Experimental Investigation of a Pulsation Reactor via Optical Methods

Abstract

:1. Introduction

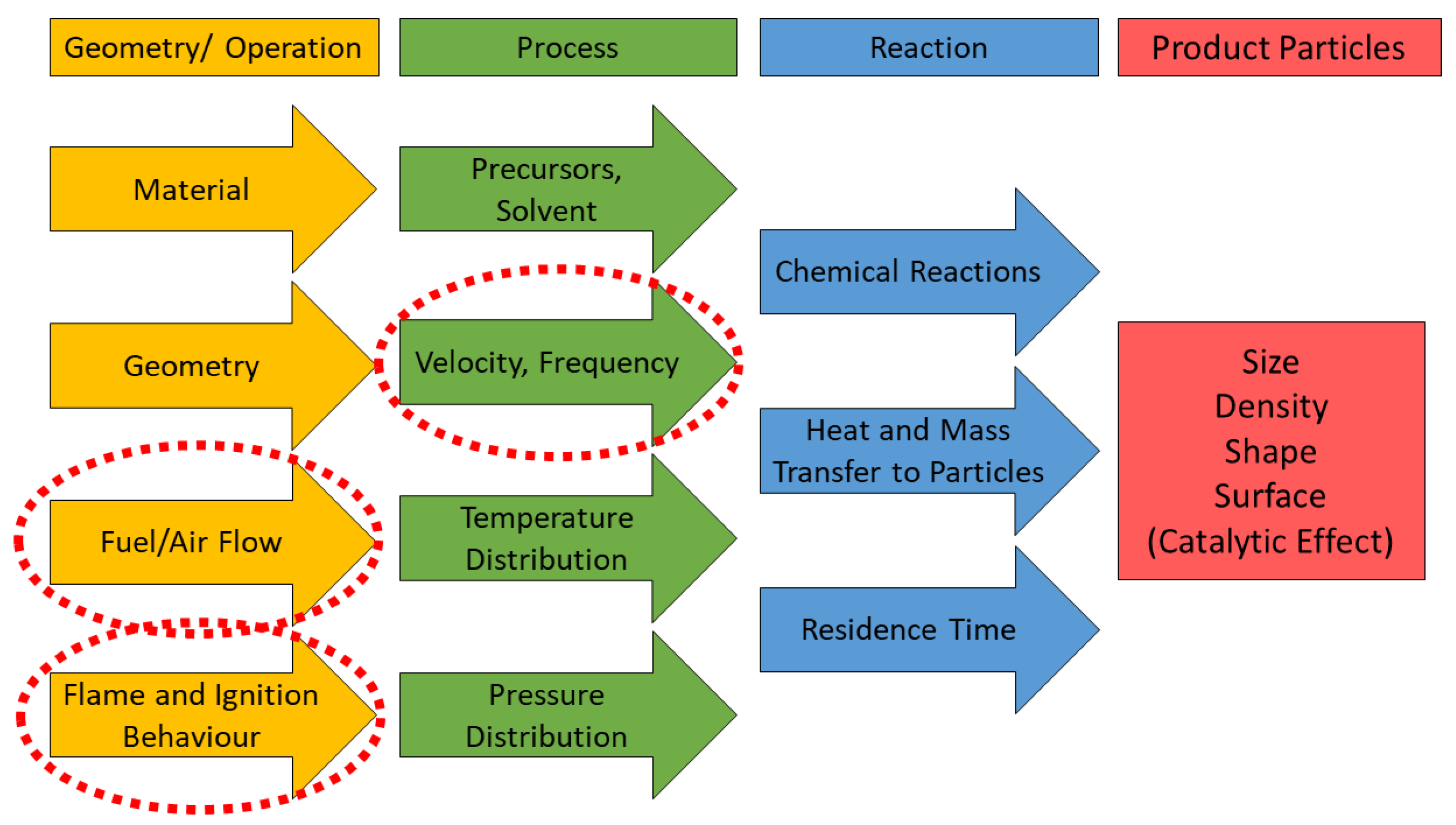

1.1. Pulsation Reactors for Material Treatment

1.2. Pulsating Combustion and the Theory of Re-Ignition Background of the PR

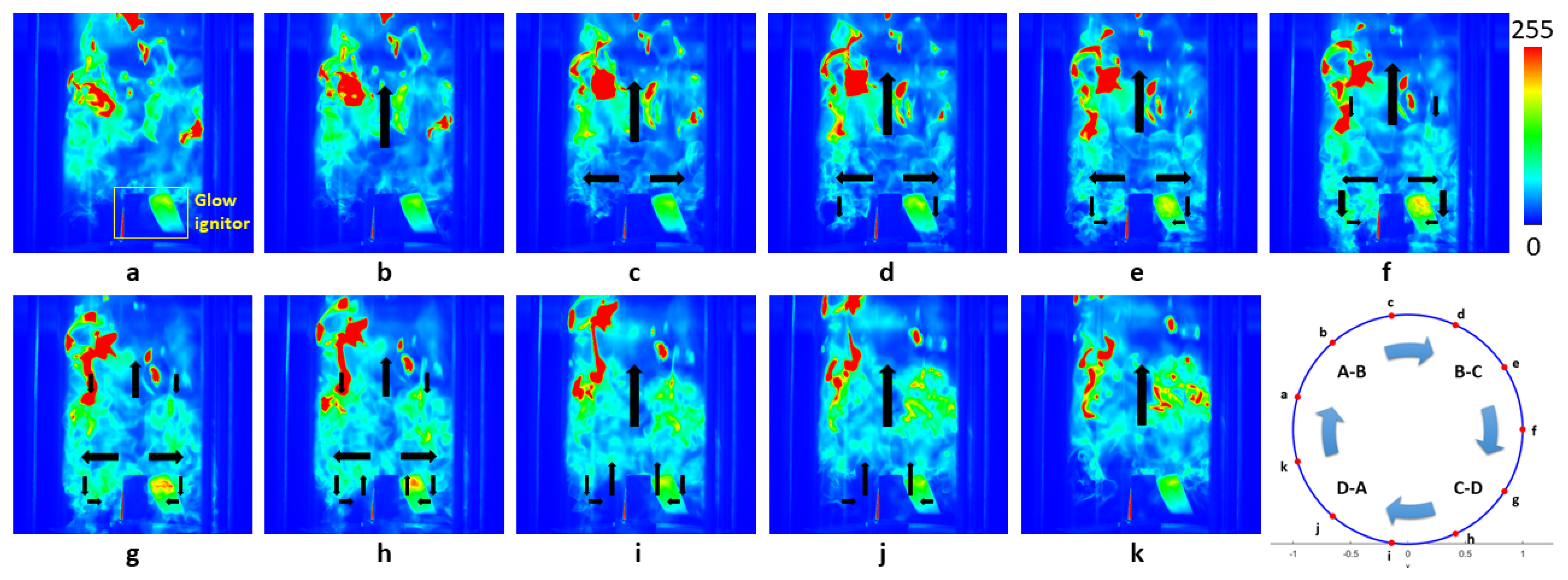

- Ignition and combustion (A→B): The combustible mixture (air and a gaseous fuel) is injected into the combustion chamber where it is ignited. The spark plug, which is usually used for the initial ignition, or the glow igniter, as in the case of the present pulsation reactor, is switched off once self-excited periodic combustion develops.

