The Content of Polycyclic Aromatic Hydrocarbons in Slavonska slanina—Traditionally Smoked and Dry-Cured Bacon

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation and Smoking

2.2. Determination of Physical-Chemical Properties

2.3. Procedure for Determination of PAHs Using the GC-MS Method

- -

- Initial temperature 50 °C for 24 s;

- -

- Gradient 25 °C min−1 from initial temperature (50 °C) to 195 °C for 90 s;

- -

- Gradient 8 °C min−1 from 195 °C to 265 °C;

- -

- Maintenance at 315 °C for 75 s with 20 °C min−1.

2.4. Statistical Analysis

3. Results and Discussion

3.1. Physico-Chemical Properties

3.2. PAH Determination

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Kovačević, D. Kemija i Tehnologija Mesa i Ribe; Prehrambeno Tehnološki Fakultet: Osijek, Croatia, 2001. [Google Scholar]

- Krvavica, M.; Đugum, J. Proizvodnja pršuta u svijetu i kod nas. MESO Prvi Hrvatski Časopis Mesu 2006, 8, 355–365. Available online: https://hrcak.srce.hr/22460 (accessed on 13 December 2021).

- Andrée, S.; Jira, W.; Schwind, K.-H.; Wagner, H.; Schwägele, F. Chemical Safety of Meat and Meat Products. Meat Sci. 2010, 86, 38–48. [Google Scholar] [CrossRef] [PubMed]

- Regulation (EU) No. 1151/2012 of the European Parliament and of the Council on Quality Schemes for Agricultural Products and Foodstuffs. Available online: https://www.ecolex.org/details/legislation/regulation-eu-no-11512012-of-the-european-parliament-and-of-the-council-on-quality-schemes-for-agricultural-products-and-foodstuffs-lex-faoc118307/ (accessed on 13 December 2021).

- Gómez, I.; Janardhanan, R.; Ibañez, F.C.; Beriain, M.J. The Effects of Processing and Preservation Technologies on Meat Quality: Sensory and Nutritional Aspects. Foods 2020, 9, 1416. [Google Scholar] [CrossRef] [PubMed]

- Sander, L.C.; Wise, S.A. Polycyclic Aromatic Hydrocarbon Structure Index; US Department of Commerce, Technology Administration, National Institute of Gaithersburg: Gaithersburg, MD, USA, 1997. [Google Scholar]

- Martorell, I.; Perello, G.; Marti-Cid, R.; Castell, V.; Llobet, J.M.; Domingo, J.L. Polycyclic Aromatic Hydrocarbons (PAH) in Foods and Estimated PAH Intake by the Population of Catalonia, Spain: Temporal Trend. Environ. Int. 2010, 36, 424–432. [Google Scholar] [CrossRef] [PubMed]

- Rozentale, I.; Zacs, D.; Bartkiene, E.; Bartkevics, V. Polycyclic Aromatic Hydrocarbons in Traditionally Smoked Meat Products from the Baltic States. Food Addit. Contam. Part B-Surveill. 2018, 11, 138–145. [Google Scholar] [CrossRef]

- Ciecierska, M.; Obiedzinski, M. Influence of Smoking Process on Polycyclic Aromatic Hydrocarbons’ Content in Meat Products. Acta Sci. Polon.-Technol. Aliment. 2007, 6, 17–28. [Google Scholar]

- Roseiro, L.C.; Gomes, A.; Patarata, L.; Santos, C. Comparative Survey of PAHs Incidence in Portuguese Traditional Meat and Blood Sausages. Food Chem. Toxicol. 2012, 50, 1891–1896. [Google Scholar] [CrossRef]

- Santos, C.; Gomes, A.; Roseiro, L.C. Polycyclic Aromatic Hydrocarbons Incidence in Portuguese Traditional Smoked Meat Products. Food Chem. Toxicol. 2011, 49, 2343–2347. [Google Scholar] [CrossRef]

- Skaljac, S.; Petrovic, L.; Tasic, T.; Ikonic, P.; Jokanovic, M.; Tomovic, V.; Dzinic, N.; Sojic, B.; Tjapkin, A.; Skrbic, B. Influence of Smoking in Traditional and Industrial Conditions on Polycyclic Aromatic Hydrocarbons Content in Dry Fermented Sausages (Petrovska Klobasa) from Serbia. Food Control 2014, 40, 12–18. [Google Scholar] [CrossRef]

