Techno-Economic Considerations on Nanocellulose’s Future Progress: A Short Review

Abstract

1. Introduction

2. Methodology

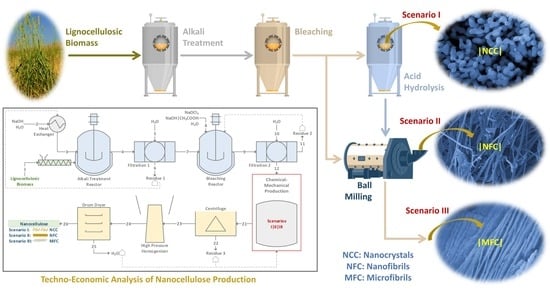

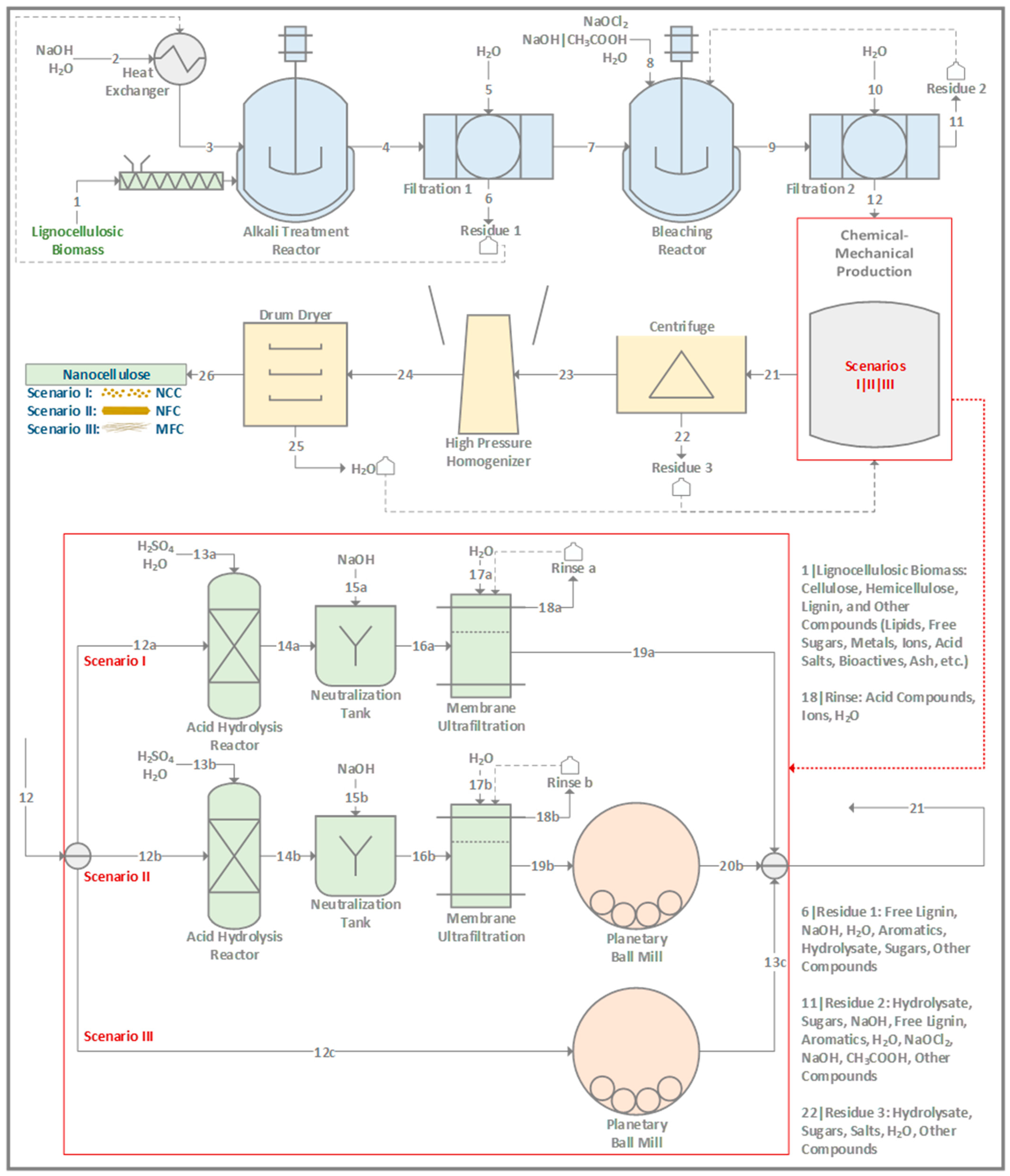

2.1. Overview of the Production Flow-Sheet

2.2. Detailed Description of Nanocellulose Producing Scenarios

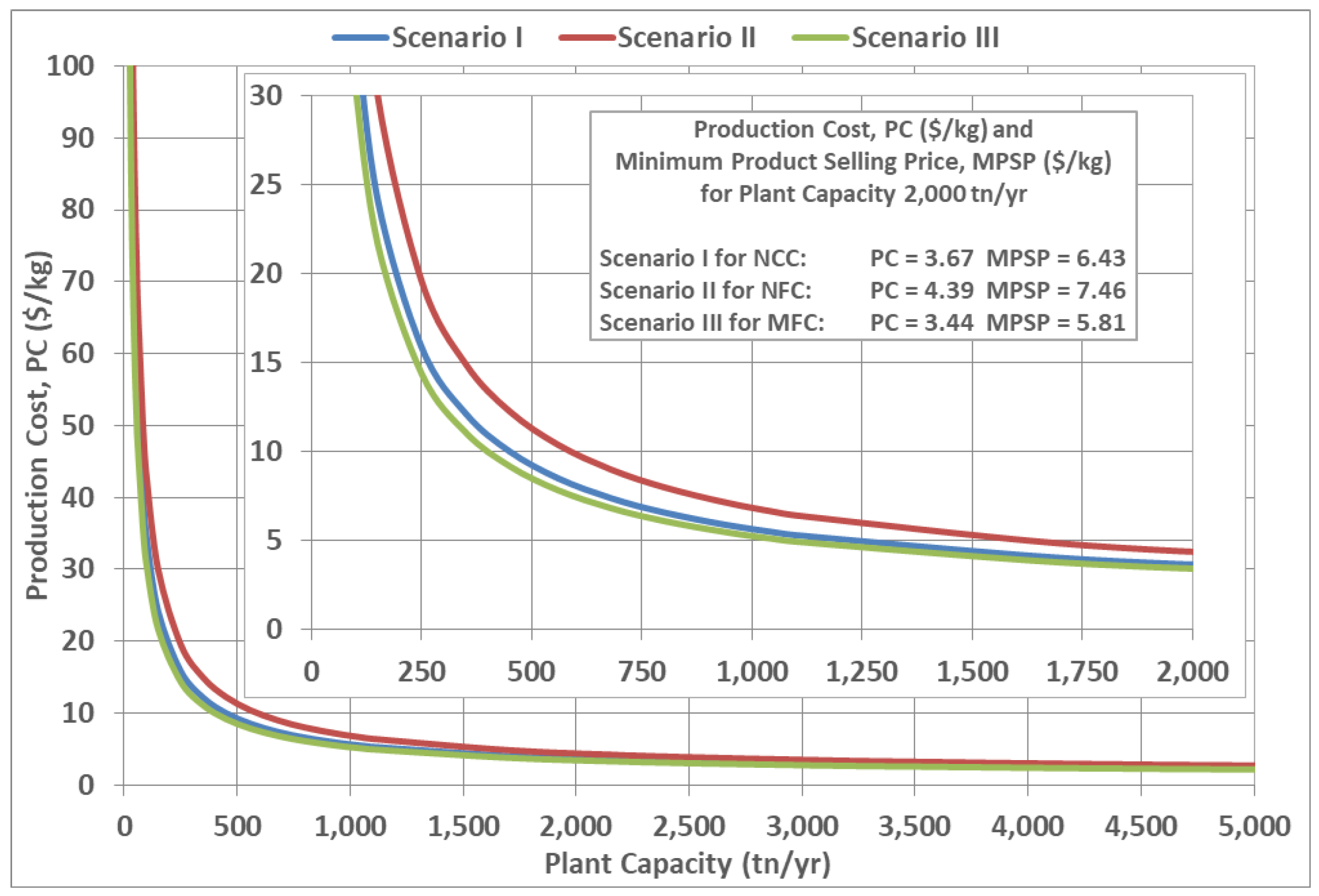

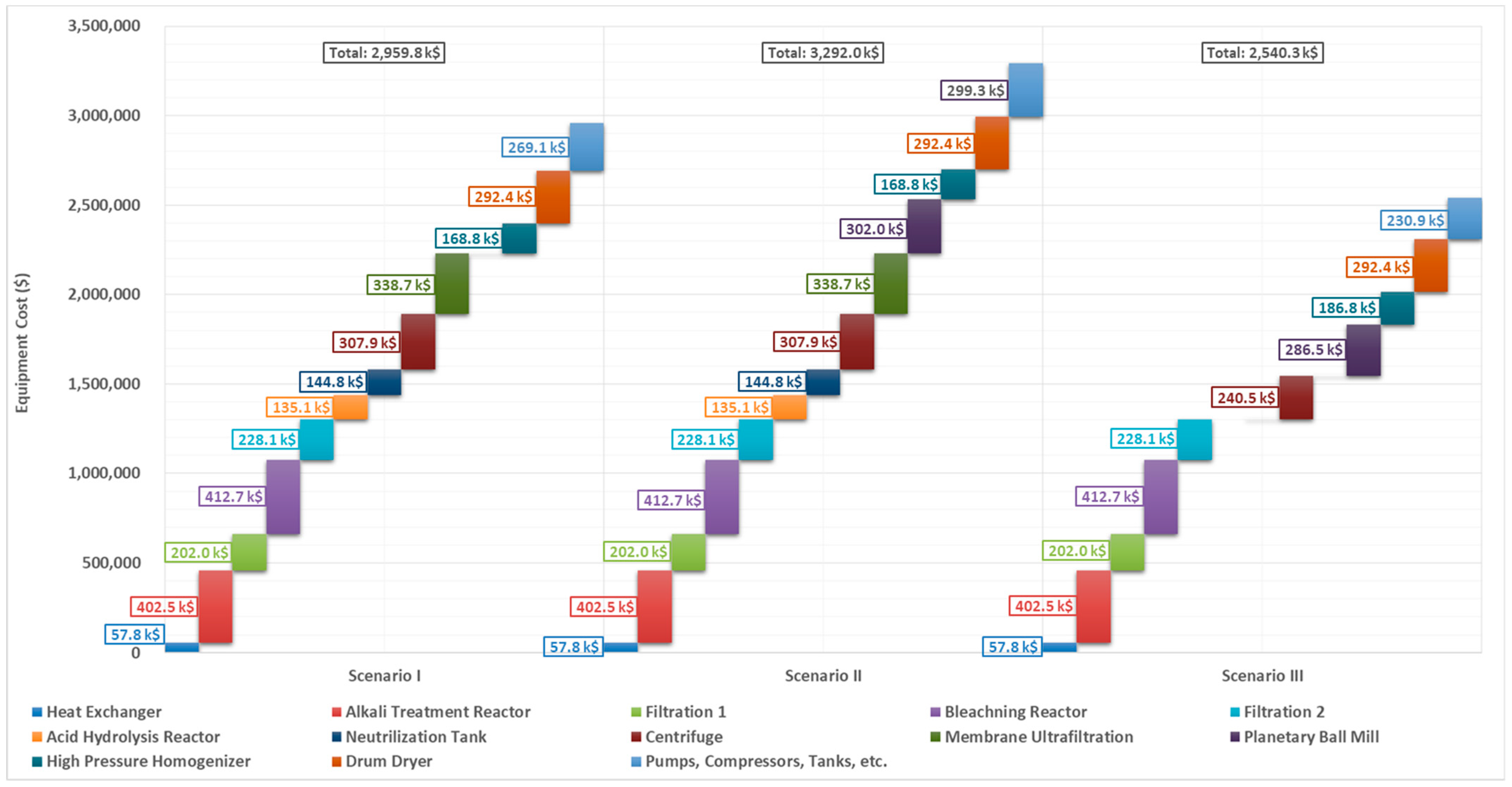

2.3. Economic Analysis and Case Studies

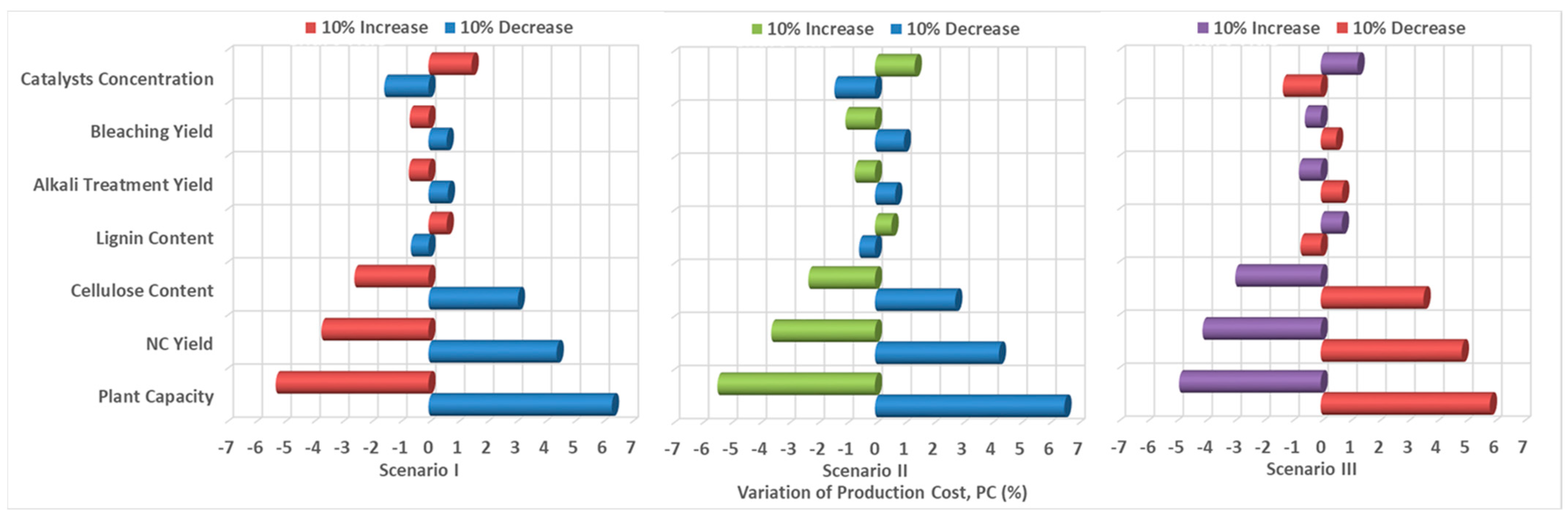

3. Analysis of New Scenarios for Nanocellulose Production

4. Techno-Economic Considerations for Nanocellulose Production

4.1. Overview of Techno-Economic Analyses of Nanocellulose Production

4.2. Nanocellulose Production Cost and Market Barriers

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFC | Annual Fixed Costs | NFC | Nanofibrillated Cellulose |

| BNC | Bacterial Nanocellulose | NP | Net Profit |

| CAGR | Compound Annual Growth Rate | OC | Other Costs |

| CAPEX | Total Fixed Capital Investment | ODC | Other Direct Costs |