- Expansion (B→C): Both the temperature and pressure increase as a consequence of the combustion process. The combustion products are pushed out of the combustion chamber through the exhaust pipe, resulting in the pressure in the combustion chamber decreasing.

- Intake (C→D): When the combustion chamber drops below the ambient value, the fresh mixture is sucked in.

- Compression (D→A): The negative gauge pressure in the combustion chamber results in a portion of the hot flue gas traveling back from the tailpipe into the combustion chamber again. It compresses and heats up the fresh mixture, which is re-ignited, and the cycle repeats.

- hot gas remnants near the inlet;

- the high temperature of the combustion chamber walls;

- the unburned mixture that can sustain the flame until the beginning of the next cycle.

1.3. Scope of the Investigations

- -

- Identify how flame behavior relates to the various stages of the combustion cycle, visualizing the turbulence present in the flame.

- -

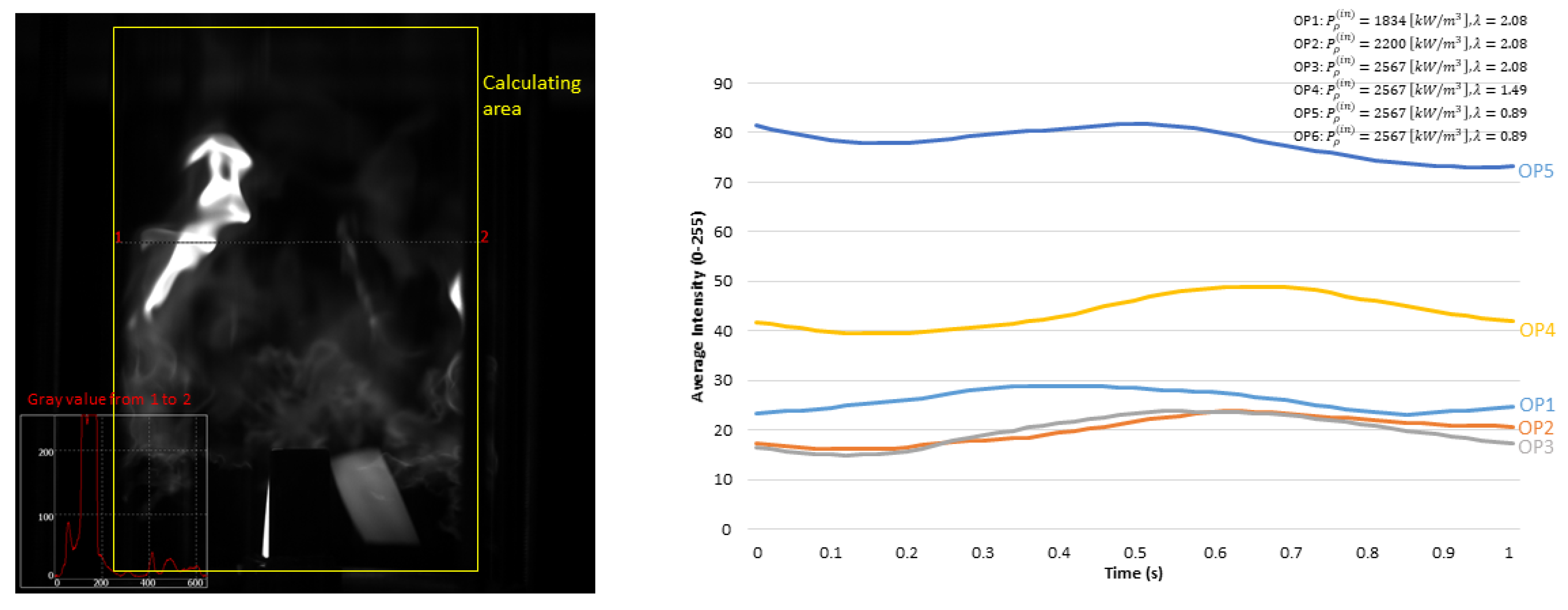

- Investigate the impact of air-fuel equivalence ratio and power density input on the flame, encompassing parameters such as flame luminosity and flame velocity. In the context of natural gas combustion, the luminosity of the flame can be used as an indicator of the radiative heat transfer, with higher luminous radiation levels correlating to increased flame temperature, and is consequent in the thermal efficiency of the combustion process [35].

- -

- A higher pulsed flame velocity signifies an increased propagation speed, resulting in a more rapid energy release into the surrounding environment, potentially leading to a higher energy transfer rate. Therefore, in this study, the estimated speed of flame propagation within a given system needs to be clarified. Additionally, the study examines the stability of the combustion process by analyzing velocity variation.

- -

- In addition, a couple of further characteristics of the process, e.g., the temporal development of the flow velocity distribution during a cycle, have been investigated and will be discussed in the results section.

