Investigation of Coal Structure and Its Differential Pore–Fracture Response Mechanisms in the Changning Block

Abstract

:1. Introduction

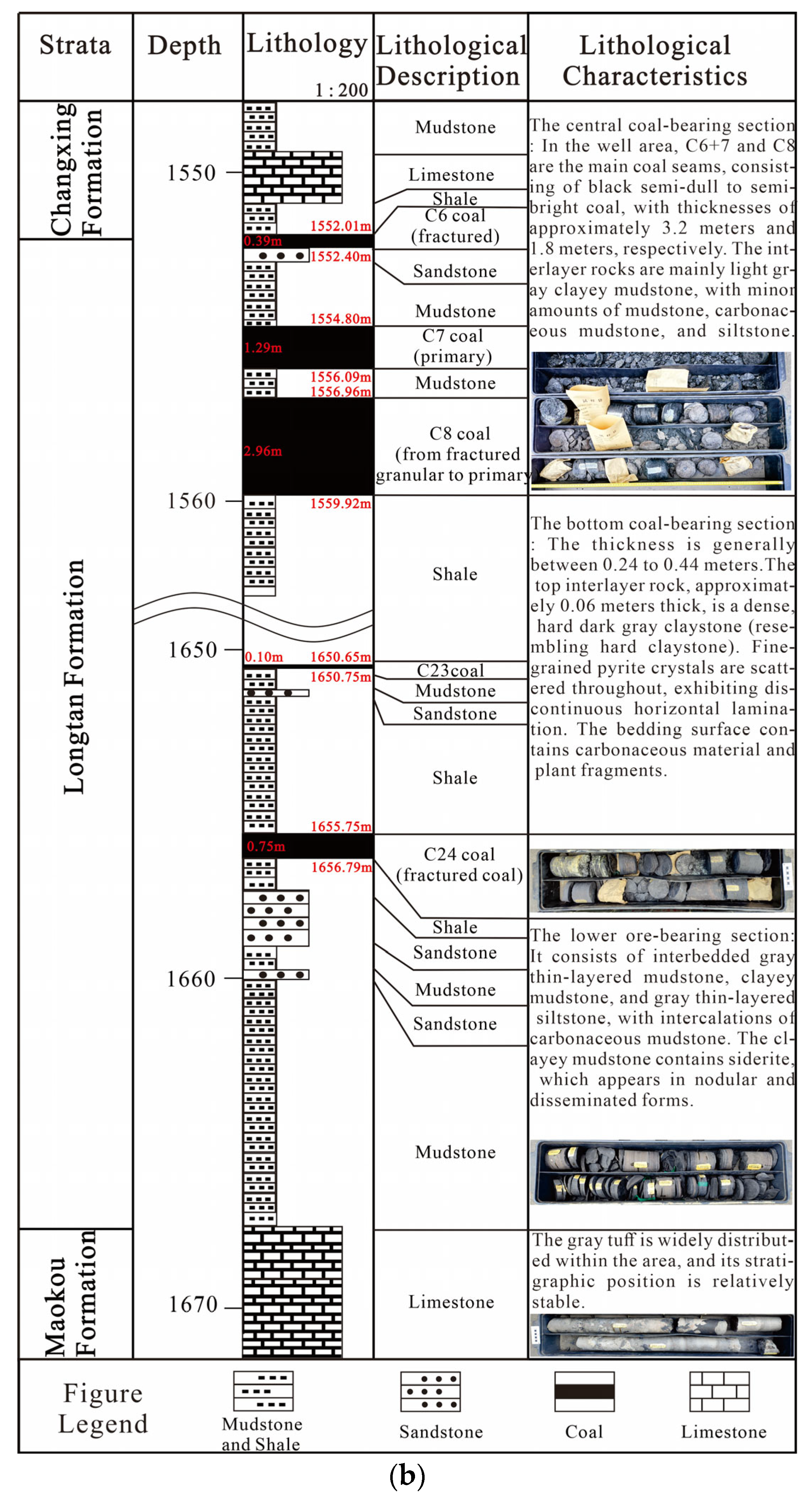

2. Geological Settings

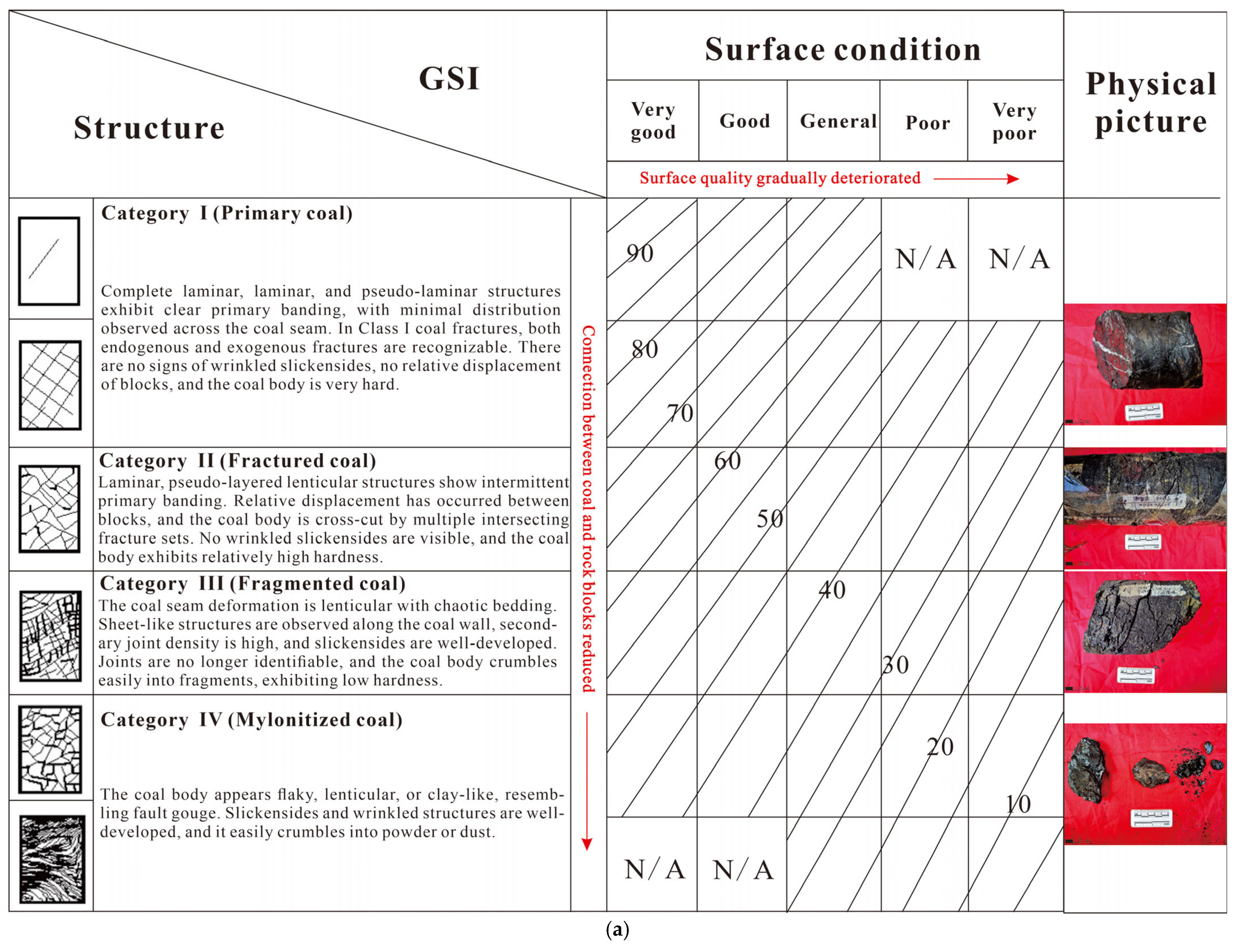

