A Study on the Influence of Natural Fractures in Tight Sandstone Reservoirs on Hydraulic Fracture Propagation Behavior and Post-Fracture Productivity

Abstract

1. Introduction

2. Numerical Model Establishment

2.1. Model Building

2.2. Model Validation

3. Numerical Simulation Results

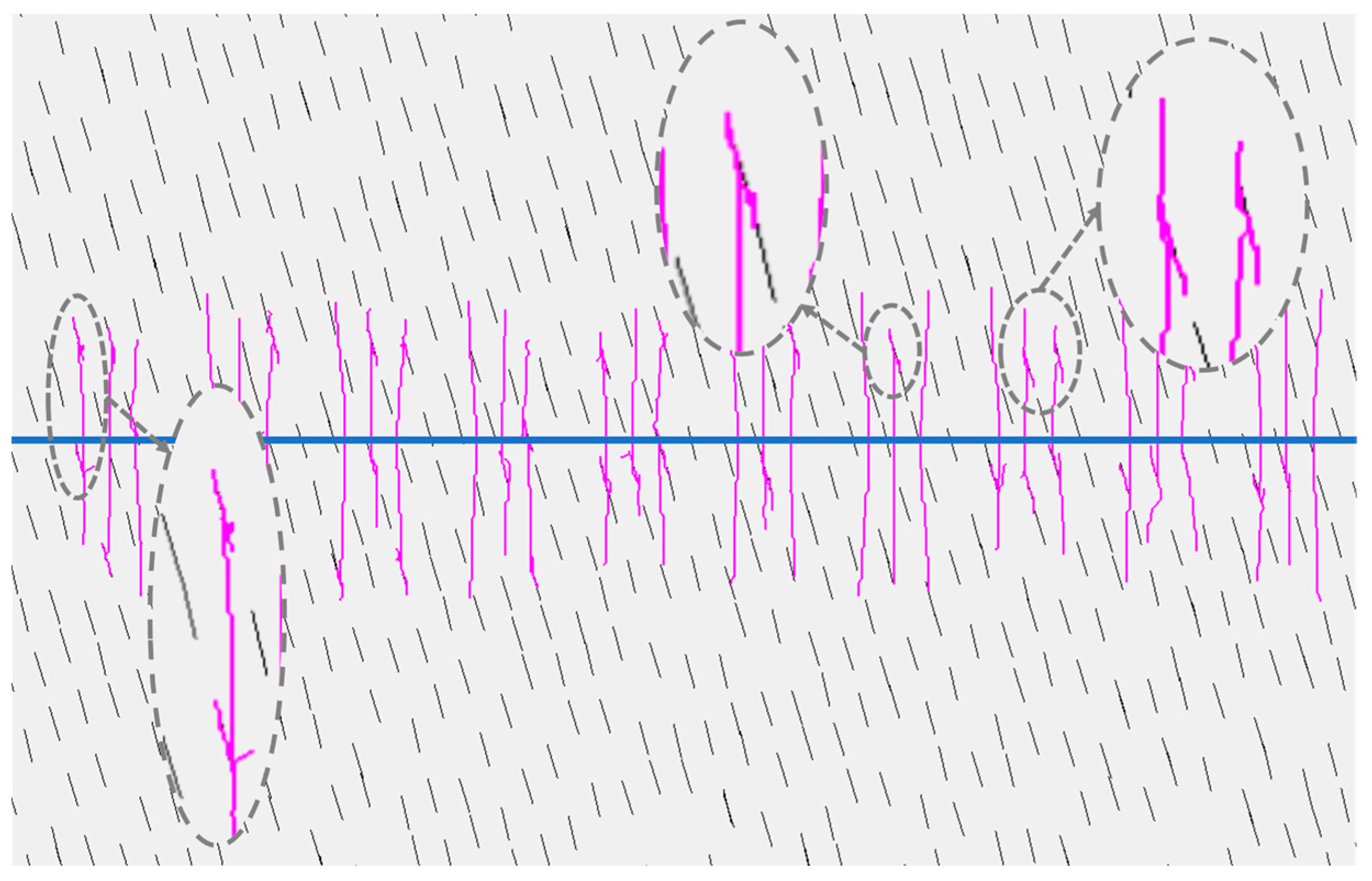

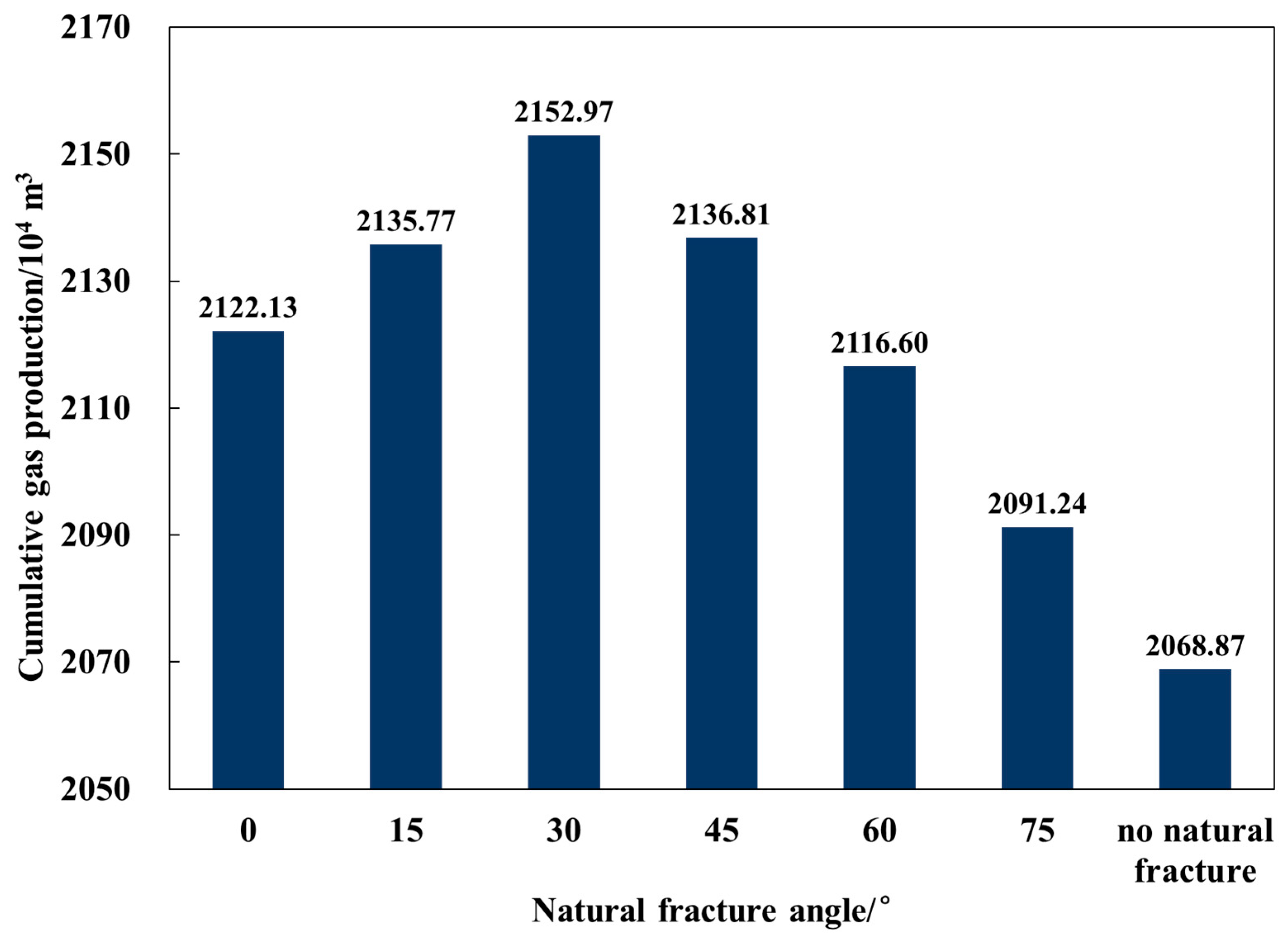

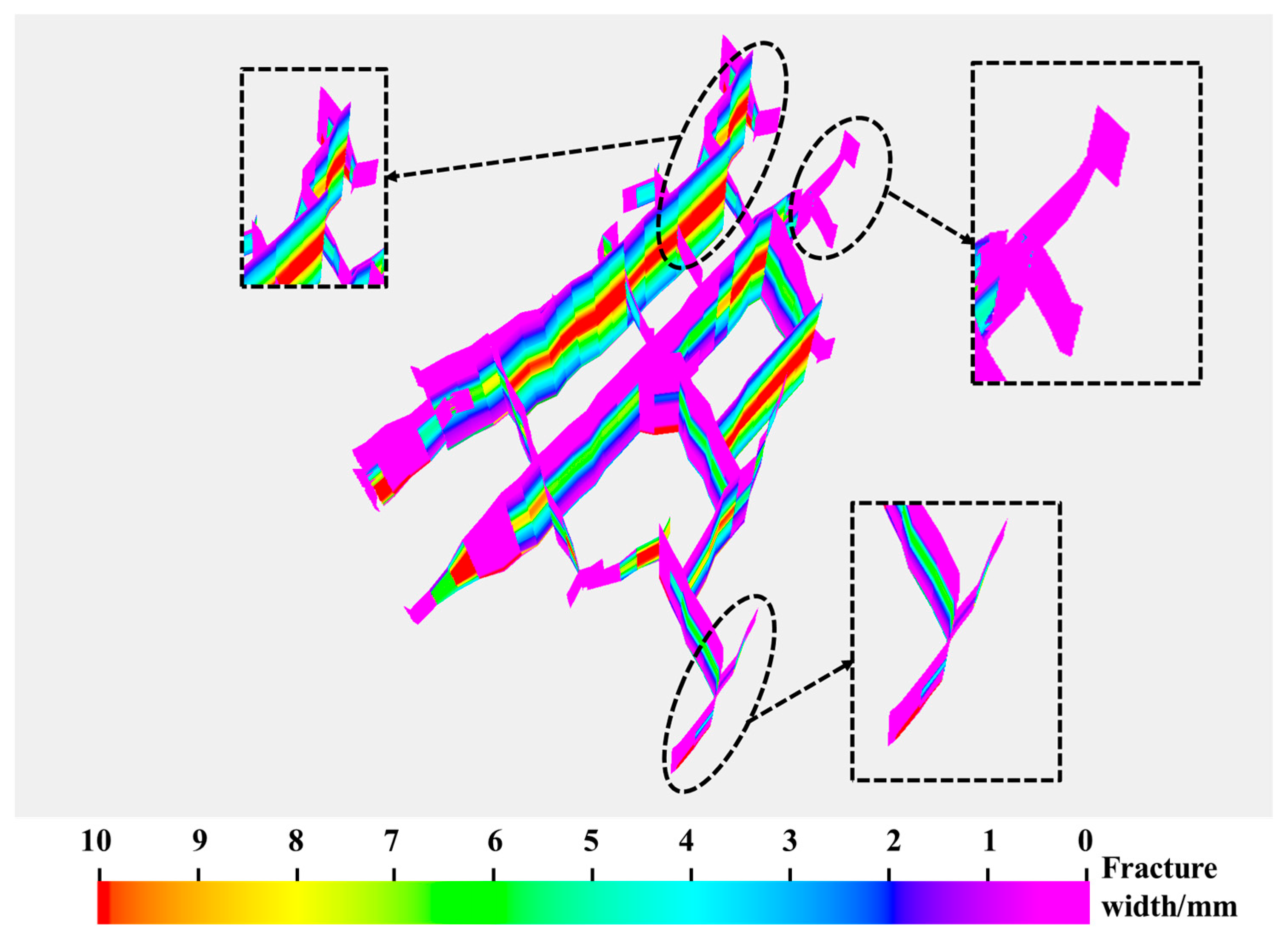

3.1. Natural Fracture Angle

3.2. Natural Fracture Density

3.3. Natural Fracture Length

4. Conclusions

- Secondary hydraulic fractures are repelled by each other and attracted to primary fractures due to induced stress. They may propagate parallel to or rapidly intertwine with primary fractures along the direction of maximum principal stress. The pore pressure decreases more sharply where hydraulic fractures intersect natural fractures.

- When natural fractures have smaller angles, more fractures are activated, secondary hydraulic fractures extend more extensively, and primary fractures are shorter, leading to a more complex fracture network. Higher natural fracture angles result in hydraulic fractures penetrating natural fractures, simplifying the fracture network.

- Higher natural fracture densities and longer lengths lead to more hydraulic fractures intersecting natural fractures, longer stimulated natural fractures, and a more complex fracture network. Lower-angle natural fractures significantly affect network complexity compared to higher-angle fractures in terms of both density and length.

