Numerical Simulation of Coal’s Mechanical Properties and Fracture Process Under Uniaxial Compression: Dual Effects of Bedding Angle and Loading Rate

Abstract

1. Introduction

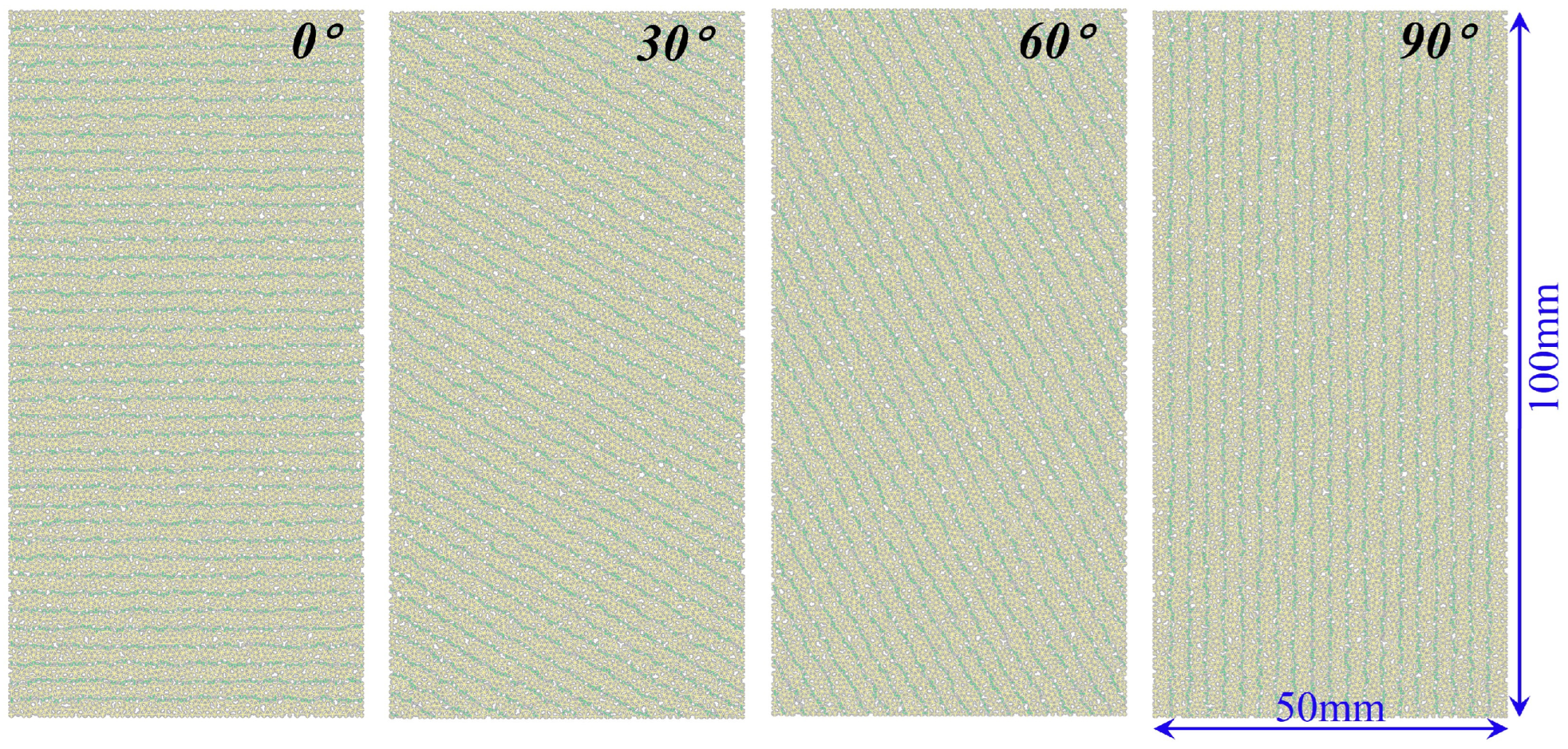

2. Numerical Modeling and Micro Parameter Assignment

3. Numerical Simulation Results

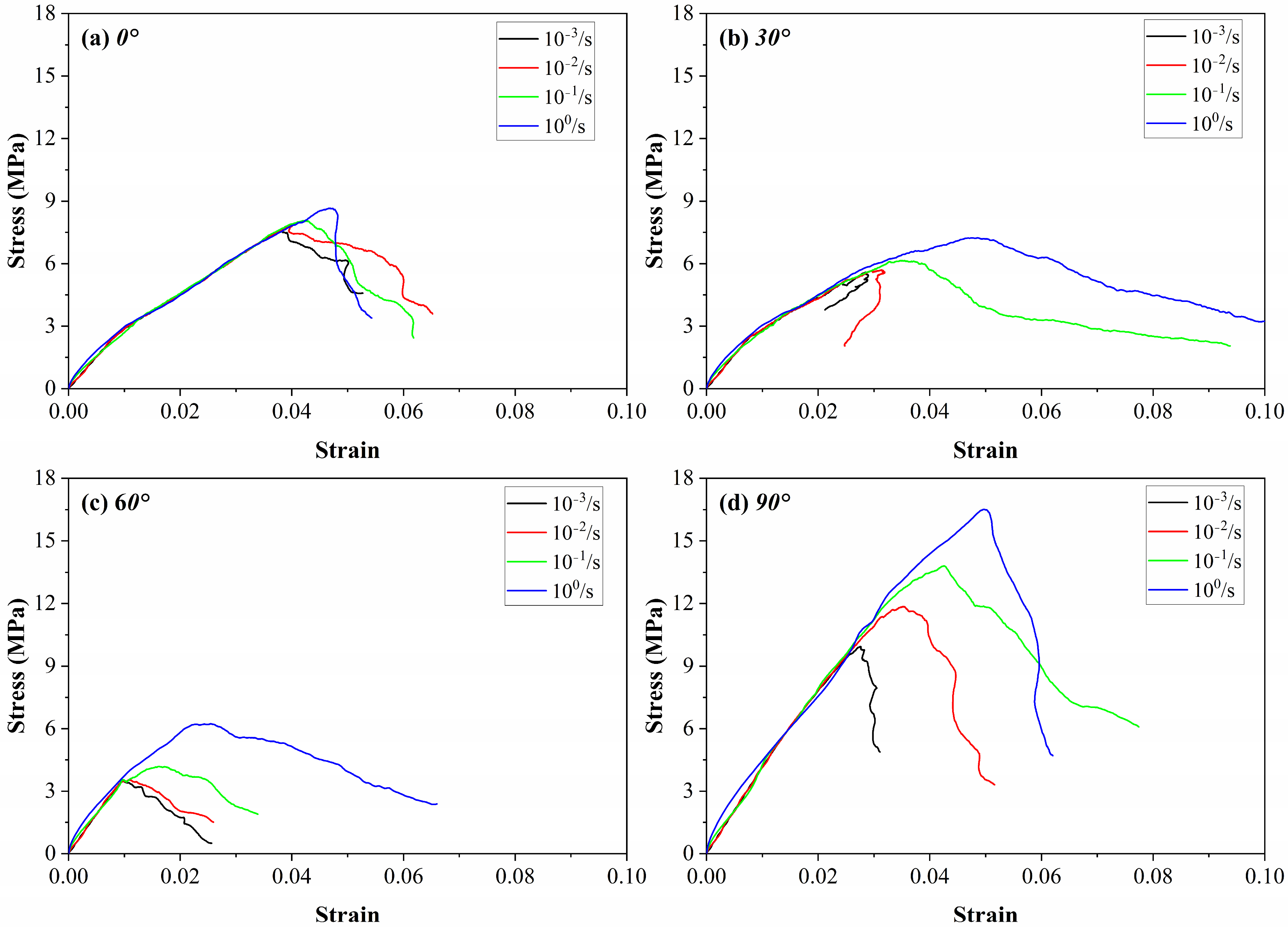

3.1. Stress–Strain and Strength

3.2. Failure Mode

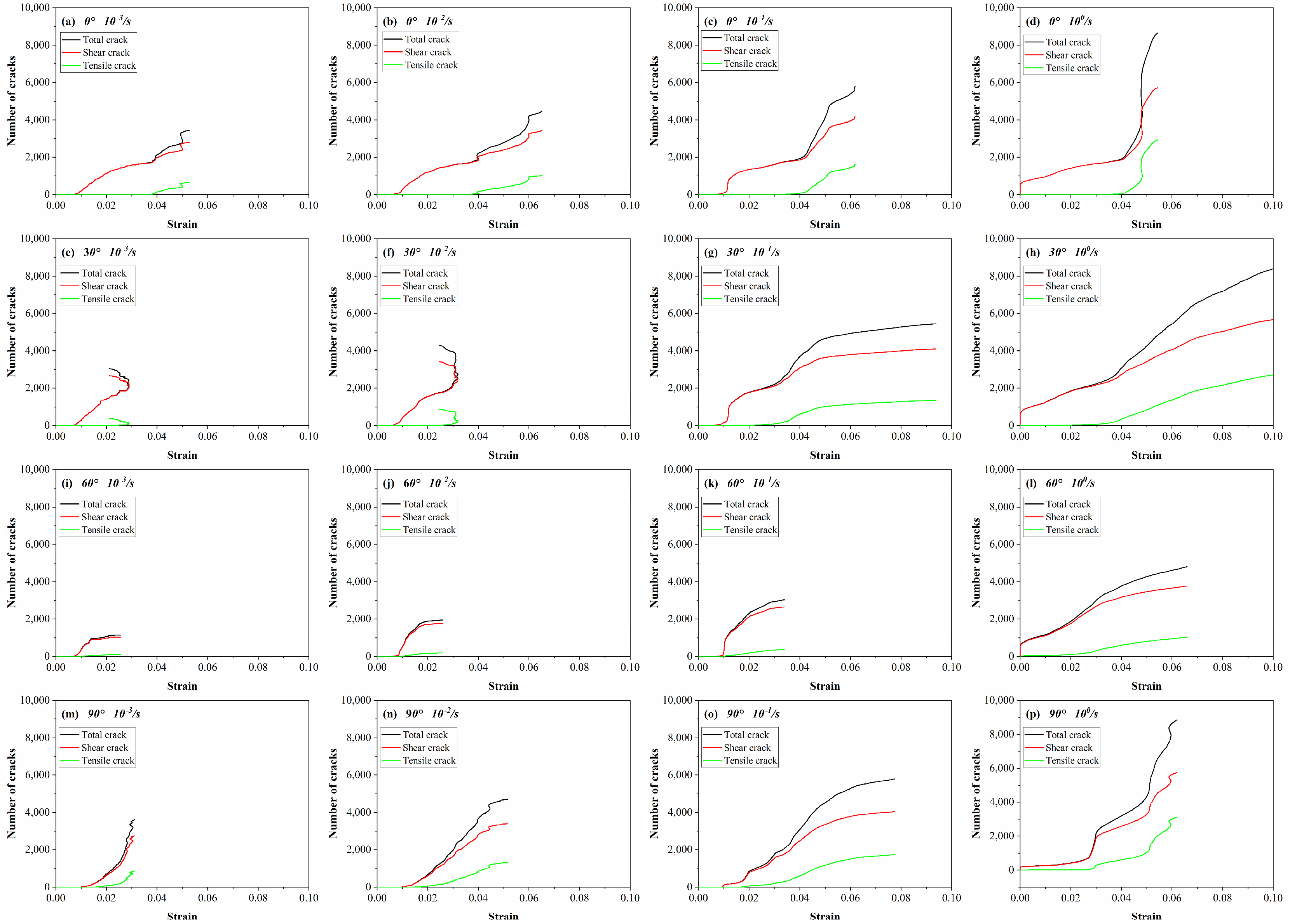

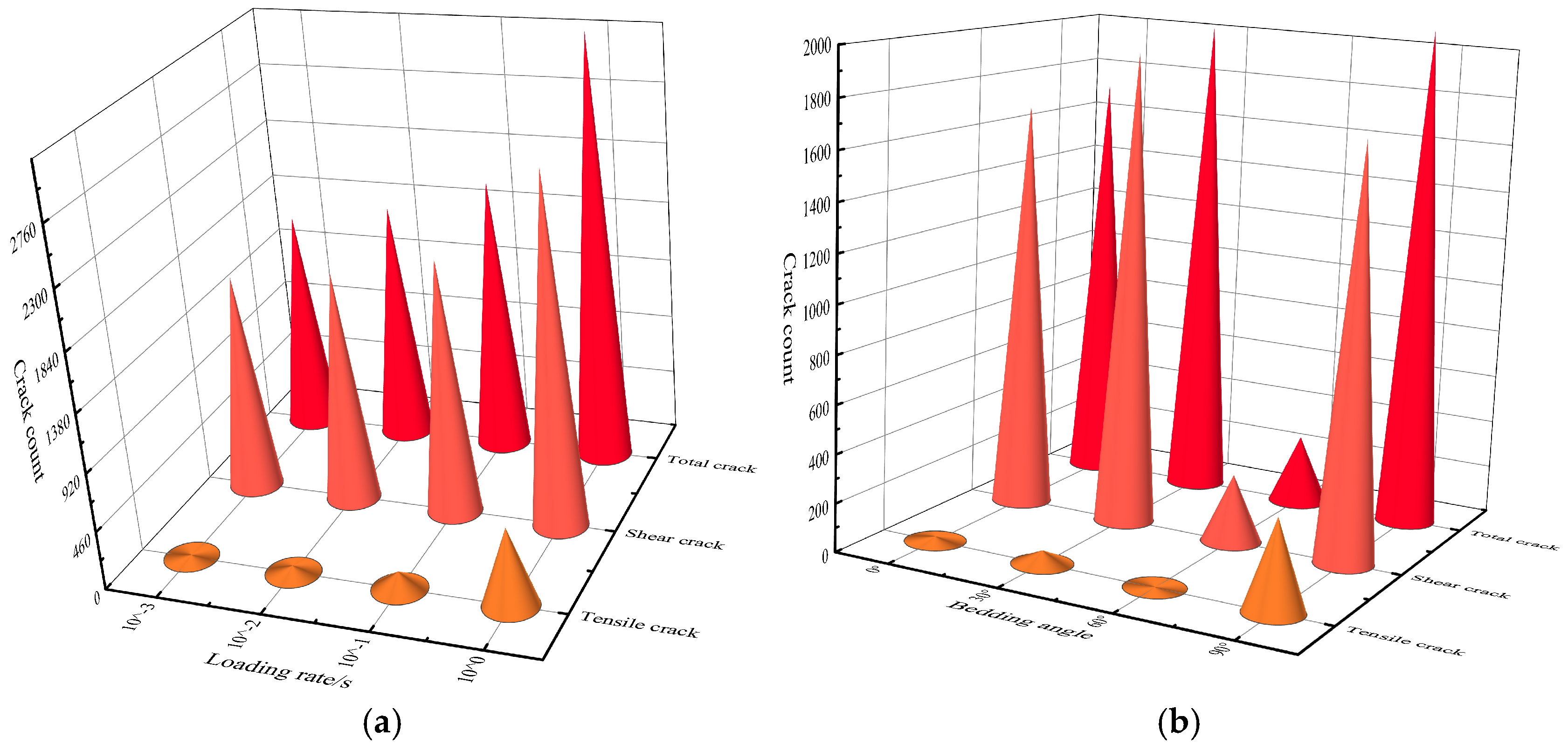

3.3. Evolution of Microcracks

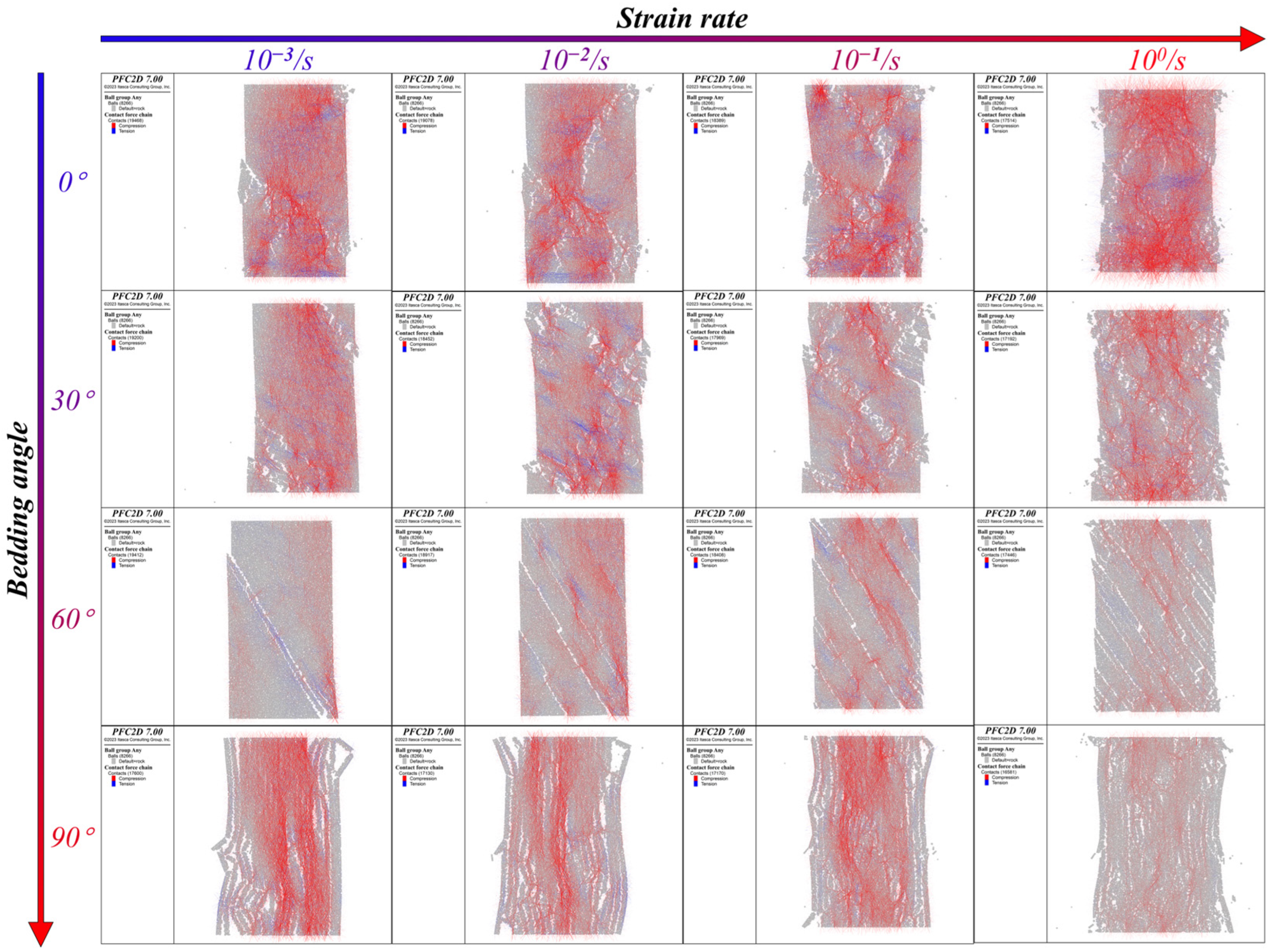

3.4. Force Chain Characteristics

4. Conclusions and Prospects

- (1)

- The loading rate significantly increased the destruction rate of the coal samples and greatly increased the extent of coal sample destruction. The bedding angle divides the failure of coal samples into two categories, which makes the post-peak failure rate of coal samples different. The UCS tends to