Grid-Based Employee Safety Behavior Risk Assessment of the Train Operation Department

Abstract

:1. Introduction

2. Literature Review

3. Grid Management Method

3.1. Safety Behavior Risk Characteristics of the Train Operation Department

3.1.1. Heterogeneity

3.1.2. Uncertainty

3.1.3. Coupling

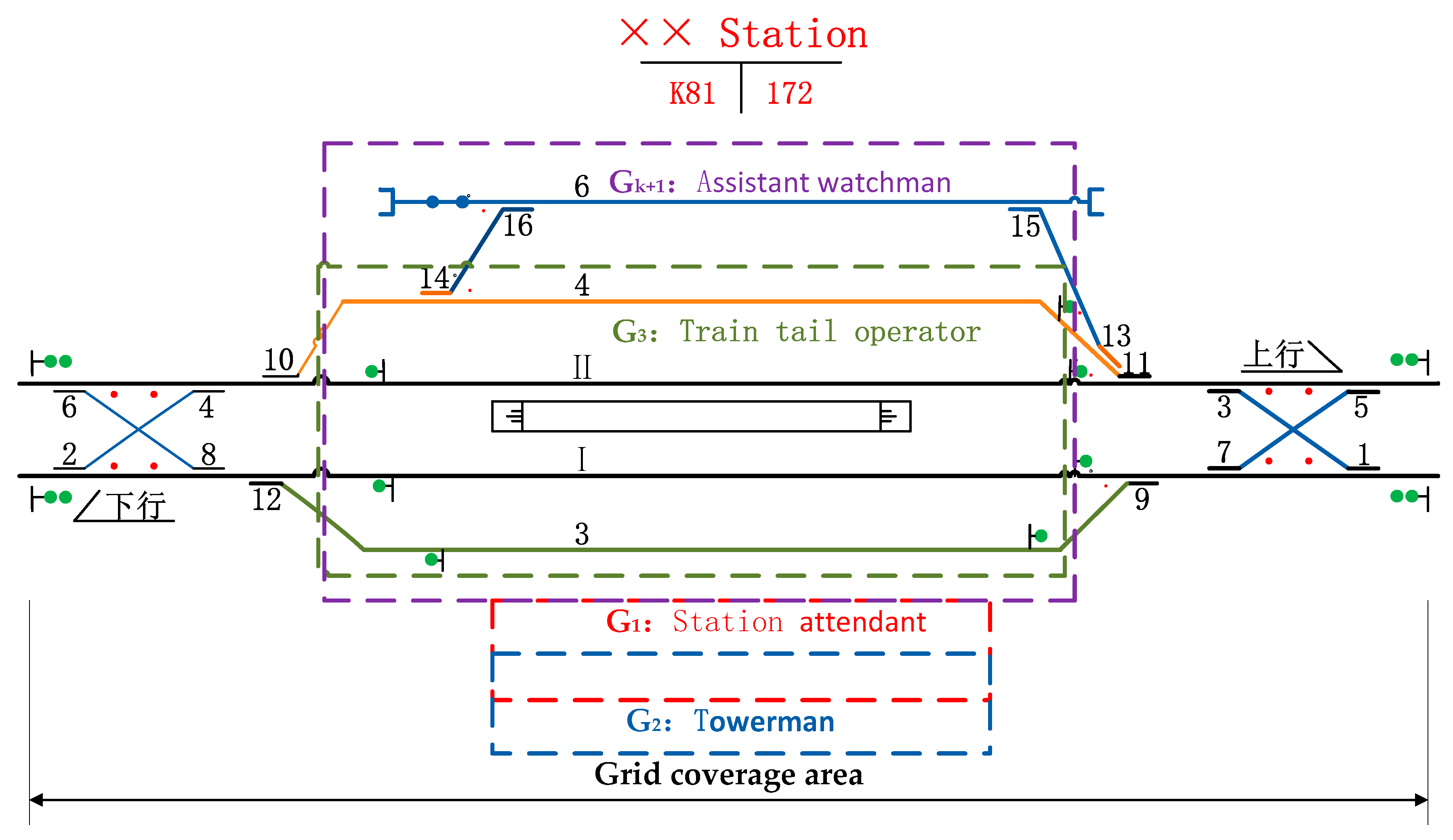

3.2. Grid Definition and Coding of the Train Operation Department

3.2.1. Grid Definition and Division Method

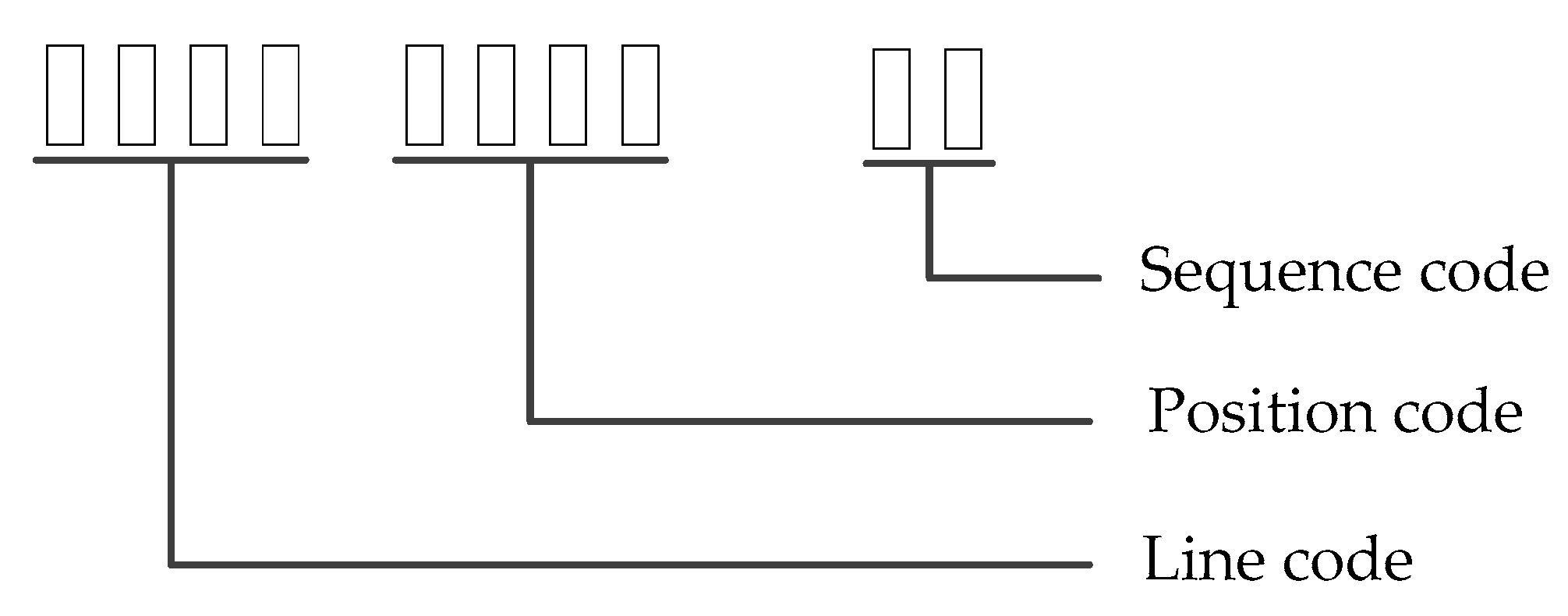

3.2.2. Grid Coding Rule

3.3. Definition and Coding of Grid Elements

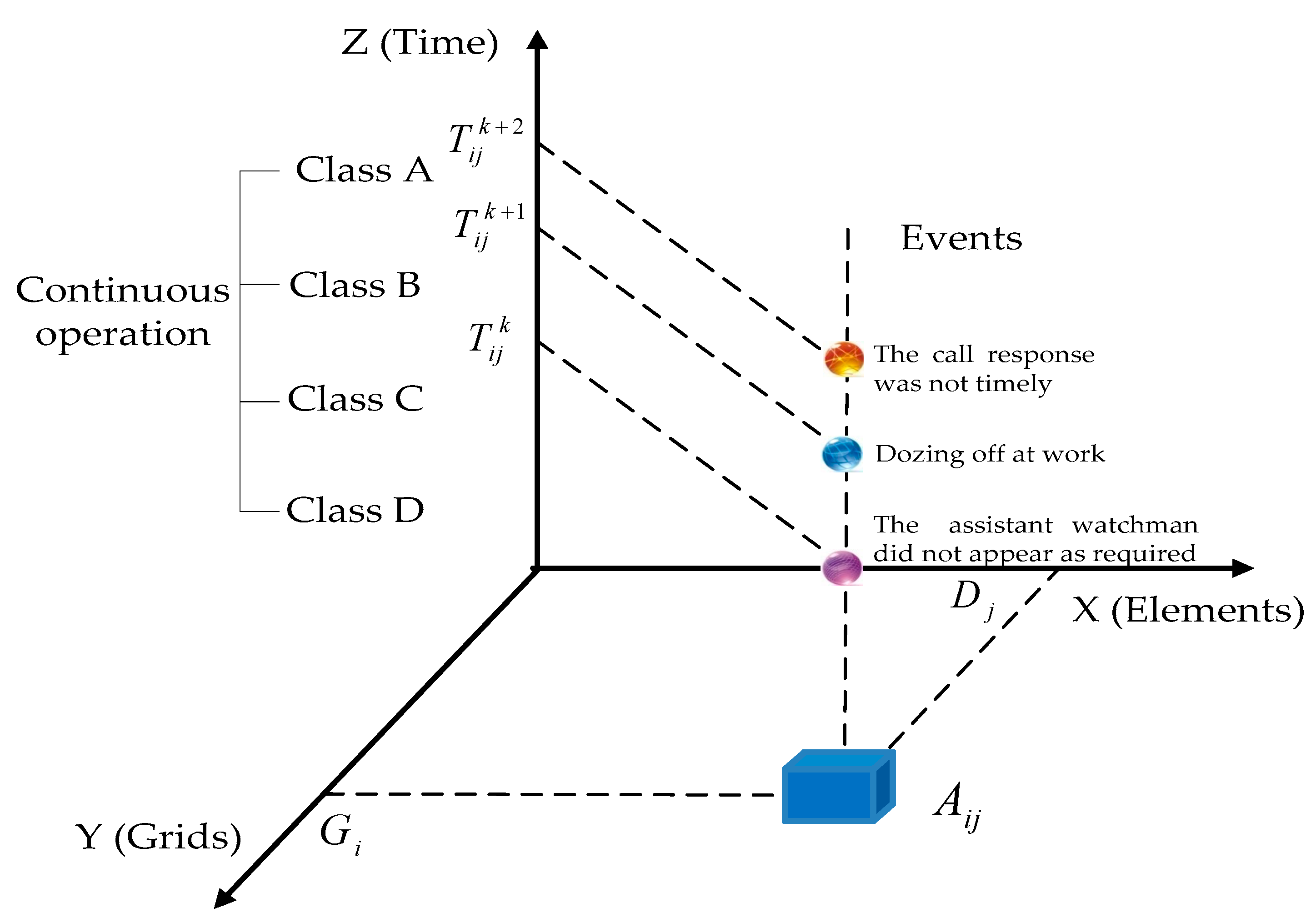

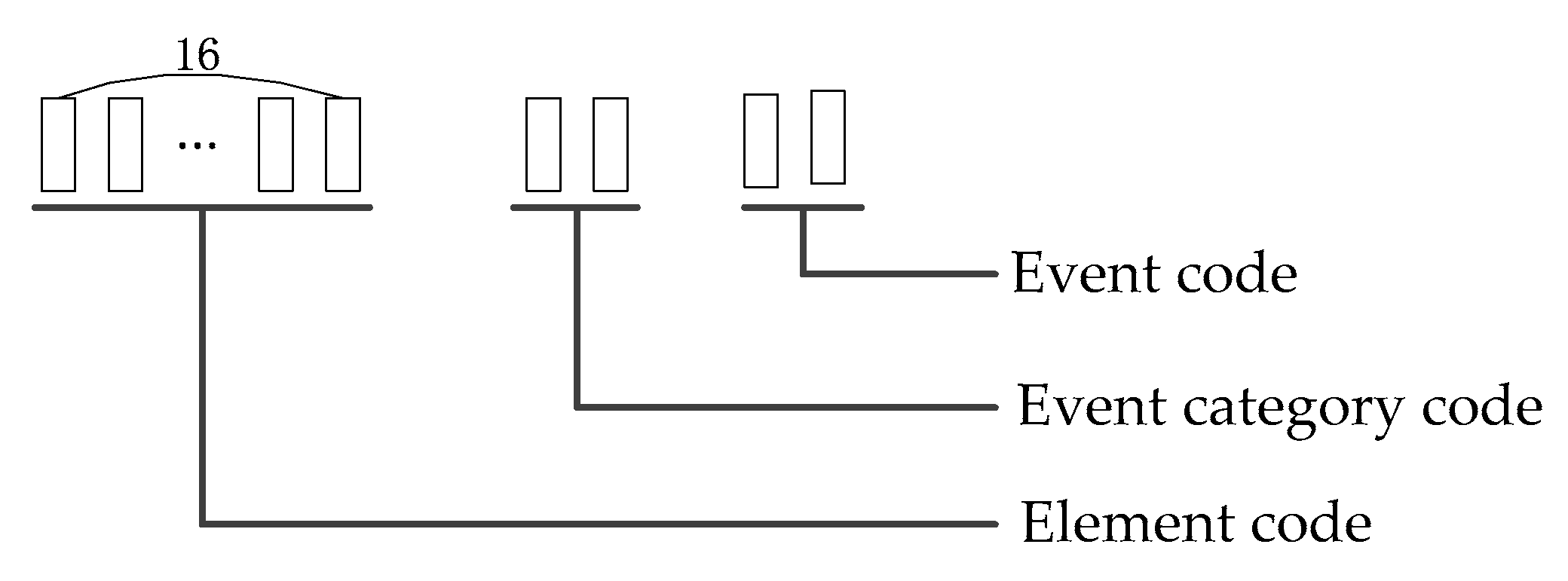

3.4. Definition and Encoding of Grid Events

4. Risk Assessment Model

4.1. Model Architecture

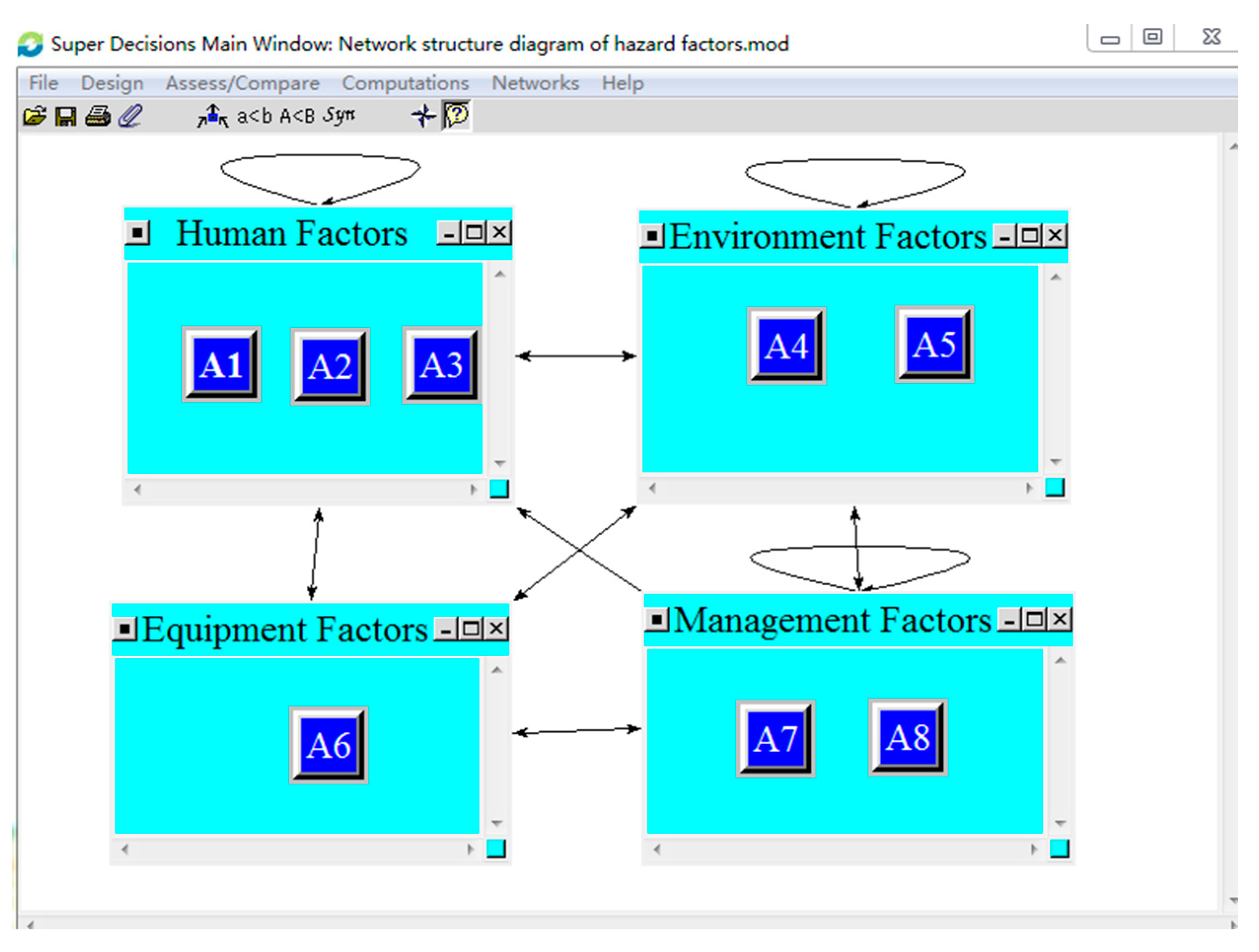

4.2. Identification of Hazard Factors

4.3. Risk Analysis of Single Grid

4.3.1. Risk Assessment Criteria

4.3.2. Weight of the Hazard Factor

4.3.3. Probability of Risk Event

