1. Introduction

With the deepening of the exploration and development of oil and gas fields, the dynamic monitoring technology of oil and gas reservoirs comes into being. Through dynamic monitoring technology, workers can effectively grasp the dynamic changes of oil and gas formations, which can help workers to do more research on the dynamic adjustment of oil and gas wells. At the same time, it can provide a perfect scientific basis for the relevant problems of oil and gas field exploitation, so as to effectively ensure the orderly development of oil and gas well exploitation.

Gas–liquid two-phase flow widely exists in petrochemical, energy power, nuclear reactor, aerospace, and other industrial fields; the study of gas–liquid two-phase flow is of great significance to the safe production in such related fields [

1,

2,

3,

4]. Production profile logging is an important monitoring technology in the development of oil and gas reservoirs; using the data can obtain the properties and production of the fluid produced by each reservoir [

5]. With the continuous development of gas reservoirs, the gas production is gradually weakened, accompanied by the production of formation water. At this time, the low-velocity gas–liquid two-phase flow will occur in the well, and a large amount of liquid will appear at the bottom of the well, which seriously affects the normal production of gas wells. Due to the complex relative motion and interaction of the phase interface in the gas–liquid two-phase flow in the wellbore, it is extremely difficult to measure the split-phase flow rate and gas holdup, and the conventional gas–liquid two-phase production profile logging methods and interpretation models are not applicable. It is urgent to establish a new low-velocity gas–liquid two-phase flow production profile logging interpretation model.

In the gas–liquid two-phase flow, the interface of the gas–liquid two-phase structure is complex and changeable. To describe the change law of gas–liquid two-phase flow in more detail, scholars define the distribution state of fluid in the pipeline as the flow pattern. The formation of the flow pattern depends on the fluid density, viscosity, pipe diameter, and the flow rate of each phase, among which the flow rate of each phase plays the most important role. After numerous physical experiments, our predecessors divided the gas–liquid two-phase flow pattern of the vertical rising pipeline into bubbly flow, slug flow, churn flow, and annular flow [

6,

7,

8].

The development of computational fluid dynamics has greatly promoted the research of the flow characteristics of gas–liquid two-phase flow in pipes. The VOF model has been widely used to solve multiphase flow problems since its development [

9]. In 2008, Schepper et al. established a 3D horizontal pipeline model and used the VOF model and PLIC method to calculate the flow condition of the air and water in the horizontal pipeline, and the calculation results could be reproduced in Baker’s horizontal well flow pattern distribution map [

10]. In 2016, Lopez et al. carried out physical experiments and CFD calculations on the gas–liquid two-phase flow in horizontal tubes. By comparing the experimental and numerical simulation results, the results show that the VOF multiphase flow model and SST k-ω can determine the gas–liquid two-phase flow pattern [

11]. In 2020, Garcia et al. discussed the application of the VOF model in ANSYS-Fluent software (ANSYS FLUENT Release 15.0) to slug flow in two-dimensional horizontal pipelines, and proposed a reduced-order model for predicting the nonlinear flow dynamics of laminar liquid–liquid flow [

12]. In the same year, to deepen the understanding of the transient characteristics of gas–liquid two-phase slug flow in horizontal pipelines, Deendarlianto et al. conducted CFD numerical simulation and experimental research on relevant phenomena [

13]. In 2023, Zhao et al. simulated the gas–liquid two-phase flow pattern of horizontal and near-horizontal wells by using the VOF model, which was consistent with the experimental observation [

14].

The most commonly used instruments for production profile logging in gas fields are spinner flowmeters (including collectors flow and arrays) and optical fiber gas holdup meters. However, the nonlinear response and low resolution of the instruments make the measurement accuracy not ideal under low flow rates. With the development of science and technology, more and more technologies are being used to measure gas–liquid two-phase flow parameters, including the capacitive method or conductometric method [

15], optical fiber method [

16], microwave method [

17], gamma ray attenuation method [

18], ultrasonic method [

19], etc. These measurement methods have their characteristics, and ultrasonic wave has unique advantages in medical and pipeline fluid parameter monitoring because it generally does not damage the measured flow field in the process of propagation and can achieve non-invasive and non-disturbing parameter detection [

20,

21]. Currently, widely used ultrasonic methods include the reflection method, transmission method, Doppler method, and imaging method [

22]. In 2004, Vatanakful et al. used a transmissive ultrasonic sensor to measure the dispersed phase holdup in a gas–liquid-solid three-phase flow [

23]. Zheng et al. studied the effect of gas phase and solid phase on the response of an ultrasonic sensor in a gas–liquid-solid three-phase flow by measuring the velocity and attenuation of ultrasonic waves through the medium [

24]. In 2016, Gong et al. suggested an ultrasonic pulse transmission method based on the ultrasonic sound pressure attenuation theory for monitoring gas holdup in gas–liquid two-phase bubble flow [

22]. In 2020, Jin et al. used ultrasonic sensors and optical fiber sensors to investigate the measurement characteristics of gas holdup by ultrasonic sensors for typical flow patterns in oil–gas–water three-phase flows vertically rising with an inner diameter of 20 mm [

25].