1.4. Investigated PR Characteristics Related to This Study

2. Experimental Method

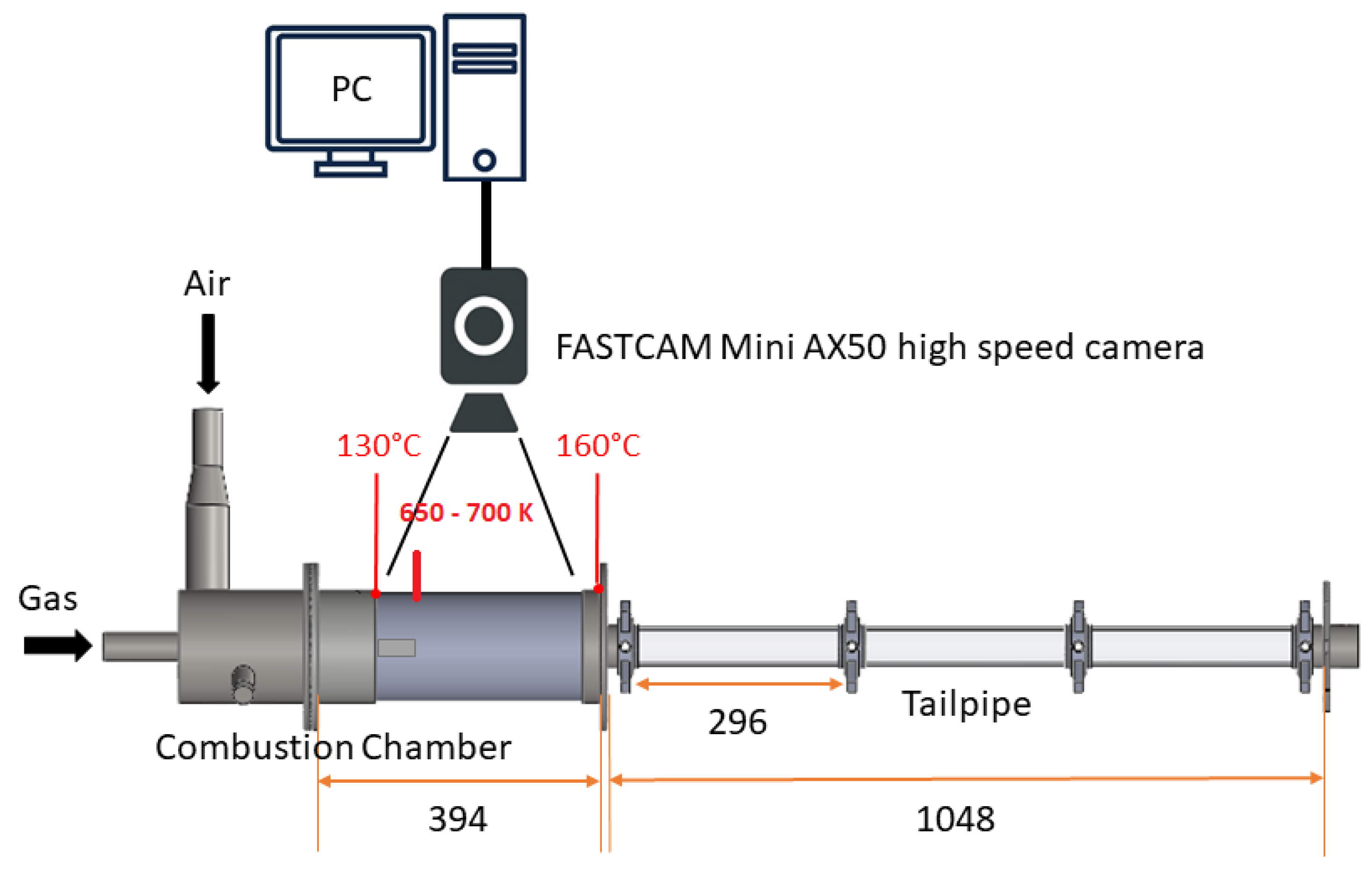

2.1. Flame Imaging via a High-Speed Camera

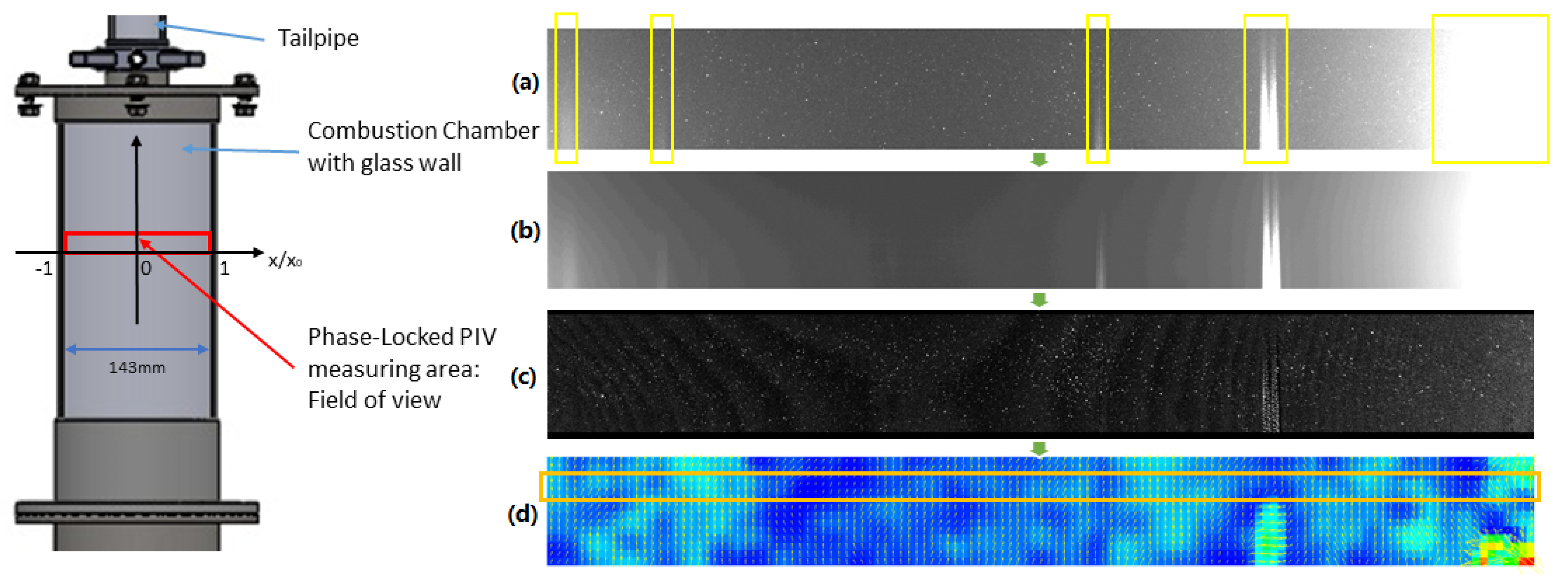

2.2. Particle Image Velocimetry (PIV) for Flow Velocity Measurements

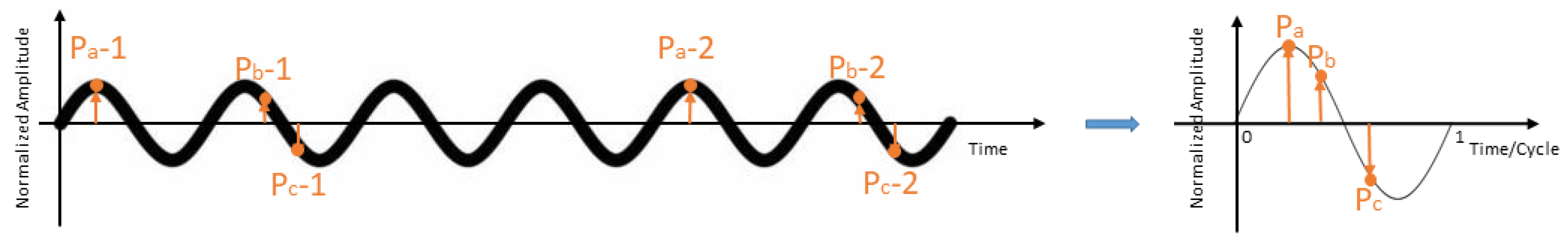

2.3. The Operation Points and Image Processing of the Flame Measurement

3. Results and Discussion

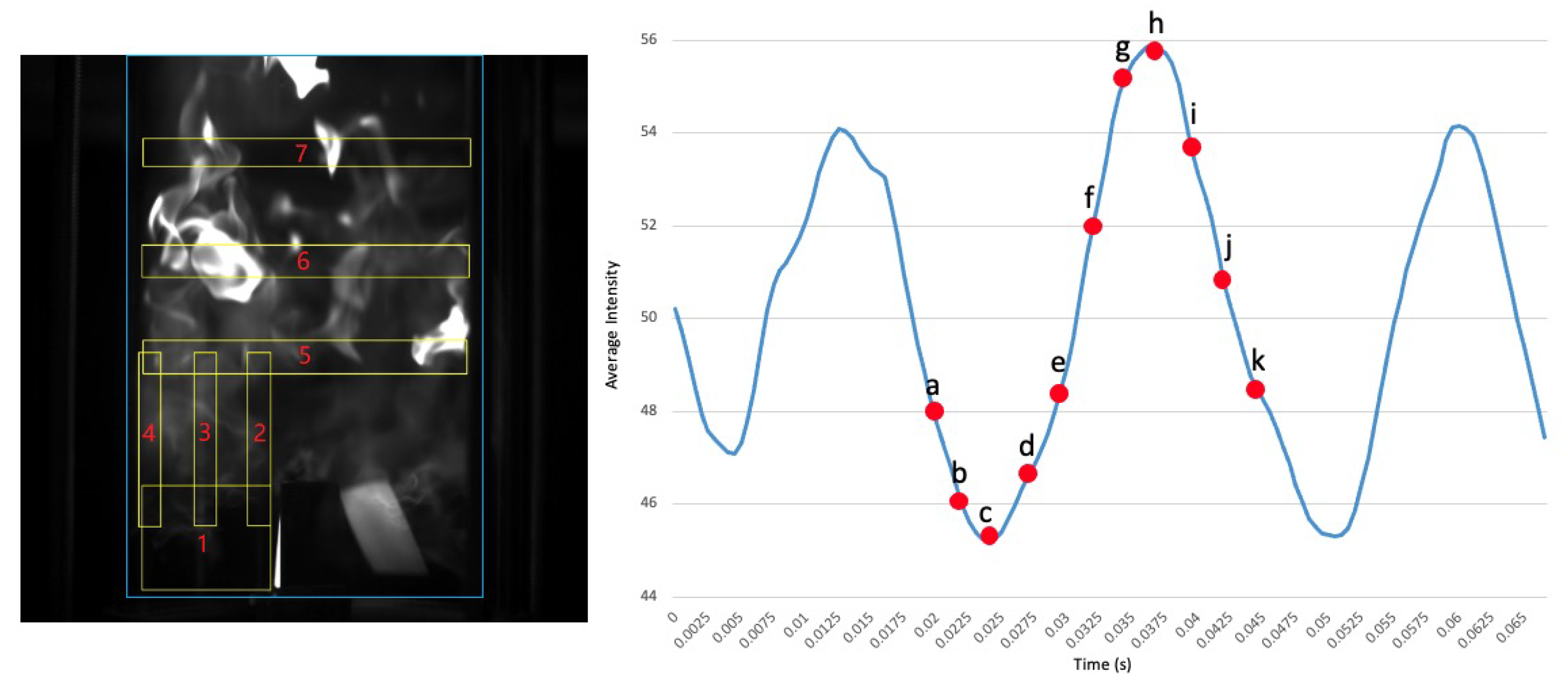

3.1. Flame Behavior

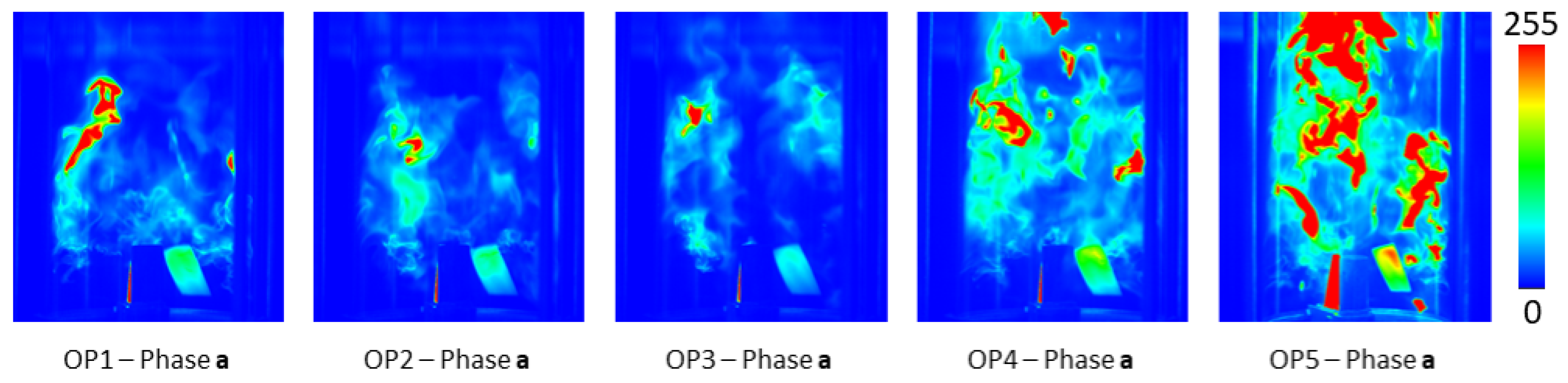

3.1.1. Flame Propagation

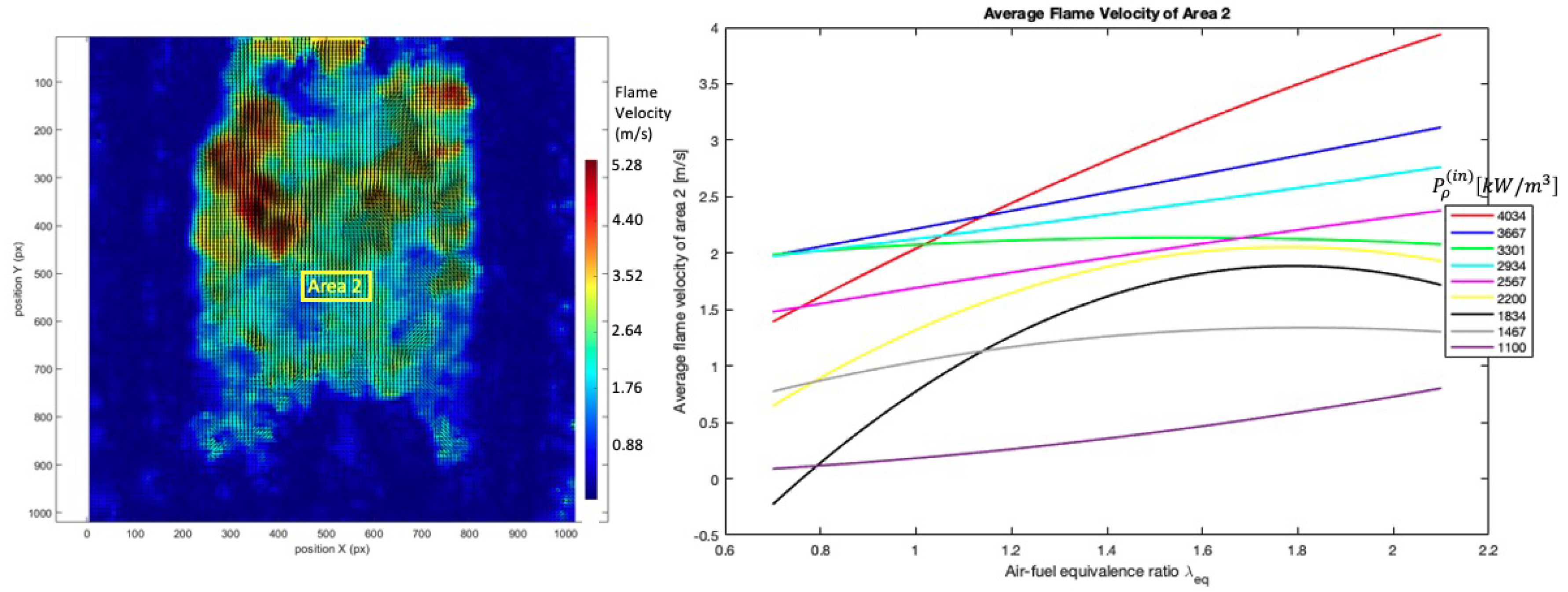

3.1.2. Flame Velocity

- -

- Combustion instability: In certain air-fuel equivalence ratio ranges, the combustion process may be affected by instabilities (aerodynamic effects, vortex motion, etc.), resulting in fluctuations in flame velocity;

- -

- Inhomogeneity of combustion mixing: In a pulsed flame system, there may be inhomogeneity in the mixing process of fuel and oxidant, resulting in spatial and temporal fluctuations in the combustion rate;

- -

- Changes in the propagation path: As the air-fuel ratio changes, the flame propagation path may change, which may be caused by turbulent flow, wall effects, etc.