4.3.4. Risk Level Calculation

4.4. Risk Evaluation of Single Grid

5. Case Study

5.1. Data Preparation

5.1.1. Data Source

5.1.2. Experts Selection

5.2. Hazard Factor Identification of “the Assistant Watchman Did Not Appear as Required” Scenario

5.3. Risk Analysis of “the Assistant Watchman Did Not Appear as Required” Scenario

5.3.1. Probability Calculation

5.3.2. Severity Calculation

5.3.3. Risk Magnitude Calculation

6. Discussion

6.1. Traditional Two-Dimensional Risk Assessment Results

6.2. Improved Two-Dimensional Risk Matrix Assessment Results Analysis

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, J.; Lei, Y. Paths between latent and active errors: Analysis of 407 railway accidents/incidents’ causes in China. Saf. Sci. 2018, 110, 47–58. [Google Scholar] [CrossRef]

- Kyriakidis, M.; Majumdar, A.; Ochieng, W.Y. Data based framework to identify the most significant performance shaping factors in railway operations. Saf. Sci. 2015, 78, 60–76. [Google Scholar] [CrossRef]

- Yin, W.; Fu, G.; Yang, C.; Jiang, Z.; Zhu, K.; Gao, Y. Fatal gas explosion accidents on Chinese coal mines and the characteristics of unsafe behaviors: 2000–2014. Saf. Sci. 2017, 92, 173–179. [Google Scholar] [CrossRef]

- Zhan, Q.; Zheng, W.; Zhao, B. A hybrid human and organizational analysis method for railway accidents based on HFACS-Railway Accidents (HFACS-RAs). Saf. Sci. 2017, 91, 232–250. [Google Scholar] [CrossRef]

- Baysari, M.T.; McIntosh, A.S.; Wilson, J.R. Understanding the human factors contribution to railway accidents and incidents in Australia. Accid. Anal. Prev. 2008, 40, 1750–1757. [Google Scholar] [CrossRef] [PubMed]

- Uğurlu, Ö.; Yıldız, S.; Loughney, S.; Wang, J. Modified human factor analysis and classification system for passenger vessel accidents (HFACS-PV). Ocean Eng. 2018, 161, 47–61. [Google Scholar] [CrossRef] [Green Version]

