Recent Advances in Catalytic Pyrolysis of Municipal Plastic Waste for the Production of Hydrocarbon Fuels

Abstract

:1. Introduction

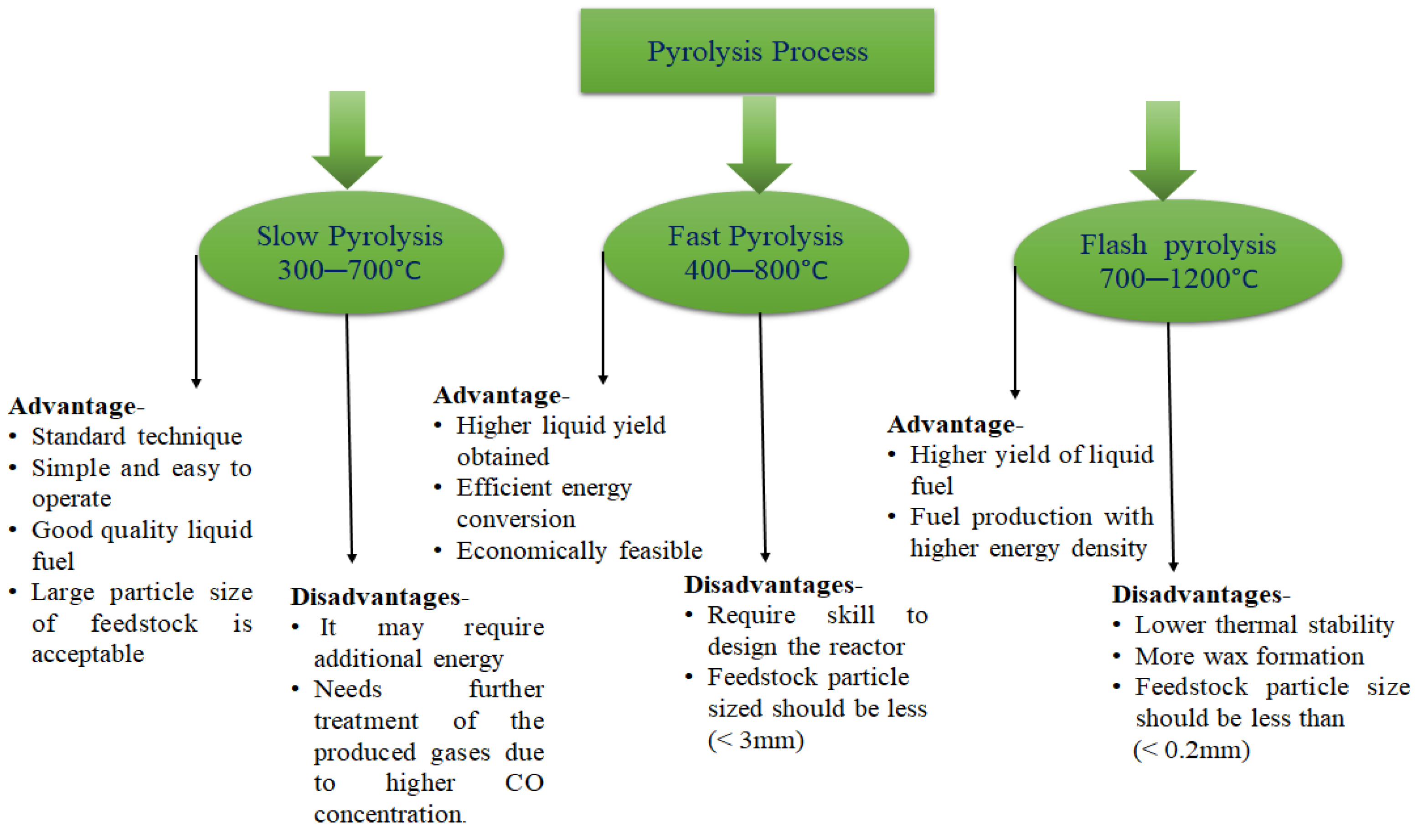

2. Thermal Decomposition of Plastic Waste

Conventional Pyrolysis Process

3. Recent Development in the Pyrolysis Process

3.1. Slow Pyrolysis Process

3.2. Fast Pyrolysis

3.3. Superfast/Ultra-Fast Pyrolysis

3.4. Catalytic Thermal Degradation (CTD)

4. Catalyst Effect on Thermal Degradation Process

4.1. Factors Affecting the Pyrolysis Process

4.2. Effect of Temperature

4.3. Effect of Pressure

4.4. Residence Time

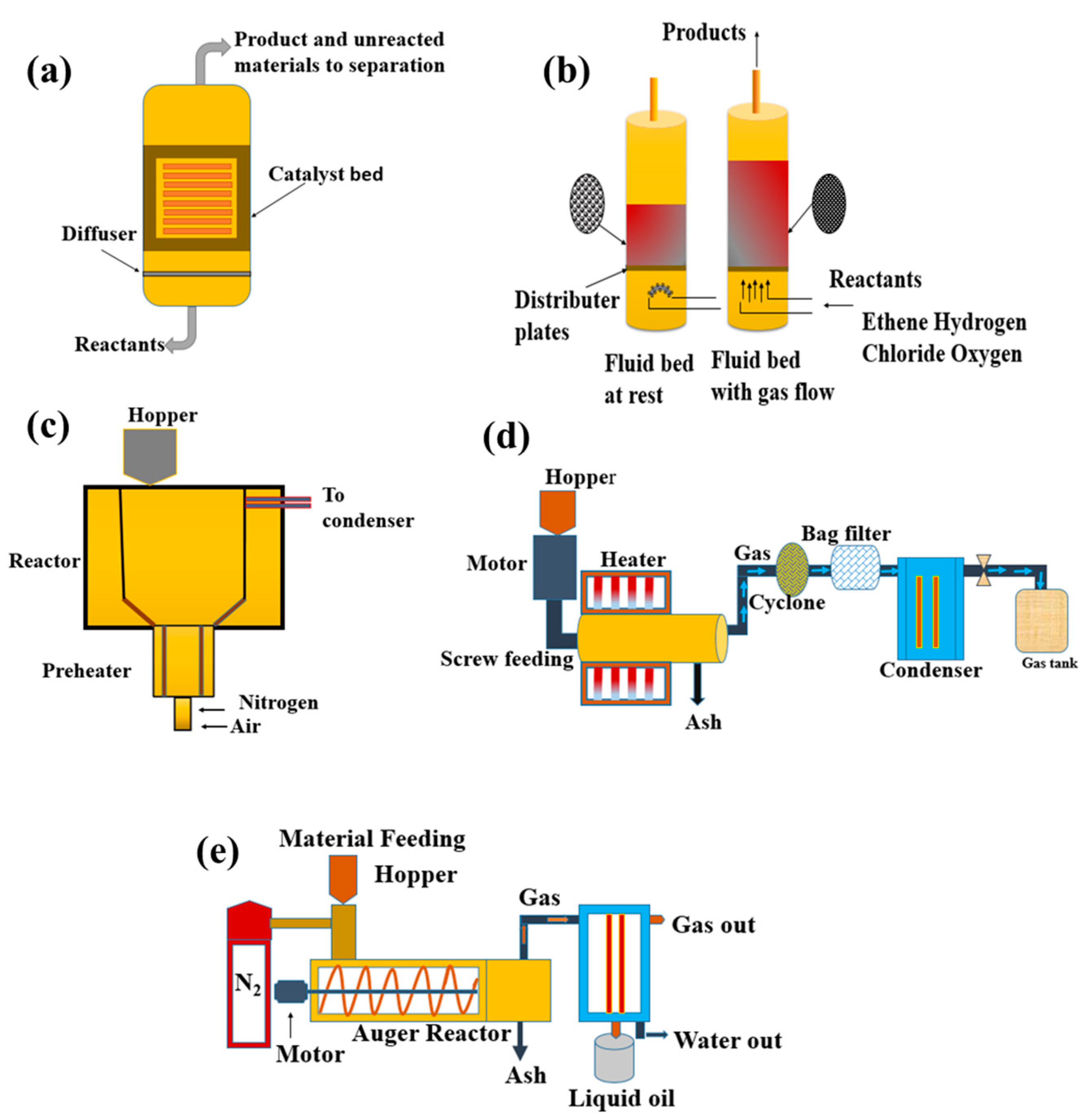

4.5. Type of Reactor

4.5.1. Fixed-Bed Reactor

4.5.2. Fluidized-Bed Reactor

4.5.3. Conical Spouted-Bed Reactor (CSBR)

4.5.4. Rotary Kiln Reactor

4.5.5. Auger Reactor

4.6. Type of Catalyst

4.6.1. Zeolite Catalyst

4.6.2. Fluid Catalytic Cracking (FCC) Catalyst

4.6.3. Bimetallic Catalyst

5. Physicochemical Properties of the Plastic Oil with and without Catalyst

| Physical Properties | No Catalyst [13] | FCC [118] | Natural Zeolite [147] | Kaolin [44] | Silica–Alumina [148] | Fly Ash [149] | Calcium Bentonite [130] | Gasoline [23] | Diesel [23] |