- Mastanjević, K.; Puljić, L.; Kartalović, B.; Grbavac, J.; Jukić Grbavac, M.; Nadaždi, H.; Habschied, K. Analysis of Polycyclic Aromatic Hydrocarbons in Heregovački Pršut—Traditionally Smoked Prosciutto. Int. J. Environ. Res. Public Health 2020, 17, 5097. [Google Scholar] [CrossRef]

- Mastanjević, K.M.; Kartalović, B.D.; Vranešević, J.M.; Novakov, N.J.; Habschied, K.J. Polycyclic Aromatic Hydrocarbons in Traditionally Smoked Slavonska Kobasica. Food Addit. Contam. Part B 2020, 13, 82–87. [Google Scholar] [CrossRef] [PubMed]

- Ziegenhals, K.; Mueller, W.-D.; Jira, W.; Speer, K. Lower contents of PAH by optimized smoking terms. Fleischwirtschaft 2008, 88, 93–97. [Google Scholar]

- Purcaro, G.; Moret, S.; Conte, L.S. Optimisation of Microwave Assisted Extraction (MAE) for Polycyclic Aromatic Hydrocarbon (PAH) Determination in Smoked Meat. Meat Sci. 2009, 81, 275–280. [Google Scholar] [CrossRef] [PubMed]

- Mastanjevic, K.; Kartalovic, B.; Petrovic, J.; Novakov, N.; Puljic, L.; Kovacevic, D.; Jukic, M.; Lukinac, J.; Mastanjevic, K. Polycyclic Aromatic Hydrocarbons in the Traditional Smoked Sausage Slavonska Kobasica. J. Food Compos. Anal. 2019, 83, 103282. [Google Scholar] [CrossRef]

- Wade, L.G. Organic Chemistry; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2006; ISBN 978-0-13-147871-8. [Google Scholar]

- Simko, P. Factors Affecting Elimination of Polycyclic Aromatic Hydrocarbons from Smoked Meat Foods and Liquid Smoke Flavorings. Mol. Nutr. Food Res. 2005, 49, 637–647. [Google Scholar] [CrossRef]

- Wenzl, T.; Zelinkova, Z. Polycyclic Aromatic Hydrocarbons in Food and Feed. In Encyclopedia of Food Chemistry; Melton, L., Shahidi, F., Varelis, P., Eds.; Academic Press: Oxford, UK, 2019; pp. 455–469. ISBN 978-0-12-814045-1. [Google Scholar]

- Commission Regulation (EC). No 1881/2006 of 19 December 2006. Setting Maximum Levels for Certain Contaminants in Foodstuffs (Text with EEA Relevance). Off. J. Eur. Union 2006, 364, 5–24. [Google Scholar]

- Zelinkova, Z.; Wenzl, T. The Occurrence of 16 EPA PAHs in Food—A Review. Polycycl. Aromat. Compd. 2015, 35, 248–284. [Google Scholar] [CrossRef] [Green Version]

- Commission Regulation (EU). No 1327/2014 of 12 December 2014. Amending Regulation (EC). No 1881/2006 as Regards Maximum Levels of Polycyclic Aromatic Hydrocarbons (PAHs) in Traditionally Smoked Meat and Meat Products and Traditionally Smoked Fish and Fishery Products Text with EEA Relevance. Off. J. Eur. Union 2014, 358, 13–14. [Google Scholar]

- Official Methods of Analysis of AOAC Internationa, 17th ed.; Association of Official Analytical Chemists, Inc.: Arlington, VA, USA, 2021.

- Bourne, M.C.; Kenny, J.F.; Barnard, J. Computer-Assisted Readout of Data from Texture Profile Analysis Curves1. J. Texture Stud. 1978, 9, 481–494. [Google Scholar] [CrossRef]

- Petrović, J.; Kartalović, B.; Ratajac, R.; Spirić, D.; Djurdjević, B.; Polaček, V.; Pucarević, M. PAHs in Different Honeys from Serbia. Food Addit. Contam. Part B 2019, 12, 116–123. [Google Scholar] [CrossRef]

- Skaljac, S.; Jokanovic, M.; Tomovic, V.; Ivic, M.; Tasic, T.; Ikonic, P.; Sojic, B.; Dzinic, N.; Petrovic, L. Influence of Smoking in Traditional and Industrial Conditions on Colour and Content of Polycyclic Aromatic Hydrocarbons in Dry Fermented Sausage “Petrovska Klobasa”. LWT-Food Sci. Technol. 2018, 87, 158–162. [Google Scholar] [CrossRef]

- Fraqueza, M.J.; Laranjo, M.; Alves, S.; Fernandes, M.H.; Agulheiro-Santos, A.C.; Fernandes, M.J.; Potes, M.E.; Elias, M. Dry-Cured Meat Products According to the Smoking Regime: Process Optimization to Control Polycyclic Aromatic Hydrocarbons. Foods 2020, 9, 91. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- US EPA National Center for Environmental Assessment, I.O.; Murphy, P. EPA’s Report on the Environment (ROE) (2008 Final Report). Available online: https://cfpub.epa.gov/ncea/risk/recordisplay.cfm?deid=190806 (accessed on 30 October 2021).