The Doppler effect is the basis for the ultrasonic Doppler method of flow measurement. The received signal frequency that is reflected or scattered on the sensor varies when the fluid being detected contains minute-moving bubbles or suspended particles. The fluid flow rate is then quantitatively measured by the frequency change value. In 2022, to explore the problem of the production profile logging of low-yield oil wells, Song et al. conducted an oil–water two-phase experimental investigation of ultrasonic Doppler logging tools based on the measurement theory of ultrasonic Doppler logging tools. Through the DCA and PCA methods, the water cut calculation chart and the ultrasonic oil flow rate prediction model are established and used in field interpretation, with a good application effect [

26]. Wang et al. proposed a novel approach to production profile logging that used a converging annular logging tool and an ultrasonic Doppler logging tool to precisely determine the flow rate of each phase of an oil–water two-phase flow at a low flow rate, and verified its measurement characteristics through experiments. Last but not least, the PLS-SVR model was established to predict the flow rate of oil and water, and compared with the measured value, the results show high accuracy [

5].

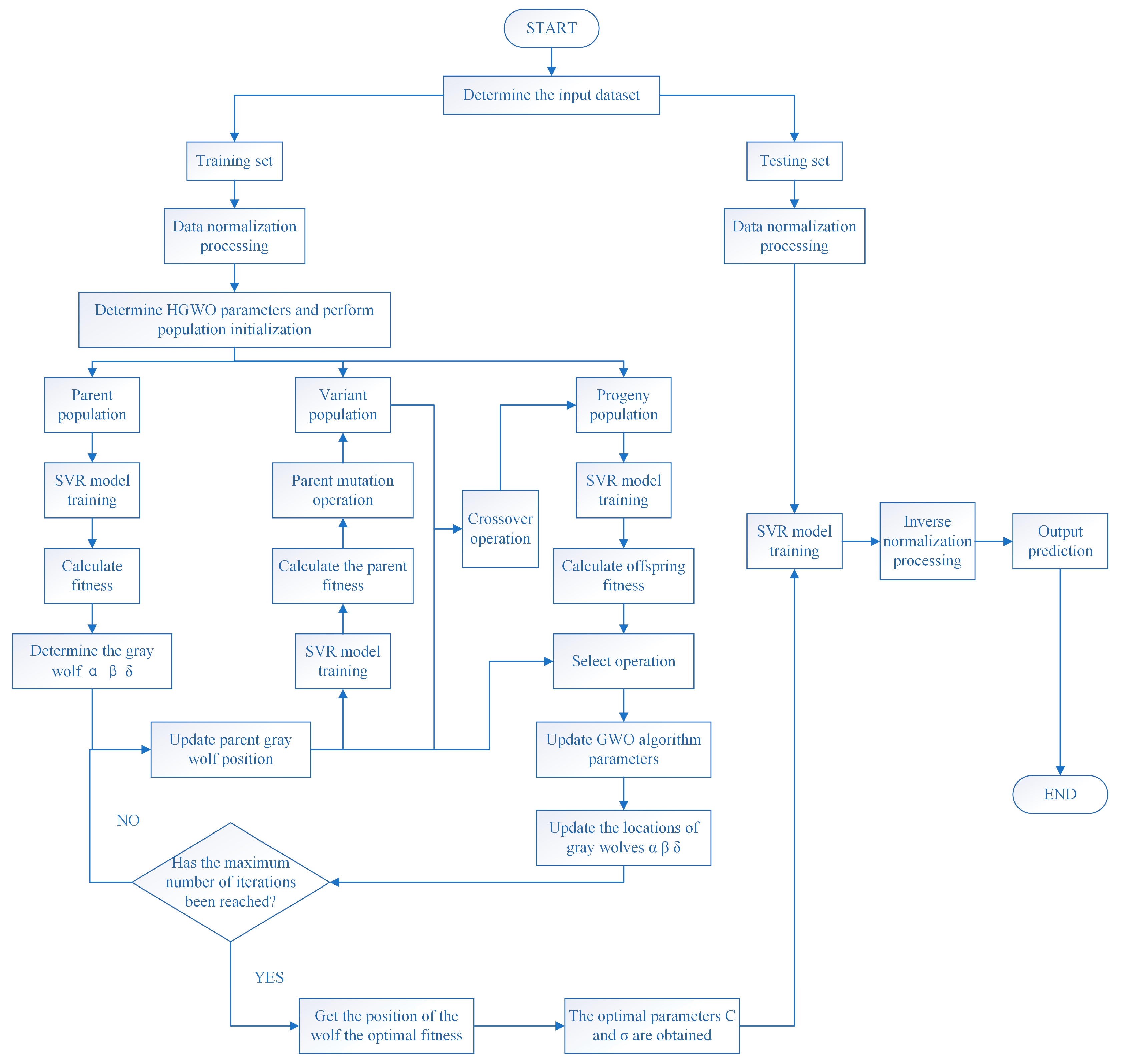

With the rise of artificial intelligence and society as a whole, more and more industries have bid farewell to traditional production methods, but have combined traditional equipment with modern scientific and technological means to enter an era of intelligence. In the production profile logging of low-yield gas wells, the phase distribution and velocity distribution of gas–liquid two-phase fluid in the wellbore become complicated due to the influence of gas well fluid accumulation, which makes the existing conventional production profile logging interpretation methods such as the drift model and slippage model not applicable. To accurately determine the gas–liquid two-phase flow parameters, the relevant knowledge of machine learning is applied to the production profile logging interpretation model. Support vector regression (SVR) is a statistical learning-based machine learning approach primarily utilized for regression issues. It has been extensively utilized in financial forecasting, data mining, biomedicine, and other fields due to its superior performance when dealing with problems involving small samples, nonlinearity, high dimensionality, and others [

