Multiscale Qualitative–Quantitative Characterization of the Pore Structure in Coal-Bearing Reservoirs of the Yan’an Formation in the Longdong Area, Ordos Basin

Abstract

1. Introduction

2. Sample Collection and Methods

2.1. Sample Collection

2.2. Experimental Methods

3. Results

3.1. Sample Basic Parameters

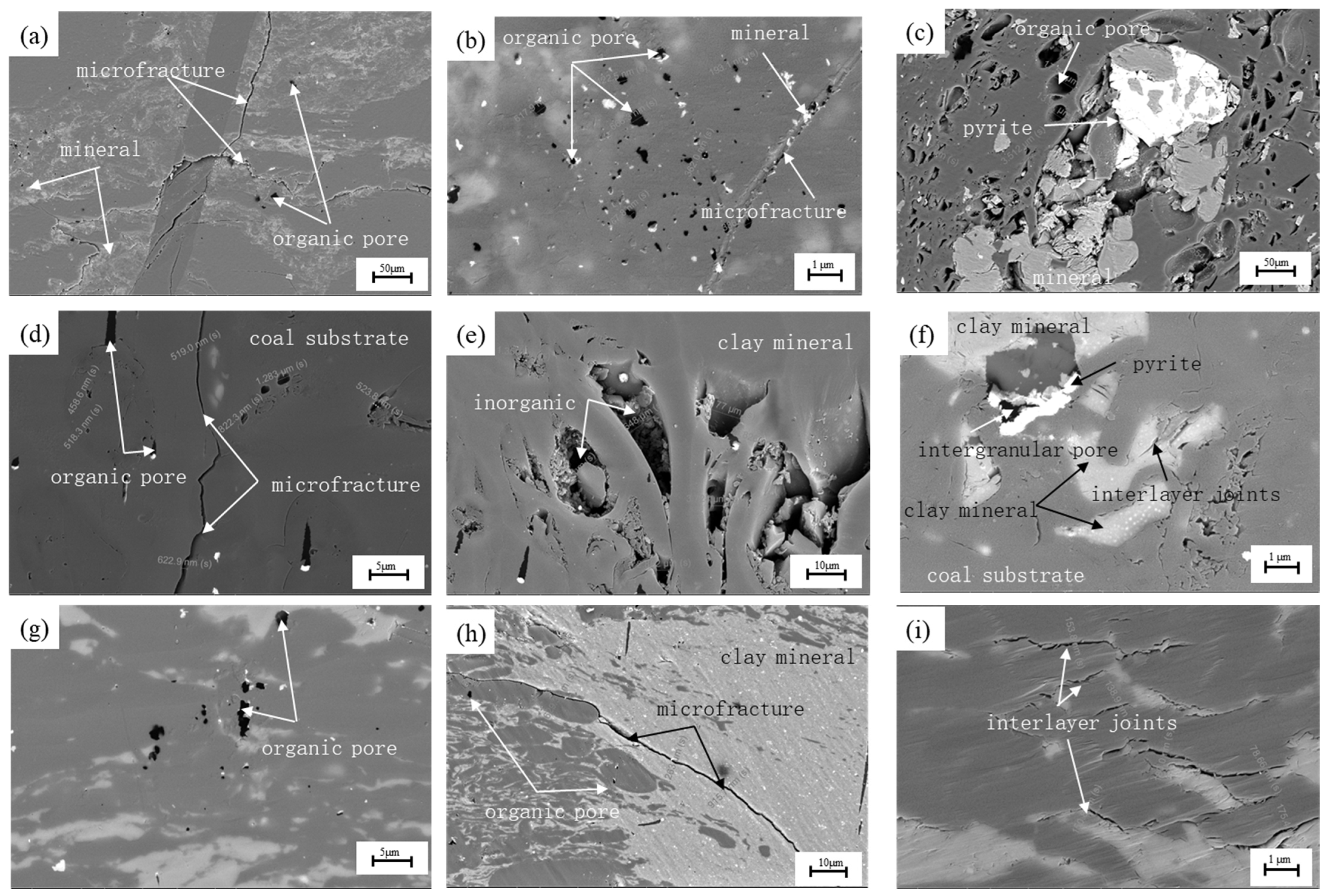

3.2. Qualitative–Semiquantitative Observation of the Pore Morphology

3.3. Quantitative Characterization of Pores

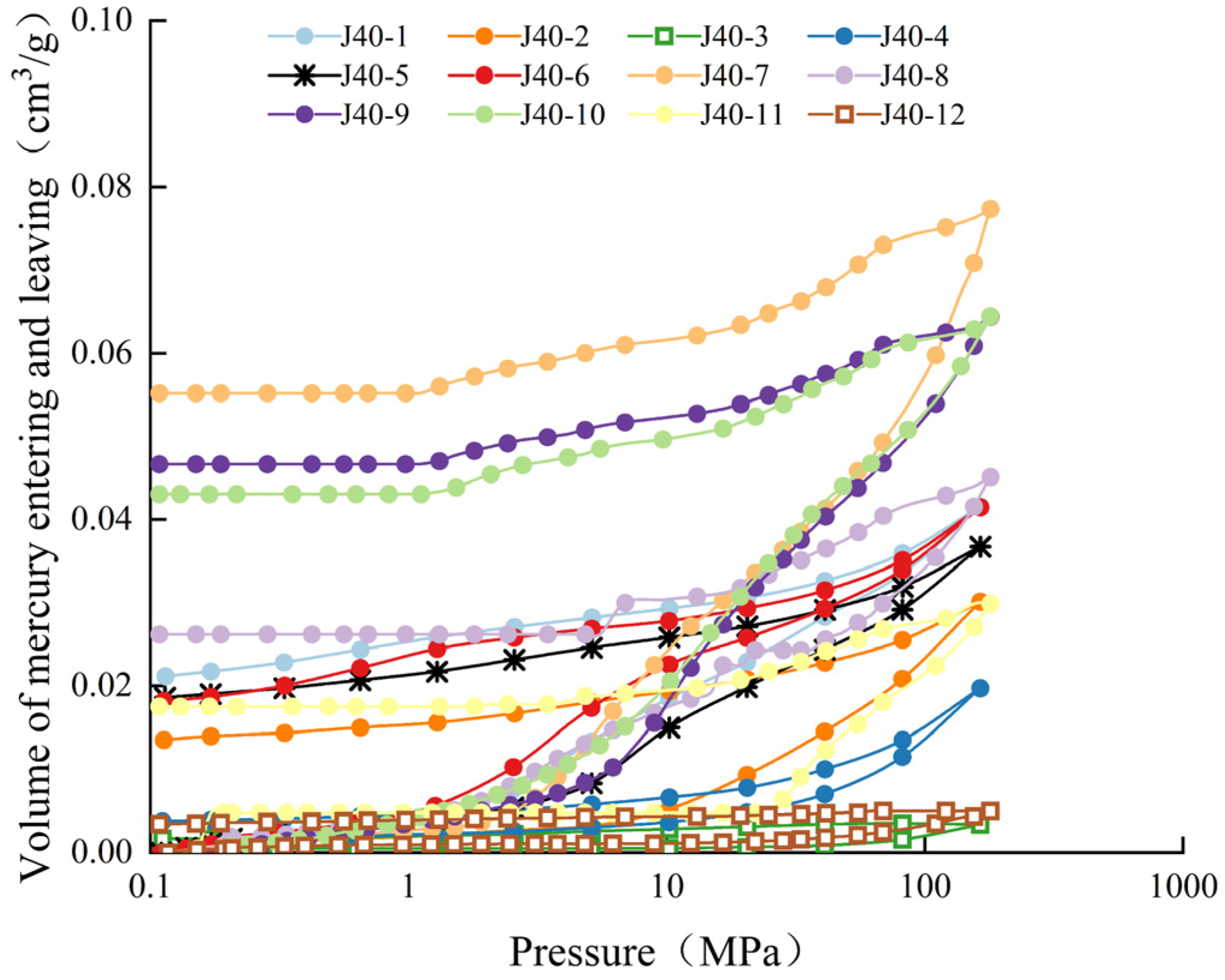

3.3.1. HPMP Experiments

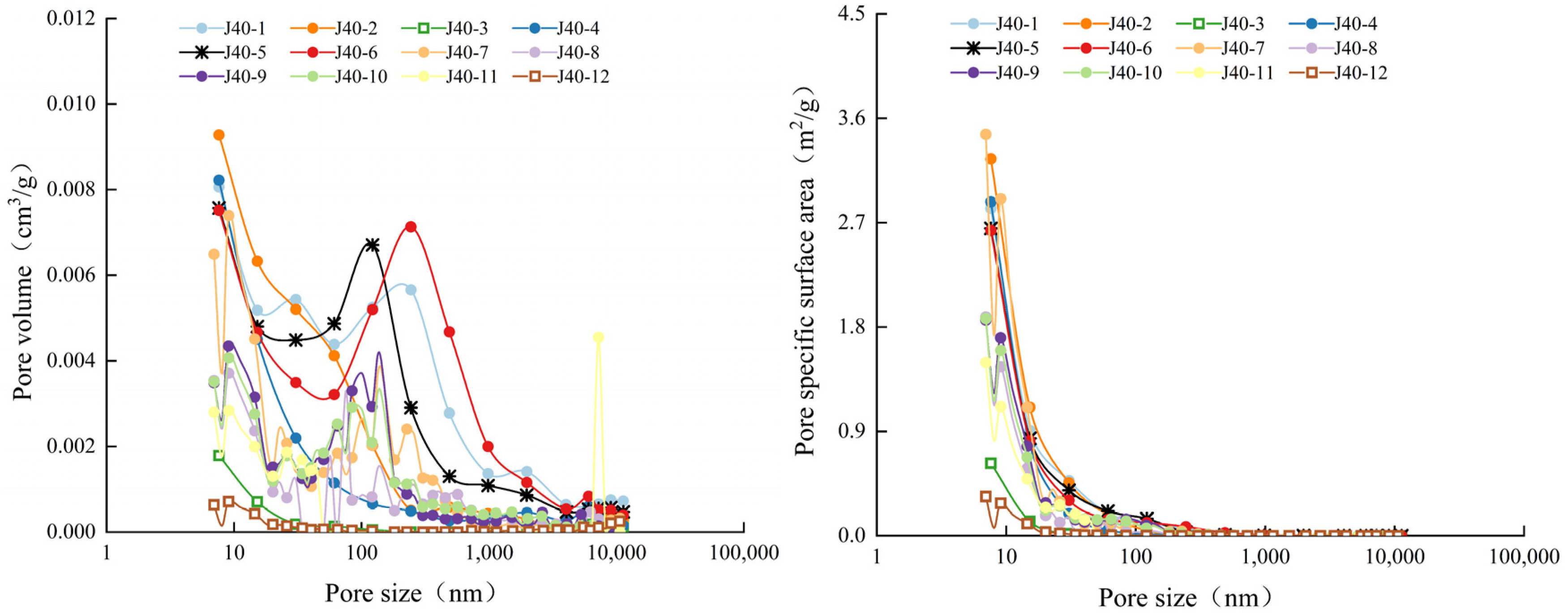

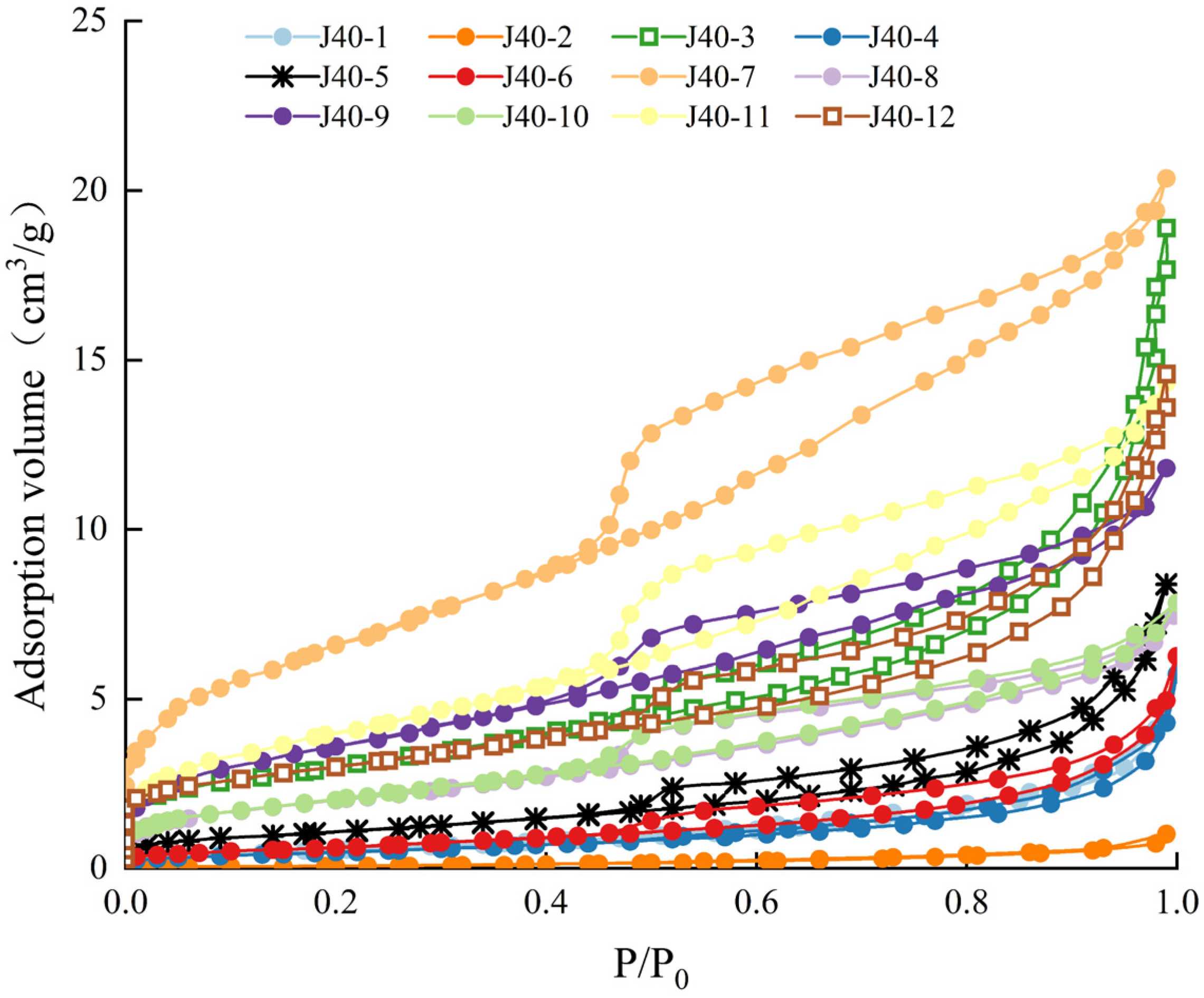

3.3.2. Low-Temperature N2 Adsorption Experiments

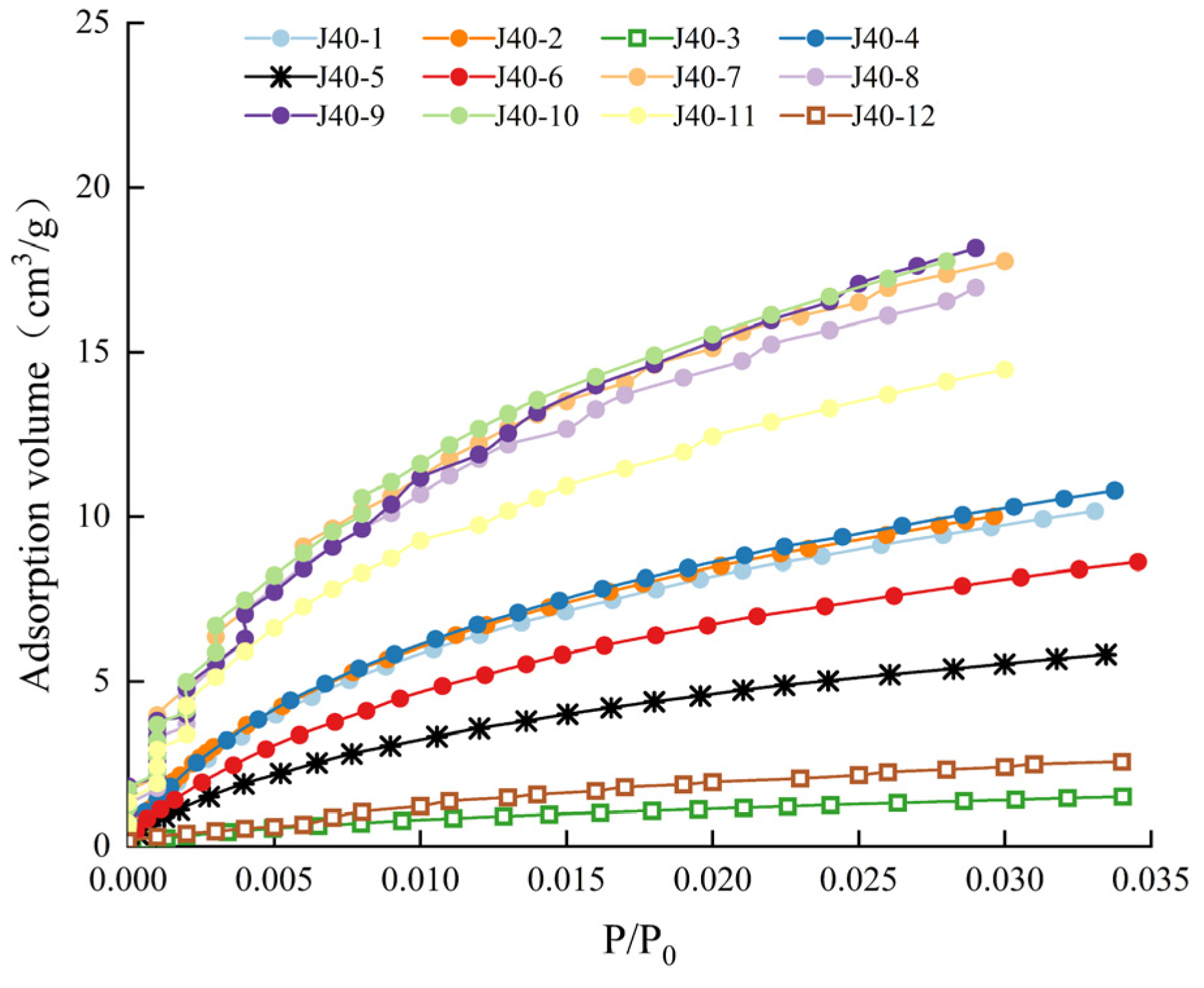

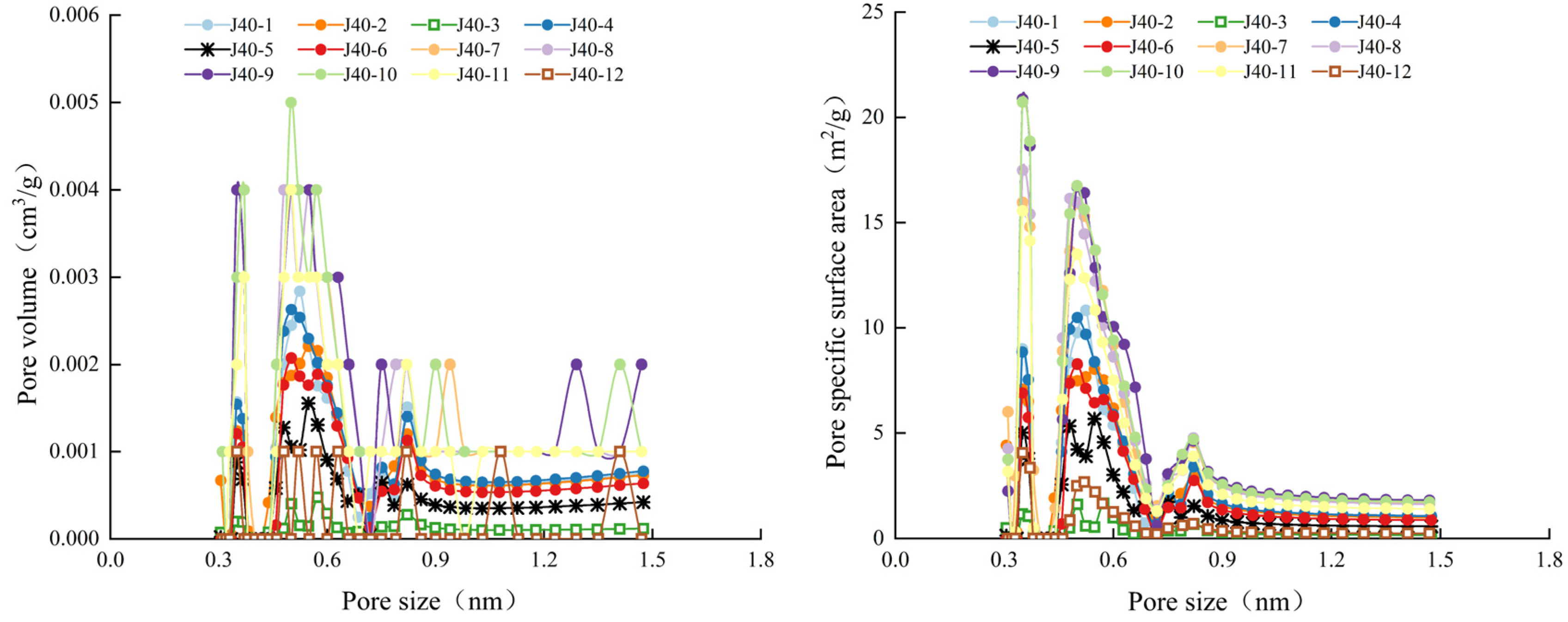

3.3.3. Low-Pressure CO2 Adsorption Experiments

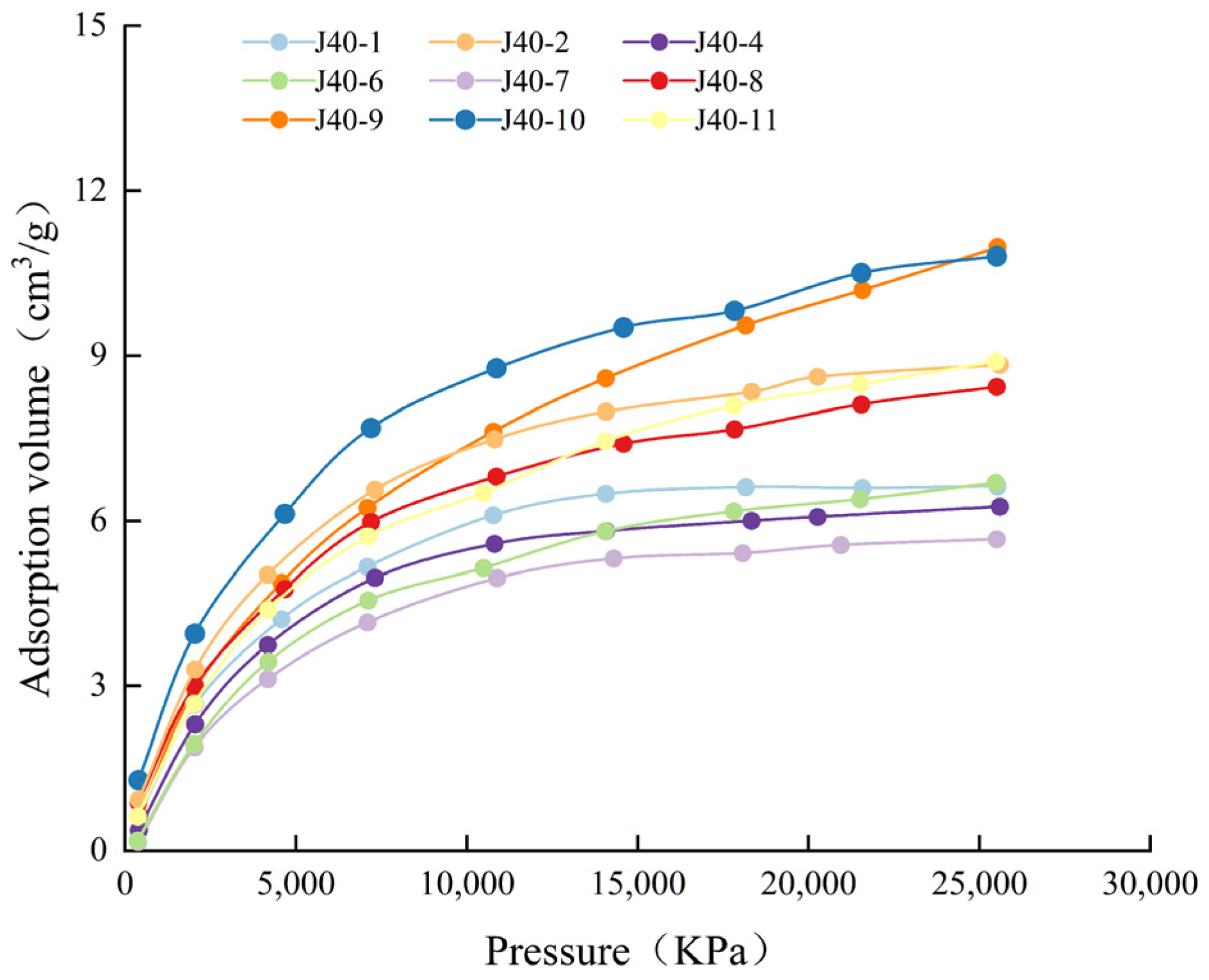

3.4. High-Pressure Methane Isothermal Adsorption Experiments

4. Discussions

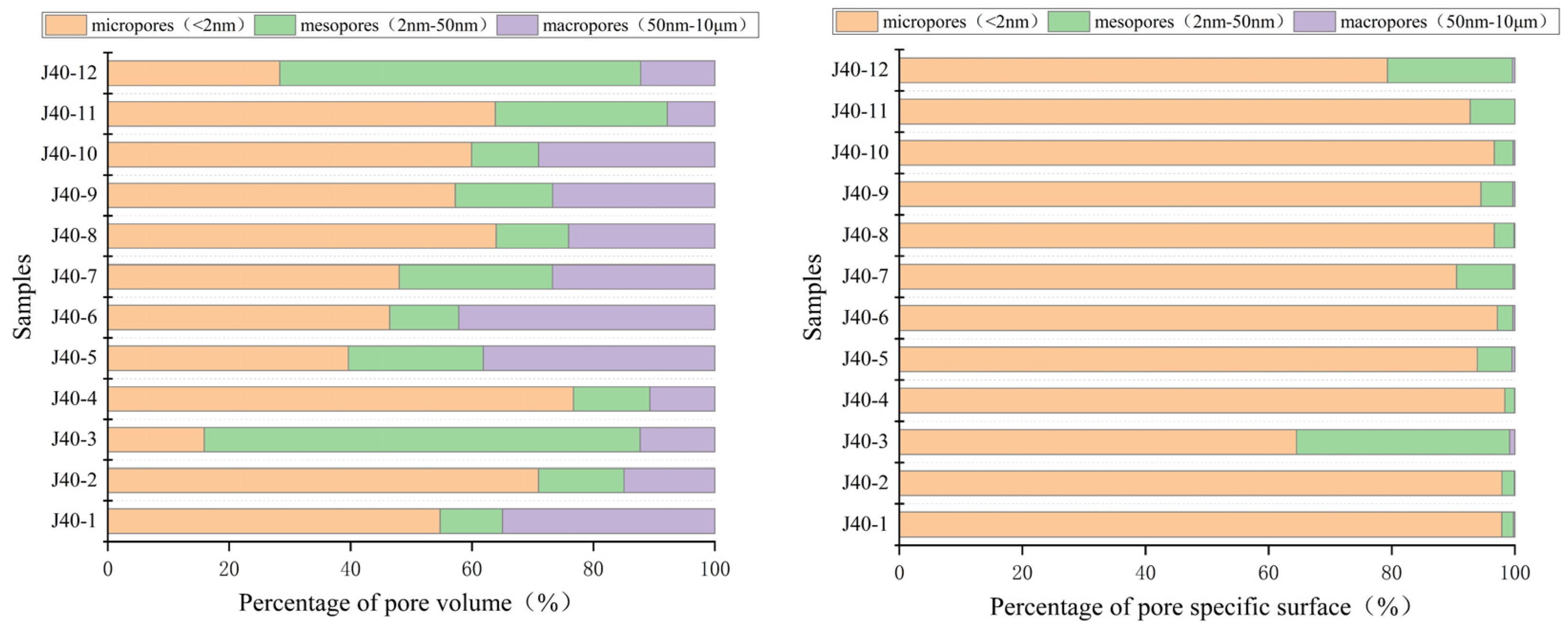

4.1. Full-Scale Pore Structure Characterization

4.2. Factors Influencing Pore Structure Development

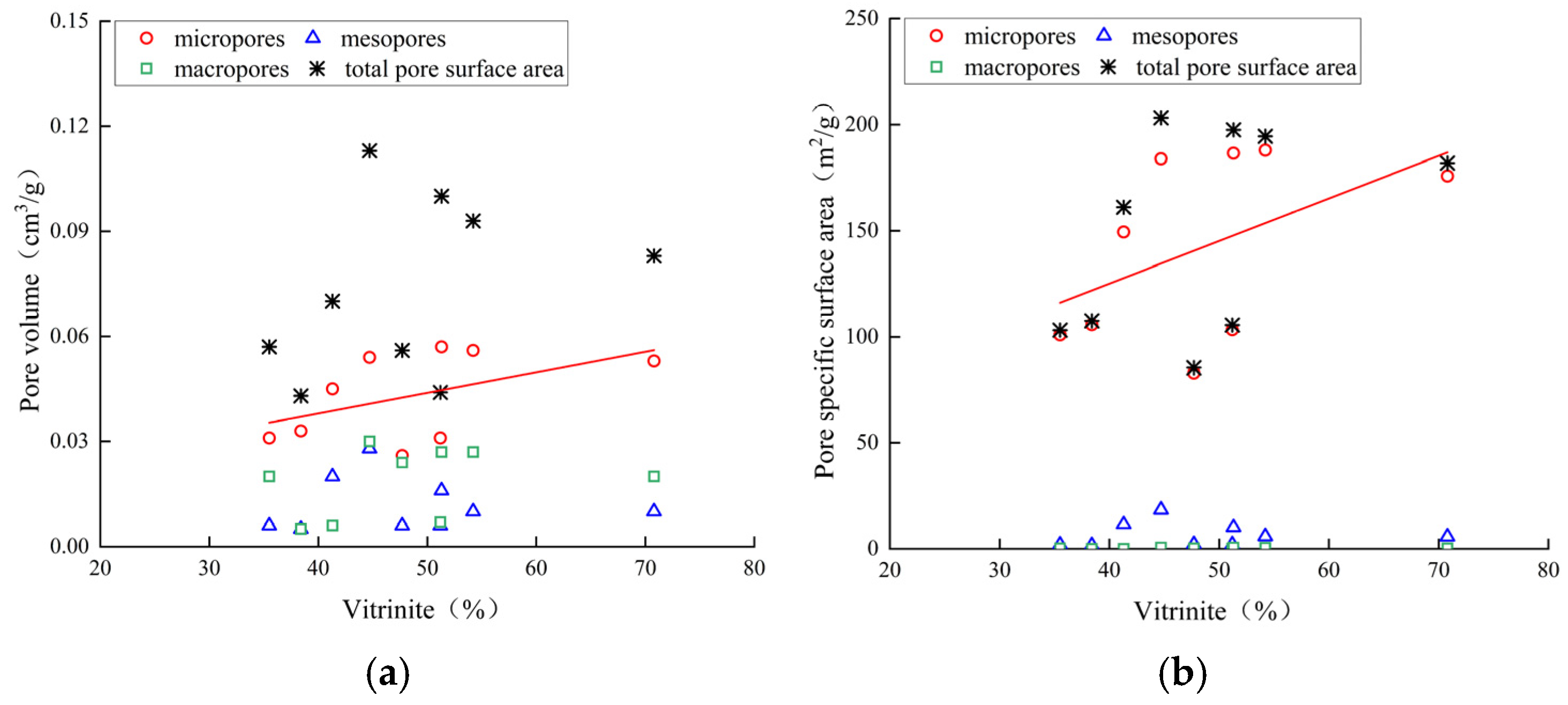

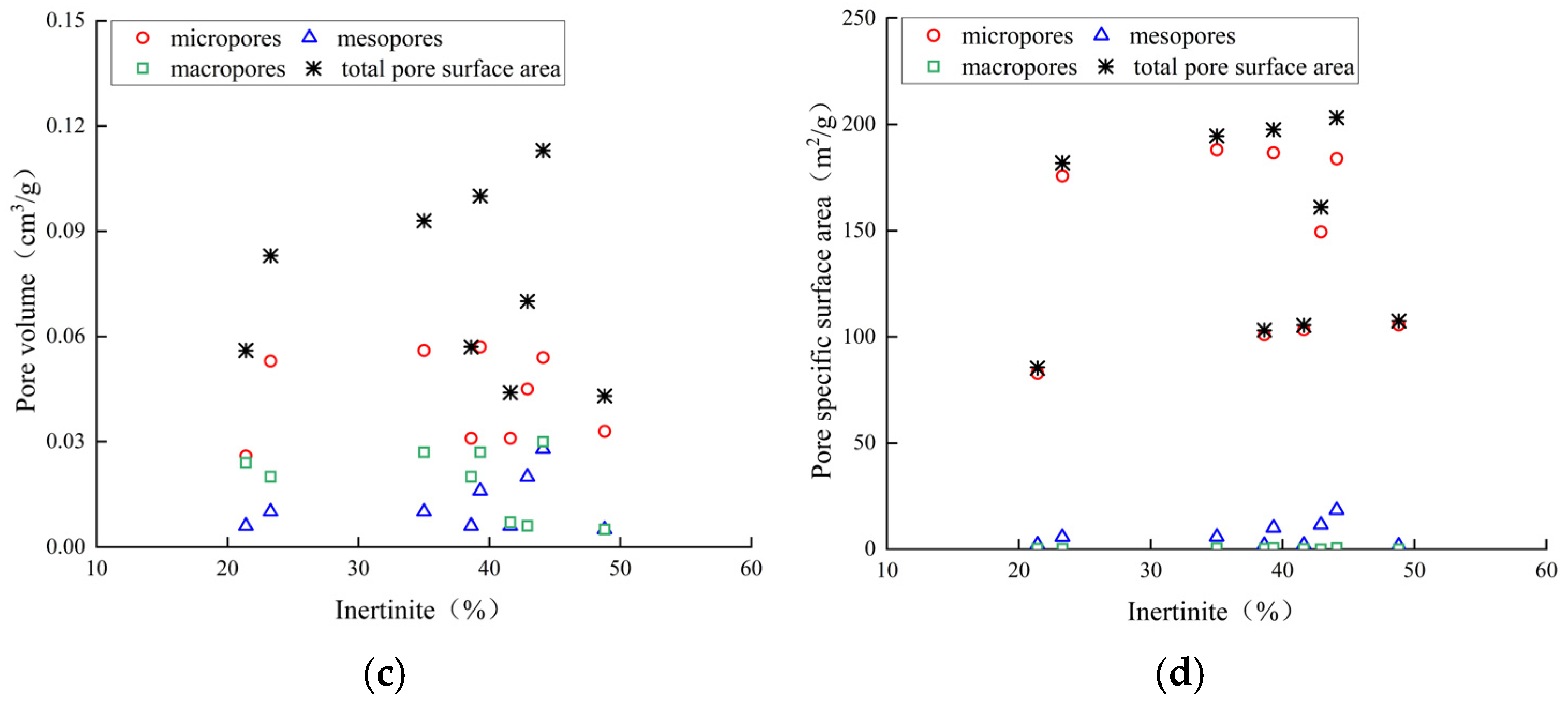