| CS | Case Study | ODPC | Other Direct Production Costs |

| CWT | Waste Treatment Costs | OPEX | Total Production Costs |

| DC | Direct Costs | PC | Production Cost |

| DPC | Direct Production Costs | POT | Pay-out Time |

| FCI | Fixed Capital Investment | PP | Product Price |

| GC | General Costs | R&I | Research and Innovation |

| GP | Gross Profit | RMC | Raw Materials Costs |

| IC | Indirect Costs | ROI | Return on Investment |

| IW | Working Capital | SEC | Specific Energy Consumption |

| KPI | Key Performance Indicator | SWC | Specific Water Consumption |

| LC | Labor Costs | TEA | Techno-economic Analysis |

| MEC | Major Equipment Costs | TEMPO | 2,2,6,6-tetramethyl-1-piperidinyloxy |

| MFC | Microfibrillated Cellulose | TR | Total Revenue |

| MPSP | Minimum Product Selling Price | TRL | Technology Readiness Level |

| NC | Nanocellulose | UC | Utilities Costs |

| NCC | Nanocrystalline Cellulose | V | Venture Profit |

References

- Wang, Q.; Yao, Q.; Liu, J.; Sun, J.; Zhu, Q.; Chen, H. Processing nanocellulose to bulk materials: A review. Cellulose 2019, 26, 7585–7617. [Google Scholar] [CrossRef]