27,

28,

29]. The prediction effect of the SVR algorithm is heavily influenced by the model parameters (penalty coefficient and kernel function parameters) that are chosen, despite its theoretical and practical advantages. Therefore, the question of how to select the appropriate parameters has always been a contentious and challenging aspect of SVR algorithm research. Cross-validation, gradient descent, grid search, and other methods are the traditional SVR parameter optimization methods [

30,

31,

32], all of which have the disadvantages of huge computation amounts and large errors.

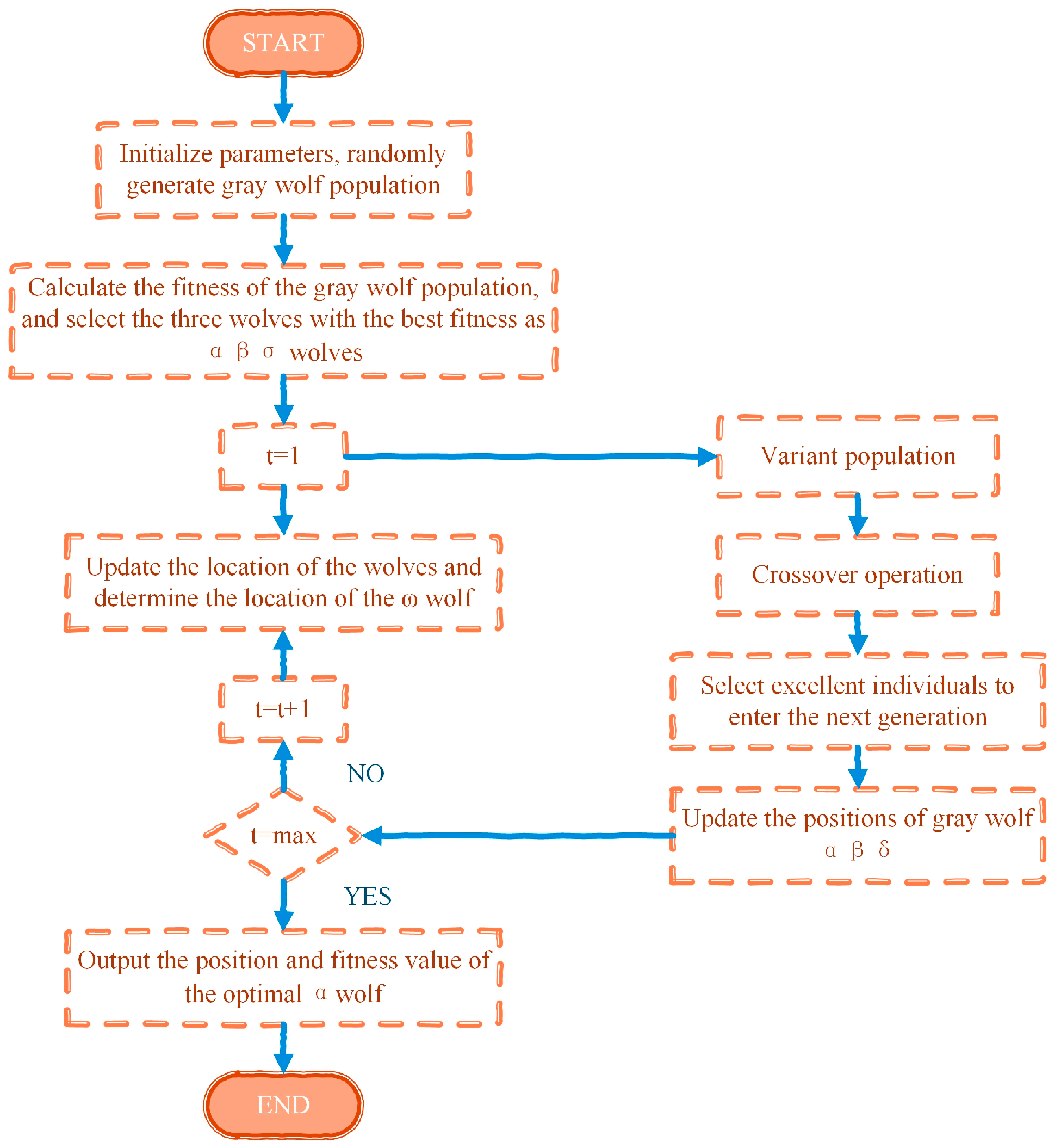

The swarm intelligence algorithm originates from imitation research on the behavioral laws of biological populations, mainly imitating the foraging process of individual biological populations. Given the foraging process of biological populations, it is abstracted into a certain swarm intelligence algorithm [

