Pyrolysis of High-Density Polyethylene Waste Plastic to Liquid Fuels—Modelling and Economic Analysis

Abstract

:1. Introduction

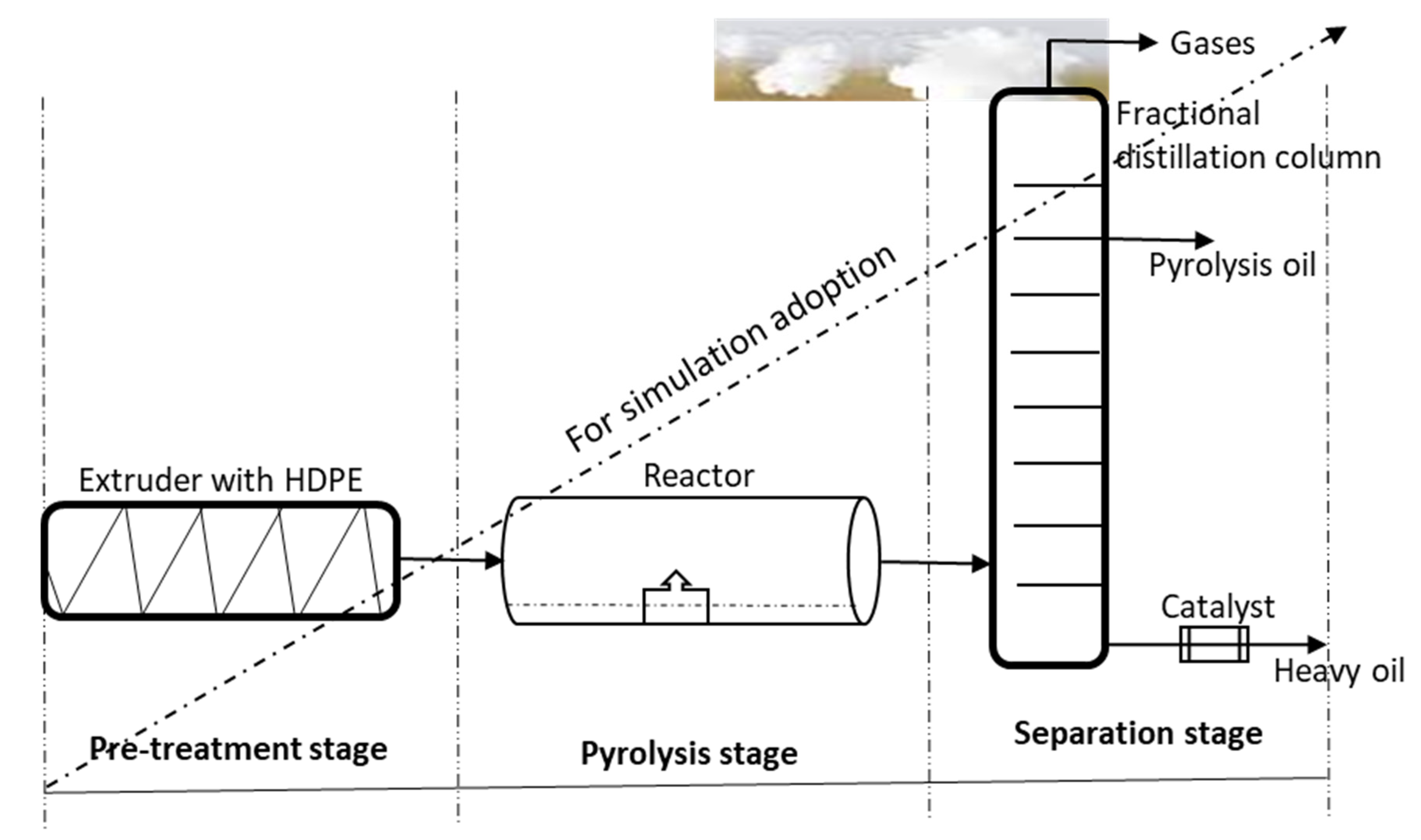

2. Techno-Economic Analysis for the Conversion of HDPE Plastic Waste to Liquid Fuel via Pyrolysis

2.1. Risk Assessment

2.2. Benefit Assessment

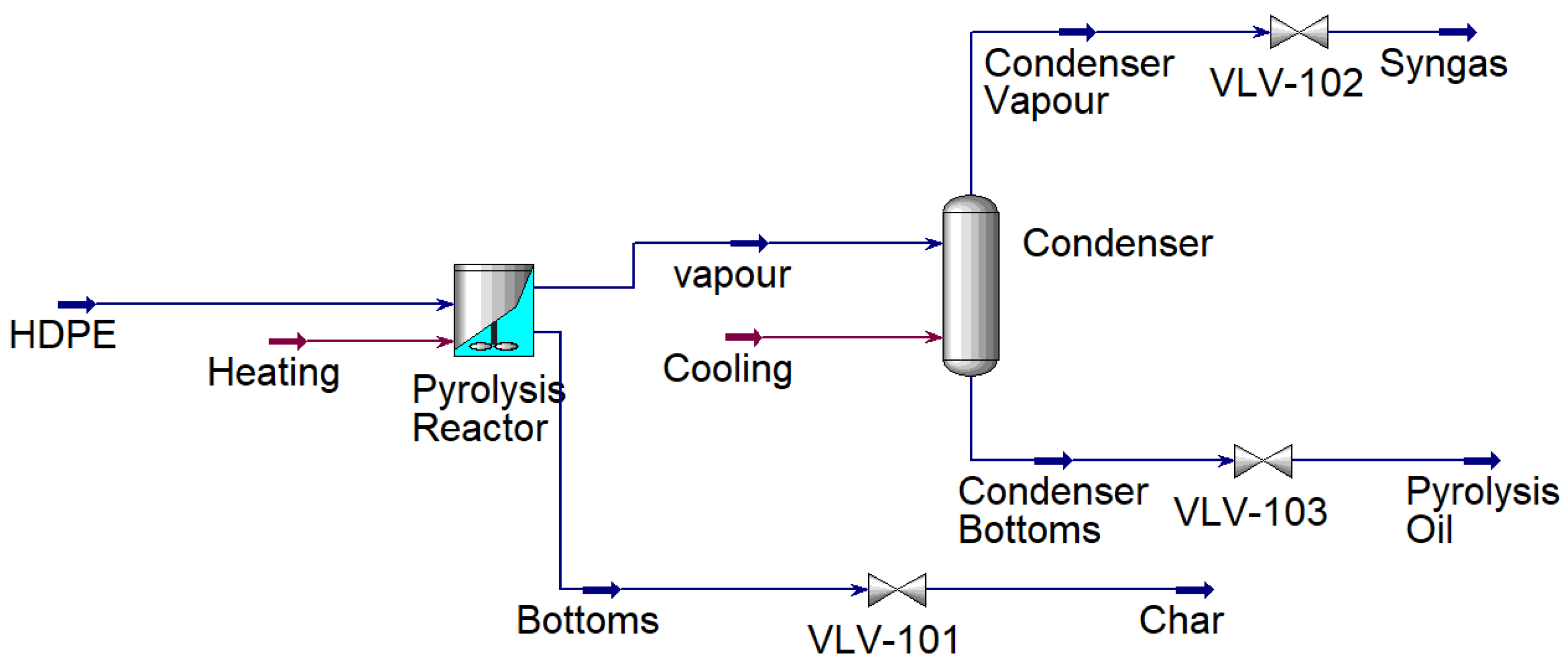

3. Aspen HYSYS Simulation for the Conversion of HDPE Waste Plastic to Liquid and Gaseous Fuel via Pyrolysis

- Steady-state conditions for the simulation process were implored.

- The pyrolysis reaction transpires into a complete gas phase.

- An unrealistic but optimistic scale price of £300/barrel of the simulated modelled pyrolysis oil was utilised.