3. Characterization of Coal Structure

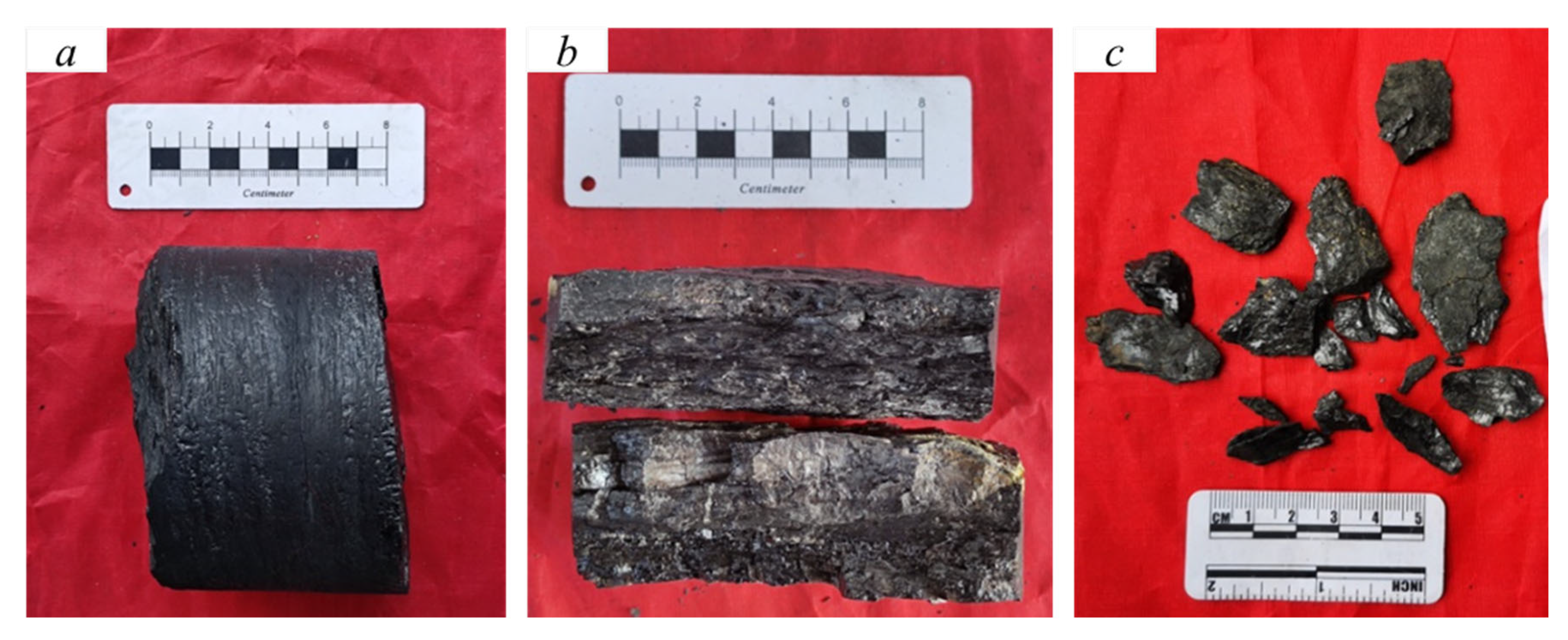

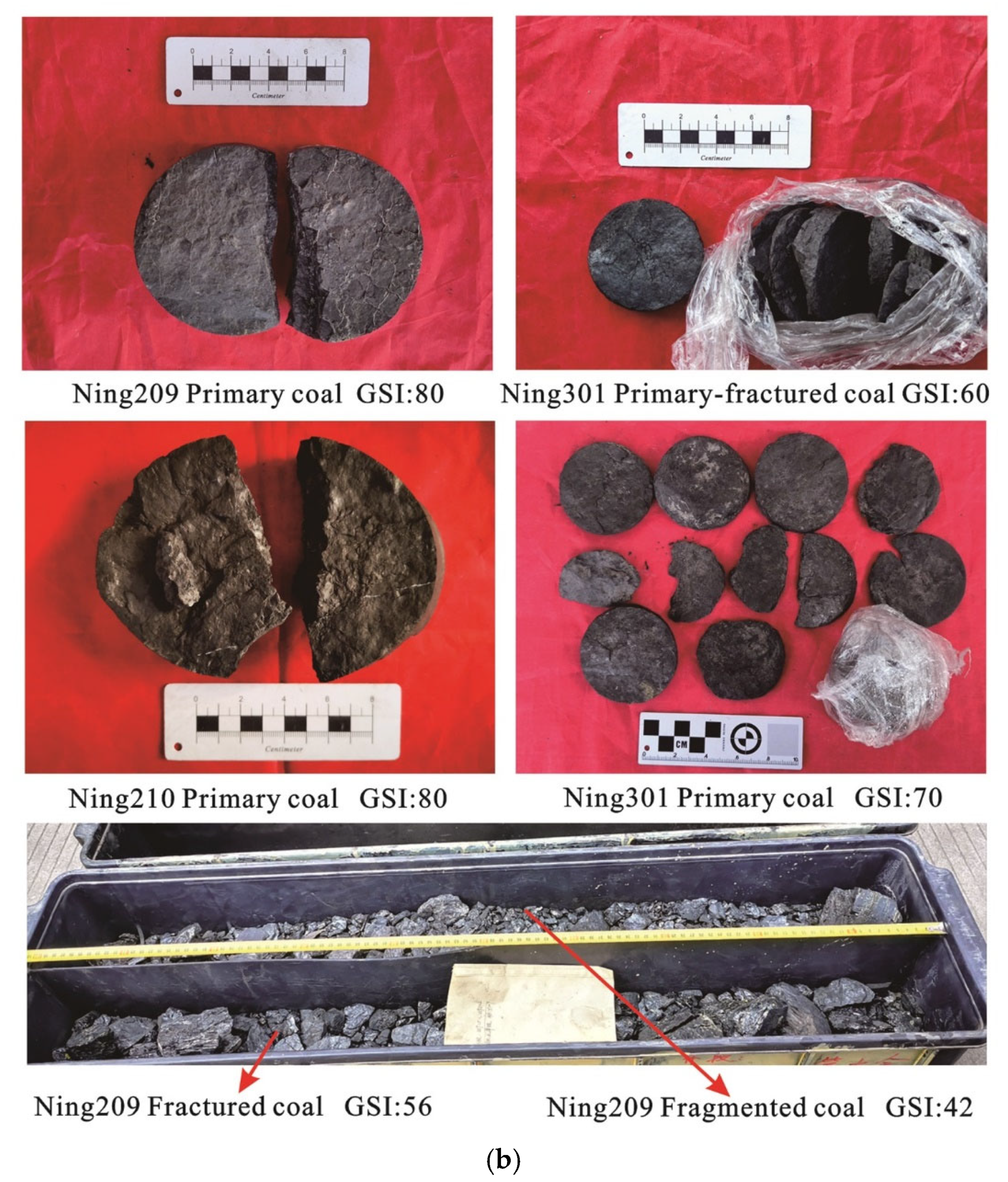

3.1. Structural Characteristics of Different Coal Bodies at a Macroscopic Scale