33]. Since genetic algorithm (GA) and ant colony optimization (ACO) were proposed, domestic and foreign scholars have successively proposed particle swarm optimization (PSO), artificial fish swarm algorithm (AFSA), firefly algorithm (FA), bat algorithm (BA), fruit fly optimization algorithm (FOA), grey wolf optimizer (GWO), whale optimization algorithm (WOA), and other swarm intelligence algorithms [

34]. The swarm intelligence algorithm has a strong robustness, extensibility, generality, and simplicity of implementation. Since it was first proposed, it has gained a lot of popularity. It has performed well in nonlinear parameter optimization problems and has been used to optimize SVR prediction model parameters [

35,

36,

37,

38].

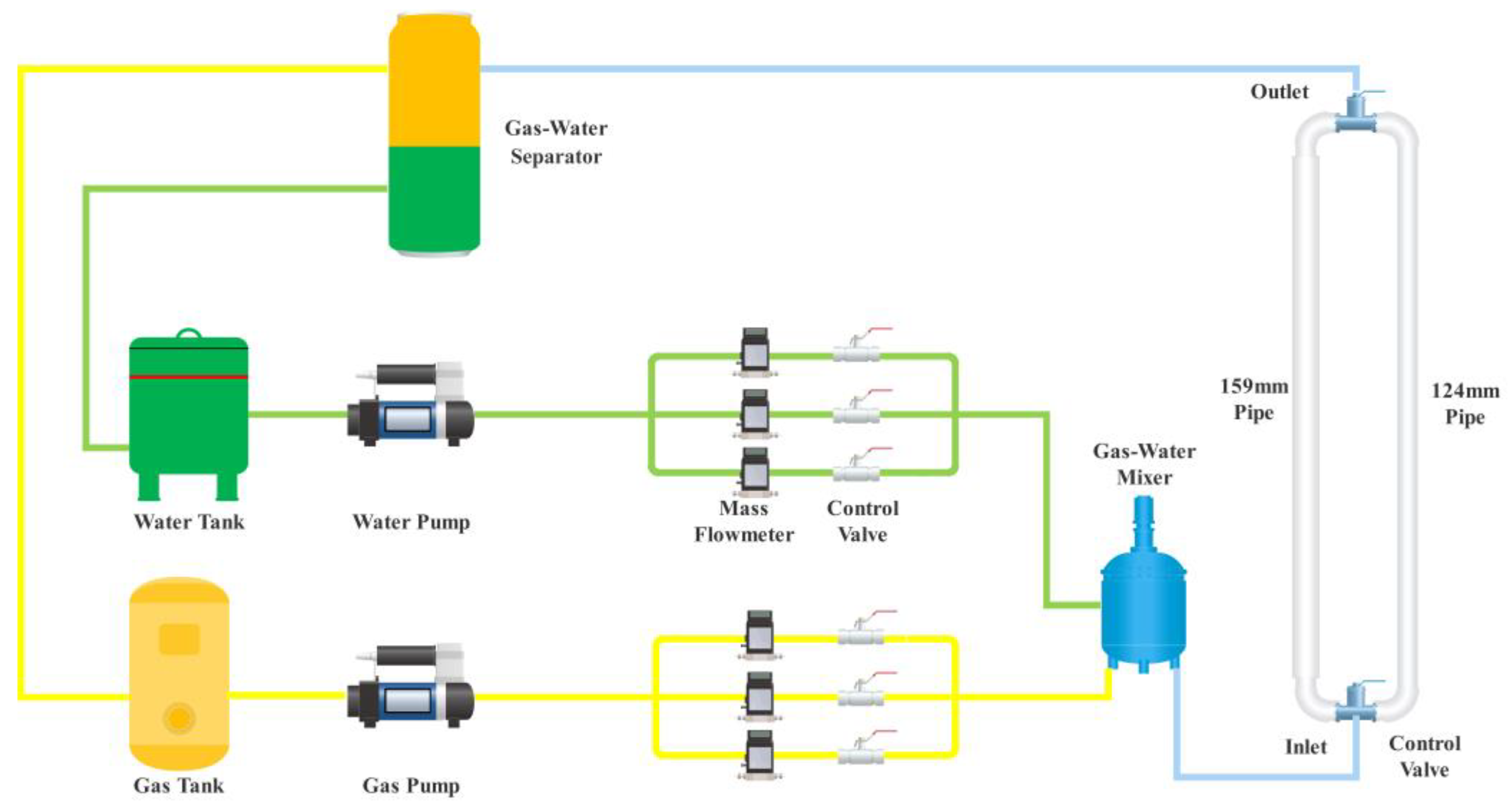

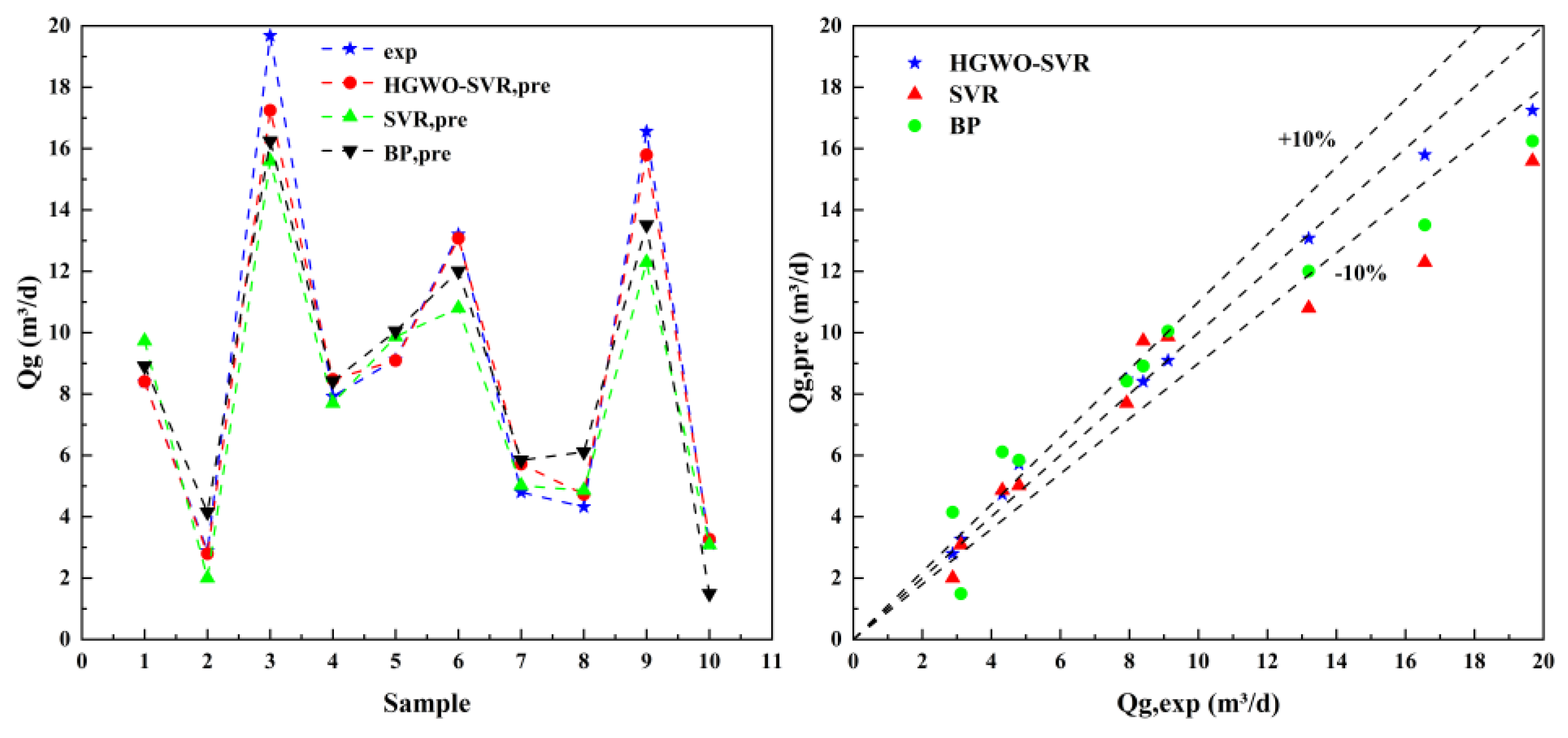

The flow pattern and velocity field distribution of gas–liquid two-phase flow at various phase flow rates are derived by numerically simulating the flow characteristics of low-velocity gas–liquid two-phase flow using CFD technology in this paper. The ultrasonic Doppler logging tool’s response to the different flow rates of gas–liquid two-phase flow is then examined through physical experiments. The correlation between the flow parameters and the characteristic parameters of the ultrasonic power spectrum was determined using distance correlation analysis. Finally, the parameters of the support vector regression prediction model were then optimized using the hybridizing gray wolf optimization with differential evolution, and the HGWO-SVR prediction model was established. Gas flow, gas holdup, and water flow are predicted, and the proposed combined optimization model’s effectiveness and accuracy are demonstrated.

2. Numerical Simulation

2.1. Creation and Meshing of Geometric Models

According to the pipe string structure of field production wells in oil and gas fields, this paper established a three-dimensional geometric model of vertical circular pipe with an inner diameter of 124 mm and a length of 20 m. The main body is a transparent plexiglass pipe, and the geometric model’s schematic is depicted in

Figure 1a.

After the geometric model is established, meshing is a necessary process for solving, a prerequisite for subsequent iterative solutions, and a key step in the entire numerical simulation calculation. The quality of meshing will directly affect the accuracy of subsequent calculation results. When building the geometric model, the convenience of volume division should be considered as much as possible. When dividing the object into meshes, the boundary line (namely the pipe wall) to which the object is attached is restricted, and the mesh density of this edge is delimited, to better control the mesh classification using structured mesh in the mesh model. All mesh types of the section of the geometric model adopted in this paper are triangular free-surface mesh types, and the side sections are divided into 1000 elements. The minimum element size of the section (circular plane) is 0.005 m, which is the order of linear elements, and is divided by program control and global variables. There are 569,569 nodes and 1,058,000 cells in total, as shown in

Figure 1b,c.

