Simulation and Experimental Validation on the Effect of Twin-Screw Pulping Technology upon Straw Pulping Performance Based on Tavares Mathematical Model

Abstract

1. Introduction

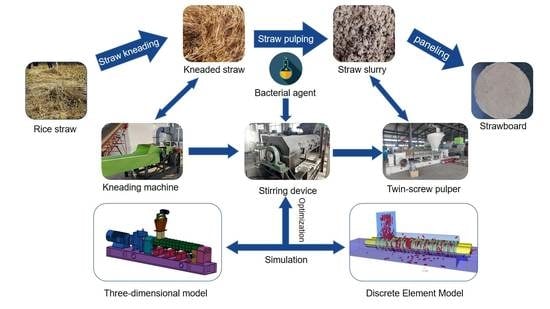

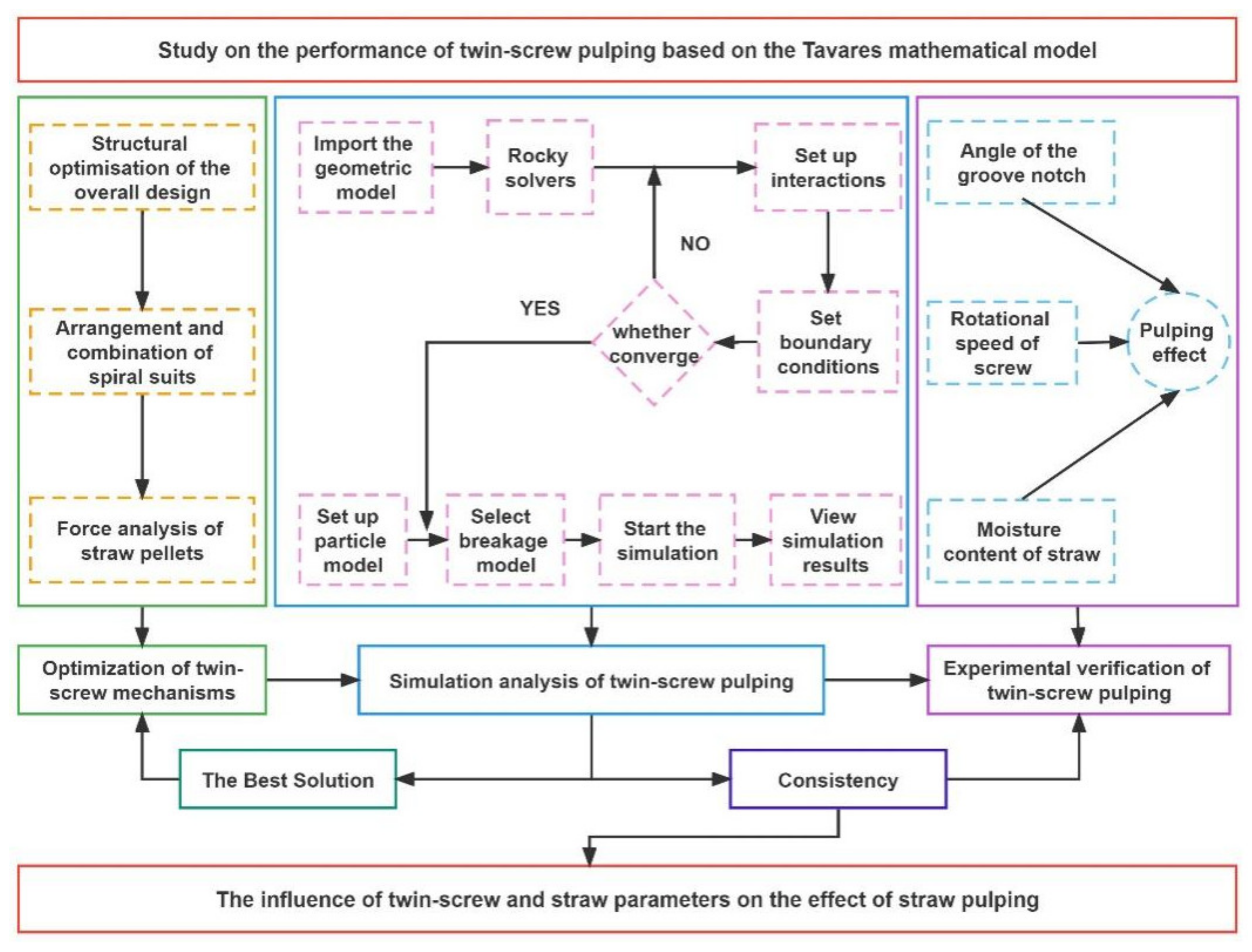

2. Materials and Methods

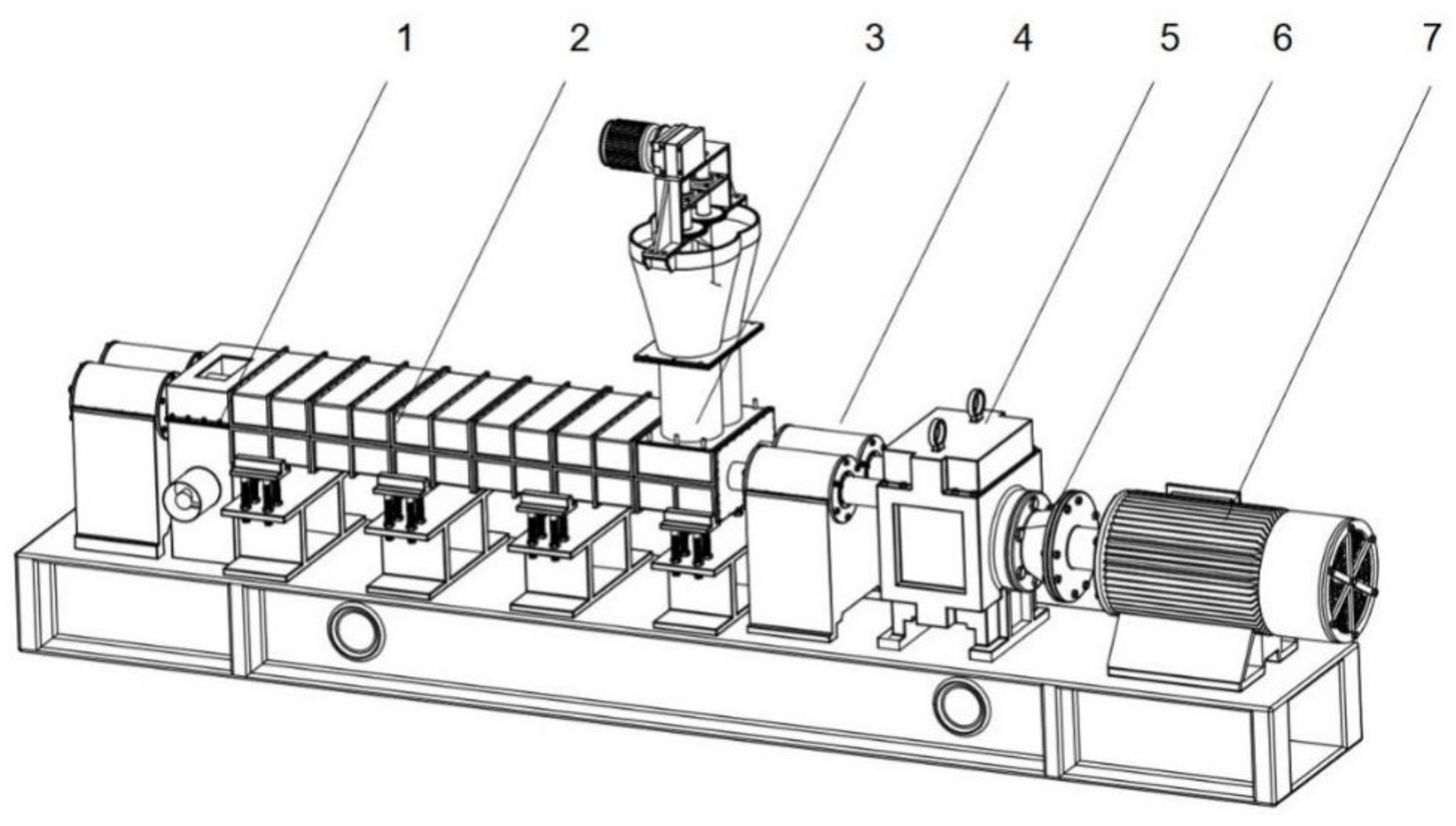

