Assessment of Energy-Efficient Spouted Bed Aerobic Composting Performance for Municipal Solid Waste: Experimental Study

Abstract

:1. Introduction

2. Materials and Methods

- Acting as the inoculant by retaining the microorganisms, enabling a continuous composting process;

- Enabling suitable bed density to maintain a stable spout as well as a carrier for the waste.

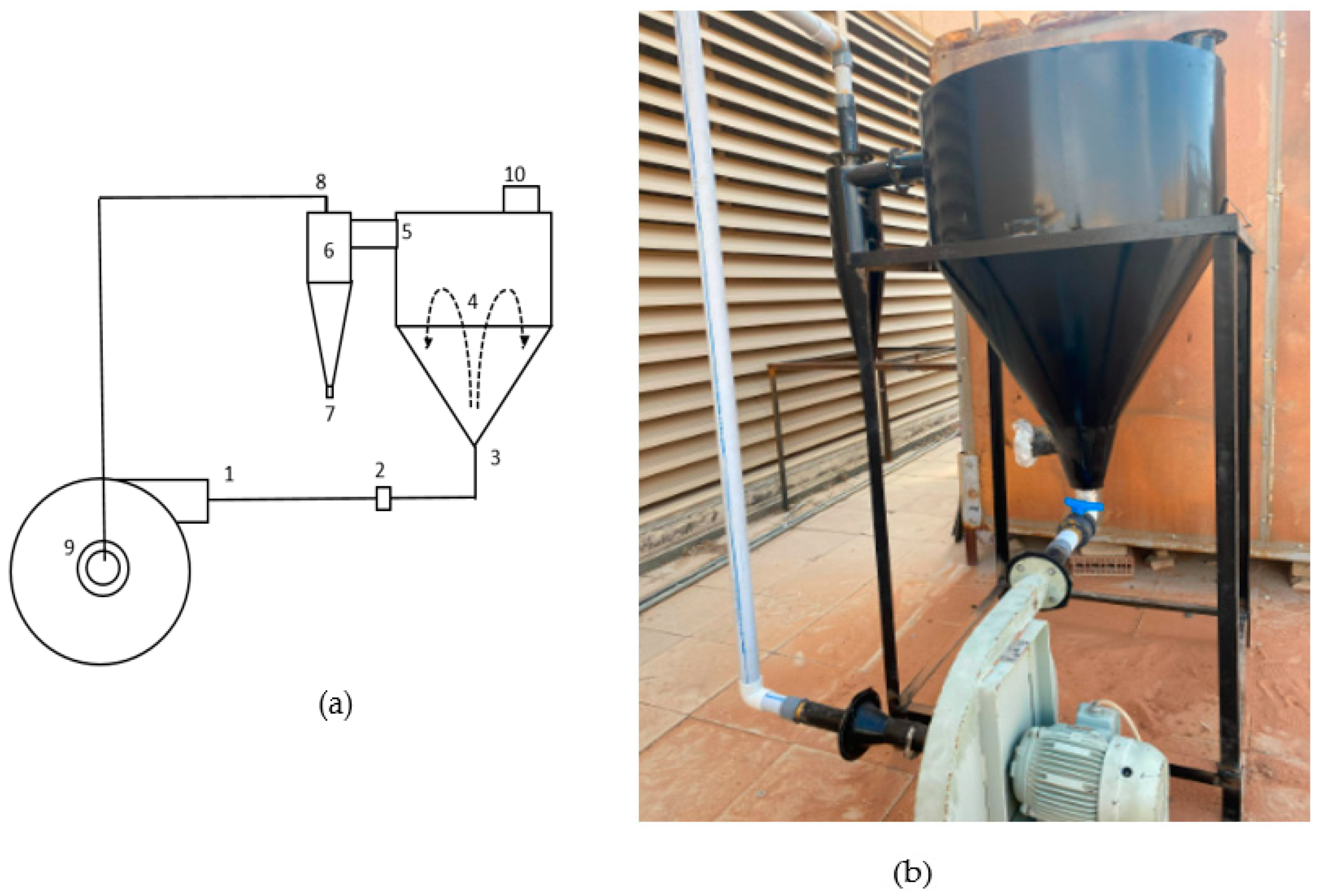

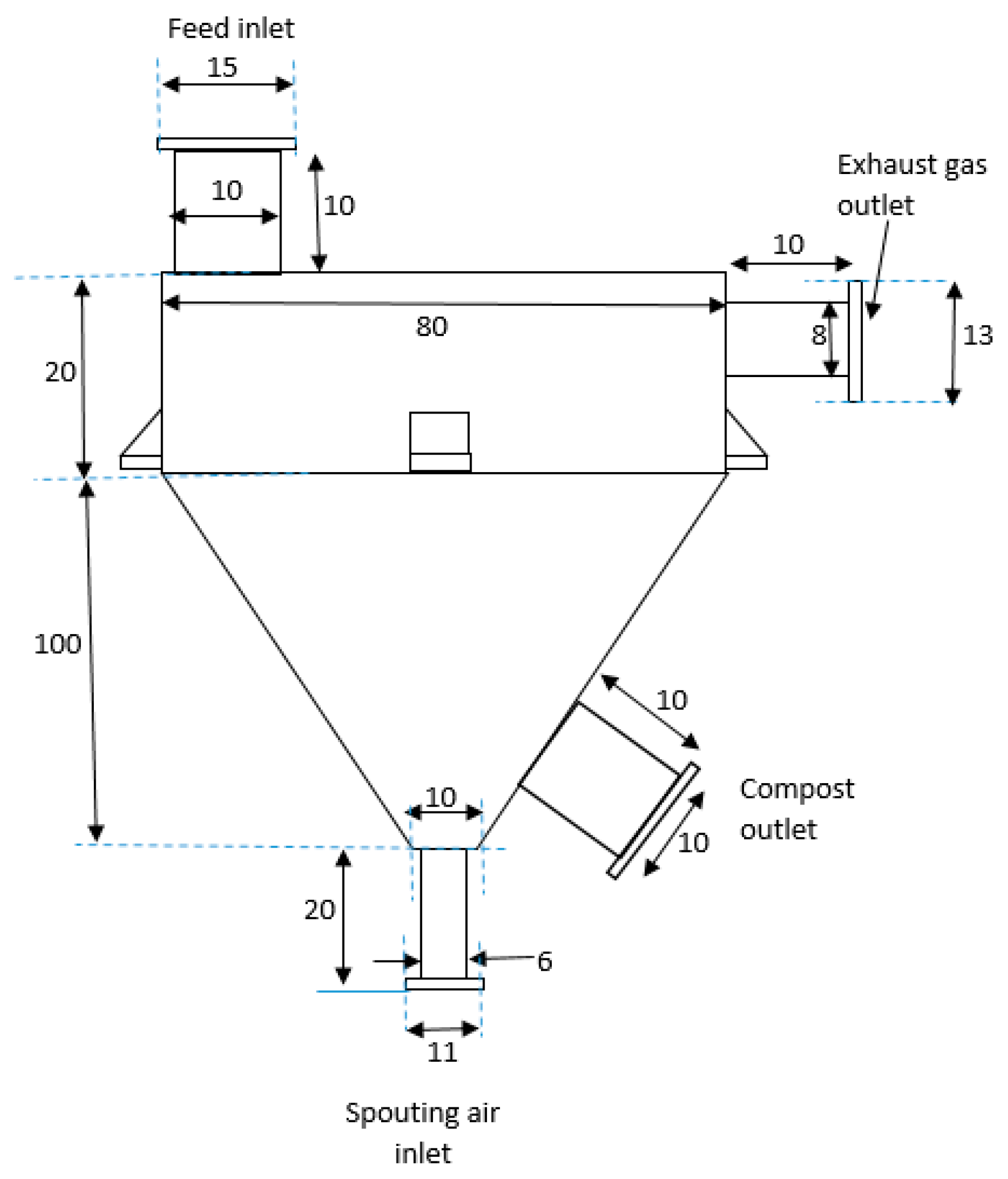