3.1. Sequence and Kinetics of HDPE Pyrolysis Conversion Reaction

3.2. Selection of Fluid Package and Chemical Components

3.3. Setup of the Simulation Model

3.4. Operational Results from Simulation

4. Cost Assessment from Aspen HYSYS Simulation Results

4.1. Capital Expenditure

4.2. Operational Expenditure

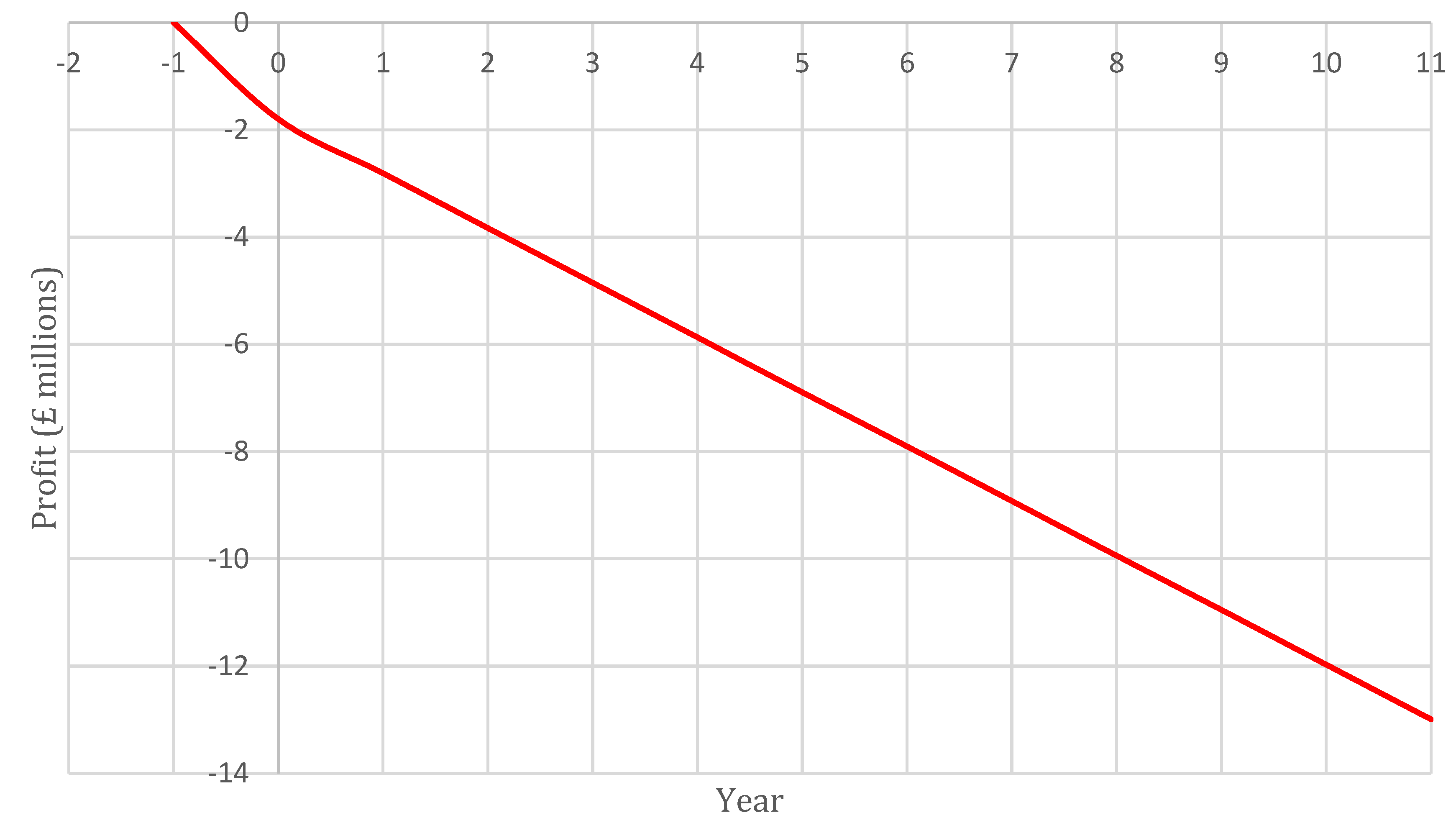

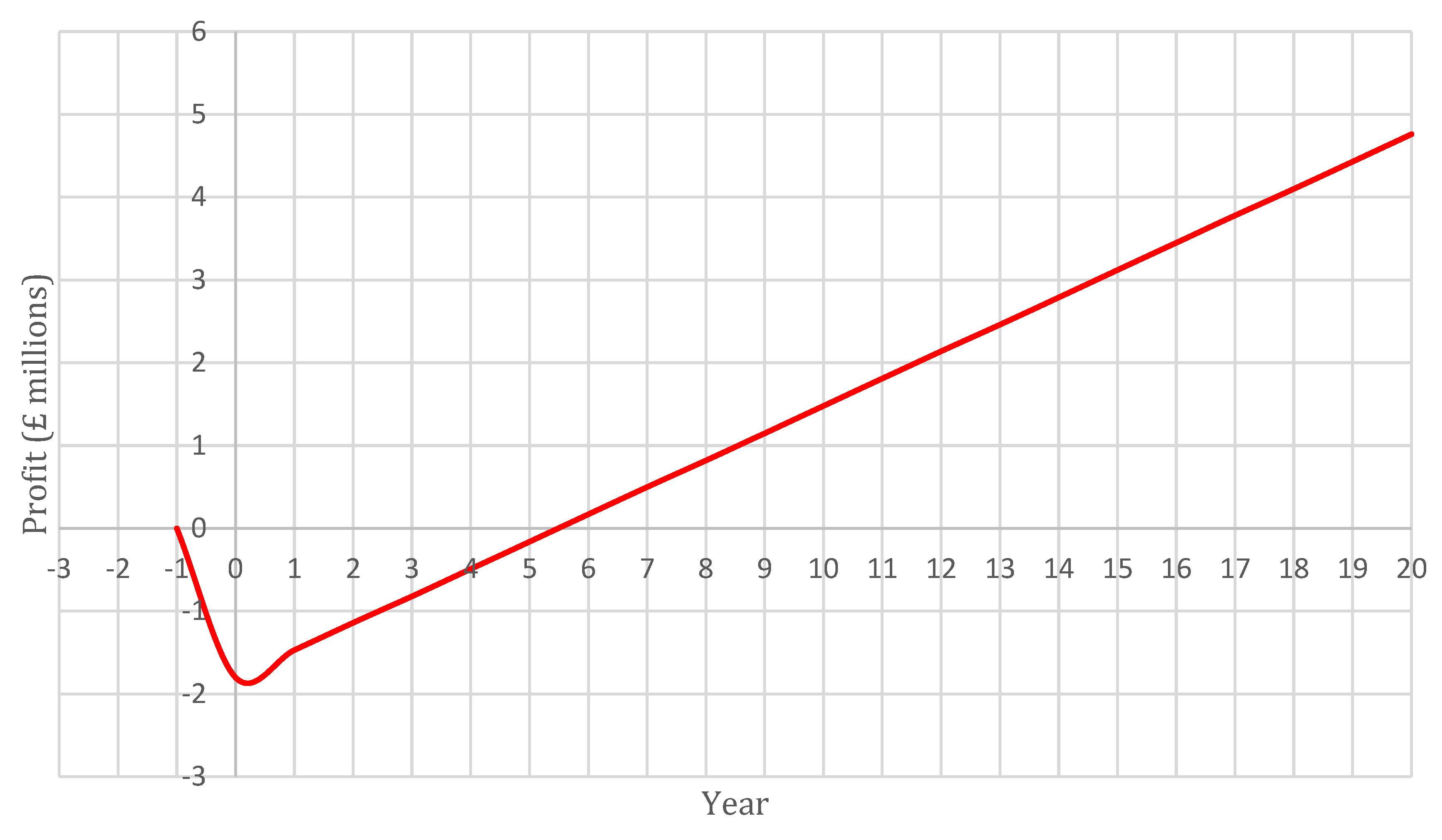

4.3. Cash Flow Statement

4.4. Cumulative Cash Flow and Net Present Value

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- OECD. Improving Markets for Recycled plastics: Trends, Prospects and Policy Responses; OECD Publishing: Paris, France, 2018. [Google Scholar]

- PlasticsEurope. Plastics—The Facts 2017: An Analysis of European Plastics Production, Demand and Waste Data [Presentation]. Available online: https://www.plasticseurope.org/application/files/5715/1717/4180/Plastics_the_facts_2017_FINAL_for_website_one_page.pdf (accessed on 7 August 2020).

- Chiemchaisri, C.; Charnnok, B.; Visvanathan, C. Recovery of plastic wastes from dumpsite as refuse-derived fuel and its utilization in small gasification system. Bioresour. Technol. J. 2010, 101, 1522–1527. [Google Scholar] [CrossRef] [PubMed]

- Aguado, J.; Serrano, D. On feedstock recycling of waste plastic. In RSC Clean Technology Monographs; Clark, J.H., Ed.; Royal Society of Chemistry: Cambridge, UK, 1999. [Google Scholar]