- Xing, Y.; Dissanayake, S.; Lu, J.; Long, S.; Lou, Y. An analysis of escalator-related injuries in metro stations in China, 2013–2015. Accid. Anal. Prev. 2017, 122, 332–341. [Google Scholar] [CrossRef]

- Liu, R.; Cheng, W.; Yu, Y.; Xu, Q.; Jiang, A.; Lv, T. An impacting factors analysis of miners’ unsafe acts based on HFACS-CM and SEM. Process Saf. Environ. Prot. 2019, 122, 221–231. [Google Scholar] [CrossRef]

- Tan, S.; Moinuddin, K. Systematic review of human and organizational risks for probabilistic risk analysis in high-rise buildings. Reliab. Eng. Syst. Saf. 2019, 188, 233–250. [Google Scholar] [CrossRef]

- Al-Sakkaf, A.; Ahmed, R.; Afifi, M. Risk Assessment Model for Heritage Buildings: Case Study of Yemen. J. Archit. Eng. 2020, 27, 04021009. [Google Scholar] [CrossRef]

- Huang, W.; Yin, D.; Xu, Y.; Zhang, R.; Xu, M. Using N-K Model to quantitatively calculate the variability in Functional Resonance Analysis Method. Reliab. Eng. Syst. Saf. 2022, 217, 108058. [Google Scholar] [CrossRef]