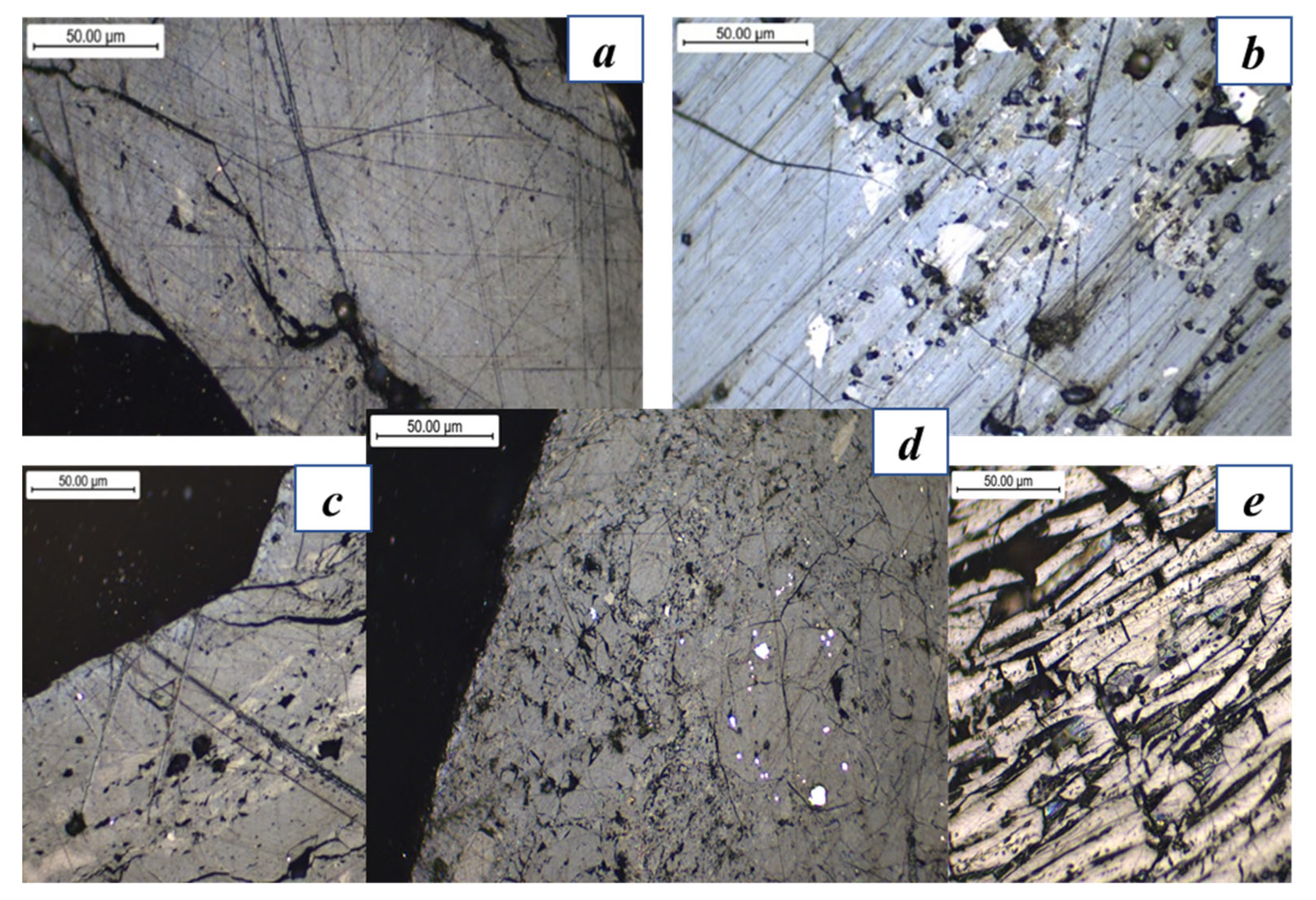

3.2. Fissure Characteristics of Coal with Different Coal Structures at a Microscopic Scale

3.2.1. Characteristics Under an Optical Microscope

3.2.2. Characteristics Under a Scanning Electron Microscope

