Development and Process Optimization of a Ready-to-Eat Snack from Rice-Cowpea Composite by a Twin Extruder

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials Preparation

2.2. Extrusion Cooking

2.3. Determination of Extrusion System Response

Specific Mechanical Energy (SME)

2.4. Properties of Extruded Products

2.4.1. Bulk Density (BD)

2.4.2. Expansion Ratio (ER)

2.4.3. Water Absorption Index and Water Solubility Index (WAI and WSI)

2.4.4. Hardness

2.4.5. Color

2.4.6. Sensory Evaluation

2.4.7. Numerical Optimization

2.5. Statistical Analysis and Experimental Design

3. Results and Discussion

3.1. Effect of Blend Ratio, Moisture Content, Barrel Temperature, and Screw Speed on the Extrudates

3.1.1. Specific Mechanical Energy (SME)

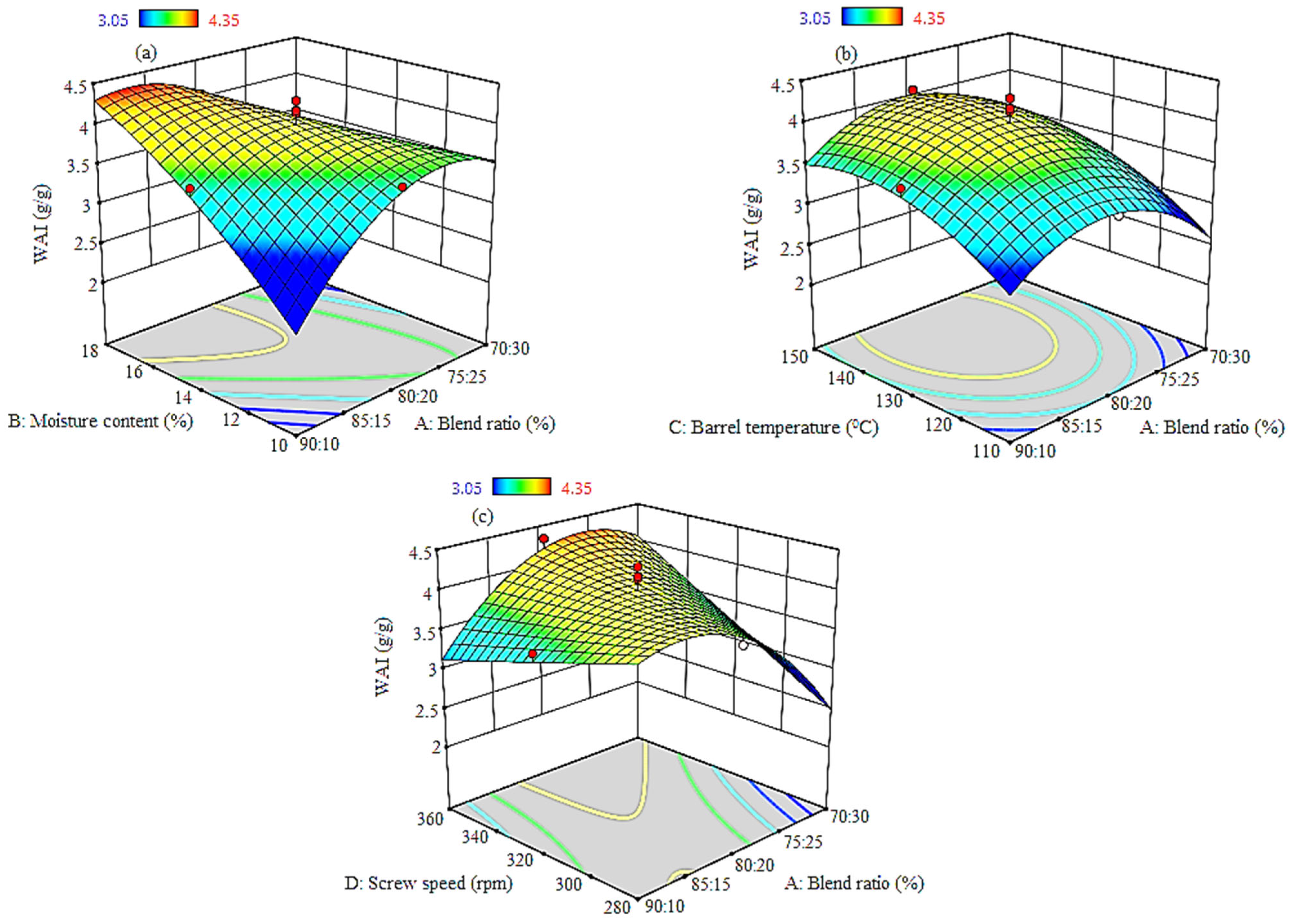

3.1.2. Water Absorption Index (WAI)

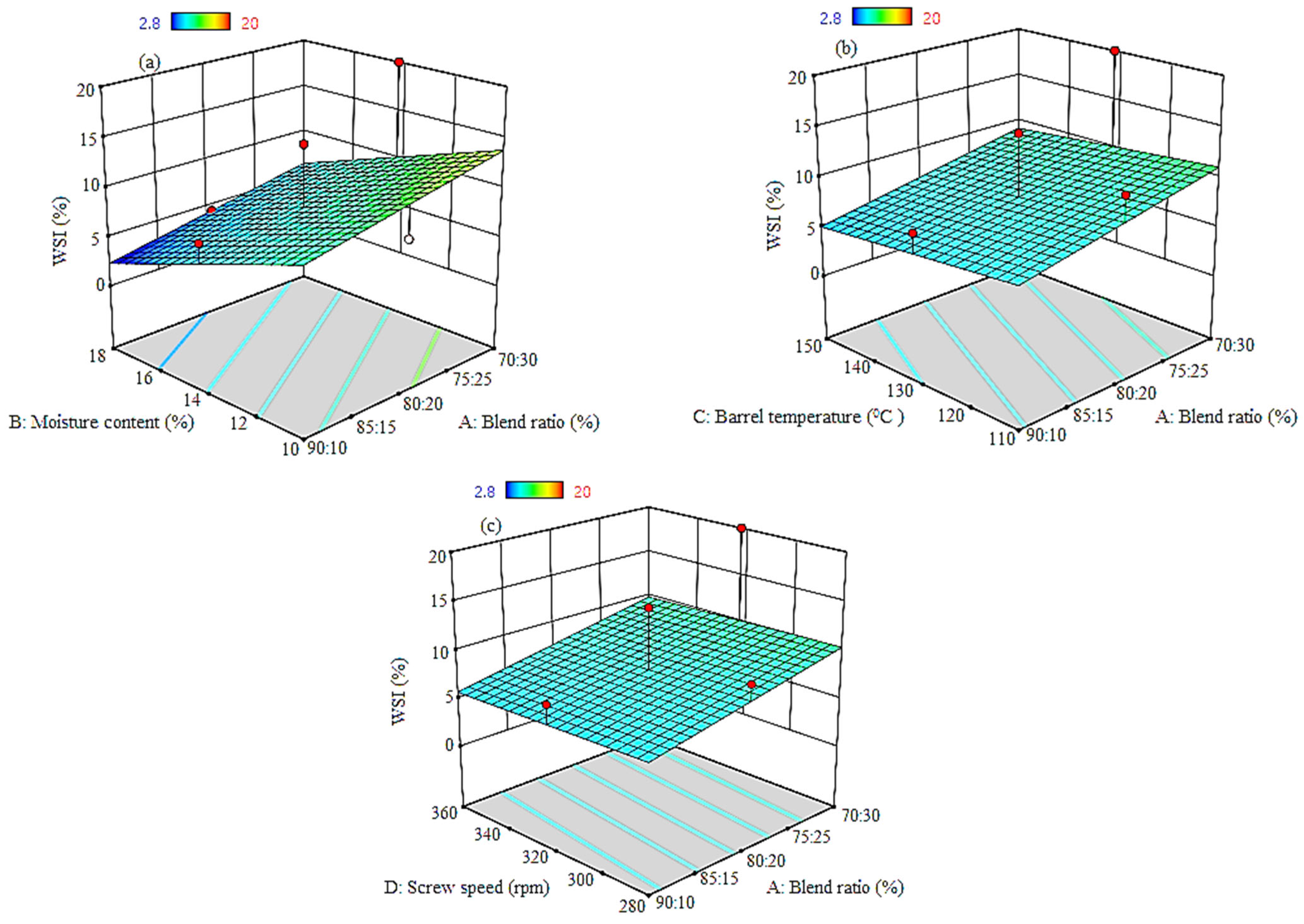

3.1.3. Water Solubility Index (WSI)

3.1.4. Total Color (TC)

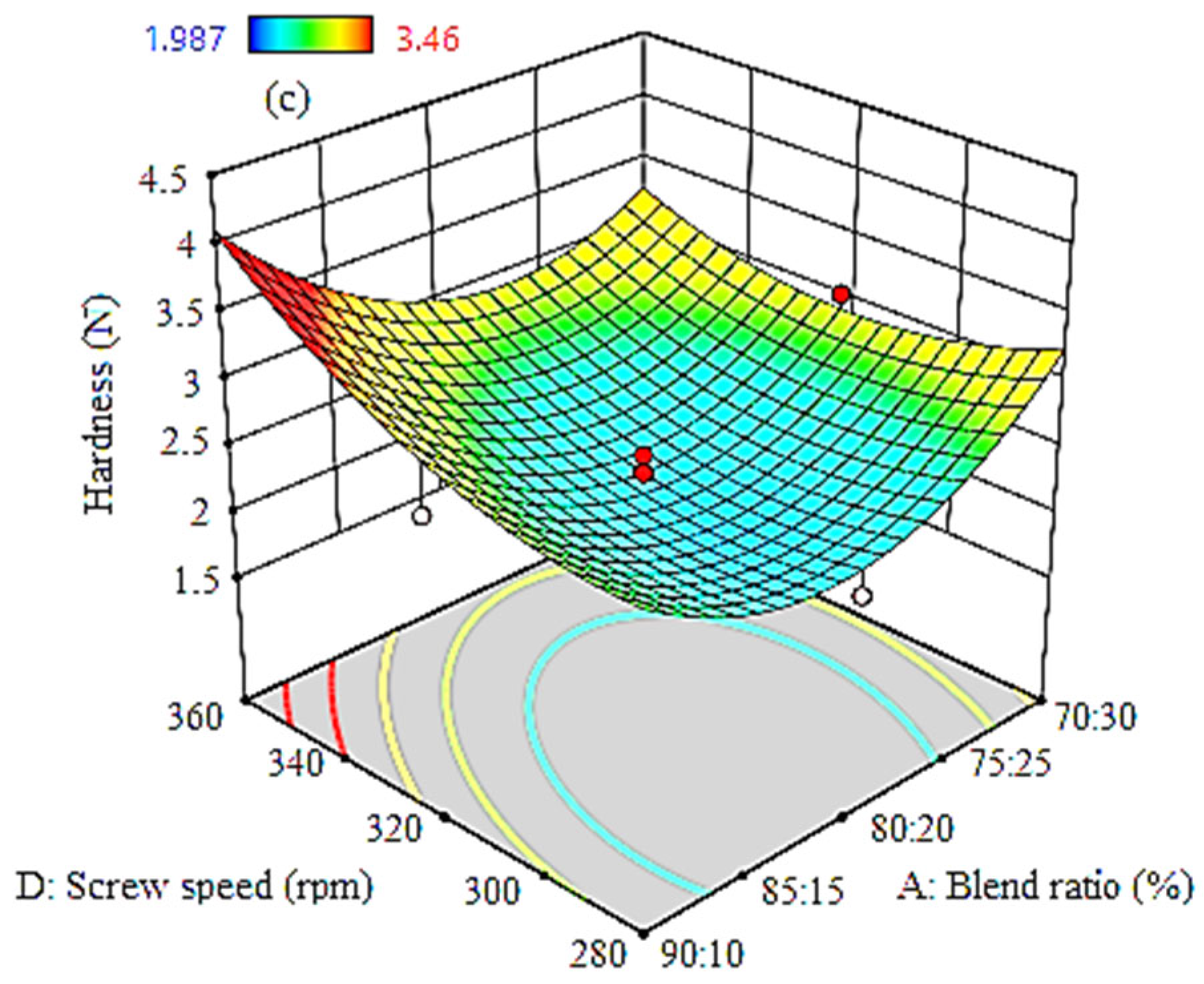

3.1.5. Hardness (HD)

3.1.6. Bulk Density (BD)

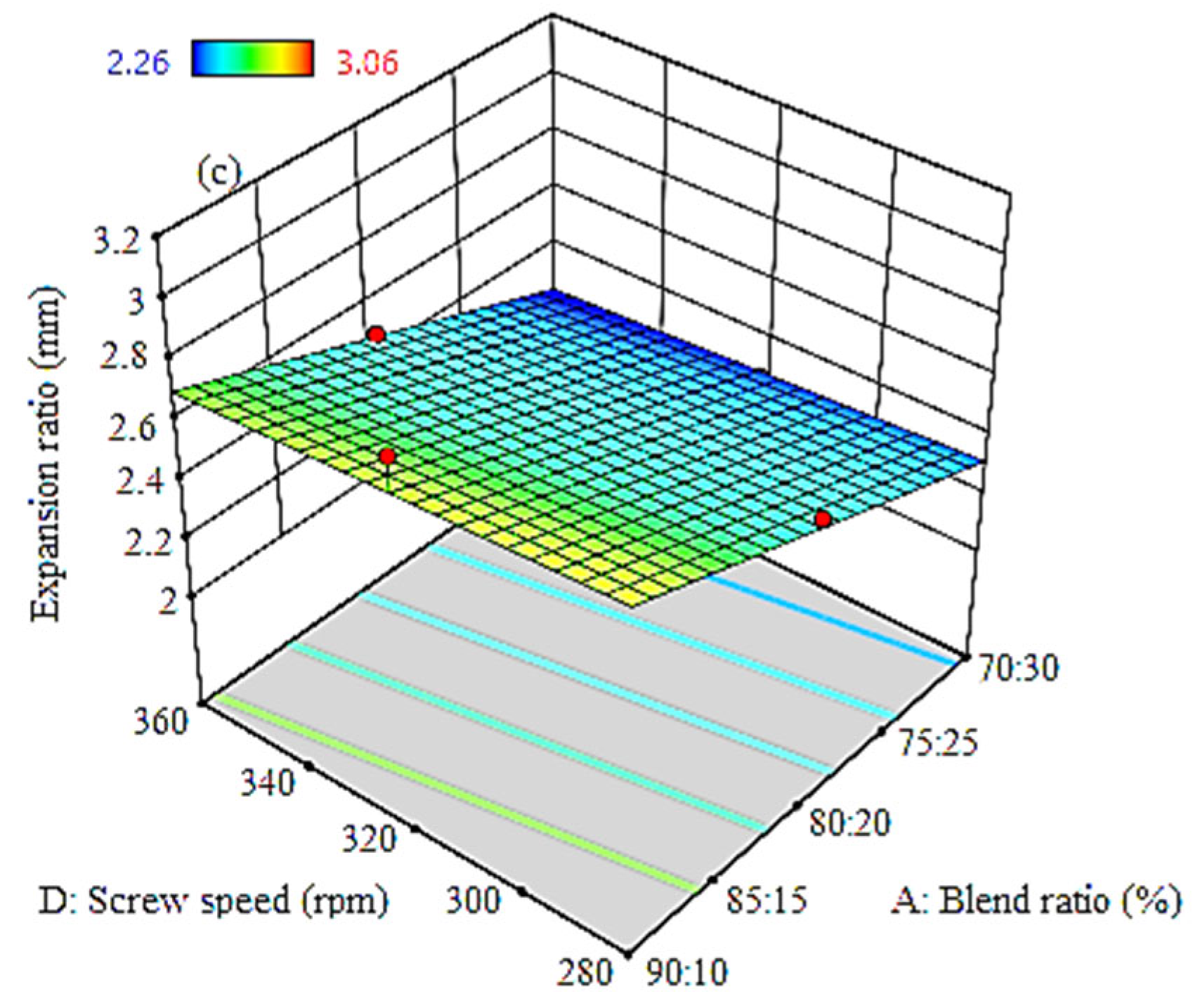

3.1.7. Expansion Ratio (ER)

3.1.8. Overall Acceptance (OA)

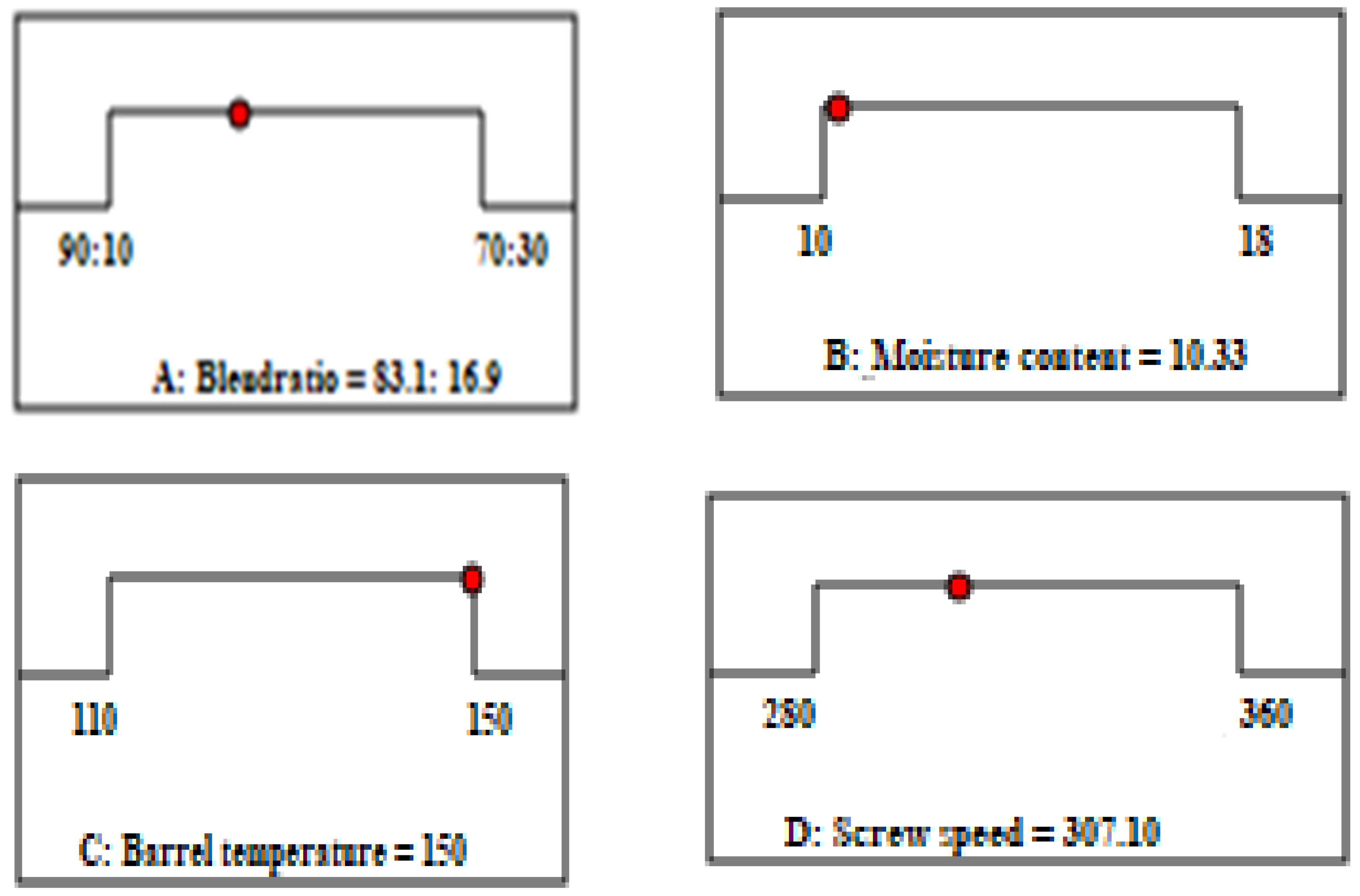

3.2. Optimization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pasqualone, A.; Costantini, M.; Teodora, E.C.; Carmine, S. Use of Legumes in Extrusion Cooking: A Review. Foods 2020, 9, 958. [Google Scholar] [CrossRef]