increase with an increasing loading rate. As the bedding angle increased, UCS decreased and then increased, and the curve was approximately “V” shaped. The minimum peak stress was 6.23 MPa when the bedding angle was 60°. The maximum peak strength was 16.5 MPa when the bedding angle was 90°;

- (2)

- Significant differences in rupture patterns and crack distributions were observed in coal samples with different bedding angles and loading rates under uniaxial compression conditions. As the loading rate increased, the peak strength of the specimen increased, and the damage intensified. As the bedding angle increased, shear cracks dominated in the model, and the crack distribution showed a trend of increasing and then decreasing. Loading rate and crack counts were positively correlated. When the bedding angle was 0°–60°, the degree of coal sample crushing was lower, and the number of cracks was also lower. When the bedding angle was 60°–90°, it had the opposite law;

- (3)

- The number of cracks increased with the increase in the loading rate. With the increase in the bedding angle, the cracks of the coal samples showed the characteristic of “increase–decrease–increase”. The crack tendency of coal samples increased with the loading rate, and the microcrack tendency changed from scattered distribution to concentrated aggregation. The range of the crack tendency of coal samples was more concentrated as the bedding angle increased. When the bedding angle was 90°, the microcrack damage tendency was highly concentrated in the 90° range;

- (4)

- As the loading rate increased, the density of compressive stress force chains inside the specimen increased and aggregated toward the ends. The density of the tensile stress force chain was basically unchanged but aggregated towards the center. As the bedding angle increased, the density of compressive