- Huang, W.; Shuai, B.; Sun, Y. Study on Coupling Risk Formation Mechanism of Railway Dangerous Goods Transportation System Based on N-K Model. Tiedao Xuebao J. China Railw. Soc. 2019, 41, 1–9. [Google Scholar]

- Kyriakidis, M.; Majumdar, A.; Ochieng, W.Y. The human performance railway operational index—A novel approach to assess human performance for railway operations. Reliab. Eng. Syst. Saf. 2018, 170, 226–243. [Google Scholar] [CrossRef]

- Lei, B.; Sun, Q.; Liu, R.; Wang, F.; Wang, F. A Segment-Based Model for Estimating the Service Life of Railway Rails. In Proceedings of the Cota International Conference of Transportation Professionals, Beijing, China, 25–27 July 2015. [Google Scholar]

- Liu, R.; Lei, B.; Wang, F.; Sun, Q.; Wang, F. Grid: A New Theory for High-Speed Railway Infrastructure Management. In Proceedings of the Transportation Research Board 94th Annual Meeting, Washington, DC, USA, 11–15 January 2015. [Google Scholar]

- Lei, B.; Zhang, Q.; Liu, R.; Wang, F.; Song, X. Grid-Based Framework for Railway Track Health Evaluation. In Proceedings of the International Conference on Green Intelligent Transportation System and Safety, Guilin, China, 1–3 July 2018. [Google Scholar]

- Lei, B.; Rengkui, L.; Feng, W.; Sun, Q. Estimating railway rail service life: A rail-grid-based approach. Transp. Res. Part A Policy Pract. 2017, 105, 54–65. [Google Scholar]

- Fan, X. Research and Thinking on Grid Service and Management of Community in City S. Procedia Eng. 2017, 174, 1177–1181. [Google Scholar] [CrossRef]

- Ghofrani, F.; He, Q.; Goverde, R.; Liu, X. Recent applications of big data analytics in railway transportation systems: A survey. Transp. Res. Part C Emerg. Technol. 2018, 90, 226–246. [Google Scholar] [CrossRef]

- Liu, P.; Yang, L.; Gao, Z.; Li, S.; Gao, Y. Fault tree analysis combined with quantitative analysis for high-speed railway accidents. Saf. Sci. 2015, 79, 344–357. [Google Scholar] [CrossRef]

- Huang, W.; Liu, Y.; Zhang, Y.; Xu, M.; Dieu, G.J.; Antwi, E. Fault Tree and Fuzzy D-S Evidential Reasoning combined approach: An application in railway dangerous goods transportation system accident analysis. Inf. Sci. 2020, 520, 117–129. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, Y.; Zuo, B.; Yu, Y.; Dieu, G.J.; Xu, Y. Using an expanded Safety Failure Event Network to analyze railway dangerous goods transportation system risk-accident. J. Loss Prev. Process Ind. 2020, 65, 104122. [Google Scholar] [CrossRef]

- Ćirović, G.; Pamučar, D. Decision support model for prioritizing railway level crossings for safety improvements: Application of the adaptive neuro-fuzzy system. Expert. Syst. Appl. 2013, 40, 2208–2223. [Google Scholar] [CrossRef]

- Klockner, K.; Toft, Y. Railway accidents and incidents: Complex socio-technical system accident modelling comes of age. Saf. Sci. 2018, 110, 59–66. [Google Scholar] [CrossRef]

- Zhu, Y.; He, G.; Zhu, X.; Qiao, G.; Zhang, G.; Heng, L. Research on Factors Affecting Employees Security Behavior Based on Structural Equation Model. Int. J. Secur. Appl. 2015, 9, 375–384. [Google Scholar] [CrossRef]

- Hsieh, M.; Wang, E.M.; Lee, W.; Li, L.; Hsieh, C.; Tsai, W.; Wang, C.; Huang, J.; Liu, T. Application of HFACS, fuzzy TOPSIS, and AHP for identifying important human error factors in emergency departments in Taiwan. Int. J. Ind. Ergon. 2018, 67, 171–179. [Google Scholar] [CrossRef]

- Qiao, W.; Liu, Q.; Li, X.; Luo, X.; Wan, Y. Using data mining techniques to analyze the influencing factor of unsafe behaviors in Chinese underground coal mines. Resour. Policy 2018, 59, 210–216. [Google Scholar] [CrossRef]

- Chai, N.; Zhou, W. Evaluating operational risk for train control system using A Revised Risk Matrix and FD-FAHP-Cloud model: A case in China. Eng. Fail. Anal. 2022, 137, 106268. [Google Scholar] [CrossRef]

- Fejdyś, M.; Wlazeł, S.; Kusiak, E.; Kaczmarek, K.; Nepelski, M.; Lubiewski, P.; Kuczyńska, E.; Jakubczyk, R.; Kamiński, G.; Foryś, Ł.; et al. Mathematical Algorithm for Risk Assessment of Police Officer in VR Training Simulation. Appl. Sci. 2022, 12, 2169. [Google Scholar] [CrossRef]

- ISO Guide 73:2009; Risk Management—Vocabulary. ISO: Geneva, Switzerland, 2009.

