Numerical Simulation of Cavitation Characteristics of a Centrifugal Pump Based on an Improved ZGB Model

Abstract

:1. Introduction

2. Computational Model and Meshing

3. Numerical Computation Theoretical Model

3.1. Selection and Correction of the Turbulence Model

3.2. Selection and Correction of the Cavitation Model

3.3. Boundary Conditions and UDF Settings

4. Analysis of Calculation Results

4.1. Cavitation Performance Results

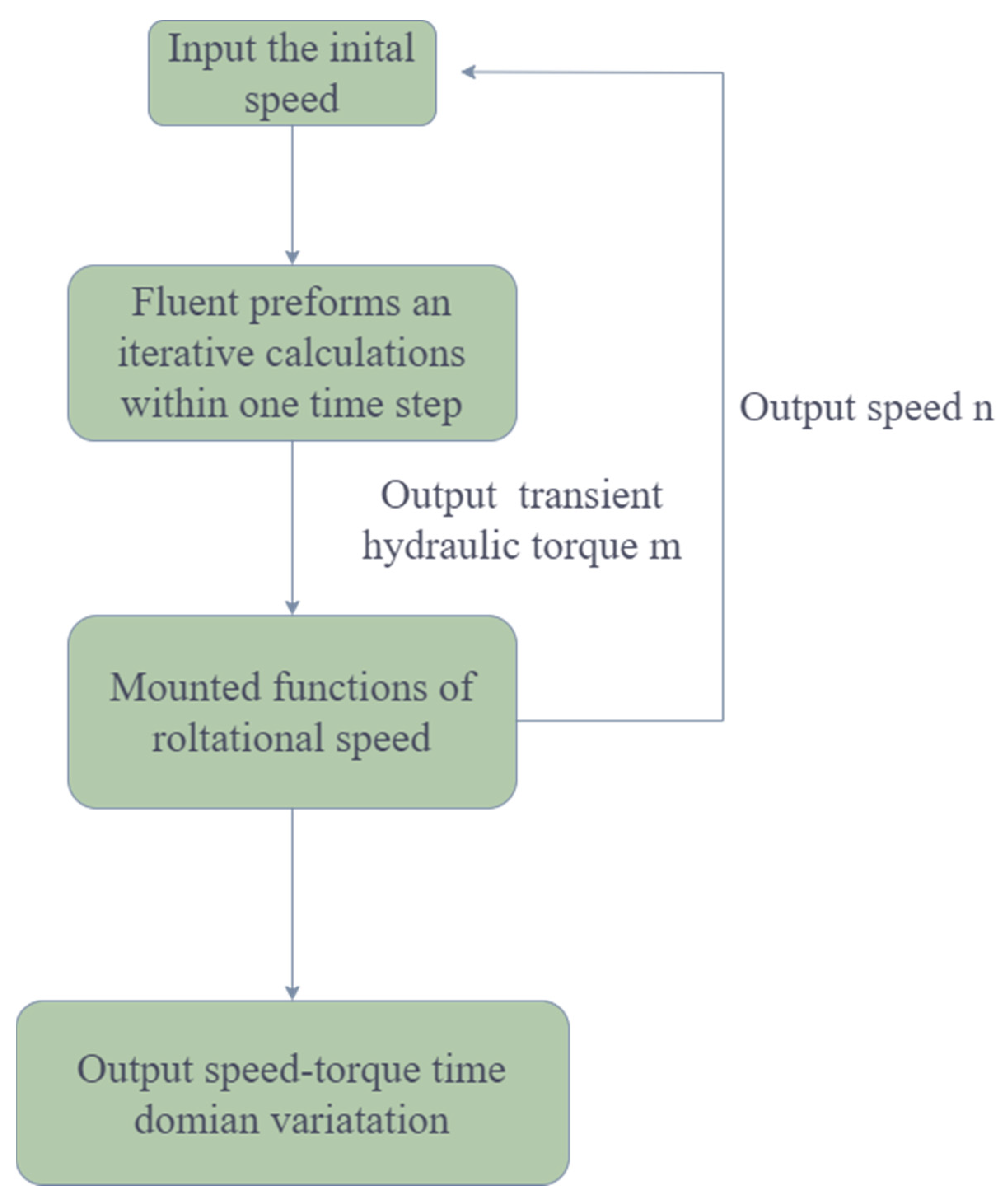

4.2. UDF Speed Output under Cavitation Conditions

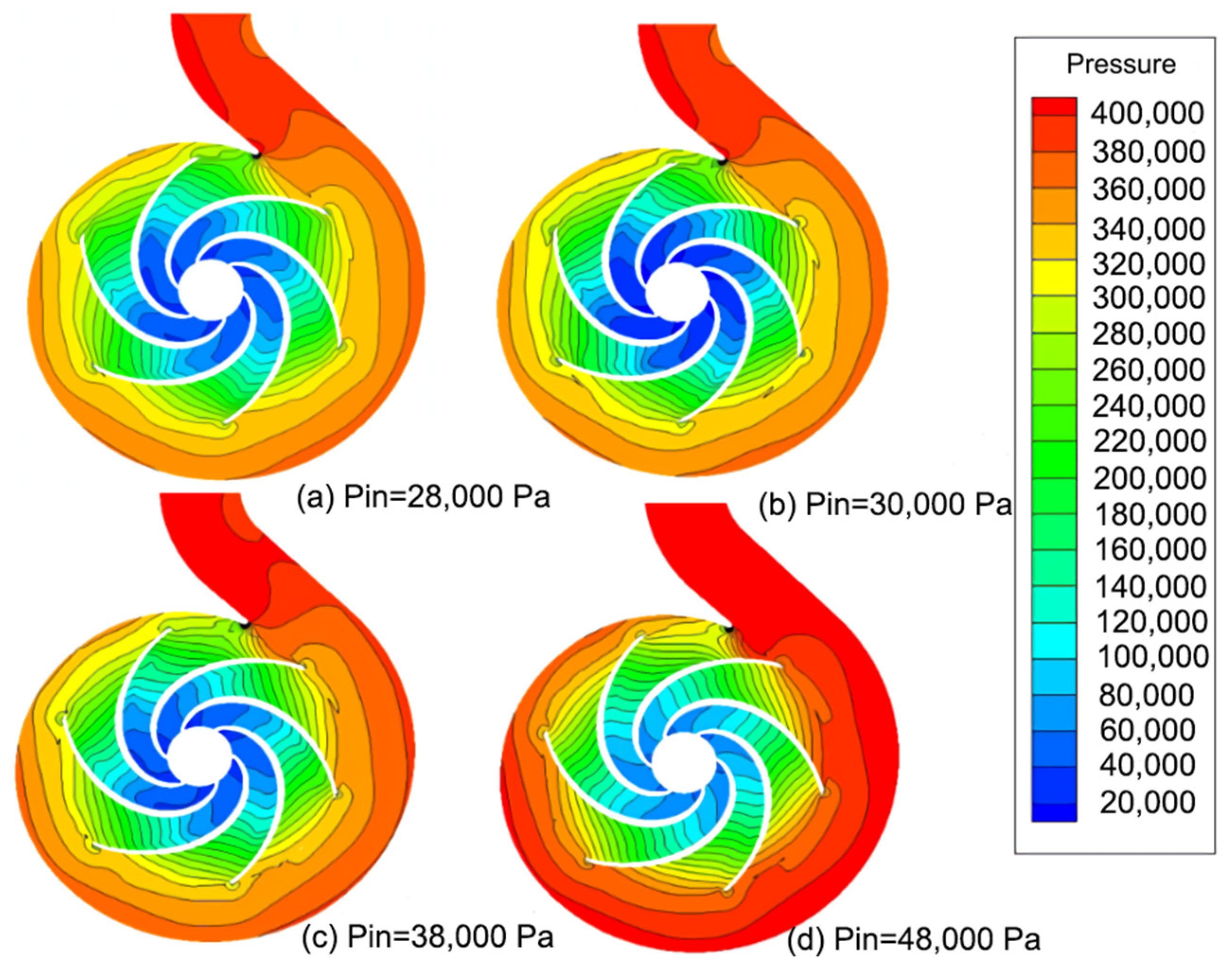

4.3. Impeller Runner Static Pressure Field Analysis

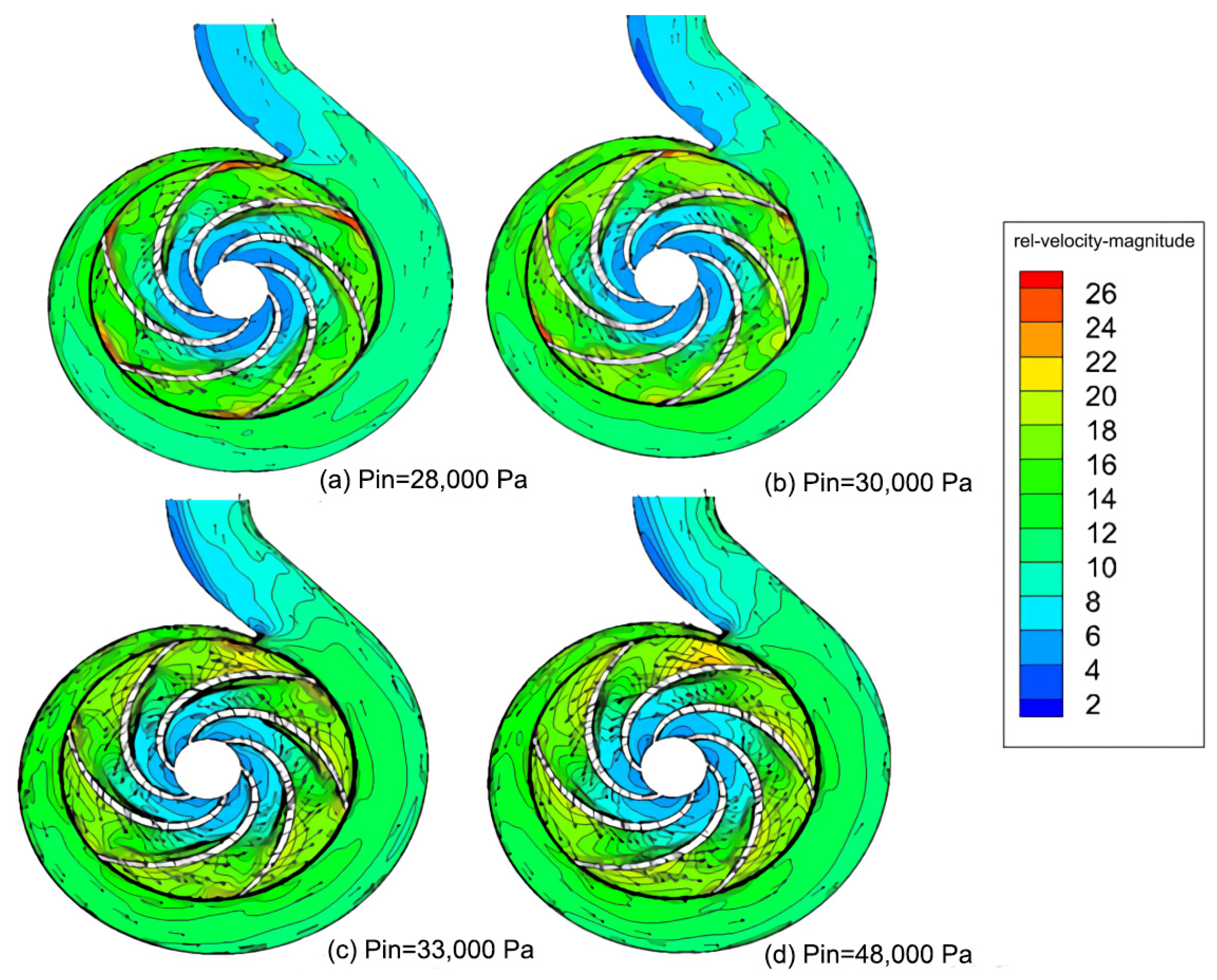

4.4. Analysis of Relative Velocity Distribution of the Impeller Runners

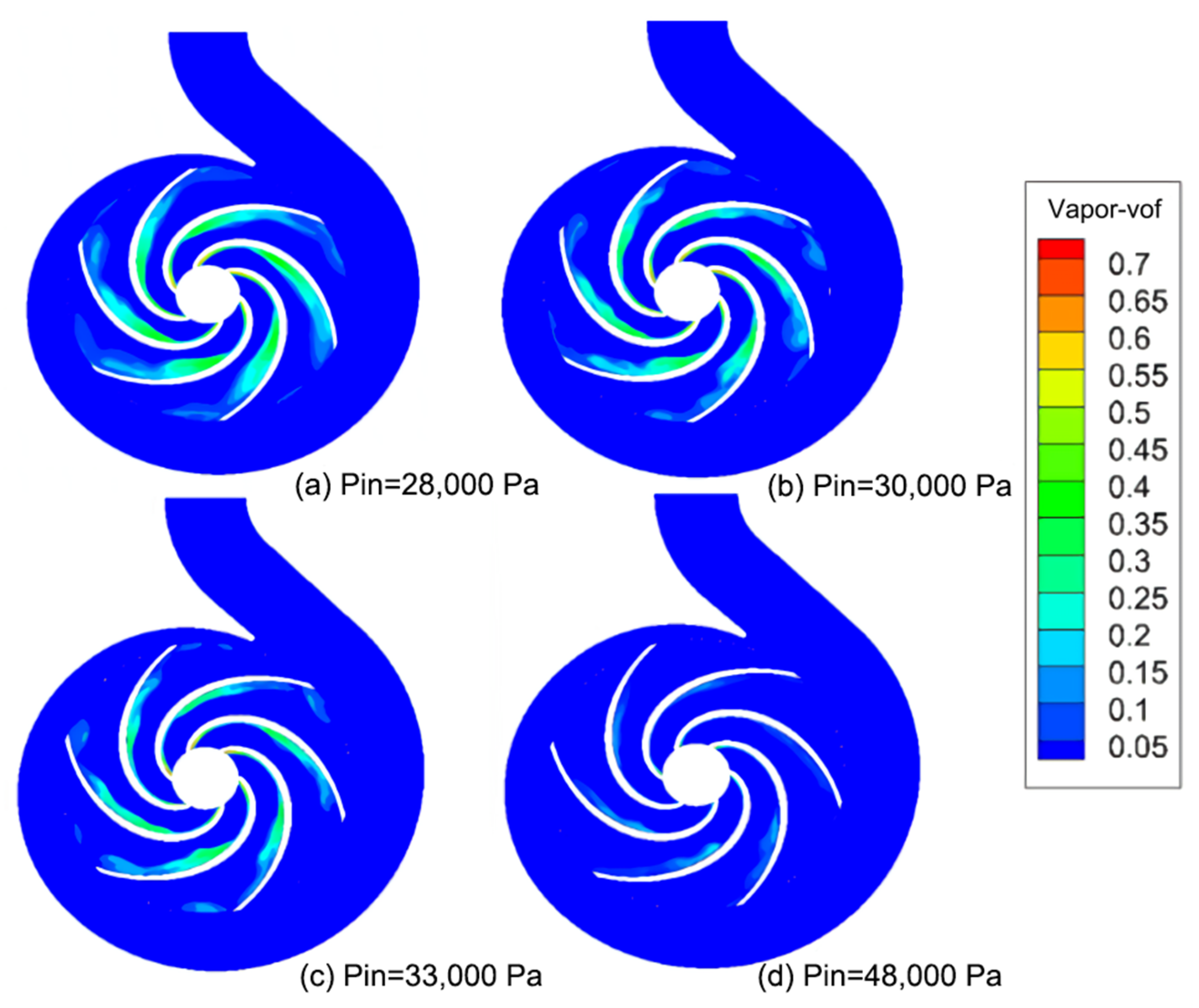

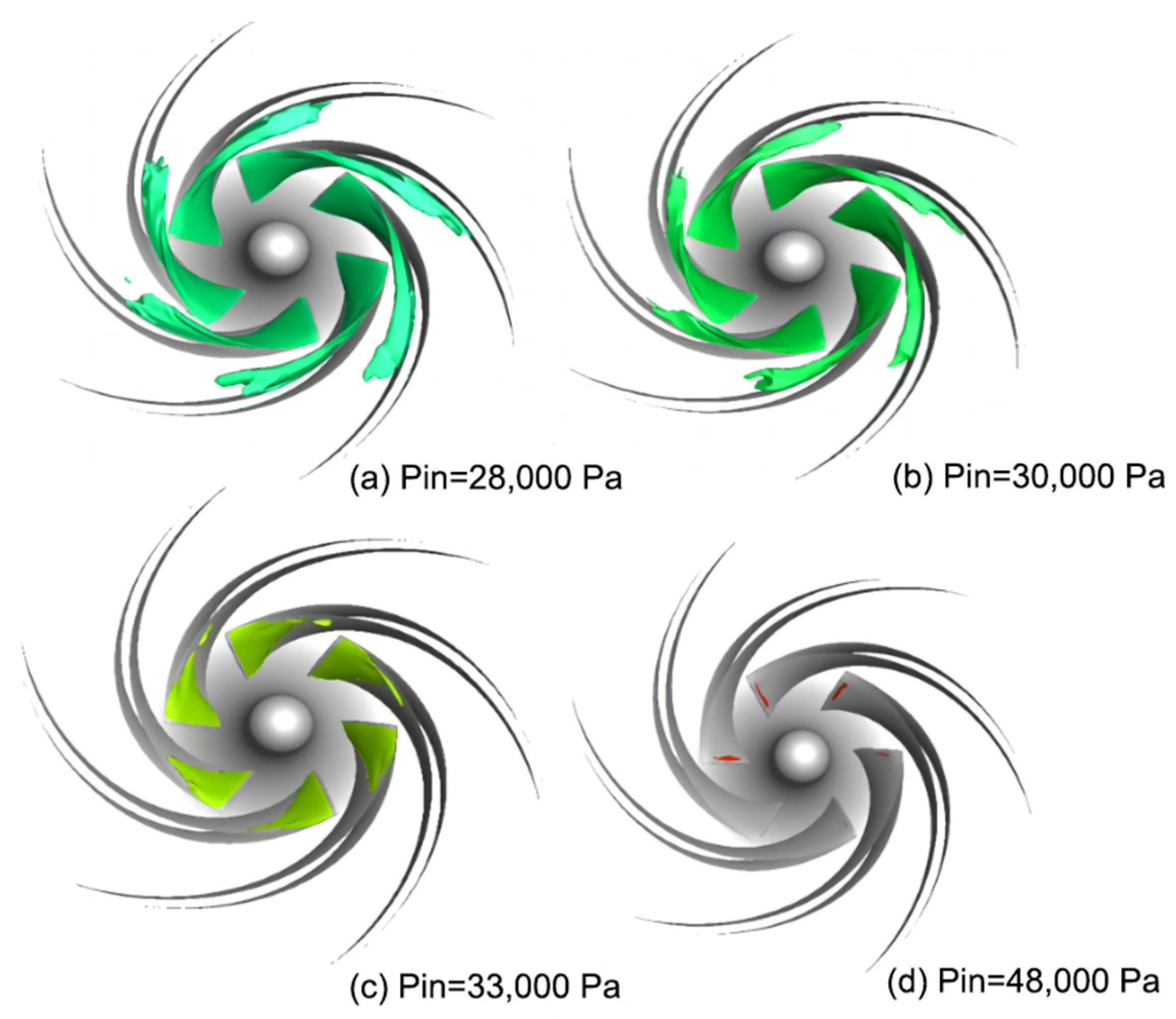