stress force chains became progressively smaller, and tensile stress force chains appeared to aggregate with increased density. The overall strength of the force chain network varied according to the law of decreasing and then increasing as both the loading rate and the bedding angle increased.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Duan, M.; Jiang, C.; Gan, Q.; Zhao, H.; Yang, Y.; Li, Z. Study on permeability anisotropy of bedded coal under true triaxial stress and its application. Transp. Porous Med. 2020, 131, 1007–1035. [Google Scholar] [CrossRef]

- Wang, R.; Pan, J.; Wang, Z.; Li, G.; Ge, T.; Zheng, H.; Wang, X. Influence of in situ stress on well test permeability and hydraulic fracturing of the Fanzhuang Block, Qinshui Basin. Energy Fuels 2021, 35, 2121–2133. [Google Scholar] [CrossRef]

- Xia, Z.-G.; Liu, S.; Bian, Z.; Song, J.; Feng, F.; Jiang, N. Mechanical properties and damage characteristics of coal/rock combination with different dip angles. KSCE J. Civ. Eng. 2021, 25, 1687–1699. [Google Scholar] [CrossRef]

- Hu, J.; He, M.C.; Li, H.R.; Tao, Z.G.; Liu, D.Q.; Cheng, T.; Peng, D. Rockburst hazard control using the excavation compensation method (ECM): A case study in the Qinling water conveyance tunnel. Engineering 2024, 34, 154–163. [Google Scholar] [CrossRef]

- Hu, J.; He, M.C.; Li, H.R.; Cheng, T.; Tao, Z.G.; Liu, D.Q.; Peng, D. Control effect of negative Poisson’s ratio (NPR) cable on impact-induced rockburst with different strain rates: An experimental investigation. Rock. Mech. Rock. Eng. 2023, 56, 5167–5180. [Google Scholar] [CrossRef]

- Li, H.R.; He, M.C.; Qiao, Y.F.; Cheng, T.; Xiao, Y.M.; Gu, Z.J. Mode I fracture properties and energy partitioning of sandstone under coupled static-dynamic loading: Implications for rockburst. Theor. Appl. Fract. Mech. 2023, 127, 104025. [Google Scholar] [CrossRef]