- Yansaneh, O.Y.; Zein, S.H. Latest Advances in Waste Plastic Pyrolytic Catalysis. Processes 2022, 10, 683. [Google Scholar] [CrossRef]

- EUROPARC. EU Strategy on Plastic Waste—Paving the Way towards a Circular Economy. 2018. Available online: https://www.europarc.org/news/2018/01/european-strategy-on-plastic-waste (accessed on 17 June 2015).

- Ellen MacArthur Foundation. The New Plastics Economy. 2016. Available online: https://www.ellenmacarthurfoundation.org/assets/downloads/EllenMacArthurFoundation_TheNewPlasticsEconomy_Pages.pdf (accessed on 27 July 2020).

- Ritchie, H. FAQs on Plastics. Available online: https://ourworldindata.org/faq-on-plastics#which-sectors-use-the-most-plastic (accessed on 27 July 2020).

- Franco-García, M.L.; Carpio-Aguilar, J.C.; Bressers, H. Towards Zero Waste, Circular Economy Boost: Waste to Resources. In Towards Zero Waste; Greening of Industry Networks Studies; Franco-García, M.L., Carpio-Aguilar, J., Bressers, H., Eds.; Springer: Cham, Switzerland, 2019; Volume 6. [Google Scholar] [CrossRef]

- Simon, J.M. Zero Waste Europe: A Zero Waste Hierarchy for Europe. 2019. Available online: https://zerowasteeurope.eu/2019/05/a-zero-waste-hierarchy-for-europe/ (accessed on 7 August 2020).

- Shukman, D. Straws: UK Government to Bring in New Controls on Plastic. 2019. Available online: https://www.bbc.co.uk/news/science-environment-48358002 (accessed on 7 August 2020).