- Nicklas, T.A.; Yang, S.J.; Baranowski, T.; Zakeri, I.; Berenson, G. Eating patterns and obesity in children: The Bogalusa Heart Study. Am. J. Prev. Med. 2003, 25, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Patil, S.S.; Brennan, C.S.; Mason, S.L.; Brennan, C.S. The effects of fortification of legumes and extrusion onthe protein digestibility of wheat based snack. Foods 2016, 5, 26. [Google Scholar] [CrossRef] [PubMed]

- Hegazy, H.S.; El-Bedawey, A.E.A.; Rahma, E.H.; Gaafar, A.M. Effect of extrusion process on nutritional, functional properties and antioxidant activity of germinated chickpea incorporated corn extrudates. Am. J. Food Sci. Nutr. Res. 2017, 4, 59–66. [Google Scholar]

- Gilani, G.S.; Xiao, C.W.; Cockell, K.A. Impact of antinutritional factors in food proteins on the digestibilityof protein and the bioavailability of amino acids and on protein quality. Br. J. Nutr. 2012, 108, S315–S332. [Google Scholar] [CrossRef]

- Urbano, G.; López-Jurado, M.; Aranda, P.; Vidal-Valverde, C.; Tenorio, E.; Porres, J. The role of phytic acid inlegumes: Antinutrient or beneficial function? J. Physiol. Biochem. 2000, 56, 283–294. [Google Scholar] [CrossRef]

- Doblado, R.; Frias, J.; Vidal-Valverde, C. Changes in vitamin C content and antioxidant capacity of raw and germinated cowpea (Vignasinensis var. carilla) seeds induced by high pressure treatment. Food Chem. 2007, 101, 918–923. [Google Scholar] [CrossRef]

- Danbaba, N.; Nkama, I.; Badau, M.H. Application of Response Surface Methodology (RSM) and Central Composite Design (CCD) to Optimize Minerals Composition of Rice Cowpea composite blends during Extrusion Cooking. Int. J. Food Sci. Nutr. Eng. 2015, 5, 40–52. [Google Scholar]