- Kamankesh, M.; Mohammadi, A.; Hosseini, H.; Modarres Tehrani, Z. Rapid Determination of Polycyclic Aromatic Hydrocarbons in Grilled Meat Using Microwave-Assisted Extraction and Dispersive Liquid–Liquid Microextraction Coupled to Gas Chromatography–Mass Spectrometry. Meat Sci. 2015, 103, 61–67. [Google Scholar] [CrossRef]

- Skrbic, B.; Durisic-Mladenovic, N.; Macvanin, N.; Tjapkin, A.; Skaljac, S. Polycyclic Aromatic Hydrocarbons In Smoked Dry Fermented Sausages with Protected Designation Of Origin Petrovska Klobasa From Serbia. Maced. J. Chem. Chem. Eng. 2014, 33, 227–236. [Google Scholar] [CrossRef] [Green Version]

- Ledesma, E.; Rendueles, M.; Diaz, M. Benzo(a)Pyrene Penetration on a Smoked Meat Product during Smoking Time. Food Addit. Contam. Part A-Chem. 2014, 31, 1688–1698. [Google Scholar] [CrossRef]

- Babic, J.M.; Kartalovic, B.D.; Skaljac, S.; Vidakovic, S.; Ljubojevic, D.; Petrovic, J.M.; Cirkovic, M.A.; Teodorovic, V. Reduction of Polycyclic Aromatic Hydrocarbons in Common Carp Meat Smoked in Traditional Conditions. Food Addit. Contam. Part B-Surveill. 2018, 11, 208–213. [Google Scholar] [CrossRef]

- Puljić, L.; Mastanjević, K.; Kartalović, B.; Kovačević, D.; Vranešević, J.; Mastanjević, K. The Influence of Different Smoking Procedures on the Content of 16 PAHs in Traditional Dry Cured Smoked Meat “Hercegovačka Pečenica”. Foods 2019, 8, 690. [Google Scholar] [CrossRef] [Green Version]

- Olatunji, O.S.; Fatoki, O.S.; Opeolu, B.O.; Ximba, B.J. Determination of Polycyclic Aromatic Hydrocarbons [PAHs] in Processed Meat Products Using Gas Chromatography—Flame Ionization Detector. Food Chem. 2014, 156, 296–300. [Google Scholar] [CrossRef]

- Reinik, M.; Tamme, T.; Roasto, M.; Juhkam, K.; Tenno, T.; Kiis, A. Polycyclic Aromatic Hydrocarbons (PAHs) in Meat Products and Estimated PAH Intake by Children and the General Population in Estonia. Food Addit. Contam. 2007, 24, 429–437. [Google Scholar] [CrossRef]

- Mastanjević, K.; Kartalović, B.; Puljić, L.; Kovačević, D.; Habschied, K. Influence of Different Smoking Procedures on Polycyclic Aromatic Hydrocarbons Formation in Traditional Dry Sausage Hercegovačka Kobasica. Processes 2020, 8, 918. [Google Scholar] [CrossRef]

- Ledesma, E.; Rendueles, M.; Diaz, M. Contamination of Meat Products during Smoking by Polycyclic Aromatic Hydrocarbons: Processes and Prevention. Food Control 2016, 60, 64–87. [Google Scholar] [CrossRef]

- Skaljac, S.; Petrovic, L.; Jokanovic, M.; Tasic, T.; Ivic, M.; Tomovic, V.; Ikonic, P.; Sojic, B.; Dzinic, N.; Skrbic, B. Influence of Collagen and Natural Casings on the Polycyclic Aromatic Hydrocarbons in Traditional Dry Fermented Sausage (Petrovska Klobasa) from Serbia. Int. J. Food Prop. 2018, 21, 667–673. [Google Scholar] [CrossRef]