- Yansaneh, O.Y.; Zein, S.H. Recent Advances on Waste Plastic Thermal Pyrolysis: A Critical Overview. Processes 2022, 10, 332. [Google Scholar] [CrossRef]

- Burlakovs, J.; Kriipsalu, M.; Porshnov, D.; Jani, Y.; Ozols, V.; Pehme, K.M.; Rudovica, V.; Grinfelde, I.; Pilecka, J.; Vincevica-Gaile, Z.; et al. Gateway of landfilled plastic waste towards circular economy in Europe. Separations 2019, 6, 25. [Google Scholar] [CrossRef] [Green Version]

- Kiran, N.; Ekinci, E.; Snape, C.E. Recycling of plastic wastes via pyrolysis. Resour. Conserv. Recycl. 2020, 29, 273–283. [Google Scholar] [CrossRef]

- Buekens, A.G.; Huang, H. Catalytic plastics cracking for recovery of gasoline-range hydrocarbons from municipal plastic wastes. Polym. Degrad Stabil. 2020, 70, 365–371. [Google Scholar] [CrossRef]

- Gonzalez, J.F.; Encinar, J.M.; Canito, J.L.; Rodriguez, J.J. Pyrolysis of automobile tyre waste, influence of operating variables and kinetics study. J. Anal. Appl. Pyrol. 2020, 58, 667–683. [Google Scholar] [CrossRef]

- Lee, K.H.; Shin, D.H.; Seo, Y.H. Liquid-phase catalytic degradation of mixtures of waste high-density polyethylene and polystyrene over spent FCC catalyst and effect of mixing proportions of reactants. J. Anal. Appl. Pyrol. 2001, 58, 789–801. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Yin, X.L.; Zhao, Z.L.; Xu, B.Y.; Chen, Y. Pyrolysis of tyre powder: Influence of operation variables on the composition and yields of gaseous product. Fuel Process. Technol. 2002, 79, 141–155. [Google Scholar] [CrossRef]

- Koc, A.; Bilgesu, A.; Alibeyli, R.; Koçak, M.C. Factorial experimental design for oxidative thermal decomposition of low-density polyethylene waste. J. Anal. Appl. Pyrol. 2004, 72, 309–315. [Google Scholar] [CrossRef]

- López, A.; de Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Adrados, A.; Aranzabal, A. Catalytic pyrolysis of plastic wastes with two different types of catalysts: ZSM-5 zeolite and Red Mud. Appl. Catal. B Environ. 2011, 104, 211–219. [Google Scholar] [CrossRef]

- Obeid, F.; Zeaiter, J.; Al-Muhtaseb, A.H.; Bouhadir, K. Thermo-catalytic pyrolysis of waste polyethylene bottles in a packed bed reactor with different bed materials and catalysts. Energy Convers. Manag. 2014, 85, 1–6. [Google Scholar] [CrossRef]

- Muhammad, C.; Onwudili, J.A.; Williams, P.T. Catalytic pyrolysis of waste plastic from electrical and electronic equipment. J. Anal. Appl. Pyrolysis 2015, 113, 332–339. [Google Scholar] [CrossRef]

- Zhang, X.; Lei, H.; Yadavalli, G.; Zhu, L.; Wei, Y.; Liu, Y. Gasoline-range hydrocarbons produced from microwave-induced pyrolysis of low-density polyethylene over ZSM-5. Fuel 2015, 144, 33–42. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.A.; Aburiazaiza, A.S.; Rehan, M.; Nizami, A.S. Catalytic pyrolysis of plastic waste: A review. Process. Saf. Environ. Prot. 2016, 102, 822–838. [Google Scholar] [CrossRef]

- Yang, J.; Rizkiana, J.; Widayatno, W.B.; Karnjanakom, S.; Kaewpanha, M.; Hao, X.; Abudula, A.; Guan, G. Fast co-pyrolysis of low-density polyethylene and biomass residue for oil production. Energy Convers. Manag. 2016, 120, 422–429. [Google Scholar] [CrossRef]

- Al-Salem, S.M. Plastics to Energy: Fuel, Chemicals, and Sustainability Implications; Elsevier: Oxford, UK, 2018. [Google Scholar]

- Sogancioglu, M.; Yel, E.; Ahmetli, G. Pyrolysis of waste high density polyethylene (HDPE) and low density polyethylene (LDPE) plastics and production of epoxy composites with their pyrolysis chars. J. Clean. Prod. 2017, 165, 369–381. [Google Scholar] [CrossRef]

- Thahir, R.; Altway, A.; Juliastuti, S.R. Susianto. Production of liquid fuel from plastic waste using integrated pyrolysis method with refinery distillation bubble cap plate column. Energy Rep. 2019, 5, 70–77. [Google Scholar] [CrossRef]