- Salem, K.S.; Starkey, H.R.; Pal, L.; Lucia, L.; Jameel, H. The topochemistry of cellulose nanofibrils as a function of mechanical generation energy. ACS Sustain. Chem. Eng. 2020, 8, 1471–1478. [Google Scholar] [CrossRef]

- Silva, F.A.G.S.; Dourado, F.; Gama, M.; Poças, F. Nanocellulose bio-Based composites for food packaging. Nanomaterials 2020, 10, 2041. [Google Scholar] [CrossRef] [PubMed]

- Thipchai, P.; Punyodom, W.; Jantanasakulwong, K.; Thanakkasaranee, S.; Hinmo, S.; Pratinthong, K.; Kasi, G.; Rachtanapun, P. Preparation and characterization of cellulose nanocrystals from bamboos and their application in cassava starch-based film. Polymers 2023, 15, 2622. [Google Scholar] [CrossRef]

- Ludwicka, K.; Kaczmarek, M.; Białkowska, A. Bacterial nanocellulose—A biobased polymer for active and intelligent food packaging applications: Recent advances and developments. Polymers 2020, 12, 2209. [Google Scholar] [CrossRef]

- Dhali, K.; Ghasemlou, M.; Daver, F.; Cass, P.; Adhikari, B. A review of nanocellulose as a new material towards environmental sustainability. Sci. Total Environ. 2021, 775, 145871. [Google Scholar] [CrossRef] [PubMed]

- Clauser, N.M.; Felissia, F.F.; Area, M.C.; Vallejos, M.E. Chapter 2—Technological and economic barriers of industrial-scale production of nanocellulose. In Micro and Nano Technologies, Green Nanomaterials for Industrial Applications; Shanker, A., Hussain, C.M., Rani, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 21–39. [Google Scholar] [CrossRef]

- Sofiah, A.G.N.; Pasupuleti, J.; Samykano, M.; Kadirgama, K.; Koh, S.P.; Tiong, S.K.; Pandey, A.K.; Yaw, C.T.; Natarajan, S.K. Harnessing nature’s ingenuity: A comprehensive exploration of nanocellulose from production to cutting-edge applications in engineering and sciences. Polymers 2023, 15, 3044. [Google Scholar] [CrossRef]

- Ai, Y.; Zhang, L.; Cui, M.; Huang, R.; Qi, W.; He, Z.; Klemes, J.J.; Su, R. Toward cleaner production of nanocellulose: A review and evaluation. Green Chem. 2022, 24, 6406–6434. [Google Scholar] [CrossRef]

