Implementation of an Improved 100 CMM Regenerative Thermal Oxidizer to Reduce VOCs Gas

Abstract

1. Introduction

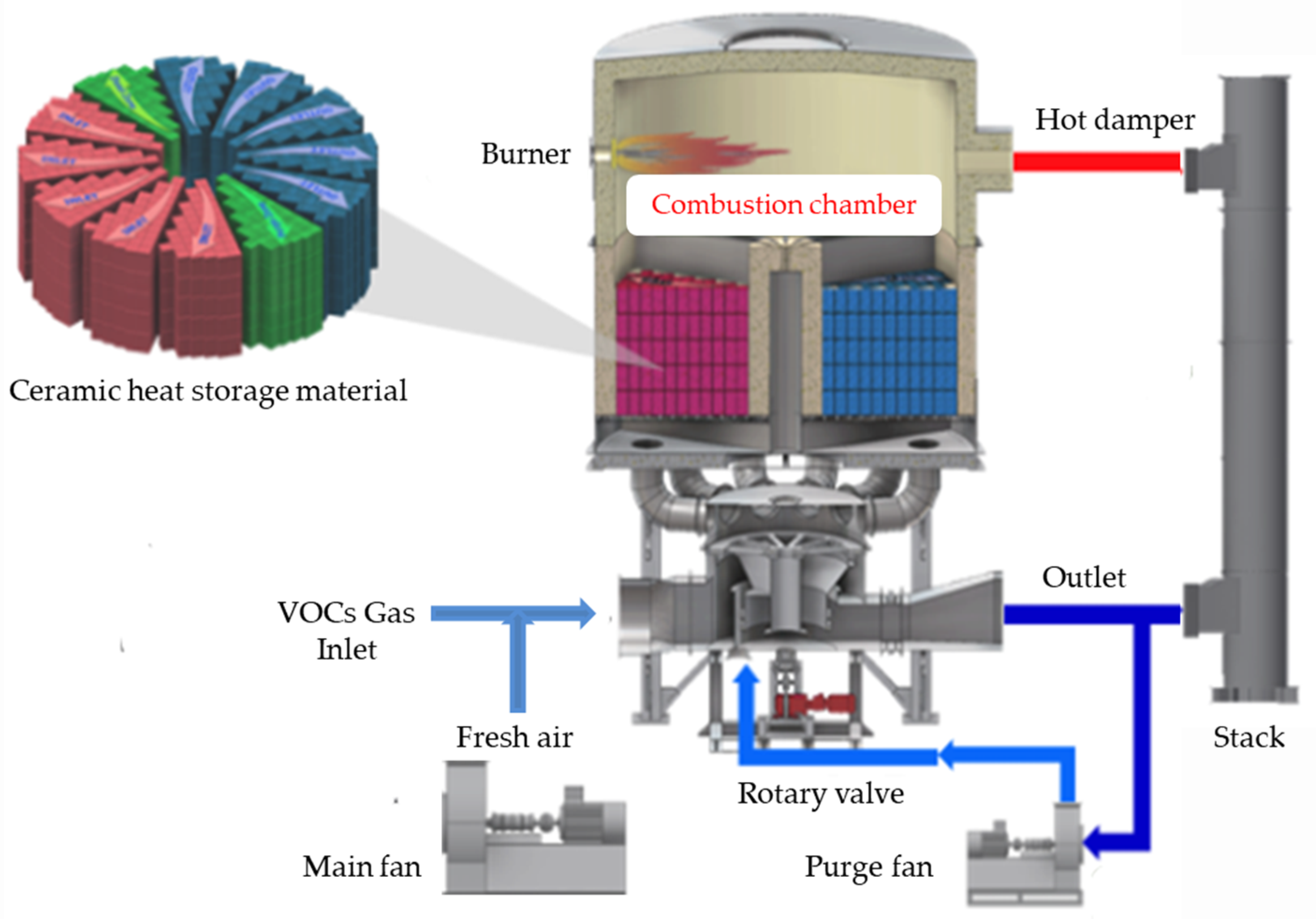

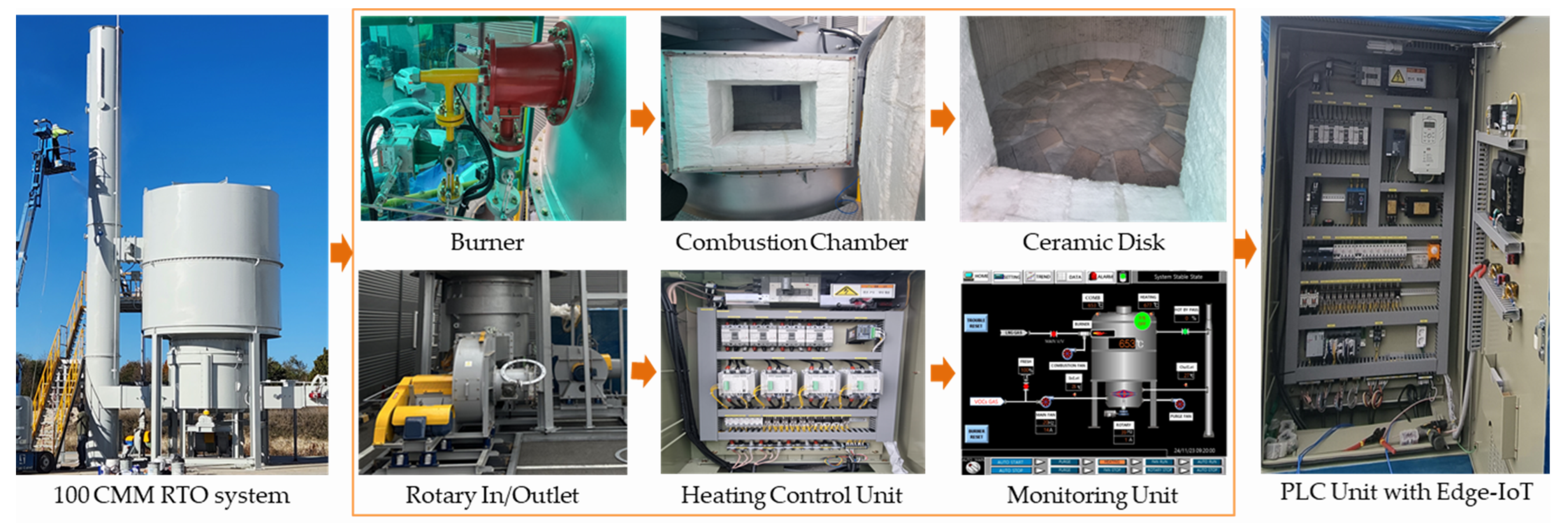

2. Implementation of Improved 100 CMM RTO

2.1. 100 and 10 CMM RTO Design

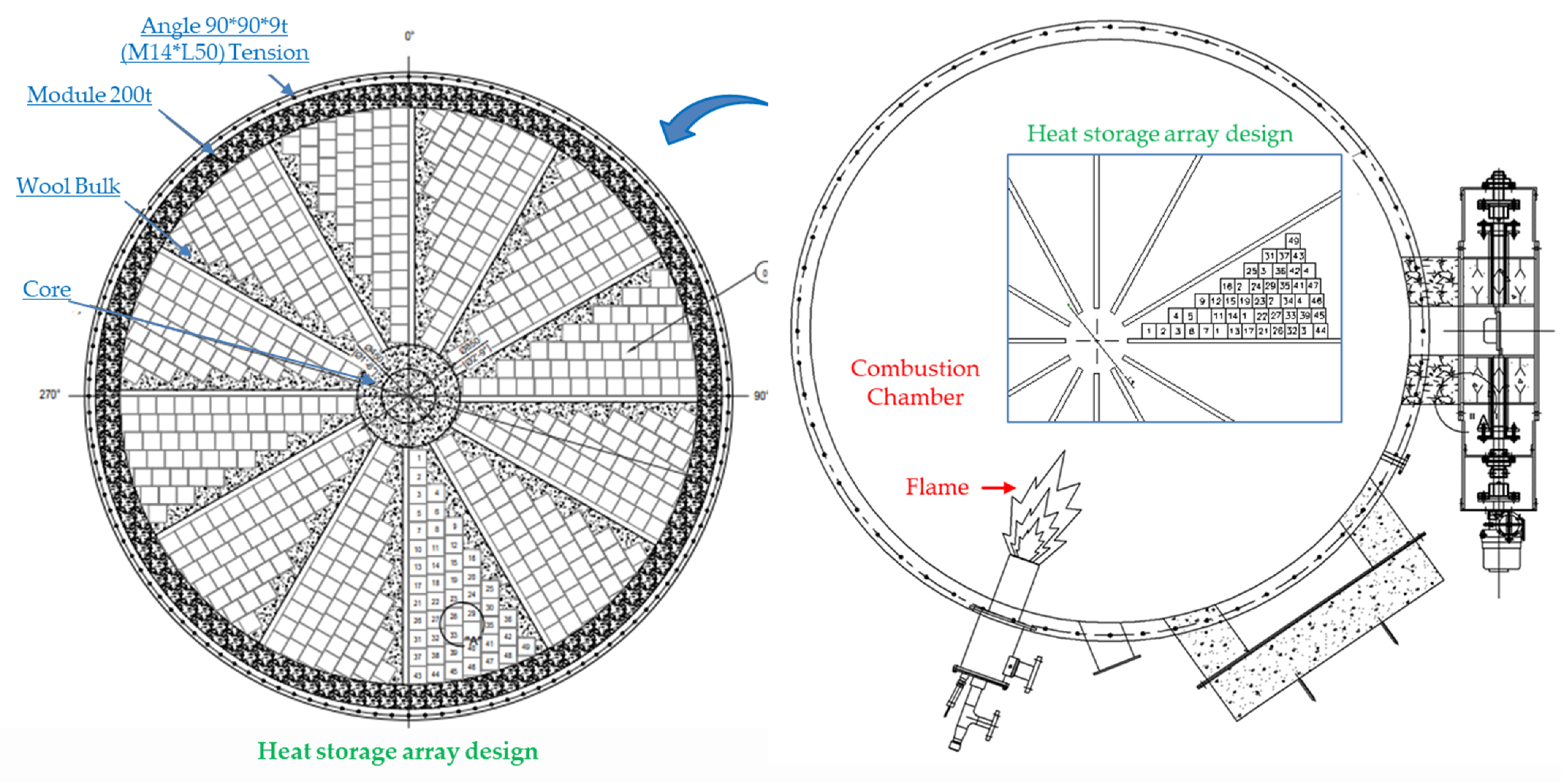

2.2. Redesign of Rotary Distributor and Disk Rotating Plate

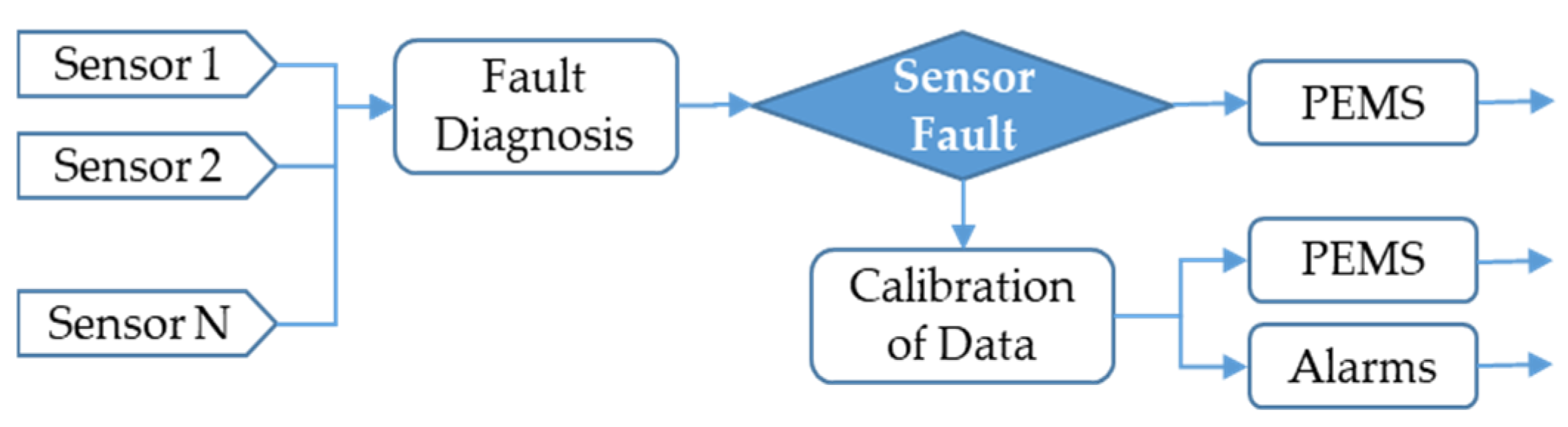

