Effects of Different Cooking Methods on Glycemic Index, Physicochemical Indexes, and Digestive Characteristics of Two Kinds of Rice

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Experimental Methods

2.2.1. Sample Processing

2.2.2. Analysis of Texture Characteristics

2.2.3. Color Analysis

2.2.4. Near-Infrared Spectroscopy

2.2.5. Microstructure Analysis after Cooking

2.2.6. Determination of Debranched Enzyme Activity

- A denotes the corresponding glucose content (mg);

- V denotes the enzyme extract volume (mL);

- N denotes the dilution ratio of the extract;

- 180 denotes the molecular weight of glucose;

- W denotes the sample weight (g);

- 30 denotes the reaction time (min).

2.2.7. Determination of Amylose Content

2.2.8. Determination of In Vitro Glycemic Index of Rice

2.2.9. Determination of Rice Digestibility

- G20 denotes the glucose content (mg) produced after the 20 min hydrolysis of G20-amylase;

- FG denotes the free glucose content (mg) in starch before the FG enzymatic hydrolysis;

- G120 denotes the glucose content (mg) produced after the 120 min hydrolysis of G120-amylase;

- TS denotes the total starch content (mg) in the sample.

2.2.10. Data Analysis

3. Results and Analysis

3.1. Analysis of Texture Characteristics

3.2. Color Analysis

3.3. Infrared Spectrum Analysis

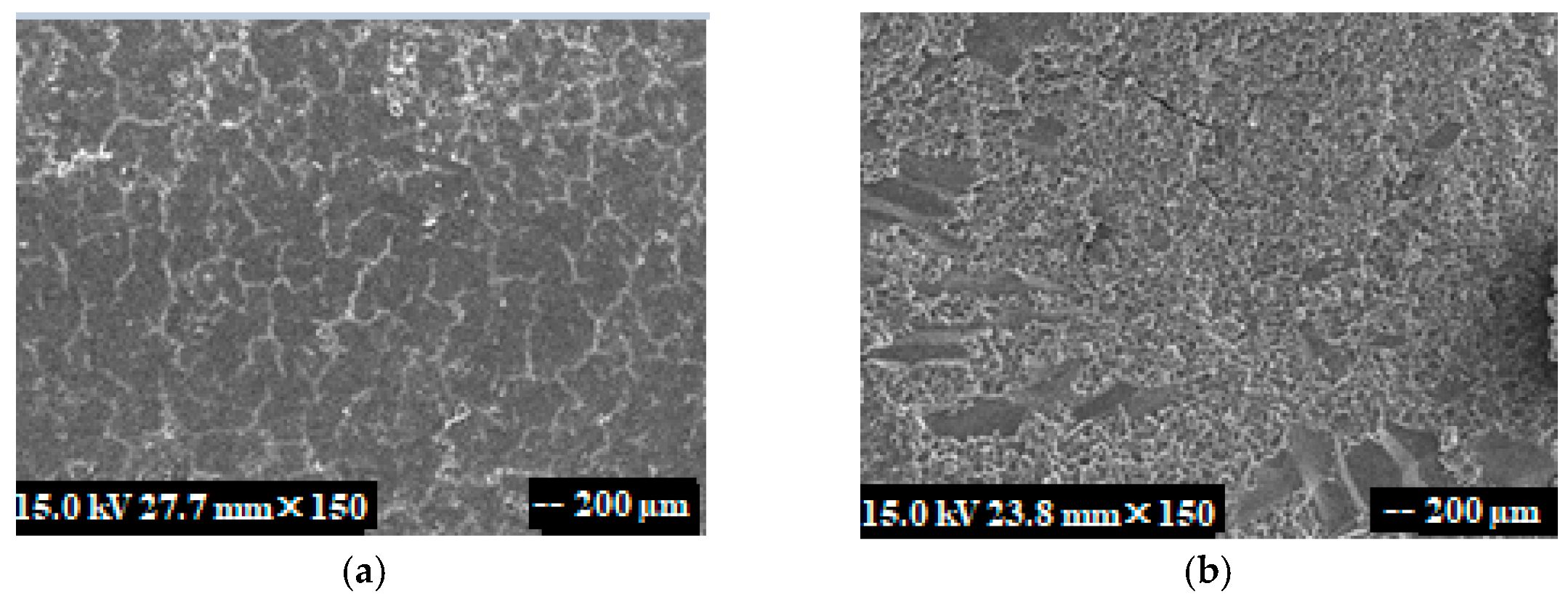

3.4. Microstructure Analysis

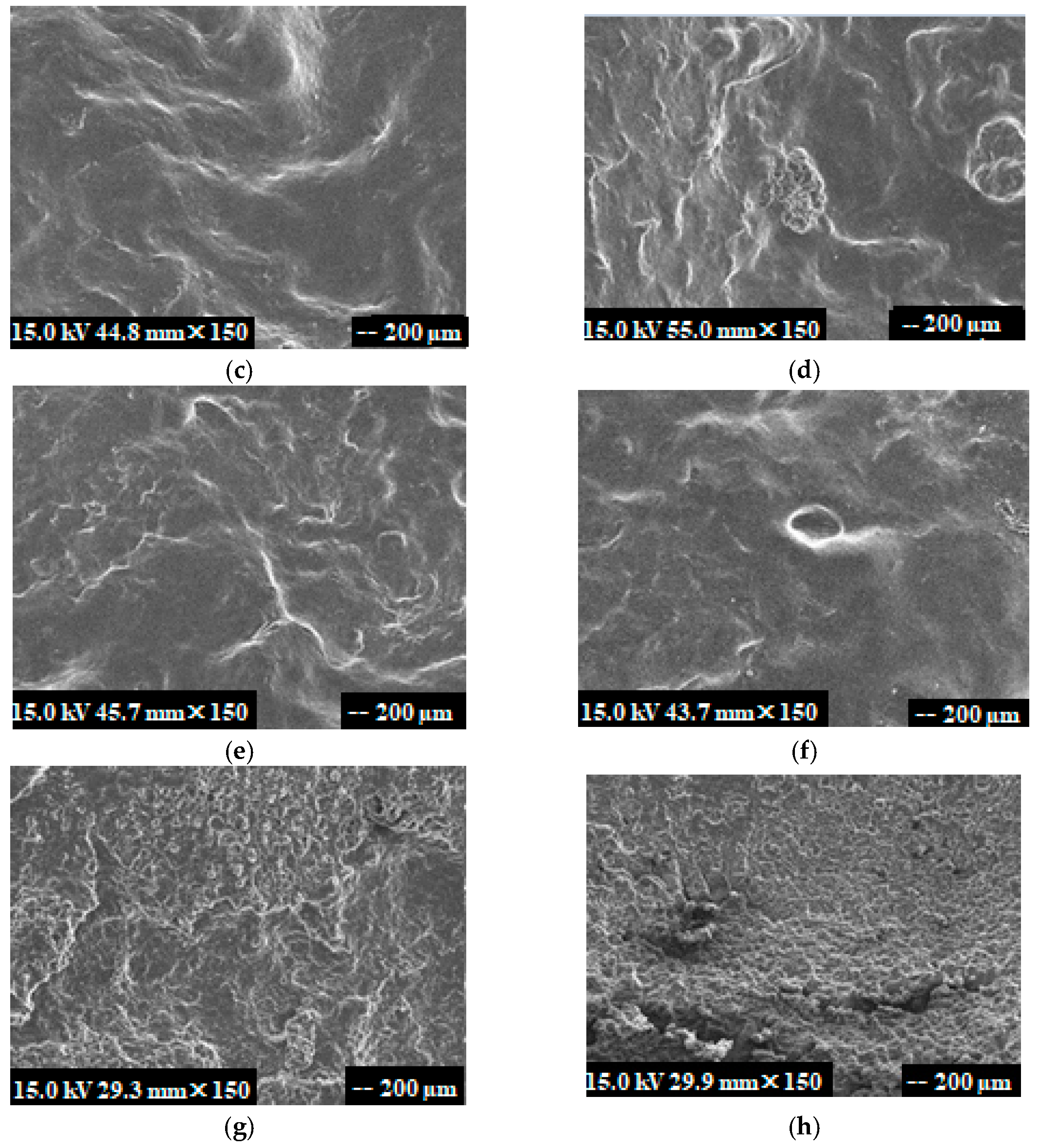

3.5. Determination of Debranched Enzyme Activity

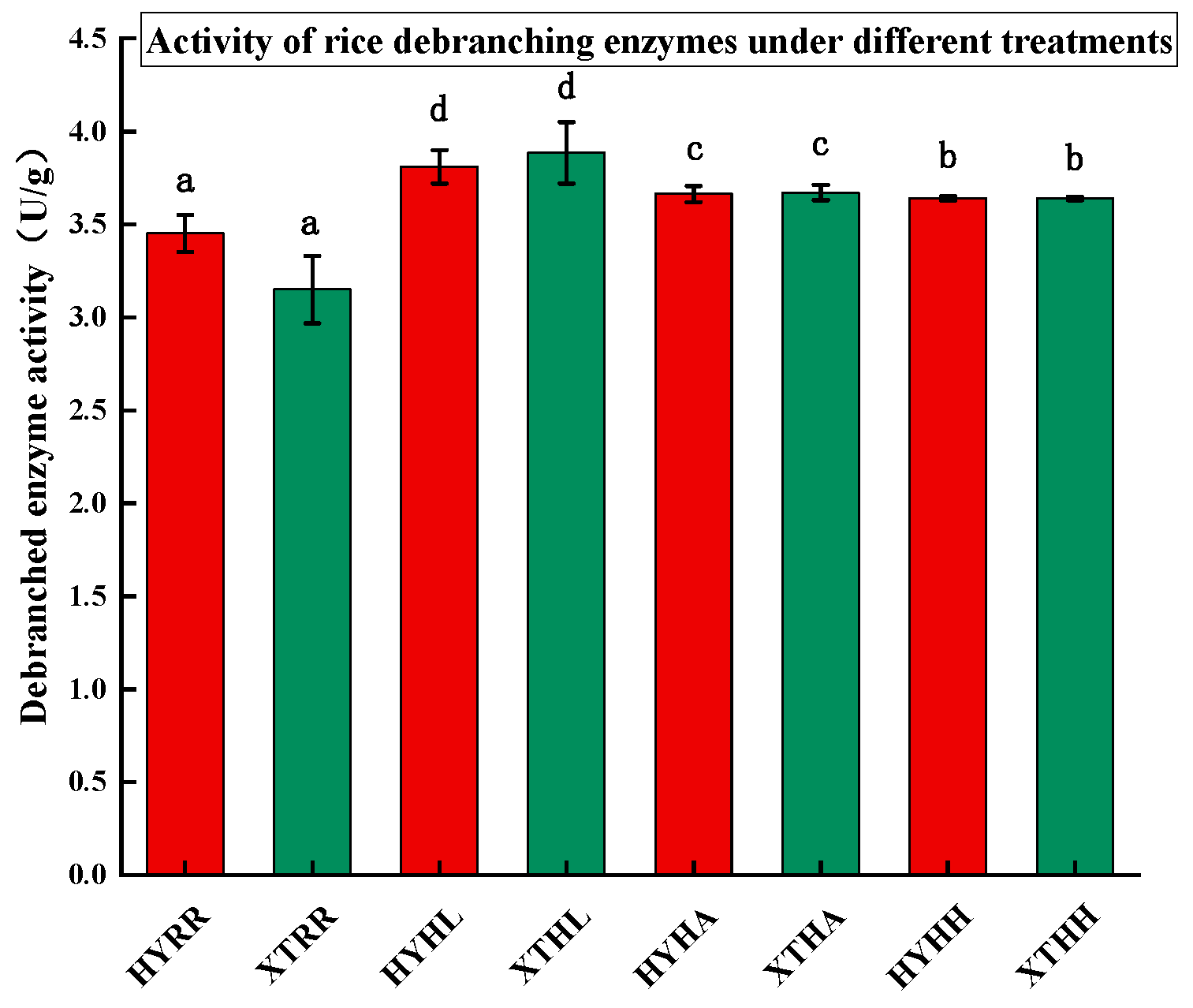

3.6. Determination of Amylose Content

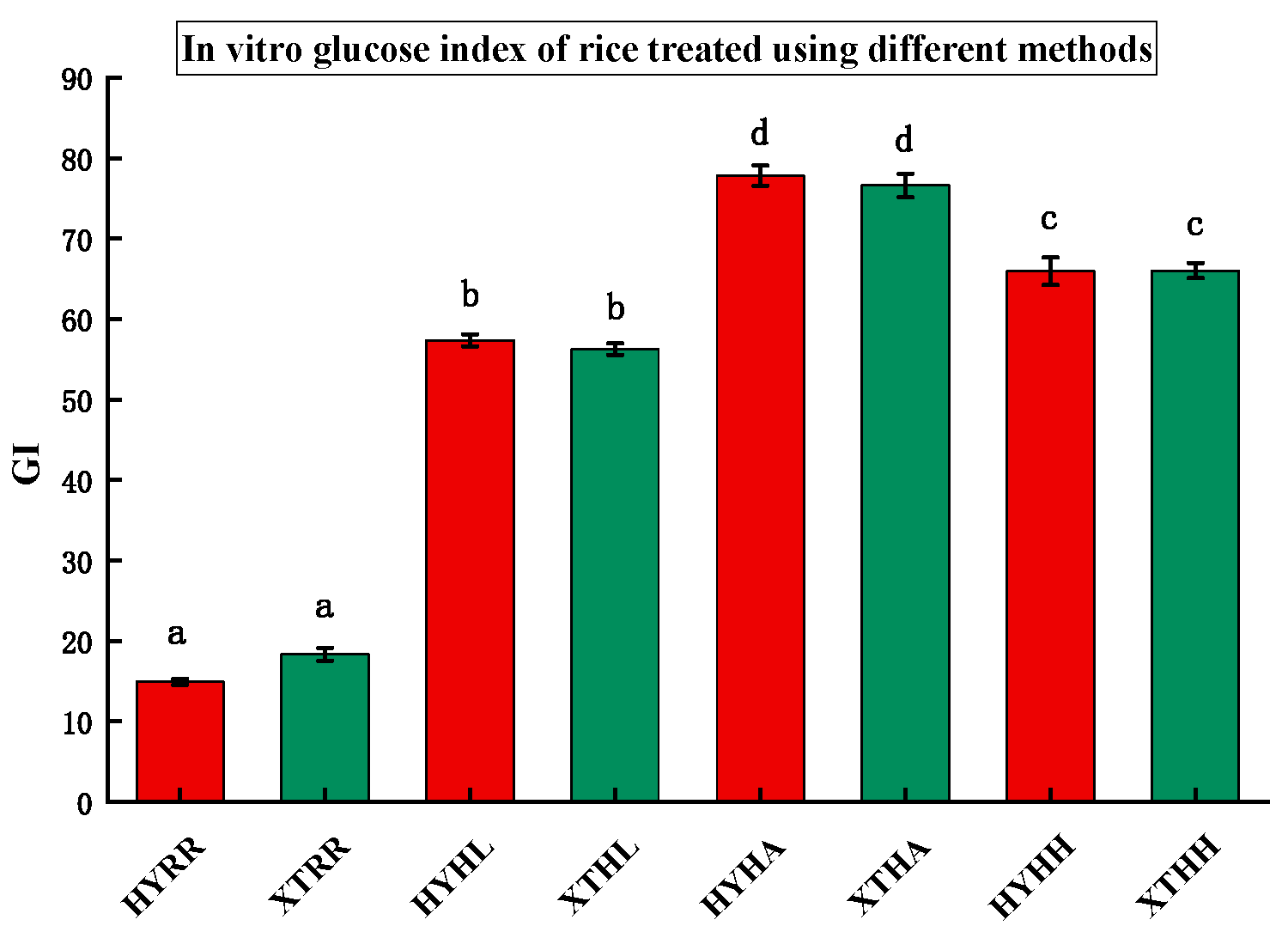

3.7. In Vitro Glucose Index Analysis of Rice

3.8. Analysis of Digestive Characteristics of Rice

3.9. Application Feasibility of Plasma Technology

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, H.; Saeedi, P.; Karuranga, S.; Pinkepank, M.; Ogurtsova, K.; Duncan, B.B.; Stein, C.; Basit, A.; Chan, J.C.N.; Mbanya, J.C.; et al. IDF Diabetes Atlas: Global, regional and country-level diabetes prevalence estimates for 2021 and projections for 2045. Diabetes Res. Clin. Pract. 2022, 183, 109119. [Google Scholar] [CrossRef] [PubMed]