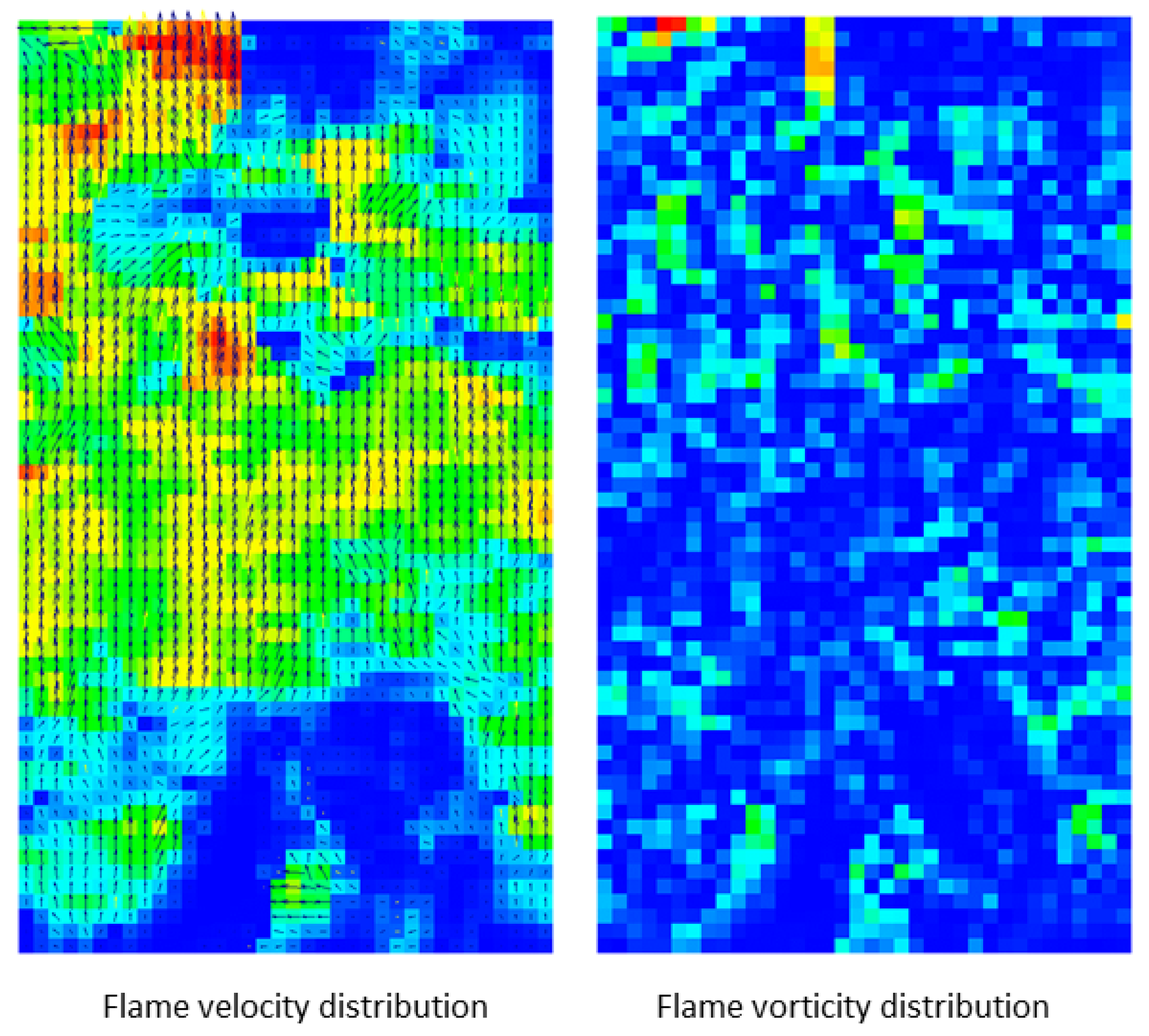

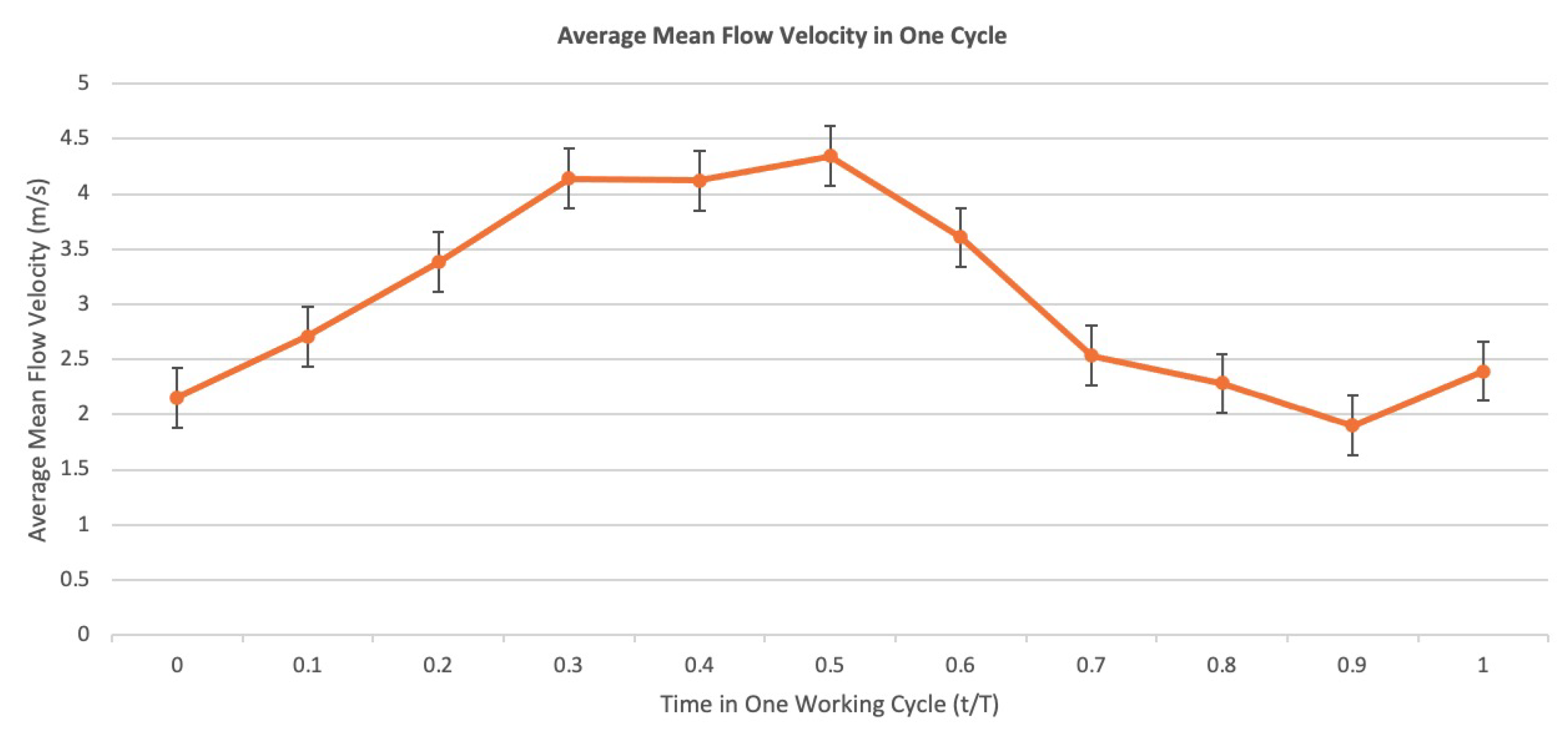

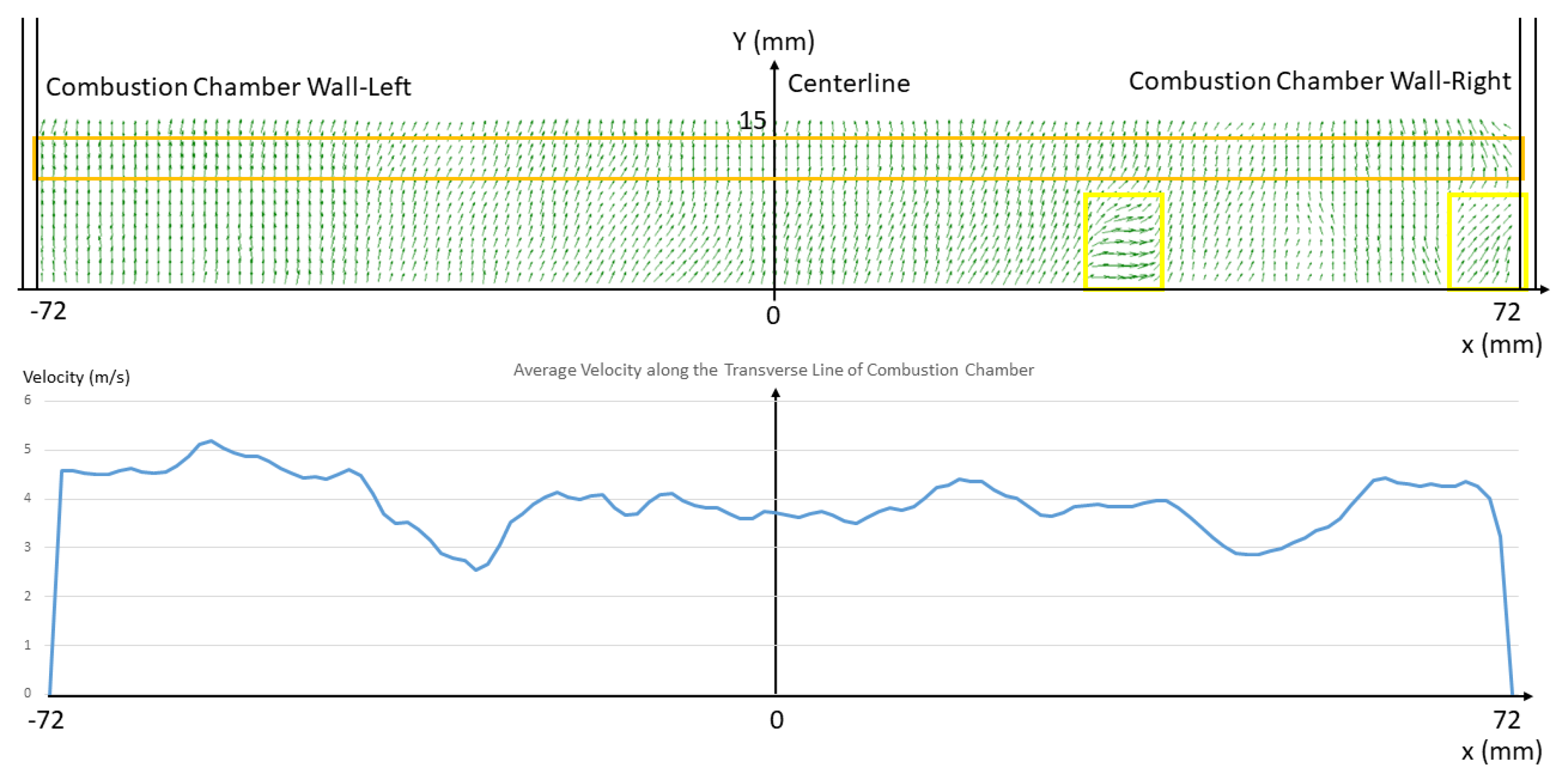

3.2. Phase-Locked PIV Measurement Result for the Flow in the PR

4. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leidolph, L.; Ambrosius, S. Method and Thermal Reactor for Creating Particles. EP1927394B1, 26 August 2009. [Google Scholar]