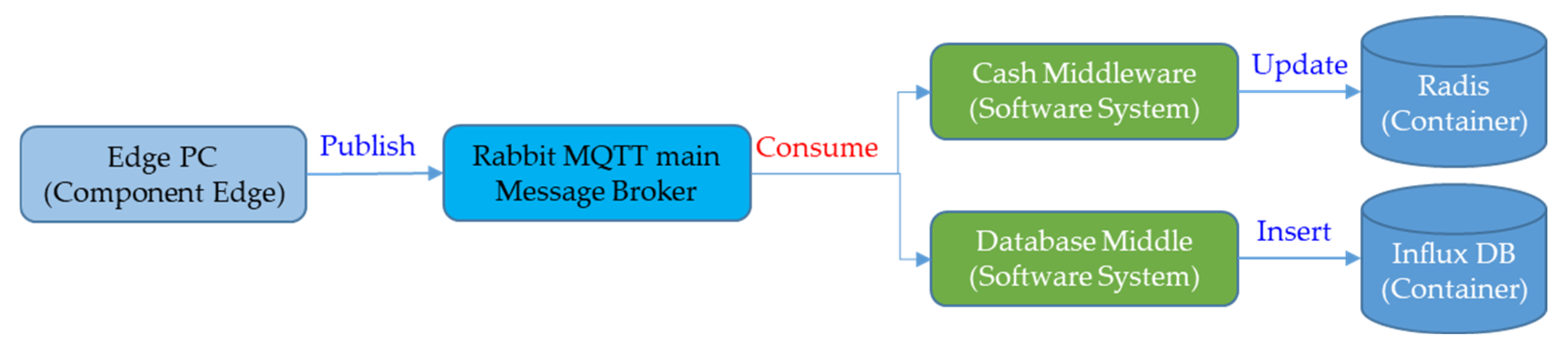

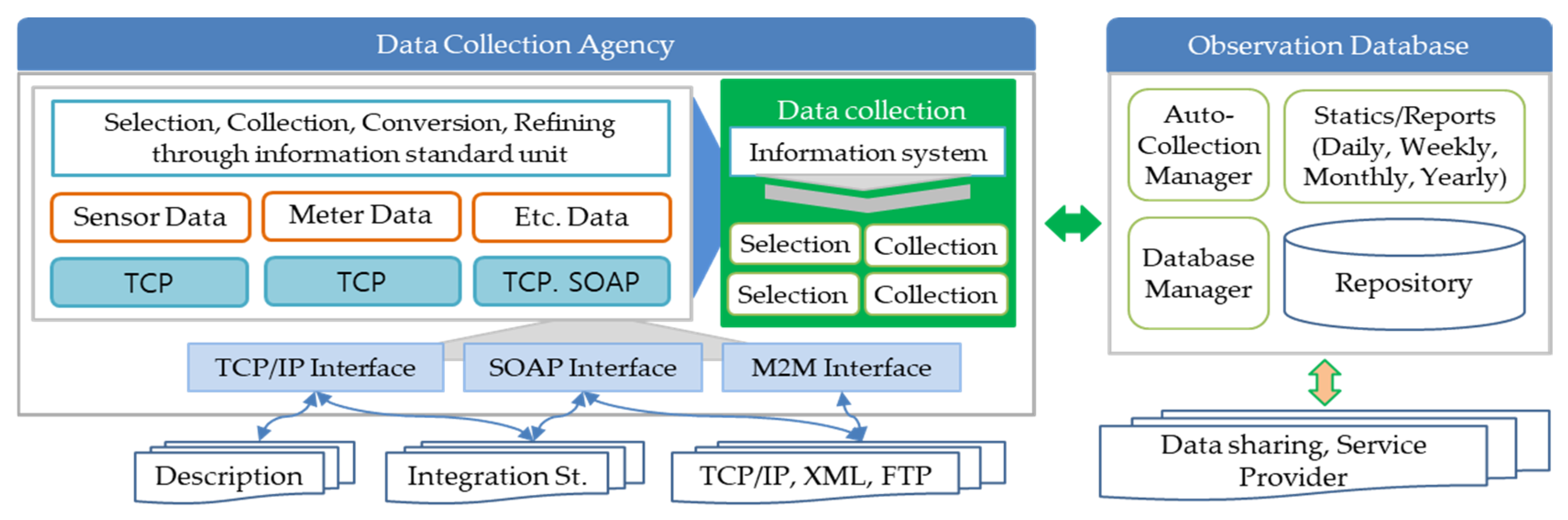

2.3. Intelligent PLC Operation Based on Edge-IoT

3. Experimental Results

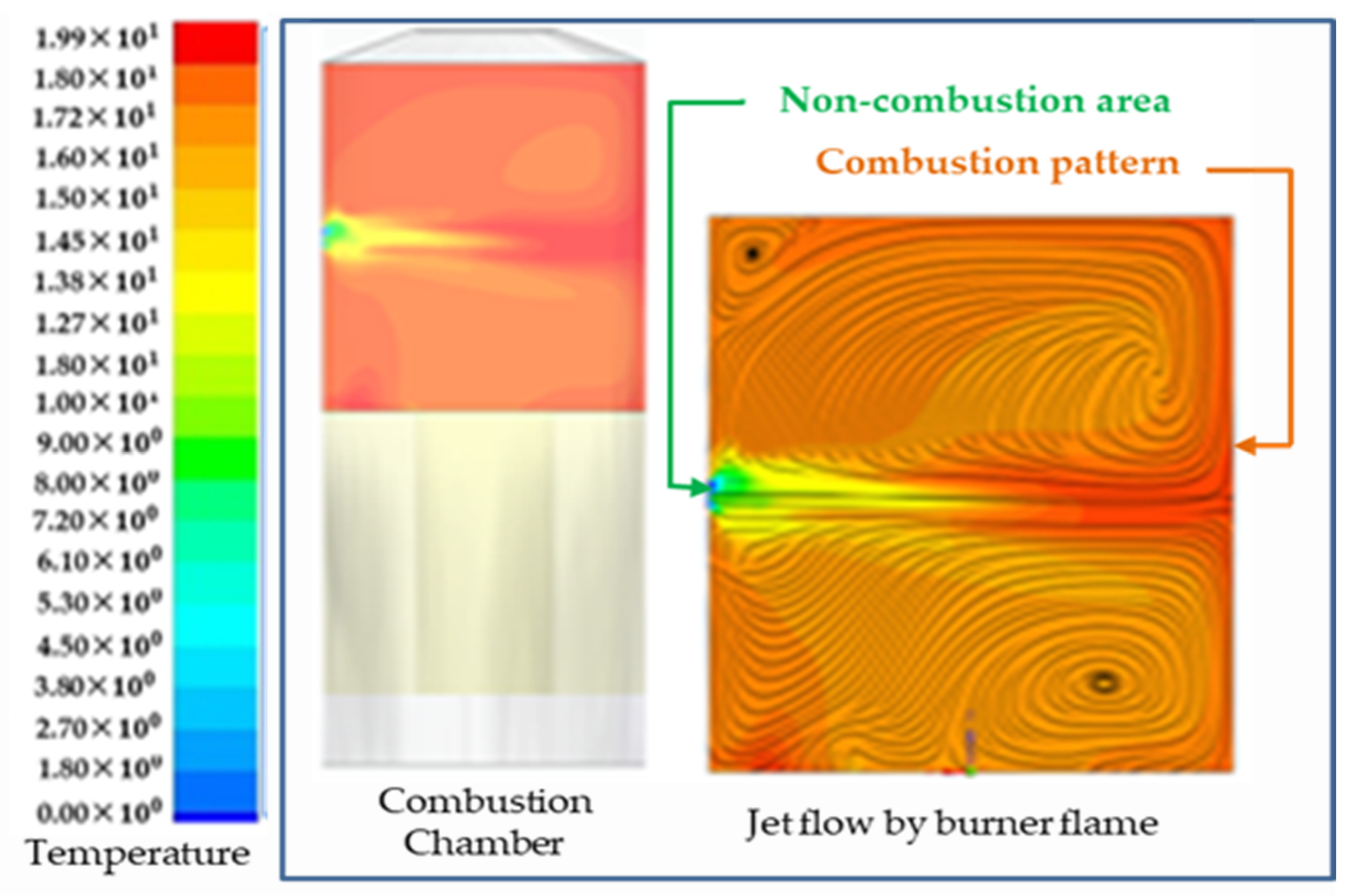

3.1. Economic Design Processes of Combustion Chamber

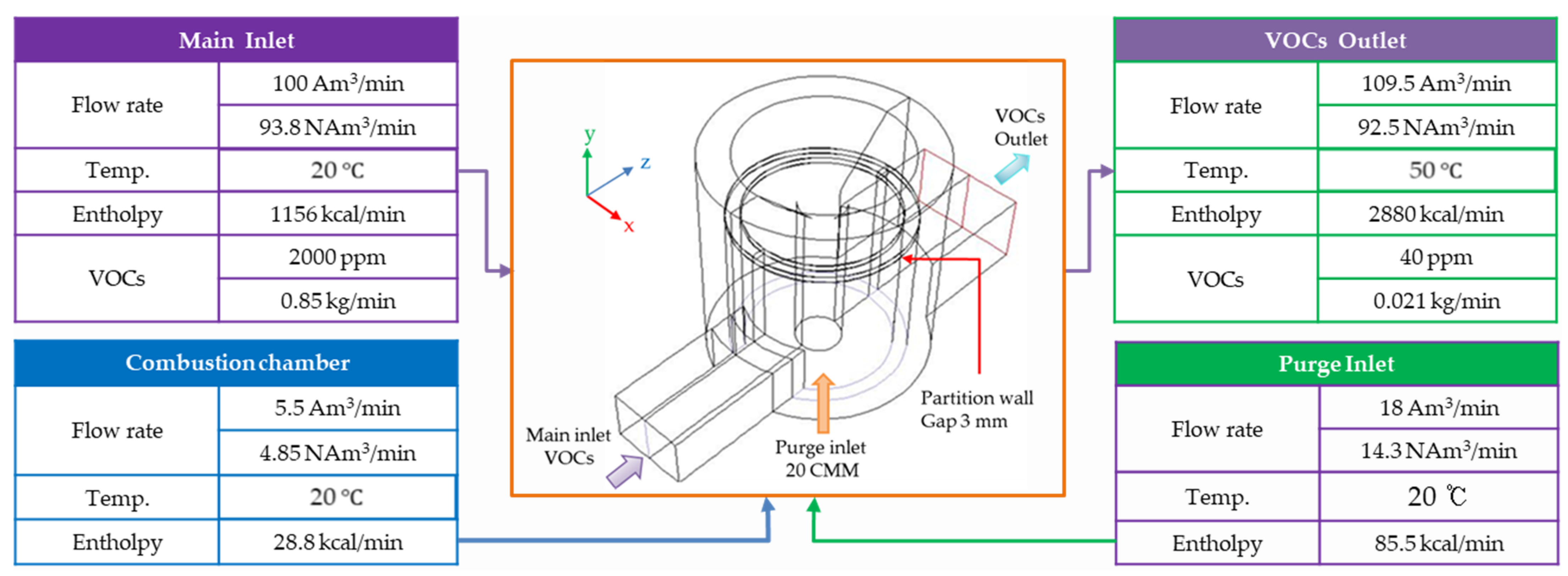

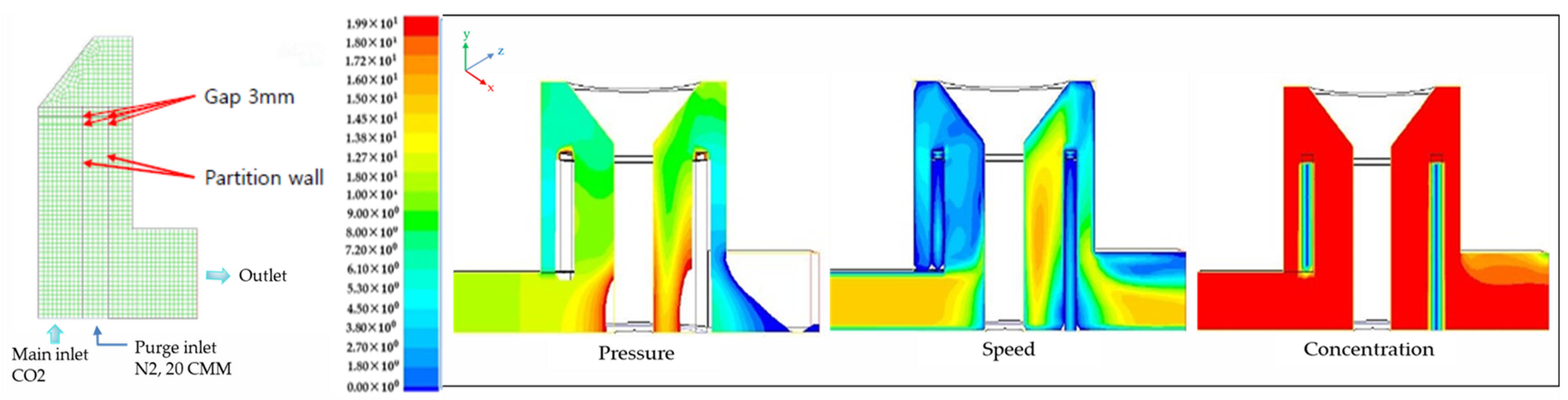

3.2. Flowability Analysis of Combustion Chamber and Rotary VOCs Gas