- Zhi, Z.N.K.Z. Clinical guidelines for prevention and treatment of type 2 diabetes mellitus in the elderly in China (2022 edition). Chin. J. Intern. Med. 2022, 61, 12–50. [Google Scholar]

- Buse, J.B.; Wexler, D.J.; Tsapas, A.; Rossing, P.; Mingrone, G.; Mathieu, C.; D’Alessio, D.A.; Davies, M.J. 2019 Update to: Management of Hyperglycemia in Type 2 Diabetes, 2018. A Consensus Report by the American Diabetes Association (ADA) and the European Association for the Study of Diabetes (EASD). Diabetes Care 2020, 43, 487–493. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.L.H.; Fan, H.R.; Ye, L.J.; Zhang, P.H. Study on the glycemic Index of rice with high resistance starch and its intervention in the regulation of blood glucose in diabetic patients. Chin. J. Nutr. 2017, 39, 197–199. [Google Scholar]

- Fitzgerald, M.A.; Rahman, S.; Resurreccion, A.P.; Concepcion, J.; Daygon, V.D.; Dipti, S.S.; Kabir, K.A.; Klingner, B.; Morell, M.K.; Bird, A.R. Identification of a major genetic determinant of glycaemic index in rice. Rice 2011, 4, 66–74. [Google Scholar] [CrossRef]