- Jakkanwar, S.A.; Rathod, R.P.; Annapure, U.S. Development of cowpea-based (Vigna unguiculata) extruded snacks with improved in vitro protein digestibility. Int. Food Res. J. 2018, 25, 804–813. [Google Scholar]

- Wikipedia Contributors. Rice. Wikipedia. Wikimedia Foundation. Available online: https://en.wikipedia.org/wiki/Rice (accessed on 5 June 2023).

- Kubala, J. What Is the Healthiest Type of Rice? Available online: https://www.healthline.com/nutrition/healthiest-rice (accessed on 5 June 2023).

- Okunola, A.A.; Adekanye, T.A.; Adewumi, A.D.; Ashamu, F.F. Assessment of rice processing operations in Ekiti State, Nigeria. Int. J. Civ. Eng. Technol. 2019, 10, 2197–2204. [Google Scholar]

- Grasso, S. Extruded snacks from industrial by-products: A review. Trends Food Sci. Technol. 2020, 99, 284–294. [Google Scholar] [CrossRef]

- Dar, A.H.; Sharma, H.K.; Kumar, N. Effect of frying time and temperature on the functional properties of carrot pomace, pulse powder and rice flour based extrudates. Int. J. Food Eng. 2014, 10, 139–147. [Google Scholar] [CrossRef]

- Hussain, S.Z.; Singh, B. Physical properties of refabricated rice as affected by extrusion: A response surface analysis. Cereal Foods World 2015, 60, 171–176. [Google Scholar] [CrossRef]

- Okunola, A.A.; Isaac-Bamgboye, A.; Olayanju, T.M.A.; Osueke, C.O.; Alahassan, E.A. Development of a rice cleaner cum grader for cottage processors in Nigeria. Int. J. Mech. Eng. Technol. 2018, 9, 2339–2351. [Google Scholar]