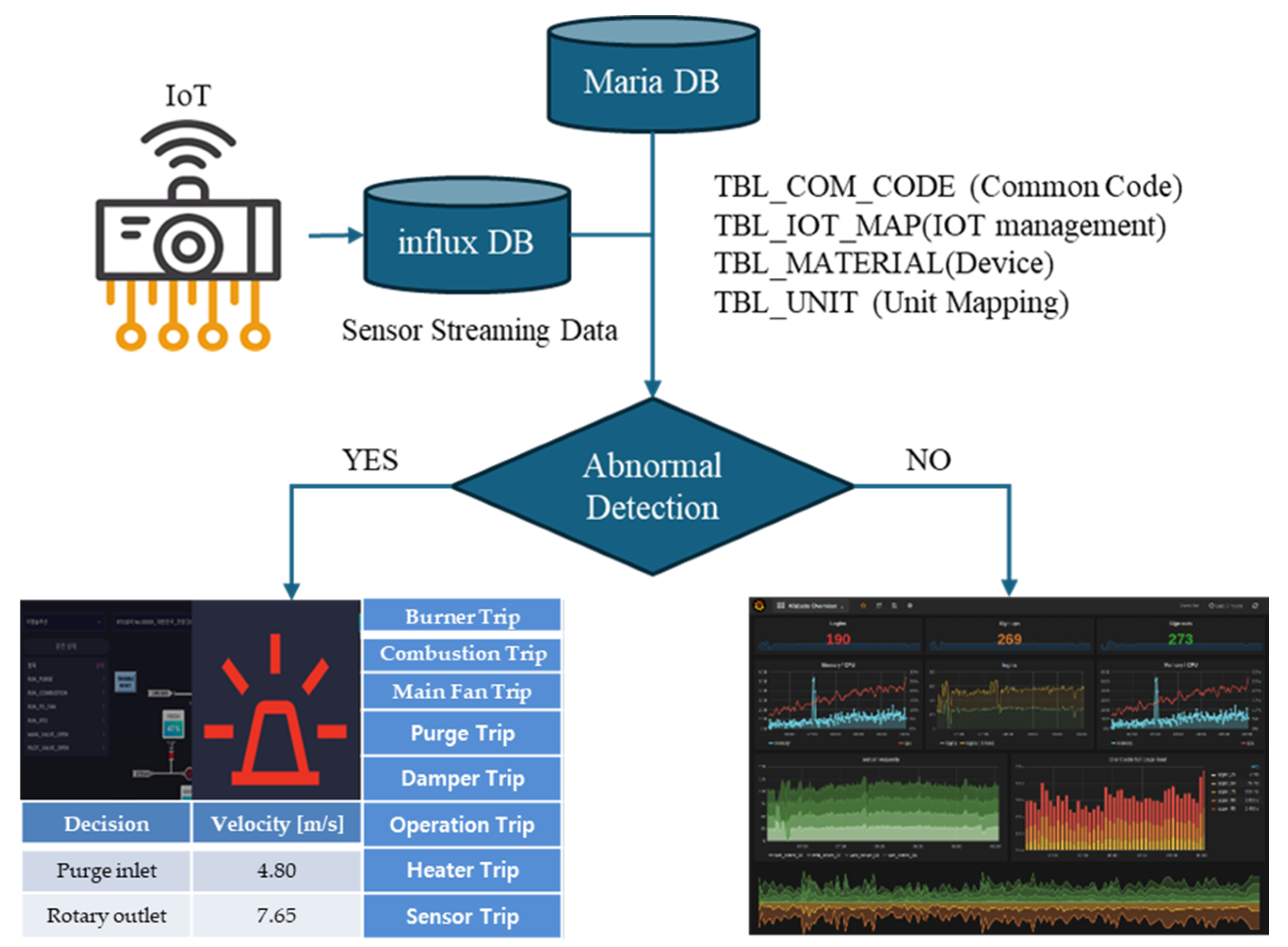

3.3. Data Visualize for RTO Analysis

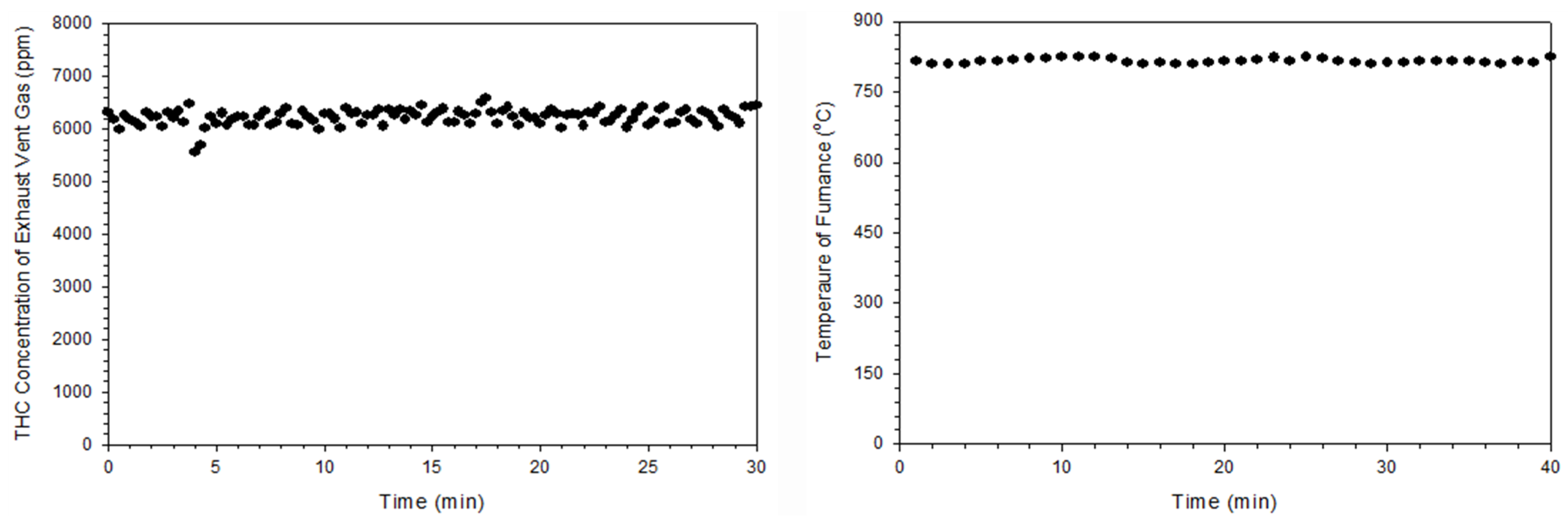

3.4. VOCs Gas Emission Test Based on Film Coating Device

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Soumyabrata, R.; Arjun, C.; Sebastian, C.P. Thermochemical CO2 Hydrogenation to Single Carbon Products: Scientific and Technological