- The cumulative gas production per well increases initially and then decreases with increasing natural fracture angles but increases with higher natural fracture densities and lengths. Lower-angle fractures yield higher cumulative gas production compared to higher-angle fractures.

- For lower natural fracture angles, smaller fracture spacings have a more significant impact on cumulative gas production per well. Optimal well productivity is achieved in areas with longer natural fractures, lower angles, and higher fracture densities.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| ET | Effective thickness [m] |

| Po | Reservoir pressure [MPa] |

| φ | Porosity [%] |

| Pm | Permeability [mD] |

| GS | Gas saturation [%] |

| SH | Maximum horizontal principal stress [MPa] |

| Sh | Minimum horizontal principal stress [MPa] |

| Sv | Overburden pressure [MPa] |

| T | Temperature [°C] |

| E | Young’s modulus [GPa] |

| ν | Poisson’s ratio |

| KIC | Fracture toughness [kPa∙m0.5] |

| MD | Measure depth [m] |

| TVD | True Vertical Depth [m] |

| L | Horizontal section length [m] |

| FS | Fracturing stages. |

| NC | Number of fracture clusters. |

| CS | Cluster spacing [m] |

| Nl | Natural fracture length [m] |

| Ns | Natural fracture spacing [m] |

| Na | Natural fracture angle [°] |

References

- Jia, C. Prospects and five future theoretical and technical challenges of the upstream petroleum industry in China. Acta Pet. Sin. 2024, 45, 1–14. [Google Scholar] [CrossRef]

- Xie, Q.; Li, J.; Ye, X.; Gao, J.; Song, Y.; Hu, S. Analysis of Water Production Factors of Gas Wells in Sulige Gas Field. J. Phys. Conf. Ser. 2024, 2860, 012023. [Google Scholar] [CrossRef]

- Carson, S.A. Independent and major equity market and commodity return sources around the time of hydraulic fracking and horizontal drilling revolution: A differences-in-decompositions approach. Econ. Innov. New Technol. 2024, 33, 26–44. [Google Scholar] [CrossRef]

- Ismail, A.; Azadbakht, S. A comprehensive review of numerical simulation methods for hydraulic fracturing. Int. J. Numer. Anal. Methods Geomech. 2024, 48, 1433–1459. [Google Scholar] [CrossRef]

- Fu, W.; Ames, B.C.; Bunger, A.P.; Savitski, A.A. Impact of Partially Cemented and Non-persistent Natural Fractures on Hydraulic Fracture Propagation. Rock Mech. Rock Eng. 2016, 49, 4519–4526. [Google Scholar] [CrossRef]

- Wen, Q.; Wang, S.; Duan, X.; Li, Y.; Wang, F.; Jin, X. Experimental investigation of proppant settling in complex hydraulic-natural fracture system in shale reservoirs. J. Nat. Gas Sci. Eng. 2016, 33, 70–80. [Google Scholar] [CrossRef]

- Fatahi, H.; Hossain, M.M.; Sarmadivaleh, M. Numerical and experimental investigation of the interaction of natural and propagated hydraulic fracture. J. Nat. Gas Sci. Eng. 2017, 37, 409–424. [Google Scholar] [CrossRef]

- Wan, L.; Chen, M.; Hou, B.; Kao, J.; Zhang, K.; Fu, W. Experimental investigation of the effect of natural fracture size on hydraulic fracture propagation in 3D. J. Struct. Geol. 2018, 116, 1–11. [Google Scholar] [CrossRef]

- Yildirim, B.; Durucan, S.; Cao, W.; Cai, W.; Shi, J.; Korre, A.; Wolf, K.H. Experimental and Numerical Investigation into Hydraulic Fracture and Natural Fracture Interaction in Shale Formations. In Proceedings of the 53rd U.S. Rock Mechanics/Geomechanics Symposium, New York, NY, USA, 23–26 June 2019; p. ARMA–2019-0437. [Google Scholar]

- Gale, J.; Elliott, S.; Li, J.Z.; Laubach, S. Natural Fracture Characterization in the Wolfcamp Formation at the Hydraulic Fracture Test Site (HFTS), Midland Basin, Texas. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Denver, CO, USA, 22–24 July 2019; p. D023S039R001. [Google Scholar]