4.5. Volume Fraction Distribution of Vacuoles in the Impeller Runner

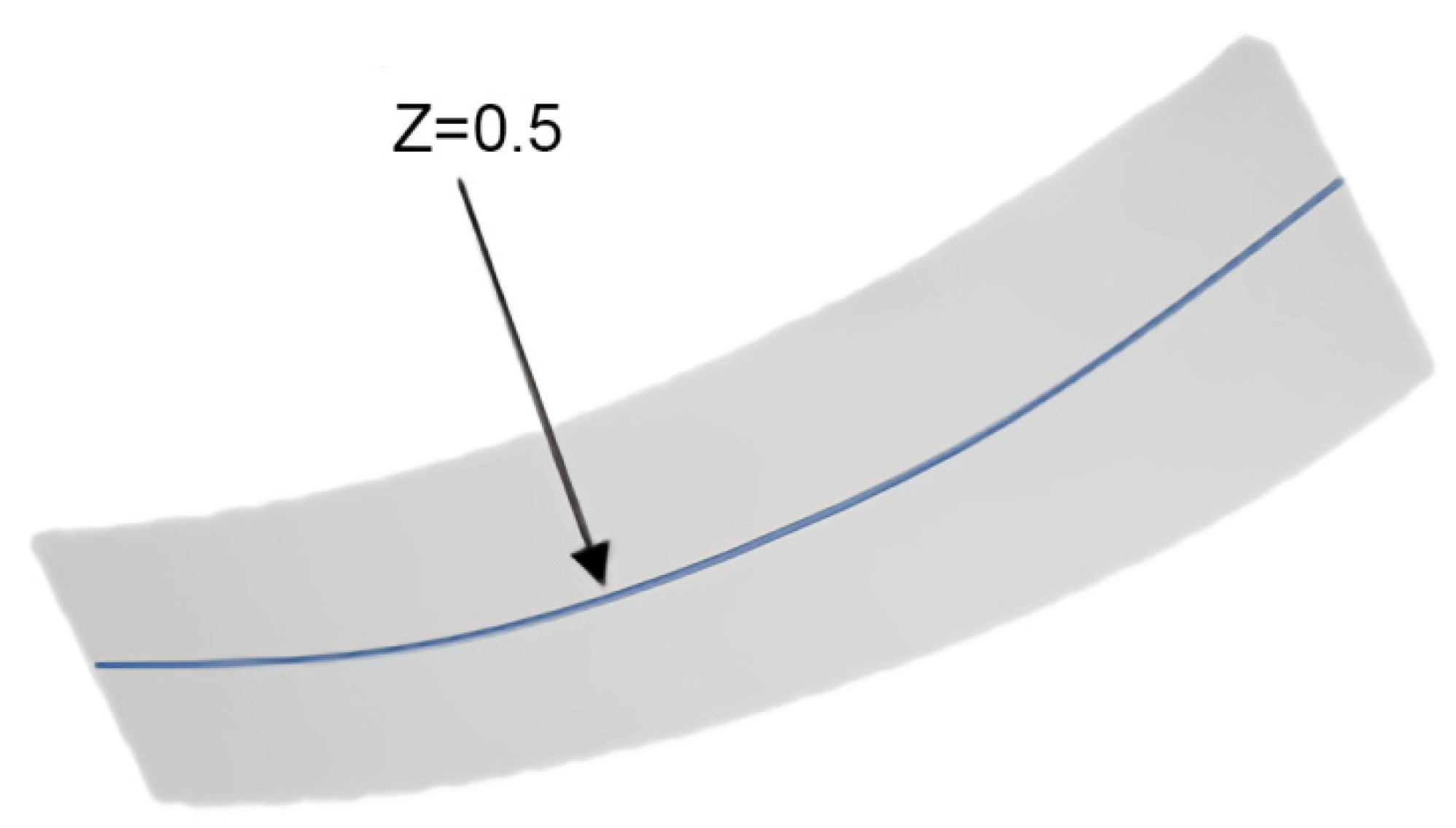

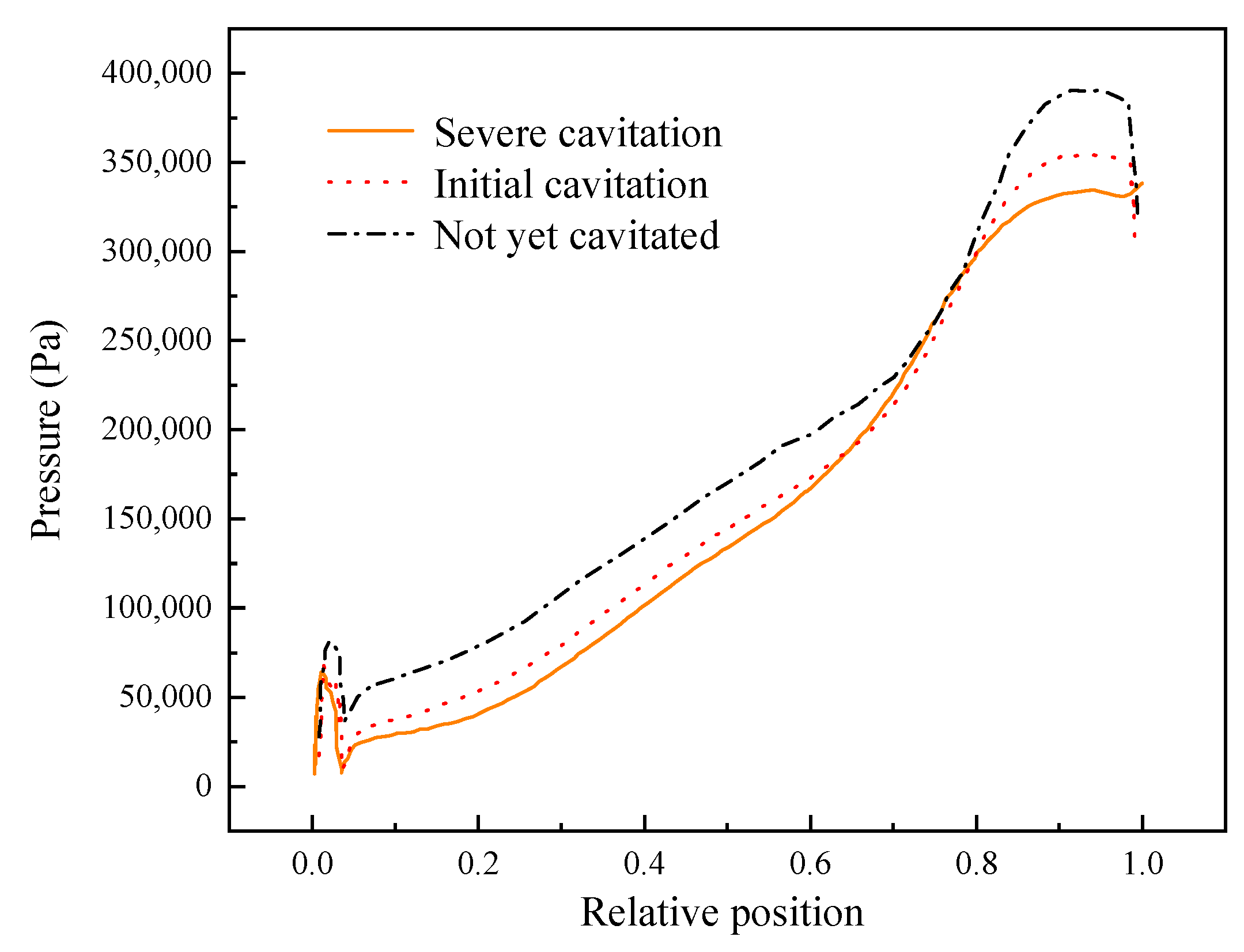

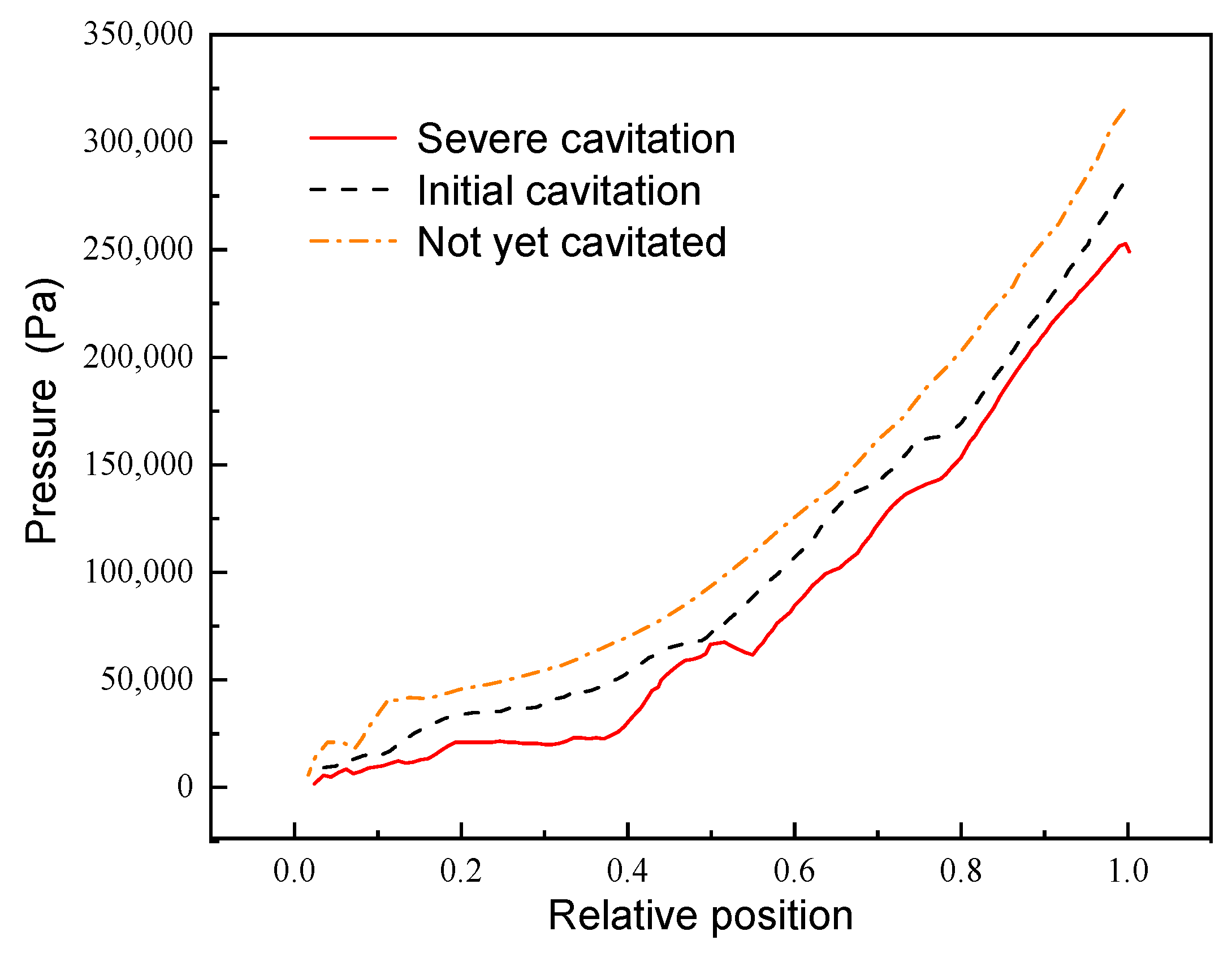

4.6. Blade Surface Load Distribution

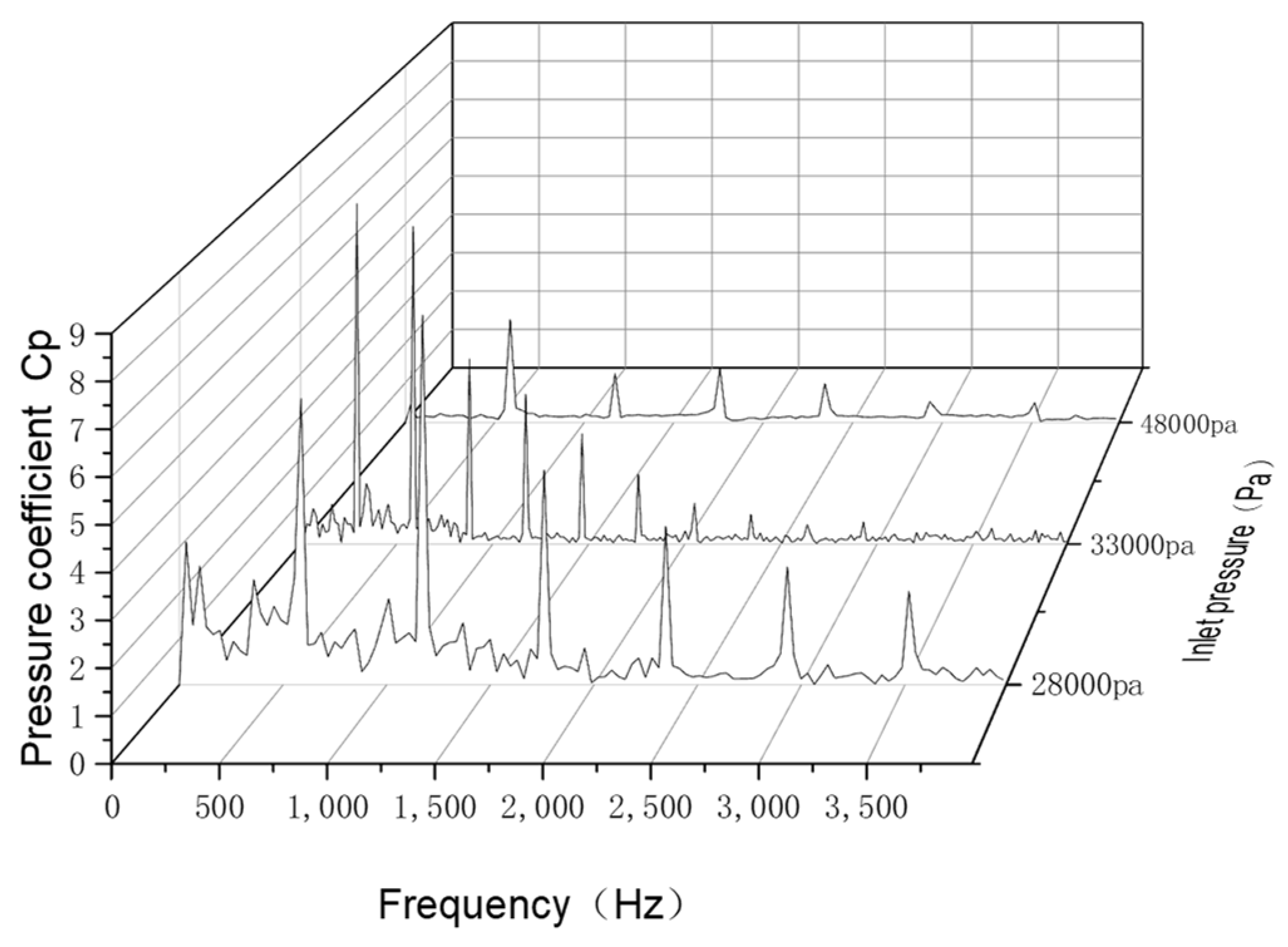

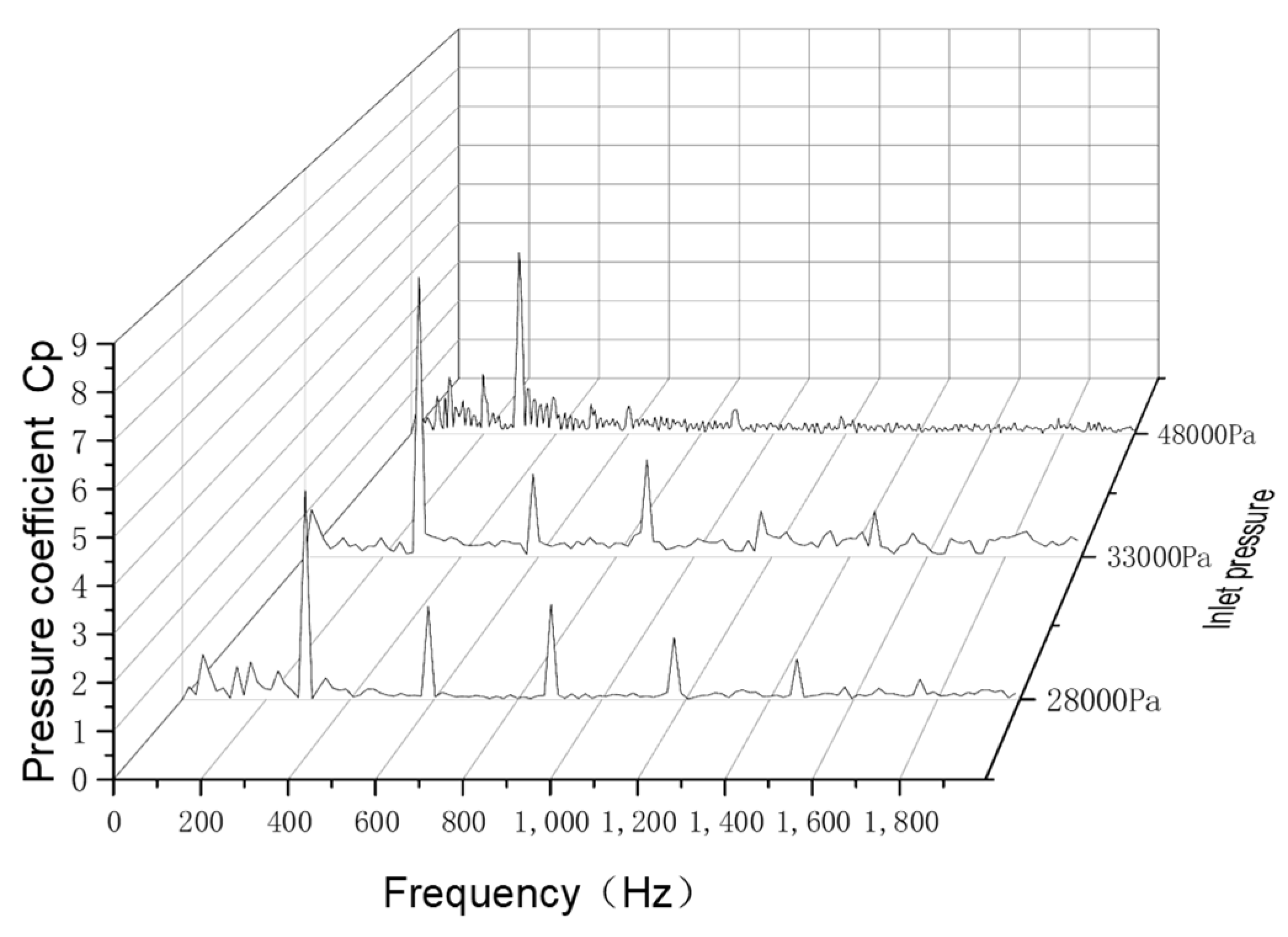

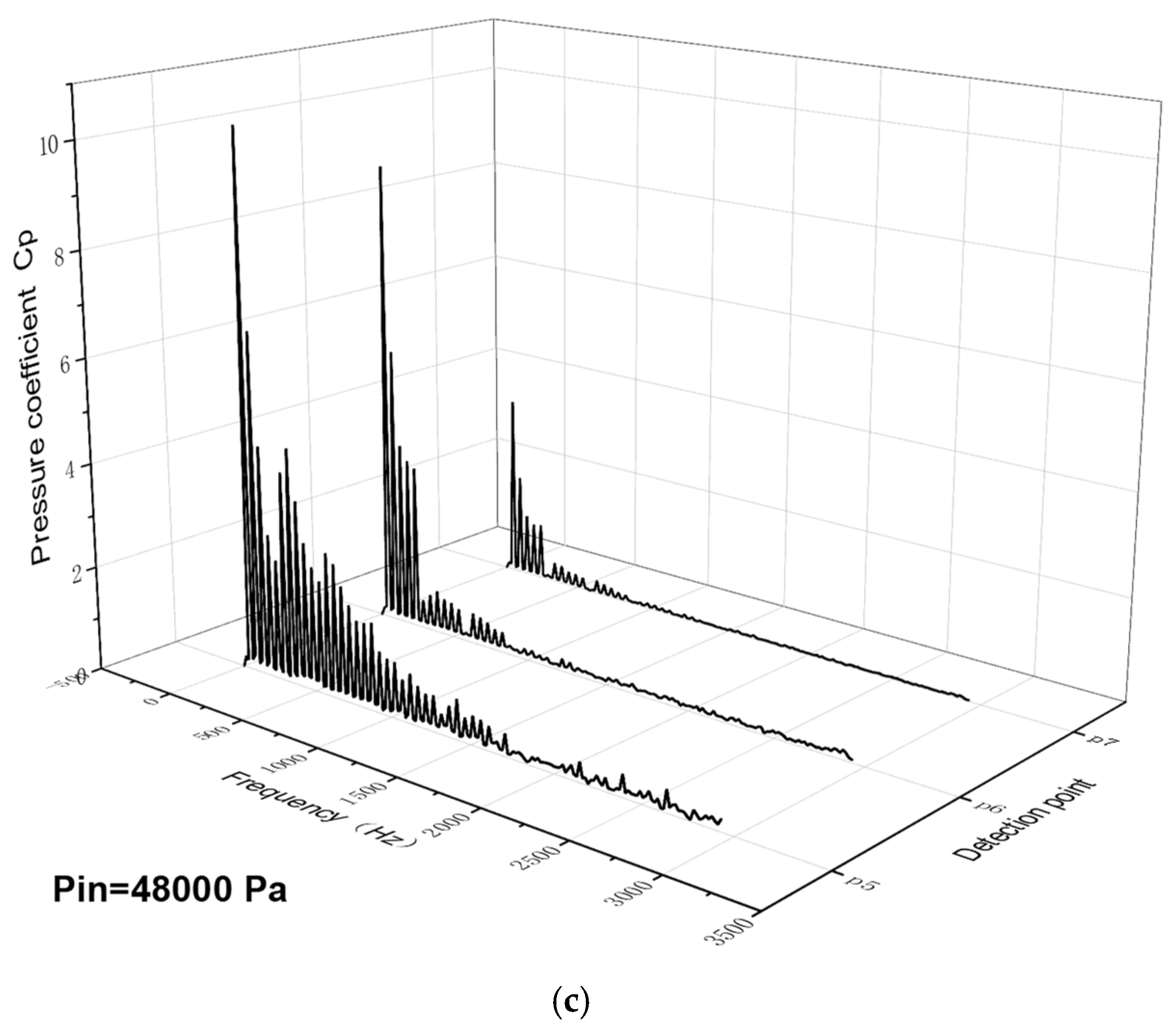

4.7. Impeller Runner Monitoring-Point Pressure-Pulsation Analysis

5. Conclusions

5.1. Innovation Points