Challenges. ACS Energy Lett. 2018, 3, 1938–1966. [Google Scholar] [CrossRef]

- Yoon, J.H. Transboundary Air Pollution and Global Governance: Singapore’s Network Strategy to Tackle the Indonesian Haze. Korean Soc. Reg. Stud. Repub. Korea 2016, 34, 51–79. Available online: https://www.dbpia.co.kr/Journal/articleDetail?nodeId=NODE08788063 (accessed on 22 November 2023).

- Bian, C.; Huang, J.; Zhong, B.; Zheng, Z.; Dang, D.; Okafor, O.C.; Liu, Y.; Wang, T. Autothermal Reforming of Volatile Organic Compounds to Hydrogen-Rich Gas. Molecules 2023, 28, 752. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Chao, M.H.; Ko, D.R. Causative Substance and Time of Mortality Presented to Emergency Department Following Acute Poisoning: 2014–2018 National Emergency Department Information System. J. Korean Soc. Clin. Toxicol. 2021, 19, 65–71. [Google Scholar] [CrossRef]

- Hasegawa, T. Gas Turbine Combustion and Ammonia Removal Technology of Gasified Fuels. Energies 2010, 3, 335–449. [Google Scholar] [CrossRef]

- Hou, S.S.; Chiang, C.Y.; Lin, T.H. Oxy-Fuel Combustion Characteristics of Pulverized Coal under O2/Recirculated Flue Gas Atmospheres. Appl. Sci. 2020, 10, 13–62. [Google Scholar] [CrossRef]