|---|---|---|---|---|---|---|---|---|---|

| Density @ 15 °C (g/cm3) | 0.860 | 0.752 | 0.868 | 0.800 | 0.770 | 0.800 | na | 0.780 | 0.807 |

| Viscosity (cSt) | 2.48 | 2.273 | 2.191 | 2.72 | 2.21 | 0.145 | 2.32 | 1.17 | 1.94.1 |

| Calorific Value (MJ/kg) | 40.42 | 43.28 | 45.58 | 46.479 | na | 41.93 | 43.28 | 42.5 | 43.5 |

| Octane Number | na | na | na | na | na | na | 81–85 | na | |

| Pour Point (°C) | 18 | −11 | 24 | −18 | na | na | na | 6 | |

| Flash Point (°C) | 35 | 29 | <10 | 40 | na | na | 42 | 52 | |

| Aniline Point (°C) | 60 | na | na | na | na | na | 71 | 77.5 | |

| API Gravity@ 60 °F | 38.1 | na | na | na | na | na | 55 | 38 | |

| Diesel Index | na | na | na | na | na | na | na | ||

| Moisture % vol | 2.4 | na | na | na | na | na | 0.4–0.5 | 0.1–0.3 |

6. Byproducts of the Catalytic Pyrolysis Process

6.1. Catalyst Effect on Solid Residue and Its Potential

6.2. Catalytic Effect on Gaseous Hydrocarbons and Its Potential

7. Future Challenges

- Design and development of the cost-effective and highly efficient pyrolysis reactor.

- Acquaint the main waste plastic pyrolysis reactor and its process.

- Understand the constraints and opportunities for improving product quality and yield via plastic pyrolysis.

- Development in the synthesis of the low-cost catalyst to enhance the plastic oil yield with upgradation.

- Development of both rapid pyrolysis and plastic-oil upgrading as long as both are aimed at producing useful and valuable products.

- Post-pyrolysis processing to increase the plastic-oil characteristics of the product.

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kaewbuddee, C.; Sukjit, E.; Srisertpol, J.; Maithomklang, S.; Wathakit, K.; Klinkaew, N.; Liplap, P.; Arjharn, W. Evaluation of Waste Plastic Oil-Biodiesel Blends as Alternative Fuels for Diesel Engines. Energies 2020, 13, 2823. [Google Scholar] [CrossRef]

- Jaganmohan, M. Fuel Market Consumption Volume in India 2011–2020; Arfica Rice Center: Cotonou, Benin, 2011. [Google Scholar]

- Pathak, S.K.; Nayyar, A.; Goel, V. Optimization of EGR Effects on Performance and Emission Parameters of a Dual Fuel (Diesel + CNG) CI Engine: An Experimental Investigation. Fuel 2021, 291, 120183. [Google Scholar] [CrossRef]

- Simsek, S.; Uslu, S.; Simsek, H.; Uslu, G. Improving the Combustion Process by Determining the Optimum Percentage of Liquefied Petroleum Gas (LPG) via Response Surface Methodology (RSM) in a Spark Ignition (SI) Engine Running on Gasoline-LPG Blends. Fuel Process. Technol. 2021, 221, 106947. [Google Scholar] [CrossRef]

- Atilhan, S.; Park, S.; El-Halwagi, M.M.; Atilhan, M.; Moore, M.; Nielsen, R.B. Green Hydrogen as an Alternative Fuel for the Shipping Industry. Curr. Opin. Chem. Eng. 2021, 31, 100668. [Google Scholar] [CrossRef]

- Saravanan, S.; Krishnamoorthy, N. Investigation on Reduction in Consequences of Adding Antioxidants into the Algae Biodiesel Blend as a CI Engine Fuel. Fuel 2020, 276, 117993. [Google Scholar] [CrossRef]

- Jha, K.K.; Kannan, T.T.M. Recycling of Plastic Waste into Fuel by Pyrolysis—A Review. Mater. Today Proc. 2020, 37, 3718–3720. [Google Scholar] [CrossRef]

- Khan, M.I.; Yasmin, T.; Shakoor, A. Technical Overview of Compressed Natural Gas (CNG) as a Transportation Fuel. Renew. Sustain. Energy Rev. 2015, 51, 785–797. [Google Scholar] [CrossRef]

- Chintala, V.; Subramanian, K.A. A Comprehensive Review on Utilization of Hydrogen in a Compression Ignition Engine under Dual Fuel Mode. Renew. Sustain. Energy Rev. 2017, 70, 472–491. [Google Scholar] [CrossRef]

- Kumar Sharma, A.; Kumar Ghodke, P.; Manna, S.; Chen, W.-H. Emerging Technologies for Sustainable Production of Biohydrogen Production from Microalgae: A State-of-the-Art Review of Upstream and Downstream Processes. Bioresour. Technol. 2021, 342, 126057. [Google Scholar] [CrossRef]

- Chen, H.; Xie, B.; Ma, J.; Chen, Y. NOx Emission of Biodiesel Compared to Diesel: Higher or Lower? Appl. Therm. Eng. 2018, 137, 584–593. [Google Scholar] [CrossRef]

- Armenise, S.; SyieLuing, W.; Ramírez-Velásquez, J.M.; Launay, F.; Wuebben, D.; Ngadi, N.; Rams, J.; Muñoz, M. Plastic Waste Recycling via Pyrolysis: A Bibliometric Survey and Literature Review. J. Anal. Appl. Pyrolysis 2021, 158, 105265. [Google Scholar] [CrossRef]

- Ghodke, P.K. High-Quality Hydrocarbon Fuel Production from Municipal Mixed Plastic Waste Using a Locally Available Low-Cost Catalyst. Fuel Commun. 2021, 8, 100022. [Google Scholar] [CrossRef]

- Sarkar, A.; Praveen, G. Utilization of Waste Biomass into Useful Forms of Energy. In Biofuels and Bioenergy; Springer: Cham, Switzerland, 2017; pp. 117–132. [Google Scholar]

- Silveira, A.V.M.; Cella, M.; Tanabe, E.H.; Bertuol, D.A. Application of Tribo-Electrostatic Separation in the Recycling of Plastic Wastes. Process Saf. Environ. Prot. 2018, 114, 219–228. [Google Scholar] [CrossRef]

- Bonifazi, G.; Capobianco, G.; Serranti, S. A Hierarchical Classification Approach for Recognition of Low-Density (LDPE) and High-Density Polyethylene (HDPE) in Mixed Plastic Waste Based on Short-Wave Infrared (SWIR) Hyperspectral Imaging. Spectrochim. Acta—Part A Mol. Biomol. Spectrosc. 2018, 198, 115–122. [Google Scholar] [CrossRef]

- Anuar Sharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A Review on Pyrolysis of Plastic Wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Ghodke, P.K.; Sharma, A.K.; Pandey, J.K.; Chen, W.-H.; Patel, A.; Ashokkumar, V. Pyrolysis of Sewage Sludge for Sustainable Biofuels and Value-Added Biochar Production. J. Environ. Manag. 2021, 298, 113450. [Google Scholar] [CrossRef]

- Donaj, P.J.; Kaminsky, W.; Buzeto, F.; Yang, W. Pyrolysis of Polyolefins for Increasing the Yield of Monomers’ Recovery. Waste Manag. 2012, 32, 840–846. [Google Scholar] [CrossRef]