- Gaurav Madhukar, M.; Arunkumar, K.N.; Lingegowda, N.S. Conversion of LDPE plastic waste into liquid fuel by thermal degradation. Int. J. Mech. Prod. Eng. 2017, 2, 104–107. [Google Scholar]

- Al-Salem, S.M.; Antelava, A.; Constantinou, A.; Manos, G.; Dutta, A. A review on thermal and catalytic pyrolysis of plastic solid waste (PSW). J. Environ. Manag. 2017, 197, 177–198. [Google Scholar] [CrossRef]

- Alla, M.M.G.; Ahmed, I.A.; Abdalla, B.K. Conversion of plastic waste to liquid fuel. Int. J. Tech. Res. Appl. 2014, 2, 29–31. [Google Scholar]

- Ghasem, N.; Henda, R. Principles of Chemical Engineering Processes: Material and Energy Balances, 2nd ed.; CRC Press—Taylor & Francis Group: Boca Raton, FL, USA, 2014. [Google Scholar]

- Butler, E.; Devlin, G.; McDonnell, K. Waste Polyolefins to Liquid Fuels via Pyrolysis: Review of Commercial State-of-the-Art and Recent Laboratory Research. Waste Biomass Valorization 2011, 2, 227–255. [Google Scholar] [CrossRef] [Green Version]

- Tdplant. Disasters at Pyrolysis Plants. 2021. Available online: https://tdplant.com/news/disasters-at-pyrolysis-plants (accessed on 22 May 2022).

- Liu, K.; Song, C.; Subramani, V. Hydrogen and Syngas Production and Purification Technologies; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels Production through Biomass Pyrolysis—A Technological Review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Eletta, O.A.A.; Ighalo, J.O. Computer aided modelling of low density polyethylene pyrolysis to produce synthetic fuels. Niger. J. Technol. 2018, 37, 945–949. [Google Scholar] [CrossRef]

- Alla, M.M.G.; Ali, S.O.A. Simulation and design for process to convert plastic waste to liquid fuel using Aspen HYSYS Program. Integr. J. Eng. Res. Technol. 2014, 1, 270–274. [Google Scholar]

- Hague, R.A. The Pre-Treatment and Pyrolysing of Biomass for the Production of Liquids for Fuel and Speciality Chemicals. Ph.D. Thesis, Aston University, Birmingham, UK, 1998. [Google Scholar]

- Low, S.L.; Connor, M.A.; Covey, G.I. Turning mixed plastic wastes into a useable liquid fuel. In Proceedings of the 6th World Congress of Chemical Engineering, Melbourne, Australia, 23–27 September 2001. [Google Scholar]

- Kusuktham, B.; Teeranachaideekul, P. Mechanical properties of high-density polyethylene/modified calcium silicate composites. Silicon 2014, 6, 179–189. [Google Scholar] [CrossRef]

- Khan Academy. Activation Energy. Available online: https://www.khanacademy.org/science/ap-biology/cellular-energetics/enzyme-structure-and-catalysis/a/activation-energy (accessed on 21 June 2022).

- Gutierrez, J.P.; Benítez, L.A.; Martínez, J.; Ale Ruiz, L.; Erdmann, E. Thermodynamic Properties for the Simulation of Crude Oil Primary Refining. Int. J. Eng. Res. Appl. 2014, 4, 190–194. [Google Scholar]

- Singh, L.K. Why We Use/Prefer PR (Peng Robinson) EOS for Aspen HYSYS Simulation and Modeling? Available online: https://www.linkedin.com/pulse/why-we-use-prefer-pr-peng-robinson-eos-aspen-hysys-beng-ceng-micheme (accessed on 21 June 2022).

- Rosen, A. Reactor Design. Available online: https://sites.tufts.edu/andrewrosen/files/2013/09/reactor_design_guide1.pdf (accessed on 8 June 2022).

- Papapetrou, M.; Kosmadakis, G. Resource, environmental, and economic aspects of SGHE. In Salinity Gradient Heat Engines; Woodhead Publishing: Sawston, UK, 2022. [Google Scholar]

- U.S. Energy Information Administration. How Many Gallons of Gasoline and Diesel Fuel Are Made from One Barrel of Oil? 2022. Available online: https://www.eia.gov/tools/faqs/faq.php?id=327&t=9 (accessed on 14 April 2022).

- Saefong, M.P. Could Oil Hit $300 a Barrel? Why Russia’s Deputy Prime Minister Seems to Think So. 21 March 2022. Available online: https://www.marketwatch.com/story/could-oil-hit-300-a-barrel-why-russias-deputy-prime-minister-seems-to-think-so-11647892464 (accessed on 20 May 2022).