4.2.1. Effects of Maceral Composition on the Pore Structure

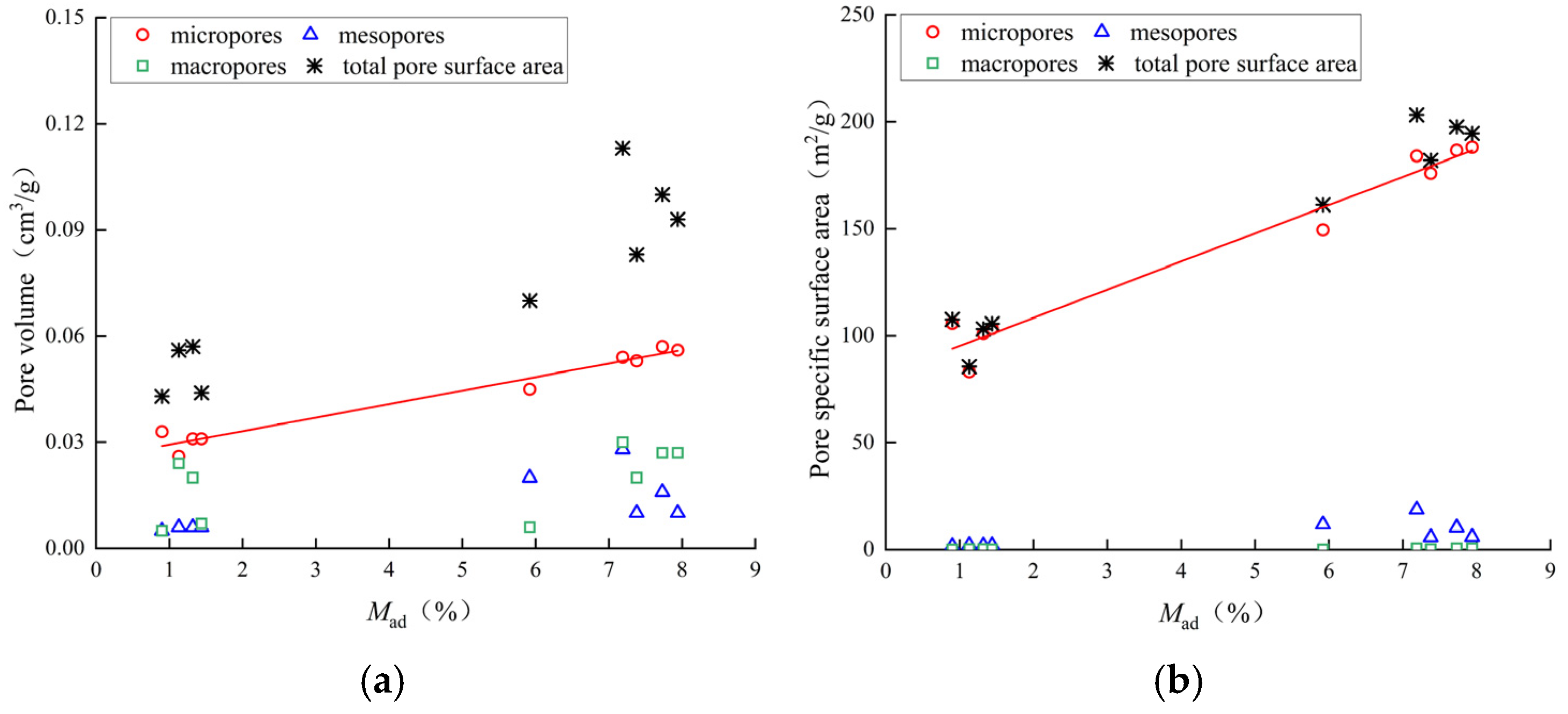

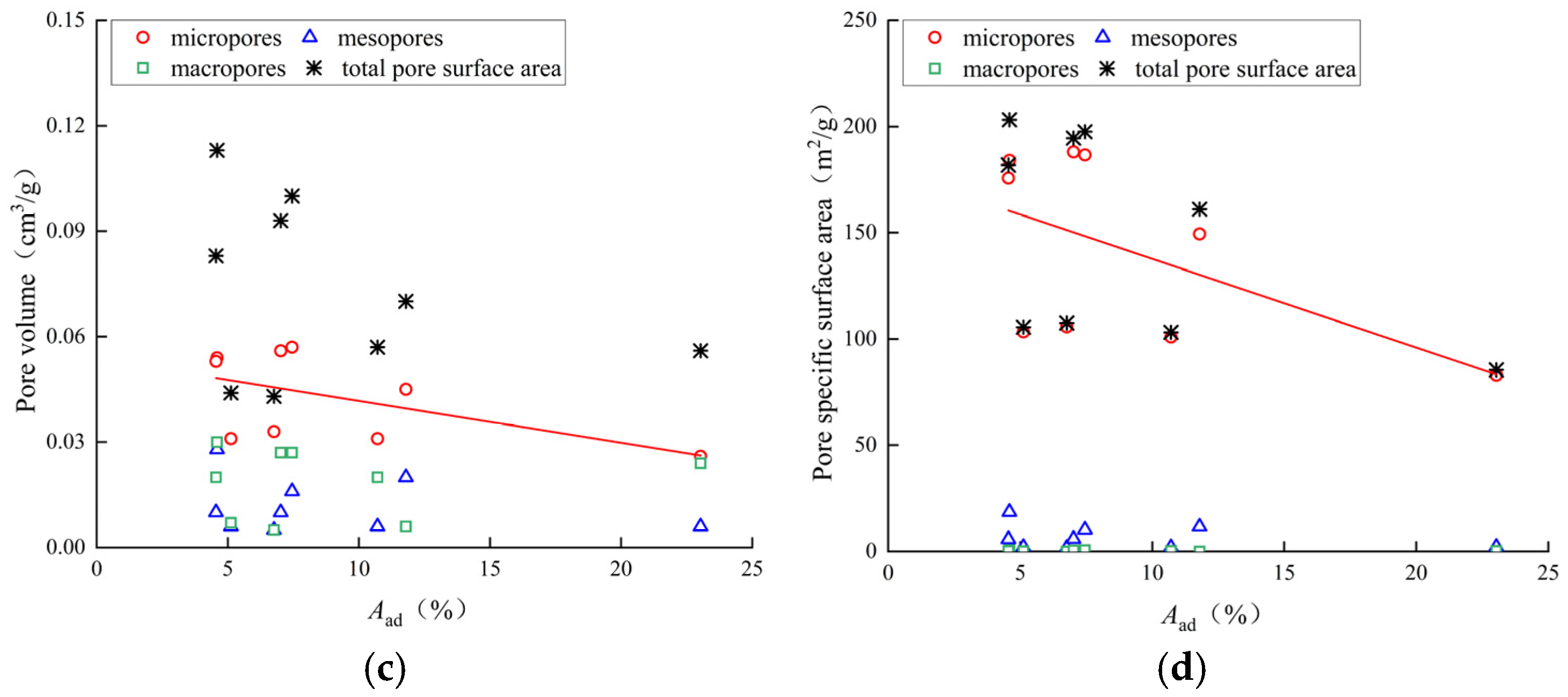

4.2.2. Effects of Moisture and Ash on the Coal Pore Structure

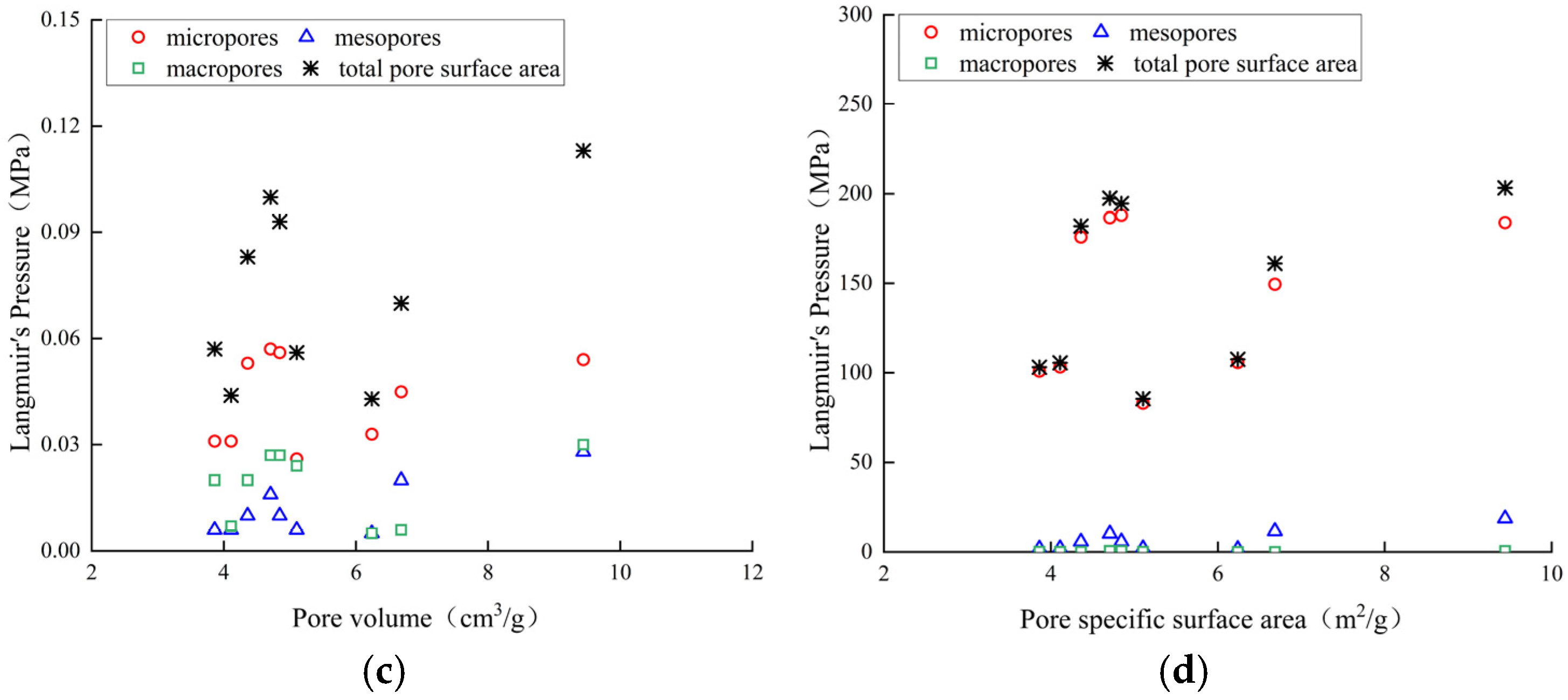

4.3. Influence of the Development of Different Pores in Coal Rock on the Gas Content

5. Conclusions

- (1)

- In the samples from the coal system of the Yan’an Formation in the Longdong area, Ordos Basin, the development of organic pores and clay mineral pores was remarkable, and microfractures and clay mineral interlayer joints could be clearly observed. The organic pore development of coal rock was obviously better than that of mudstone. The abundant organic pore development in coal rock provides a good carrier for the occurrence of coalbed gas.

- (2)

- The pore size distribution of the sample showed a multi-modal state, the contribution of micropores was significant in the coal rocks, although micropores dominated, but macropores also existed, in the carbonaceous mudstones, and the mudstones were dominated by mesopores. In terms of the specific surface area, micropores contributed the most, especially in the coal rocks and the carbonaceous mudstones, and the contributions of the mesopores and macropores were negligible.