2.1. Experimental Setup

2.1.1. Establishing a Mathematical Model of Twin-Screw Pulping Machine

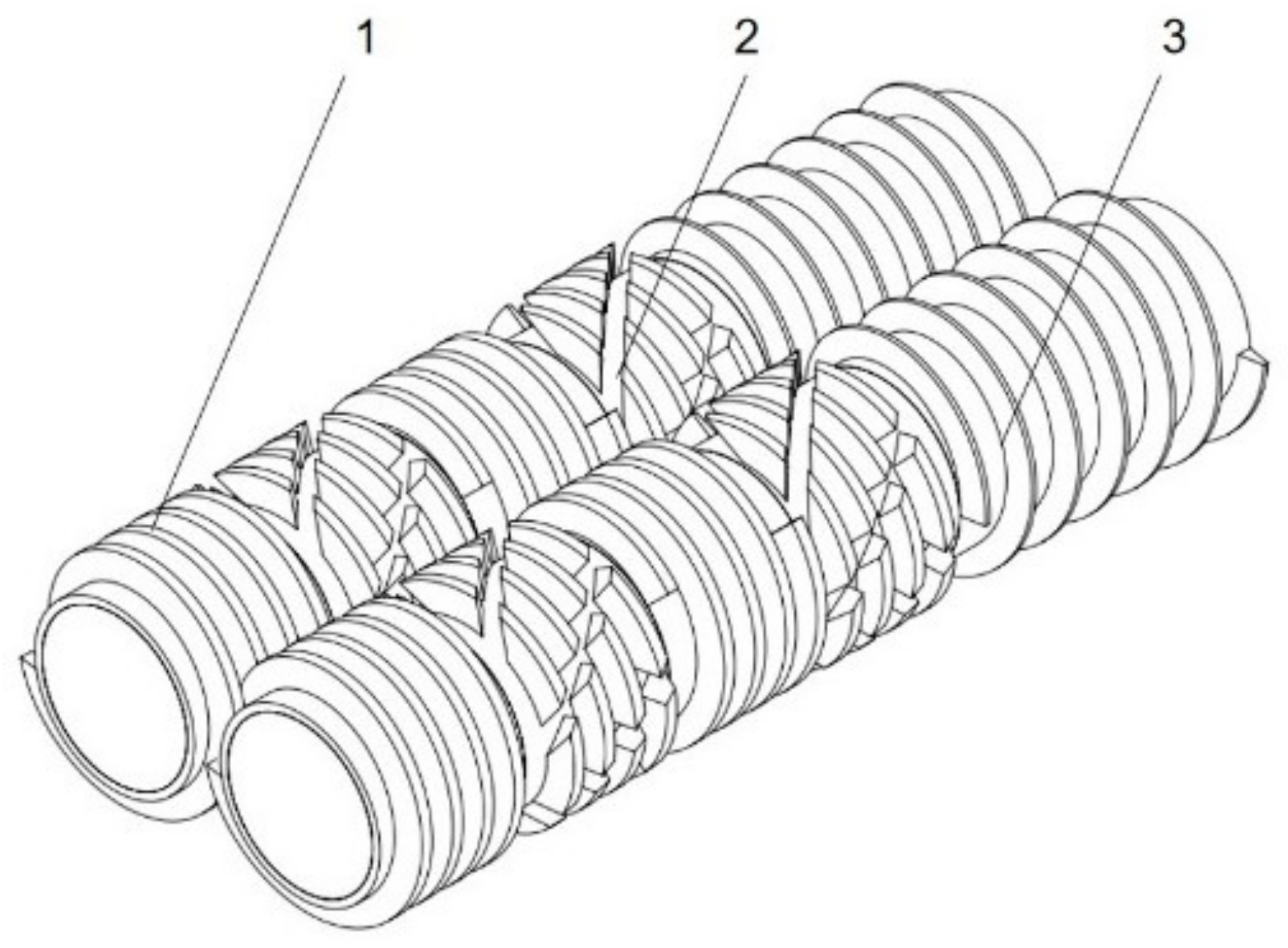

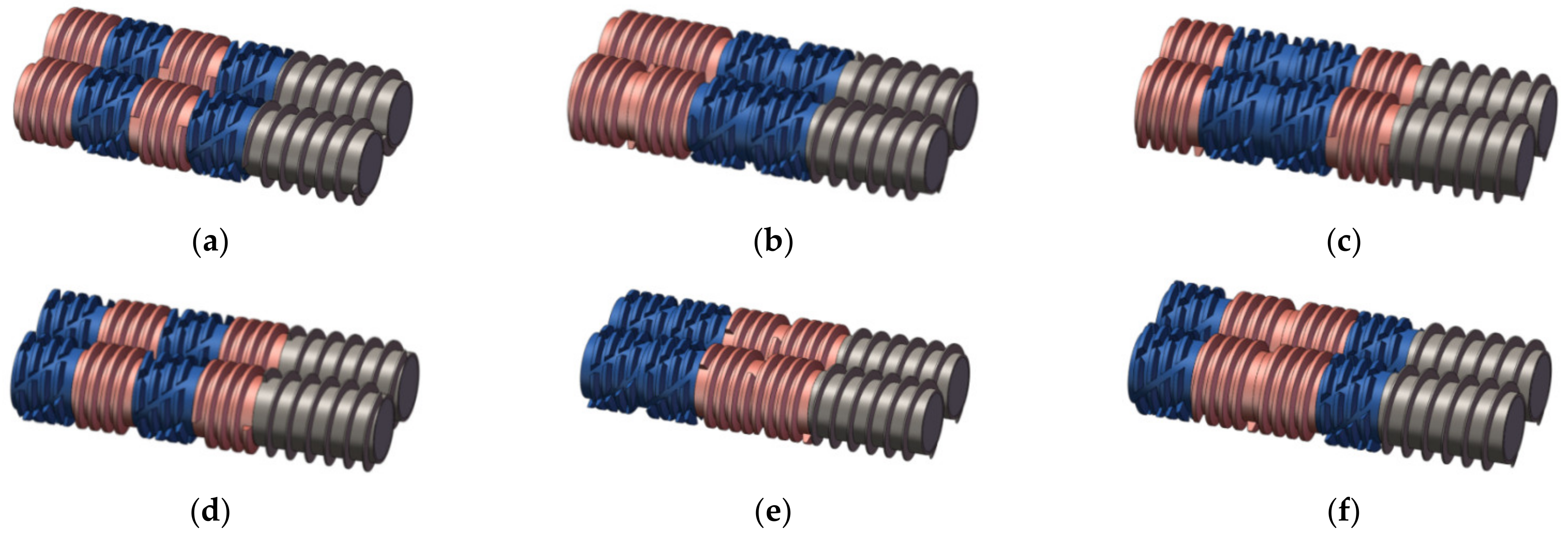