- Markets Insider. Oil Live Price. 21 March 2022. Available online: https://markets.businessinsider.com/commodities/oil-price?type=wti?utm_source=feedly (accessed on 14 April 2022).

- Herc. Budget Impact Analysis. US Department of Veterans Affairs. 19 March 2021. Available online: https://www.herc.research.va.gov/include/page.asp?id=budget-impact-analysis (accessed on 21 May 2022).

- Fernando, J. Net Present Value (NPV). Available online: https://www.investopedia.com/terms/n/npv.asp (accessed on 21 May 2022).

- Sinnott, R.; Towler, G. Chemical Engineering Design; Elsevier Butterworth-Heinemann: Amsterdam, The Netherlands, 2020; pp. 297–392. [Google Scholar]

- Oko, E. Process Economics: NPV and IRR Calculations; University of Hull: Hull, UK, 2020; pp. 2–4. [Google Scholar]

- Trading Economics. Colombia Interest Rate—2022 Data—1998–2021 Historical—2023 Forecast—Calendar. 2022. Available online: https://tradingeconomics.com/colombia/interest-rate# (accessed on 21 May 2022).

- Country Economy. Colombia National Debt 2020. 2022. Available online: https://countryeconomy.com/national-debt/colombia (accessed on 21 May 2022).

- Kenton, W. Cost of Equity. 31 August 2021. Available online: https://www.investopedia.com/terms/c/costofequity.asp (accessed on 18 July 2022).

- Ansari, M.N.M.; Ismail, H.; Zein, S.H.S. Effect of Multi-walled Carbon Nanotubes on Mechanical Properties of Feldspar Filled Polypropylene Composites. J. Reinf. Plast. Compos. 2009, 28, 2473–2485. [Google Scholar] [CrossRef]

- Al-Qadri, A.A.; Ahmed, U.; Abdul Jameel, A.G.; Zahid, U.; Usman, M.; Ahmad, N. Simulation and Modelling of Hydrogen Production from Waste Plastics: Technoeconomic Analysis. Polymers 2022, 14, 2056. [Google Scholar] [CrossRef]

- Fivga, A.; Dimitriou, I. Pyrolysis of plastic waste for production of heavy fuel substitute: A techno-economic assessment. Energy 2018, 149, 865–874. [Google Scholar] [CrossRef]

- Chai, S.-P.; Zein, S.H.S.; Mohamed, A.R. COx-Free Hydrogen and Carbon Nanofibers Produced from Direct Decomposition of Methane on Nickel-Based Catalysts. J. Nat. Gas Chem. 2006, 15, 253–258. [Google Scholar] [CrossRef]

| Waste Plastic | Liquid Fuel | Other Valuable Products | Reference |

|---|---|---|---|

| Polyethylene (PE) and polystyrene (PS) | Fuel oil of styrene, gas, and green wax | Pyrolysis gas and wax | Buekens and Huang [16] |

| Municipal plastic wastes (MPW) | Gasoline (paraffins, olefins, and aromatics) | Naphthenes and iso-alkanes (C5–C8) | Gonzalez et al. [17] |

| Automobile polymers | Fuel oil | Gases and char | Lee et al. [18] |

| Mixture of HDP|Es and PS | Fuel oil | Pyrolysis gas | Leung et al. [19] |

| Polymeric powder | Pyrolysis gas | Koc et al. [20] | |

| Low-density polyethylene (LDPE) | Alcohols, aldehydes, ketones, olefins, saturated paraffins, and carboxylic acids | López et al. [21] | |

| MPW | Pyrolysis oils | Pyrolysis gas | Obeid et al. [22] |

| PEs | Liquid fuels {paraffins (≤C44), olefins (≤C22), aromatics (≤C14), and alcohols (C16 and C17)} | Muhammad et al. [23] | |

| Plastic waste electrical and electronic equipment (WEEE) | Gasoline (paraffins, olefins, and aromatics) | Zhang et al. [24] | |

| LDPE | Gasoline (paraffins, olefins, and aromatics) | Miandad et al. [25] | |

| Waste plastics | A review (pyrolysis oils) | Gases and chars | Yang et al. [26] |

| LDPE and biomass residue | Pyrolysis oils | Pyrolysis gases | Al-Salem [27] |

| Waste plastics | Pyrolysis oils | Pyrolysis gases | Sogancioglu et al. [28] |

| LDPE and HDPE | Epoxy composites | Pyrolysis chars | Thahir et al. [29] |

| Polypropylene (PP) | Liquid fuel (kerosene, gasoline, and diesel) | Pyrolysis gases and chars | Gaurav et al. [30] |

| Pyrolysis Product | Composition | Weight Percentage (%) | Weight Percentage (%) by Adeniyi et al. [38] |