- Li, G. A study on the engineering geological coupling theory. J. Eng. Geol. 2001, 9, 435–442. [Google Scholar]

- Xue, Y.; Liu, Y.; Zhang, T. Research on formation mechanism of coupled disaster risk. J. Nat. Dis. 2013, 22, 44–50. [Google Scholar]

- Zhang, Y. Selecting risk response strategies considering project risk interdependence. Int. J. Proj. Manag. 2016, 34, 819–830. [Google Scholar] [CrossRef] [Green Version]

- Fregnan, E.; Baum, T.; Palomba, F.; Bacchelli, A. A survey on software coupling relations and tools. Inf. Softw. Technol. 2019, 107, 159–178. [Google Scholar] [CrossRef] [Green Version]

- Jiang, S.; Fan, H. Credit risk contagion coupling with sentiment contagion. Phys. A 2018, 512, 186–202. [Google Scholar] [CrossRef]

- He, H.; Dou, L.; Gong, S.; He, J.; Zheng, Y.; Zhang, X. Microseismic and electromagnetic coupling method for coal bump risk assessment based on dynamic static energy principles. Saf. Sci. 2019, 114, 30–39. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, Q. Risk Assessment of Shunting Derailment Based on Coupling. Symmetry 2019, 11, 1359. [Google Scholar] [CrossRef] [Green Version]

- IEC 31010-2009; Risk Management–Risk Assessment Techniques. ISO: Geneva, Switzerland, 2009.

- Huang, W.; Shuai, B.; Zhang, G. Improved WBS-RBS based identification of risks in railway transportation of dangerous goods. China Saf. Sci. J. 2018, 28, 93. [Google Scholar]

- Huang, W.; Shuai, B.; Zuo, B.; Xu, Y.; Antwi, E. A systematic railway dangerous goods transportation system risk analysis approach: The 24 model. J. Loss Prev. Process Ind. 2019, 61, 94–103. [Google Scholar] [CrossRef]

- Williams, T.M. The two-dimensionality of project risk. Int. J. Proj. Manag. 1996, 14, 185–186. [Google Scholar] [CrossRef]

- Hong, Y.; Pasman, H.J.; Quddus, N.; Mannan, M. Supporting risk management decision making by converting linguistic graded qualitative risk matrices through Interval Type-2 Fuzzy Sets. Process Saf. Environ. Prot. 2019, 134, 308–322. [Google Scholar] [CrossRef]

- Abrahamsen, E.B.; Abrahamsen, H.B.; Milazzo, M.F.; Selvik, J.T. Using the ALARP principle for safety management in the energy production sector of chemical industry. Reliab. Eng. Syst. Saf. 2018, 169, 160–165. [Google Scholar] [CrossRef]

- Kheybari, S.; Rezaie, F.M.; Farazmand, H. Analytic network process: An overview of applications. Appl. Math. Comput. 2020, 367, 124780. [Google Scholar] [CrossRef]

- Farias LM, S.; Santos, L.C.; Gohr, C.F.; Rocha, L.O. An ANP-based approach for lean and green performance assessment. Resour. Conserv. Recycl. 2019, 143, 77–89. [Google Scholar] [CrossRef]

- Cayir Ervural, B.; Zaim, S.; Demirel, O.F.; Aydin, Z.; Delen, D. An ANP and fuzzy TOPSIS-based SWOT analysis for Turkey’s energy planning. Renew. Sust. Energy Rev. 2018, 82, 1538–1550. [Google Scholar] [CrossRef]

- Arsić, S.; Nikolić, D.; Mihajlović, I.; Fedajev, A.; Zivkovic, Z. A New Approach within ANP-SWOT Framework for Prioritization of Ecosystem Management and Case Study of National Park Djerdap, Serbia. Ecol. Econ. 2018, 146, 85–95. [Google Scholar] [CrossRef]

- Ghaemi Rad, T.; Sadeghi-Niaraki, A.; Abbasi, A.; Choi, S. A methodological framework for assessment of ubiquitous cities using ANP and DEMATEL methods. Sust. Cities Soc. 2018, 37, 608–618. [Google Scholar] [CrossRef]

| Sequence Number | Grid | Post | Area Coverage | Area (m2) |

|---|---|---|---|---|

| 1 | Station attendant | North–south direction: k81 + 169 m–k81 + 175 m. East–west direction: 16–22 m from the center line of Track 4. | 36 | |

| 2 | Towerman | North–south direction: k81 + 169 m–k81 + 175 m East–west direction: 16–22 m from the center line of Track 4. | 36 | |

| 3 | Train tail operator | North–south direction: k81 + 087 m–k81 + 257 m East–west direction: center line of track 3—center line of Track 4 (20 m). | 3400 | |

| … | … | … | … | … |

| k | Passenger clerk | Passenger platform (175 m × 12 m) | 2100 | |

| Assistant watchman | North–south direction: k80 + 632 m–k81 + 705 m East–west direction: center line of Track 4 to the outside of the safety line (25 m) | 26,825 |

| Categories | Responsibilities |

|---|---|

| Duty officer | Comprehensively understand and master the key points of station safety production, supervise and guide the on-site operation, coordinate and deal with various emergencies, and strengthen the patrol inspection during key periods. |

| Station attendant | According to the plan and dispatch order, organize and deal with the receiving and dispatching work of stations and yards. |

| Assistant watchman | Assist attendant to receive and dispatch trains. |

| Towerman | According to the station watchman’s order and shunting operation plan, deal with the operation of blocking, arranging access, opening and closing signal, monitoring receiving and dispatching function, and shunting. |

| Yardmaster | Organize and direct the dispatching team to complete marshalling, pick-up, and delivery operations according to the dispatching operation plan. |

| Link member | Responsible for the breakdown of train and push watch in the shunting operation; confirms the vehicle connection status. |

| Dispatcher | According to daily shift plan and dispatch order, prepare and issue phase plan, and organize implementation. |

| Train statistician | Organize and check the existing trains, compile the train marshalling order list, and handle the formalities with the head of operation or locomotive conductor. |