- Onwudili, J.A.; Insura, N.; Williams, P.T. Composition of Products from the Pyrolysis of Polyethylene and Polystyrene in a Closed Batch Reactor: Effects of Temperature and Residence Time. J. Anal. Appl. Pyrolysis 2009, 86, 293–303. [Google Scholar] [CrossRef]

- Marcilla, A.; Beltrán, M.I.; Navarro, R. Thermal and Catalytic Pyrolysis of Polyethylene over HZSM5 and HUSY Zeolites in a Batch Reactor under Dynamic Conditions. Appl. Catal. B Environ. 2009, 86, 78–86. [Google Scholar] [CrossRef]

- Fakhrhoseini, S.M.; Dastanian, M. Predicting Pyrolysis Products of PE, PP, and PET Using NRTL Activity Coefficient Model. J. Chem. 2013, 2013, 7–9. [Google Scholar] [CrossRef]

- Ahmad, I.; Ismail Khan, M.; Khan, H.; Ishaq, M.; Tariq, R.; Gul, K.; Ahmad, W. Pyrolysis Study of Polypropylene and Polyethylene Into Premium Oil Products. Int. J. Green Energy 2015, 12, 663–671. [Google Scholar] [CrossRef]

- Cepeliogullar, O.; Putun, A.E. Utilization of Two Different Types of Plastic Wastes from Daily and Industrial Life. J. Selcuk Univ. Nat. Appl. Sci. 2013, 2, 694–706. [Google Scholar]

- Miranda, R.; Yang, J.; Roy, C.; Vasile, C. Vacuum Pyrolysis of PVC I. Kinetic Study. Polym. Degrad. Stab. 1999, 64, 127–144. [Google Scholar] [CrossRef]

- Chintala, V.; Godkhe, P.; Phadtare, S.; Tadpatrikar, M.; Pandey, J.K.; Kumar, S. A Comparative Assessment of Single Cylinder Diesel Engine Characteristics with Plasto-Oils Derived from Municipal Mixed Plastic Waste. Energy Convers. Manag. 2018, 166, 579–589. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Yang, Y.; Wang, J.; Leeke, G.A. Pyro-Oil and Wax Recovery from Reclaimed Plastic Waste in a Continuous Auger Pyrolysis Reactor. Energies 2020, 13, 2040. [Google Scholar] [CrossRef] [Green Version]

- Singh, R.K.; Ruj, B. Time and Temperature Depended Fuel Gas Generation from Pyrolysis of Real World Municipal Plastic Waste. Fuel 2016, 174, 164–171. [Google Scholar] [CrossRef]

- Suriapparao, D.V.; Kumar, D.A.; Vinu, R. Microwave Co-Pyrolysis of PET Bottle Waste and Rice Husk: Effect of Plastic Waste Loading on Product Formation. Sustain. Energy Technol. Assess. 2022, 49, 101781. [Google Scholar] [CrossRef]

- Chattopadhyay, J.; Pathak, T.S.; Srivastava, R.; Singh, A.C. Catalytic Co-Pyrolysis of Paper Biomass and Plastic Mixtures (HDPE (High Density Polyethylene), PP (Polypropylene) and PET (Polyethylene Terephthalate)) and Product Analysis. Energy 2016, 103, 513–521. [Google Scholar] [CrossRef]

- Bhoi, P.R.; Rahman, M.H. Hydrocarbons Recovery through Catalytic Pyrolysis of Compostable and Recyclable Waste Plastics Using a Novel Desk-Top Staged Reactor. Environ. Technol. Innov. 2022, 27, 102453. [Google Scholar] [CrossRef]

- Rahman, M.H.; Bhoi, P.R.; Saha, A.; Patil, V.; Adhikari, S. Thermo-Catalytic Co-Pyrolysis of Biomass and High-Density Polyethylene for Improving the Yield and Quality of Pyrolysis Liquid. Energy 2021, 225, 120231. [Google Scholar] [CrossRef]

- Wijayanti, H.; Irawan, C.; Aulia, N. Copyrolysis of Rice Husk and Plastic Bags Waste from Low-Density Polyethylene (LDPE) for Improving Pyrolysis Liquid Product. IOP Conf. Ser. Earth Environ. Sci. 2022, 963, 012012. [Google Scholar] [CrossRef]

- Janajreh, I.; Adeyemi, I.; Elagroudy, S. Gasification Feasibility of Polyethylene, Polypropylene, Polystyrene Waste and Their Mixture: Experimental Studies and Modeling. Sustain. Energy Technol. Assess. 2020, 39, 100684. [Google Scholar] [CrossRef]

- Hakeem, I.G.; Aberuagba, F.; Musa, U. Catalytic Pyrolysis of Waste Polypropylene Using Ahoko Kaolin from Nigeria. Appl. Petrochem. Res. 2018, 8, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Burra, K.G.; Wang, Z.; Li, J.; Che, D.; Gupta, A.K. On Deconvolution for Understanding Synergistic Effects in Co-Pyrolysis of Pinewood and Polypropylene. Appl. Energy 2020, 279, 115811. [Google Scholar] [CrossRef]

- Bai, B.; Wang, W.; Jin, H. Experimental Study on Gasification Performance of Polypropylene (PP) Plastics in Supercritical Water. Energy 2020, 191, 116527. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, C.; Bai, B.; Jin, H.; Wei, W. Study on the Polystyrene Plastic Degradation in Supercritical Water/CO2 Mixed Environment and Carbon Fixation of Polystyrene Plastic in CO2 Environment. J. Hazard. Mater. 2022, 421, 126763. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.; Ahmad, N.; Maafa, I.M.; Ahmed, U.; Akhter, P.; Shehzad, N.; Amjad, U.E.S.; Hussain, M. Thermal Conversion of Polystyrene Plastic Waste to Liquid Fuel via Ethanolysis. Fuel 2020, 279, 118498. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, G.; Zhu, J.; Wang, Y.; Yang, H.; Jin, L.; Hu, H. Insight into Synergistic Effect of Co-Pyrolysis of Low-Rank Coal and Waste Polyethylene with or without Additives Using Rapid Infrared Heating. J. Energy Inst. 2022, 102, 384–394. [Google Scholar] [CrossRef]

- Duque, J.V.F.; Martins, M.F.; Debenest, G.; Orlando, M.T.D.A. The Influence of the Recycling Stress History on LDPE Waste Pyrolysis. Polym. Test. 2020, 86, 106460. [Google Scholar] [CrossRef]

- Wei, Y.; Fakudze, S.; Zhang, Y.; Ma, R.; Shang, Q.; Chen, J.; Liu, C.; Chu, Q. Co-Hydrothermal Carbonization of Pomelo Peel and PVC for Production of Hydrochar Pellets with Enhanced Fuel Properties and Dechlorination. Energy 2022, 239, 122350. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, J.; Wang, G.; Wang, H.; Sun, M. Thermal and Kinetic Analysis of Coal with Different Waste Plastics (PVC) in Cocombustion. Energy Fuels 2018, 32, 2145–2155. [Google Scholar] [CrossRef]

- Mansor, W.N.W.; Razali, N.A.; Abdullah, S.; Jarkoni, M.N.K.; Sharin, A.B.E.; Abd Kadir, N.H.; Ramli, A.; Chao, H.R.; Lin, S.L.; Jalaludin, J. A Review of Plastic-Derived Diesel Fuel as a Renewable Fuel for Internal Combustion Engines: Application, Challanges and Global Potential 2021. IOP Conf. Ser. Earth Environ. Sci. 2022, 1013, 012014. [Google Scholar] [CrossRef]

- Kasar, P.; Sharma, D.K.; Ahmaruzzaman, M. Thermal and Catalytic Decomposition of Waste Plastics and Its Co-Processing with Petroleum Residue through Pyrolysis Process. J. Clean. Prod. 2020, 265, 121639. [Google Scholar] [CrossRef]

- Mortezaeikia, V.; Tavakoli, O. Thermogravimetric Kinetics of Catalytic and Non-Catalytic Microwave-Assisted Pyrolysis of Waste Abs Plastic. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Lazzarotto, I.P.; Ferreira, S.D.; Junges, J.; Bassanesi, G.R.; Manera, C.; Perondi, D.; Godinho, M. The Role of CaO in the Steam Gasification of Plastic Wastes Recovered from the Municipal Solid Waste in a Fluidized Bed Reactor. Process Saf. Environ. Prot. 2020, 140, 60–67. [Google Scholar] [CrossRef]

- PCB Annual Report for the Year 2018–19 on Implementation of Plastic Waste Management Rules. Cent. Pollut. Control. Board 2019, 17, 1–18.

