Analysis and Modeling of the Onion Peeling Process in the Blowing Compressed Air Method

Abstract

:1. Introduction

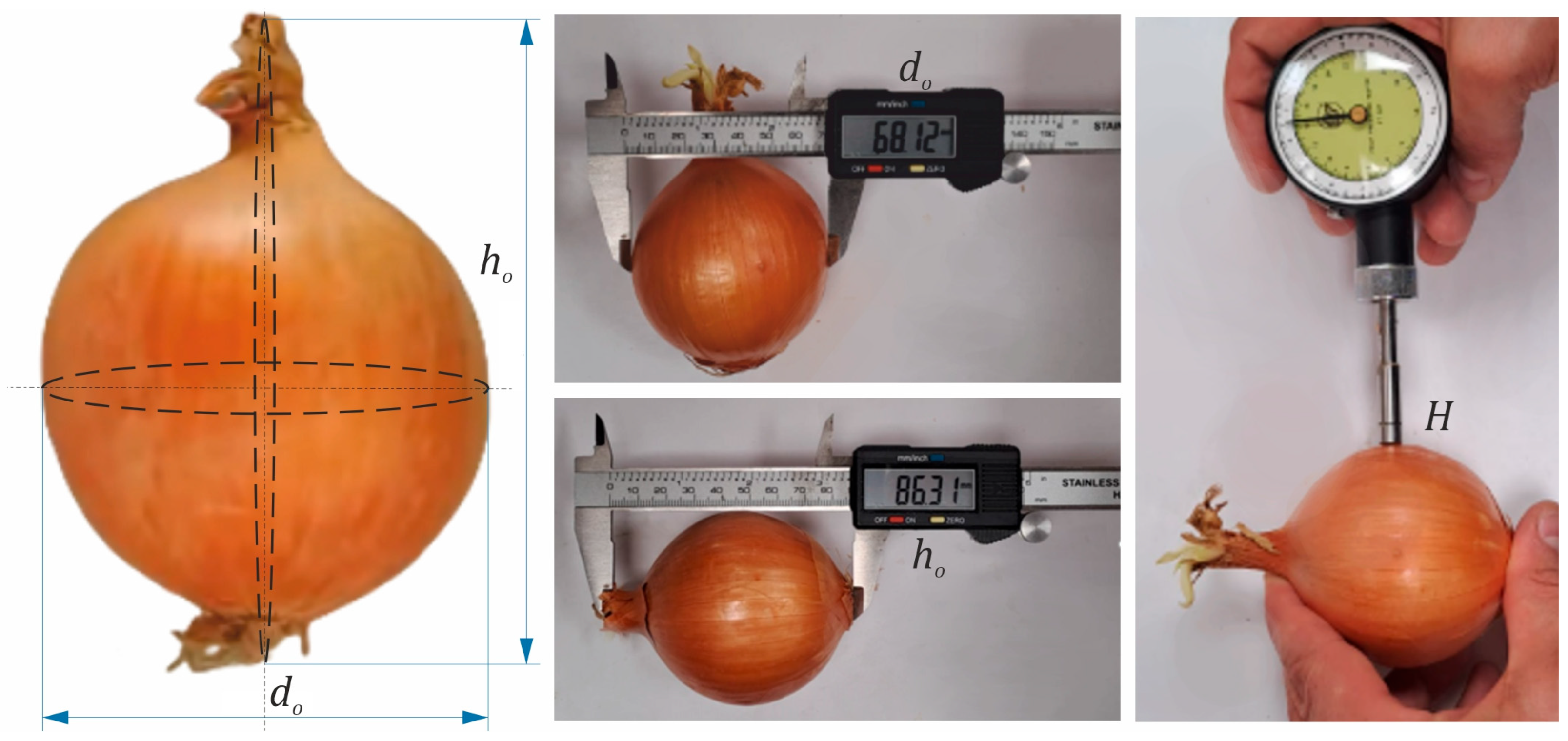

2. Materials and Methods

2.1. Plant Material

2.2. The Process of Mechanical Onion Peeling

2.2.1. Cutting System–Scaly Leaves and Roots’ Removal

2.2.2. Onion Peel Removal Method

2.3. Statistical Analysis

3. Results

3.1. Analysis of Variance

3.2. Determination of the Nature of the Influence of Independent Variables on the Peeling Effect

3.3. Assuming the Final Predictive Model Mp = f(t,p)

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bochat, A.; Zastempowski, M.; Wachowicz, M. Cutting Tests of the Outer Layer of Material Using Onion as an Example. Materials 2021, 14, 2360. [Google Scholar] [CrossRef]