- Ferreira, P.J.T.; Lourenço, A.F. Nanocelluloses: Production, characterization and market. In Nanotoxicology in Safety Assessment of Nanomaterials. Advances in Experimental Medicine and Biology; Louro, H., Silva, M.J., Eds.; Springer: Cham, Switzerland, 2022; Volume 1357, pp. 129–151. [Google Scholar] [CrossRef]

- Randhawa, A.; Dutta, S.D.; Ganguly, K.; Patil, T.V.; Patel, D.K.; Lim, K.-T. A review of properties of nanocellulose, its synthesis, and potential in biomedical applications. Appl. Sci. 2022, 12, 7090. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From fundamentals to advanced applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef]

- Pradeep, H.K.; Patel, D.H.; Onkarappa, H.S.; Prasanna, G.D.; Prateeksha, C.C. Role of nanocellulose in industrial and pharmaceutical sectors-A review. Int. J. Biol. Macromol. 2022, 207, 1038–1047. [Google Scholar] [CrossRef]

- Kim, J.H.; Shim, B.S.; Kim, H.S.; Lee, Y.J.; Min, S.K.; Jang, D.; Abas, Z.; Kim, J. Review of nanocellulose for sustainable future materials. Int. J. Precis. Eng. Manuf.-Green Technol. 2015, 2, 197–213. [Google Scholar] [CrossRef]

- Tayeb, A.H.; Amini, E.; Ghasemi, S.; Tajvidi, M. Cellulose nanomaterials—Binding properties and applications: A review. Molecules 2018, 23, 2684. [Google Scholar] [CrossRef]

- Qi, Y.; Guo, Y.; Liza, A.A.; Yang, G.; Sipponen, M.H.; Guo, J.; Li, H. Nanocellulose: A review on preparation routes and applications in functional materials. Cellulose 2023, 30, 4115–4147. [Google Scholar] [CrossRef]

- Padhi, S.; Singh, A.; Routray, W. Nanocellulose from agro-waste: A comprehensive review of extraction methods and applications. Rev. Environ. Sci. Biotechnol. 2023, 22, 1–27. [Google Scholar] [CrossRef]

- de Amorim, J.D.P.; de Souza, K.C.; Duarte, C.R.; da Silva Duarte, I.; de Assis Sales Ribeiro, F.; Silva, G.S.; de Farias, P.M.A.; Sting, A.; Costa, A.F.S.; Vinhas, G.M.; et al. Plant and bacterial nanocellulose: Production, properties and applications in medicine, food, cosmetics, electronics and engineering. A review. Environ. Chem. Lett. 2020, 18, 851–869. [Google Scholar] [CrossRef]

- Ghilan, A.; Nicu, R.; Ciolacu, D.E.; Ciolacu, F. Insight into the latest medical applications of nanocellulose. Materials 2023, 16, 4447. [Google Scholar] [CrossRef]

- Thomas, P.; Duolikun, T.; Rumjit, N.P.; Moosavi, S.; Lai, C.W.; Johan, M.R.B.; Fen, L.B. Comprehensive review on nanocellulose: Recent developments, challenges and future prospects. J. Mech. Behav. Biomed. Mater. 2020, 110, 103884. [Google Scholar] [CrossRef] [PubMed]

- Delepierre, G.; Vanderfleet, O.M.; Niinivaara, E.; Zakani, B.; Cranston, E.D. Benchmarking cellulose nanocrystals Part II: New industrially produced materials. Langmuir 2021, 37, 8393–8409. [Google Scholar] [CrossRef] [PubMed]

- Pulp and Paper Technology. Available online: https://www.pulpandpaper-technology.com/suppliers/fiberlean-technologies (accessed on 17 May 2023).

- Xie, H.; Du, H.; Yang, X.; Si, C. Recent strategies in preparation of cellulose nanocrystals and cellulose nanofibrils derived from raw cellulose materials. Int. J. Polym. Sci. 2018, 2018, 7923068. [Google Scholar] [CrossRef]

- Roopchund, R.; Andrew, J.; Sithole, B. Using a systematic review to develop a cellulose nanocrystals production framework for use as a design baseline and optimization tool. S. Afr. J. Chem. Eng. 2023, 44, 344–355. [Google Scholar] [CrossRef]

- Joe, C. Top Companies in Nanocellulose Market by Size, Share, Historical and Future Data & CAGR. Vantage Market Research. Available online: https://v-mr.biz/nanocellulose-market (accessed on 18 May 2023).