| Passenger duty officer | Organize, guide, and inspect the team to complete various passenger transport services. |

| Passenger clerk | Responsible for the safety service of passengers entering and leaving the station and waiting for the train; responsible for checking, recovering, supplementing, and receiving the tickets of passengers entering and leaving the station; counting the number of passengers getting on and off the train; checking and blocking dangerous goods. |

| Ticket seller | Responsible for the sale of railway tickets: booking, expediting, processing refund, and updating change in procedures. |

| Cargo duty officer | Organize and lead the completion of cargo transportation, loading and unloading, delivery, and other operations according to the freight work plan. |

| Freight operator | Handle the operation of cargo transport, storage, unloading, supervision, and delivery. |

| Train tailor operator | Responsible for the installation and removal of the tailing device and the receiving and delivery of the returning equipment and fill in the operation ledger. |

| Categories | Subevents |

|---|---|

| Dispatch command management work is not in place | The marshalling train runs in violation of plan, does not prepare, and conveys operational and stage plans; inaccurate control of current train, etc. |

| Failure to meet the train as required | Incorrect operation of equipment buttons, unqualified train delivery, irregular presence of field personnel, etc. |

| Shunting standards are not implemented | Change the operation plan without authorization, and prepare the wrong route for the shunting operation; the shunting operation personnel do not call and answer according to the provisions, etc. |

| Anti-slip measures are not in place | Failure to take anti-slip measures according to the provisions, anti-slip equipment management is not in place, etc. |

| Organization of abnormal railway running is not in place | Failure to implement the standard for “Abnormal Train Transfer” when equipment is faulty, failure to implement relevant provisions during construction, blind train release due to bad weather, etc. |

| Equipment management is not in place | Transportation equipment is out of control and out of repair, the tailing device is out of control and out of repair, etc. |

| Safety management dereliction of duty | Lack of rules and regulations management, dereliction of duty in cadre safety management, training and education management is not in place, labor discipline violations on duty, etc. |

| Failed to implement railway crossing and off-road management measures | The blocking management of railway station is not in place, the protective net is not repaired in time, the crossing guard system is violated, etc. |

| Personal safety card control measures are not in place | Inadequate occupational health management, illegal access to railway or improper protection, inadequate control of critical operations, etc. |

| Implementation of fire prevention and explosion prevention management system is not in place | Lack of fire safety management, no regular inspection of fire facilities, etc. |

| Defects in road traffic safety management | Failure to establish traffic safety management system, illegal driving, etc. |

| Construction safety operation management is not in place | Approval of construction plans beyond the authority, construction organization work is not in place, blind opening without confirming the opening conditions, etc. |

| Main Categories | Hazard Factors |

|---|---|

| Human factors | Obsessive–compulsive symptom |

| Sensitive of interpersonal relationship | |

| Somatization | |

| Environment factors | Foggy conditions |

| Poor public safety environment | |

| Management factors | Lack of safety management system |

| Safety checks were not in place | |

| Performance evaluation was not standardized | |

| Employment mechanism was not perfect |

| Language Description | Frequency Range | Average Range | Qualitative Estimate (Number/Year) | Probability Range | Grade |

|---|---|---|---|---|---|

| Remote | 1 in 35 years to 1 in 175 years | 1 in 100 years | 0.01 | 1 | |

| Rare | 1 in 7 years to 1 in 35 years | 1 in 20 years | 0.05 | 2 | |

| Infrequent | 1 in 1.75 years to 1 in 7 years | 1 in 4 years | 0.25 | 3 | |

| Occasional | 1 in 3 months to 1 in 1.75 years | 1 in 9 months | 1.25 | 4 | |

| Regular | 1 in 20 days to 1 in 3 months | 1 in 2 months | 6.25 | 5 |

| Language Description | Qualitative Description | Casualty Estimate | Qualitative Estimate (Number/Year) |

|---|---|---|---|

| Minor | Minor injury | 0.005 | 1 |

| Marginal | Multiple minor injuries | 0.025 | 2 |

| Moderate | Single serious injury | 0.125 | 3 |

| Severe | Multiple serious injuries or single fatal injury | 0.625 | 4 |

| Catastrophic | 2–5 fatal injuries | 3.125 | 5 |

| Risk Scores | Risk Category | Description |

|---|---|---|

| [1,6] | Negligible | Risk is acceptable with/without the agreement of the railway authority |

| [7,12] | Tolerable | Acceptable with adequate control and with the agreement of the railway authority |

| [13,18] | Undesirable | Shall only be accepted when risk reduction is impracticable and with the agreement of the railway authority |

| [19,25] | Intolerable | Risk must be reduced in exceptional circumstances |

| Time | Qualitative Description |

|---|---|

| 12 January 2016 | At 4:05, a yardmaster failed to inspect vehicles in the station as required. |

| 28 March 2017 | At 9:30, an assistant watchman did not attend the operational learning program organized by the station. |

| 23 December 2017 | 18 safety problems were found during the annual safety audit. |

| 8 December 2018 | The lowest temperature at night reached –20 °C. |

| 5 April 2019 | At 8:25, an assistant watchman did not take over as required. |

| 7 June 2019 | At 15:20, a signalman failed to watch the train after it entered the line. |

| 7 July 2019 | At 3:30, a signalman was on duty in a bad state of mind. |

| 28 July 2019 | At 7:15, a yellow warning for lightning was issued. |

| 15 November 2019 | At 16:00, based on on-duty personnel inspection, it was found that one to two lines between the water well cover were not covered. |

