Abstract

A public health emergency of international concern, such as a pandemic, disrupts the normal operation of the global supply chain, which necessitates in-depth research on supply chain management. In this paper, we used bibliometric and content analysis to provide a systematic analysis of the supply chain industry from this background. The descriptive analysis provides insights into the publication growth trajectory, in terms of the contributing authors, countries, and subject categories, which presents an intuitive display of previous research. In addition, the existing research mainly covers three dimensions of supply chain disruption, strategies, and sustainability, which can be clustered into supply chain disruption, disruption recovery, reconfiguration, digital intelligence, optimization, and sustainability. By revisiting the supply chain industry, we explored the transformation of its characteristics in the pandemic, covering themes ranging from expansion to contraction, from traditional to digital intelligence, and from fragile to sustainability, which suggests potential research directions for future studies. This contributes to the further research of supply chain management during the pandemic and provides supply chain managers with a practical approach for dealing with supply chain disruption risks and improving supply chain sustainability in this context.

1. Introduction

The outbreaks ofpublic health emergencies of international concern (PHEICs), such as the coronavirus disease 2019 (COVID-19), have brought the importance of supply chain management (SCM) to the forefront of public awareness [1]. In today’s intensely competitive international business environment, specialization has created longer and more complex supply chains (SCs). Any small problem can quickly spread into a global SC disruption [2]. Faced with this contingency, various SC strategies must be explored by researchers to offer solutions to recover from SC disruptions and achieve sustainable SC management. The SC industry has been closely connected with economic and social life; in the past 20 years, severe acute respiratory syndrome (SARS), Ebola, as well as COVID-19 and other PHEICs, have disrupted SC operations, which has undoubtedly brought serious challenges to all links of the basic SC, such as the medical, food, and humanitarian sectors [3]. Therefore, finding appropriate SC strategies to mitigate SC disruption and achieve SC sustainability is a major issue that needs to be urgently addressed.

The disastrous impact of SARS on the global economy and human health in 2003 raised deep concerns, causing the World Health Organization (WHO) to formulate International Health Regulations (IHRs) in 2005. After the significant concern raised by SARS in 2003, the first “public health emergency of international concern” declared by the revised IHR (2005) was influenza A (H1N1) in 2009 [4]. The SC has been frequently affected by disease outbreaks in recent years. The WHO covered 1438 pandemics from 2011 to 2018 [5]. Only three of these were considered PHEICs: Poliomyelitis (2014 to present), Ebola (2014 and 2018), and Zika (2016). In addition, COVID-19 (2020 to present) has disrupted the global SC due to strict international trade restrictions [6]. Compared with other pandemics, PHEICs have tremendous negative impacts on the SC, especially owing to the prevalence of globalization today, the SC industries of all countries are tightly intertwined. The division of labor in this global value chain scheme, while efficient, is vulnerable to PHEICs.

These SC disruption risks have raised interest in society, and scholars have started to conduct academic research on SC risks, SC strategy, and sustainability under PHEICs. In SC risk management, many researchers focus on risk identification, risk types, risk factors, risk management, and risk mitigation. There are two types of risk: one is uncertainty risk and the other is disruption risk, which affects the robustness, resilience, and sustainability of the SC [7].

In addition, academic researchers have increasingly been interested in the significance of SC strategies during PHEICs, involving factors such as sustainable SCM, SC risk management, and SC resilience management. Interestingly, before 2009, scholars mainly studied food SC and food security against the background of PHEICs [8]. Hu, et al. [9] compared the similarities and differences in supply chain management in PHEICs between China and the United States, highlighting the great changes that have occurred in this field. Moreover, scholars have also broadened their research scope by covering diverse industries such as manufacturing SC, service SC, and healthcare SC. Besides this fact, the traditional SC concentrates on the process of production, transportation, distribution, and sale, while under PHEICs, more attention has been paid to the SC network structure, remanufacture, recovery, and innovation management. Especially for PHEICs in recent years, the research directions related to emerging SCM, such as SC reconstruction, SC optimization, SC digital transformation, and sustainable SC, have deeply engaged the attention of SC practitioners and researchers.

Some scholars have made contributions to this field. For instance, Queiroz, et al. [10], Chowdhury, et al. [11], Sajjad [12], Qrunfleh, et al. [13] focused on COVID-19′s impact on SC recovery and resilience. In particular, Cardoso, et al. [14], Das and Roy [15], Rejeb, et al. [16] focused on the analysis of the literature related to food SC in the context of COVID-19. Pournader, et al. [17], Spieske and Birkel [18] concentrated on SC risk management during the COVID-19 pandemic. All these review articles have contributed to SC research in the context of pandemics. However, the existing research lacks a panoramic view of SC topics in the PHEIC context, i.e., from the perspective of SC disruptions, SC recovery strategies, and SC sustainability integration. In addition, most of the articles are based on the study of SC in a single field, and there is a lack of research on SC across domains and basic domains such as daily consumption and healthcare. Moreover, most of the existing review studies are focused on COVID-19, while there is a lack of studies on a larger pandemic of the same magnitude. These are the current research gaps in this field. This study fills those gaps.

To fill these research gaps, we try to describe the status quo, construct an integrative framework of the supply chain management in PHEIC-related fields through which the existing literature is systematized, and propose future research opportunities and new perspectives in rethinking the supply chain management during PHEICs. To this end, some main research questions (RQs) are proposed:

RQ1: What are the research profiles of the studies evaluating supply chain management in PHEIC-related fields, including publication trends, influential authors, contributing countries, and subject categories?

RQ2: What have been the main themes of this research topic in the past severe years?

RQ3: Which direction does the supply chain industry tend toward when facing a PHEIC?

To answer these research questions, we adopted bibliometric and content analysis methods to explore the research status, hotspots, and future research directions in this field, which reveal a panorama of supply-chain-related research in PHEICs and re-examine SC issues on a global scale. The main contributions of this study are as follows: Firstly, this study broadens the focus to different PHEICs rather than COVID-19 alone, enriching the research on the impact of PHEICs in different periods on the SC. Secondly, this study explores an SC analysis framework in the context of the pandemic, including SC disruption, strategies, and sustainability, which reveals and integrates the existing literature on SC disruption, disruption recovery, reconstruction, digital intelligence, optimization, and sustainability, aspects that are missing in the previous literature. Third, this paper prompts a rethinking of the supply chain characteristics before and after a pandemic and explains the reconstruction and upgrading of SCs from a new perspective. This contributes to further research on SCs during a pandemic and provides SC managers with a practical approach to dealing with SC disruptions and improving the sustainability of SCs in this context.

2. Materials and Methods

2.1. Methods

A literature review is a collection of specific concepts, theory, and practical application of domain experts in their research field, which is of great significance to developing domain knowledge [19]. We used content analysis and bibliometric analysis to investigate SCM issues during PHEICs. Content analysis is an efficient method for qualitative analysis, making valid inferences from data to context [20]. An exhaustive content analysis was conducted in our study, and in-depth views were extracted from the existing literature on the subtopics in this field. Compared with a traditional literature review, the bibliometric method overcomes the shortcoming of susceptibility to subjective cognition [21]. In the bibliometric method, computer algorithms are used to re-encode the metadata in a specific field, which facilitates the objective identification of research hotspots and reduces the cognitive bias of researchers by integrating the views of diverse scholars in this field [22]. Additionally, this method has generally been used to identify the research status, evolution trends, research hotspots, and possible future directions of a specific research topic in recent years [23]. There are several types of bibliometric research, such as descriptive analysis, topic clustering analysis, co-citation analysis, citation analysis, co-word analysis, and coupling analysis. Supply chain management during PHEICs is a research area with broad implications in terms of research value. To systematically uncover the current state, major research hotspots, and dynamic evolutionary trends in this field, we used descriptive analysis and thematic cluster analysis, which are of key importance for SC managers and scholars to gain a deeper understanding of this field.

The descriptive analysis provides basic information about a specific research field and helps scholars quickly grasp the development status of this field. The data for this analysis were extracted using Bibexcel software, which enables the collection of relevant information with Web of Science (WoS) categories, including the publication count, citation count, countries, authors, and h-index, which can be imported into Excel for further statistical analysis [24].