- Rebouillat, S.; Pla, F. State of the art manufacturing and engineering of nanocellulose: A review of available data and industrial applications. J. Biomater. Nanobiotechnol. 2013, 4, 165–188. [Google Scholar] [CrossRef]

- Jirathampinyo, S.; Chumchoochart, W.; Tinoi, J. Integrated Biobased Processes for Nanocellulose Preparation from Rice Straw Cellulose. Processes 2023, 11, 1006. [Google Scholar] [CrossRef]

- Skočaj, M. Bacterial nanocellulose in papermaking. Cellulose 2019, 26, 6477–6488. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Arantes, V.; Dias, I.K.R.; Berto, G.L.; Pereira, B.; Marotti, B.S.; Nogueira, C.F.O. The current status of the enzyme-mediated isolation and functionalization of nanocelluloses: Production, properties, techno-economics, and opportunities. Cellulose 2020, 27, 10571–10630. [Google Scholar] [CrossRef]

- Salem, K.S.; Barrios, N.; Jameel, H.; Pal, L.; Lucia, K. Computational and experimental insights into the molecular architecture of water-cellulose networks. Matter 2023, 6, 1366–1381. [Google Scholar] [CrossRef]

- de Assis, C.A.; Houtman, C.; Phillips, R.; Bilek, E.M.; Rojas, O.J.; Pal, L.; Peresin, M.S.; Jamel, H.; Gonzalez, R. Conversion economics of forest biomaterials: Risk and financial analysis of CNC manufacturing. Biofuel. Bioprod. Biorefin. 2017, 11, 682–700. [Google Scholar] [CrossRef]

- Vanhatalo, K.M.; Parviainen, K.E.; Dahl, O.P. Techno-economic analysis of simplified microcrystalline cellulose process. Bioresources 2014, 9, 4741–4755. [Google Scholar] [CrossRef][Green Version]

- Rosales-Calderon, O.; Pereira, B.; Arantes, V. Economic assessment of the conversion of bleached eucalyptus Kraft pulp into cellulose nanocrystals in a stand-alone facility via acid and enzymatic hydrolysis. Biofuel. Bioprod. Biorefin. 2021, 15, 1775–1788. [Google Scholar] [CrossRef]

- Ospina-Varón, R.A.; López-Suárez, F.E.; Aristizábal-Marulanda, V. Prefeasibility study for the nanocellulose production from biomass in the Colombian context. Biomass Convers. Biorefin. 2022, 12, 1–12. [Google Scholar] [CrossRef]

- Bondancia, T.J.; Batista, G.; de Aguiar, J.; Lorevice, M.V.; Cruz, A.J.; Marconcini, J.M.; Mattoso, L.H.C.; Farinas, C.S. Cellulose nanocrystals from sugar cane bagasse using organic and/or inorganic acids: Techno-economic analysis and life cycle assessment. ACS Sustain. Chem. Eng. 2022, 10, 4660–4676. [Google Scholar] [CrossRef]

- Bondancia, T.J.; de Aguiar, J.; Batista, G.; Cruz, A.J.; Marconcini, J.M.; Mattoso, L.H.C.; Farinas, C.S. Production of nanocellulose using citric acid in a biorefinery concept: Effect of the hydrolysis reaction time and techno-economic analysis. Ind. Eng. Chem. Res. 2020, 59, 11505–11516. [Google Scholar] [CrossRef]

- Qing, E.B.C.; Wen, J.K.C.K.; Liang, L.S.; Ying, L.Q.; Jie, L.Q.; Mubarak, N.M. Pilot study of synthesis of nanocrystalline cellulose using waste biomass via ASPEN plus simulation. Mater. Sci. Technol. 2020, 3, 364–370. [Google Scholar] [CrossRef]

- Lan, K.; Xu, Y.; Kim, H.; Ham, C.; Kelley, S.S.; Park, S. Techno-economic analysis of producing xylo-oligosaccharides and cellulose microfibers from lignocellulosic biomass. Biores. Technol. 2021, 340, 125726. [Google Scholar] [CrossRef]

- Blair, M.J.; Mabee, W.E. Techno-economic and market analysis of two emerging forest biorefining technologies. Biofuel. Bioprod. Biorefin. 2021, 15, 1301–1317. [Google Scholar] [CrossRef]

- Behera, B.; Laavanya, D.; Balasubramanian, P. Techno-economic feasibility assessment of bacterial cellulose biofilm production during the Kombucha fermentation process. Biores. Technol. 2022, 346, 126659. [Google Scholar] [CrossRef]

- Dourado, F.; Fontão, A.; Leal, M.; Rodrigues, A.C.; Gama, M. Chapter 12—Process modeling and techno-economic evaluation of an industrial bacterial nanocellulose fermentation process. In Bacterial Nanocellulose; Gama, M., Dourado, F., Bielecki, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; pp. 199–214. [Google Scholar] [CrossRef]

- Jasmania, L.; Thielemans, W. Preparation of nanocellulose and its potential application. Int. J. Nanomater. Nanotechnol. Nanomed. 2018, 4, 14–21. [Google Scholar] [CrossRef]

- Pradhan, D.; Jaiswal, A.K.; Jaiswal, S. Emerging technologies for the production of nanocellulose from lignocellulosic biomass. Carbohydr. Polym. 2022, 285, 119258. [Google Scholar] [CrossRef] [PubMed]