| Experts | Age | Educational Background | Professional Title | Years of Working |

|---|---|---|---|---|

| Expert 1 | 45 | Junior College | Engineer | 22 years |

| Expert 2 | 50 | Junior College | Senior Engineer | 28 years |

| Expert 3 | 30 | Graduate Student | Engineer | 5 years |

| Expert 4 | 42 | Undergraduate | Engineer | 21 years |

| Expert 5 | 35 | Undergraduate | Assistant Engineer | 13 years |

| Main Categories | Hazards |

|---|---|

| Human factors | Obsessive–compulsive symptom |

| Business assessment is not up to standard, | |

| Environment factors | |

| Lighting, ventilation, heat preservation, and other post conditions were poor, | |

| Equipment factors | |

| Management factors | Operating standards and procedures were not standardized, |

| Safety checks were not in place, |

| Hazards | Functions | Data | Induced Intensity | Comments |

|---|---|---|---|---|

| Obsessive symptom, | (SCL-90) test n = 2.5 | 0.006 | SCL-90: Symptom Check List-90, represents a list of 90 symptoms | |

| Somatization, | (SCL-90) test n = 1.6 | 0.003 | SCL-90: Symptom Check List-90, represents a list of 90 symptoms | |

| Business assessment was not up to standard, | Monthly safety production knowledge test score 85 | 0.0015 | Due to the importance of railway safety, the Shenshuo Railway stipulates that the examination score of 80 is qualified | |

| Cold weather, | The lowest temperature of the day was −24 °C | 0.01 | According to the expert advice and the influence of low temperature on human body function, selecting different induced intensity values | |

| Lighting, ventilation, heat preservation, and other post conditions were poor, | Poor lighting conditions in the station at night | 0.003 | Assigning values according to field operation conditions | |

| Equipment failure, | The battery capacity was insufficient, which affected the intercom call reliability | 0.004 | Assigning values according to equipment inspection and maintenance statistics | |

| Operating standards and procedures were not standardized, | No mobile phone management system | 0.003 | Assigning values according to daily check statistics | |

| Safety checks were not in place, | During the working week, checking was done twice | 0.02 | Assigning values according to the inspection statistics of the superior safety inspectors |

| Hazards | Normalized by Cluster | Limiting |

|---|---|---|

| Obsessive–compulsive symptom, | 0.37 | 0.19 |

| Somatization, | 0.22 | 0.12 |

| Business assessment was not up to standard, | 0.41 | 0.21 |

| Cold weather, | 0.61 | 0.10 |

| Lighting, ventilation, heat preservation, and other post conditions were poor, | 0.39 | 0.06 |

| Equipment failure, | 0.20 | 0.06 |

| Operating standards and procedures were not standardized, | 0.33 | 0.11 |

| Safety checks were not in place, | 0.47 | 0.15 |

| Grid Codes | Numerical Value | Risk Levels |

|---|---|---|

| 00010044010003020201 | 6 | Negligible |

| 00010044010003030201 | 8 | Tolerable |

| 00010044010003040201 | 6 | Negligible |

| 00010044010003050201 | 6 | Negligible |

| 00010044010003060201 | 8 | Tolerable |

| 00010044010003070201 | 6 | Negligible |

| 00010044010003080201 | 8 | Tolerable |

| 00010044010003090201 | 4 | Negligible |

| 00010044010003100201 | 6 | Negligible |

| Date | Time | Three Violations Description | Inspection Situation |

|---|---|---|---|

| 5 January 2016 | 5:30 | Sleeping on duty | Yellow notice |

| 20 March 2016 | 23:30 | Trains were not received in time | White notice |

| 11 June 2016 | 17:00 | The busy board was not filled in timely | White notice |

| 3 August 2016 | 14:00 | Failed to use intercom to answer call in time | White notice |

| 26 November 2016 | 11:50 | Not standing in the correct position to meet the train | Yellow notice |

| 17 January 2017 | 13:00 | The busy board was not filled | Yellow notice |

| 9 May 2017 | 4:30 | Doze off on duty | White notice |

| 19 September 2017 | 15:45 | Not standing in the correct position to meet the train | Yellow notice |

| 22 November 2017 | 7:20 | Trains were not received in time | White notice |

| 27 February 2018 | 10:00 | Walkie-talkies were not carried in field operation | Yellow notice |

| 9 June 2018 | 2:30 | Sleeping on duty | Yellow notice |

| 21 August 2018 | 10:15 | Failed to use intercom to answer call in time | White notice |

| 5 October 2018 | 13:30 | Doze off on duty | White notice |

| 17 November 2018 | 22:00 | No pick-up train | Yellow notice |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Qi, C.; Ma, M. Grid-Based Employee Safety Behavior Risk Assessment of the Train Operation Department. Processes 2022, 10, 913. https://doi.org/10.3390/pr10050913

Zhang H, Qi C, Ma M. Grid-Based Employee Safety Behavior Risk Assessment of the Train Operation Department. Processes. 2022; 10(5):913. https://doi.org/10.3390/pr10050913

Chicago/Turabian StyleZhang, Huafeng, Changmao Qi, and Mingyuan Ma. 2022. "Grid-Based Employee Safety Behavior Risk Assessment of the Train Operation Department" Processes 10, no. 5: 913. https://doi.org/10.3390/pr10050913

APA StyleZhang, H., Qi, C., & Ma, M. (2022). Grid-Based Employee Safety Behavior Risk Assessment of the Train Operation Department. Processes, 10(5), 913. https://doi.org/10.3390/pr10050913