- (3)

- An increase in the vitrinite content favored the development of micropores, while an increase in Mad promoted the development of adsorption pores, resulting in increases in the microporous volume and specific surface area. The pore volume and specific surface area were negatively correlated with the ash yield, indicating that an increase in the ash yield leads to a decrease in the pore volume and specific surface area.

- (4)

- The specific surface areas of pores in coal affected the gas content primarily by influencing the amount of adsorbed gas. The specific surface areas of pores significantly impacted the storage capacity of adsorbed gas in coal.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, S.M. Ordos Basin superposed evolution and structural controls of coal forming activities. Earth Sci. Front. 2017, 24, 54–63. [Google Scholar]

- Xu, F.; Hou, W.; Xiong, X.; Xu, B.; Wu, P.; Wang, H.; Feng, K.; Yun, J.; Li, S.; Zhang, L.; et al. The status and development strategy of coalbed methane industry in China. Pet. Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; Huang, S.P.; Ma, F.; Sun, Q.P.; Li, F.H.; Pan, S.Q.; Tian, G.W. Resource types, formation, distribution and prospects of coal-measure gas. Pet. Explor. Dev. 2019, 46, 433–442. [Google Scholar]

- Jiang, W.; Zhang, P.; Li, D.; Li, Z.; Wang, J.; Duan, Y.; Wu, J.; Liu, N. Reservoir characteristics and gas production potential of deep coalbed methane: Insights from the no. 15 coal seam in shouyang block, Qinshui Basin, China. Unconv. Resour. 2022, 2, 12–20. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A. Determination of the Extent of the Rock Destruction Zones around a Gasification Channel on the Basis of Strength Tests of Sandstone and Claystone Samples Heated at High Temperatures up to 1200 °C and Exposed to Water. Energies 2021, 14, 6464. [Google Scholar] [CrossRef]

- Wei, Q.; Li, X.; Hu, B.; Zhang, X.; Zhang, J.; He, Y.; Zhang, Y.; Zhu, W. Reservoir characteristics and coalbed methane resource evaluation of deep-buried coals: A case study of the No.13−1 coal seam from the Panji Deep Area in Huainan Coalfield, Southern North China. J. Petrol. Geol. 2019, 179, 867–884. [Google Scholar] [CrossRef]