2.1. Design of Spouted Bed Composting Machine

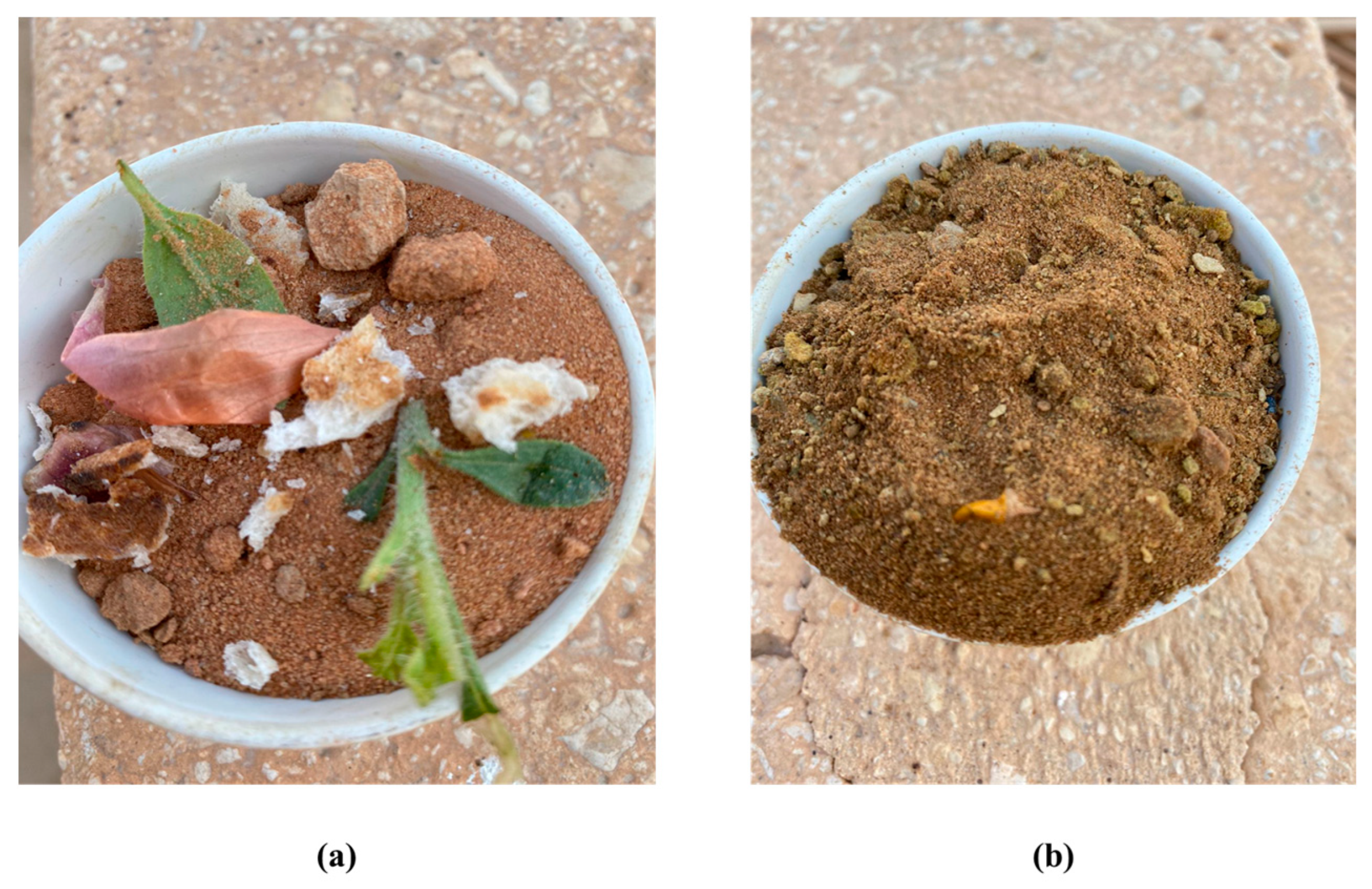

2.2. Substrate

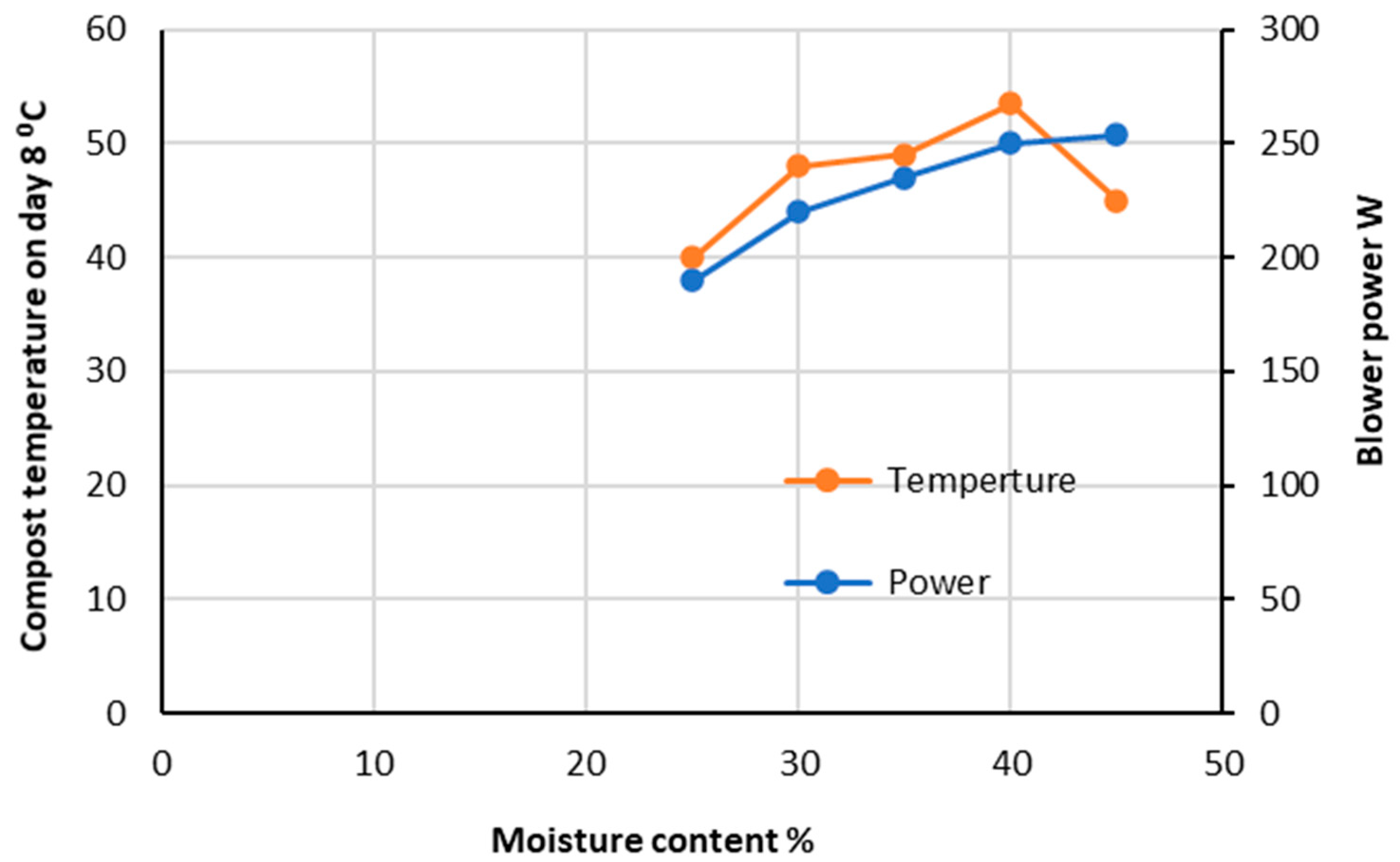

2.3. Optimum Moisture Content Required

3. Results and Discussion

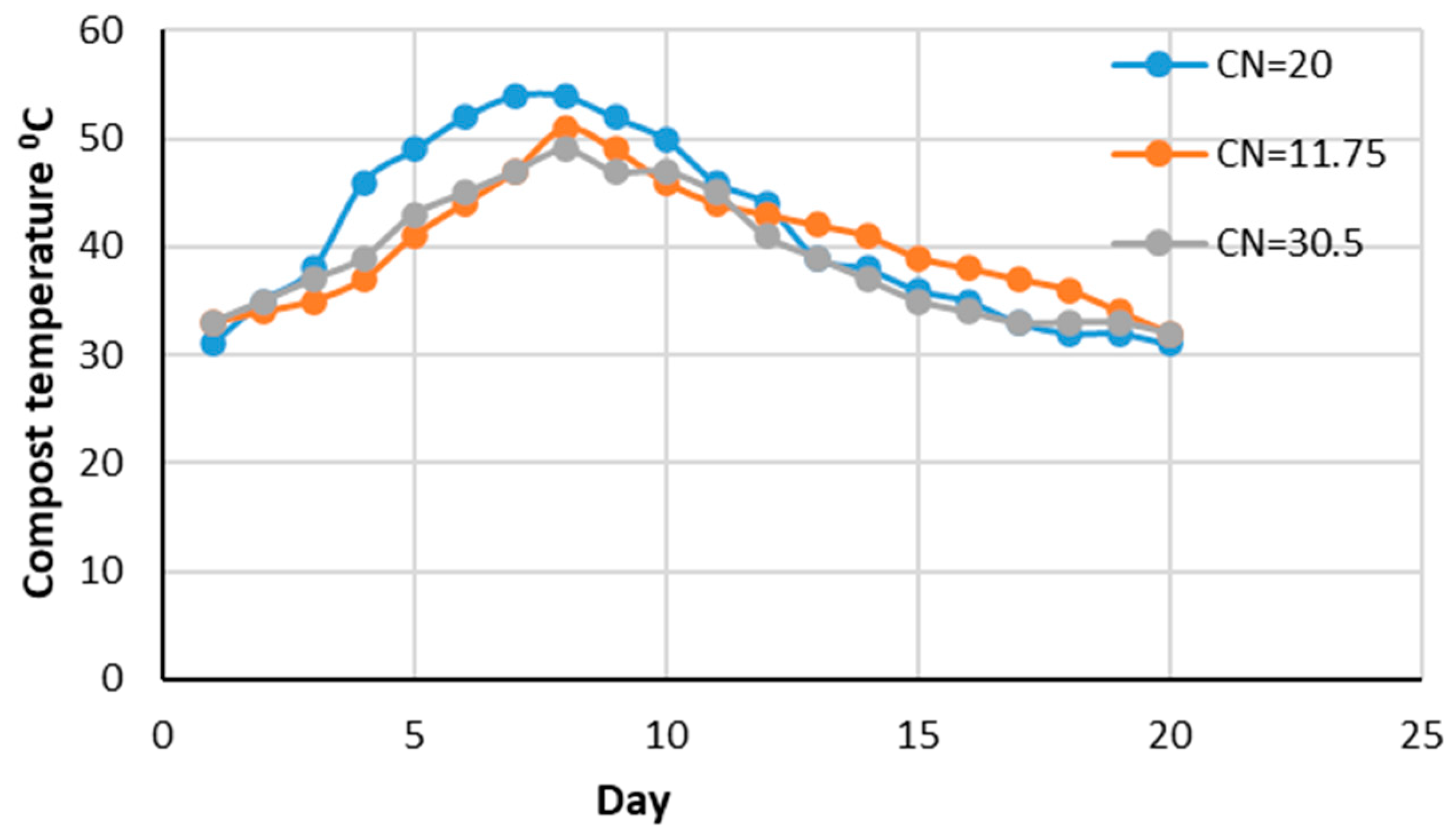

3.1. Effect of C/N Ratio on Composting Performance

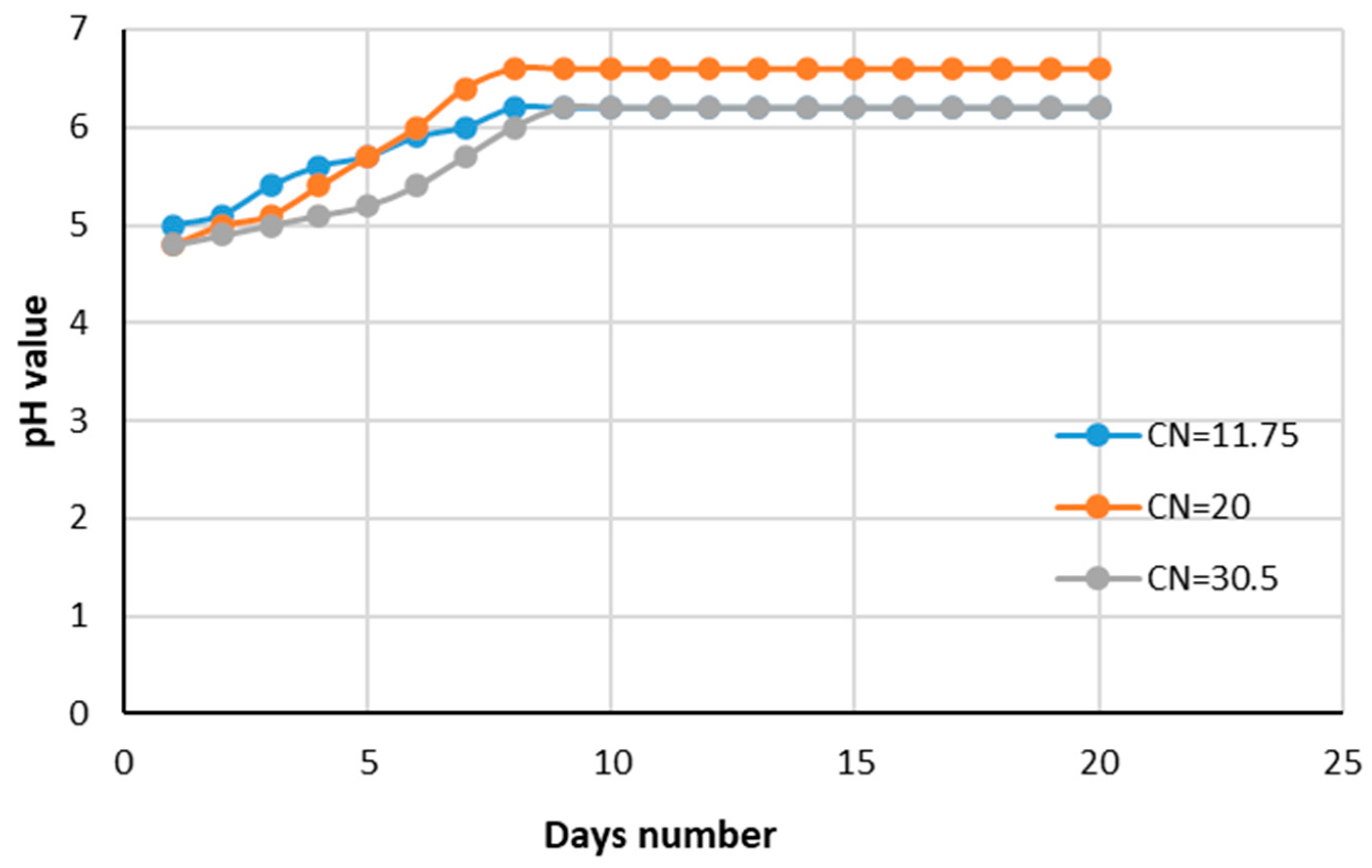

3.2. Effect of pH on Composting Performance

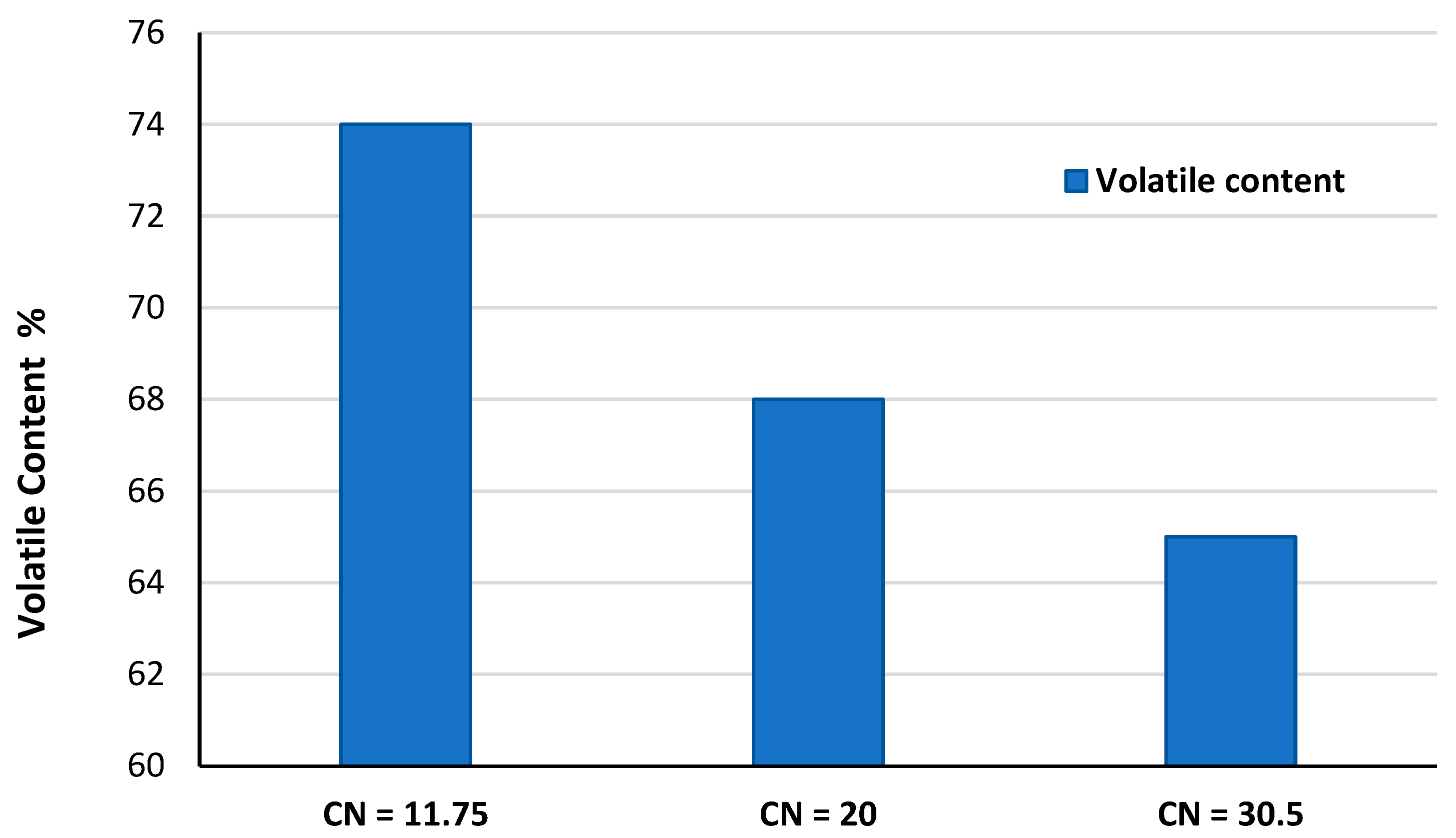