- Dehghan, A.N. An experimental investigation into the influence of pre-existing natural fracture on the behavior and length of propagating hydraulic fracture. Eng. Fract. Mech. 2020, 240, 107330. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, X.; Peng, X.; Zhang, Y.; Chen, H.; He, J. Influence of natural fractures on propagation of hydraulic fractures in tight reservoirs during hydraulic fracturing. Mar. Pet. Geol. 2022, 138, 105505. [Google Scholar] [CrossRef]

- Zhang, Y.; Long, A.; Zhao, Y.; Zang, A.; Wang, C. Mutual impact of true triaxial stress, borehole orientation and bedding inclination on laboratory hydraulic fracturing of Lushan shale. J. Rock Mech. Geotech. Eng. 2023, 15, 3131–3147. [Google Scholar] [CrossRef]

- Gonzalez, M.; Taleghani, A.D.; Olson, J.E. A Cohesive Model for Modeling Hydraulic Fractures in Naturally Fractured Formations. In Proceedings of the SPE Hydraulic Fracturing Technology Conference, Woodlands, TX, USA, 3–5 February 2015; p. D031S007R002. [Google Scholar]

- Guo, J.; Zhao, X.; Zhu, H.; Zhang, X.; Pan, R. Numerical simulation of interaction of hydraulic fracture and natural fracture based on the cohesive zone finite element method. J. Nat. Gas Sci. Eng. 2015, 25, 180–188. [Google Scholar] [CrossRef]

- Wu, K.; Olson, J.E. Numerical Investigation of Complex Hydraulic-Fracture Development in Naturally Fractured Reservoirs. SPE Prod. Oper. 2016, 31, 300–309. [Google Scholar] [CrossRef]

- Chong, Z.; Li, X.; Chen, X.; Zhang, J.; Lu, J. Numerical Investigation into the Effect of Natural Fracture Density on Hydraulic Fracture Network Propagation. Energies 2017, 10, 914. [Google Scholar] [CrossRef]

- Chen, Z.; Jeffrey, R.G.; Zhang, X.; Kear, J. Finite-Element Simulation of a Hydraulic Fracture Interacting With a Natural Fracture. SPE J. 2016, 22, 219–234. [Google Scholar] [CrossRef]

- Dahi Taleghani, A.; Gonzalez-Chavez, M.; Yu, H.; Asala, H. Numerical simulation of hydraulic fracture propagation in naturally fractured formations using the cohesive zone model. J. Pet. Sci. Eng. 2018, 165, 42–57. [Google Scholar] [CrossRef]

- Shrivastava, K.; Agrawal, S.; Kumar, A.; Sharma, M.M. 3-D Interactions of Hydraulic Fractures with Natural Fractures. In Proceedings of the SPE International Hydraulic Fracturing Technology Conference and Exhibition, Muscat, Oman, 16–18 October 2018; p. D023S018R001. [Google Scholar]

- Li, Z.-Q.; Li, X.-L.; Yu, J.-B.; Cao, W.-D.; Liu, Z.-F.; Wang, M.; Liu, Z.-F.; Wang, X.-H. Influence of existing natural fractures and beddings on the formation of fracture network during hydraulic fracturing based on the extended finite element method. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 58. [Google Scholar] [CrossRef]

- Zhao, H.; Li, W.; Wang, L.; Fu, J.; Xue, Y.L.; Zhu, J.J.; Li, S.Q. The Influence of the Distribution Characteristics of Complex Natural Fracture on the Hydraulic Fracture Propagation Morphology. Front. Earth Sci. 2022, 9, 784931. [Google Scholar] [CrossRef]

- Dong, Y.; Tian, W.; Li, P.; Zeng, B.; Lu, D. Numerical investigation of complex hydraulic fracture network in naturally fractured reservoirs based on the XFEM. J. Nat. Gas Sci. Eng. 2021, 96, 104272. [Google Scholar] [CrossRef]

- Xiong, D.; Ma, X. Influence of natural fractures on hydraulic fracture propagation behaviour. Eng. Fract. Mech. 2022, 276, 108932. [Google Scholar] [CrossRef]

- Hu, Y.; Gan, Q.; Hurst, A.; Elsworth, D. Investigation of coupled hydro-mechanical modelling of hydraulic fracture propagation and interaction with natural fractures. Int. J. Rock Mech. Min. Sci. 2023, 169, 105418. [Google Scholar] [CrossRef]