- Li, H.R.; Qiao, Y.F.; He, M.C.; Shen, R.X.; Gu, Z.J.; Cheng, T.; Xiao, Y.M.; Tang, J. Effect of water saturation on dynamic behavior of sandstone after wetting-drying cycles. Eng. Geol. 2023, 319, 107105. [Google Scholar] [CrossRef]

- Bésuelle, P.; Desrues, J.; Raynaud, S. Experimental characterisation of the localisation phenomenon inside a Vosges sandstone in a triaxial cell. Int. J. Rock. Mech. Min. Sci. 2000, 37, 1223–1237. [Google Scholar] [CrossRef]

- Wong, R.H.C.; Chau, K.T.; Tang, C.A.; Lin, P. Analysis of crack coalescence in rock-like materials containing three flaws- part I: Experimental approach. Int. J. Rock Mech. Min. Sci. 2001, 38, 909–924. [Google Scholar] [CrossRef]

- Hao, X.; Wang, S.; Xu, Q.; Yang, D.; Zhang, Q.; Jin, D.; Wei, Y. Influences of confining pressure and bedding angles on the deformation, fracture and mechanical characteristics of slate. Constr. Build. Mater. 2020, 243, 118255. [Google Scholar] [CrossRef]

- Duan, M.; Jiang, C.; Guo, X.; Yang, K.; Tang, J.; Yin, Z.; Hu, X. Experimental study on mechanics and seepage of coal under different bedding angle and true triaxial stress state. Bull. Eng. Geol. Environ. 2022, 81, 1–16. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Chen, S.; Shao, Z.; Zhou, C.; Fu, S. Effects of bedding planes on mechanical characteristics and crack evolution of rocks containing a single pre-existing flaw. Eng. Geol. 2021, 293, 106325. [Google Scholar] [CrossRef]

- Yuan, T.; Wei, Y.; Chen, S.; Liu, W.; Zhao, L.; Zhang, X. Study on Mechanical Properties and Crack Propagation of Raw Coal with Different Bedding Angles based on CT Scanning. ACS Omega 2022, 7, 27185–27195. [Google Scholar] [CrossRef] [PubMed]

- Fang, X.; Wu, C.; Zhang, H.; Jiang, X.; Li, G.; Zhang, Z.; Liu, N. Energy Evolution of Coal During Uniaxial Compression under Different Bedding Intersection Angles and its Controlling Effect on the Failure Process. Nat. Resour. Res. 2024, 33, 813–830. [Google Scholar] [CrossRef]

- Huang, L.; Li, B.; Li, C.; Wu, B.; Wang, J. Research on anisotropic characteristics and energy damage evolution mechanism of bedding coal under uniaxial compression. Energy 2024, 301, 131659. [Google Scholar] [CrossRef]

- Yin, Q.; Wu, S.; Meng, Y.; Wu, J.; Zhang, Q.; Jing, H. Experimental and numerical investigation on mode I fracture properties of bedded rocks. Theor. Appl. Fract. Mech. 2023, 124, 103807. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Yang, S.-Q.; Tian, W.; Wu, S. Experimental and DEM study on failure behavior and stress distribution of flawed sandstone specimens under uniaxial compression. Theor. Appl. Fract. Mech. 2022, 118, 103266. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Einstein, H.H. Crack coalescence in molded gypsum and Carrara marble: Part 2-microscopic observations and interpretation. Rock Mech. Rock. Eng. 2009, 42, 513–545. [Google Scholar] [CrossRef]

- Ge, R.; Ghadiri, M.; Bonakdar, T.; Zheng, Q.; Zhou, Z.; Larson, I.; Hapgood, K. Deformation of 3D printed agglomerates: Multiscale experimental tests and DEM simulation. Chem. Eng. Sci. 2020, 217, 115526. [Google Scholar] [CrossRef]

- Yue, Z.; Meng, F.; Zhou, X.-L.; Wang, X.; Zhang, L.; Wang, Z.-Q. Influence of non-persistent joint aperture and inclination angle on the shear behavior and fracture mode of solid rock and concrete material. Constr. Build. Mater. 2022, 316, 125892. [Google Scholar] [CrossRef]

- Xiang, F.; Kulatilake, P.H.W.; Chen, X. Mechanical behavior of rock-like jointed blocks with multi-non-persistent joints under uniaxial loading: A particle mechanics approach. Eng. Geol. 2015, 190, 17–32. [Google Scholar]

- Xu, H.; Qin, Y.; Wang, G.; Fan, C.; Wu, M.; Wang, R. Discrete element study on meso-mechanical behavior of crack propagation in coal samples with two prefabricated fissures under biaxial compression. Powder Technol. 2020, 375, 42–59. [Google Scholar] [CrossRef]