2.2. VOF Multiphase Flow Model

In numerical simulations, the flow is treated as transient and the problem is three-dimensional, so computational fluid dynamics (CFD) methods must be used to solve it. This polyphase coding can solve mass, momentum, and energy conservation equations and describe physically closed models through different methods and strategies. To solve the above problems, the flow characteristics of gas–liquid two-phase flow with low velocity in a vertical ascending pipe are simulated by using the VOF model of multiphase flow in computational fluid dynamics method.

In 1981, Hirt and Nichols first proposed the VOF model [

9]. The VOF model is a surface tracking method built on a fixed Euler grid, which is an Euler method in which the fluid moves through a fixed computational grid or grid cells [

13]. In this model, it is assumed that the two or more fluids involved in the simulated flow are incompatible with each other, but the fluids can be distributed within the computational domain at scales defined by the volume size of the computational grid [

39]. In the VOF model, the computational domain is divided into small computational units, and the phase interface of each computational unit is tracked by introducing the phase volume fraction. Within each control volume, the sum of all phase volume fractions is 1. The attribute region assigned by all variables in the calculation domain is shared by all phase fluids, and this attribute is called volume average value. The volume fraction of any phase at any position is known. Therefore, whether the fluid properties in a given unit are single-phase or multiphase mixtures depends on the value of phase volume fraction. For example, in the gas–liquid two-phase flow, the volume fraction of liquid phase fluid is assumed to be denoted as

in the grid cell. When

is 0, it means that the grid cell does not contain liquid phase fluid, but is filled with gas phase fluid. When

is 1, it means that all the grid cells are filled with liquid fluid. When the value of

is between 0 and 1, it means that there is a gas–liquid two-phase fluid phase interface in the grid cell. The governing equations of the VOF multiphase flow model are as follows:

Phase volume fraction equation (continuity equation):

Tracking the interface between phases is accomplished by solving the continuity equation for the volume fraction of one or more phases. For the phase

q, the equation is as follows:

In Equation (1),

represents the volume fraction of phase

q;

stands for time, s;

is the velocity vector, m/s;

is the mass source term. By default, the right source phase of Equation (1) is zero, but it is not zero when you specify a constant or user-defined mass source for each phase.

represents the fluid density of phase

q. The calculation of the volume fraction of the main phase is based on the constraints of Equation (2):

Phase property equation:

The properties that appear in the transport equations are determined by the phasing present in each control volume. In general, for the n-phase system, the average density is calculated using Equation (3):

Momentum equation:

By solving a single momentum equation over the entire region, the resulting velocity field is shared by the phases. The momentum equation depends on the volume ratio of all phases through the properties

and

, and the equation is as follows:

In Equation (4), is the hydrodynamic viscosity, Pa·s; is the acceleration of gravity, m/s2; is the surface tension, N/m3; is the pressure, Pa.

Energy conservation equation:

The energy equation is also shared among the phases and is expressed as follows:

In Equation (5),

represents the total energy, including internal energy, kinetic energy, and potential energy, J/kg;

denotes the effective heat conductivity, W/(m·K);

stands for temperature, K;

represents the source term, including radiation and other user-defined volumetric heat sources.

in Equation (5) is mass-averaged to obtain Equation (6).

In Equation (6), represents the energy shared by phase .

2.3. Boundary Conditions and Control Parameter Settings

For simulating gas–liquid two-phase flow, this paper makes use of water and air as fluid materials, both of which are incompressible fluids, and their heat transfer is negligible. Since the flow of air and water is an incompressible flow, the properties of the fluid such as density and viscosity are not affected by temperature and pressure, and the fluid density and viscosity are constant constants.

Table 1 depicts the fluid medium’s physical parameters used in the simulation. The inlet (below the pipe) boundary of the pipe selects the velocity inlet boundary, and the outlet (above the pipe) boundary selects the pressure outlet boundary; the surrounding wall is still considered a no-slip wall surface, selection pressure solver for transient simulation; the simulation of environmental pressure is set to the standard atmospheric pressure; considering the influence of gravity and surface tension factor, the acceleration of gravity g = 9.8 m/s

2 is set along the straight direction of the pipeline.

This paper mainly studies the fluid charging problem in the vertical circular tube. To better deal with the problem of the distribution of fluid velocity field at the same time in the complex interface, complex surface, and all points of space in the two-phase flow, the VOF model is selected according to the principle that the multiphase flow model is selected under the condition of simplified simulation. Among them, the

model is selected for the turbulence model. The

k-ε model has the characteristics of wide application range and reasonable solution accuracy, and the effect of solving the fully developed turbulence issue is better. The following are the equations for the

k-ε model’s dissipation rate

and turbulent kinetic energy

:

In Equations (7) and (8),

represents the generation term of turbulent kinetic energy caused by the average velocity gradient.

represents the generation term of turbulent kinetic energy caused by buoyancy; in compressible turbulence, the contribution of fluctuating expansion to the total dissipation rate is shown by

.

and

represent the custom source terms of turbulent kinetic energy and dissipation rate.