- Baloch, R.A.; Baloch, S.U.; Baloch, S.K.; Baloch, H.N.; Badini, S.A.; Bashir, W.; Baloch, A.B.; Baloch, J. Economic analysis of onion (Allium cepa L.) production and marketing in District Awaran. Balochistan. J. Econ. Sustain. Dev. 2014, 5, 192–205. [Google Scholar]

- Hedgez, L.J.; Lister, C. The nutritional attributes of Allium species. In Crop & Food Research Confidential Report; New Zealand Institute for Crop & Food Research Limited: Christchurch, New Zealand, 2007; No. 1814. [Google Scholar]

- Fernandes, A.; Gois, A.; Mendes, F.; Perestrelo, R.; Medina, S.; Câmara, J.S. Typicality Assessment of Onions (Allium cepa) from Different Geographical Regions Based on the Volatile Signature and Chemometric Tools. Foods 2020, 9, 375. [Google Scholar] [CrossRef]

- Batiha, G.E.S.; Beshbishy, A.M.; Ikram, M.; Mulla, Z.S.; Abd El-Hack, M.; Taha, A.E.; Algammal, A.M.; Elewa, Y.H.A. The Pharmacological Activity, Biochemical Properties, and Pharmacokinetics of the Major Natural Polyphenolic Flavonoid: Quercetin. Foods 2020, 9, 374. [Google Scholar] [CrossRef]

- Adnan, N.H. Design and Development of a Portable Onion Peeler Machine. Ph.D. Thesis, Faculty of Mechanical Engineering, Universiti Teknologi Malaysia, Johor, Malaysia, 2010. [Google Scholar]

- Woźniak, P.; Nosal, S.; Bieńczak, A. Analysis of technology and machining devices for peeling onion in the food industry. MATEC Web Conf. 2021, 343, 01006. [Google Scholar] [CrossRef]

- Woźniak, P.; Bieńczak, A.; Kiczek, T.; Gaszek, K. Analysis of the technology of mechanical onion cleaning in industrial machines. Agric. Hortic. For. Tech. 2022, 2, 53–60. [Google Scholar]

- Ghaffari, H.; Marghoub, N.; Sheikh-Darabadi, M.S.; Hakimi, A.; Abbasi, F. Physical properties of three Iranian onion varieties. Int. Res. J. Appl. Basic Sci. 2013, 7, 587–593. [Google Scholar]

- Kumawat, L.; Raheman, H. Determination of engineering properties of onion crop required for designing an onion harvester. Cogent Eng. 2023, 10, 2191404. [Google Scholar] [CrossRef]

- Martínez, A.R.; Paz, J.F.; Ares, L.A. Evaluation of local onion lines from northwest Spain. Span. J. Agric. Res. 2005, 3, 90–97. [Google Scholar] [CrossRef]

- Mieszkalski, L. Mathematical modelling of the shape of the onion tube saccharin (Allium cepa L.) by the parametric equations. Tech. Prog. Food Proc. 2015, 2, 68–71. [Google Scholar]

- Mieszkalski, L. Mathematical modelling of the shape of the basic parts morphological sugar onion (Allium cepa L.). Tech. Prog. Food Proc. 2016, 1, 40–47. [Google Scholar]

- Ambrose, D.C.P. Engineering Properties of Peeled and Unpeeled Multiplier Onion. Curr. Agric. Res. J. 2020, 8, 232–238. [Google Scholar] [CrossRef]

- Bahnasawy, A.H.; El-Haddad, Z.A.; El-Ansary, M.Y.; Sorour, H.M. Physical and mechanical properties of some Egyptian onion cultivars. J. Food Eng. 2004, 62, 255–261. [Google Scholar] [CrossRef]