| Traditional Smoking | Industrial Smoking | |

|---|---|---|

| Protein [%] | 21.09 b ± 0.04 | 22.18 a ± 0.02 |

| Fat [%] | 35.74 a ± 0.02 | 33.09 b ± 0.05 |

| Moisture [%] | 39.57 b ± 0.05 | 40.74 a ± 0.01 |

| Collagen [%] | 2.16 a ± 0.02 | 1.83 b ± 0.04 |

| pH | 5.59 a ± 0.02 | 5.58 a ± 0.01 |

| aw | 0.92 a ± 0.01 | 0.92 a ± 0.01 |

| L* | 62.37 a ± 0.49 | 61.88 a ± 1.56 |

| a* | 8.17 b ± 0.19 | 8.82 a ± 0.26 |

| b* | 17.80 a ± 0.21 | 17.07 b ± 0.27 |

| Hardness (kg) | 7.91 a ± 0.10 | 5.81 b ± 0.35 |

| Springiness (mm) | 0.57 a ± 0.09 | 0.74 a ± 0.03 |

| Cohesiveness | 0.58 b ± 0.04 | 0.71 a ± 0.02 |

| Chewiness (kg∙mm) | 2.61 a ± 0.11 | 3.05 a ± 0.32 |

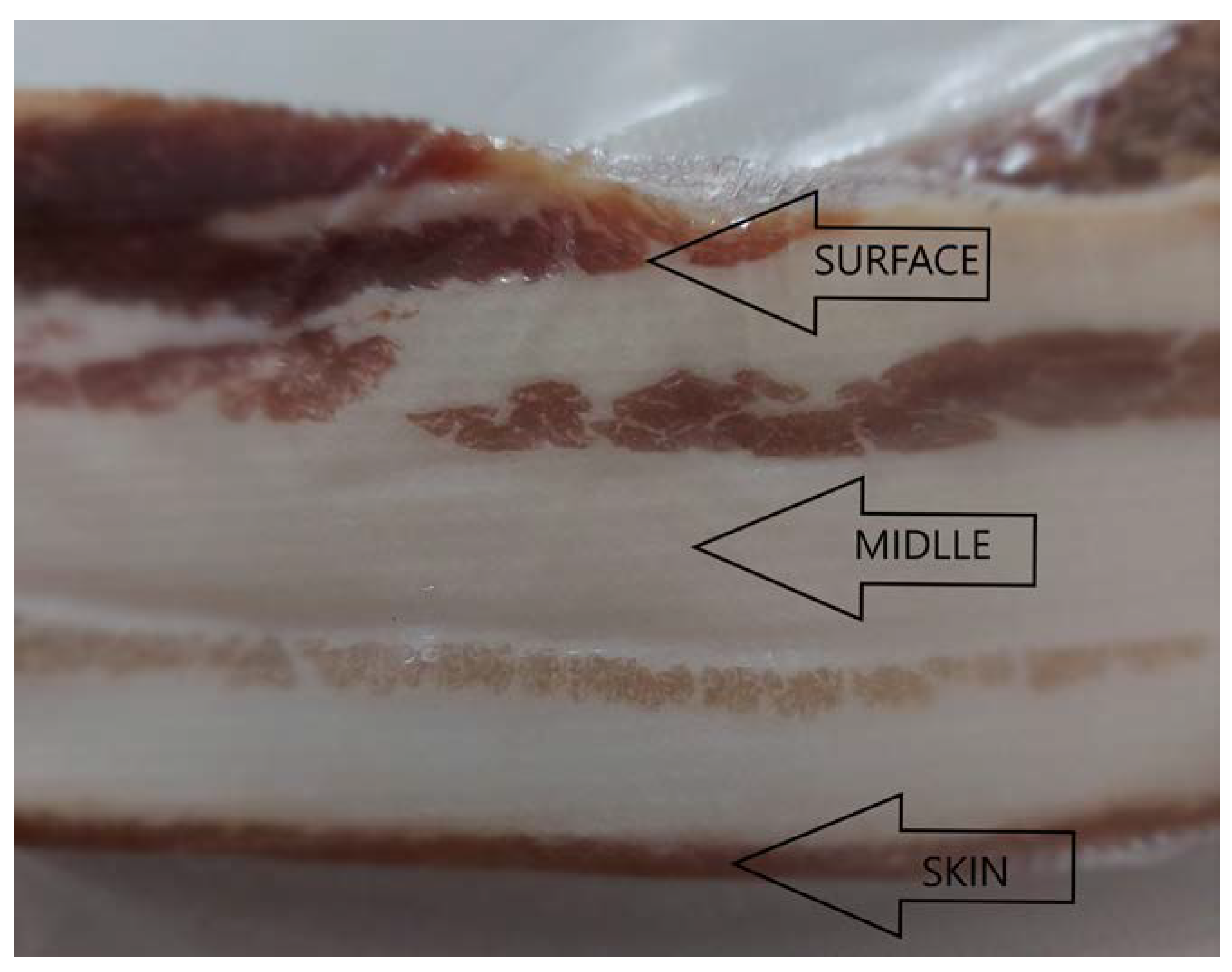

| PAH | Traditional Smoking—Middle | Traditional Smoking—Surface | Traditional Smoking—Skin | Industrial Smoking—Middle | Industrial Smoking—Surface | Industrial Smoking—Skin |