Thematic cluster analysis is generally regarded as a “poor man’s factor analysis” [25], which can provide a general overview of a plethora of studies in the literature and highlight the research hotspots in the field. VOSviewer was employed for cluster analysis in this study based on the principle of similarity [26]. Compared with other bibliometric software, such as Citespace, Ucinet, and Scimago, this software has a unique advantage in visualizing knowledge network maps in a simple and easy-to-understand way.

2.2. Data Collection

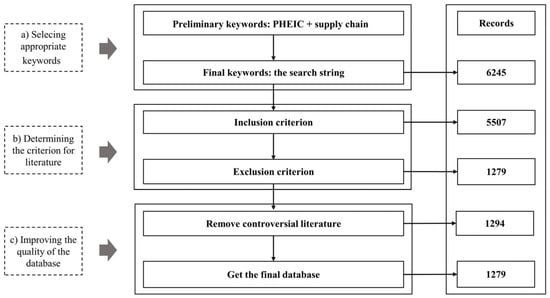

In this study, the literature related to supply chain management during PHEICs was retrieved from the WoS Core Collection. The reason for selecting this database is that it is regarded as the world’s most widely used and authoritative database of publications and citations [27], with high scientific impact and quality-oriented studies for bibliometric analysis [28]. In line with the suggestions of Tranfield, et al. [29], the following three steps were implemented to ensure the reliability of the data-screening process. The detailed retrieval process is shown in Figure 1.

Figure 1.

The procedure implemented to collect data.

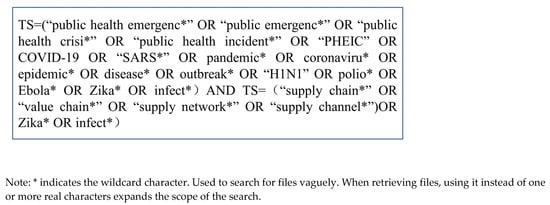

In the keyword selection stage, we defined keywords for both ‘PHEIC’ and ‘supply chain’ separately. These fields’ main keywords were identified and analyzed through the preliminary browsing of the papers related to these fields. The search string used in WoS Core Collection is shown in Figure 2. A total of 6245 papers were obtained using this search string.

Figure 2.

The keyword search string.

In the second step, a series of inclusion and exclusion criteria were applied to the secondary literature screening, which can be seen in Table 1. To make the selected literature more comprehensive, the literature with candidate keywords in the title, abstract, and keywords was included. Then, we limited the time from 2003 to 2022 (May). The starting point was selected as 2003 with the emergence of SARS. This epidemic, which is considered the first national public health emergency of the 21st century, has been considered highly concerning by the WHO. Then, journal articles were selected based on the publication type, and the language was limited to English. Consequently, 5507 records related to supply chain management during PHEICs were retrieved.

Table 1.

Inclusion and exclusion criteria for screening records.

Furthermore, two researchers independently reviewed the full text of articles and filtered irrelevant articles according to the inclusion and exclusion criteria. Nearly half of the literature was excluded. One of the reasons was that they were beyond the scope of the current study (e.g., completely belonging to biological or chemical pharmacology). Another reason was that they had no strong connection to the study of supply chain management during PHEICs (e.g., the impact of issues such as chronic diseases or human immunodeficiency virus (HIV) on SCs). After excluding irrelevant articles, 1294 articles were retained.

It is worth mentioning that for quality improvement, it was decided to also consider foodborne diseases, as an important source of PHEICs, in our analysis. Thus, the articles related to the impact of foodborne diseases on food safety were also included. The coincidence rate of the retrieved articles was 0.988, and all disputes and inconsistencies were fully discussed by all authors until a consensus was reached; ultimately, 1279 articles were left.

3. Results

3.1. Publication Trend

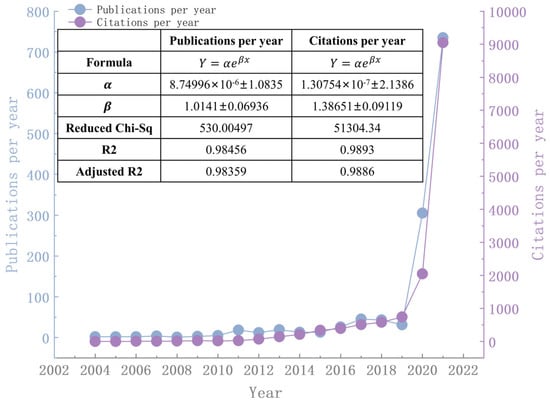

Publication trend reflects the development of a special research topic, and the trend of citations reveals the importance of this research area. Figure 3 shows the growth trajectory of the publications related to supply chain management during PHEICs, published from 2003 to 2022 (May). Before 2010, the papers published in this field were less than 10 papers per year, suggesting that the impacts of PHEICs on the supply chain industry did not receive much scholarly attention during this period. Since the WHO declared H1N1 as a PHEIC in 2009, the related articles gradually increased. There were four other epidemic outbreaks during 2010–2019, which urged scholars to advance research for the prediction, preparation, and response of supply chain management during PHEICs [30].

Figure 3.

The publication and citation trends (N = 1279).

However, the outbreak of COVID-19 in 2020 has had a catastrophic impact on certain supply chain sectors. A series of government policies (e.g., lockdowns, restrictions on movement, international trade restrictions, and retail store shutdowns) have disrupted the SC and indirectly led to a worldwide depression, which requires researchers to redouble their efforts toward providing SC strategies. Therefore, this research area has seen an exponential increase in papers since 2020.

To better describe the growth trend, we constructed the index growth rate (the specific function is expressed as () to fit publication and citation trends [31], with the R2 equal to 0.98456 and 0.9893, indicating an exponential increase in publications and citations, which shows that researchers have been highly involved in this field, and research on this topic has developed rapidly in recent years.

3.2. Author Analysis

Author analysis introduces the most influential authors in this field. The top ten leading authors in this field can be found in Table 2. Identifying these influential authors enables a quick overview of research frontiers in the field. Ivanov was found to be the most prolific author in this field with 14 publications; he addressed SC ripple effects and disruption risk issues in the face of PHEICs. He was particularly interested in the role of digitalization, Industry 4.0, and transparency in improving supply chain resilience and performance. Paul et al. (ranked second) emphasized the impact of COVID-19 on various industries, including manufacturing, services, and food and beverage. Nasir, et al. [32] proposed that digital twins and SC network transformation are key for a visual supply chain. Kumar published 10 papers on this topic, focusing on pharmaceutical and food supply chain management during PHEICs. He contributed to SC risk and disruption management issues and encouraged using technologies such as blockchain, artificial intelligence, and Industry 4.0 to improve SC resilience during PHEICs [33,34]. Luthra investigated sustainable and humanitarian SC and the use of big data and retail SC to improve supply chain resilience when facing a pandemic. Moktadir made key contributions to the study of COVID-19 and SC issues with pioneering research on the drivers of SC resilience and sustainability in the post-pandemic era [35]. There is a close collaboration between these key authors, who have made ground-breaking contributions to the field.

Table 2.

The top ten impactful authors.

Moreover, the h-index developed by Hirsch [36] was used to evaluate researchers’ scientific output [37]. Specifically, the h-index of a researcher means that they have at most a number of h papers cited at least h times, and a higher h-index index indicates a greater article influence [38]. Ivanov had a high h-index of 10, demonstrating his outstanding contributions to this area.

3.3. Country Analysis

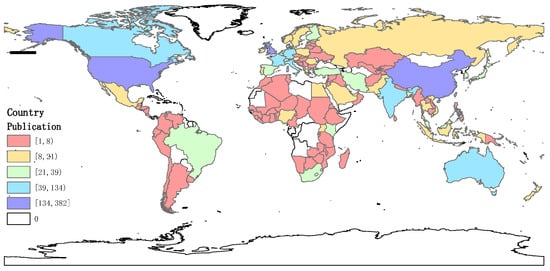

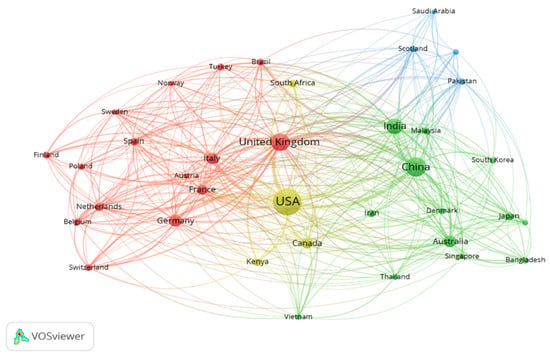

The country analysis introduces the countries that have greatly contributed to this research field and the degree of close ties between them. Figure 4 presents the global geographic distribution of the literature published in various countries. As can be seen, the highest contributors are indicated in purple, representing the United States (382), China (217), and the United Kingdom (186), which shows that these three countries have made significant contributions to the development of this field in the past several years. Detailed information on the ten countries with prolific research is listed in Table 3.