2.1.2. Twin-Screw Structure Arrangement

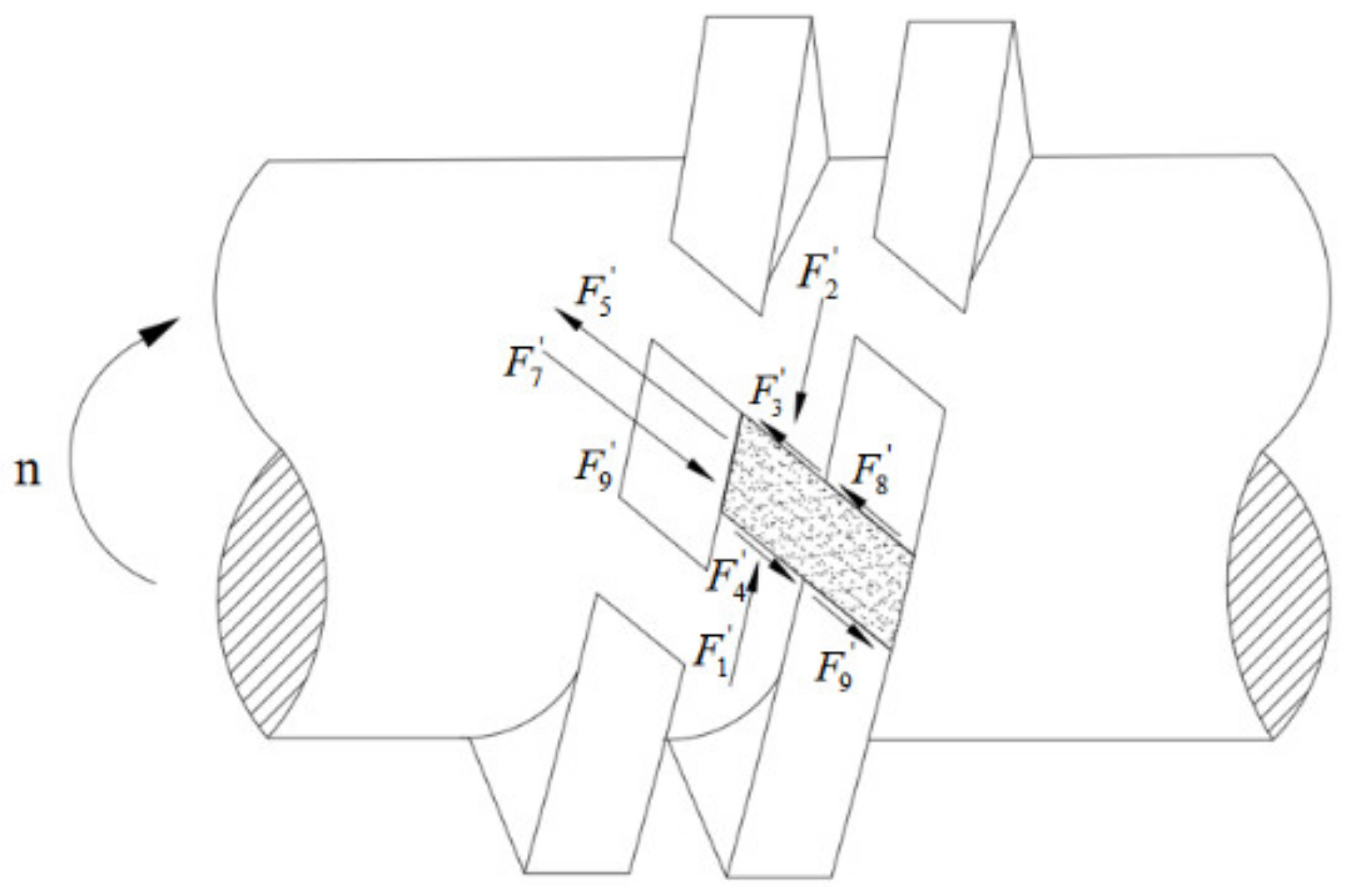

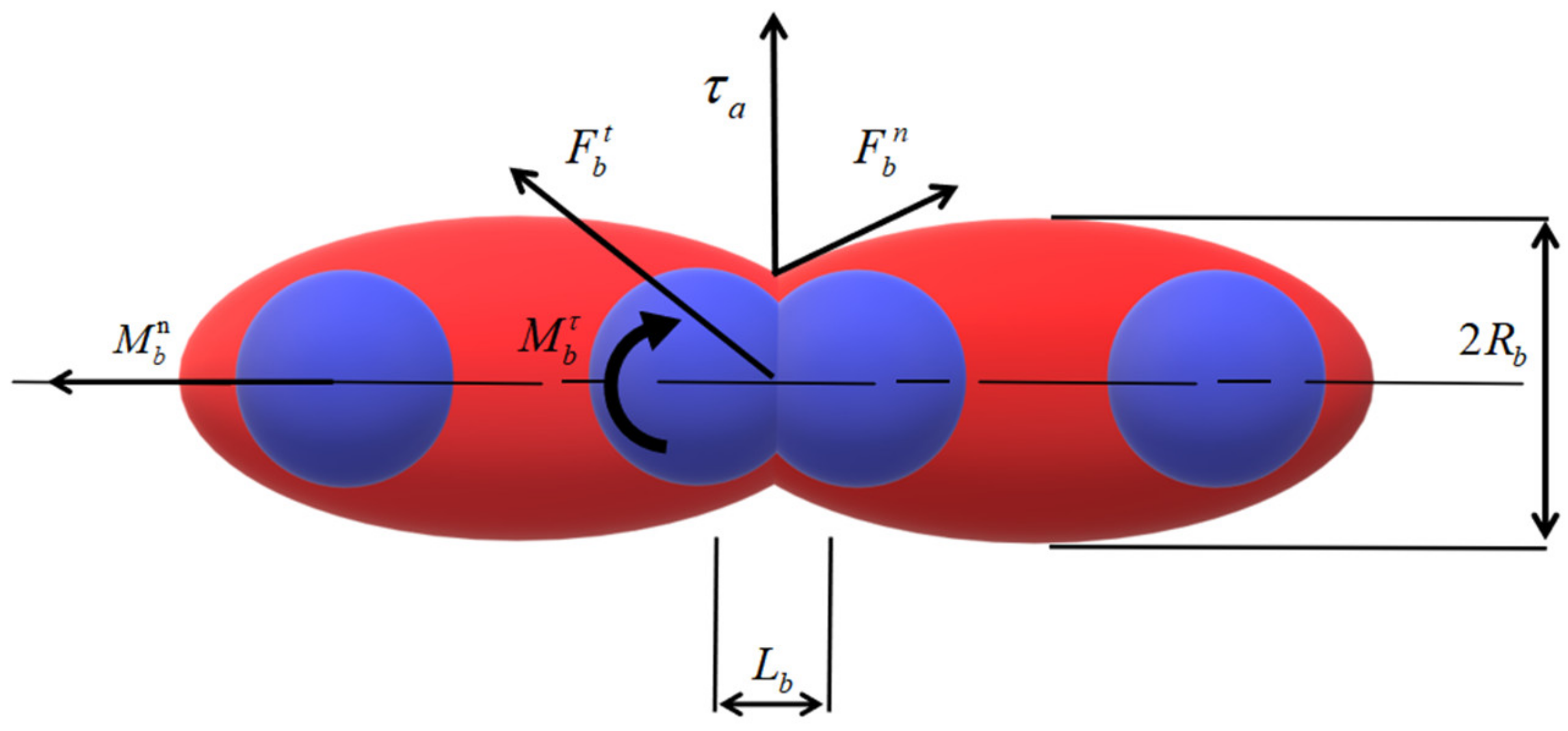

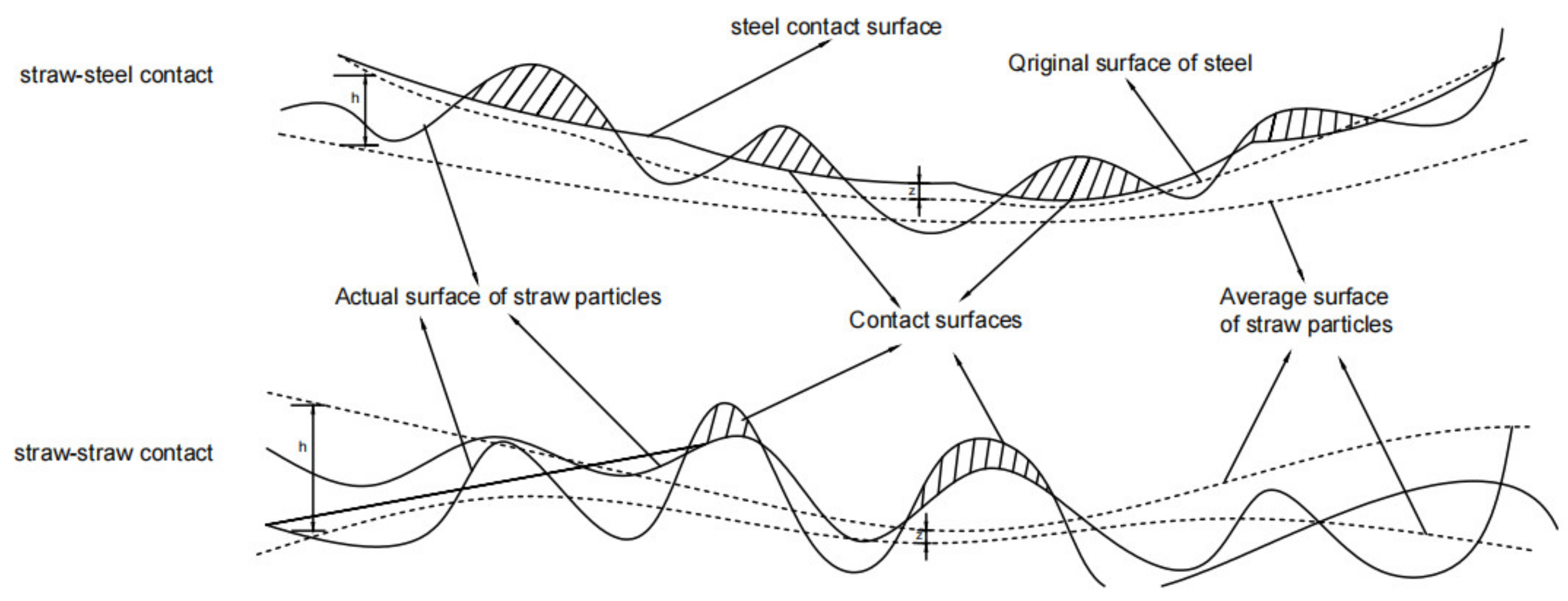

2.1.3. Force Analysis of Straw Particles

- 1.

- Force analysis of twin-screw on straw particles;

- 2.

- Force analysis between straw particles;