- Tosh, S.M.; Yada, S. Dietary fibres in pulse seeds and fractions: Characterization, functional attributes and applications. Food Res. Int. 2010, 43, 450–460. [Google Scholar] [CrossRef]

- Singh, B.; Rachna Hussain, S.Z.; Sharma, S. Response Surface Analysis and Process Optimization of Twin-Screw Extrusion Cooking of Potato-Based Snacks. J. Food Process. Preserv. 2014, 39, 270–281. [Google Scholar] [CrossRef]

- Elina, M.; Cornelio, N.N.; Henry, L.; Theobald, C.E.M. Sensory evaluation of extruded quality protein maize-based supplementary foods. Afr. J. Food Sci. 2016, 10, 105–111. [Google Scholar] [CrossRef]

- Olaniran, A.F.; Okonkwo, C.E.; Osemwegie, O.O.; Iranloye, Y.M.; Afolabi, Y.T.; Alejolowo, O.O.; Nwonuma, C.O.; Badejo, T.E. Production of a complementary food: Influence of cowpea soaking time on the nutritional, antinutritional, and antioxidant properties of the cassava-cowpea-orange-fleshed potato blends. Int. J. Food Sci. 2020, 2020, 8873341. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Association of Official Analytical Chemist Official Methods of Analysis, 18th ed.; Current through Revision 2, 2007 (Online); AOAC International: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Hussain, S.Z.; Ali, F.; Jabeen, R.; Zargar, I. Twin screw extrusion cooking of lotus rhizome and broken rice flour blends: A response surface analysis. J. Sci. Ind. Res. 2017, 76, 485–493. [Google Scholar]