5.2. Computer Equipment

5.3. Research Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| ns | Specific speed |

| Q | Flow rate |

| H | Head |

| ne | Rotational speed |

| Z | Number of blades |

| k | Turbulent kinetic energy |

| ε | Turbulent dissipation rate |

| Gk | Turbulent kinetic energy generation term |

| Curvature correction coefficient | |

| ρv | Density of gas phase |

| Density of mixed homogeneous phase | |

| Density of liquid phase | |

| Nucleation volume fraction | |

| Evaporation coefficient | |

| Condensation coefficient | |

| Bubble radius | |

| Maximum vacuole radius | |

| Evaporation coefficient | |

| Ccond | Condensation coefficient |

| Time step | |

| n’ | Rotational speed in the previous time step |

| m | Previous time step’s output hydraulic torque |

| P | Shaft output power |

| Motor’s rotational inertia |

References

- Wang, F. Advances in computational modeling of rotational turbulence in fluid machinery. J. Agric. Mach. 2016, 47, 1–14. [Google Scholar]

- Gu, W.; He, Y.; Hu, T. Noise characteristics and bubble interface transients in axisymmetric body bubble flow. J. Shanghai Jiaotong Univ. 2000, 34, 1026–1030. [Google Scholar]

- Zhao, C.; Wang, C.; Wei, Y.; Zhang, X. Experiments on cavitation flow field and ballistic characteristics of slender body underwater motion. Explos. Impact 2017, 37, 439–446. [Google Scholar]

- Savar, M.; Kozmar, H.; Sutlovic, I. Improving centrifugal pump efficiency by impeller trimming. Desalination 2009, 249, 654–659. [Google Scholar] [CrossRef]

- Zhao, G. Research on Cavitation Flow Instability and Its Control in Centrifugal Pumps; Lanzhou University of Technology: Lanzhou, China, 2018. [Google Scholar]