- Dong, D.D.; Yang, J.S.; Hu, Q.J.; Cui, S.T.; Sun, F.J.; Zhang, J.D.; Cui, X.R. Pore structure characteristics of low-rank coal reservoirs with different ash yields and their implications for recoverability of coalbed methane-a case study from the Erlian Basin, northeastern China. Front. Earth Sci. 2023, 17, 18–29. [Google Scholar] [CrossRef]

- Li, W.; Li, J.; Hu, C.Q.; Xiao, Q.L. Research on Pore-Fracture Characteristics and Adsorption Performance of Main Coal Seams in Lvjiatuo Coal Mine. Processes 2023, 11, 1700. [Google Scholar] [CrossRef]

- Wang, D.X.; Hu, H.Y.; Wang, T.; Tang, T.; Li, W.P.; Zhu, G.G.; Chen, X.Y. Difference between of coal and shale pore structural characters based on gas adsorption experiment and multifractal analysis. Fuel 2024, 371, 132044. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Wei, Q.; Sun, K.; Zhang, G.; Wang, F. Characterization of Full-Sized Pore Structure and Fractal Characteristics of Marine–Continental Transitional Longtan Formation Shale of Sichuan Basin, South China. Energy Fuels 2017, 31, 10490–10504. [Google Scholar] [CrossRef]

- Wang, T.; Tian, F.; Deng, Z.; Hu, H. The Characteristic Development of Micropores in Deep Coal and Its Relationship with Adsorption Capacity on the Eastern Margin of the Ordos Basin, China. Minerals 2023, 13, 302. [Google Scholar] [CrossRef]

- Liu, S.; Sang, S.; Wang, G. FIB-SEM and X-ray CT characterization of interconnected pores in high-rank coal formed from regional metamorphism. J. Pet. Sci. Eng. 2017, 148, 21–31. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, S.; Wang, J.; Hu, Q.; Wang, M.; Chao, J. Applying fractal theory to characterize the pore structure of lacustrine shale from the Zhanhua Depression in Bohai Bay Basin, Eastern China. Energy Fuels 2018, 32, 7539–7556. [Google Scholar] [CrossRef]

- Yang, R.; He, S.; Yi, J.; Hu, Q. Nano-scale pore structure and fractal dimension of organic-rich Wufeng-Longmaxi shale from Jiaoshiba area, Sichuan Basin: Investigations using FESEM, gas adsorption and helium pycnometry. Mar. Pet. Geol. 2016, 70, 27–45. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, G.; Fan, L.; Zhang, D.; Shao, M.; Ding, R.; Li, Y.; Hu, H.; Deng, Z. Full-scale pore and microfracture characterization of deep coal reservoirs: A case study of the Benxi Formation coal in the Daning–Jixian block, China. Int. J. Energy Res. 2024, 2024, 5772264. [Google Scholar] [CrossRef]