- Reshi, M.; Shafiq, F.; Hussain, S.Z.; Naseer, B.; Amin, T. Physicochemical properties of iron-fortified, low glycemic index (GI) barley based extruded ready-to-eat snacks developed using twin-screw extruder. J. Food Process. Preserv. 2020, 44, e14606. [Google Scholar] [CrossRef]

- Rathod, R.P.; Annapure, U.S. Effect of extrusion process on ant nutritional factors and protein and starch digestibility of lentil splits. LWT-Food Sci. Technol. 2015, 66, 114–123. [Google Scholar] [CrossRef]

- Thakur, R.R.; Shahi, N.C.; Mangaraj, S.; Lohani, U.C.; Chand, K. Development of an organic coating powder and optimization of process parameters for shelf life enhancement of button mushrooms (Agaricus bisporus). J. Food Process. Preserv. 2011, 45, e15306. [Google Scholar] [CrossRef]

- Okunola, A.A.; Okunola, C.O.; Ofuya, T. Acceptability and sensory evaluation of maize and cowpea products stored with some essential oils. Int. J. Agric. Res. Food Prod. 2019, 4, 30–35. [Google Scholar]

- Stat-Ease Inc. Design Expert 11.1.0.1 Software, Stat-Ease Design Expert 11.1.0.1 Latest Scene and P2P Download; Stat-Ease, Inc.: Minneapolis, MN, USA, 2018. [Google Scholar]

- Seth, D.; Rajamannickam, G. Development of extruded snacks using soy, sorghum, millet and rice blend—A response surface methodology approach. Int. J. Food Sci. 2012, 47, 1526–1531. [Google Scholar] [CrossRef]

- Wani, S.A.; Kumar, P. Development and parameter optimization of health promising extrudate based on fenugreek oat and pea. Food Biosci. 2016, 14, 34–40. [Google Scholar] [CrossRef]

- IBM. SPSS, 21.0 Version Statistical Software; IBM Corporation: Armonk, NY, USA, 2012. [Google Scholar]

- Yu, L. Extrusion Processing of Protein Rich Food Formulations; Department of Food Science and Agricultural Chemistry McGill University: Montreal, QC, Canada, 2011; pp. 1–209. [Google Scholar]

- Dogan, H.; Gueven, A.; Hicsasmaz, Z. Extrusion cooking of lentil flour (Lens culinaris–Red)–corn starch–corn oil mixtures. Int. J. Food Prop. 2013, 16, 341–358. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Zhu, S.; Wang, Q. Texturization behaviour of peanut–soy bean/wheat protein mixtures during high moisture extrusion cooking. Int. J. Food Sci. Technol. 2018, 53, 2535–2541. [Google Scholar] [CrossRef]

- Matysiak, A.; Wójtowicz, A.; Oniszczuk, T. Process Efficiency and Energy Consumption During the Extrusion of Potato and Multigrain Formulations. Agric. Eng. 2018, 22, 49–57. [Google Scholar] [CrossRef]

- Meng, X.; Threinen, D.; Hansen, M.; Driedger, D. Effects of extrusion conditions on system parameters and physical properties of a chickpea flour-based snack. Food Res. Int. 2010, 43, 650–658. [Google Scholar] [CrossRef]

- Kongolo, J.I.; Da Silva, L.S.; Wokadala, O.C.; Du Plessis, B.; Husselman, J.; Ngcobo, M.E.; Emmambux, N.M.; Daneel, M. Pasting, thermal, gel texture, resistant starch and colour properties of unripe banana flour from 10 desert banana varieties cultivated in South Africa. J. Food Meas. Charact. 2017, 11, 1056–1064. [Google Scholar] [CrossRef]

- Pandey, S.; Kumar, A.; Rao, P.S. Optimization, modeling, and characterization study for the physicochemical properties of raw banana and defatted soy composite extrudates. Food Chem. 2021, 339, 127865. [Google Scholar] [CrossRef] [PubMed]

- Yousf, N.; Nazir, F.; Salim, R.; Ahsan, H.; Sirwal, A. Water solubility index and water absorption index of extruded product from rice and carrot blend. J. Pharmacogn. Phytochem. 2017, 6, 2165–2168. [Google Scholar]

- Sibel, Y.; Fahrettin, G. Response surface methodology for evaluation of physical and functional properties of extruded snack foods developed from food-by-products. J. Food Eng. 2008, 86, 122–132. [Google Scholar]

- Cuj-Laines, R.; Hernández-Santos, B.; Reyes-Jaquez, D.; Delgado-Licon, E.; Juárez-Barrientos, J.M.; Rodríguez-Miranda, J. Physicochemical properties of ready-to-eat extruded nixtamalized maize-based snacks enriched with grasshopper. Int. J. Food Sci. Technol. 2018, 53, 1889–1895. [Google Scholar] [CrossRef]

- Nagaraju, M.; Tiwari, V.K.; Sharma, A. Effect of extrusion on physical and functional properties of millet based extrudates: A review. J. Pharmacogn. Phytochem. 2021, 9, 1850–1854. [Google Scholar]

- Altaf, U.; Hussain, S.Z.; Qadri, T.; Iftikhar, F.; Naseer, B.; Rather, A.H. Investigation on mild extrusion cooking for development of snacks using rice and chickpea flour blends. J. Food Sci. Technol. 2020, 58, 1143–1155. [Google Scholar] [CrossRef]

- Hagenimana, A.; Ding, X.; Fang, T. Evaluation of rice flour modified by extrusion cooking. J. Cereal Sci. 2006, 43, 38–46. [Google Scholar] [CrossRef]

- Köksel, H.; Ryu, G.-H.; Basman, A.; Demiralp, H.; Ng, P.K.W. Effects of extrusion variables on the properties of waxy hulless barley extrudates. Food/Nahrung 2004, 48, 19–24. [Google Scholar] [CrossRef]

- de Mesa, N.J.E.; Alavi, S.; Singh, N.; Shi, Y.-C.; Dogan, H.; Sang, Y. Soy protein-fortified expanded extrudates: Baseline study using normal corn starch. J. Food Eng. 2009, 90, 262–270. [Google Scholar] [CrossRef]

- Robin, F.; Theoduloz, C.; Gianfrancesco, A.; Pineau, N.; Schuchmann, H.P.; Palzer, S. Starch transformation in bran-enriched extruded wheat flour. Carbohydr. Polym. 2011, 85, 65–74. [Google Scholar] [CrossRef]