|---|---|---|---|

| Pyrolysis oil | C7–C25 | 92.79 | 92.88 |

| Syngas | H2, C1–C4, traces of C5 and C6 | 2.26 | 2.22 |

| Carbon char | Elemental carbon only | 4.95 | 4.90 |

| Capital Expenditure | £ (2019 Basis) |

|---|---|

| Equipment costs | |

| 998,500 |

| 199,500 |

| 11,980 |

| Subtotal A: Total equipment costs | 1,209,980 |

| Other costs | |

| 12,050 |

| 205,509 |

| 12,099 |

| 120,099 |

| 241,065 |

| Subtotal B: Total other costs | 590,822 |

| Total fixed capital (A + B): | 1,800,802 |

| Operational Expenditure | £ (2019 Basis) |

|---|---|

| Variable costs | |

| 0 |

| Negligible |

| 35,544 |

| Negligible |

| Subtotal A: Total variable costs | 35,544 |

| Fixed costs | |

| 1691 |

| 482,130 |

| 96,426 |

| 96,426 |

| 241,065 |

| 187,000 |

| 18,700 |

| 37,400 |

| |

| Subtotal B: Total fixed costs | 1,179,538 |

| Direct production costs (A + B): | 1,215,151 |

| 60,707 |

| 60,707 |

| 121,415 |

| Subtotal C: Total overhead costs | 243,830 |

| Annual production cost (A + B + C): | 1,457,981 |

| Production cost (£/kg) | 1.66 |

| Cash Flow | 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|---|

| Incomes (£) | |||||

| Pyrolysis oil sales | - | 441,000 | 441,000 | 441,000 | 441,000 |

| Total: | - | 441,000 | 441,000 | 441,000 | 441,000 |

| Outgoings (£) | |||||

| HDPE feedstock | - | - | - | - | - |

| CAPEX | (1,800,802) | - | - | - | - |

| OPEX | - | (1,457,981) | (1,457,981) | (1,457,981) | (1,457,981) |

| Corporation tax (19%) | - | - | - | - | - |

| Total: | (1,800,802) | (1,457,981) | (1,457,981) | (1,457,981) | (1,457,981) |

| Annual total (£) | (1,800,802) | (1,016,981) | (1,016,981) | (1,016,981) | (1,016,981) |

| Final total (£) | (1,800,802) | (2,817,783) | (3,834,764) | (4,851,745) | (5,868,726) |

| Cash Flow | 2020 | 2021 | 2022 | 2023 | 2024 |

|---|---|---|---|---|---|

| Incomes (£) | |||||

| Pyrolysis oil sales | - | 2,205,000 | 2,205,000 | 2,205,000 | 2,205,000 |

| Total: | - | 2,205,000 | 2,205,000 | 2,205,000 | 2,205,000 |

| Outgoings (£) | |||||

| HDPE feedstock | - | - | - | - | - |

| CAPEX | (1,800,802) | - | - | - | - |

| OPEX | - | (1,457,981) | (1,457,981) | (1,457,981) | (1,457,981) |

| Corporation tax (19%) | - | (418,950) | (418,950) | (418,950) | (418,950) |

| Total: | (1,800,802) | (1,876,931) | (1,876,931) | (1,876,931) | (1,876,931) |

| Annual total (£) | (1,800,802) | 328,069 | 328,069 | 328,069 | 328,069 |

| Final total (£) | (1,800,802) | (1,472,733) | (1,144,664) | (816,595) | (488,526) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zein, S.H.; Grogan, C.T.; Yansaneh, O.Y.; Putranto, A. Pyrolysis of High-Density Polyethylene Waste Plastic to Liquid Fuels—Modelling and Economic Analysis. Processes 2022, 10, 1503. https://doi.org/10.3390/pr10081503

Zein SH, Grogan CT, Yansaneh OY, Putranto A. Pyrolysis of High-Density Polyethylene Waste Plastic to Liquid Fuels—Modelling and Economic Analysis. Processes. 2022; 10(8):1503. https://doi.org/10.3390/pr10081503

Chicago/Turabian StyleZein, Sharif H., Connor T. Grogan, Osman Y. Yansaneh, and Aditya Putranto. 2022. "Pyrolysis of High-Density Polyethylene Waste Plastic to Liquid Fuels—Modelling and Economic Analysis" Processes 10, no. 8: 1503. https://doi.org/10.3390/pr10081503

APA StyleZein, S. H., Grogan, C. T., Yansaneh, O. Y., & Putranto, A. (2022). Pyrolysis of High-Density Polyethylene Waste Plastic to Liquid Fuels—Modelling and Economic Analysis. Processes, 10(8), 1503. https://doi.org/10.3390/pr10081503