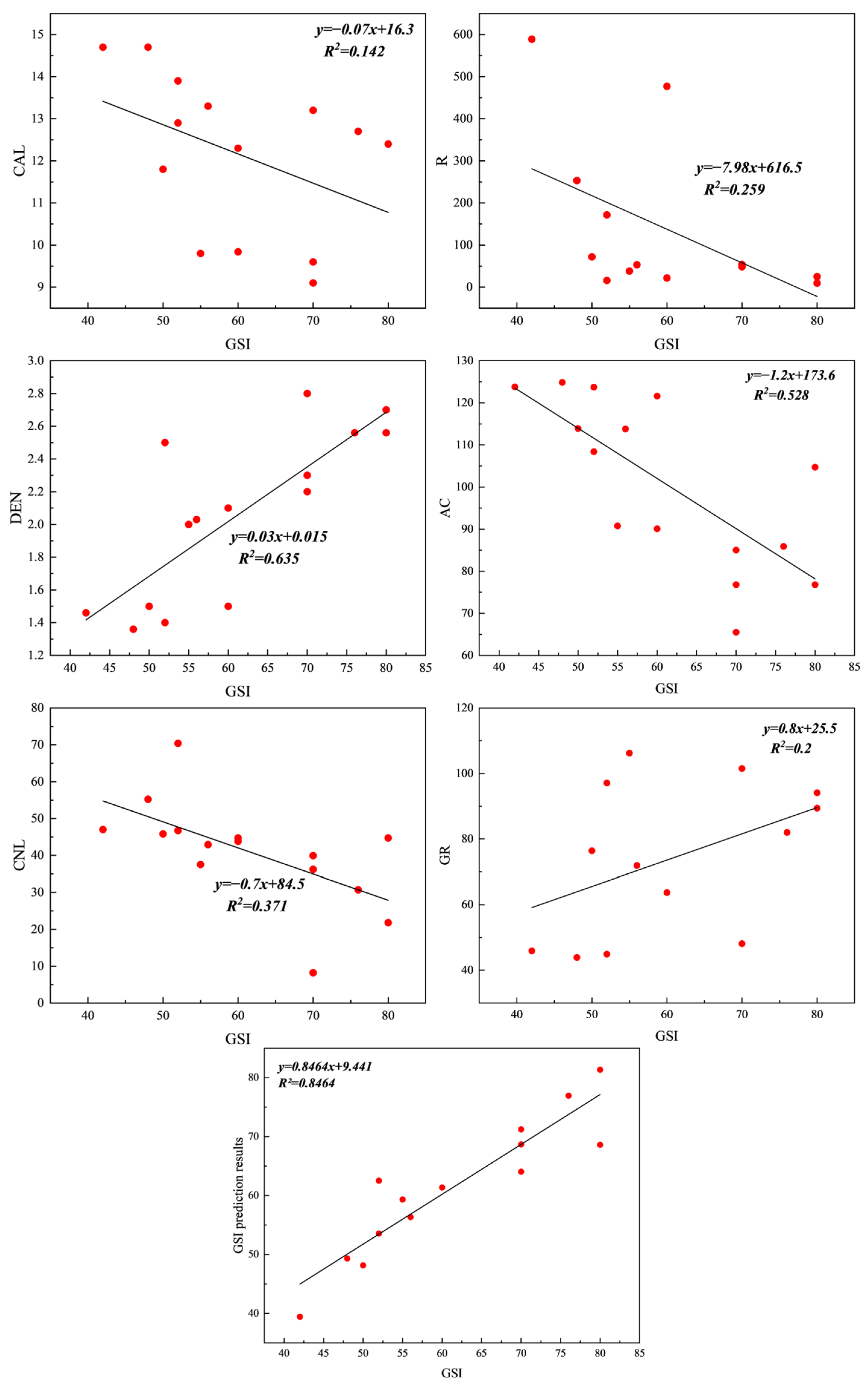

3.3. Logging Identification of Coal Structure

y = 81.908 − 0.026*R − 0.025*GR + 4.27*CAL + 0.291*CNL − 0.871*AC + 3.678*DEN

4. Pore Structure Characteristics of Coal Reservoirs with Different Coal Structures