- Global Plastics Production Forecast 2025–2050; Statista: Singapore, 2022.

- Kaminsky, W.; Schmidt, H.; Simon, C.M. Recycling of Mixed Plastics by Pyrolysis in a Fluidised Bed. Macromol. Symp. 2000, 152, 191–199. [Google Scholar] [CrossRef]

- Obeid, F.; Zeaiter, J.; Al-Muhtaseb, A.H.; Bouhadir, K. Thermo-Catalytic Pyrolysis of Waste Polyethylene Bottles in a Packed Bed Reactor with Different Bed Materials and Catalysts. Energy Convers. Manag. 2014, 85, 1–6. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P. Conventional Pyrolysis of Plastic Waste for Product Recovery and Utilization of Pyrolytic Gases for Carbon Nanotubes Production. Environ. Sci. Pollut. Res. 2022, 29, 20007–20016. [Google Scholar] [CrossRef]

- Chintala, V.; Kumar, S.S.; Pandey, J.K.J.K.; Sharma, A.K.A.K.; Kumar, S.S. Solar Thermal Pyrolysis of Non-Edible Seeds to Biofuels and Their Feasibility Assessment. Energy Convers. Manag. 2017, 153, 482–492. [Google Scholar] [CrossRef]

- Suriapparao, D.V.; Boruah, B.; Raja, D.; Vinu, R. Microwave Assisted Co-Pyrolysis of Biomasses with Polypropylene and Polystyrene for High Quality Bio-Oil Production. Fuel Process. Technol. 2018, 175, 64–75. [Google Scholar] [CrossRef]

- Sivagami, K.; Divyapriya, G.; Selvaraj, R. Catalytic Pyrolysis of Polyolefin and Multilayer Packaging Based Waste Plastics: A Pilot Scale Study. Process Saf. Environ. Prot. 2021, 149, 497–506. [Google Scholar] [CrossRef]

- Rajendran, K.M.; Chintala, V.; Sharma, A.; Pal, S.; Pandey, J.K.J.K.; Ghodke, P.; Moorthy Rajendran, K.; Chintala, V.; Sharma, A.; Pal, S.; et al. Review of Catalyst Materials in Achieving the Liquid Hydrocarbon Fuels from Municipal Mixed Plastic Waste (MMPW). Mater. Today Commun. 2020, 24, 100982. [Google Scholar] [CrossRef]

- Sipra, A.T.; Gao, N.; Sarwar, H. Municipal Solid Waste (MSW) Pyrolysis for Bio-Fuel Production: A Review of Effects of MSW Components and Catalysts. Fuel Process. Technol. 2018, 175, 131–147. [Google Scholar] [CrossRef]

- Lu, J.S.; Chang, Y.; Poon, C.S.; Lee, D.J. Slow Pyrolysis of Municipal Solid Waste (MSW): A Review. Bioresour. Technol. 2020, 312, 123615. [Google Scholar] [CrossRef]

- Sogancioglu, M.; Yel, E.; Ahmetli, G. Pyrolysis of Waste High Density Polyethylene (HDPE) and Low Density Polyethylene (LDPE) Plastics and Production of Epoxy Composites with Their Pyrolysis Chars. J. Clean. Prod. 2017, 165, 369–381. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Rashid, U.; Khalina, A.; Ilyas, R.A. Pyrolysis of Polypropylene Plastic Waste into Carbonaceous Char: Priority of Plastic Waste Management amidst COVID-19 Pandemic. Sci. Total Environ. 2022, 803, 149911. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. The Effect of Slow Pyrolysis on the Conversion of Packaging Waste Plastics (PE and PP) into Fuel. Waste Manag. 2018, 79, 615–624. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P. Impact of Fast and Slow Pyrolysis on the Degradation of Mixed Plastic Waste: Product Yield Analysis and Their Characterization. J. Energy Inst. 2019, 92, 1647–1657. [Google Scholar] [CrossRef]

- Hussein, Z.A.; Shakor, Z.M.; Alzuhairi, M.; Al-Sheikh, F. Thermal and Catalytic Cracking of Plastic Waste: A Review. Int. J. Environ. Anal. Chem. 2021, 1–18. [Google Scholar] [CrossRef]

- Lubongo, C.; Congdon, T.; McWhinnie, J.; Alexandridis, P. Economic Feasibility of Plastic Waste Conversion to Fuel Using Pyrolysis. Sustain. Chem. Pharm. 2022, 27, 100683. [Google Scholar] [CrossRef]

- Sharuddin, S.D.A.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. Pyrolysis of Plastic Waste for Liquid Fuel Production as Prospective Energy Resource. IOP Conf. Ser. Mater. Sci. Eng. 2018, 334, 012001. [Google Scholar] [CrossRef]

- Kataki, R.; Bordoloi, N.J.; Saikia, R.; Sut, D.; Narzari, R.; Gogoi, L.; Bhuyan, N. Waste Valorization to Fuel and Chemicals Through Pyrolysis: Technology, Feedstock, Products, and Economic Analysis. In Waste to Wealth; Springer: Singapore, 2018; pp. 477–514. [Google Scholar] [CrossRef]

- Fang, S.; Gu, W.; Chen, L.; Yu, Z.; Dai, M.; Lin, Y.; Liao, Y.; Ma, X. Ultrasonic Pretreatment Effects on the Co-Pyrolysis of Municipal Solid Waste and Paper Sludge through Orthogonal Test. Bioresour. Technol. 2018, 258, 5–11. [Google Scholar] [CrossRef] [PubMed]

- Hafeez, S.; Pallari, E.; Manos, G.; Constantinou, A. Catalytic Conversion and Chemical Recovery; Elsevier Inc.: Amsterdam, The Netherlands, 2018; ISBN 9780128131404. [Google Scholar]

- Chen, W.H.; Cheng, C.L.; Lee, K.T.; Lam, S.S.; Ong, H.C.; Ok, Y.S.; Saeidi, S.; Sharma, A.K.; Hsieh, T.H. Catalytic Level Identification of ZSM-5 on Biomass Pyrolysis and Aromatic Hydrocarbon Formation. Chemosphere 2021, 271, 129510. [Google Scholar] [CrossRef] [PubMed]

- Muhammad, C.; Onwudili, J.A.; Williams, P.T. Thermal Degradation of Real-World Waste Plastics and Simulated Mixed Plastics in a Two-Stage Pyrolysis–Catalysis Reactor for Fuel Production. Energy Fuels 2015, 29, 2601–2609. [Google Scholar] [CrossRef]

- Zhou, N.; Dai, L.; Lyu, Y.; Wang, Y.; Li, H.; Cobb, K.; Chen, P.; Lei, H.; Ruan, R. A Structured Catalyst of ZSM-5/SiC Foam for Chemical Recycling of Waste Plastics via Catalytic Pyrolysis. Chem. Eng. J. 2022, 440, 135836. [Google Scholar] [CrossRef]

- Mangesh, V.L.; Padmanabhan, S.; Tamizhdurai, P.; Ramesh, A. Experimental Investigation to Identify the Type of Waste Plastic Pyrolysis Oil Suitable for Conversion to Diesel Engine Fuel. J. Clean. Prod. 2020, 246, 119066. [Google Scholar] [CrossRef]

- Chen, D.; Yin, L.; Wang, H.; He, P. Pyrolysis Technologies for Municipal Solid Waste: A Review. Waste Manag. 2014, 34, 2466–2486. [Google Scholar] [CrossRef] [PubMed]

- Onwudili, J.A.; Muhammad, C.; Williams, P.T. Influence of Catalyst Bed Temperature and Properties of Zeolite Catalysts on Pyrolysis-Catalysis of a Simulated Mixed Plastics Sample for the Production of Upgraded Fuels and Chemicals. J. Energy Inst. 2019, 92, 1337–1347. [Google Scholar] [CrossRef]

- Muneer, B.; Zeeshan, M.; Qaisar, S.; Razzaq, M.; Iftikhar, H. Influence of In-Situ and Ex-Situ HZSM-5 Catalyst on Co-Pyrolysis of Corn Stalk and Polystyrene with a Focus on Liquid Yield and Quality. J. Clean. Prod. 2019, 237, 117762. [Google Scholar] [CrossRef]