- Sung, Y.M.; Kim, S.T.; Jang, B.H.; Oh, C.Y.; Jee, T.Y.; Park, S.I.; Park, K.S.; Chang, S.Y. Nitric Oxide Emission Reduction in Reheating Furnaces through Burner and Furnace Air-Staged Combustions. Energies 2021, 14, 1599. [Google Scholar] [CrossRef]

- Park, H.M.; Yoon, D.H.; Jung, H.M.; Jeon, D.H. Development of Porous Plate Scrubbers and Simulation of IPA Treatment Efficiency to Improve Dust Collection and Deodorization. Saf. Cult. Res. 2021, 13, 339–349. [Google Scholar] [CrossRef]

- Sadkin, I.; Mukhina, M.; Kopyev, E.; Sharypov, O.; Alekseenko, S. Low-Emission Waste-to-Energy Method of Liquid Fuel Combustion with a Mixture of Superheated Steam and Carbon Dioxide. Energies 2023, 16, 5745. [Google Scholar] [CrossRef]

- Choi, B.S.; Yi, J. Simulation and Optimization on the Regenerative Thermal Oxidation of Volatile Organic Compounds. Chem. Eng. J. 2000, 76, 103–114. [Google Scholar] [CrossRef]

- Khakimova, L.; Popov, E.; Cheremisin, A. Insights on In Situ Combustion Modeling Based on a Ramped Temperature Oxidation Experiment for Oil Sand Bitumen. Energies 2023, 16, 6738. [Google Scholar] [CrossRef]

- Jeon, D.H.; Jeng, S.W. Pre-treatment Method of Irregular Process Emissions for High-Efficiency Combustion Treatment of Volatile Organic Compounds. In Proceedings of the Autumn Conference of the Korea Gas Association, Daegu, Republic of Korea, 21–25 June 2021. [Google Scholar]

- Yoon, D.H.; Han, B.S.; Lim, T.Y.; Yang, E.C. Implementation of 100CMM Thermal Storage Combustion Oxidizer for VOCs Reduction. In Proceedings of the 2022 International Conference on Control, Automation and Systems, Busan, Republic of Korea, 27 November–1 December 2022; pp. 1–25. Available online: https://ieeexplore.ieee.org/xpl/conhome/10003266 (accessed on 26 April 2024).

- Park, H.M.; Jung, H.M.; Lee, D.H.; Lim, T.Y.; Yoon, D.H. VOCs Oxidation Treatment and Waste Heat Recovery Technology through the Implementation of Heat Storage Type Combustion Oxidation Device. Korean J. Saf. Cult. 2022, 17, 285–298. [Google Scholar] [CrossRef]

- Park, H.M.; Yoon, D.H.; Jeon, D.H.; Min, H.K. Nitrogen Oxide Reduction Type Regenerative Thermal Oxidation System and Nitrogen Oxide Reduction Method Thereof. U.S. Patent US20230228205A1, 16 July 2024. [Google Scholar]

- Park, H.M.; Yoon, D.H.; Jeon, D.H.; Min, H.K. Multistage Variable Type Waste Heat Storage and Recovery Apparatus and Method Thereof. U.S. Patent US2023/0228500A1, 20 July 2023. [Google Scholar]

- Korea Testing Laboratory (KTL), Republic of Korea. Available online: www.ktl.re.kr (accessed on 26 April 2024).

- Javed, A.; Heljanko, K.; Buda, A.; Framling, K. CEFIoT; A fault-tolernant IoT Architecture for Edge and Cloud. In Proceedings of the 2018 IEEE 4th World Forum on Internet of Things (WF-IoT), Singapore, 5–8 February 2018. [Google Scholar]

- Rabinovich, M.; Xiao, Z.; Aggarwal, A. Computing on the Edge: A Platform for Replicating Internet Applications. In Web Content Caching and Distribution; Springer: Dordrecht, The Netherlands, 2024; pp. 57–77. [Google Scholar]

- Kreps, J.; Narkhede, N.; Rao, J. Kafka: A Distributed Messaging System for Log Processing. In Proceedings of the NetDB 2011, Athens, Greece, 12 June 2011; pp. 1–7. [Google Scholar]

| Process | Usage Specification | Unit | Design Data | |

|---|---|---|---|---|

| 100 CMM | 10 CMM | |||

| Main fan | Air volume | m3/min | 100 | 10 |

| Pressure | mmAq | 400 | 400 | |

| Power | kW | 15 | 2.2 | |

| Current | A | 39.5 | 5.8 | |

| Purge fan | Air volume | m3/min | 20 | 2 |

| Pressure | mmAq | 700 | 500 | |

| Power | kW | 5.5 | 2.2 | |

| Current | A | 14.5 | 5.8 | |

| Combustion fan | Air volume | m3/min | 8 | 1 |

| Pressure | mmAq | 800 | 700 | |

| Power | kW | 3.7 | 1.5 | |

| Current | A | 9.7 | 3.9 | |

| Burner | Capacity | kcal/h | 100,000 | 15,000 |

| Fuel (LNG Gas) | kcal/Nm3 | - | - | |

| Supply pressure | mmAq | 2500 | 2500 | |

| Usage pressure | mmAq | 500 | 500 | |

| Combustion air pressure | mmAq | 800 | 700 | |

| Rotary | Power | kW | 1.5 | 0.75 |

| Current | A | 4 | 2 | |

| Temperature | Combustion chamber | °C | 800 | 800 |

| Inlet temperature | °C | 20 | 20 | |

| Outlet temperature | °C | 60 ± 3 | 60 ± 3 | |

| Thermal efficiency | % | 95 | 95 | |

| Substance material to be treated (Toluene calorific value) | ppm | VOCs~2000 | ||