- Leonora, N.; Thompson, L.U. Blood glucose lowering effects of brown rice in normal and diabetic subjects. Int. J. Food Sci. Nutr. 2006, 57, 151–158. [Google Scholar]

- Ranawana, D.V.; Tan, W.J.K.; Quek, Y.C.R.; Henry, C.J. The impact of eating methods on eating rate and glycemic response in healthy adults. Physiol. Behav. 2015, 139, 505–510. [Google Scholar]

- Panlasigui, L.N.; Thompson, L.U.; Juliano, B.O.; Perez, C.M.; Greenberg, G.R. Rice varieties with similar amylose content differ in starch digestibility and glycemic response in humans. Am. J. Clin. Nutr. 1991, 54, 871–877. [Google Scholar] [CrossRef]

- Li, X.; Jiang, Y.; Tao, Y.; Li, W.Q.; Wang, F.Q.; Chen, Z.H.; Xu, Y.; Wang, J.; Fan, F.J.; Zhu, J.P.; et al. Research Progress of Rice with Low Glycemic Index. Chin. J. Rice Sci. 2022, 36, 336–347. [Google Scholar]

- Kunyanee, K.; Luangsakul, N. The impact of heat moisture treatment on the physicochemical properties and in vitro glycemic index of rice flour with different amylose contents and associated effects on rice dumpling quality. LWT 2022, 154, 112694. [Google Scholar] [CrossRef]

- Sajilata, M.G.; Singhal, R.S.; Kulkarni, P.R. Resistant starch—A review. Compr. Rev. Food Sci. Food Saf. 2006, 5, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Darandakumbura, H.D.K.; Wijesinghe, D.G.N.G.; Prasantha, B.D.R. Effect of processing conditions and cooking methods on resistant starch, dietary fiber and glycemic index of rice. Trop. Agric. Res. 2013, 24, 163–174. [Google Scholar]

- Lee, J.S.; Cho, S.M.; Kim, B.K.; Han, J.A. Development of a cooked rice model for bibimbap and resulting physico-digestive properties. Food Sci. Biot. 2016, 25, 489–495. [Google Scholar] [CrossRef] [PubMed]

- Stewart, Y.-T.C.M.L. Effect of variety and cooking method on resistant starch content of white rice and subsequent postprandial glucose response and appetite in humans. Asia Pac. J. Clin. Nutr. 2013, 22, 372–379. [Google Scholar]

- Liu, M.; Shen, Y.H. A Plasma Low Pressure High Temperature Steam Food Preservation Equipment. Chinese Patent CN114668096A, 28 June 2022. Available online: https://www.cnipa.gov.cn/ (accessed on 20 June 2023).