Figure 4.

Global geographic distribution of the publications by country.

Table 3.

The total number and citation of the papers according to country.

Apart from China, another developing country in this list is India (134), which mainly focuses on food SC and food safety. These top ten highly research-producing countries have contributed to approximately 57.46% of all the publications related to supply chain management during PHEICs, suggesting that researchers in these countries were highly interested in SC issues during PHEICs. In terms of citation per article, Germany ranked first with 23.39, followed by France (18.42), the Netherlands (17.36), and Australia (16.59), which indicates that the papers published in these countries are more profound and extensive.

VOSviewer was employed to analyze the cooperation between countries for research on this topic. A threshold of the number of national publications was set to 15, and 36 items were generated, as shown in Figure 5. The circle size is proportional to the number of publications, and the width of the lines represents the closeness of the cooperation between countries. Not surprisingly, countries with the largest publications cooperated closely with others. In particular, the United States, China, the United Kingdom, and India formed a solid cooperation network. This is due to globalization since the supply chain management in every country in the world has been disrupted by PHEICs, and the impact is severe and widespread. This implies that close academic cooperation is indispensable to addressing the impact of PHEICs.

Figure 5.

Cooperation network analysis according to country.

3.4. Subject Category

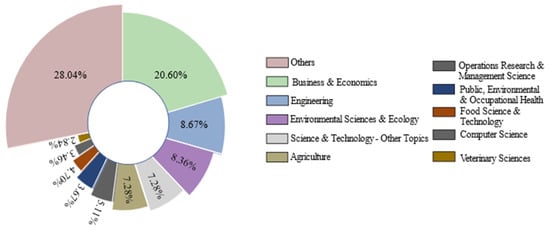

The analysis of subject category reveals which subjects are mainly studied in this field, with the possibility of interdisciplinary subjects. Figure 6 depicts all the categories in this scientific research field, of which the top ten research areas are marked. It can be intuitively observed that the top ten subject categories accounted for 71.97% of the total sample articles. In particular, “business and economics” stood out with one-fifth of the articles in this category (20.60%), followed by “engineering” with 168 (8.67%) and “environmental sciences and ecology” with 162 (8.36%). Interestingly, “science and technology” with 141 (7.28%), “agriculture” with 141 (7.28%), “operation research management science” with 99 (5.11%), and “food science and technology” with 91 (4.70%) also occupy a certain important position, illustrating that the fields of digital transformation, intelligent manufacturing, food SC, and food security are valuable subjects for research development.

Figure 6.

The top 10 subject categories.

4. Thematic Analysis

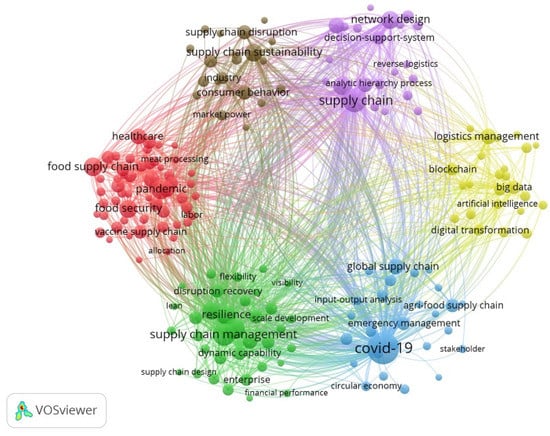

In this part of the analysis, VOSviewer was performed to analyze thematic clusters. To begin with, we imported the raw data into this software for operation and then processed the original data according to the cluster results. To reduce potential deviations, we processed keywords in two steps: (a) excluding meaningless keywords (e.g., “countries”, “tool”, “identification”, “perspective”, and “experience”); (b) amalgamating keywords with the same meaning (e.g., “coronavirus disease” and “COVID-19”). After adjusting the parameters repeatedly, a satisfactory result, in line with the actual situation, was obtained and is presented in Figure 7, which depicts a thematic cluster map of the studies involving supply chain management during PHEICs, with 1279 papers published during 2003–2022 (May), including a total of 184 items divided into 6 clusters. Each cluster represents different research topics, with six distinct colors. All these topics display the entire research framework concerning supply chain management during PHEICs, which will be further analyzed in the next section.

Figure 7.

Thematic cluster map of research on supply chain management during PHEICs.

4.1. Cluster 1 (Red): Supply Chain Disruption during PHEICs

Based on the findings, PHEICs have posed a severe threat to different industries or sectors of SC, as they destroyed the normal SC operation and led to SC interruption or paralysis. The disruption to the food system and health sector is of primary concern to scholars.

For the food system, they believe that the epidemic has disrupted the food SC (from production to consumption), with factors such as production constraints [39], panic buying [40], price volatility [41], food loss, and food waste [42]. In particular, most scholars focus on the storage, packaging, transportation, and recycling of fresh and perishable food SC [43,44]. Some scholars focus on how to solve the disruption risk of the food SC. Local and short-food SC, as well as community support, can ensure food access and availability and enhance SC resilience in the food sector [45].

In addition, closely associated with the presence of foodborne diseases, food security also gained scholars’ attention. Contamination [46], fraud [47], and lack of nutrition [48] are dominant issues in this theme. These crises have also brought issues related to the quality assurance of perishable foods and the lack of food nutrition to the forefront. These facts have prompted further research into traceability systems [49].

Most importantly, some scholars are concerned about healthcare SC, especially the supply chain management of vaccines and essential supplies. Due to the frequent occurrence of fraud, transportation challenges, and insufficient supply of vaccines, problems such as insufficient production, untimely transportation, and stockpiling for key medical suppliers have frequently emerged. Vaccine expiration and record fraud are still prevailing issues [50]. Additionally, the supply capacity of essential supplies such as personal protective equipment (PPE), masks, and thermometers, is far from meeting the surge in demands [51]. Currently, extensive research is underway on how to alleviate these shortages. Researchers have proposed various measures to solve these problems, such as the encouragement of investment in delivery strategies [52], the implementation of a “controlled temperature” chain [53], and the use of technology.

4.2. Cluster 2 (Green): Supply Chain Disruption Recovery during PHEICs

There are two main aspects of SC disruption risk during PHEICs: one is a series of ripple effects caused by SC disruption due to government restrictions [54], which are very different from daily operational risks [55,56]. The other is the bullwhip effects caused by information transparency and asymmetry [57], which result from the shift in consumer patterns and preferences [58]. Furthermore, disruptions in internal production processes may also occur [59].

Research on SC recovery strategies has focused on supply networks, procurement capabilities, and SC recovery models. Some scholars believe that a collaborative and interactive SC network helps to recover the SC rapidly [60]. Some researchers emphasize that companies can recover the SC through flexible procurement capabilities, such as emergency procurement [61] and diversified procurement [62]. In addition, some other scholars have facilitated supply chain recovery by designing resilient SCs. For instance, Ivanov and Dolgui [63] proposed a low-certainty-need SC to mitigate supply chain disruption risks.

For the factors of SC recovery, the existing studies mainly focus on three perspectives: government, business, and consumer. In terms of government-level factors, the impact of industry regulatory efforts [64] and government subsidies [65] on SC recovery has been widely studied. At the firm level, some scholars argued that the corporate culture and supplier selection might impact SC recovery. Specifically, a multi-channel supplier selection enables companies to maintain stable operations when facing a PHEIC. Guo, Yu, Zhou and Lyu [65] found that PHEICs changed the consumer demand structure at the consumer level, causing suppliers to reallocate resources to prioritize consumers’ daily and emergency needs.