2.2. Simulation Test

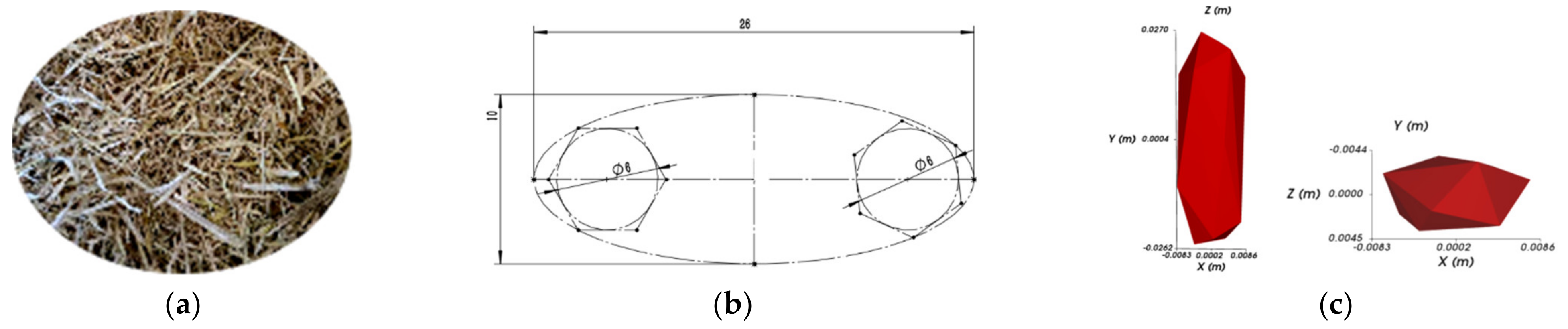

2.2.1. Simulation Model

2.2.2. Parameter Setting

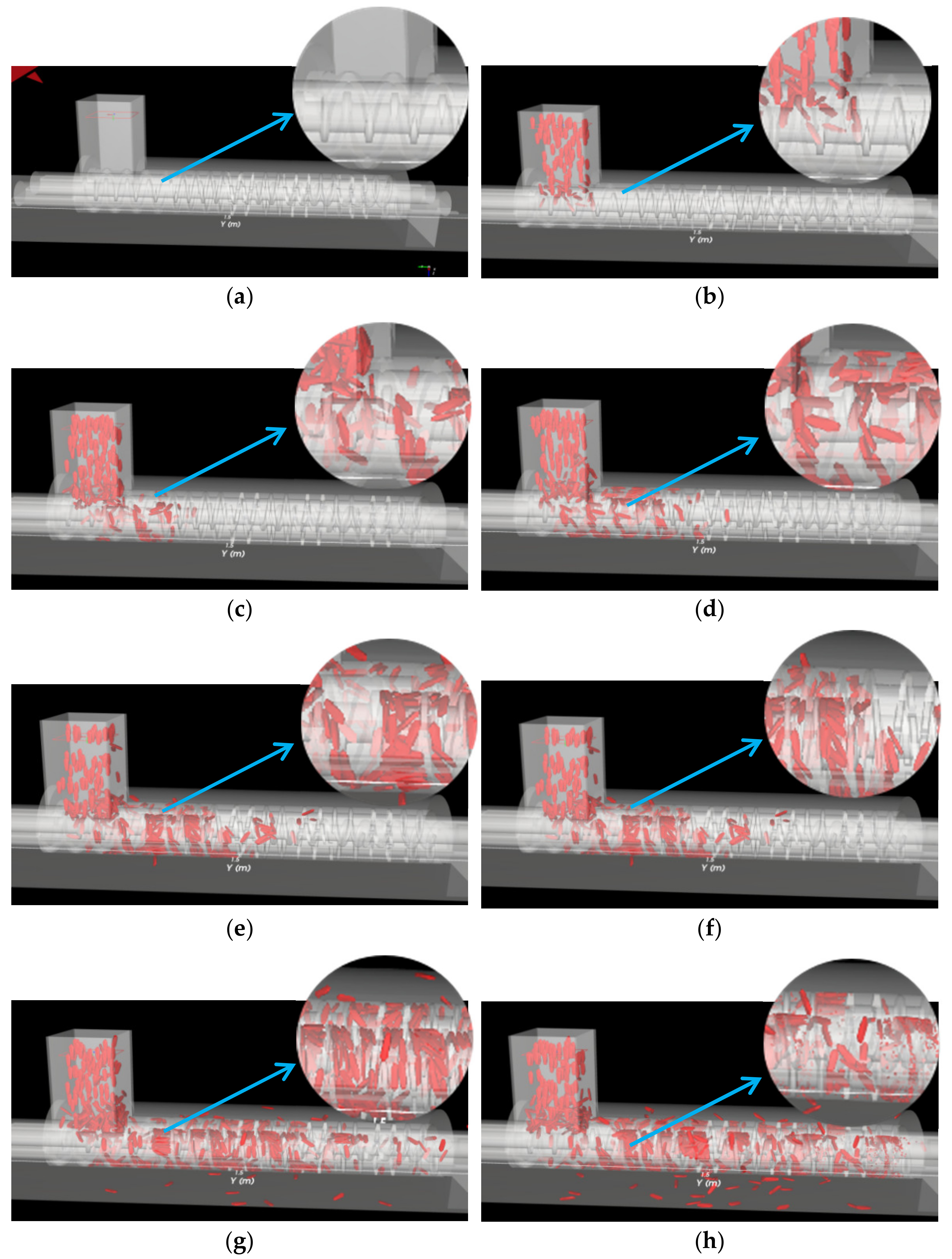

2.2.3. Simulation Process

2.3. Experimental Study

2.3.1. Trial Preparation