- Scheirs, J. Overview of Commercial Pyrolysis Processes for Waste Plastics. In Feedstock Recycling and Pyrolysis of Waste Plastics: Converting Waste Plastics into Diesel and Other Fuels; John Wiley: Hoboken, NJ, USA, 2006; pp. 381–433. [Google Scholar] [CrossRef]

- Mahdavi, H.; Eden, N.T.; Doherty, C.M.; Acharya, D.; Smith, S.J.D.; Mulet, X.; Hill, M.R. Underlying Polar and Nonpolar Modification MOF-Based Factors That Influence Permanent Porosity in Porous Liquids. ACS Appl. Mater. Interfaces 2022, 14, 23392–23399. [Google Scholar] [CrossRef] [PubMed]

- Kalargaris, I.; Tian, G.; Gu, S. The Utilisation of Oils Produced from Plastic Waste at Different Pyrolysis Temperatures in a DI Diesel Engine. Energy 2017, 131, 179–185. [Google Scholar] [CrossRef]

- Mastral, F.J.; Esperanza, E.; Garciía, P.; Juste, M. Pyrolysis of High-Density Polyethylene in a Fluidised Bed Reactor. Influence of the Temperature and Residence Time. J. Anal. Appl. Pyrolysis 2002, 63, 1–15. [Google Scholar] [CrossRef]

- Susastriawan, A.A.P.; Sandria, A. Experimental Study the Influence of Zeolite Size on Low-Temperature Pyrolysis of Low-Density Polyethylene Plastic Waste. Therm. Sci. Eng. Prog. 2020, 17, 100497. [Google Scholar] [CrossRef]

- Adnan; Shah, J.; Jan, M.R. Effect of Polyethylene Terephthalate on the Catalytic Pyrolysis of Polystyrene: Investigation of the Liquid Products. J. Taiwan Inst. Chem. Eng. 2015, 51, 96–102. [Google Scholar] [CrossRef]

- Osman, Y.; Yansaneh, S.H.Z. Recent Advances on Waste Plastic Thermal Pyrolysis: A Critical Overview. Processes 2022, 10, 332. [Google Scholar]

- Lopez, G.; Amutio, M.; Elordi, G.; Artetxe, M.; Altzibar, H.; Olazar, M. A Conical Spouted Bed Reactor for the Valorisation of Waste Tires. In Proceedings of the 13th International Conference on Fluidization—New Paradigm in Fluidization Engineering, Gyeong-Ju, Korea, 16–21 May 2010. [Google Scholar]

- Krishnamoorthy, V.; Dhanasekaran, R.; Rana, D.; Saravanan, S.; Rajesh Kumar, B. A Comparative Assessment of Ternary Blends of Three Bio-Alcohols with Waste Cooking Oil and Diesel for Optimum Emissions and Performance in a CI Engine Using Response Surface Methodology. Energy Convers. Manag. 2018, 156, 337–357. [Google Scholar] [CrossRef]

- Ghodke, P.; Krishna, S.V. Effect of Heterogeneous Catalyst on Esterification of Pyrolysis Oil. In Springer Proceeding in Energy; Springer: Cham, Switzerland, 2018; pp. 219–229. [Google Scholar]

- Kalargaris, I.; Tian, G.; Gu, S. Experimental Evaluation of a Diesel Engine Fuelled by Pyrolysis Oils Produced from Low-Density Polyethylene and Ethylene–Vinyl Acetate Plastics. Fuel Process. Technol. 2017, 161, 125–131. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Antelava, A.; Constantinou, A.; Manos, G.; Dutta, A. A Review on Thermal and Catalytic Pyrolysis of Plastic Solid Waste (PSW). J. Environ. Manag. 2017, 197, 177–198. [Google Scholar] [CrossRef]

- Musale, H.K.; Bhattacharyulu, Y.C.; Bhoyar, R.K.; Student, P.G.; Professor, A. Design Consideration Of Pyrolysis Reactor For Production Of Bio-Oil. Int. J. Eng. Trends Technol. 2013, 5, 83–85. [Google Scholar]

- Hasan, M.M.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Jahirul, M.I. Energy Recovery from Municipal Solid Waste Using Pyrolysis Technology: A Review on Current Status and Developments. Renew. Sustain. Energy Rev. 2021, 145, 111073. [Google Scholar] [CrossRef]

- Fogler, H.S. Elements of Chemical Reaction Engineering; Printice-Hall International Editions: Hoboken, NJ, USA, 2016; ISBN 9780133887518. [Google Scholar]

- Palomar-Torres, A.; Torres-Jimenez, E.; Kegl, B.; Bombek, G.; Volmajer-Valh, J.; Lešnik, L. Catalytic Pyrolysis of Plastic Wastes for Liquid Oils’ Production Using ZAP USY Zeolite as a Catalyst. Int. J. Environ. Sci. Technol. 2022, 1–14. [Google Scholar] [CrossRef]

- Luo, W.; Fan, Z.; Wan, J.; Hu, Q.; Dong, H.; Zhang, X. Study on the Reusability of Kaolin as Catalysts for Catalytic Pyrolysis of Low-Density Polyethylene. Fuel 2021, 302, 121164. [Google Scholar] [CrossRef]

- Mohabeer, C.; Guilhaume, N.; Laurenti, D.; Schuurman, Y. Microwave-Assisted Pyrolysis of Biomass with and without Use of Catalyst in a Fluidised Bed Reactor: A Review. Energies 2022, 15, 3258. [Google Scholar] [CrossRef]

- Elordi, G.; Olazar, M.; Lopez, G.; Amutio, M.; Artetxe, M.; Aguado, R.; Bilbao, J. Catalytic Pyrolysis of HDPE in Continuous Mode over Zeolite Catalysts in a Conical Spouted Bed Reactor. J. Anal. Appl. Pyrolysis 2009, 85, 345–351. [Google Scholar] [CrossRef]

- Fernandez, E.; Santamaria, L.; Amutio, M.; Artetxe, M.; Arregi, A.; Lopez, G.; Bilbao, J.; Olazar, M. Role of Temperature in the Biomass Steam Pyrolysis in a Conical Spouted Bed Reactor. Energy 2022, 238, 122053. [Google Scholar] [CrossRef]

- Arabiourrutia, M.; Elordi, G.; Lopez, G.; Borsella, E.; Bilbao, J.; Olazar, M. Characterization of the Waxes Obtained by the Pyrolysis of Polyolefin Plastics in a Conical Spouted Bed Reactor. J. Anal. Appl. Pyrolysis 2012, 94, 230–237. [Google Scholar] [CrossRef]

- Fantozzi, F.; Colantoni, S.; Bartocci, P.; Desideri, U. Rotary Kiln Slow Pyrolysis for Syngas and Char Production From Biomass and Waste. J. Eng. Gas Turbines Power. 2007, 129, 901–907. [Google Scholar] [CrossRef]

- Park, K.B.; Choi, M.J.; Chae, D.Y.; Jung, J.; Kim, J.S. Separate Two-Step and Continuous Two-Stage Pyrolysis of a Waste Plastic Mixture to Produce a Chlorine-Depleted Oil. Energy 2022, 244, 122583. [Google Scholar] [CrossRef]

- Butler, E.; Devlin, G.; Meier, D.; McDonnell, K. A Review of Recent Laboratory Research and Commercial Developments in Fast Pyrolysis and Upgrading. Renew. Sustain. Energy Rev. 2011, 15, 4171–4186. [Google Scholar] [CrossRef] [Green Version]

- Lin, H.T.; Huang, M.S.; Luo, J.W.; Lin, L.H.; Lee, C.M.; Ou, K.L. Hydrocarbon Fuels Produced by Catalytic Pyrolysis of Hospital Plastic Wastes in a Fluidizing Cracking Process. Fuel Process. Technol. 2010, 91, 1355–1363. [Google Scholar] [CrossRef]

- Yang, R.-X.; Jan, K.; Chen, C.-T.; Chen, W.-T.; Wu, K.C.-W. Thermochemical Conversion of Plastic Waste into Fuels, Chemicals, and Value-Added Materials: A Critical Review and Outlooks. ChemSusChem 2022, e202200171. [Google Scholar] [CrossRef]