- Kaur, A.; Kaur, S.; Singh, M.; Singh, N.; Shevkani, K.; Singh, B. Effect of banana flour, screw speed and temperature on extrusion behaviour of corn extrudates. J. Food Sci. Technol. 2014, 52, 4276–4285. [Google Scholar] [CrossRef] [PubMed]

| Name | Goal | Lower Limit | Upper Limit | Lower Weight | Upper Weight | Importance |

|---|---|---|---|---|---|---|

| BR | in range | 70:30 | 90:10 | 1 | 1 | 3 |

| MC | in range | 10.00 | 18.00 | 1 | 1 | 3 |

| BT | in range | 110.00 | 150.00 | 1 | 1 | 3 |

| SS | in range | 280.00 | 360.00 | 1 | 1 | 3 |

| SME | Minimize | 47.10 | 102.27 | 1 | 1 | 3 |

| BD | Minimize | 251.30 | 593.30 | 1 | 1 | 3 |

| ER | Maximize | 2.26 | 3.06 | 1 | 1 | 3 |

| HD | Minimize | 1.99 | 3.46 | 1 | 1 | 3 |

| WAI | in range | 3.05 | 4.35 | 1 | 1 | 3 |

| WSI | in range | 2.80 | 20.00 | 1 | 1 | 3 |

| TC | in range | 36.85 | 45.89 | 1 | 1 | 3 |

| OA | Maximize | 5.20 | 8.10 | 1 | 1 | 3 |

| Run | BR (%) | MC (%) | BT (°C) | SS (rpm) | SME (Wh/kg) | WAI (g/g) | WSI (%) | TC | HD (N) | BD (Kg/m³) | ER (mm) | OA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 80:20 | 10 | 130 | 320 | 92.16 | 3.63 | 8.4 | 40.48 | 1.99 | 266.8 | 2.93 | 7.55 |

| 2 | 75:25 | 16 | 140 | 340 | 84.86 | 4.06 | 6.8 | 41.58 | 3.02 | 354.3 | 2.47 | 5.3 |

| 3 | 80:20 | 14 | 130 | 280 | 66.3 | 3.71 | 10 | 40.62 | 2.14 | 396.9 | 2.58 | 6.7 |

| 4 | 85:15 | 16 | 120 | 340 | 84.86 | 4.03 | 7.6 | 40.02 | 3.23 | 541.4 | 2.49 | 5.2 |

| 5 | 80:20 | 14 | 130 | 360 | 82.94 | 4.33 | 4.8 | 41.16 | 2.89 | 309.8 | 2.48 | 6.25 |

| 6 | 85:15 | 16 | 140 | 340 | 73.98 | 4.26 | 4.4 | 41.38 | 3.46 | 413.3 | 2.69 | 6.45 |

| 7 | 80:20 | 14 | 130 | 320 | 77.82 | 3.97 | 3.6 | 40.2 | 2.31 | 498.4 | 2.38 | 6.9 |

| 8 | 85:15 | 16 | 140 | 300 | 65.28 | 4.35 | 2.8 | 39.1 | 2.14 | 443.2 | 2.56 | 6.9 |

| 9 | 80:20 | 14 | 130 | 320 | 75.78 | 3.78 | 3.6 | 40.71 | 2.31 | 489.3 | 2.43 | 6.65 |

| 10 | 75:25 | 16 | 140 | 300 | 74.88 | 3.34 | 2.8 | 45.72 | 2.86 | 481.5 | 2.27 | 5.85 |

| 11 | 85:15 | 12 | 120 | 300 | 84.48 | 3.38 | 7.6 | 44.5 | 3.08 | 441.4 | 2.54 | 5.65 |

| 12 | 75:25 | 16 | 120 | 300 | 65.28 | 3.39 | 10 | 37.85 | 2.05 | 508.4 | 2.41 | 7.45 |

| 13 | 80:20 | 14 | 130 | 320 | 77.82 | 4.17 | 5.2 | 39.77 | 2.32 | 521.5 | 2.38 | 7.05 |

| 14 | 75:25 | 12 | 120 | 300 | 80.64 | 3.33 | 10 | 45.89 | 2.55 | 506.5 | 2.47 | 7.35 |

| 15 | 80:20 | 18 | 130 | 320 | 55.3 | 4.05 | 4.4 | 37.42 | 2.96 | 541 | 2.61 | 5.45 |

| 16 | 85:15 | 12 | 140 | 340 | 84.86 | 3.05 | 16.8 | 40.43 | 2.82 | 434.6 | 2.56 | 6.3 |

| 17 | 75:25 | 12 | 120 | 340 | 87.04 | 3.58 | 9.6 | 39.08 | 2.76 | 536.1 | 2.4 | 6.1 |

| 18 | 70:30 | 14 | 130 | 320 | 77.82 | 3.21 | 20 | 39.39 | 3.03 | 593.3 | 2.26 | 6.9 |

| 19 | 80:20 | 14 | 130 | 320 | 77.82 | 3.64 | 14.4 | 42.12 | 2.13 | 481 | 2.42 | 7.4 |

| 20 | 75:25 | 12 | 140 | 300 | 65.28 | 3.76 | 10.4 | 36.85 | 2.94 | 513.2 | 2.39 | 7.15 |

| 21 | 80:20 | 14 | 130 | 320 | 77.82 | 4.29 | 6.4 | 40.62 | 2.45 | 489.2 | 2.42 | 7.7 |

| 22 | 80:20 | 14 | 150 | 320 | 65.28 | 4.07 | 6 | 42.73 | 2.23 | 416.9 | 2.32 | 7.5 |

| 23 | 85:15 | 12 | 140 | 300 | 84.48 | 3.95 | 12 | 44.52 | 2.98 | 361.3 | 2.78 | 8.1 |

| 24 | 90:10 | 14 | 130 | 320 | 88.06 | 3.61 | 8 | 39.96 | 2.73 | 437.3 | 2.86 | 7.5 |

| 25 | 80:20 | 14 | 110 | 320 | 47.1 | 3.3 | 11.6 | 44.54 | 2.6 | 251.3 | 3.06 | 7.45 |

| 26 | 85:15 | 16 | 120 | 300 | 71.04 | 3.61 | 5.2 | 39 | 2.54 | 554.2 | 2.68 | 5.75 |

| 27 | 80:20 | 14 | 130 | 320 | 77.82 | 4.14 | 6.8 | 37.64 | 2.17 | 487.7 | 2.28 | 6.9 |

| 28 | 75:25 | 16 | 120 | 340 | 76.16 | 3.75 | 6.8 | 41.56 | 2.9 | 581.5 | 2.31 | 5.8 |

| 29 | 85:15 | 12 | 120 | 340 | 97.92 | 3.37 | 7.6 | 40.1 | 3.01 | 449.8 | 2.46 | 7.6 |