- Schluter, O.; Ehlbeck, J.; Hertel, C.; Habermeyer, M.; Roth, A.; Engel, K.H.; Holzhauser, T.; Knorr, D.; Eisenbrand, G. Opinion on the use of plasma processes for treatment of foods. Mol. Nutr. Food Res. 2013, 57, 920–927. [Google Scholar] [CrossRef]

- Mir, S.A.; Shah, M.A.; Mir, M.M. Understanding the role of plasma technology in food industry. Food Bioprocess Technol. 2016, 9, 734–750. [Google Scholar] [CrossRef]

- Usman, I.; Afzaal, M.; Imran, A.; Saeed, F.; Afzal, A.; Ashfaq, I.; Shah, Y.A.; Islam, F.; Azam, I.; Tariq, I.; et al. Recent updates and perspectives of plasma in food processing: A review. Int. J. Food Prop. 2023, 26, 552–566. [Google Scholar] [CrossRef]

- Oliveira, M.; Fernandez-Gomez, P.; Alvarez-Ordonez, A.; Prieto, M.; Lopez, M. Plasma-activated water: A cutting-edge technology driving innovation in the food industry. Food Res. Int. 2022, 156, 111368. [Google Scholar] [CrossRef]

- Zhu, L.; Bi, S.; Wu, G.; Zhang, H.; Wang, L.; Qian, H.; Qi, X.; Jiang, H. Comparative analysis of the texture and physicochemical properties of cooked rice based on adjustable rice cooker. LWT 2020, 130, 109650. [Google Scholar] [CrossRef]

- Shen, R.L.; Zhang, W.J.; Dong, J. Preparation, structural characteristics and digestibility of resistant starches from highland barley, oats and buckwheat starches. J. Food Nutr. Res. 2016, 55, 303–312. [Google Scholar]

- Wang, S.; Luo, H.; Zhang, J.; Zhang, Y.; He, Z.; Wang, S. Alkali-induced changes in functional properties and in vitro digestibility of wheat starch: The role of surface proteins and lipids. J. Agric. Food Chem. 2014, 62, 3636–3643. [Google Scholar] [CrossRef] [PubMed]

- Goni, I.; Garcia-Alonso, A.; Saura-Calixto, F. A starch hydrolysis procedure to estimate glycemic index. Nutr. Res. 1997, 17, 427–437. [Google Scholar] [CrossRef]

- Englyst, H.N.; Kingman, K.S.; Cummings, J.H. Classification and measurement of nutritionally important starch fractions. Eur. J. Clin. Nutr. 1992, 46, 33–50. [Google Scholar]

- Li, W.Q.; Zhang, K.H. Study on the influence factors of rice color. Grain Process. 2011, 36, 33–35. (In Chinese) [Google Scholar]

- Genkawa, T.; Ahamed, T.; Noguchi, R.; Takigawa, T.; Ozaki, Y. Simple and rapid determination of free fatty acids in brown rice by FTIR spectroscopy in conjunction with a second-derivative treatment. Food Chem. 2016, 191, 7–11. [Google Scholar] [CrossRef]

- Samyor, D.; Deka, S.C.; Das, A.B. Phytochemical and antioxidant profile of pigmented and non-pigmented rice cultivars of Arunachal Pradesh, India. Int. J. Food Prop. 2015, 19, 1104–1114. [Google Scholar] [CrossRef]

- Giang, L.T.; Thien, T.L.T.; Yen, D.H. Rapid classification of rice in northern vietnam by using FTIR spectroscopy combined with chemometrics methods. Vietnam J. Chem. 2020, 58, 372–379. [Google Scholar] [CrossRef]