3.3. Volatile Content Variation during the Composting Process

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, A.H.; López-Maldonado, E.A.; Alam, S.S.; Khan, N.A.; López, J.R.L.; Herrera, P.F.M.; Abutaleb, A.; Ahmed, S.; Singh, L. Municipal solid waste generation and the current state of waste-to-energy potential: State of art review. Energy Convers. Manag. 2022, 267, 115905. [Google Scholar] [CrossRef]

- Iyamu, H.; Anda, M.; Ho, G. A review of municipal solid waste management in the BRIC and high-income countries: A thematic framework for low-income countries. Habitat Int. 2019, 95, 102097. [Google Scholar] [CrossRef]

- Dalmo, F.C.; Simão, N.M.; de Lima, H.Q.; Jimenez AC, M.; Nebra, S.; Martins, G.; Palacios-Bereche, R.; de Mello Sant’Ana, P.H. Energy recovery overview of municipal solid waste in São Paulo State, Brazil. J. Clean. Prod. 2019, 212, 461–474. [Google Scholar] [CrossRef]

- Goswami, S. Propensity for Segregation of Household Municipal Solid Waste: An Empirical Study. In North-East Research Conclave; Springer Nature: Singapore, 2022; pp. 271–288. [Google Scholar]

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Ding, Y.; Zhao, J.; Liu, J.-W.; Zhou, J.; Cheng, L.; Zhao, J.; Shao, Z.; Iris, Ç.; Pan, B.; Li, X.; et al. A review of China’s municipal solid waste (MSW) and comparison with international regions: Management and technologies in treatment and resource utilization. J. Clean. Prod. 2021, 293, 126144. [Google Scholar] [CrossRef]

- Kiyasudeen, S.K.; Ibrahim, M.H.; Quaik, S.; Ahmed Ismail, S.; Ibrahim, M.H.; Quaik, S.; Ismail, S.A. Introduction to Organic Wastes and Its Management. In Prospects of Organic Waste Management and the Significance of Earthworms; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1–21. [Google Scholar]