- Teo, H.L.; Wahab, R.A. Towards an eco-friendly deconstruction of agro-industrial biomass and preparation of renewable cellulose nanomaterials: A review. Int. J. Biol. Macromol. 2020, 161, 1414–1430. [Google Scholar] [CrossRef]

- Sinquefield, S.; Ciesielski, P.N.; Li, K.; Gardner, D.J.; Ozcan, S. Nanocellulose dewatering and drying: Current state and future perspectives. ACS Sustain. Chem. Eng. 2020, 8, 9601–9615. [Google Scholar] [CrossRef]

- Squinca, P.; Bilatto, S.; Badino, A.C.; Farinas, C.S. Nanocellulose production in future biorefineries: An integrated approach using tailor-made enzymes. ACS Sustain. Chem. Eng. 2020, 8, 2277–2286. [Google Scholar] [CrossRef]

- Global Nanocellulose Market (2020 to 2030)—Production and Pricing Report. Available online: https://www.businesswire.com/news/home/20201029005772/en/Global-Nanocellulose-Market-2020-to-2030---Production-and-Pricing-Report---ResearchAndMarkets.com (accessed on 17 May 2023).

- Balea, A.; Fuente, E.; Monte, M.C.; Merayo, N.; Campano, C.; Negro, C.; Blanco, A. Industrial application of nanocelluloses in papermaking: A review of challenges, technical solutions, and market perspectives. Molecules 2020, 25, 526. [Google Scholar] [CrossRef] [PubMed]

- Aoudi, B.; Boluk, Y.; El-Din, M.G. Recent advances and future perspective on nanocellulose-based materials in diverse water treatment applications. Sci. Total Environ. 2022, 843, 156903. [Google Scholar] [CrossRef] [PubMed]

- Norrrahim, M.N.F.; Kasim, N.A.M.; Knight, V.F.; Ujang, F.A.; Janudin, N.; Razak, M.A.I.A.; Shah, N.A.A.; Noor, S.A.M.; Jamal, S.H.; Ong, K.K.; et al. Nanocellulose: The next super versatile material for the military. Mater. Adv. 2021, 2, 1485–1506. [Google Scholar] [CrossRef]

| Cost/Value | Scenario I | Scenario II | Scenario III |

|---|---|---|---|

| Major Equipment Costs, MEC (USD) | 2,959,817 | 3,292,008 | 2,540,261 |

| Other Direct Costs, ODC (USD) | 8,109,898 | 9,020,102 | 6,960,317 |

| Direct Costs, DC (USD) | 11,069,715 | 12,312,111 | 9,500,578 |

| Indirect Costs, IC (USD) | 2,190,264 | 2,436,086 | 1,879,794 |

| Other Costs, OC (USD) | 2,071,872 | 2,304,406 | 1,778,183 |

| Fixed Capital Investment, FCI (USD) | 15,331,851 | 17,052,602 | 13,158,555 |

| Working Capital, IW (USD) | 2,299,778 | 2,557,890 | 1,973,783 |

| Total Fixed Capital Investment, CAPEX (USD) | 17,631,629 | 19,610,493 | 15,132,338 |