- Xi, Z.; Tang, S.; Wang, J.; Yang, G.; Li, L. Formation and development of pore structure in marine continental transitional shale from northern China across a maturation gradient: Insights from gas adsorption and mercury intrusion. Int. J. Coal Geol. 2018, 200, 87–102. [Google Scholar] [CrossRef]

- Li, X.C.; Gao, J.X.; Zhang, S.; Li, Y.; Wang, M.Y.; Lu, W.D. Combined Characterization of Scanning Electron Microscopy, Pore and Crack Analysis System, and Gas Adsorption on Pore Structure of Coal with Different Volatilization. Earth Sci. 2022, 47, 1876–1889. [Google Scholar]

- Tang, X.; Li, J.H. Transmission Electron Microscopy: New Advances and Applications for Earth and Planetary Sciences. Earth Sci. 2021, 46, 1374–1415. [Google Scholar]

- Clarkson, C.R.; Haghshenas, B.; Ghanizadeh, A.; Qanbari, F.; Williams-Kovacs, J.D.; Riazi, N.; Debuhr, C.; Deglint, H.J. Nanopores to megafractures: Current challenges and methods, for shale gas reservoir and hydraulic fracture characterization. J. Nat. Gas Sci. Eng. 2016, 31, 612–657. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Shen, Y.; Ji, W. Fractal Characterization of Pore Structure and Its Influence on Salt Ion Diffusion Behavior in Marine Shale Reservoirs. Int. J. Hydrogen Energy 2020, 45, 28520–28530. [Google Scholar] [CrossRef]

- Hu, X.; Wu, C.W.; Yang, X.C.; Cheng, Q.H.; Zhu, W.T.; Ma, L.; Zhu, X.G.; Xu, B.R. Microscopic Pore Structure and Coalbed Methane Desorption Law in Low-Permeability Coal Seams. Spec. Oil Gas Reserv. 2024, 31, 129–135. [Google Scholar]

- Cui, X.; Bustin, R.M.; Dipple, G. Selective transport of CO2, CH4, and N2 in coals: Insights from modeling of experimental gas adsorption data. Fuel 2004, 83, 293–303. [Google Scholar] [CrossRef]

- Li, A.; Ding, W.; He, J.; Dai, P.; Yin, S.; Xie, F. Investigation of Pore Structure and Fractal Characteristics of Organic-Rich Shale Reservoirs: A Case Study of Lower Cambrian Qiongzhusi Formation in Malong Block of Eastern Yunnan Province, South China. Mar. Pet. Geol. 2016, 70, 46–57. [Google Scholar] [CrossRef]

- Adeyilola, A.; Nordeng, S.; Hu, Q.H. Porosity and Pore Networks in Tight Dolostone-Mudstone Reservoirs: Insights from the Devonian Three Forks Formation, Williston Basin, USA. J. Earth Sci. 2022, 33, 462–481. [Google Scholar] [CrossRef]

- Mahamud, M.M.; Menéndez, J.M.; Álvarez, A. Fractal Analysis of CO2 and N2 Adsorption Data to Assess Textural Changes during Char Gasification. Fuel Process. Technol. 2019, 189, 15–27. [Google Scholar] [CrossRef]

- Li, S.; Tang, D.; Xu, H.; Yang, Z. Advanced characterization of physical properties of coals with different coal structures by nuclear magnetic resonance and X-ray computed tomography. Comput. Geosci. 2012, 48, 220–227. [Google Scholar] [CrossRef]

- Xin, F.; Xu, H.; Tang, D.; Cao, L. An Improved Method to Determine Accurate Porosity of Low-Rank Coals by Nuclear Magnetic Resonance. Fuel Process. Technol. 2020, 205, 106435. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, Y.; Wang, Z.; Huang, X. Quantitative study on coal and shale pore structure and surface roughness based on atomic force microscopy and image processing. Fuel 2019, 244, 78–90. [Google Scholar] [CrossRef]

- Rouquerol, J.; Avnir, D.; Fairbridge, C.W.; Everett, D.H.; Haynes, J.M.; Pernicone, N.; Ramsay, J.D.; Sing, K.S.W.; Unger, K.K. Recommendations for the characterization of porous solids (Technical Report). Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

- Hainbuchner, M.; Hinde, A.L.; Baron, M.; Rauch, H.; Radlinski, A.P.; Mastalerz, M.; Lin, J.S.; Fan, L.; Thiyagarajan, P. Application of SAXS and SANS in evaluation of porosity, pore size distribution and surface area of coal. Int. J. Coal Geol. 2004, 59, 245–271. [Google Scholar]

- GB/T 6948-2008; Method of Determining Microscopically the Reflectance of Vitrinite in Coal. Standardization Administration of China: Beijing, China, 2008.

- GB/T 8899-2013; Determination of Maceral Group Composition and Minerals in Coal. Standardization Administration of China: Beijing, China, 2013.

- GB/T 30732-2014; Proximate Analysis of Coal—Instrumental Method. Standardization Administration of China: Beijing, China, 2014.

- GB/T 21650.2-2008; Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 2: Analysis of Mesopores and Macropores by Gas Adsorption. Standardization Administration of China: Beijing, China, 2008.

- GB/T 21650.3-2011; Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption—Part 3: Analysis of Micropores by Gas Adsorption. Standardization Administration of China: Beijing, China, 2011.

- GB/T 19560-2008; Experimental Method of High-Pressure Isothermal Adsorption to Coal. Standardization Administration of China: Beijing, China, 2008.

- Zhao, D.; Guo, Y.; Mao, X.; Lu, C.; Li, M.; Qian, F. Micro-nanopore characteristics of anthracite based on mercury injection, nitrogen adsorption and FESEM. J. China Coal Soc. 2017, 42, 1517–1526. [Google Scholar]

- Li, Z.; Liu, D.; Cai, Y.; Wang, Y.; Teng, J. Adsorption Pore Structure and Its Fractal Characteristics of Coals by N2 Adsorption Desorption and FESEM Image Analyses. Fuel 2019, 257, 116031. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.F.; Kong, D.T.; Liu, H.Q. Pore Structure of Shales from High Pressure Mercury Injection and Nitrogen Adsorption Method. Nat. Gas Geosci. 2013, 24, 450–455. [Google Scholar]

- Okolo, G.; Everson, R.; Neomagus, H.; Roberts, M.; Sakurovs, R. Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques. Fuel 2015, 141, 293–304. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, Y.; Wang, Y. Fractal Characteristics of Micro- and Mesopores in the Longmaxi Shale. Energies 2020, 13, 1349. [Google Scholar] [CrossRef]

- Pan, J.; Wang, K.; Hou, Q.; Niu, Q.; Wang, H.; Ji, Z. Micro-pores and fractures of coals analysed by field emission scanning electron microscopy and fractal theory. Fuel 2016, 164, 277–285. [Google Scholar] [CrossRef]

- Zhang, K.; Cheng, Y.; Li, W.; Hao, C.; Hu, B.; Jiang, J. Microcrystalline Characterization and Morphological Structure of Tectonic Anthracite Using XRD, Liquid Nitrogen Adsorption, Mercury Porosimetry, and Micro-CT. Energy Fuels 2019, 33, 10844–10851. [Google Scholar] [CrossRef]

- Lai, F.; Li, Z.; Zhang, W.; Dong, H.; Kong, F.; Jiang, Z. Investigation of pore characteristics and irreducible water saturation of tight reservoir using experimental and theoretical methods. Energy Fuels 2018, 32, 3368–3397. [Google Scholar] [CrossRef]

- Pan, J.; Zhu, H.; Hou, Q.; Wang, H.; Wang, S. Macromolecular and Pore Structures of Chinese Tectonically Deformed Coal Studied by Atomic Force Microscopy. Fuel 2015, 139, 94–101. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Che, Y.; Tang, D.; Tang, S.; Huang, W. Petro-physical Characterization of Coals by Low-field Nuclear Magnetic Resonance (NMR). Fuel 2010, 89, 1371–1380. [Google Scholar] [CrossRef]

- Hu, H.; Hao, F.; Lin, J.; Lu, Y.; Ma, Y.; Li, Q. Organic matter hosted pore system in the Wufeng-Longmaxi (O3w-S11) shale, Jiaoshiba area, Eastern Sichuan Basin, China. Int. J. Coal Geol. 2017, 173, 40–50. [Google Scholar] [CrossRef]

- Zhang, S.S.; Wu, C.F.; Liu, H. Comprehensive characteristics of pore structure and factors influencing micropore development in the Laochang mining area, eastern Yunnan, China. J. Pet. Sci. Eng. 2020, 190, 107090. [Google Scholar] [CrossRef]

- Zhu, G.G.; Xie, Z.T.; Wang, T.; Hu, H.Y.; Wang, D.X. Microscopic pore structure characteristics of Shanxi Formation coal reservoir in Daning-Jixian Block. Saf. Coal Mines 2024, 55, 31–42. [Google Scholar]