- Peng, X.; Jiang, Y.; Chen, Z.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.-S. Recycling municipal, agricultural and industrial waste into energy, fertilizers, food and construction materials, and economic feasibility: A review. Environ. Chem. Lett. 2023, 21, 765–801. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Panja, A.; Kumar, R.; Ram, H.; Meena, R.K.; Basak, N. Municipal solid waste compost: A comprehensive bibliometric data-driven review of 50 years of research and identification of future research themes. Environ. Sci. Pollut. Res. 2023, 30, 86741–86761. [Google Scholar] [CrossRef]

- Wang, C.; Xu, J.; Yang, Z.; Zhang, Z.; Cai, Z. A field study of polychlorinated dibenzo-p-dioxins and dibenzofurans formation mechanism in a hazardous waste incinerator: Emission reduction strategies. J. Clean. Prod. 2019, 232, 1018–1027. [Google Scholar] [CrossRef]

- Khan, S.; Anjum, R.; Raza, S.T.; Bazai, N.A.; Ihtisham, M. Technologies for Municipal Solid Waste Management: Current Status, Challenges, and Future Perspectives. Chemosphere 2022, 288, 132403. [Google Scholar] [CrossRef]

- Gautam, M.; Agrawal, M. Greenhouse Gas Emissions from Municipal Solid Waste Management: A Review of the Global Scenario. In Carbon Footprint Case Studies: Municipal Solid Waste Management, Sustainable Road Transport, and Carbon Sequestration; Springer: Berlin/Heidelberg, Germany, 2021; pp. 123–160. [Google Scholar]

- Kaneesamkandi, Z.; Sayeed, A. Evaluation of Multi-Utility Models with Municipal Solid Waste Combustion as the Primary Source under Specific Geographical and Operating Conditions. Energies 2023, 16, 5696. [Google Scholar] [CrossRef]

- Ayilara, M.S.; Olanrewaju, O.S.; Babalola, O.O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Eden, M.; Gerke, H.H.; Houot, S. Organic waste recycling in agriculture and related effects on soil water retention and plant available water: A review. Agron. Sustain. Dev. 2017, 37, 1–21. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S. Solid waste issue: Sources, composition, disposal, recycling, and valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar] [CrossRef]

- Keener, H.M.; Dick, W.A.; Hoitink, H.A. Composting and beneficial utilization of composted by-product materials. Land Appl. Agric. Ind. Munic. By-Prod. 2000, 6, 315–341. [Google Scholar]

- Choudhary, V.; Machavaram, R. A Comprehensive Review of Sustainable Soil Organic Growing Media for Mat-Type Paddy Seedling Nurseries Under Indian Agronomical Condition. J. Soil Sci. Plant Nutr. 2023, 23, 1515–1534. [Google Scholar] [CrossRef]

- Schulz, H.; Dunst, G.; Glaser, B. Positive effects of composted biochar on plant growth and soil fertility. Agron. Sustain. Dev. 2013, 33, 817–827. [Google Scholar] [CrossRef]

- Mengistu, T.; Gebrekidan, H.; Kibret, K.; Woldetsadik, K.; Shimelis, B.; Yadav, H. Comparative effectiveness of different composting methods on the stabilization, maturation and sanitization of municipal organic solid wastes and dried faecal sludge mixtures. Environ. Syst. Res. 2017, 6, 1–16. [Google Scholar] [CrossRef]

- Azis, F.A.; Rijal, M.; Suhaimi, H.; Abas, P.E. Patent Landscape of Composting Technology: A Review. Inventions 2022, 7, 38. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V. Pretreatment methods to improve anaerobic biodegradability of organic municipal solid waste fractions. Chem. Eng. J. 2014, 240, 24–37. [Google Scholar] [CrossRef]

- Wichuk, K.M.; Tewari, J.P.; McCartney, D. Plant Pathogen Eradication During Composting: A Literature Review. Compos. Sci. Util. 2011, 19, 244–266. [Google Scholar] [CrossRef]

- Sarkar, S.; Pal, S.; Chanda, S. Optimization of a Vegetable Waste Composting Process with a Significant Thermophilic Phase. Procedia Environ. Sci. 2016, 35, 435–440. [Google Scholar] [CrossRef]

- Pergola, M.; Persiani, A.; Pastore, V.; Palese, A.M.; D’adamo, C.; De Falco, E.; Celano, G. Sustainability Assessment of the Green Compost Production Chain from Agricultural Waste: A Case Study in Southern Italy. Agronomy 2020, 10, 230. [Google Scholar] [CrossRef]

- Sobel, R. Microencapsulation in the Food Industry: A Practical Implementation Guide; Academic Press: Cambridge, MA, USA, 2022. [Google Scholar]

- Moliner, C.; Marchelli, F.; Bosio, B.; Arato, E. Modelling of Spouted and Spout-Fluid Beds: Key for Their Successful Scale Up. Energies 2017, 10, 1729. [Google Scholar] [CrossRef]

- Billings, J.S. The Principles of Ventilation and Heating: And Their Practical Application; Engineering & Building Record: New York, NY, USA, 1889. [Google Scholar]