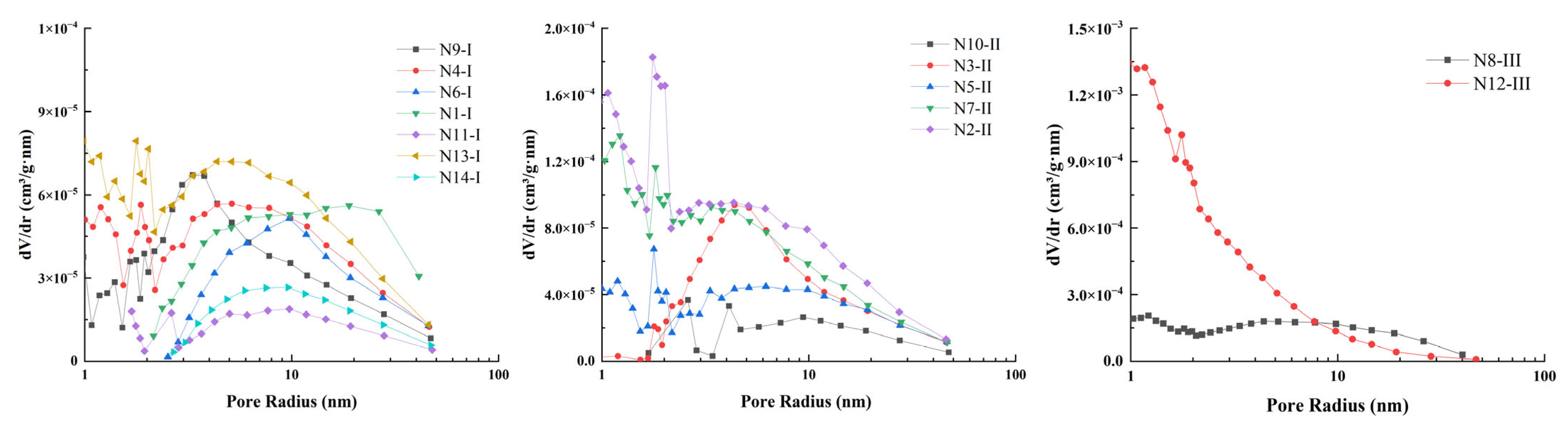

4.1. Adsorption Characteristics of Liquid Nitrogen

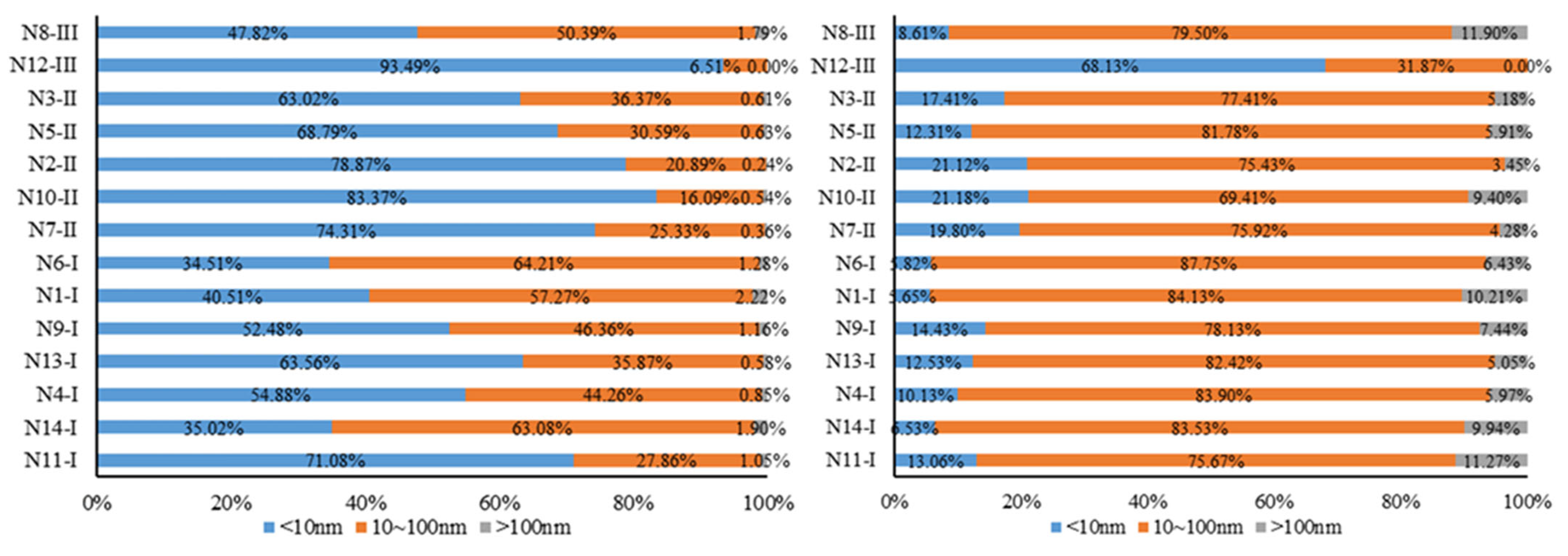

4.2. Pore Size/Specific Surface Area Distribution Characteristics

5. Conclusions

- (1)