- Rasul Jan, M.; Shah, J.; Gulab, H. Catalytic Conversion of Waste High-Density Polyethylene into Useful Hydrocarbons. Fuel 2013, 105, 595–602. [Google Scholar] [CrossRef]

- Ruhul, A.M.; Kalam, M.A.; Masjuki, H.H.; Fattah, I.M.R.; Reham, S.S.; Rashed, M.M. State of the Art of Biodiesel Production Processes: A Review of the Heterogeneous Catalyst. RSC Adv. 2015, 5, 101023–101044. [Google Scholar] [CrossRef]

- Yansaneh, O.Y.; Zein, S.H. Latest Advances in Waste Plastic Pyrolytic Catalysis. Processes 2022, 10, 683. [Google Scholar] [CrossRef]

- Figueiredo, A.L.; Araujo, A.S.; Linares, M.; Peral, Á.; García, R.A.; Serrano, D.P.; Fernandes, V.J. Catalytic Cracking of LDPE over Nanocrystalline HZSM-5 Zeolite Prepared by Seed-Assisted Synthesis from an Organic-Template-Free System. J. Anal. Appl. Pyrolysis 2016, 117, 132–140. [Google Scholar] [CrossRef]

- Ubando, A.T.; Chueh, C.-C.; Jin, L.; Belbessai, S.; Azara, A.; Abatzoglou, N. Recent Advances in the Decontamination and Upgrading of Waste Plastic Pyrolysis Products: An Overview. Processes 2022, 10, 733. [Google Scholar] [CrossRef]

- Inayat, A.; Klemencova, K.; Grycova, B.; Sokolova, B.; Lestinsky, P. Thermo-Catalytic Pyrolysis of Polystyrene in Batch and Semi-Batch Reactors: A Comparative Study. Waste Manag. Res. 2021, 39, 260–269. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Y.; Sun, Z. Application of CoNi Intercalated Vermiculite Catalyst in Pyrolysis of Plastic. J. Phys. Conf. Ser. 2021, 1885, 032030. [Google Scholar]

- Panda, A.K. Thermo-Catalytic Degradation of Different Plastics to Drop in Liquid Fuel Using Calcium Bentonite Catalyst. Int. J. Ind. Chem. 2018, 9, 167–176. [Google Scholar] [CrossRef] [Green Version]

- Kumagai, S.; Hasegawa, I.; Grause, G.; Kameda, T.; Yoshioka, T. Thermal Decomposition of Individual and Mixed Plastics in the Presence of CaO or Ca(OH)2. J. Anal. Appl. Pyrolysis 2015, 113, 584–590. [Google Scholar] [CrossRef]

- Lopez-Urionabarrenechea, A.; de Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Adrados, A. Catalytic Stepwise Pyrolysis of Packaging Plastic Waste. J. Anal. Appl. Pyrolysis 2012, 96, 54–62. [Google Scholar] [CrossRef]

- Senthil Kumar, P.; Bharathikumar, M.; Prabhakaran, C.; Vijayan, S.; Ramakrishnan, K. Conversion of Waste Plastics into Low-Emissive Hydrocarbon Fuels through Catalytic Depolymerization in a New Laboratory Scale Batch Reactor. Int. J. Energy Environ. Eng. 2017, 8, 167–173. [Google Scholar] [CrossRef] [Green Version]

- Kassargy, C.; Awad, S.; Burnens, G.; Kahine, K.; Tazerout, M. Gasoline and Diesel-like Fuel Production by Continuous Catalytic Pyrolysis of Waste Polyethylene and Polypropylene Mixtures over USY Zeolite. Fuel 2018, 224, 764–773. [Google Scholar] [CrossRef]

- Sangpatch, T.; Supakata, N.; Kanokkantapong, V.; Jongsomjit, B. Fuel Oil Generated from the Cogon Grass-Derived Al–Si (Imperata cylindrica (L.) Beauv) Catalysed Pyrolysis of Waste Plastics. Heliyon 2019, 5, e02324. [Google Scholar] [CrossRef] [Green Version]

- Lei, J.; Yuan, G.; Weerachanchai, P.; Lee, S.W.; Li, K.; Wang, J.Y.; Yang, Y. Investigation on Thermal Dechlorination and Catalytic Pyrolysis in a Continuous Process for Liquid Fuel Recovery from Mixed Plastic Wastes. J. Mater. Cycles Waste Manag. 2018, 20, 137–146. [Google Scholar] [CrossRef]

- Costa, P.; Pinto, F.; Mata, R.; Marques, P.; Paradela, F.; Costa, L. Validation of the Application of the Pyrolysis Process for the Treatment and Transformation of Municipal Plastic Wastes. Chem. Eng. Trans. 2021, 86, 859–864. [Google Scholar]

- Fekhar, B.; Gombor, L.; Miskolczi, N. Pyrolysis of Chlorine Contaminated Municipal Plastic Waste: In-Situ Upgrading of Pyrolysis Oils by Ni/ZSM-5, Ni/SAPO-11, Red Mud and Ca(OH)2 Containing Catalysts. J. Energy Inst. 2019, 92, 1270–1283. [Google Scholar] [CrossRef]

- Zhou, N.; Dai, L.; Lyu, Y.; Li, H.; Deng, W.; Guo, F.; Chen, P.; Lei, H.; Ruan, R. Catalytic Pyrolysis of Plastic Wastes in a Continuous Microwave Assisted Pyrolysis System for Fuel Production. Chem. Eng. J. 2021, 418, 129412. [Google Scholar] [CrossRef]

- Hedlund, J.; Zhou, M.; Faisal, A.; Öhrman, O.G.W.; Finelli, V.; Signorile, M.; Crocellà, V.; Grahn, M. Controlling Diffusion Resistance, Selectivity and Deactivation of ZSM-5 Catalysts by Crystal Thickness and Defects. J. Catal. 2022, 410, 320–332. [Google Scholar] [CrossRef]

- Ateş, F.; Miskolczi, N.; Borsodi, N. Comparision of Real Waste (MSW and MPW) Pyrolysis in Batch Reactor over Different Catalysts. Part I: Product Yields, Gas and Pyrolysis Oil Properties. Bioresour. Technol. 2013, 133, 443–454. [Google Scholar] [CrossRef]

- Fadillah, G.; Fatimah, I.; Sahroni, I.; Musawwa, M.M.; Mahlia, T.M.I.; Muraza, O. Recent Progress in Low-Cost Catalysts for Pyrolysis of Plastic Waste to Fuels. Catalysts 2021, 11, 837. [Google Scholar] [CrossRef]

- Wong, S.L.; Ngadi, N.; Abdullah, T.A.T.; Inuwa, I.M. Conversion of Low Density Polyethylene (LDPE) over ZSM-5 Zeolite to Liquid Fuel. Fuel 2017, 192, 71–82. [Google Scholar] [CrossRef]

- Sivagami, K.; Kumar, K.V.; Tamizhdurai, P.; Govindarajan, D.; Kumar, M.; Nambi, I. Conversion of Plastic Waste into Fuel Oil Using Zeolite Catalysts in a Bench-Scale Pyrolysis Reactor. RSC Adv. 2022, 12, 7612–7620. [Google Scholar] [CrossRef]

- Kim, J.Y.; Heo, S.; Choi, J.W. Effects of Phenolic Hydroxyl Functionality on Lignin Pyrolysis over Zeolite Catalyst. Fuel 2018, 232, 81–89. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.A.; Aburiazaiza, A.S.; Rehan, M.; Nizami, A.S. Catalytic Pyrolysis of Plastic Waste: A Review. Process Saf. Environ. Prot. 2016, 102, 822–838. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.S. Catalytic Pyrolysis of Plastic Waste: Moving toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7, 27. [Google Scholar] [CrossRef] [Green Version]

- Subhaschandra, T.; Nath, T.; Neeranjan, H. A Lab Scale Waste to Energy Conversion Study for Pyrolysis of Plastic with and without Catalyst: Engine Emissions Testing Study. Fuel 2020, 277, 118176. [Google Scholar] [CrossRef]