- Mieszkalski, L. Bezier curves in modelling the shapes of biological objects. Agric. For. Eng. 2014, 64, 117–128. [Google Scholar]

- Bieńczak, A.; Dembicki, D.; Woźniak, P.; Ignasiak, Ł.; Obidziński, S. Analysis of mechanical properties of common onions. J. Res. Appl. Agric. Eng. 2017, 62, 12–15. [Google Scholar]

- Guiné, R.P.F.; Barroca, M.J. Influence of freeze-drying treatment on the texture of mushrooms and onions. Croat. J. Food Sci. Technol. 2016, 3, 26–31. [Google Scholar]

- Hole, C.C.; Drew, R.L.; Gray, D. Humidity and mechanical properties of onion peels. Postharvest Biol. Technol. 2000, 19, 229–237. [Google Scholar] [CrossRef]

- Naik, R.; Annamali, S.J.K.; Ambrose, D.C.P. Development of batch type multiplier onion peeler. In Proceedings of the International Agricultural Engineering Conference, Bangkok, Thailand, 3–6 December 2007. [Google Scholar]

- Wang, L. Performance Testing of an Onion Peeling Machine Using Response Surface Methodology; Michigan State University: East Lansing, MI, USA, 1993. [Google Scholar]

- Ghanem, T.H.; Badr, M.M.; Nagy, K.S.; Darwish, E.A. Evaluation of performance of an onion peeling machine. Process Eng. 2020, 37, 95–106. [Google Scholar] [CrossRef]

- Kate, A.E.; Pawar, D.A.; Chakraborty, S.K.; Gorepatti, K. Development and evaluation of onion bulb descaler for removal and collection of surface dry peel. J. Food Sci. Technol. 2022, 59, 2448–2459. [Google Scholar] [CrossRef]

- De Laurentiis, V.; Corrado, S.; Sala, S. Quantifying household waste of fresh fruit and vegetables in the EU. Waste Manag. 2018, 77, 238–251. [Google Scholar] [CrossRef]

- Benito-Roman, O.; Alonso-Riano, P.; Díaz de Cerio, E.; Sanz, M.T.; Beltran, S. Semi-continuous hydrolysis of onion peel wastes with subcritical water: Pectin recovery and oligomers identification. J. Environ. Chem. Eng. 2022, 10, 107439. [Google Scholar] [CrossRef]

- Choi, I.S.; Cho, E.J.; Moon, J.-H.; Bae, H.-J. Onion peel waste as a valorization resource for the by-products quercetin and biosugar. Food Chem. 2015, 188, 537–542. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.; Ahmad, N.; Lu, K.; Sun, Z.; Wei, C.; Zheng, X.; Yang, R. Nitrogen-doped carbon derived from onion waste as anode material for high performance sodium-ion battery. Solid State Ionics 2020, 346, 115223. [Google Scholar] [CrossRef]

- Kim, H.M.; Song, Y.; Wi, S.G.; Baea, H.-J. Production of D-tagatose and bioethanol from onion waste by an integrating bioprocess. J. Biotech. 2017, 260, 84–90. [Google Scholar] [CrossRef] [PubMed]

- Munir, M.T.; Kheirkhah, H.; Baroutian, S.; Quek, S.Y.; Young, B.R. Subcritical Water Extraction of Bioactive Compounds from Waste Onion Peel. J. Clean. Prod. 2018, 183, 487–494. [Google Scholar] [CrossRef]

- Thivya, P.; Bhosale, Y.K.; Anandakumar, S.; Hema, V.; Sinija, V.R. Study on the characteristics of gluten/alginate-cellulose/onion waste extracts composite film and its food packaging application. Food Chem. 2022, 390, 133221. [Google Scholar] [CrossRef] [PubMed]

- Prodromidis, P.; Mourtzinos, I.; Biliaderis, C.G.; Moschakis, T. Stability of natural food colorants derived from onion leaf wastes. Food Chem. 2022, 386, 132750. [Google Scholar] [CrossRef]

- Maghfurah, F.; Effendi, R.; Aini, M.N. Design of Onion Epidermis Peeling and Onion Smoothing Machine with Rubber Friction Method Application. J. Polimesin 2020, 18, 39–46. [Google Scholar]