- Observations of core samples at various scales indicate the development of Type I coal (primary coal), Type II coal (fractured coal and partially primary coal), and Type III coal (fragmented coal and partially mylonitized coal) in the study area. Under an optical microscope, fractures in Type I coal appear as linear, jagged, or zigzag patterned, forming network fractures when multiple cracks intersect. In contrast, Type II and Type III coal, subjected to stronger tectonic stress, exhibit increased and enlarged fractures, with rearranged particle alignment on both sides, leading to fractures. Scanning electron microscope observations reveal that Type I and II coal mainly develops primary pores, metamorphic pores, and mineral pores, while Type III coal primarily develops exogenous pores, which are less stable and irregular in shape.

- (2)

- Using correlation analysis, a multiple linear regression model was established between the Geological Strength Index (GSI) and logging curves, delineating identification intervals for different coal structures. The GSI for Type I coal ranges from 70 to 100, that for Type II coal from 45 to 70, and that for Type III coal from 0 to 45.

- (3)

- Experimental results indicate that the volume and specific surface area of coal rock samples are primarily dominated by micropores and small pores. As coal seam fragmentation increases, the total pore volume and specific surface area also increase. The nitrogen adsorption curves of deep coal reservoirs in the Longtan Formation of the Changning Block exhibit Type IV characteristics, with adsorption hysteresis loops combining features of Types H3 and H4. The pore systems mainly include plate-shaped, wedge-shaped, slit-shaped, and ink-bottle-shaped pores.

- (4)

- Based on the experimental results, it can be concluded that coal structure fragmentation generates more micropores, contributing to greater pore volume. Changes in coal structure alter the proportion of micropores, affecting the coal’s gas adsorption capacity. Pores with diameters around 1.3 nm have the largest specific surface area and highest gas adsorption capacity. Type III coal contains the most such pores, resulting in the highest gas adsorption. The adsorption–desorption curves also show that Type III coal has the greatest adsorption capacity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, N.; Wang, S.D.; Wu, J.Q.; Li, Z.; Wang, X.Y. Full-Scale Pore Structure Characterization and Its Impact on Methane Adsorption Capacity and Seepage Capability: Differences between Shallow and Deep Coal from the Tiefa Basin in Northeastern China. Fractal Fract. 2024, 8, 48. [Google Scholar] [CrossRef]

- Wang, X.; Chen, T.J.; Xu, H. Thickness distribution prediction for tectonically deformed coal with a deep belief network: A case study. Energies 2020, 13, 1169. [Google Scholar] [CrossRef]

- Zhang, B.B.; Li, J.; Shen, J.P.; Zhang, S.Y. Pore Structure and Methane Adsorption Characteristics of Primary Structural and Tectonic Coals. Chem. Technol. Fuels Oils 2024, 59, 1279–1289. [Google Scholar]

- Zhang, H.; Zhang, X.B.; Zhang, Y.G.; Wang, Z.Z. The characteristics of methane adsorption capacity and behavior of tectonic coal. Front. Earth Sci. 2023, 10, 1034341. [Google Scholar] [CrossRef]

- Yang, H.; Bi, W.Y.; Zhang, Y.G.; Yu, J.K.; Yan, J.W.; Lei, D.J.; Ma, Z.N. Effect of tectonic coal structure on methane adsorption. J. Environ. Chem. Eng. 2021, 9, 106294. [Google Scholar] [CrossRef]

- Pillalamarry, M.; Harpalani, S.; Liu, S.M. Gas diffusion behavior of coal and its impact on production from coalbed methane reservoirs. Int. J. Coal Geol. 2011, 86, 342–348. [Google Scholar] [CrossRef]

- Ju, Y.W.; Li, X.S. New research progress on the ultrastructure of tectonically deformed coals. Prog. Nat. Sci. 2009, 19, 1455–1466. [Google Scholar] [CrossRef]

- Liu, J.; Chang, S.L.; Zhang, S.; Li, Y.R.; Chen, Q. Integrated seismic–geological prediction of tectonic coal via main controlling factors. Acta Geophys. 2022, 70, 173–190. [Google Scholar] [CrossRef]

- Shi, J.X.; Zhao, X.Y.; Zeng, L.B.; Zhang, Y.Z.; Dong, S.Q. Identification of coal structures by semi-supervised learning based on limited labeled logging data. Fuel 2023, 337, 127191. [Google Scholar] [CrossRef]

- Tong, Z.Z.; Meng, Y.J.; Zhang, J.C.; Wu, Y.N.; Li, Z.; Wang, D.S.; Li, X.Q.; Ou, G.X. Coal structure identification based on geophysical logging data: Insights from Wavelet Transform (WT) and Particle Swarm Optimization Support Vector Machine (PSO-SVM) algorithms. Int. J. Coal Geol. 2024, 282, 104435. [Google Scholar] [CrossRef]