- Saeaung, K.; Phusunti, N.; Phetwarotai, W.; Assabumrungrat, S.; Cheirsilp, B. Catalytic Pyrolysis of Petroleum-Based and Biodegradable Plastic Waste to Obtain High-Value Chemicals. Waste Manag. 2021, 127, 101–111. [Google Scholar] [CrossRef] [PubMed]

- Palos, R.; Rodríguez, E.; Gutiérrez, A.; Bilbao, J.; Arandes, J.M. Cracking of Plastic Pyrolysis Oil over FCC Equilibrium Catalysts to Produce Fuels: Kinetic Modeling. Fuel 2022, 316, 123341. [Google Scholar] [CrossRef]

- Aisien, E.T.; Otuya, I.C.; Aisien, F.A. Thermal and Catalytic Pyrolysis of Waste Polypropylene Plastic Using Spent FCC Catalyst. Environ. Technol. Innov. 2021, 22, 101455. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Haghighi, M.N.; Yeganeh, H. Evaluation of Pyrolysis Product of Virgin High Density Polyethylene Degradation Using Different Process Parameters in a Stirred Reactor. Fuel Process. Technol. 2013, 109, 90–95. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Haghighi, M.N.; Yeganeh, H.; McDonald, A.G. Evaluation of Pyrolysis Process Parameters on Polypropylene Degradation Products. J. Anal. Appl. Pyrolysis 2014, 109, 272–277. [Google Scholar] [CrossRef]

- Orozco, S.; Artetxe, M.; Lopez, G.; Suarez, M.; Bilbao, J.; Olazar, M. Conversion of HDPE into Value Products by Fast Pyrolysis Using FCC Spent Catalysts in a Fountain Confined Conical Spouted Bed Reactor. ChemSusChem 2021, 14, 4291–4300. [Google Scholar] [CrossRef] [PubMed]

- Wen, X.; Chen, X.; Tian, N.; Gong, J.; Liu, J.; Rümmeli, M.H.; Chu, P.K.; Mijiwska, E.; Tang, T. Nanosized Carbon Black Combined with Ni2O3 as “Universal” Catalysts for Synergistically Catalyzing Carbonization of Polyolefin Wastes to Synthesize Carbon Nanotubes and Application for Supercapacitors. Environ. Sci. Technol. 2014, 48, 4048–4055. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Yu, J.; Ma, C.; Bikane, K.; Sun, L. Catalytic Performance and Debromination of Fe–Ni Bimetallic MCM-41 Catalyst for the Two-Stage Pyrolysis of Waste Computer Casing Plastic. Chemosphere 2020, 248, 125964. [Google Scholar] [CrossRef]

- Han, J.; Xiong, Z.; Zhang, Z.; Zhang, H.; Zhou, P.; Yu, F. The Influence of Texture on Co/SBA–15 Catalyst Performance for Fischer–Tropsch Synthesis. Catalysts 2019, 8, 661. [Google Scholar] [CrossRef] [Green Version]

- Sridhar, A.; Rahman, M.; Infantes-Molina, A.; Wylie, B.J.; Borcik, C.G.; Khatib, S.J. Bimetallic Mo-Co/ZSM-5 and Mo-Ni/ZSM-5 Catalysts for Methane Dehydroaromatization: A Study of the Effect of Pretreatment and Metal Loadings on the Catalytic Behavior. Appl. Catal. A Gen. 2020, 589, 117247. [Google Scholar] [CrossRef]

- Zhou, H.; Saad, J.M.; Li, Q.; Xu, Y. Steam Reforming of Polystyrene at a Low Temperature for High H2/CO Gas with Bimetallic Ni-Fe/ZrO2 Catalyst. Waste Manag. 2020, 104, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.; Sun, J.; Abbas, M.; Wang, P.; Chen, Y.; Chen, J. Hydrophobic SiO2 Supported Fe-Ni Bimetallic Catalyst for the Production of High-Calorie Synthetic Natural Gas. Appl. Catal. A Gen. 2020, 590, 117302. [Google Scholar] [CrossRef]

- Damodharan, D.; Rajesh Kumar, B.; Gopal, K.; De Poures, M.V.; Sethuramasamyraja, B. Utilization of Waste Plastic Oil in Diesel Engines: A Review. Rev. Environ. Sci. Biotechnol. 2019, 18, 681–697. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sahoo, P.K.; Singhal, S.; Joshi, G. Exploration of Upstream and Downstream Process for Microwave Assisted Sustainable Biodiesel Production from Microalgae Chlorella Vulgaris. Bioresour. Technol. 2016, 216, 793–800. [Google Scholar] [CrossRef] [PubMed]

- Khan, K.; Kumar, G.; Sharma, A.K.; Kumar, P.S.; Mandal, C.; Chintala, V. Performance and Emission Characteristics of a Diesel Engine Using Complementary Blending of Castor and Karanja Biodiesel. Biofuels 2018, 9, 53–60. [Google Scholar] [CrossRef]

- Chintala, V.; Sharma, A.K.; Karn, A.; Vardhan, H.; Pandey, J.K. Utilization of Biomass-Derived Pyro-Oils in Compression Ignition (CI) Engines–Recent Developments. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 27, 1–5. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sharma, P.K.; Chintala, V.; Khatri, N.; Patel, A. Environment-Friendly Biodiesel/Diesel Blends for Improving the Exhaust Emission and Engine Performance to Reduce the Pollutants Emitted from Transportation Fleets. Int. J. Environ. Res. Public Health 2020, 17, 3896. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Sahoo, P.K.; Singhal, S. Comparative Evolution of Biomass Production and Lipid Accumulation Potential of Chlorella Species Grown in a Bubble Column Photobioreactor. Biofuels 2016, 7, 389–399. [Google Scholar] [CrossRef]

- Sharma, A.K.; Sharma, A.; Singh, Y.; Chen, W.H. Production of a Sustainable Fuel from Microalgae Chlorella Minutissima Grown in a 1500 L Open Raceway Ponds. Biomass Bioenergy 2021, 149, 106073. [Google Scholar] [CrossRef]

- Syamsiro, M.; Saptoadi, H.; Norsujianto, T.; Noviasri, P.; Cheng, S.; Alimuddin, Z.; Yoshikawa, K. Fuel Oil Production from Municipal Plastic Wastes in Sequential Pyrolysis and Catalytic Reforming Reactors. Energy Procedia 2014, 47, 180–188. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.J.; Park, Y.K.; Jeong, K.E.; Kim, T.W.; Chae, H.J.; Park, S.H.; Jeon, J.K.; Kim, S.S. Catalytic Degradation of Polyethylene over SBA-16. Korean J. Chem. Eng. 2010, 27, 1446–1451. [Google Scholar] [CrossRef]

- Nalluri, P.; Prem Kumar, P.; Ch Sastry, M.R. Experimental Study on Catalytic Pyrolysis of Plastic Waste Using Low Cost Catalyst. Mater. Today Proc. 2020, 45, 7216–7221. [Google Scholar] [CrossRef]

- Thahir, R.; Altway, A.; Juliastuti, S.R. Susianto Production of Liquid Fuel from Plastic Waste Using Integrated Pyrolysis Method with Refinery Distillation Bubble Cap Plate Column. Energy Rep. 2019, 5, 70–77. [Google Scholar] [CrossRef]

- Ratnasari, D.K.; Nahil, M.A.; Williams, P.T. Catalytic Pyrolysis of Waste Plastics Using Staged Catalysis for Production of Gasoline Range Hydrocarbon Oils. J. Anal. Appl. Pyrolysis 2017, 124, 631–637. [Google Scholar] [CrossRef]

- Sembiring, F.; Purnomo, C.W.; Purwono, S. Catalytic Pyrolysis of Waste Plastic Mixture Catalytic Pyrolysis of Waste Plastic Mixture. IOP Conf. Ser. Mater. Sci. Eng. 2018, 316, 012020. [Google Scholar] [CrossRef]

- Qiu, B.; Deng, N.; Zhang, Y.; Wan, H. Application of Industrial Solid Wastes in Catalytic Pyrolysis. Asia-Pacific J. Chem. Eng. 2018, 13, e2150. [Google Scholar] [CrossRef]

- Jamradloedluk, J.; Lertsatitthanakorn, C. Characterization and Utilization of Char Derived from Fast Pyrolysis of Plastic Wastes. Procedia Eng. 2014, 69, 1437–1442. [Google Scholar] [CrossRef] [Green Version]