- Barrozo, M.A.; Borel, L.D.; Lira, T.S.; Ataíde, C.H. Fluid dynamics analysis and pyrolysis of brewer’s spent grain in a spouted bed reactor. Particuology 2018, 42, 199–207. [Google Scholar] [CrossRef]

- Richard, T.L.; Hamelers, H.; Veeken, A.; Silva, T. Moisture Relationships in Composting Processes. Compos. Sci. Util. 2002, 10, 286–302. [Google Scholar] [CrossRef]

- Clark, G. Technologies for compost production from plant byproducts. In Byproducts from Agriculture and Fisheries: Adding Value for Food, Feed, Pharma, and Fuels; Wiley: Hoboken, NJ, USA, 2019; pp. 545–562. [Google Scholar]

- Sayara, T.; Basheer-Salimia, R.; Hawamde, F.; Sánchez, A. Recycling of Organic Wastes through Composting: Process Performance and Compost Application in Agriculture. Agronomy 2020, 10, 1838. [Google Scholar] [CrossRef]

- Liew, C.S.; Yunus, N.M.; Chidi, B.S.; Lam, M.K.; Goh, P.S.; Mohamad, M.; Sin, J.C.; Lam, S.M.; Lim, J.W.; Lam, S.S. A review on recent disposal of hazardous sewage sludge via anaerobic digestion and novel composting. J. Hazard. Mater. 2021, 423, 126995. [Google Scholar] [CrossRef] [PubMed]

- Pallai, E.; Szentmarjay, T.; Mujumdar, A.S. Spouted Bed Drying, in Handbook of Industrial Drying; CRC Press: Boca Raton, FL, USA, 2020; pp. 453–488. [Google Scholar]

- Lasaridi, K.; Protopapa, I.; Kotsou, M.; Pilidis, G.; Manios, T.; Kyriacou, A. Quality assessment of composts in the Greek market: The need for standards and quality assurance. J. Environ. Manag. 2006, 80, 58–65. [Google Scholar] [CrossRef]

- Mishra, S.K.; Yadav, K.D. Assessment of the effect of particle size and selected physico-chemical and biological parameters on the efficiency and quality of composting of garden waste. J. Environ. Chem. Eng. 2022, 10, 107925. [Google Scholar] [CrossRef]

- Margaritis, M.; Dimos, V.; Malamis, D.; Loizidou, M. An experimental investigation of the composting process in an innovative home composting System: The influence of additives. Clean. Mater. 2023, 8, 100185. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Oviedo-Ocaña, E.R.; Manyoma, P.C.; Marmolejo-Rebellón, L.F.; Torres-Lozada, P.; Barrena, R.; Sánchez, A.; Komilis, D. Influence of mixing ratio and turning frequency on the co-composting of biowaste with sugarcane filter cake: A mixture experimental design. Waste Biomass-Valorization 2019, 11, 2475–2489. [Google Scholar] [CrossRef]

- Azim, K.; Soudi, B.; Boukhari, S.; Perissol, C.; Roussos, S.; Alami, I.T. Composting parameters and compost quality: A literature review. Org. Agric. 2017, 8, 141–158. [Google Scholar] [CrossRef]

- Available online: https://www.astm.org/mnl44-3rd-eb.html (accessed on 13 October 2023).

| Food Content | C/N | |||

|---|---|---|---|---|

| Spinach | 88.43 | 34.70 | 4.16 | 8.34 |

| Orange | 75.89 | 45.78 | 3.27 | 14 |

| Banana | 90.58 | 46.26 | 1.66 | 27.86 |

| Bread | 22.29 | 46.40 | 5.34 | 8.68 |

| Corn husk | 7.81 | 79.11 | 1.54 | 51.37 |

| Corn | 25 | 43 | 0.7 | 61.42 |

| Rice | 61.35 | 44.12 | 4.55 | 9.69 |

| Onion peel | 8.02 | 35.8 | 1.83 | 19.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaneesamkandi, Z.; Sayeed, A. Assessment of Energy-Efficient Spouted Bed Aerobic Composting Performance for Municipal Solid Waste: Experimental Study. Processes 2023, 11, 3427. https://doi.org/10.3390/pr11123427

Kaneesamkandi Z, Sayeed A. Assessment of Energy-Efficient Spouted Bed Aerobic Composting Performance for Municipal Solid Waste: Experimental Study. Processes. 2023; 11(12):3427. https://doi.org/10.3390/pr11123427

Chicago/Turabian StyleKaneesamkandi, Zakariya, and Abdul Sayeed. 2023. "Assessment of Energy-Efficient Spouted Bed Aerobic Composting Performance for Municipal Solid Waste: Experimental Study" Processes 11, no. 12: 3427. https://doi.org/10.3390/pr11123427

APA StyleKaneesamkandi, Z., & Sayeed, A. (2023). Assessment of Energy-Efficient Spouted Bed Aerobic Composting Performance for Municipal Solid Waste: Experimental Study. Processes, 11(12), 3427. https://doi.org/10.3390/pr11123427