- Wang, H.; Yang, S.; Zhou, D.; Wang, Q. Influence of non-intersecting cemented natural fractures on hydraulic fracture propagation behavior. J. Struct. Geol. 2024, 181, 105111. [Google Scholar] [CrossRef]

- Schlumberger. Petrel E&P Software Platform, 2024; Schlumberger: Houston, TX, USA, 2009. [Google Scholar]

- Wang, H.; Zhou, D. Mechanistic study on the effect of seepage force on hydraulic fracture initiation. Fatigue Fract. Eng. Mater. Struct. 2024, 47, 1602–1619. [Google Scholar] [CrossRef]

- Valkó, P.P.; Lee, W.J. A Better Way to Forecast Production from Unconventional Gas Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 20–22 September 2010; p. SPE–134231-MS. [Google Scholar]

| Reservoir physical parameters | Effective thickness, ET/m | 17.6 |

| Reservoir pressure, Po/MPa | 32 | |

| Porosity, φ/% | 9.1 | |

| Permeability, Pm/mD | 0.28 | |

| Gas saturation, GS/% | 64 | |

| Maximum horizontal principal stress, SH/MPa | 47 | |

| Minimum horizontal principal stress, Sh/MPa | 44 | |

| Overburden pressure, Sv/MPa | 78 | |

| Temperature, T/°C | 92 | |

| Rock mechanical parameters | Young’s modulus, E/GPa | 40 |

| Poisson’s ratio, ν | 0.2 | |

| Fracture toughness, KIC/kPa∙m0.5 | 1319 | |

| Wellbore parameters | MD/m | 4800 |

| TVD/m | 3274 | |

| Horizontal section length, L/m | 1200 | |

| Fracturing stages, FS | 9 | |

| Number of fracture clusters, NC | 3 | |

| Cluster spacing, CS/m | 15 |

| Scheme | Natural Fracture Length, Nl/m | Natural Fracture Spacing, Ns/m | Natural Fracture Angle, Na/° | Scheme | Natural Fracture Length, Nl/m | Natural Fracture Spacing, Ns/m | Natural Fracture Angle, Na/° |

|---|---|---|---|---|---|---|---|

| 1 | 20 | 25 | 30 | 7 | 20 | 25 | 60 |

| 2 | 30 | 25 | 30 | 8 | 30 | 25 | 60 |

| 3 | 50 | 25 | 30 | 9 | 50 | 25 | 60 |

| 4 | 20 | 40 | 30 | 10 | 20 | 40 | 60 |

| 5 | 30 | 40 | 30 | 11 | 30 | 40 | 60 |

| 6 | 50 | 40 | 30 | 12 | 50 | 40 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, T.; Yu, X.; Zhang, L.; Su, X.; Wu, Y.; Jie, Y.; Wang, H.; Zhou, D. A Study on the Influence of Natural Fractures in Tight Sandstone Reservoirs on Hydraulic Fracture Propagation Behavior and Post-Fracture Productivity. Processes 2024, 12, 2813. https://doi.org/10.3390/pr12122813

Gu T, Yu X, Zhang L, Su X, Wu Y, Jie Y, Wang H, Zhou D. A Study on the Influence of Natural Fractures in Tight Sandstone Reservoirs on Hydraulic Fracture Propagation Behavior and Post-Fracture Productivity. Processes. 2024; 12(12):2813. https://doi.org/10.3390/pr12122813

Chicago/Turabian StyleGu, Tuan, Xiang Yu, Linpeng Zhang, Xu Su, Yibei Wu, Yenan Jie, Haiyang Wang, and Desheng Zhou. 2024. "A Study on the Influence of Natural Fractures in Tight Sandstone Reservoirs on Hydraulic Fracture Propagation Behavior and Post-Fracture Productivity" Processes 12, no. 12: 2813. https://doi.org/10.3390/pr12122813

APA StyleGu, T., Yu, X., Zhang, L., Su, X., Wu, Y., Jie, Y., Wang, H., & Zhou, D. (2024). A Study on the Influence of Natural Fractures in Tight Sandstone Reservoirs on Hydraulic Fracture Propagation Behavior and Post-Fracture Productivity. Processes, 12(12), 2813. https://doi.org/10.3390/pr12122813