| - | smoke (4 degrees or higher) | |||

| - | Stench (over 4 degrees) | |||

| VOC generation | kg/h | 43 | ||

| VOC | Emission Concentration | Emissions | Unit Combustion Heat | Amount of Heat Burned |

|---|---|---|---|---|

| ppm | kg/h | kcal/kg | kcal/h | |

| Methacrylic acid | 2000 | 43 | 5150 | 221,540 |

| Tag Name | Description | Type | Range | I/O |

|---|---|---|---|---|

| Analog value | Combustion chamber temp. | real | - | AI |

| Combustion chamber value | real | - | AI | |

| Input temperature | real | - | AI | |

| Exhaust temperature | real | - | AI | |

| FD Fan: Frequency setting | real | 0~60 | AI | |

| FD FNA: Current value | real | - | AI | |

| Rotary: Frequency setting | real | 0~60 | AI | |

| Rotary: Current value | real | - | AI | |

| Fresh damper open value | real | 0~100 | AI | |

| Hot damper open value | real | 0~100 | AI | |

| Trip information | FD Fan Trip | bool | 0 or 1 | DI |

| Rotatory Trip | bool | 0 or 1 | DI | |

| Purge Fan Trip | bool | 0 or 1 | DI | |

| Combustion Fan Trip | bool | 0 or 1 | DI | |

| Fresh Damper Trip | bool | 0 or 1 | DI | |

| Hot Damper Trip | bool | 0 or 1 | DI | |

| Combustion chamber overheat | bool | 0 or 1 | DI | |

| Combustion chamber: high | bool | 0 or 1 | DI | |

| Combustion chamber: low | bool | 0 or 1 | DI | |

| Incoming temperature: High | bool | 0 or 1 | DI | |

| Exhaust temperature: High. | bool | 0 or 1 | DI | |

| In/Outlet GAS Trip | bool | 0 or 1 | DI |

| Trip Style | Out of Order |

|---|---|

| Burner Trip | Burner off, Fresh Damper Close, Hot bypass Damper Close, RTO Fan Run, Purge Fan Run, Combustion Fan Run, Rotary Run, Main Fan Run |

| Combustion Trip | Burner off, Fresh Damper Open, Hot bypass damper Open, RTO Fan Stop, Purge Fan Stop, Combustion Fan Stop, Rotary Stop, Main Fan Run |

| Main Fan Trip | Burner off, Fresh Damper Open, Hot bypass Damper Open, RTO Fan Stop, Purge Fan Stop, Combustion Fan Stop, Rotary Stop, Main Fan Stop |

| Heat Storage Material Items | Configuration Material | Design Specifications |

|---|---|---|

| Recovery energy | Heat accumulator passing temperature | 735 °C |

| Heat storage material recovery calorific value | 1,911,341 Kcal/h | |

| Heat storage material | Heat exchange rate | 31,856 Kcal/h |

| Total area of heat storage material | 2 m3 | |

| Pressure loss | A heat storage material | 100 mmAq |

| Stack | 5 mmAq | |

| Rotary | 3 mmAq | |

| a sudden zoom | 45 mmAq | |

| Etc. | 100 mmAq | |

| Total | 253 mmAq |

| Economic Items | Monthly Maintenance Costs |

|---|---|

| Normal heating fuel production | 802,106 kcal/h ÷ 15,000 kcal/Nm3·LNG × 0.5 h/day × 3 day/month × 700 $/Nm3·LNG = 56,147 $/month |

| Fuel production per hour | 0 day/month × 30 day/month × 700/Nm3·LNG Total monthly fuel use cost: 56,147/month |

| Power usage | Total 63 kWh × 0.8 × 60 $/kWh × 24 h/day × 30 day/month = 2,177,280 $/month. Monthly electricity cost: 2,177,280 $/month Monthly RTO Total fuel and power cost: 2,233,427/month |

| Geometry | Velocity [m/s] | Pressure [mmAq] |

|---|---|---|

| Main inlet | 14 | 24.45 |

| Purge inlet | 4.80 | 3,711,178 |

| Rotary outlet | 7.65 | 0.02 |

| Sortation | Unit | Inlet | Outlet | VOCs Reduction Rate (%) |

|---|---|---|---|---|

| Total hydrocarbon (THC) | ppm | 6221.27 | 155.55 | 97.90 |

| Nitrogen oxide | ppm | - | 2.49 | - |

| Exhaust gas temperature | °C | - | 70.13 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.-M.; Jung, H.-M.; Lee, D.-H.; Park, H.-N.; Lim, T.-Y.; Yoon, J.-H.; Yoon, D.-H. Implementation of an Improved 100 CMM Regenerative Thermal Oxidizer to Reduce VOCs Gas. Processes 2024, 12, 2814. https://doi.org/10.3390/pr12122814

Park H-M, Jung H-M, Lee D-H, Park H-N, Lim T-Y, Yoon J-H, Yoon D-H. Implementation of an Improved 100 CMM Regenerative Thermal Oxidizer to Reduce VOCs Gas. Processes. 2024; 12(12):2814. https://doi.org/10.3390/pr12122814

Chicago/Turabian StylePark, Hoon-Min, Hyun-Min Jung, Dae-Hee Lee, Hei-Na Park, Tae-Young Lim, Jong-Hwa Yoon, and Dal-Hwan Yoon. 2024. "Implementation of an Improved 100 CMM Regenerative Thermal Oxidizer to Reduce VOCs Gas" Processes 12, no. 12: 2814. https://doi.org/10.3390/pr12122814

APA StylePark, H.-M., Jung, H.-M., Lee, D.-H., Park, H.-N., Lim, T.-Y., Yoon, J.-H., & Yoon, D.-H. (2024). Implementation of an Improved 100 CMM Regenerative Thermal Oxidizer to Reduce VOCs Gas. Processes, 12(12), 2814. https://doi.org/10.3390/pr12122814