- Wang, Y.F.; Zhang, W.L.; Huang, D.; Dou, Y. The advance of starch-debranching enzyme and the application. China Brew 2008, 27, 25–26. [Google Scholar]

- Jenkins, D.J.A.; Wolever, T.M.S.; Taylor, R.H.; Barker, H.; Fielden, H.; Baldwin, J.M.; Bowling, A.C.; Newman, H.C.; Jenkins, A.L.; Goff, D.V. Glycemic index of foods: A physiological basis for carbohydrate exchange. Am. J. Clin. Nutr. 1981, 34, 362–366. [Google Scholar] [CrossRef]

- Riccardi, G.; Rivellese, A.A.; Giacco, R. Role of glycemic index and glycemic load in the healthy state, in prediabetes, and in diabetes. Am. J. Clin. Nutr. 2008, 87, 269–274. [Google Scholar] [CrossRef]

- Mann, J.; Cummings, J.H.; Englyst, H.N.; Key, T.; Liu, S.; Riccardi, G.; Summerbell, C.; Uauy, R.; van Dam, R.M.; Venn, B.; et al. FAO/WHO scientific update on carbohydrates in human nutrition: Conclusions. Eur. J. Clin. Nutr. 2007, 61 (Suppl. S1), S132–S137. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zhang, W.Q. Food glycemic index and glycemic load in the prevention and treatment of chronic diseases. Chin. J. Med. Clin. 2014, 14, 1062–1064. [Google Scholar]

| Sample Name | Processing Mode |

|---|---|

| XTRR | Xiantao raw rice |

| HYRR | Heyuan raw rice |

| XTHL | Xiantao rice cooked at high temperature and low pressure using plasma equipment |

| HYHL | Heyuan rice cooked at high temperature and low pressure using plasma equipment |

| XTHA | Xiantao rice cooked at high-temperature atmospheric pressure using a household cooker |

| HYHA | Heyuan rice cooked at high-temperature atmospheric pressure using a household cooker |

| XTHH | Xiantao rice cooked at high pressure and high temperature |

| HYHH | Heyuan rice cooked at high pressure and high temperature |

| Treatment Mode | Hardness/g | Elasticity | Adhesiveness | Mastication | Resilience |

|---|---|---|---|---|---|

| XTRR | 1214.64 ± 24.19 a | 0.18 ± 0.01 c | 10.24 ± 0.58 d | 3.05 ± 0.19 c | 0.02 ± 0.00 d |

| XTHL | 198.69 ± 10.51 d | 0.65 ± 0.03 a | 37.74 ± 1.38 c | 94.75 ± 4.22 b | 0.15 ± 0.01 b |

| XTHA | 205.32 ± 9.18 c | 0.46 ± 0.03 b | 39.73 ± 2.01 b | 94.02 ± 7.13 b | 0.10 ± 0.01 c |

| XTHH | 445.69 ± 16.92 b | 0.62 ± 0.03 a | 48.86 ± 3.17 a | 129.84 ± 8.48 a | 0.24 ± 0.02 a |

| HYRR | 1393.98 ± 25.82 a | 0.38 ± 0.02 d | 18.45 ± 0.84 c | 2.41 ± 0.16 d | 0.02 ± 0.00 d |

| HYHL | 132.07 ± 4.66 d | 0.44 ± 0.01 c | 35.46 ± 2.19 b | 95.65 ± 5.32 b | 0.19 ± 0.01 b |

| HYHA | 176.69 ± 3.71 c | 0.47 ± 0.03 b | 34.62 ± 2.96 b | 91.67 ± 7.16 c | 0.16 ± 0.00 c |

| HYHH | 276.80 ± 6.19 b | 0.67 ± 0.04 a | 53.66 ± 3.98 a | 153.52 ± 6.73 a | 0.23 ± 0.01 a |