How to achieve SC disruption recovery in the three stages of PHEICs is a great concern in this field. Most scholars have studied SC management in terms of three stages: preparation, response, and recovery. Specifically, the concrete approaches employed in the three stages of SC management are the avenues through which risks can be mitigated [66]. Firstly, researchers highlighted the roles of predictive analysis in the preparatory phase, especially the demand forecast [67]. Moreover, proactive and reactive measures are prevalent in the response phase. Thirdly, an innovative inventory strategy and flexible production strategy are mainly adopted in the recovery stage [68].

4.3. Cluster 3: (Blue) Supply Chain Reconstruction during PHEICs

SC reconstruction highlights the reallocation of resources and the readjustment of SC structure and organization, especially in the global SC [69]. The destruction of the global SC has a worldwide rather than domestic impact. Therefore, countries must give full play to comparative advantages and cooperate for SC reconstruction to optimize the allocation of supply chain resources and improve the resilience and adaptability of the supply chain when facing a PHEIC.

To expand on this subject, SC reconstruction mainly involves three departments: humanitarian SC, global SC, and agri-food SC. Humanitarian SC is unique to disaster management, redistributing critical supplies where needed [70], reflecting the reallocation of resources in SC restructuring. New supply chain network structures, such as short chains, localization trends, diversified supply channels, and offshoring, also play supporting roles in agri-food SC and global SC.

In this context, circular economy, short supply chains, and other new supply chains have become prevalent; disaster management and emergency management should work together to reconstruct supply networks. For example, local SC [71], reshoring [72], and multiple supply channels [73] are effective means to address the main issues (e.g., excessive dependence on foreign materials, trade restrictions, and port closure) on the global SC and agri-product SC. Meanwhile, researchers highlighted the role of government institutions, such as trade or governance regimes, data-driven industries, and the collaboration of stakeholders, to overcome drastic disruptions during PHEICs.

4.4. Cluster 4: (Yellow) Supply Chain Digital Intelligence during PHEICs

The different application scenarios of digitally intelligent SCs have become mainstream in this research field. Many studies indicate that digital technology and Industry 4.0 play a key role in resisting the disruption risk during PHEICs [74]. Because these technologies ensure end-to-end SC visibility, enterprises can monitor the SC in real time and deal with potential risks promptly.

On the one hand, PHEICs make the supply chain fuzzy, fraudulent, and difficult to predict [75]. The digital transformation of supply chains provides a new perspective for supply chain disruption during PHEICs and is used in various scenarios. For example, big data and blockchain technology have been widely researched in the field of SC, such as agriculture food SC [76], vaccine SC [77], and global supply network, which suggests that it is an effective and convenient technology in the traceability, visualization, integration, and sharing of supply chains. Moreover, digital twin models were generally used in designing sophisticated SC models [78].

On the other hand, due to panic buying for high-demand goods [79] and changes in the consumption mode [80], suppliers are unable to match the demand, resulting in the need for the study of SC intelligence. Intelligence also brings new opportunities to supply chain management during PHEICs. Additive manufacturing, also known as 3D printing technology, has been employed in particular to solve the shortage of necessary items such as medical equipment [81]. In addition, artificial intelligence, automation, and other technologies also play significant roles in improving the efficiency of the SC and ensuring continuity in business operations and end-to-end visibility [78].

4.5. Cluster 5: (Purple) Supply Chain Optimization during PHEICs

SC optimization means improved decision-making schemes under constraints or limited resources. Research studies have revealed that simulation [82], system dynamics [83], and decision support systems are required for decision making [84]. In addition, the objectives of SC optimization can be discussed from two perspectives: enterprises and public organizations. For companies, a PHEIC makes them change the goals of SC optimization. In other words, this strategy aims to understand the degree of damage and response mechanism of SCs against the background of PHEICs, thus helping to realize efficient and feasible decision-making processes and improve the SC system’s resilience and viability. For example, a fuzzy input–output optimization model was designed to support decision making [85].

SC optimization also refers to the use of mathematical models and engineering system thinking to study optimization models for improvement in enterprise or industry performance, cost reduction, and internal organization distribution [86]. Researchers commonly employ SC simulation, algorithms, and decision support systems to realize SC system optimization, including cost optimization [87], enterprise performance improvement, and inventory plan optimization [88]. According to the existing literature, the simulation of system dynamics is a mainstream simulation method that SC scholars use to measure resilience indicators (such as warehouse, supply, logistics, demand, and suppliers) and the extent of SC damage. Meanwhile, Figure 7 shows that items such as close-loop SC, reverse logistics, and green supply chain management, albeit less frequently studied, are essential to SC optimization.

4.6. Cluster 6: (Brown) Supply Chain Sustainability during PHEICs

SC sustainability means integrating the economy, society, and environment into the SC system [89]. The existing research emphasizes the pivotal role of the recycling of capital, the continuous availability of the labor force, environmental friendliness, the continuity of business, and long-term cooperation among SC members [35] in coping with the disruption caused by PHEICs.

Additionally, the shift in consumption patterns from offline to online has increased packaging waste [90], which leads to the opposition between the economy and the environment, and has increased researchers’ concern. Furthermore, driven by the goal of sustainability, studies on concrete and innovative measures such as knowledge management [91], local food systems [92], and waste management [93] have entered the academic field.

In addition, supply chain sustainability in the context of the pandemic ensures efficient operational and economic performance and rapid response to uncertain environments, especially during PHEICs. This helps strengthen enterprises’ sustainable development capacity [35]. Therefore, the driving factors that influence supply chain sustainability were also discussed [94]. More and more scholars pay attention to the driving factors of supply chain sustainability, such as risk management ability, agility, resilience, rapid response ability, and digitization level.

5. Discussion

This paper, through a review of the supply-chain-related literature in the context of PHEICs, found that most of the current research in this area focuses on SC disruption, strategy, and sustainability. Specifically, the relevant literature in this area has centered on disruption, disruption recovery, reconstruction, digital intelligence, optimization, and sustainability. We further discussed the transformation of the SC during the pre-and post-epidemic periods and possible future research directions by providing meaningful insights that can serve as a reference for SC researchers and managers.

A PHEIC is a force majeure that causes SC disruption and severely affects the daily lives of humans as well as production operations. It has become critical for organizations to reduce SC disruption risk and improve SC resilience in times of unexpected events. One of the important tools to ensure SC resilience is SC management, but most of the existing research is only post facto reactive, which is not enough. In the design of SC strategies, a proactive approach needs to be given even greater attention. Anticipatory functions in advance, as well as timely reactions in mid-event, require SC reconfiguration for the optimal allocation of elements. In addition, the use of digital intelligence measures is also indispensable. In the past, the issues related to SC disruption recovery were thoroughly investigated, but they were still based on general events. For an event as intense and sudden as PHEICs, the impact on the SC is perhaps even more deadly. Exploring the changes in SC characteristics before and after a pandemic is essential for SC managers and practitioners, as it can better guide scholars in responding to any pandemics that they may face in the future.

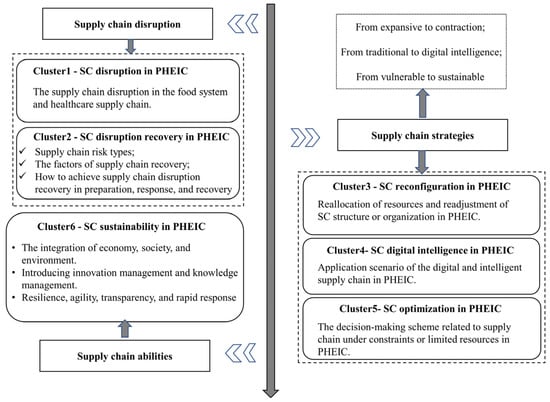

This study reconsidered supply chain management during PHEICs, by exploring research on SC themes ranging from expansion to contraction, from traditional to digital intelligence, and from fragile to sustainability, during the pre-and post-pandemic periods. The specific SC research framework is illustrated in Figure 8.

Figure 8.

A framework for supply chain research in the context of PHEICs.