,

, and

are constant, and generally take

= 1.44,

= 1.92,

= 0.09;

and

denote the turbulent Prandtl number of

and

, respectively. Generally,

= 1.0,

= 1.3;

represents turbulent viscosity, and the calculation formula is shown in Equation (9).

In Equation (9), is a constant, and generally, = 0.09.

The liquid phase is referred to as the secondary phase when employing the VOF model, while the gas phase is referred to as the prime phase. When setting the boundary conditions at the velocity inlet, it is necessary to input the average velocity of the inlet fluid, the volume fraction of the second phase fluid, the hydraulic diameter and turbulence intensity, and other model-related parameters. The hydraulic diameter is equal to the inner diameter of the vertical circular pipe, and the turbulence intensity needs to be calculated according to the Reynolds value. The following formula can be used to determine the Reynolds number

and the turbulence intensity

:

In Equations (10) and (11), is the pipe inner diameter, m; is the average flow rate of the fluid, m/s; is the fluid density, kg/m3; is the fluid viscosity, mPa·s.

At the middle and late stage of production, most gas wells will produce less than 5000 m3/d of surface gas per well, and some will even produce around 1000 m3/d. A low-velocity gas–liquid two-phase flow simulation scheme is designed in accordance with the actual situation of low-yield gas wells. The daily surface gas volume range is defined as 1000–4000 m3/d, and the total underground flow is designed to be 10, 20, and 30 m3/d, according to the gas volume coefficient (Bg) of the corresponding block being 1/130. The water cut of gas–liquid two phases is 10%, 30%, 50%, 70%, and 90%, a total of 15 simulation points.

2.4. Simulation Results and Analysis

The study of the gas–liquid two-phase flow law is based on the flow pattern of gas–liquid two-phase flow. The flow pattern’s variation law is simulated using the simulation scheme for a variety of total flow rates and water cuts.

Figure 2 shows the flow pattern distribution diagram under the condition of different water cuts with the total flow rate of gas–water two-phase 20 m

3/d, which is presented in the form of a cloud map.

Figure 2a–e, respectively, represent the distribution characteristics of gas–liquid two-phase flow patterns when the water cut is 90%, 70%, 50%, 30%, and 10%, in which blue represents liquid phase and red represents gas phase. It may be seen from

Figure 2 that when the total flow rate of the gas–liquid two-phase is 20 m

3/d, no matter how small the water cut is, the flow pattern is a typical bubbly flow. At this time, numerous bubbles will continue to be produced in the vertical circular tube, and the size and time interval of the bubbles are different. In the continuous liquid phase, the bubbles are not evenly distributed. Most of the bubbles exist in the pipeline in the shape of ellipses or narrow lengths, and the bubble diameter is much smaller than the inner diameter of the pipeline. With the continuous reduction in the water cut, that is, the continuous increase in the gas flow rate, the number and size of the bubbles in the pipeline continue to increase.

Figure 3 shows the phase distribution diagrams under different total flow rates with a 10% water cut in the gas–water two-phase. The distribution characteristics of the gas–liquid two-phase flow patterns with total flow rates of 10 m

3/d, 20 m

3/d, and 30 m

3/d, respectively, are depicted in

Figure 3a–c. It is evident from

Figure 3 that, in the event of the same water cut, an increase in the total flow rate will result in an increase in the relative number and size of the bubbles in the pipeline. In addition, it is possible to explain that the only flow pattern that exists for the gas–liquid two-phase low flow rate in the vertically rising pipeline is typical bubbly flow.

The gas–liquid two-phase flow velocity was used to further quantitatively characterize the characteristics of the gas–liquid two-phase flow, and the velocity distribution law was analyzed under various total flow rates and water cuts under bubble flow. This provided a foundation for determining the parameters of the gas–liquid two-phase interpretation model in low-yield gas wells.

Figure 4 shows the distribution diagram of the phase state and velocity field under various water cuts with a total flow rate of 20 m

3/d for the gas–water two-phase. The position intercepted is the XY plane at 12 m of the vertical pipeline. The left side is the phase state distribution diagram and the right side is the contour map of the velocity field. Combining the left and right figures, it can be seen that the velocity contour map at the position where the gas phase is located presents a high value, that is, the rising speed of bubbles in the vertical rising pipe is faster than that of water, and the overall velocity value of the gas–liquid two-phase exhibits a downward trend as the water cut increases. The maximum rising speed of bubbles with a 10% water cut is about 1.1 m/s, and then gradually decreases to about 0.24 m/s with a 90% water cut.

Figure 5 shows the phase state distribution and velocity field distribution of the various total flow rates of the gas–water two-phase when the water cut is 50%. The overall velocity values of the gas–liquid two-phase show an upward trend with the increase in the total flow rate when the water cut is the same.