| 30 | 75:25 | 12 | 140 | 340 | 102.27 | 4.19 | 8.4 | 44.3 | 2.29 | 386.3 | 2.47 | 7.05 |

| Specific Mechanical Energy (Linear) | ||||||

|---|---|---|---|---|---|---|

| Source | SS | Df | MS | F-Value | p-Value | |

| Model | 1937.82 | 4 | 484.46 | 6.01 | 0.0016 | significant |

| A-BR | 39.96 | 1 | 39.96 | 0.4957 | 0.4879 | |

| B-MC | 1125.46 | 1 | 1125.46 | 13.96 | 0.0010 | |

| C-BT | 25.69 | 1 | 25.69 | 0.3186 | 0.5775 | |

| D-SS | 746.72 | 1 | 746.72 | 9.26 | 0.0054 | |

| Residual | 2015.54 | 25 | 80.62 | |||

| Lack of Fit | 159.56 | 24 | 6.65 | 3.06 | 0.1081 | not significant |

| Pure Error | 3.47 | 5 | 0.6936 | |||

| Cor Total | 3953.37 | 29 | ||||

| Water Absorption Index (Quadratic) | ||||||

|---|---|---|---|---|---|---|

| Source | SS | Df | MS | F-Value | p-Value | |

| Model | 3.22 | 14 | 0.2297 | 4.18 | 0.0047 | significant |

| A-BR | 0.0817 | 1 | 0.0817 | 1.48 | 0.2418 | |

| B-MC | 0.3800 | 1 | 0.3800 | 6.91 | 0.0190 | |

| C-BT | 0.6868 | 1 | 0.6868 | 12.49 | 0.0030 | |

| D-SS | 0.2440 | 1 | 0.2440 | 4.440 | 0.0524 | |

| AB | 0.4970 | 1 | 0.4970 | 9.04 | 0.0089 | |

| AC | 0.0004 | 1 | 0.0004 | 0.0073 | 0.9332 | |

| AD | 0.3422 | 1 | 0.3422 | 6.22 | 0.0248 | |

| BC | 0.0002 | 1 | 0.0002 | 0.0041 | 0.9498 | |

| BD | 0.1681 | 1 | 0.1681 | 3.06 | 0.1009 | |

| CD | 0.0462 | 1 | 0.0462 | 0.8405 | 0.3738 | |

| A2 | 0.6292 | 1 | 0.6292 | 11.44 | 0.0041 | |

| B2 | 0.0530 | 1 | 0.0530 | 0.9637 | 0.3418 | |

| C2 | 0.1876 | 1 | 0.1876 | 3.14 | 0.0846 | |

| D2 | 0.000 | 1 | 0.000 | 0.0005 | 0.9817 | |

| Residual | 0.8250 | 15 | 0.0550 | |||

| Lack of Fit | 0.5135 | 10 | 0.0514 | 0.8243 | 0.6296 | not significant |

| Pure Error | 0.3115 | 5 | 0.0623 | |||

| Cor Total | 4.04 | 29 | ||||

| Water Solubility Index (Linear) | ||||||

|---|---|---|---|---|---|---|

| Source | SS | Df | MS | F-Value | p-Value | |

| Model | 111.95 | 4 | 27.99 | 1.97 | 0.01308 | significant |

| A-BR | 25.63 | 1 | 25.63 | 1.80 | 0.1918 | |

| B-MC | 80.67 | 1 | 80.67 | 5.67 | 0.0252 | |

| C-BT | 5.23 | 1 | 5.23 | 0.3671 | 0.5500 | |

| D-SS | 0.4267 | 1 | 0.4267 | 0.0300 | 0.864 | |

| Residual | 355.92 | 25 | 14.24 | |||

| Lack of Fit | 275.07 | 20 | 13.75 | 0.8505 | 0.6444 | not significant |

| Pure Error | 80.85 | 5 | 16.17 | |||

| Cor Total | 467.87 | |||||

| Hardness (Quadratic) | ||||||

|---|---|---|---|---|---|---|

| Source | SS | DF | MF | F-Value | p-Value | |

| Model | 3.09 | 14 | 0.2206 | 2.48 | 0.0459 | significant |

| A-BR | 0.0705 | 1 | 0.0705 | 0.7933 | 0.3872 | |

| B-MC | 0.1194 | 1 | 0.1194 | 1.34 | 0.2646 | |

| C-BT | 0.0023 | 1 | 0.0023 | 0.0254 | 0.8754 | |

| D-SS | 0.6179 | 1 | 0.6179 | 6.95 | 0.0187 | |

| AB | 0.0421 | 1 | 0.0421 | 0.473 | 0.507 | |

| AC | 0.1084 | 1 | 0.108 | 1.220 | 0.2869 | |

| AD | 0.0917 | 1 | 0.091 | 1.030 | 0.326 | |

| BC | 0.0799 | 1 | 0.079 | 0.899 | 0.358 | |

| BD | 0.8478 | 1 | 0.847 | 9.540 | 0.007 | |

| CD | 0.0636 | 1 | 0.063 | 0.715 | 0.410 | |

| A2 | 0.8608 | 1 | 0.860 | 9.680 | 0.007 | |

| B2 | 0.1580 | 1 | 0.158 | 1.780 | 0.202 | |

| C2 | 0.1223 | 1 | 0.122 | 1.381 | 0.259 | |

| D2 | 0.2078 | 1 | 0.207 | 2.34 | 0.147 | |

| Residual | 1.33 | 15 | 0.0889 | |||

| Lack of Fit | 1.54 | 10 | 0.1543 | 2.71 | 0.1416 | not significant |

| Pure Error | 0.0384 | 5 | 0.0077 | |||

| Cor Total | 4.42 | 29 | ||||

| Bulk density (Linear) | ||||||

|---|---|---|---|---|---|---|

| Source | SS | Df | MS | F-Value | p-Value | |

| Model | 48746.54 | 4 | 12186.64 | 1.83 | 0.15584 | not significant |

| A-BR | 12177.02 | 1 | 12177.02 | 1.82 | 0.1889 | |

| B-MC | 26467.04 | 1 | 26467.04 | 3.96 | 0.0575 | |

| C-BT | 6680.01 | 1 | 6680.01 | 1.00 | 0.3267 | |

| D-SS | 3422.48 | 1 | 3422.48 | 0.5127 | 0.4806 | |

| Residual | 1.669 × 105 | 25 | 6675.52 | |||

| Lack of Fit | 1.659 × 105 | 20 | 8293.01 | 40.34 | 0.0003 | significant |

| Pure Error | 1027.83 | 5 | 205.57 | |||

| Cor Total | 2.156 × 105 | 29 | ||||

| Expansion Ratio (Linear) | ||||||