|---|---|---|---|---|---|---|

| Nap | 157.75 a ± 0.92 | 79.00 a,b ± 0.75 | 27.46 b ± 0.64 | 64.20 b ± 0.56 | 21.62 b ± 0.64 | 18.62 b ± 0.35 |

| Anl | 325.00 a ± 1.71 | 179.62 a ± 0.97 | 179.76 a ± 1.02 | 16.28 b ± 0.65 | <LOQ | <LOQ |

| Ane | 4.79 a ± 0.70 | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ |

| Fln | 157.62 a ± 1.62 | 86.76 a ± 0.69 | 142.53 a ± 0.71 | <LOQ | <LOQ | <LOQ |

| Ant | 102.31 a ± 1.13 | 48.19 a ± 0.48 | 119.20 a ± 0.77 | <LOQ | <LOQ | <LOQ |

| Phen | 432.88 a ± 3.11 | 210.38 a ± 0.78 | 504.17 a ± 1.69 | <LOQ | <LOQ | <LOQ |

| Flt | 42.23 a ± 0.85 | 20.49 a ± 0.56 | 50.37 a ± 0.56 | <LOQ | <LOQ | <LOQ |

| BaA | 13.59 a ± 0.33 | 9.72 a ± 0.63 | 16.53 a ± 0.84 | <LOQ | <LOQ | <LOQ |

| Pyr | 53.15 a ± 0.64 | 37.34 a ± 0.77 | 31.97 a ± 0.88 | <LOQ | <LOQ | <LOQ |

| Chry | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ |

| BbF | 1.25 a ± 0.10 | 0.89 a ± 0.06 | 0.84 a ± 0.11 | <LOQ | <LOQ | <LOQ |

| BkF | 3.84 a ± 0.08 | 3.65 a ± 0.10 | 3.69 a ± 0.14 | <LOQ | <LOQ | <LOQ |

| BaP | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ |

| DahA | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ |

| BghiP | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ |

| InP | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ | <LOQ |

| ∑PAH4 | 14.84 a ± 0.25 | 10.61 a ± 0.69 | 17.37 a ± 0.74 | <LOQ | <LOQ | <LOQ |

| ∑PAH16 | 1294.41 a ± 4.65 | 676.04 a ± 1.33 | 1076.52 a ± 5.90 | 80.48 b ± 0.89 | 21.62 b ± 0.63 | 18.62 b ± 0.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kartalović, B.; Puljić, L.; Kovačević, D.; Markovčić, M.; Vranešević, J.; Habschied, K.; Mastanjević, K. The Content of Polycyclic Aromatic Hydrocarbons in Slavonska slanina—Traditionally Smoked and Dry-Cured Bacon. Processes 2022, 10, 268. https://doi.org/10.3390/pr10020268

Kartalović B, Puljić L, Kovačević D, Markovčić M, Vranešević J, Habschied K, Mastanjević K. The Content of Polycyclic Aromatic Hydrocarbons in Slavonska slanina—Traditionally Smoked and Dry-Cured Bacon. Processes. 2022; 10(2):268. https://doi.org/10.3390/pr10020268

Chicago/Turabian StyleKartalović, Brankica, Leona Puljić, Dragan Kovačević, Mateo Markovčić, Jelena Vranešević, Kristina Habschied, and Krešimir Mastanjević. 2022. "The Content of Polycyclic Aromatic Hydrocarbons in Slavonska slanina—Traditionally Smoked and Dry-Cured Bacon" Processes 10, no. 2: 268. https://doi.org/10.3390/pr10020268

APA StyleKartalović, B., Puljić, L., Kovačević, D., Markovčić, M., Vranešević, J., Habschied, K., & Mastanjević, K. (2022). The Content of Polycyclic Aromatic Hydrocarbons in Slavonska slanina—Traditionally Smoked and Dry-Cured Bacon. Processes, 10(2), 268. https://doi.org/10.3390/pr10020268