- Tomporowski, D.; Nitka, M.; Tejchman, J. Application of the 3D DEM in the modelling of fractures in pre-flawed marble specimens during uniaxial compression. Eng. Fract. Mech. 2023, 277, 108978. [Google Scholar] [CrossRef]

- Li, H.R.; He, M.C.; Qiao, Y.F.; Cheng, T. Burst behavior and its proneness evaluation of bedding coal. Chin. J. Rock. Mech. Eng. 2024, 43, 2178–2188. [Google Scholar]

- Lei, B.; Zuo, J.; Liu, H.-Y.; Wang, J.; Xu, F.; Li, H.-T. Experimental and numerical investigation on shale fracture behavior with different bedding properties. Eng. Fract. Mech. 2021, 245, 107639. [Google Scholar] [CrossRef]

- Li, Y.; Yang, S.-Q.; Liu, Z.-L.; Sun, B.-W.; Yang, J.; Xu, J. Study on mechanical properties and deformation of coal specimens under different confining pressure and strain rate. Theor. Appl. Fract. Mech. 2022, 118, 103287. [Google Scholar] [CrossRef]

- Gong, S.; Wang, Z.; Zhou, L. Dynamic fracture mechanics and energy distribution rate response characteristics of coal containing bedding structure. PLoS ONE 2021, 16, e0247908. [Google Scholar] [CrossRef]

- Su, Q.; Ma, Q.; Ma, D.; Yuan, P. Dynamic mechanical characteristic and fracture evolution mechanism of deep roadway sandstone containing weakly filled joints with various angles. Int. J. Rock. Mech. Min. Sci. 2021, 137, 104552. [Google Scholar] [CrossRef]

- Liu, X.; Chen, H.; Liu, B.; Deng, W.; Liu, Q.; Zhang, Z. Experimental and numerical study on failure characteristics and mechanism of coal under different quasi-static loading rates. Theor. Appl. Fract. Mech. 2022, 121, 103478. [Google Scholar] [CrossRef]

- Chen, Z.; Yuan, Y.; Qin, Z.; Wang, W.; Li, H. The mechanism of crack propagation under dynamic loading stress at different rates. Comp. Part. Mech. 2024. [Google Scholar] [CrossRef]

- Tan, L.; Ren, T.; Yang, X.; He, X. A numerical simulation study on mechanical behaviour of coal with bedding planes under coupled static and dynamic load. Int. J. Min. Sci. Technol. 2018, 28, 791–797. [Google Scholar] [CrossRef]

- Yang, S.Q.; Huang, Y.H.; Jing, H.W.; Liu, X.R. Discrete element modeling on fracture coalescence behavior of red sandstone containing two unparallel fissures. Eng. Geol. 2014, 178, 28–48. [Google Scholar] [CrossRef]

- Debecker, B.; Vervoort, A. Two-dimensional discrete element simulations of the fracture behaviour of slate. Int. J. Rock. Mech. Min. Sci. 2013, 61, 161–170. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, C.; Wang, W.L.; Xian, Z. A meso-level study on mechanical properties of bedding coal under uniaxial compression. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 4036–4047. [Google Scholar]

- Yang, S.Q.; Sun, B.W.; Tian, W.L. Discrete element simulation of the mechanical properties of shale with different bedding inclinations under conventional triaxial compression. Chin. J. Eng. 2022, 44, 430–439. [Google Scholar]

- Zhao, H.; Hou, J.C.; Zhang, L.; Zhao, M.H. Towards concrete-rock interface shear containing similar triangular asperities. Int. J. Rock. Mech. Min. 2021, 137, 104547. [Google Scholar] [CrossRef]

- Ma, G.; Chang, X.-L.; Zhou, W.; Ng, T.-T. Mechanical response of rockfills in a simulated true triaxial test: A combined FDEM study. Geomech. Eng. 2014, 7, 317–333. [Google Scholar] [CrossRef]

- Nie, Z.H.; Qi, Q.; Wang, X.; Zhu, Y.G. DEM investigation of strain behaviour and force chain evolution of gravel–sand mixtures subjected to cyclic loading. Particuology 2022, 68, 13–28. [Google Scholar] [CrossRef]

- Huang, Y.; Li, J.; Teng, Y.; Dong, X.; Wang, X.; Kong, G.; Song, T. Numerical simulation study on macroscopic mechanical behaviors and micro-motion characteristics of gangues under triaxial compression. Powder Technol. 2017, 320, 668–684. [Google Scholar] [CrossRef]

- Li, H.R.; Qiao, Y.F.; Shen, R.X.; He, M.C.; Cheng, T.; Xiao, Y.M.; Tang, J. Effect of water on mechanical behavior and acoustic emission response of sandstone during loading process: Phenomenon and mechanism. Eng. Geol. 2021, 294, 106386. [Google Scholar] [CrossRef]