5.1. Supply Chain from Expansion to Contraction

In the era of globalization and division of labor, the SC industry continues to expand globally, improving economic operations’ efficiency. However, this globalized division of labor also creates a complex and fragile supply chain, causing any disruption in the SC to trigger chain-wide damages or even paralysis [95]. To mitigate supply disruptions, downstream manufacturers improve supply reliability by providing subsidies or diversifying supply by adopting dual-sourcing strategies [96]. In addition, short chains and localized SCs were in the spotlight during the outbreak [97], and these solutions reduced the bullwhip and ripple effects of supply chain disruption risks. In this context, the SC continues to shift from expansionary to contractionary phases, especially in national security. Therefore, contractionary SCs or short chains, rather than long chains, are particularly important in the context of the pandemic. However, this is not to ignore the role of long chains but to choose the right SC links to fit different scenarios.

5.2. Supply Chain from Traditional to Digital Intelligence

The digital economy has become key to reorganizing global resources and reshaping the structure of the global economy [98]. Compared with the traditional SC, the digitally intelligent SC has transparency, agility, rapid responsiveness, and resilience [99]. Ivanov and Dolgui [78] found that by achieving end-to-end SC visualization, we can respond to SC risk issues promptly and effectively. The key to mitigating SC risk is whole-chain management, not partial management, with particular emphasis on the role of digital technology in the recovery process [100]. Furthermore, the SC industry is deeply integrated with advanced technologies such as the Internet, big data, and artificial intelligence so that each link in the SC system can carry out a high-efficiency and low-cost division of labor and collaboration, thus enabling SCs to recover from disruptions [18]. Therefore, in the context of PHEICs, the supply chain industry must be transformed from traditional to digital intelligence to better improve SC resilience and reduce SC risks.

5.3. Supply Chain from Vulnerable to Sustainability

In general, supply chains’ vulnerability is positively correlated with the complexity of their operational activities [101]. With the complexity of the international division of labor, the inherent vulnerability of global industrial chains has come to the fore when facing an external event, especially a PHEIC. In terms of the economy, shutdown in production, transport delays, and demand changes exert a major effect on the supply and demand sides of the SC, which causes economic depression [102]. From a social perspective, companies have reduced the priority of creating a safe and healthy work environment, which puts employees at risk [103]. In addition, economic recession and work disruptions also cause mass unemployment of low-skilled workers, reducing social welfare [104]. Regarding the environment, scholars are concerned about the environmental impact of distributing and recycling personal protective equipment [105]. Sustainability is the key capability of the supply chain to withstand this shock [106]. SC sustainability represents the three bottom-line dimensions of environment, society, and economy [89]. The meaning of SC sustainability is constantly evolving. For example, the Triple-A framework proposed by Lee [107], emphasizing that all SC departments should adapt to the complex dynamic environment and highlighting the process of integration and collaboration among participants. Furthermore, Cohen and Kouvelis [108] put forward the Triple A&R framework, adding robustness, resilience, and realignment to the original model, and more emphasis on SC recovery from interruption and even sustainable development of SC. Moreover, researchers are also concentrating on improving the response-ability, visibility, viability, and sustainability of the supply chain management during PHEICs [109,110]. Therefore, how to transform the supply chain from fragile to sustainability in the context of PHEICs is a major issue that needs to be addressed in the future, both in theory and in practice.

6. Conclusions and Future Direction

6.1. Conclusions

The study on supply chain management during PHEICs has significantly advanced in the past two years due to the outbreak of COVID-19. The exponential growth of publications indicates that scholars have paid unprecedented attention to this field since 2020. We employed bibliometric and content analysis tools to systematize the literature in this field, combining quantitative and qualitative analyses, providing the current status, research hotspots, and future opportunities for researchers.

Our analysis reached some major conclusions: (1) Supply-chain-related issues in the context of the pandemic are a promising research direction that still requires further research by relevant researchers and practitioners. We found that the United States, China, the United Kingdom, India, and Australia have made significant contributions to the field and have formed a close intellectual network among themselves, while the papers published in Germany and France are more popular. The research field related to supply chain management during PHEICs is interdisciplinary and mainly covers “business and field economics”, “engineering” and “environmental sciences and ecology”. (2) Most importantly, we found a supply chain analysis framework in a pandemic context, covering six main clusters: SC disruption, disruption recovery, reconfiguration, digital intelligence, optimization, and sustainability. These six clusters cover SC disruption issues, recovery strategies, and SC sustainability during a pandemic, which are the hotspots in this field. (3) The transformation from an expansive SC to a contracting SC, from a traditional SC to a digitally intelligent SC, and from a vulnerable SC to a sustainable SC are inevitable trends in response to PHEICs.

6.2. Future Directions

From a theoretical perspective, future research directions should explore the theoretical background and internal mechanisms of SC disruptions. In addition, the propagation mechanisms of the bullwhip and ripple effects are likely to be groundbreaking in the future. In addition, the availability or sustainability of the workforce in SC will remain a meaningful and interesting research topic in the future. Finally, SC sustainability has received considerable attention in the short term, but long-term SC sustainability is still fraught with uncertainty and requires further research.

From a practical perspective, the integration of humanitarian and emergency management into SC management may be a future possibility. In addition, the further exploration of what kind of SC network can be adapted to the post-epidemic era is also a potential future research direction. In addition, due to social distancing, the use of technology to solve the last-mile problem can greatly improve the efficiency of SCs in the future.

6.3. Limitations

Naturally, our review has certain limitations, which need to be addressed in future work in this area. First, our dataset originates from the WoS, and we initially only focuse on the quality of articles more than the quantity. The second limitation of our review is that the results of the bibliometric analysis might be slightly different from the real research status. However, we try to derive an understanding of the dynamic research in this field from the meaning of the literature itself.

Author Contributions

Conceptualization, J.L. (Jianli Luo) and Y.B.; methodology, M.H.; software, M.H.; validation, J.L. (Jianli Luo) and J.L. (Jia Li); formal analysis, J.L. (Jia Li); investigation, Y.B.; resources, J.L. (Jianli Luo); data curation, M.H.; writing—original draft preparation, J.L. (Jianli Luo); writing—review and editing, M.H.; visualization, Y.B.; supervision, J.L. (Jia Li); project administration, Y.B.; funding acquisition, J.L. (Jia Li). All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Philosophy and Social Science Planning Project of Zhejiang Province in China (21NDJC318YBM).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All research data in this study were obtained from the Web of Science Core Collection database.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Harland, C.M.; Knight, L.; Patrucco, A.S.; Lynch, J.; Telgen, J.; Peters, E.; Tatrai, T.; Ferk, P. Practitioners’ learning about healthcare supply chain management in the COVID-19 pandemic: A public procurement perspective. Int. J. Oper. Prod. Manag. 2021, 41, 178–189. [Google Scholar] [CrossRef]

- Kovacs, G.; Sigala, I.F. Lessons learned from humanitarian logistics to manage supply chain disruptions. J. Supply Chain Manag. 2021, 57, 41–49. [Google Scholar] [CrossRef]

- Ali, I.; Arslan, A.; Khan, Z.; Tarba, S.Y. The Role of Industry 4.0 Technologies in Mitigating Supply Chain Disruption: Empirical Evidence from the Australian Food Processing Industry. IEEE Trans. Eng. Manag. 2021. [Google Scholar] [CrossRef]

- Leong, W.Y. COVID-19’s impact on travel medicine surpasses that of all other emerging viral diseases. J. Travel Med. 2020, 27, taaa221. [Google Scholar] [CrossRef] [PubMed]

- Hudecheck, M.; Sirén, C.; Grichnik, D.; Wincent, J. How companies can respond to the Coronavirus. In MIT Sloan Management Review; MIT Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Wilder-Smith, A.; Osman, S. Public health emergencies of international concern: A historic overview. J. Travel Med. 2020, 27, taaa227. [Google Scholar] [CrossRef] [PubMed]

- Lotfi, R.; Sheikhi, Z.; Amra, M.; AliBakhshi, M.; Weber, G.-W. Robust optimization of risk-aware, resilient and sustainable closed-loop supply chain network design with Lagrange relaxation and fix-and-optimize. Int. J. Logist. Res. Appl. 2021, ahead-of-print. [CrossRef]

- Dagg, P.J.; Butler, R.J.; Murray, J.G.; Biddle, R.R. Meeting the requirements of importing countries: Practice and policy for on-farm approaches to food safety. Rev. Sci. Tech. Off. Int. Epizoot. 2006, 25, 685–700. [Google Scholar] [CrossRef]