- Cui, X.P.; Tang, Y.C.; Huang, H.D.; Wang, L.Q.; Wang, J.X.; Guo, Z.F.; Ma, C.; Sun, M. Coal structure prediction based on type-2 fuzzy inference system for multi-attribute fusion: A case study in South Hengling Block, Qinshui Basin, China. Minerals 2023, 13, 589. [Google Scholar] [CrossRef]

- Wang, K.; Guo, L.; Xu, C.; Wang, W.J.; Yang, T.; Lin, S.S.; Cai, Y.B. Multiscale characteristics of pore-fracture structures in coal reservoirs and their influence on coalbed methane (CBM) transport: A review. Geoenergy Sci. Eng. 2024, 242, 213181. [Google Scholar] [CrossRef]

- Hou, S.H.; Wang, X.M.; Wang, X.J.; Yuan, Y.D.; Pan, S.D.; Wang, X.M. Pore structure characterization of low volatile bituminous coals with different particle size and tectonic deformation using low pressure gas adsorption. Int. J. Coal Geol. 2017, 183, 1–13. [Google Scholar] [CrossRef]

- Li, F.L.; Jiang, B.; Song, Y.; Cheng, G.X.; Lu, G.W. Multifractal behavior of the micro- and mesopore structures of brittle tectonically deformed coals and its influence on methane adsorption capacity. Energy Fuels 2021, 35, 3042–3064. [Google Scholar] [CrossRef]

- Cheng, Y.P.; Lei, Y. Causality between tectonic coal and coal and gas outbursts. J. China Coal Soc. 2021, 46, 180–198. (In Chinese) [Google Scholar]

- Li, C.L.; Yang, Z.B.; Sun, H.S.; Ma, Y.Y.; Zhang, Z.G.; Li, Y.Y.; Li, G. Construction of a logging interpretation model for coal structure from multi-coal seams area. J. China Coal Soc. 2020, 45, 721–730. (In Chinese) [Google Scholar]

- Wang, T.; Deng, Z.; Hu, H.Y.; Wang, H.Y.; Jiang, Z.X.; Wang, D.X. Study on the pore structure and multifractal characteristics of medium- and high-rank coals based on the gas adsorption method: A case study of the Benxi Formation in the eastern margin of the Ordos Basin. Energy Fuels 2024, 38, 4102–4121. [Google Scholar] [CrossRef]

- Fang, J.C.; Li, Q.; Yin, T.T.; Cai, Y.D. Investigation on the nanopore heterogeneity in coals and its influence on methane adsorption: A multifractal theory study. ACS Omega 2024, 9, 19504–19516. [Google Scholar] [CrossRef]

- Cheng, G.X.; Jiang, B.; Li, M.; Liu, J.G.; Li, F.L. Effects of pore structure on methane adsorption behavior of ductile tectonically deformed coals: An inspiration to coalbed methane exploitation in structurally complex areas. J. Nat. Gas Sci. Eng. 2020, 74, 103083. [Google Scholar] [CrossRef]

- Zhang, J.J.; Wei, C.T.; Chu, X.X.; Vandeginste, V.; Ju, W. Multifractal analysis in characterizing adsorption pore heterogeneity of middle- and high-rank coal reservoirs. ACS Omega 2020, 5, 19385–19401. [Google Scholar] [CrossRef]

- Li, Y.B.; Song, D.Y.; Liu, S.M.; Pan, J.M. Characterization of ultramicropores and analysis of their evolution in tectonically deformed coals by low-pressure CO₂ adsorption, XRD, and HRTEM techniques. Energy Fuels 2020, 34, 9436–9449. [Google Scholar] [CrossRef]

- Khormali, A.; Ahmadi, S.; Kazemzadeh, Y. Inhibition of barium sulfate precipitation during water injection into oil reservoirs using various scale inhibitors. Arab. J. Sci. Eng. 2023, 48, 9383–9399. [Google Scholar] [CrossRef]

- Liu, S.G.; Yang, Y.; Deng, B.; Zhong, Y.; Wen, L.; Sun, W.; Li, Z.W.; Jansa, L.; Li, J.X.; Song, J.M.; et al. Tectonic evolution of the Sichuan basin, southwest China. Earth-Sci. Rev. 2021, 213, 103470. [Google Scholar] [CrossRef]

- Luo, Q.Y.; Xiao, Z.H.; Dong, C.Y.; Ye, X.Z.; Li, H.J.; Zhang, Y.; Ma, Y.; Ma, L.; Xu, Y.H. The geochemical characteristics and gas potential of the Longtan formation in the eastern Sichuan Basin, China. J. Pet. Sci. Eng. 2019, 179, 1102–1113. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Zuo, Y.H.; Yang, M.H.; Huang, W.M.; Xu, L.; Zheng, Z.Y.; Zeng, J.C. Hydrocarbon generation and expulsion histories of the Upper Permian Longtan Formation in the Eastern Sichuan Basin, Southwest China. ACS Omega 2023, 8, 19329–19340. [Google Scholar] [CrossRef] [PubMed]

- Cheng, G.X.; Jiang, B.; Li, M.; Zhu, M. Structural evolution of southern Sichuan Basin (South China) and its control effects on tectonic fracture distribution in Longmaxi shale. J. Struct. Geol. 2021, 153, 104465. [Google Scholar] [CrossRef]

- GB/T 30050-2013; Classification of Coal Structure. China Standard Press: Beijing, China, 2013.