- Mohamad, N.S.; Sulaiman, R.; Lai, M.; Hussain, N. Comparison between conventional and alternative peeling methods on peeling efficiencies of Malaysian “Chok Anan” mango (Mangifera indica L.) fruit. Int. Food Res. J. 2017, 24, 1934–1940. [Google Scholar]

- Setyowati, A.L.; Dwijayanti, D.; Sultan, M. Related factors of carpal tunnel syndrome (CTS) among onion peel peeler worker at Segiri Samarinda, east Kalimantan. J. Fak. Kesehat. Masy. Univ. Ahmad Daulan 2015, 9, 125–132. [Google Scholar]

- Tereshkin, O.; Horielkov, D.; Dmytrevskyi, D.; Chervonyi, V. The study of influence of the process of mechanical additional peeling on the surface onion layer at combined process of peeling. EUREKA Life Sci. 2016, 6, 24–30. [Google Scholar] [CrossRef]

- El-Ghobashy, H.; Bhansawi, A.; Ali, S.A.; Afify, M.T.; Emara, Z. Development and evaluation of an onion peeling machine. Misr J. Agric. Eng. 2012, 29, 663–682. [Google Scholar] [CrossRef]

- Ravichandran, P.; Anbu, C.; Kumar, R.S.; Sakthivel, A.; Thenralarasu, S. Design and fabrication of automatic onion peeling and cutting machine. Int. J. Sci. Technol. Res. 2019, 8, 2067–2070. [Google Scholar]

- Publications Office of the, EU. COMMISSION REGULATION (EC) No 1508/2001 of 24 July 2001 Laying down the Marketing Standard for Onions and Amending Regulation (EEC); Publications Office of the EU: Luxembourg, 2001; No 2213/83. [Google Scholar]

- Piepiórka-Stepuk, J.; Mierzejewska, S.; Sterczyńska, M.; Jakubowski, M.; Marczuk, M.; Andrejko, D.; Sobczak, P. Analysis and modelling of the regeneration process of chemical solutions after brewing equipment peeling in a Peeling in Place system based on changes in turbidity. J. Clean. Prod. 2019, 237, 117745. [Google Scholar] [CrossRef]

- Hegazy, R.A.; Sorour, H.M.; Ghazy, A.A.; El-Yamany, A.; Hafez, Y.M. Industries suitable for small-scale agricultural development of onion peeling machine. Fresenius Environ. Bull. 2020, 29, 9393–9402. [Google Scholar]

- Osman, N.A.; Muhamood, A.N.; Ramli, A. The development and evaluation of onion peeling machine for SMEs industry. Politeknik & Kolej Komuniti. J. Eng. Technol. 2020, 5, 10–13. [Google Scholar]

- Strivastava, A.; VanEe, G.; Ledebuhr, R.; Welch, D.; Wang, L. Design and development of an onion peeling machine. Appl. Eng. Agric. 1997, 13, 167–173. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woźniak, P.; Bieńczak, A.; Nosal, S.; Piepiórka-Stepuk, J.; Sterczyńska, M. Analysis and Modeling of the Onion Peeling Process in the Blowing Compressed Air Method. Processes 2023, 11, 3138. https://doi.org/10.3390/pr11113138

Woźniak P, Bieńczak A, Nosal S, Piepiórka-Stepuk J, Sterczyńska M. Analysis and Modeling of the Onion Peeling Process in the Blowing Compressed Air Method. Processes. 2023; 11(11):3138. https://doi.org/10.3390/pr11113138

Chicago/Turabian StyleWoźniak, Paweł, Agata Bieńczak, Stanisław Nosal, Joanna Piepiórka-Stepuk, and Monika Sterczyńska. 2023. "Analysis and Modeling of the Onion Peeling Process in the Blowing Compressed Air Method" Processes 11, no. 11: 3138. https://doi.org/10.3390/pr11113138

APA StyleWoźniak, P., Bieńczak, A., Nosal, S., Piepiórka-Stepuk, J., & Sterczyńska, M. (2023). Analysis and Modeling of the Onion Peeling Process in the Blowing Compressed Air Method. Processes, 11(11), 3138. https://doi.org/10.3390/pr11113138