- Hu, J.; Zeng, A.Z.; Zhao, L. A comparative study of public-health emergency management. Ind. Manag. Data Syst. 2009, 109, 976–992. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Ivanov, D.; Dolgui, A.; Wamba, S.F. Impacts of epidemic outbreaks on supply chains: Mapping a research agenda amid the COVID-19 pandemic through a structured literature review. Ann. Oper. Res. 2020, 319, 1159–1196. [Google Scholar] [CrossRef]

- Chowdhury, P.; Paul, S.K.; Kaisar, S.; Moktadir, M.A. COVID-19 pandemic related supply chain studies: A systematic review. Transp. Res. Part E Logist. Transp. Rev. 2021, 148, 102271. [Google Scholar] [CrossRef]

- Sajjad, A. The COVID-19 pandemic, social sustainability and global supply chain resilience: A review. Corp. Gov. Int. J. Bus. Soc. 2021, 21, 1142–1154. [Google Scholar] [CrossRef]

- Qrunfleh, S.; Vivek, S.; Merz, R.; Mathivathanan, D. Mitigation themes in supply chain research during the COVID-19 pandemic: A systematic literature review. Benchmarking Int. J. 2022, ahead-of-print. [CrossRef]

- Cardoso, B.; Cunha, L.; Leiras, A.; Goncalves, P.; Yoshizaki, H.; de Brito, I.; Pedroso, F. Causal Impacts of Epidemics and Pandemics on Food Supply Chains: A Systematic Review. Sustainability 2021, 13, 9799. [Google Scholar] [CrossRef]

- Das, N.K.; Roy, A. COVID-19 and agri-food value chain: A systematic review and bibliometric mapping. J. Agribus. Dev. Emerg. Econ. 2022, 12, 442–462. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Appolloni, A.; Iranmanesh, M.; Treiblmaier, H.; Jagtap, S. Exploring Food Supply Chain Trends in the COVID-19 Era: A Bibliometric Review. Sustainability 2022, 14, 12437. [Google Scholar] [CrossRef]

- Pournader, M.; Kach, A.; Talluri, S. A Review of the Existing and Emerging Topics in the Supply Chain Risk Management Literature. Decis. Sci. 2020, 51, 867–919. [Google Scholar] [CrossRef]

- Spieske, A.; Birkel, H. Improving supply chain resilience through industry 4.0: A systematic literature review under the impressions of the COVID-19 pandemic. Comput. Ind. Eng. 2021, 158, 107452. [Google Scholar] [CrossRef]

- Atkins, S.; Murphy, K. Reflection: A review of the literature. J. Adv. Nurs. 1993, 18, 1188–1192. [Google Scholar] [CrossRef]

- Zupic, I.; Cater, T. Bibliometric Methods in Management and Organization. Organ. Res. Methods 2015, 18, 429–472. [Google Scholar] [CrossRef]

- Chen, C.M. Science Mapping: A Systematic Review of the Literature. J. Data Inf. Sci. 2017, 2, 1–40. [Google Scholar] [CrossRef]

- Krippendorff, K. Content Analysis: An Introduction to Its Methodology; SAGE Publications: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Cobo, M.J.; Lopez-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. Science Mapping Software Tools: Review, Analysis, and Cooperative Study Among Tools. J. Am. Soc. Inf. Sci. Technol. 2011, 62, 1382–1402. [Google Scholar] [CrossRef]

- Persson, O.; Danell, R.; Schneider, J.W. How to use Bibexcel for various types of bibliometric analysis. Celebr. Sch. Commun. Stud. Festschr. Olle Persson His 60th Birthd. 2009, 5, 9–24. [Google Scholar]

- Edwards, A.W.; Cavalli-Sforza, L.L. A method for cluster analysis. Biometrics 1965, 362–375. [Google Scholar] [CrossRef]

- Rodriguez, A.; Laio, A. Clustering by fast search and find of density peaks. Science 2014, 344, 1492–1496. [Google Scholar] [CrossRef] [PubMed]

- Birkle, C.; Pendlebury, D.A.; Schnell, J.; Adams, J. Web of Science as a data source for research on scientific and scholarly activity. Quant. Sci. Stud. 2020, 1, 363–376. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, W.; Yang, Y.; Yang, Y.; Man, X. State of the art on food waste research: A bibliometrics study from 1997 to 2014. J. Clean. Prod. 2017, 140, 840–846. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Lu, X.; Horn, A.L.; Su, J.; Jiang, J. A Universal Measure for Network Traceability. Omega Int. J. Manag. Sci. 2019, 87, 191–204. [Google Scholar] [CrossRef]

- de Solla Price, D.J.; Page, T. Science since babylon. Am. J. Phys. 1961, 29, 863–864. [Google Scholar] [CrossRef]

- Nasir, S.B.; Ahmed, T.; Karmaker, C.L.; Ali, S.M.; Paul, S.K.; Majumdar, A. Supply chain viability in the context of COVID-19 pandemic in small and medium-sized enterprises: Implications for sustainable development goals. J. Enterp. Inf. Manag. 2021, 35, 100–124. [Google Scholar] [CrossRef]

- Frederico, G.F.; Kumar, V.; Garza-Reyes, J.A.; Kumar, A.; Agrawal, R. Impact of I4.0 technologies and their interoperability on performance: Future pathways for supply chain resilience post-COVID-19. Int. J. Logist. Manag. 2021, ahead-of-print. [CrossRef]

- Kazancoglu, Y.; Ozbiltekin-Pala, M.; Sezer, M.D.; Luthra, S.; Kumar, A. Resilient reverse logistics with blockchain technology in sustainable food supply chain management during COVID-19. Bus. Strategy Environ. 2022, ahead-of-print. [CrossRef]

- Karmaker, C.L.; Ahmed, T.; Ahmed, S.; Ali, S.M.; Moktadir, M.A.; Kabir, G. Improving supply chain sustainability in the context of COVID-19 pandemic in an emerging economy: Exploring drivers using an integrated model. Sustain. Prod. Consum. 2021, 26, 411–427. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, J.E. An index to quantify an individual’s scientific research output. Proc. Natl. Acad. Sci. USA 2005, 102, 16569–16572. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, J.E. Does the h index have predictive power? Proc. Natl. Acad. Sci. USA 2007, 104, 19193–19198. [Google Scholar] [CrossRef] [PubMed]

- Alonso, S.; Cabrerizo, F.J.; Herrera-Viedma, E.; Herrera, F. h-Index: A review focused in its variants, computation and standardization for different scientific fields. J. Informetr. 2009, 3, 273–289. [Google Scholar] [CrossRef]

- Nordhagen, S.; Igbeka, U.; Rowlands, H.; Shine, R.S.; Heneghan, E.; Tench, J. COVID-19 and small enterprises in the food supply chain: Early impacts and implications for longer-term food system resilience in low- and middle-income countries. World Dev. 2021, 141, 105405. [Google Scholar] [CrossRef]

- Hao, N.; Wang, H.H.; Zhou, Q. The impact of online grocery shopping on stockpile behavior in Covid-19. China Agric. Econ. Rev. 2020, 12, 459–470. [Google Scholar] [CrossRef]

- Agyei, S.K.; Isshaq, Z.; Frimpong, S.; Adam, A.M.; Bossman, A.; Asiamah, O. COVID-19 and food prices in sub-Saharan Africa. Afr. Dev. Rev. Rev. Afr. Dev. 2021, 33, S102–S113. [Google Scholar] [CrossRef]

- Rivera-Ferre, M.G.; Lopez-i-Gelats, F.; Ravera, F.; Oteros-Rozas, E.; di Masso, M.; Binimelis, R.; El Bilali, H. The two-way relationship between food systems and the COVID19 pandemic: Causes and consequences. Agric. Syst. 2021, 191, 103134. [Google Scholar] [CrossRef]

- LeBlanc, D.I.; Villeneuve, S.; Beni, L.H.; Otten, A.; Fazil, A.; McKellar, R.; Delaquis, P. A national produce supply chain database for food safety risk analysis. J. Food Eng. 2015, 147, 24–38. [Google Scholar] [CrossRef]

- Capelli, F.; Tappi, S.; Gritti, T.; de Aguiar Saldanha Pinheiro, A.C.; Laurita, R.; Tylewicz, U.; Spataro, F.; Braschi, G.; Lanciotti, R.; Gomez Galindo, F.; et al. Decontamination of Food Packages from SARS-CoV-2 RNA with a Cold Plasma-Assisted System. Appl. Sci. 2021, 11, 4177. [Google Scholar] [CrossRef]