- Mou, P.; Pan, J.; Niu, Q.; Wang, Z.; Li, Y.; Song, D. Coal Pores: Methods, Types and Characteristics. Energy Fuels 2021, 35, 7467–7484. [Google Scholar] [CrossRef]

| Samples | Stratum (Geology) | Lithology | Ro /% | Vitrinite/% | Exinite /% | Inertinite /% | Minerals /% | Mad /% | Aad /% | Vad /% | FCad /% |

|---|---|---|---|---|---|---|---|---|---|---|---|

| J40-1 | Yan’an Group | coal | 0.97 | 35.50 | 0.40 | 38.60 | 25.50 | 1.32 | 10.71 | 36.88 | 51.09 |

| J40-2 | Yan’an Group | coal | 0.96 | 51.20 | 3.50 | 41.60 | 3.80 | 1.44 | 5.12 | 30.70 | 62.74 |

| J40-3 | Yan’an Group | shale | / 1 | / | / | / | / | 1.89 | 85.77 | / | / |

| J40-4 | Yan’an Group | coal | 0.88 | 38.40 | 6.70 | 48.80 | 6.20 | 0.90 | 6.76 | 28.83 | 63.51 |

| J40-5 | Yan’an Group | carbonaceous mudstone (geology) | 0.73 | 17.50 | 4.40 | 8.00 | 70.10 | 1.04 | 55.06 | 18.78 | 25.12 |

| J40-6 | Yan’an Group | coal | 0.80 | 47.70 | 2.10 | 21.40 | 28.80 | 1.13 | 23.03 | 28.64 | 47.20 |

| J40-7 | Yan’an Group | coal | 0.71 | 44.70 | 3.40 | 44.10 | 7.80 | 7.19 | 4.59 | 25.86 | 62.37 |

| J40-8 | Yan’an Group | coal | 0.53 | 70.80 | 1.40 | 23.30 | 4.50 | 7.38 | 4.55 | 34.81 | 53.27 |

| J40-9 | Yan’an Group | coal | 0.54 | 51.30 | 3.00 | 39.30 | 6.40 | 7.73 | 7.45 | 30.68 | 54.15 |

| J40-10 | Yan’an Group | coal | 0.49 | 54.20 | 4.00 | 35.00 | 6.80 | 7.94 | 7.02 | 32.98 | 52.07 |

| J40-11 | Yan’an Group | coal | 0.57 | 41.30 | 6.90 | 42.90 | 8.90 | 5.92 | 11.79 | 31.53 | 50.76 |

| J40-12 | Yan’an Group | shale | / | / | / | / | / | 1.97 | 86.42 | / | / |

| Samples | High-Pressure Mercury Compression | Low-Temperature Nitrogen Adsorption (DFT) | Low-Pressure Carbon Dioxide Adsorption (DFT) | |||||

|---|---|---|---|---|---|---|---|---|

| Pore Volume (cm3/g) | Specific Surface Area (m2/g) | Pore Volume (cm3/g) | Specific Surface Area (m2/g) | Average Pore Diameter (nm) | Pore Volume (cm3/g) | Specific Surface Area (m2/g) | Average Pore Diameter (nm) | |

| J40-1 | 0.042 | 4.596 | 0.007 | 2.000 | 20.505 | 0.031 | 100.980 | 0.747 |

| J40-2 | 0.030 | 5.049 | 0.007 | 2.169 | 20.505 | 0.031 | 103.380 | 0.747 |

| J40-3 | 0.003 | 0.772 | 0.025 | 10.749 | 19.540 | 0.005 | 14.520 | 0.747 |

| J40-4 | 0.020 | 3.934 | 0.006 | 1.751 | 20.505 | 0.033 | 105.800 | 0.747 |

| J40-5 | 0.037 | 4.289 | 0.011 | 3.481 | 20.505 | 0.018 | 56.540 | 0.747 |

| J40-6 | 0.042 | 4.122 | 0.007 | 2.214 | 20.505 | 0.026 | 83.049 | 0.747 |

| J40-7 | 0.078 | 14.017 | 0.029 | 18.980 | 19.540 | 0.054 | 183.720 | 0.748 |

| J40-8 | 0.045 | 7.508 | 0.010 | 5.854 | 19.540 | 0.053 | 175.830 | 0.748 |

| J40-9 | 0.065 | 9.693 | 0.017 | 10.345 | 19.540 | 0.057 | 186.620 | 0.748 |

| J40-10 | 0.065 | 9.217 | 0.011 | 5.979 | 19.540 | 0.056 | 188.000 | 0.748 |

| J40-11 | 0.030 | 6.453 | 0.021 | 11.696 | 19.540 | 0.045 | 149.420 | 0.748 |

| J40-12 | 0.005 | 1.148 | 0.020 | 11.315 | 19.540 | 0.008 | 26.120 | 0.748 |

| Samples | Langstroth Pressure PL/(MPa) | Langstroth Volume VL/(m3/t) |

|---|---|---|

| J40-1 | 3.862 | 7.942 |

| J40-2 | 4.110 | 7.420 |

| J40-4 | 6.240 | 8.325 |

| J40-6 | 5.104 | 6.996 |

| J40-7 | 9.442 | 14.654 |

| J40-8 | 4.361 | 10.407 |

| J40-9 | 4.706 | 12.645 |

| J40-10 | 4.845 | 9.895 |

| J40-11 | 6.684 | 11.082 |

| Samples | Pore Volume/(cm3/g) | Specific Surface Area/(m2/g) | ||||||

|---|---|---|---|---|---|---|---|---|

| Microporous | Mesoporous | Macroporous | Total Hole Volume | Microporous | Mesoporous | Macroporous | Total Specific Surface Area (TSA) | |

| J40-1 | 0.031 | 0.006 | 0.020 | 0.057 | 100.980 | 1.947 | 0.251 | 103.178 |

| J40-2 | 0.031 | 0.006 | 0.007 | 0.044 | 103.380 | 2.095 | 0.129 | 105.604 |

| J40-3 | 0.005 | 0.021 | 0.004 | 0.029 | 14.622 | 7.856 | 0.191 | 22.670 |

| J40-4 | 0.033 | 0.005 | 0.005 | 0.043 | 105.800 | 1.670 | 0.075 | 107.574 |

| J40-5 | 0.018 | 0.010 | 0.017 | 0.044 | 56.540 | 3.385 | 0.286 | 60.212 |

| J40-6 | 0.026 | 0.006 | 0.024 | 0.056 | 83.049 | 2.160 | 0.280 | 85.488 |

| J40-7 | 0.054 | 0.028 | 0.030 | 0.113 | 183.951 | 18.685 | 0.606 | 203.242 |

| J40-8 | 0.053 | 0.010 | 0.020 | 0.083 | 175.830 | 5.820 | 0.285 | 181.936 |

| J40-9 | 0.057 | 0.016 | 0.027 | 0.100 | 186.620 | 10.281 | 0.641 | 197.542 |

| J40-10 | 0.056 | 0.010 | 0.027 | 0.093 | 188.000 | 5.938 | 0.557 | 194.495 |

| J40-11 | 0.045 | 0.020 | 0.006 | 0.070 | 149.420 | 11.648 | 0.050 | 161.118 |

| J40-12 | 0.008 | 0.017 | 0.004 | 0.029 | 26.555 | 6.792 | 0.140 | 33.486 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Shi, B.; Wang, T.; Lin, J.; Li, B.; Fan, S.; Liu, J. Multiscale Qualitative–Quantitative Characterization of the Pore Structure in Coal-Bearing Reservoirs of the Yan’an Formation in the Longdong Area, Ordos Basin. Processes 2024, 12, 2787. https://doi.org/10.3390/pr12122787

Wang R, Shi B, Wang T, Lin J, Li B, Fan S, Liu J. Multiscale Qualitative–Quantitative Characterization of the Pore Structure in Coal-Bearing Reservoirs of the Yan’an Formation in the Longdong Area, Ordos Basin. Processes. 2024; 12(12):2787. https://doi.org/10.3390/pr12122787

Chicago/Turabian StyleWang, Rong, Baohong Shi, Tao Wang, Jiahao Lin, Bo Li, Sitong Fan, and Jiahui Liu. 2024. "Multiscale Qualitative–Quantitative Characterization of the Pore Structure in Coal-Bearing Reservoirs of the Yan’an Formation in the Longdong Area, Ordos Basin" Processes 12, no. 12: 2787. https://doi.org/10.3390/pr12122787

APA StyleWang, R., Shi, B., Wang, T., Lin, J., Li, B., Fan, S., & Liu, J. (2024). Multiscale Qualitative–Quantitative Characterization of the Pore Structure in Coal-Bearing Reservoirs of the Yan’an Formation in the Longdong Area, Ordos Basin. Processes, 12(12), 2787. https://doi.org/10.3390/pr12122787