- Kudra, T. Pulse-Combustion Drying: Status and Potentials. Dry. Technol. 2008, 26, 1409–1420. [Google Scholar] [CrossRef]

- Fraenkel, S.; Nogueira, J.; Carvalho, J.; Costa, F. Heat transfer coefficients for drying in pulsating flows. Int. Commun. Heat Mass Transf. 1998, 25, 471–480. [Google Scholar] [CrossRef]

- Klaus, C.; Wegner, K.; Rammelt, T.; Ommer, M. New Challenges in Thermal Processing. Interceram Int. Ceram. Rev. 2021, 70, 22–25. [Google Scholar] [CrossRef]

- Hoffmann, C.; Ommer, M. Reaktoren für Fluid-Feststoff-Reaktionen: Pulsationsreaktoren; Springer Spektrum: Berlin/Heidelberg, Germany, 2019; pp. 1–19. [Google Scholar] [CrossRef]

- Begand, S. Herstellung Nanoskaliger Oxidpulver Durch Thermisch Gesteuerte Synthese in Einem Pulsationsreaktor. Ph.D. Thesis, Der Naturwissenschaftlich-Technischen Fakultät der Chemie, Pharmazie und Werkstoffwissenschaften der Universitat des Saarlandes, Saarbrücken, Germany, 2001. [Google Scholar]

- Heidinger, S.; Spranger, F.; Dostál, J.; Zhang, C.; Klaus, C. Material Treatment in the Pulsation Reactor—From Flame Spray Pyrolysis to Industrial Scale. Sustainability 2022, 14, 3232. [Google Scholar] [CrossRef]

- Dostál, J.; Heidinger, S.; Klaus, C.; Unz, S.; Beckmann, M. Effects of Fuel Input on Pulsation Reactor Behavior—An Experimental Study. Processes 2023, 11, 444. [Google Scholar] [CrossRef]

- Xu, W.; Jiang, G.; An, L.; Liu, Y. Numerical and experimental study of acoustically enhanced heat transfer from a single particle in flue gas. Combust. Sci. Technol. 2018, 190, 1158–1177. [Google Scholar] [CrossRef]

- Heidinger, S.; Unz, S.; Beckmann, M. Heat and Mass Transfer to Particles in One-Dimensional Oscillating Flows. Processes 2023, 11, 173. [Google Scholar] [CrossRef]

- Von Helmholtz, H. On the Sensations of Tone as a Physiological Basis for the Theory of Music. Nature 1875, 12, 449–452. [Google Scholar] [CrossRef]

- Dahm, B. Ein Beitrag zum Instationären Wärmeübergang auf Teilchen im Hinblick auf Eine Verfahrenstechnische Optimierung des Schmidtrohres. Ph.D. Thesis, Hochschule für Architektur und Bauwesen Weimar, Weimar, Germany, 1975. [Google Scholar]

- Klaus, C.; Wegner, K.; Ommer, M. Partikelsynthese im Pulsationsreaktor—Von der Idee zur Produktion. In Proceedings of the 30 Deutscher Flammentag, Hannover-Garbsen, Germany, 28–29 September 2021; pp. 582–590. [Google Scholar]

- Putnam, A.A.; Belles, F.E.; Kentfield, J.A.C. Pulse Combustion. Prog. Energy Combust. Sci. 1986, 12, 43–79. [Google Scholar] [CrossRef]

- Rayleigh, L.; Strutt, J.W. The Explanation of Certain Acoustical Phenomena. Nature 1878, 18, 319–321. [Google Scholar] [CrossRef]

- Rayleigh, L.; Strutt, J.W. The Theory of Sound; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar] [CrossRef]

- Lieuwen, T.C.; Yang, V. Combustion Instabilities in Gas Turbine Engines: Operational Experience, Fundamental Mechanisms, and Modeling; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2005. [Google Scholar] [CrossRef]

- Zinn, B.T. A Theoretical Study of Non-Linear damping by helmholtz resonators. J. Sound Vib. 1970, 13, 347–356. [Google Scholar] [CrossRef]

- Tang, P.K.; Sirignano, W.A. Theory of a Generalized Helmholtz Resonator. J. Sound Vib. 1973, 26, 247–262. [Google Scholar] [CrossRef]

- Ahrens, F.W.; Kartsounes, G.T. Pulse Combustion Technology for Heating Applications: Quarterly Progress Report April–June 1978; Argonne National Laboratory (ANL): Argonne, IL, USA, 1978. [Google Scholar]

- Panton, R.L.; Miller, J.M. Resonant Frequencies of Cylindrical Helmholtz Resonators. J. Acoust. Soc. Am. 1975, 57, 1533–1535. [Google Scholar] [CrossRef]

- Howe, M.S. On the Helmholtz Resonator. J. Sound Vib. 1976, 45, 427–440. [Google Scholar] [CrossRef]

- Großgebauer, S. Mathematische Modellierung und Experimentelle Untersuchung von Selbstständig Pulsierenden Brennern zur Stoffbehandlung. Ph.D. Thesis, Technische Universität Dresden, Dresden, Germany, 2008. [Google Scholar]

- Zhonghua, W. Mathematical Modeling of Pulse Combustion and its Applications to Innovative Thermal Drying Techniques. Ph.D. Thesis, National University of Singapore, Singapore, 2007. [Google Scholar]

- Meng, X.; de Jong, W.; Kudra, T. A State-of-the-Art Review of Pulse Combustion: Principles, Modeling, Applications and R&D Issues. Renew. Sustain. Energy Rev. 2016, 55, 73–114. [Google Scholar]

- Uemichi, A.; Kanetsuki, I.; Kaneko, S. (Eds.) Combustion Oscillation in Gas Turbine Combustor for Fuel Mixture of Hydrogen and Natural Gas. In Proceedings of the ASME 2017 Pressure Vessels and Piping Conference, Waikoloa, HI, USA, 16–20 July 2017. [Google Scholar] [CrossRef]

- Plavnik, G. (Ed.) Pulse Combustion Technology. In Proceedings of the 14th Annual North American Waste-to-Energy Conference, Tampa, FL, USA, 1–3 May 2006. [CrossRef]