- De Paulo Farias, D.; de Araujo, F.F. Will COVID-19 affect food supply in distribution centers of Brazilian regions affected by the pandemic? Trends Food Sci. Technol. 2020, 103, 361–366. [Google Scholar] [CrossRef] [PubMed]

- Binter, C.; Straver, J.M.; Haggblom, P.; Bruggeman, G.; Lindqvist, P.-A.; Zentek, J.; Andersson, M.G. Transmission and control of Salmonella in the pig feed chain: A conceptual model. Int. J. Food Microbiol. 2011, 145, S7–S17. [Google Scholar] [CrossRef]

- Montgomery, H.; Haughey, S.A.; Elliott, C.T. Recent food safety and fraud issues within the dairy supply chain (2015–2019). Glob. Food Secur. Agric. Policy Econ. Environ. 2020, 26, 100447. [Google Scholar] [CrossRef] [PubMed]

- Grema, H.A.; Kwaga, J.K.P.; Bello, M.; Umaru, O.H. Understanding fish production and marketing systems in North-western Nigeria and identification of potential food safety risks using value chain framework. Prev. Vet. Med. 2020, 181, 105038. [Google Scholar] [CrossRef]

- Farooq, U.; Tao, W.; Alfian, G.; Kang, Y.-S.; Rhee, J. ePedigree Traceability System for the Agricultural Food Supply Chain to Ensure Consumer Health. Sustainability 2016, 8, 839. [Google Scholar] [CrossRef]

- Yong, B.; Shen, J.; Liu, X.; Li, F.; Chen, H.; Zhou, Q. An intelligent blockchain-based system for safe vaccine supply and supervision. Int. J. Inf. Manag. 2020, 52, 102024. [Google Scholar] [CrossRef]

- Aljadeed, R.; AlRuthia, Y.; Balkhi, B.; Sales, I.; Alwhaibi, M.; Almohammed, O.; Alotaibi, A.J.; Alrumaih, A.M.; Asiri, Y. The Impact of COVID-19 on Essential Medicines and Personal Protective Equipment Availability and Prices in Saudi Arabia. Healthcare 2021, 9, 290. [Google Scholar] [CrossRef]

- Weintraub, R.L.; Subramanian, L.; Karlage, A.; Ahmad, I.; Rosenberg, J. COVID-19 Vaccine to Vaccination: Why Leaders Must Invest in Delivery Strategies Now. Health Aff. 2021, 40, 33–41. [Google Scholar] [CrossRef]

- Lydon, P.; Zipursky, S.; Tevi-Benissan, C.; Djingarey, M.H.; Gbedonou, P.; Youssouf, B.O.; Zaffran, M. Economic benefits of keeping vaccines at ambient temperature during mass vaccination: The case of meningitis A vaccine in Chad. Bull. World Health Organ. 2014, 92, 86–92. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.D.S.; Aviso, K.B. Modelling the Economic Impact and Ripple Effects of Disease Outbreaks. Process Integr. Optim. Sustain. 2020, 4, 183–186. [Google Scholar] [CrossRef]

- Althaf, S.; Babbitt, C.W. Disruption risks to material supply chains in the electronics sector. Resour. Conserv. Recycl. 2021, 167, 105248. [Google Scholar] [CrossRef]

- Dohale, V.; Ambilkar, P.; Gunasekaran, A.; Verma, P. Supply chain risk mitigation strategies during COVID-19: Exploratory cases of “make-to-order” handloom saree apparel industries. Int. J. Phys. Distrib. Logist. Manag. 2021, 52, 109–129. [Google Scholar] [CrossRef]

- Gocer, F. A Novel Interval Value Extension of Picture Fuzzy Sets into Group Decision Making: An Approach to Support Supply Chain Sustainability in Catastrophic Disruptions. IEEE Access 2021, 9, 117080–117096. [Google Scholar] [CrossRef]

- Zighan, S. Managing the great bullwhip effects caused by COVID-19. J. Glob. Oper. Strateg. Sourc. 2021, 15, 28–47. [Google Scholar] [CrossRef]

- Habermann, M.; Blackhurst, J.; Metcalf, A.Y. Keep Your Friends Close? Supply Chain Design and Disruption Risk. Decis. Sci. 2015, 46, 491–526. [Google Scholar] [CrossRef]

- Ivanov, D.; Sokolov, B.; Dolgui, A. The Ripple effect in supply chains: Trade-off ‘efficiency-flexibility-resilience’ in disruption management. Int. J. Prod. Res. 2014, 52, 2154–2172. [Google Scholar] [CrossRef]

- Taskin, S.; Lodree, E.J. Inventory decisions for emergency supplies based on hurricane count predictions. Int. J. Prod. Econ. 2010, 126, 66–75. [Google Scholar] [CrossRef]

- Liu, K.S.; Lin, M.H. Performance Assessment on the Application of Artificial Intelligence to Sustainable Supply Chain Management in the Construction Material Industry. Sustainability 2021, 13, 12767. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Low-Certainty-Need (LCN) supply chains: A new perspective in managing disruption risks and resilience. Int. J. Prod. Res. 2019, 57, 5119–5136. [Google Scholar] [CrossRef]

- Pecchia, L.; Piaggio, D.; Maccaro, A.; Formisano, C.; Iadanza, E. The Inadequacy of Regulatory Frameworks in Time of Crisis and in Low-Resource Settings: Personal Protective Equipment and COVID-19. Health Technol. 2020, 10, 1375–1383. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Yu, X.N.; Zhou, C.F.; Lyu, G.Y. Government subsidies for preventing supply disruption when the supplier has an outside option under competition. Transp. Res. Part Logist. Transp. Rev. 2021, 147, 102218. [Google Scholar] [CrossRef]

- Gurtu, A.; Johny, J. Supply Chain Risk Management: Literature Review. Risks 2021, 9, 16. [Google Scholar] [CrossRef]

- Yue, X.H.; Liu, J. Demand forecast sharing in a dual-channel supply chain. Eur. J. Oper. Res. 2006, 174, 646–667. [Google Scholar] [CrossRef]

- Xia, Y.S.; Yang, M.H.; Golany, B.; Gilbert, S.M.; Yu, G. Real-time disruption management in a two-stage production and inventory system. IIE Trans. 2004, 36, 111–125. [Google Scholar] [CrossRef]

- Bing, X.; Bloemhof-Ruwaard, J.; Chaabane, A.; van der Vorst, J. Global reverse supply chain redesign for household plastic waste under the emission trading scheme. J. Clean. Prod. 2015, 103, 28–39. [Google Scholar] [CrossRef]

- Altay, N.; Kovacs, G.; Spens, K. The evolution of humanitarian logistics as a discipline through a crystal ball. J. Humanit. Logist. Supply Chain Manag. 2021, 11, 577–584. [Google Scholar] [CrossRef]

- McEwan, K.; Marchand, L.; Shang, M.; Bucknell, D. Potential implications of COVID-19 on the Canadian pork industry. Can. J. Agric. Econ. Rev. Can. D Agroecon. 2020, 68, 201–206. [Google Scholar] [CrossRef]

- Pourhejazy, P.; Ashby, A. Reshoring Decisions for Adjusting Supply Chains in a Changing World: A Case Study from the Apparel Industry. Int. J. Environ. Res. Public Health 2021, 18, 4873. [Google Scholar] [CrossRef]

- Yadav, V.S.; Tripathi, S.; Singh, A.R. Bi-objective optimization for sustainable supply chain network design in omnichannel. J. Manuf. Technol. Manag. 2019, 30, 972–986. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Onyeaka, H.; Ukwuru, M.; Anumudu, C.; Anyogu, A. Food fraud in insecure times: Challenges and opportunities for reducing food fraud in Africa. Trends Food Sci. Technol. 2022, 125, 26–32. [Google Scholar] [CrossRef]

- Yadav, V.S.; Singh, A.R.; Raut, R.D.; Govindarajan, U.H. Blockchain technology adoption barriers in the Indian agricultural supply chain: An integrated approach. Resour. Conserv. Recycl. 2020, 161, 104877. [Google Scholar] [CrossRef]