- López, A.; de Marco, I.; Caballero, B.M.; Adrados, A.; Laresgoiti, M.F. Deactivation and Regeneration of ZSM-5 Zeolite in Catalytic Pyrolysis of Plastic Wastes. Waste Manag. 2011, 31, 1852–1858. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.H.; Cho, M.H.; Kang, B.S.; Kim, J.S. Pyrolysis of a Fraction of Waste Polypropylene and Polyethylene for the Recovery of BTX Aromatics Using a Fluidized Bed Reactor. Fuel Process. Technol. 2010, 91, 277–284. [Google Scholar] [CrossRef]

- Leng, S.; Wang, X.; Wang, J.; Liu, Y.; Ma, F.; Zhong, X. Waste Tire Pyrolysis for the Production of Light Hydrocarbons over Layered Catalysts. Energy Technol. 2015, 3, 851–855. [Google Scholar] [CrossRef]

| Type of Plastic | Fixed Carbon (%) | Moisture Content (%) | Ash (%) | Volatile Matter (%) | References |

|---|---|---|---|---|---|

| PET | 14.5 | NA | 0.7 | 84.8 | [29] |

| PET | 13.9 | NA | NA | 84.1 | [30] |

| HDPE | NA | NA | 0.8 | 97.15 | [30] |

| HDPE | 16.85 | NA | NA | 83.15 | [31] |

| HDPE | 0.00 | 0.00 | 0.01 | 99.99 | [32] |

| LDPE | 0.68 | 0.30 | 3.37 | 95.61 | [33] |

| LDPE | 0.051 | 0.11 | 0.023 | 99.816 | [34] |

| PP | 1.62 | 0.16 | 4.45 | 93.77 | [35] |

| PP | 1.0 | NA | NA | 96.9 | [30] |

| PP | 0.5 | NA | 0.00 | 99.5 | [36] |

| PP | 0.43 | 0.29 | 0.00 | 99.28 | [37] |

| PS | 1.05 | 0.32 | 0.09 | 98.54 | [38] |

| PS | 0.22 | 0.00 | 0.00 | 99.78 | [39] |

| PS | 0.071 | 0.09 | 0.025 | 99.814 | [34] |

| PE | 0.07 | NA | NA | 99.93 | [40] |

| PE | 0.00 | 0.2 | 0.4 | 99.4 | [41] |

| PVC | 1.97 | 0.65 | 0.11 | 97.92 | [42] |

| PVC | 4.10 | 0.00 | 0.01 | 95.89 | [43] |

| PA | 0.69 | 0.00 | 0.00 | 99.7 | [44] |

| ABS | 0.04 | 0.10 | 0.99 | 98.87 | [45] |

| ABS | 9.6 | 0.00 | 13.6 | 76.8 | [46] |

| PBT | 2.88 | 0.16 | 0.00 | 97.12 | [45] |

| MPW | 5.34 | 0.86 | 1.21 | 93.45 | [13] |

| MPW | 3.5 | 0.00 | 3.3 | 93.2 | [47] |

| Name of Pyrolysis | Temperature Range | Residence Time | Heating Rate (°C/s) | Feed Stock Size (mm) | Liquid (wt.%) | Solid (wt.%) | Gases (wt.%) |

|---|---|---|---|---|---|---|---|

| Slow pyrolysis | 300–700 °C | 10–100 min | 0.1–1 | 5–50 | 30 | 35 | 35 |

| Fast pyrolysis | 400–800 °C | 0.5–2 s | 10–100 | <3 | 40–70 | 15–25 | 10–20 |

| Flash pyrolysis | 700–1200 °C or above | <0.5 s | 1000 | <0.2 | 10–20 | 10–15 | 60–80 |

| Feedstock | Reactor Type | Heating Rate (°C min−1) | Reaction Temperature (°C) | Concentration of Catalyst | Type of Catalyst | Reaction Products | References | ||

|---|---|---|---|---|---|---|---|---|---|

| Liquid Hydrocarbons | Solid Residue | Gaseous Hydrocarbons | |||||||

| PS | Batch Reactor | 10 | 500 | Pelletized | MgO | 88 | 10 | 2 | [107] |

| Plastic waste (PS+PE) | TL- 200 Tube furnace | 10 | 480 | 10% | Organic vermiculite | 80.6 | 0.1 | 19.4 | [108] |

| PS+PE | TL-200 Tube furnace | 10 | 480 | 10% | Co/Vermiculites | 73.2 | 0.1 | 26.7 | [108] |

| PS+PE (Plastic waste) | TL-200 Tube furnace | 10 | 480 | 10% | Ni/Vermiculites | 70.7 | 1.3 | 28.0 | [108] |

| PS+PE (Plastic waste) | TL-200 Tube furnace | 10 | 480 | 10% | Co-Ni/Vermiculites | 73.9 | 0.1 | 26.0 | [108] |

| PP+LDPE+ HDPE | Batch reactor | 20 | 500 | 33.3% | Calcium bentonite | 81.3 | 12.7 | 6 | [109] |

| PP+PE+PS+PET | Vertical tube reactor | 600 | 100% | Ca(OH)2 | 52.2 | 9.0 | 27.7 | [110] | |

| PP+PE+PS+PET | Vertical tube reactor | 600 | 100% | Cao | 46.7 | 31.8 | 17.6 | [110] | |

| Mixed plastic waste | Semi-batch reactor | 20 | 440 20 °C/min | 10% | ZSM-5 | 56.9 | 3.2 | 40.4 | [111] |

| Mixed plastic | Batch reactor | - | 240 | - | Activated carbon | 82.43 | 15.22 | 2.35 | [112] |

| Mixed plastic | Batch reactor | - | 240 | - | Charcoal | 95.54 | 2.33 | 2.13 | [112] |

| Mixed plastic | Vertical reactor | - | 500 | 10% | USY-Zeolite | 70–80 | [113] | ||

| Mixed plastic waste | Batch glass reactor | 5 | 350 | 10% | Al–Si | 93.11 | 9.27 | 0.36 | [114] |

| Mixed plastic waste | Stirred tank reactor | 10 | 450 | 1.65 kg/h 60 g catalyst (36.36%) | Fe-restructured clay | 83.73 | [115] | ||

| Mixed plastic waste | Vertical tube reactor | 20 | 500 | - | CaCO3 | 68 | 5.7 | 26.3 | [52] |

| Mixed plastic waste | Fixed-batch reactor | 5.5 | 400 | - | - | 86 | 8 | 6 | [116] |

| Mixed plastic waste | Fixed-bed reactor | 10 | 600 | 10% | FCC | 69 | 28 | 3 | [74] |

| Mixed plastic waste | Batch reactor | 15 | 510 | 5% 1:1:2 | Red mud: Ca(OH): Ni/SAPO | 64.2–71.9 | - | - | [117] |

| Mixed plastic waste | Continuous microwave-assisted pyrolysis system | - | 620 | 10% pelletized form | ZSM-5 | 48.9 | - | 49.0 | [118] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pal, S.; Kumar, A.; Sharma, A.K.; Ghodke, P.K.; Pandey, S.; Patel, A. Recent Advances in Catalytic Pyrolysis of Municipal Plastic Waste for the Production of Hydrocarbon Fuels. Processes 2022, 10, 1497. https://doi.org/10.3390/pr10081497

Pal S, Kumar A, Sharma AK, Ghodke PK, Pandey S, Patel A. Recent Advances in Catalytic Pyrolysis of Municipal Plastic Waste for the Production of Hydrocarbon Fuels. Processes. 2022; 10(8):1497. https://doi.org/10.3390/pr10081497

Chicago/Turabian StylePal, Shashank, Anil Kumar, Amit Kumar Sharma, Praveen Kumar Ghodke, Shyam Pandey, and Alok Patel. 2022. "Recent Advances in Catalytic Pyrolysis of Municipal Plastic Waste for the Production of Hydrocarbon Fuels" Processes 10, no. 8: 1497. https://doi.org/10.3390/pr10081497

APA StylePal, S., Kumar, A., Sharma, A. K., Ghodke, P. K., Pandey, S., & Patel, A. (2022). Recent Advances in Catalytic Pyrolysis of Municipal Plastic Waste for the Production of Hydrocarbon Fuels. Processes, 10(8), 1497. https://doi.org/10.3390/pr10081497