- Raine, R.; Thorwarth, H. Performance and Combustion Characteristics of a Glow-Ignition Two-Stroke Engine; SAE Technical Papers; SAE International Headquarters: Warrendale, PA, USA, 2004. [Google Scholar] [CrossRef]

- Pan, K.; Wallace, J.S. Numerical studies of the ignition characteristics of a high-pressure gas jet in compression ignition engines with glow plug ignition assist: Part 2-Effects of multi-opening glow plug shields. Int. J. Engine Res. 2018, 19, 977–1001. [Google Scholar] [CrossRef]

- Mcallister, S.; Chen, J.Y.; Fernandez-Pello, A. Fundamentals of Combustion Processes; Springer: New York, NY, USA, 2011. [Google Scholar] [CrossRef]

- Glassman, I.; Yetter, R.A.; Glumac, N.G. (Eds.) Combustion, 5th ed.; Academic Press: Boston, MA, USA, 2015; pp. 655–680. [Google Scholar]

- Candel, S.; Huynh, C.; Poinsot, T. Some Modeling Methods of Combustion Instabilities. In Unsteady Combustion; Culick, F., Heitor, M.V., Whitelaw, J.H., Eds.; Springer: Dordrecht, The Netherlands, 1996; pp. 83–112. [Google Scholar] [CrossRef]

- Marble, F.E.; Candel, S.M. An analytical study of the non-steady behavior of large combustors. Symp. (Int.) Combust. 1979, 17, 761–769. [Google Scholar] [CrossRef]

- Menon, S.; Jou, W.H. Large-Eddy simulations of combustion instability in an axisymmetric Ramjet combustor. Combust. Sci. Technol. 1991, 75, 53–72. [Google Scholar] [CrossRef]

- Javadi, S.M.; Moghiman, M. Experimental Study of Natural Gas Temperature Effects on the Flame Luminosity and No Emission. Int. J. Spray Combust. Dyn. 2012, 4, 175–184. [Google Scholar] [CrossRef]

- Abu-Jrai, A.M.; Al-Muhtaseb, A.H.; Hasan, A.O. Combustion, performance, and selective catalytic reduction of NOx for a diesel engine operated with combined tri fuel (H2, CH4, and conventional diesel). Energy 2017, 119, 901–910. [Google Scholar] [CrossRef]

- Cheng, Q.; Ahmad, Z.; Kaario, O.; Vuorinen, V.; Larmi, M. Effect of Hydrogen Enhancement on Natural Flame Luminosity of Tri-Fuel Combustion in an Optical Engine. Energies 2022, 15, 9080. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, L.; Geng, C.; Chen, B.; Liu, H.; Yao, M. Natural Flame Luminosity and Emission Spectra of Diesel Spray Flame under Oxygen-Enriched Condition in an Optical Constant Volume Vessel. In Proceedings of the SAE International Powertrains, Fuels and Lubricants Meeting, Heidelberg, Germany, 17–19 September 2018. [Google Scholar] [CrossRef]

- Keller, J.O.; Saito, K. Measu rements of the Combusting Flow in a Pulse Combustor. Combust. Sci. Technol. 1987, 53, 137–163. [Google Scholar] [CrossRef]

- Raffel, M.; Willert, C.; Scarano, F.; Kähler, C.J.; Wereley, S.T.; Kompenhans, J. Particle Image Velocimetry—A Practical Guide, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 2018; Volume 1, pp. 1–669. [Google Scholar]

- Photron. Product Datasheet Mini AX FASTCAM Series by Photron; Photron USA, Inc.: San Diego, CA, USA, 2017. [Google Scholar]

- Gaydon, A. The Spectroscopy of Flames; Springer: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Cheng, T.S.; Wu, C.Y.; Li, Y.H.; Chao, Y.C. Chemiluminescence measurements of local equivalence ratio in a partially premixed flame. Combust. Sci. Technol. 2006, 178, 1821–1841. [Google Scholar] [CrossRef]

- Xi, Z.; Fu, Z.; Sabir, S.W.; Hu, X.; Jiang, Y.; Zhang, T. Experimental Analysis on Flame Flickering of a Swirl Partially Premixed Combustion. Energies 2018, 11, 2430. [Google Scholar] [CrossRef]

- Hasse, L.; Dunckel, M. Hot Wire and Hot Film Anemometers. In Air-Sea Interaction: Instruments and Methods; Dobson, F., Hasse, L., Davis, R., Eds.; Springer: Boston, MA, USA, 1980; pp. 47–63. [Google Scholar] [CrossRef]

- Weik, M.H. Computer Science and Communications Dictionary; Kluwer Academic Publishers: Norwell, MA, USA, 2000. [Google Scholar]

- Benim, A.C.; Syed, K.J. Chapter 3—Properties of Hydrogen-Containing Fuels. In Flashback Mechanisms in Lean Premixed Gas Turbine Combustion; Benim, A.C., Syed, K.J., Eds.; Academic Press: Boston, MA, USA, 2015; pp. 19–24. [Google Scholar] [CrossRef]

| Operation Point | Power Density Input [kW/m3] | Air-Fuel Equivalence Ratio | Airflow Rate [Nm3/h] | Gasflow Rate [Nm3/h] | Frequency [Hz] | Glow Ignition |

|---|---|---|---|---|---|---|

| OP1 | 1834 | 2.08 | 25 | 1.25 | 40.37 | Yes |

| OP2 | 2200 | 2.08 | 30 | 1.50 | 40.09 | Yes |

| OP3 | 2567 | 2.08 | 35 | 1.75 | 38.92 | Yes |

| OP4 | 2567 | 1.49 | 25 | 1.75 | 41.08 | Yes |

| OP5 | 2567 | 0.89 | 15 | 1.75 | 41.49 | Yes |

| OP6 | 2567 | 0.89 | 15 | 1.75 | 41.49 | No |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Dostál, J.; Heidinger, S.; Günther, S.; Odenbach, S. Experimental Investigation of a Pulsation Reactor via Optical Methods. Processes 2024, 12, 385. https://doi.org/10.3390/pr12020385

Zhang C, Dostál J, Heidinger S, Günther S, Odenbach S. Experimental Investigation of a Pulsation Reactor via Optical Methods. Processes. 2024; 12(2):385. https://doi.org/10.3390/pr12020385

Chicago/Turabian StyleZhang, Chunliang, Jakub Dostál, Stefan Heidinger, Stefan Günther, and Stefan Odenbach. 2024. "Experimental Investigation of a Pulsation Reactor via Optical Methods" Processes 12, no. 2: 385. https://doi.org/10.3390/pr12020385

APA StyleZhang, C., Dostál, J., Heidinger, S., Günther, S., & Odenbach, S. (2024). Experimental Investigation of a Pulsation Reactor via Optical Methods. Processes, 12(2), 385. https://doi.org/10.3390/pr12020385