scholar] [CrossRef][Green Version]

- Lin, T.; Song, H.; Gu, Q.; Xing, T.; Tong, C.; Zhang, W.; Li, T. Case study: Multi-component thermal fluid technology to enhance production on thin-bedded heavy oil reservoir in Bohai Bay of China. Energy Rep. 2025, 13, 2245–2254. [Google Scholar] [CrossRef]

- Yang, S.; Yang, E.; Qi, Z.; Yan, W.; Tian, J.; Dong, M.; Jiang, X.; Hu, S. Review on mechanisms of petrophysical properties variation during thermal fluids injection into heavy oil reservoirs. Geoenergy Sci. Eng. 2024, 240, 23. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, Y.S.; Yang, D. Mesoscopic characteristics of in-situ thermal pyrolysis of oil shale by water injection steam. Chin. J. Rock. Mech. Eng. 2020, 39, 1634–1647. (In Chinese) [Google Scholar] [CrossRef]

- Necmettin, M. High Pressure Nitrogen Injection for Miscible/Immiscible Enhanced Oil Recovery. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Port-of-Spain, Trinidad and Tobago, 27–30 April 2003; Society of Petroleum Engineers: Richardson, TX, USA, 2003. [Google Scholar] [CrossRef]

- Azad, M.S.; Alnuaim, S.; Awotunde, A.A. Stochastic Optimization of Cyclic Steam Stimulation in Heavy Oil Reservoirs. In Proceedings of the SPE Kuwait Oil and Gas Show and Conference, Kuwait City, Kuwait, 8–10 October 2013; Society of Petroleum Engineers: Richardson, TX, USA, 2013. [Google Scholar] [CrossRef]

- Luo, E.; Fan, Z.; Hu, Y.; Zhao, L.; Bo, B.; Yu, W.; Liang, H.; Liu, M.; Liu, Y.; He, C. An efficient optimization framework of cyclic steam stimulation with experimental design in extra heavy oil reservoirs. Energy 2020, 192, 116601. [Google Scholar] [CrossRef]

- Eickmeier, J.R.; Ersoy, D.; Ramey, H.J. Wellbore Temperatures and Heat Losses During Production or Injection Operations. J. Can. Pet. Technol. 1970, 9, 6. [Google Scholar] [CrossRef]

- Ali, S.M.F. Heavy oil—Evermore mobile. J. Pet. Sci. Eng. 2003, 37, 5–9. [Google Scholar] [CrossRef]

- Webber, J.B.W.; Corbett, P.; Semple, K.T.; Ogbonnaya, U.; Teel, W.S.; Masiello, C.A.; Fisher, Q.J.; Valenza, J.J.; Song, Y.Q.; Hu, Q. An NMR study of porous rock and biochar containing organic material. Microporous Mesoporous Mater. 2013, 178, 94–98. [Google Scholar] [CrossRef]

- Singer, P.; Rylander, E.; Jiang, T.; McLin, R.; Lewis, R.E.; Sinclair, S.M. 1D and 2D NMR core-log integration in organic shale. In Proceedings of the International Symposium of the Society of Core Analysts, Napa Valley, CA, USA, 16–19 September 2013; Society of Core Analysts: Napa Valley, CA, USA, 2013. [Google Scholar]

- Li, X.; Zhang, Q.; Liu, P. Investigation on the microscopic damage mechanism of fracturing fluids to low-permeability sandstone oil reservoir by nuclear magnetic resonance. J. Pet. Sci. Eng. 2022, 209, 109821. [Google Scholar] [CrossRef]

- Zhou, S.; Deng, Y.; Wang, H.; Pan, Z.; Yan, D. Connectivity and permeability of Zhuhai tight sandstone heterogeneous reservoirs from western Pearl River Mouth Basin (China) by nuclear magnetic resonance. Appl. Geochem. J. Int. Assoc. Geochem. Cosmochem. 2022, 143, 105381. [Google Scholar] [CrossRef]

- Dai, C.L.; Ji, W.J.; Jiang, H.Q.; Zhao, F.L.; Ji, C.W.; Qin, T. Performance experiment on thermal thixotropic system for deep channeling plugging in steam huff and puff wells. J. China Univ. Petrol. 2010, 34, 167–171. (In Chinese) [Google Scholar] [CrossRef]

- Albertoni, A.; Lake, L.W. Inferring Interwell Connectivity Only from Well-Rate Fluctuations in Waterfloods. SPE Reserv. Eval. Eng. 2002, 6, 6–16. [Google Scholar] [CrossRef]

- Zhang, D.J.; Guo, H.M.; Dai, J.C.; Wang, Z.H. Study on steam channeling in steam flooding of heavy oil reservoir. China Meas. Technol. 2004, 30, 45–50. (In Chinese) [Google Scholar] [CrossRef]

- Dong, Y.Q.; Wang, Z.M. Some notes about correiation coefficient ρ. Coll. Math. 2008, 24, 182–186. [Google Scholar]

- Wang, F.J.; Xu, H.; Liu, Y.K.; Meng, X.H.; Liu, L.C.F. Mechanism of Low Chemical Agent Adsorption by High Pressure for Hydraulic Fracturing-Assisted Oil Displacement Technology: A Study of Molecular Dynamics Combined with Laboratory Experiments. Langmuir ACS J. Surf. Colloids 2023, 39, 16628–16636. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.; Liao, J.; Gao, X.L. Study on reservoir variation and remaining oil enrichment law in mid-late stage of steam flooding in heavy oil reservoir. In Proceedings of the 15th Five-Province (City, District) Heavy Oil Mining Technology, Tianjin, China, 13–16 October 2010; Tianjin Petroleum Society: Tianjin, China; Liaoning Petroleum Society: Dalian, China; Henan Petroleum Society: Zhengzhou, China; Xinjiang Petroleum Society: Urumqi, China; Shandong Petroleum Society: Dongying, China, 2010; pp. 443–447. [Google Scholar]

- Song, T.; Li, Y.Q.; Lyu, X.L.; Yan, Z.; Tang, X.; Zi, J.; Liu, Z. Mechanism and Effect of Flue Gas Assisted Steam Flooding in Heavy Oil Reservoir. Xinjiang Pet. Geol. 2025, 1–8. Available online: https://link.cnki.net/urlid/65.1107.TE.20250618.1303.002 (accessed on 15 September 2025).

- Sun, R.Y.; Ma, Z.C.; Zhang, J.S.; Xu, T.; Liu, C. Effect of steam flooding on core wettability of low permeability heavy oil reservoir. Spec. Oil Gas Reserv. 2013, 20, 69–71+144–145. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).