- Yan, Y.T.; Li, J.C.; Li, X. Dynamic viscoelastic model for rock joints under compressive loading. Int. J. Rock. Mech. Min. Sci. 2022, 154, 105123. [Google Scholar] [CrossRef]

- Li, Z.; Gao, Y.H.; Liu, P.; Li, L.; De, X. Discrete element study on evolution of force-chain during salix grains dense molding. Acta Energiae Solaris Sin. 2019, 40, 3186–3195. [Google Scholar]

- Liu, W.; Cheng, W.; Liu, X.; Zhang, Z.; Yue, Z.; Yang, L.; Shen, A. Effects of Loading Rate and Notch Geometry on Dynamic Fracture Behavior of Rocks Containing Blunt V-Notched Defects. Rock. Mech. Rock. Eng. 2024, 57, 2501–2521. [Google Scholar] [CrossRef]

- Feng, P.; Xu, Y.; Dai, F. Effects of dynamic strain rate on the energy dissipation and fragment characteristics of cross-fissured rocks. Int. J. Rock. Mech. Min. Sci. 2021, 138, 104600. [Google Scholar] [CrossRef]

| Micro-Parameters | Values |

|---|---|

| Minimum radius of the particle, Rmin/mm | 0.28 |

| Ratio of maximum to minimum of radius, Rrat | 1.66 |

| Density of the particle, ρ/(kg·m−3) | 1400 |

| Friction coefficient, μ | 0.5 |

| Young’s modulus of the particle, EC/GPa | 2.25 |

| Ratio of normal to shear stiffness of the particle, kn/ks | 3.0 |

| Parallel bonding radius factor, λ | 1.0 |

| Young’s modulus of the parallel bond, /GPa | 2.25 |

| Ratio of normal to shear stiffness of the parallel bond, | 3.0 |

| Average bond normal strength, σn,mean/MPa | 12.5 |

| Standard deviation of bond normal strength, σn,dev/MPa | 1.25 |

| Average bond tangential strength, τs,mean/MPa | 12.5 |

| Standard deviation of bond tangential strength, τs,dev/MPa | 1.25 |

| Bedding Angle α/° | Loading Rate/s | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10−3 | 10−2 | 10−1 | 100 | |||||||||

| Total Crack | Shear Crack | Tensile Crack | Total Crack | Shear Crack | Tensile Crack | Total Crack | Shear Crack | Tensile Crack | Total Crack | Shear Crack | Tensile Crack | |

| 0 | 1722 | 1703 | 19 | 1867 | 1810 | 57 | 2122 | 1985 | 137 | 3308 | 2706 | 602 |

| 30 | 2017 | 1962 | 55 | 2467 | 2311 | 156 | 2760 | 2529 | 231 | 4062 | 3309 | 753 |

| 60 | 285 | 282 | 3 | 702 | 680 | 22 | 1793 | 1681 | 112 | 2458 | 2287 | 171 |

| 90 | 2085 | 1710 | 375 | 2800 | 2238 | 562 | 3512 | 2757 | 755 | 4290 | 3263 | 1027 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ou, J.; Niu, J.; Wang, B.; Zhang, W.; Zhao, J.; Lyu, B.; Zhan, B.; Ma, Y. Numerical Simulation of Coal’s Mechanical Properties and Fracture Process Under Uniaxial Compression: Dual Effects of Bedding Angle and Loading Rate. Processes 2024, 12, 2661. https://doi.org/10.3390/pr12122661

Ou J, Niu J, Wang B, Zhang W, Zhao J, Lyu B, Zhan B, Ma Y. Numerical Simulation of Coal’s Mechanical Properties and Fracture Process Under Uniaxial Compression: Dual Effects of Bedding Angle and Loading Rate. Processes. 2024; 12(12):2661. https://doi.org/10.3390/pr12122661

Chicago/Turabian StyleOu, Jianchun, Jizhan Niu, Bican Wang, Wei Zhang, Jing Zhao, Benming Lyu, Beihuai Zhan, and Yue Ma. 2024. "Numerical Simulation of Coal’s Mechanical Properties and Fracture Process Under Uniaxial Compression: Dual Effects of Bedding Angle and Loading Rate" Processes 12, no. 12: 2661. https://doi.org/10.3390/pr12122661

APA StyleOu, J., Niu, J., Wang, B., Zhang, W., Zhao, J., Lyu, B., Zhan, B., & Ma, Y. (2024). Numerical Simulation of Coal’s Mechanical Properties and Fracture Process Under Uniaxial Compression: Dual Effects of Bedding Angle and Loading Rate. Processes, 12(12), 2661. https://doi.org/10.3390/pr12122661