- Li, Y.; Feng, G.; Li, X.; Si, Q.; Zhu, Z. An experimental study on the cavitation vibration characteristics of a centrifugal pump at normal flow rate. J. Mech. Sci. Technol. 2018, 32, 4711–4720. [Google Scholar] [CrossRef]

- Zhang, D.; Pan, D.; Shi, W.; Zhang, X. Numerical simulation of cavitation flow and its induced pressure pulsation in axial flow pumps. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2014, 42, 34–38. [Google Scholar]

- Tseng, C.C.; Wang, L.J. Investigations of Empirical Coefficients of Cavitation and Turbulence Model Through Steady and Unsteady Turbulent Cavitating Flows. Comput. Fluids 2014, 103, 262–274. [Google Scholar] [CrossRef]

- Morgut, M.; Nobile, E.; Bilus, I. Comparison of Mass Transfer Models for the Numerical Prediction of Sheet Cavitation around a Hydrofoil. Multiph. Flow 2011, 37, 620–626. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Wang, Y.; Zhang, H.; Huang, H. Influence of the Empirical Coefficients of Cavitation Model on Predicting Cavitating Flow in Centrifugal Pump. Nav. Archit. Ocean Eng. 2014, 6, 119–131. [Google Scholar] [CrossRef]

- Stavropoulos-Vasilakis, E.; Kyriazis, N.; Jadidbonab, H.; Koukouvinis, P.; Gavaises, M. Review of Numerical Methodologies for Modeling Cavitation. Cavitation Bubble Dyn. 2021, 1–35. [Google Scholar] [CrossRef]

- Supponen, O.; Farhat, M.; Obreschkow, D. High-speed imaging of high pressures produced by cavitation bubbles. In Proceedings of the International Conference on High-Speed Imaging and Photonics 2018, Enschede, The Netherlands, 8–12 October 2018. [Google Scholar]

- Ghorbani, M.; Alcan, G.; Yilmaz, D.; Unel, M.; Kosar, A. Visualization and image processing of spray structure under the effect of cavitation phenomenon. J. Phys. Conf. 2015, 656, 012115. [Google Scholar] [CrossRef]

- Asuaje, M.; Bakir, F.; Kouidri, S.; Kenyery, F.; Rey, R. Numerical modelization of the flow in centrifugal pump: Volute influence in velocity and pressure fields. Int. J. Rotating Mach. 2005, 3, 244–255. [Google Scholar] [CrossRef]

- Li, X. Study on the Flow Mechanism of Supercavitation around Water Wings; Beijing University of Technology: Beijing, China, 2008. [Google Scholar]

- Yakhot, V.; Orszag, S.A. Renormalization group analysis of turbulence. i. Basic theory. J. Sci. Comput. 1986, 1, 3–51. [Google Scholar] [CrossRef]

- Spalart, P.R.; Shur, M. On the sensitization of turbulence models to rotation and curvature. Aerosp. Sci. Technol. 1997, 1, 297–302. [Google Scholar] [CrossRef]

- Minemura, K.; Murakami, M. A theoretical study on air bubble motion in a centrifugal pump impeller. J. Fluids Eng. 1980, 102, 446–453. [Google Scholar] [CrossRef]

- Murakami, M.; Minemura, K.; Takimoto, M. Effects of entrained air on the performance of centrifugal pumps under cavitating conditions. Trans. Jpn. Soc. Mech. 1980, 23, 1435–1442. [Google Scholar]

- Wang, J.; Wang, Y.; Liu, H. Rotating Corrected-Based Cavitation Model for a Centrifugal Pump. J. Fluids Eng. 2018, 140, 111301. [Google Scholar]

- Sun, H.; Yuan, S.; Luo, Y.; Guo, Y. Analysis of non-constant flow inside a centrifugal pump with the joint action of water and electricity. J. Drain. Irrig. Mach. Eng. 2016, 34, 122–127,150. [Google Scholar]

- Guo, Y. Study on the Non-Constant Characteristics of Centrifugal Pump Torque and Speed; Jiangsu University: Zhenjiang, China, 2017. [Google Scholar]

| Program | Option 1 | Option 2 | Option 3 | Option 4 |

|---|---|---|---|---|

| Number of grids | 1,184,528 | 1,823,592 | 2,913,525 | 3,519,625 |

| Design head/m | 34 | 34 | 34 | 34 |

| Calculated head/m | 38.1 | 36.9 | 36.2 | 36.2 |

| Boundary Type | Boundary Conditions | Computational Domain |

|---|---|---|

| Import | Total pressure inlet | Import section |

| Inlet-section extension wall | Fixed non-slip wall surface | Import section |

| Worm-shell wall surface | Fixed non-slip wall surface | Snail-shell Domain |

| Blade | Rotating non-slip wall surface | Impeller field |

| Impeller front and rear cover plate | Rotating non-slip wall surface | Impeller field |

| Exit-section extension wall | Fixed non-slip wall surface | Export section |

| Export | Mass flow outlet | Export section |

| Working Condition Point | Inlet Pressure/Pa | Effective Cavitation Margin/m | Percentage Drop in Head | Degree of Cavitation |

|---|---|---|---|---|

| Working condition 1 | 48,000 | 4.76 | 0 | No cavitation |

| Working condition 2 | 33,000 | 3.23 | 1% | Cavitation initial inception |

| Working condition 3 | 30,000 | 2.93 | 3% | Critical cavitation |

| Working condition 4 | 28,000 | 2.72 | 5% | Severe cavitation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Sun, L.; Zhou, Y.; Liu, Y.; Zhao, F. Numerical Simulation of Cavitation Characteristics of a Centrifugal Pump Based on an Improved ZGB Model. Processes 2023, 11, 438. https://doi.org/10.3390/pr11020438

Wang J, Sun L, Zhou Y, Liu Y, Zhao F. Numerical Simulation of Cavitation Characteristics of a Centrifugal Pump Based on an Improved ZGB Model. Processes. 2023; 11(2):438. https://doi.org/10.3390/pr11020438

Chicago/Turabian StyleWang, Jun, Lun Sun, Yilong Zhou, Yaohui Liu, and Fujian Zhao. 2023. "Numerical Simulation of Cavitation Characteristics of a Centrifugal Pump Based on an Improved ZGB Model" Processes 11, no. 2: 438. https://doi.org/10.3390/pr11020438

APA StyleWang, J., Sun, L., Zhou, Y., Liu, Y., & Zhao, F. (2023). Numerical Simulation of Cavitation Characteristics of a Centrifugal Pump Based on an Improved ZGB Model. Processes, 11(2), 438. https://doi.org/10.3390/pr11020438