|---|---|---|---|---|---|---|

| Source | SS | Df | MS | F-Value | p-Value | |

| Model | 0.5088 | 4 | 0.1272 | 5.32 | 0.0031 | significant |

| A-BR | 0.3197 | 1 | 0.3197 | 13.36 | 0.0012 | |

| B-MC | 0.0287 | 1 | 0.0287 | 1.20 | 0.2838 | |

| C-BT | 0.1520 | 1 | 0.1520 | 6.35 | 0.0185 | |

| D-SS | 0.0084 | 1 | 0.0084 | 0.3527 | 0.5579 | |

| Residual | 0.5980 | 25 | 0.0239 | |||

| Lack of Fit | 26.01 | 20 | 1.30 | 1.55 | 0.3314 | not significant |

| Pure Error | 0.0156 | 5 | 0.0031 | |||

| Cor Total | 2.156 × 105 | 29 | ||||

| Overall Acceptance (Linear) | ||||||

|---|---|---|---|---|---|---|

| Source | SS | Df | MS | F-Value | p-Value | |

| Model | 6.30 | 4 | 1.58 | 3.23 | 0.0287 | significant |

| A-BR | 0.0504 | 1 | 0.0504 | 0.1034 | 0.7504 | |

| B-MC | 4.86 | 1 | 4.86 | 9.97 | 0.0041 | |

| C-BT | 0.2204 | 1 | 0.2204 | 0.4522 | 0.5075 | |

| D-SS | 1.17 | 1 | 1.17 | 2.40 | 0.1338 | |

| Residual | 12.19 | 25 | 0.4875 | |||

| Lack of Fit | 11.45 | 20 | 0.5726 | 3.90 | 0.0687 | not significant |

| Pure Error | 0.7350 | 5 | 0.1470 | |||

| Cor Total | 18.49 | 29 | ||||

| Samples | MC (%) | CP (%) | TA (%) | CF (%) | CFAT (%) | CHO (%) |

|---|---|---|---|---|---|---|

| Rice flour | 10.1 ± 0.02 c | 13.11 ± 0.01 b | 4.68 ± 0.01 c | 2.96 ± 0.06 b | 8.56 ± 0.01 c | 60.54 ± 0.10 b |

| Cowpea flour | 7.98 ± 0.01 b | 24.48 ± 0.03 c | 4.01 ± 0.01 b | 2.49 ± 0.01 a | 7.94 ± 0.03 b | 53.11 ± 0.05 a |

| Optimized extrudate | 5.99 ± 0.04 a | 6.73 ± 0.01 a | 0.96 ± 0.02 a | 3.04 ± 0.02 b | 2.60 ± 0.04 a | 80.70 ± 0.01 c |

| Samples | Fe (mg/100kg) | P (mg/100kg) | Mn (mg/100kg) | Cu (mg/100kg) | Na (mg/100kg) |

|---|---|---|---|---|---|

| Rice flour | 0.46 ± 0.012 b | 110.89 ± 0.19 c | 0.07 ± 0.00 b | 0.078 ± 0.00 a | 0.02 ± 0.00 a |

| Cowpea flour | 0.53 ± 0.042 c | 106.57 ± 1.27 b | 0.06 ± 0.00 b | 0.8 ± 0.00 b | 0.02 ± 0.00 a |

| Optimized extrudate | 0.41 ± 0.07 a | 16.21 ± 0.03 a | 0.02 ± 0.00 a | 0.06 ± 0.01 a | 23.44 ± 0.04 b |

| Regression | SME | WAI | WSI | TC | HD | BD | ER | OA |

|---|---|---|---|---|---|---|---|---|

| SD | 8.90 | 2.2345 | 3.77 | 2.42 | 0.2982 | 81.70 | 0.1547 | 0.6982 |

| R2 | 0.4902 | 0.7958 | 0.2393 | 0.4216 | 0.6984 | 0.2261 | 0.2497 | 0.3408 |

| Mean | 77.44 | 3.78 | 8.07 | 40.97 | 2.64 | 456.25 | 2.51 | 6.73 |

| Adj. R2 | 0.4086 | 0.6053 | 0.1176 | 0.0000 | 0.4169 | 0.1022 | 0.3733 | 0.2354 |

| C.V % | 11.59 | 6.21 | 46.77 | 5.92 | 11.31 | 17.91 | 6.16 | 10.37 |

| Pred. R2 | 0.2038 | 0.1570 | −0.0912 | −0.0702 | −0.6999 | −0.1869 | 0.2058 | 0.0115 |

| PRESS | 3147.57 | 3.41 | 510.53 | 182.37 | 7.52 | 2.556 × 105 | 0.8791 | 18.28 |

| Adeq.prec. | 8.0482 | 7.2765 | 4.7607 | NA | 5.1122 | 5.0581 | 7.8659 | 6.3150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Okunola, A.A.; Dottie, E.P.; Moses, O.I.; Adekanye, T.A.; Okonkwo, C.E.; Kaveh, M.; Szymanek, M.; Aremu, C.O. Development and Process Optimization of a Ready-to-Eat Snack from Rice-Cowpea Composite by a Twin Extruder. Processes 2023, 11, 2159. https://doi.org/10.3390/pr11072159

Okunola AA, Dottie EP, Moses OI, Adekanye TA, Okonkwo CE, Kaveh M, Szymanek M, Aremu CO. Development and Process Optimization of a Ready-to-Eat Snack from Rice-Cowpea Composite by a Twin Extruder. Processes. 2023; 11(7):2159. https://doi.org/10.3390/pr11072159

Chicago/Turabian StyleOkunola, Abiodun Afolabi, Ewhoritsemogha Priscilla Dottie, Olumuyiwa Isaac Moses, Timothy Adesoye Adekanye, Clinton E. Okonkwo, Mohammad Kaveh, Mariusz Szymanek, and Charity O. Aremu. 2023. "Development and Process Optimization of a Ready-to-Eat Snack from Rice-Cowpea Composite by a Twin Extruder" Processes 11, no. 7: 2159. https://doi.org/10.3390/pr11072159

APA StyleOkunola, A. A., Dottie, E. P., Moses, O. I., Adekanye, T. A., Okonkwo, C. E., Kaveh, M., Szymanek, M., & Aremu, C. O. (2023). Development and Process Optimization of a Ready-to-Eat Snack from Rice-Cowpea Composite by a Twin Extruder. Processes, 11(7), 2159. https://doi.org/10.3390/pr11072159