| Sample Groups | ||||||

|---|---|---|---|---|---|---|

| XTRR | 88.48 ± 1.54 a | −0.80 ± 0.07 b | 6.45 ± 0.39 b | - | - | - |

| XTHL | 86.68 ± 1.88 b | −0.96 ± 0.05 c | 6.08 ± 0.09 c | −1.80 ± 0.03 a | −0.16 ± 0.01 b | −0.37 ± 0.02 b |

| XTHA | 82.76 ± 2.46 c | −0.95 ± 0.09 c | 5.35 ± 0.33 d | −5.72 ± 0.19 b | −0.15 ± 0.03 b | −1.10 ± 0.09 c |

| XTHH | 81.88 ± 0.98 d | −0.23 ± 0.01 a | 8.09 ± 0.18 a | −6.60 ± 0.32 c | 0.57 ± 0.03 a | 1.64 ± 0.11 a |

| HYRR | 90.70 ± 1.37 a | −0.80 ± 0.05 b | 6.45 ± 0.39 b | - | - | - |

| HYHL | 82.38 ± 1.83 c | −0.79 ± 0.06 b | 4.74 ± 0.22 d | −8.32 ± 0.62 b | 0.01 ± 0.00 b | −1.71 ± 0.09 c |

| HYHA | 86.66 ± 1.90 b | −0.93 ± 0.06 c | 6.34 ± 0.51 c | −4.04 ± 0.15 a | −0.13 ± 0.01 c | −0.11 ± 0.01 b |

| HYHH | 74.18 ± 0.99 d | 0.83 ± 0.02 a | 9.61 ± 0.29 a | −16.52 ± 1.19 c | 1.63 ± 0.09 a | 3.16 ± 0.23 a |

| Treatment Mode | RDS (%) | SDS (%) | RS (%) |

|---|---|---|---|

| HYRR | 0.58 ± 0.02 a | 10.83 ± 0.54 b | 23.98 ± 0.61 a |

| XTRR | 4.33 ± 0.29 b | 6.27 ± 0.34 a | 39.02 ± 1.42 b |

| HYHL | 12.1 ± 1.06 c | 63.92 ± 3.50 d | 88.60 ± 3.10 c |

| XTHL | 12.69 ± 1.01 c | 48.29 ± 2.65 c | 89.40 ± 3.58 c |

| HYHA | 11.35 ± 0.62 d | 27.24 ± 1.64 a | 61.42 ± 1.07 d |

| XTHA | 8.59 ± 0.40 b | 34.05 ± 1.10 b | 57.36 ± 2.54 c |

| HYHH | 9.43 ± 0.53 c | 37.55 ± 1.20 c | 53.02 ± 1.20 a |

| XTHH | 8.16 ± 0.54 a | 37.29 ± 0.61 c | 54.55 ± 1.58 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, F.; Li, C.; Li, J.; Chang, G.; Wang, Y.; Campardelli, R.; Perego, P.; Cai, C. Effects of Different Cooking Methods on Glycemic Index, Physicochemical Indexes, and Digestive Characteristics of Two Kinds of Rice. Processes 2023, 11, 2167. https://doi.org/10.3390/pr11072167

Yao F, Li C, Li J, Chang G, Wang Y, Campardelli R, Perego P, Cai C. Effects of Different Cooking Methods on Glycemic Index, Physicochemical Indexes, and Digestive Characteristics of Two Kinds of Rice. Processes. 2023; 11(7):2167. https://doi.org/10.3390/pr11072167

Chicago/Turabian StyleYao, Feng, Chuanpeng Li, Junyang Li, Guoli Chang, Yuliang Wang, Roberta Campardelli, Patrizia Perego, and Chenggang Cai. 2023. "Effects of Different Cooking Methods on Glycemic Index, Physicochemical Indexes, and Digestive Characteristics of Two Kinds of Rice" Processes 11, no. 7: 2167. https://doi.org/10.3390/pr11072167

APA StyleYao, F., Li, C., Li, J., Chang, G., Wang, Y., Campardelli, R., Perego, P., & Cai, C. (2023). Effects of Different Cooking Methods on Glycemic Index, Physicochemical Indexes, and Digestive Characteristics of Two Kinds of Rice. Processes, 11(7), 2167. https://doi.org/10.3390/pr11072167