- Kumar, N.; Upreti, K.; Upreti, S.; Alam, M.S.; Agrawal, M. Blockchain integrated flexible vaccine supply chain architecture: Excavate the determinants of adoption. Hum. Behav. Emerg. Technol. 2021, 3, 1106–1117. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control 2021, 32, 775–788. [Google Scholar] [CrossRef]

- Li, X.; Zhou, Y.; Wong, Y.D.; Wang, X.; Yuen, K.F. What influences panic buying behaviour? A model based on dual-system theory and stimulus-organism-response framework. Int. J. Disaster Risk Reduct. 2021, 64, 102484. [Google Scholar] [CrossRef]

- Shokoohyar, S.; Gorizi, A.J.; Ghomi, V.; Liang, W.M.; Kim, H.J. Sustainable Transportation in Practice: A Systematic Quantitative Review of Case Studies. Sustainability 2022, 14, 2617. [Google Scholar] [CrossRef]

- Arora, P.K.; Arora, R.; Haleem, A.; Kumar, H. Application of additive manufacturing in challenges posed by COVID-19. Mater. Today Proc. 2021, 38, 466–468. [Google Scholar] [CrossRef]

- Ferreira, W.D.; Armellini, F.; De Santa-Eulalia, L.A. Simulation in industry 4.0: A state-of-the-art review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Cuong, T.N.; Kim, H.S.; You, S.S.; Nguyen, D.A. Seaport throughput forecasting and post COVID-19 recovery policy by using effective decision-making strategy: A case study of Vietnam ports. Comput. Ind. Eng. 2022, 168, 108102. [Google Scholar] [CrossRef] [PubMed]

- Jurasky, W.; Moder, P.; Milde, M.; Ehm, H.; Reinhart, G. Transformation of semantic knowledge into simulation-based decision support. Robot. Comput. Integr. Manuf. 2021, 71, 102174. [Google Scholar] [CrossRef]

- Aviso, K.B.; Mayol, A.P.; Promentilla, M.A.B.; Santos, J.R.; Tan, R.R.; Ubando, A.T.; Yu, K.D.S. Allocating human resources in organizations operating under crisis conditions: A fuzzy input-output optimization modeling framework. Resour. Conserv. Recycl. 2018, 128, 250–258. [Google Scholar] [CrossRef]

- Ivanov, D.; Sokolov, B.; Kaeschel, J. A multi-structural framework for adaptive supply chain planning and operations control with structure dynamics considerations. Eur. J. Oper. Res. 2010, 200, 409–420. [Google Scholar] [CrossRef]

- Alikhani, R.; Torabi, S.A.; Altay, N. Retail supply chain network design with concurrent resilience capabilities. Int. J. Prod. Econ. 2021, 234, 108042. [Google Scholar] [CrossRef]

- Bam, L.; McLaren, Z.M.; Coetzee, E.; von Leipzig, K.H. Reducing stock-outs of essential tuberculosis medicines: A system dynamics modelling approach to supply chain management. Health Policy Plan. 2017, 32, 1127–1134. [Google Scholar] [CrossRef]

- Sarkis, J. Supply chain sustainability: Learning from the COVID-19 pandemic. Int. J. Oper. Prod. Manag. 2021, 41, 63–73. [Google Scholar] [CrossRef]

- Chen, Z.; Tan, A. Exploring the circular supply chain to reduce plastic waste in singapore. Logforum 2021, 17, 271–286. [Google Scholar] [CrossRef]

- Al-Omoush, K.S.; Palacios-Marques, D.; Ulrich, K. The impact impact of intellectual capital on supply chain agility and collaborative knowledge creation in responding to unprecedented pandemic crises. Technol. Forecast. Soc. Chang. 2022, 178, 121603. [Google Scholar] [CrossRef]

- Bhavani, R.V.; Gopinath, R. The COVID19 pandemic crisis and the relevance of a farm-system-for-nutrition approach. Food Secur. 2020, 12, 881–884. [Google Scholar] [CrossRef]

- Babbitt, C.W.; Babbitt, G.A.; Oehman, J.M. Behavioral impacts on residential food provisioning, use, and waste during the COVID-19 pandemic. Sustain. Prod. Consum. 2021, 28, 315–325. [Google Scholar] [CrossRef] [PubMed]

- Hussain, M.; Khan, M.; Al-Aomar, R. A framework for supply chain sustainability in service industry with Confirmatory Factor Analysis. Renew. Sustain. Energy Rev. 2016, 55, 1301–1312. [Google Scholar] [CrossRef]

- Craighead, C.W.; Blackhurst, J.; Rungtusanatham, M.J.; Handfield, R.B. The severity of supply chain disruptions: Design characteristics and mitigation capabilities. Decis. Sci. 2007, 38, 131–156. [Google Scholar] [CrossRef]

- Li, G.; Liu, M.Q.; Zheng, H. Subsidization or Diversification? Mitigating Supply Disruption with Manufacturer Information Sharing. Omega Int. J. Manag. Sci. 2022, 112, 102670. [Google Scholar] [CrossRef]

- Sharma, H.B.; Vanapalli, K.R.; Cheela, V.R.S.; Ranjan, V.P.; Jaglan, A.K.; Dubey, B.; Goel, S.; Bhattacharya, J. Challenges, opportunities, and innovations for effective solid waste management during and post COVID-19 pandemic. Resour. Conserv. Recycl. 2020, 162, 105052. [Google Scholar] [CrossRef]

- Ganichev, N.A.; Koshovets, O.B. Forcing the Digital Economy: How will the Structure of Digital Markets Change as a Result of the COVID-19 Pandemic. Stud. Russ. Econ. Dev. 2021, 32, 11–22. [Google Scholar] [CrossRef]

- Birkel, H.; Wehrle, M. Small- and Medium-Sized Companies Tackling the Digital Transformation of Supply Chain Processes: Insights from a Multiple Case Study in the German Manufacturing Industry. IEEE Trans. Eng. Manag. 2022, ahead-of-print. [CrossRef]

- Paul, S.K.; Chowdhury, P. A production recovery plan in manufacturing supply chains for a high-demand item during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 104–125. [Google Scholar] [CrossRef]

- Chopra, S.; Sodhi, M.S. Reducing the Risk of Supply Chain Disruptions. In MIT Sloan Management Review; MIT Press: Cambridge, MA, USA, 2014; Volume 55. [Google Scholar]

- Chauhan, V.; Baksh, A. COVID-19 Pandemic: Concerns, Impact and Continuity Strategies for Small Businesses in India. Indian J. Econ. Dev. 2021, 17, 681–692. [Google Scholar] [CrossRef]

- Axe, J.; Wilson-Mah, R.; Dahlquist-Axe, H. COVID-19 workplace adaptation and recovery in the resort municipality of Whistler, BC, Canada. Int. J. Workplace Health Manag. 2022, 15, 375–392. [Google Scholar] [CrossRef]

- Wang, J.J. The labour surplus and COVID-19: The outlook for Chinese migrant low-skilled workers. Account. Financ. 2021, 62, 577–596. [Google Scholar] [CrossRef]

- Rizan, C.; Reed, M.; Bhutta, M.F. Environmental impact of personal protective equipment distributed for use by health and social care services in England in the first six months of the COVID-19 pandemic. J. R. Soc. Med. 2021, 114, 250–263. [Google Scholar] [CrossRef] [PubMed]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable supply chains: An introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Lee, H.L. The triple-A supply chain. Harv. Bus. Rev. 2004, 82, 102–113. [Google Scholar]

- Cohen, M.A.; Kouvelis, P. Revisit of AAA Excellence of Global Value Chains: Robustness, Resilience, and Realignment. Prod. Oper. Manag. 2021, 30, 633–643. [Google Scholar] [CrossRef]

- Burgos, D.; Ivanov, D. Food retail supply chain resilience and the COVID-19 pandemic: A digital twin-based impact analysis and improvement directions. Transp. Res. Part E Logist. Transp. Rev. 2021, 152, 102412. [Google Scholar] [CrossRef] [PubMed]

- Soundararajan, V.; Sahasranamam, S.; Khan, Z.; Jain, T. Multinational enterprises and the governance of sustainability practices in emerging market supply chains: An agile governance perspective. J. World Bus. 2021, 56, 101149. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).