- Feng, C.; Li, X.J.; Xu, E.Y.; Sui, H.; Xue, F.; Xie, H.G. Microstructure characteristics of tectonic coal and primary coal: A case study of Guizhou, China. Nat. Resour. Res. 2023, 32, 2901–2926. [Google Scholar] [CrossRef]

- Rai, S.; Rai, A.; Kumar, K.; Naik, A.S.; Singh, N.S.; Srivastava, D.K.; Singh, P.K. Study of micro-structures and their relation with occurrence of mineral matter in Ramagundam Coals, Godavari Basin, India: Implications on coal and hydrocarbon industries. J. Geol. Soc. India 2022, 98, 88–92. [Google Scholar] [CrossRef]

- Li, Y.; Yang, J.H.; Pan, Z.J.; Tong, W.S. Nanoscale pore structure and mechanical property analysis of coal: An insight combining AFM and SEM images. Fuel 2020, 260, 116352. [Google Scholar] [CrossRef]

- SY/T5162-2021; Scanning Electron Microscope Analysis Method of Rock Samples. National Energy Administration: Beijing, China, 2021.

- Zhang, K.; Meng, Z.P.; Jin, Y.; Wang, B.Y. Fractal characteristics of pore structures on different coal structures and its research significance. Coal Sci. Technol. 2023, 51, 198–206. [Google Scholar]

- Guo, H.J.; Yu, Y.J.; Wang, K.; Yang, Z.; Wang, L.; Xu, C. Kinetic characteristics of desorption and diffusion in raw coal and tectonic coal and their influence on coal and gas outburst. Fuel 2023, 343, 127883. [Google Scholar] [CrossRef]

- Li, F.L.; Jiang, B.; Cheng, G.X.; Song, Y.; Tang, Z. Structural and evolutionary characteristics of pores-microfractures and their influence on coalbed methane exploitation in high-rank brittle tectonically deformed coals of the Yangquan mining area, northeastern Qinshui Basin, China. J. Pet. Sci. Eng. 2019, 174, 1290–1302. [Google Scholar]

- Xu, X.K.; Meng, Z.P.; Wang, Y. Experimental comparisons of multiscale pore structures between primary and disturbed coals and their effects on adsorption and seepage of coalbed methane. J. Pet. Sci. Eng. 2019, 174, 704–715. [Google Scholar] [CrossRef]

- Wang, P.; Su, X.B.; Han, Y.; Fan, C.; Zhang, Y.Z. Quantitative characterization of coal structure and its significance. Coal Mine Saf. 2014, 45, 12–15. (In Chinese) [Google Scholar]

- Guo, J.; Chen, C.M.; Cai, G.B.; Wen, H.; Li, S. Exploring acoustic wave propagation and equivalent path in quasi-porous medium of loose coal mass. Nat. Resour. Res. 2024, 33, 389–403. [Google Scholar] [CrossRef]

- Liu, D.M.; Qiu, F.; Liu, N.; Cai, Y.D.; Guo, Y.L.; Zhao, B.; Qiu, Y.K. Pore structure characterization and its significance for gas adsorption in coals: A comprehensive review. Unconv. Resour. 2022, 2, 139–157. [Google Scholar] [CrossRef]

- Wei, Q.; Li, X.Q.; Hu, B.L.; Zhang, X.Q.; Zhang, J.Z.; He, Y.K.; Zhang, Y.C.; Zhu, W.W. Reservoir characteristics and coalbed methane resource evaluation of deep-buried coals: A case study of the No. 13–1 coal seam from the Panji Deep Area in Huainan Coalfield, Southern North China. J. Pet. Sci. Eng. 2019, 179, 867–884. [Google Scholar] [CrossRef]

- Pan, Z.J.; Wood, D.A. Coalbed methane (CBM) exploration, reservoir characterisation, production, and modelling: A collection of published research (2009–2015). J. Nat. Gas Sci. Eng. 2015, 26, 1472–1484. [Google Scholar] [CrossRef]

- GB/T 21650.2-2008; Determination of Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 2: Analysis of Mesopores and Macropores by Gas Adsorption. China Standard Press: Beijing, China, 2008.

- Song, Y.; Jiang, B.; Liu, J.G. Nanopore structural characteristics and their impact on methane adsorption and diffusion in low to medium tectonically deformed coals: Case study in the Huaibei coal field. Energy Fuels 2017, 31, 6711–6723. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Zhao, S.; Chen, X.; Zhang, J.; Li, B.; Ding, J.; Zhu, N.; Fang, R.; Zhang, H.; Yang, X.; et al. Investigation of Coal Structure and Its Differential Pore–Fracture Response Mechanisms in the Changning Block. Processes 2024, 12, 2784. https://doi.org/10.3390/pr12122784

Yang X, Zhao S, Chen X, Zhang J, Li B, Ding J, Zhu N, Fang R, Zhang H, Yang X, et al. Investigation of Coal Structure and Its Differential Pore–Fracture Response Mechanisms in the Changning Block. Processes. 2024; 12(12):2784. https://doi.org/10.3390/pr12122784

Chicago/Turabian StyleYang, Xuefeng, Shengxian Zhao, Xin Chen, Jian Zhang, Bo Li, Jieming Ding, Ning Zhu, Rui Fang, Hairuo Zhang, Xinyu Yang, and et al. 2024. "Investigation of Coal Structure and Its Differential Pore–Fracture Response Mechanisms in the Changning Block" Processes 12, no. 12: 2784. https://doi.org/10.3390/pr12122784

APA StyleYang, X., Zhao, S., Chen, X., Zhang, J., Li, B., Ding, J., Zhu, N., Fang, R., Zhang, H., Yang, X., & Wang, Z. (2024). Investigation of Coal Structure and Its Differential Pore–Fracture Response Mechanisms in the Changning Block. Processes, 12(12), 2784. https://doi.org/10.3390/pr12122784