Figure 3b shows the flow pattern diagram of the gas–water two-phase flow rate of 20 m³/d and water cut of 10%. The position of the flow pattern diagram is the YZ plane at the center of the pipeline. The 20 m long pipeline was divided into upper and lower parts, and the bubbly flow in the middle of the upper and lower parts (3~7 m, 13~17 m) was divided at an equal interval of 1 m, respectively. The flow velocity of gas–liquid two-phase at this depth position was obtained, and the relationship between the flow velocity and the radial position of the pipeline was established, as shown in

Figure 6. The different color curves in

Figure 6 represent radial velocity profiles at different pipe heights. On the whole, each curve obviously presents an irregular peak-shaped distribution, and the peak positions of each curve are different. The peak positions of the fluid velocity curves represent the positions of the bubbles in the pipes.

As can be seen from

Figure 6, the gas–liquid two-phase flow velocity range of the 3~7 m pipeline is 0.04~0.47 m/s, and the gas–liquid two-phase flow velocity range of the 13~17 m pipeline is 0.07~0.67 m/s. The steeper peak velocity of each curve represents the rising velocity of the bubbles, and the flatter part of the curve represents the flow velocity of the surrounding liquid phase. The overall velocity of the upper part is slightly higher than that of the lower part, and the overall curve is significantly more stable than that of the lower part. Overall, the interval of the fluid flow rate is increased when the increase in the pipe height decreases after a periodic first increase, which is mainly due to the pipe gas superficial velocity being low; the tube gas and liquid phase being in shearing action to promote each other by gas existing in the form of tiny air bubbles; and small bubbles rising constantly in the process of polymerization and bursting. The convergence of small bubbles into large bubbles will lead to an increase in the fluid velocity, and the collapse of large bubbles into small bubbles will lead to a decrease in the fluid velocity.

The gas holdup is of great significance to gas production profile logging, and its main purpose is to determine the fluid properties and assist in the calculation of the fluid flow rates in each phase. Gas holdup, also known as void fraction, refers to the proportion of the gas phase area to the total flow cross-section area in a two-phase flow [

40]. When the gas–liquid two-phase flow is relatively stable in the numerical simulation, the gas holdup is calculated by replacing the area ratio with the ratio of the volume of the gas phase to the total volume.

Figure 7 is the relationship between the gas holdup and the total flow rate and water cut of the gas–water two-phase obtained by the numerical simulation. When the total flow rate remains the same, it is evident that the gas holdup decreases as the water cut rises. When the water cut is the same, the gas holdup increases with the increase in the total flow rate, and the increase in the gas holdup decreases with the increase in the equal interval flow rate. In the low-velocity gas–liquid two-phase flow, the gas holdup value is very small, and the maximum gas holdup value in the figure is only 7.98%, which means that there will be a lot of liquid accumulation in the underground of the low-yield gas wells, which increases the difficulty of interpretation of the gas production profile logging data in low-yield gas wells.

5. Conclusions

The dynamic monitoring of oil and gas wells is the key to the development of oil and gas fields. However, the current method based on conventional production profile interpretation cannot achieve the expected effect. The aim of this study was to test a practical approach for the dynamic monitoring of low-yielding gas wells using an ultrasonic Doppler logging instrument and a machine learning technique.

In the first part, the flow pattern and velocity field distribution of the gas–liquid two-phase flow with a low flow velocity are studied by CFD numerical simulation technology based on the production rate and well depth structure of actual produced low-yielding gas wells. It is found that the flow pattern is a typical bubbly flow when the gas–liquid two-phase flow has a low flow rate in the vertical riser pipeline, and the number and size of bubbles in the pipeline continue to increase with the continuous increase in the gas phase flow. The bubble rises faster than the water phase, and with the increase in the water cut, the overall velocity of the two phases decreases. In addition, in low-yielding gas wells, the water holdup is almost above 90%.

In the second part, the ultrasonic Doppler logging instrument is used to carry out a physical experiment examining the low velocity gas–liquid two-phase flow, and the characteristic parameters of the ultrasonic power spectrum under different gas–liquid two-phase flow conditions are obtained, and the gas holdup is obtained by the quick closing valve method. Through the distance correlation analysis between the flow parameters and the extracted ultrasonic power spectrum characteristic parameters in the process of gas–liquid two-phase flow at low flow rate, it is obtained that the gas flow and gas holdup have a good correlation with many ultrasonic power spectrum characteristic parameters. However, the water phase flow rate is not strongly correlated with the characteristic parameters of the ultrasonic power spectrum.

In the third part, the HGWO-SVR model is established to predict the flow parameters of the low flow rate gas–liquid two-phase, and the data set is based on the experimental data in the second part. Through the comparative analysis of the SVR and BP prediction methods, it is proved that the HGWO-SVR model has the best prediction effect, and the multiple prediction results are better. The HGWO-SVR model is adopted to predict the gas–liquid two-phase flow parameter, the gas flow rate and gas holdup have a good predictive effect, and the water flow prediction error is larger. The proposal in this situation of production profile logging using a gas stringer ultrasound Doppler tool and flow-concentrating spinner flowmeter is a combined measurement to improve the accuracy of water flow interpretation. It is suggested that the combination of the ultrasonic Doppler logging instrument and flow-concentrating spinner flowmeter should be used to improve the accuracy of the water phase flow interpretation when logging the production profile of low-yielding gas wells in fields.