| Raw Materials Costs, RMC (USD/yr) | 905,327 | 901,869 | 778,369 |

| Utilities Costs, UC (USD/yr) | 379,606 | 1,091,048 | 772,536 |

| Labor Costs, LC (USD/yr) | 147,660 | 147,660 | 147,660 |

| Waste Treatment Costs, CWT (USD/yr) | 148,039 | 148,039 | 110,636 |

| Other Direct Production Costs, ODPC (USD/yr) | 930,638 | 1,030,571 | 804,050 |

| Direct Production Costs, DPC(USD/yr) | 2,511,271 | 3,319,187 | 2,613,252 |

| Annual Fixed Costs, AFC (USD/yr) | 2,943,715 | 3,274,100 | 2,526,442 |

| General Costs, GC (USD/yr) | 176,471 | 192,216 | 155,837 |

| Total Production Costs, OPEX (USD/yr) | 7,342,332 | 8,789,837 | 6,883,896 |

| Production Cost, PC (USD/kg) | 3.67 | 4.39 | 3.44 |

| Minimum Product Selling Price, MPSP (USD/kg) | 6.43 | 7.46 | 5.81 |

| Product Price, PP (USD/kg) | 8.36 | 9.70 | 7.55 |

| Total Revenue, TR (USD/yr) | 16,720,338 | 19,407,406 | 15,107,268 |

| Gross Profit, GP (USD/yr) | 9,378,006 | 10,617,569 | 8,223,372 |

| Net Profit, NP (USD/yr) | 5,455,596 | 6,161,415 | 4,769,614 |

| Return on Investment, ROI (%) | 21.85% | 21.69% | 21.66% |

| Pay-out Time, POT (yr) | 2.19 | 2.17 | 2.16 |

| Venture Profit, V (USD/yr) | 1,929,270 | 2,239,316 | 1,743,146 |

| Specific Energy Consumption, SEC (kWhel/kg) | 0.38 | 1.03 | 1.02 |

| Specific Water Consumption, SWC (kg/kg) | 0.59 | 0.60 | 0.27 |

| Cost/Value | Base Case Study (CS1) | Optimized Case Study (CS2) |

|---|---|---|

| Fixed-Capital Investment, FCI (USD) | 15,331,851 | 14,625,463 |

| Total Fixed-Capital Investment, CAPEX (USD) | 17,631,629 | 16,819,282 |

| Total Production Costs, OPEX (USD/yr) | 7,342,332 | 6,723,320 |

| Production Cost, PC (USD/kg) | 3.67 | 3.36 |

| Minimum Product Selling Price, MPSP (USD/kg) | 6.43 | 7.46 |

| Product Price, PP (USD/kg) | 8.36 | 9.70 |

| Total Revenue, TR (USD/yr) | 16,720,338 | 16,720,338 |

| Gross Profit, GP (USD/yr) | 9,378,006 | 9,997,019 |

| Net Profit, NP (USD/yr) | 5,455,596 | 5,729,783 |

| Return on Investment, ROI (%) | 21.85% | 24.34% |

| Pay-out Time, POT (yr) | 2.19 | 2.03 |

| Venture Profit, V (USD/yr) | 1,929,270 | 2,365,926 |

| Specific Energy Consumption, SEC (kWhel/kg) | 0.38 | 0.32 |

| Specific Water Consumption, SWC (kg/kg) | 0.59 | 0.48 |

| Ref. # | Raw Material | Production Technology | Research Scenarios | Capacity 1 (tn/yr) | Product Type(s) | Cost/ Price 1 (USD/kg) | Start Year | Country |

|---|---|---|---|---|---|---|---|---|

| [32] | Dissolving pulp | Size reduction and acid hydrolysis | Acid recovery and plant co-location or not | 17,500 | NCC | 3.6– 4.4 2 | 2019 | USA |

| [33] | Bleached softwood Kraft pulp | Mechanical (milling) and acid hydrolysis | Standalone or integrated to an existing plant | 30,000 | MFC | 1.8 2 | 2014 | Finland |

| [34] | Bleached eucalyptus Kraft pulp | Acid and enzymatic hydrolysis | Alternative hydrolysis processes | 4250 | NCC | 7.8– 50 2 | 2017 | Brazil |

| [35] | Sugarcane bagasse | Thermochemical pretreatment and alkaline/acid hydrolysis | Various pretreatment and extraction methods | 400,000–460,000 | Non- specified NC | 0.7– 3.1 2 | 2022 | Colombia |

| [36,37] | Sugarcane bagasse | Pretreatment, enzymatic and acid hydrolysis | Organic and inorganic acid catalysts | 1500– 2400 | NCC NFC | 6.9– 10.9 3 | 2021 | Brazil |

| [38] | Oil palm fronds | Thermochemical pretreatment and acid hydrolysis | Base, best and worst case scenarios | 25,000 | NCC | 1.2– 1.5 3 | 2020 | Malaysia |

| [39] | Miscanthus | Alkali treatment and bleaching | Biorefinery with multiple products | 18,000– 91,000 | MFC | 1.5– 3 2 | 2019 | Korea |

| [40] | Woodchips | Mechanical treatment and bleaching | Various biorefining scenarios | 42,000 | NCC NCF | 1.7– 2.5 3 | 2021 | Canada |

| This study | Phalaris aquatica | Chemical and mechanical protocols | Different scenarios and types of NC | 2000– 2800 | NCC NFC MFC | 3.4–3.7 2 4.0–4.4 2 3.1–3.4 2 | 2023 | Greece |

| [41] | Commercial saccharose | Fermentation and extrusion | Single scenario | 60,000 | BC film | 63.8 2 | 2022 | India |

| [42] | Beet molasses | Multi-step fermentation | Single scenario | 500 | BC | 14.8 2 | 2016 | Portugal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Penloglou, G.; Basna, A.; Pavlou, A.; Kiparissides, C. Techno-Economic Considerations on Nanocellulose’s Future Progress: A Short Review. Processes 2023, 11, 2312. https://doi.org/10.3390/pr11082312

Penloglou G, Basna A, Pavlou A, Kiparissides C. Techno-Economic Considerations on Nanocellulose’s Future Progress: A Short Review. Processes. 2023; 11(8):2312. https://doi.org/10.3390/pr11082312

Chicago/Turabian StylePenloglou, Giannis, Aikaterini Basna, Alexandros Pavlou, and Costas Kiparissides. 2023. "Techno-Economic Considerations on Nanocellulose’s Future Progress: A Short Review" Processes 11, no. 8: 2312. https://doi.org/10.3390/pr11082312

APA StylePenloglou, G., Basna, A., Pavlou, A., & Kiparissides, C. (2023). Techno-Economic Considerations on Nanocellulose’s Future Progress: A Short Review. Processes, 11(8), 2312. https://doi.org/10.3390/pr11082312