2.3.2. Box-Behnken Experimental Design

2.4. Validation Experiment

2.4.1. Twin-Screw Structure Verification Experiment

2.4.2. Straw Moisture Content Verification Experiment

2.4.3. Screw Speed Verification Experiment

3. Results and Discussions

3.1. Simulation Results

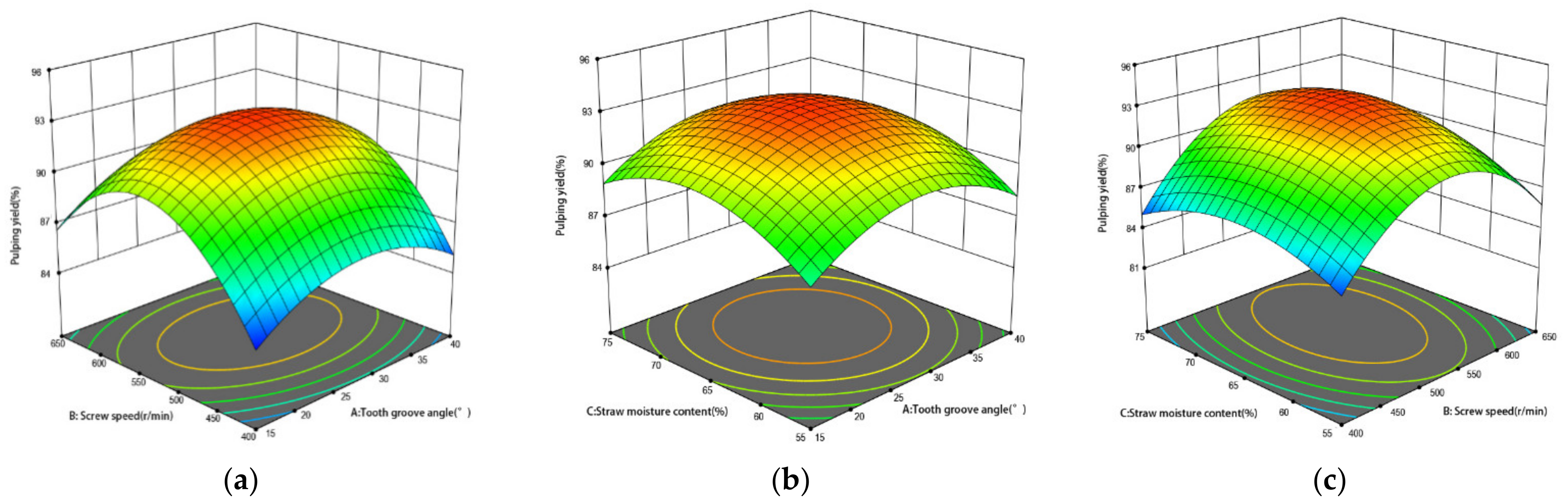

3.2. Multi-Factor Experiment Results

3.2.1. Multi-Factor Experiment Results and Analysis

3.2.2. Box-Behnken Experiment Results

3.3. Results of the Validation Experiment

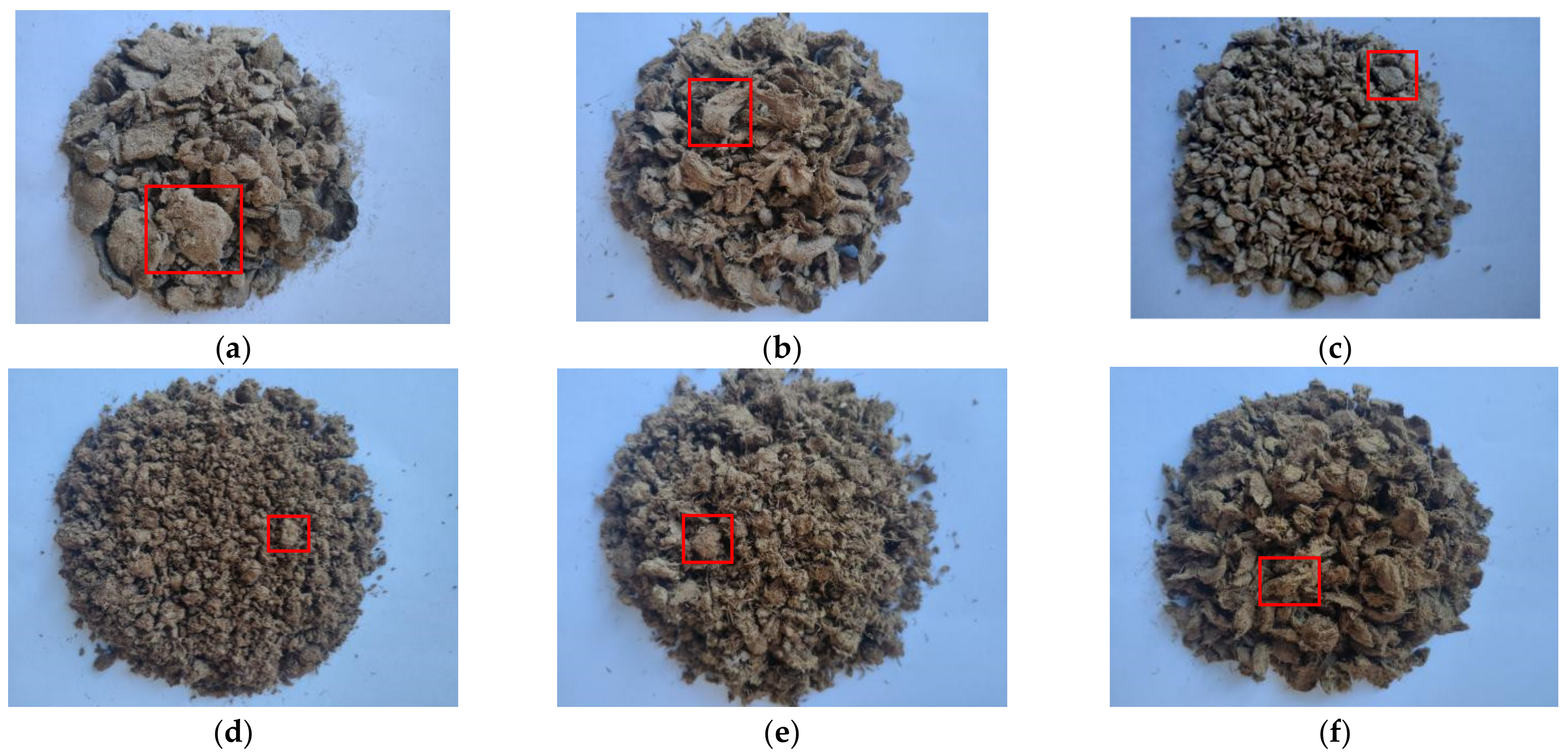

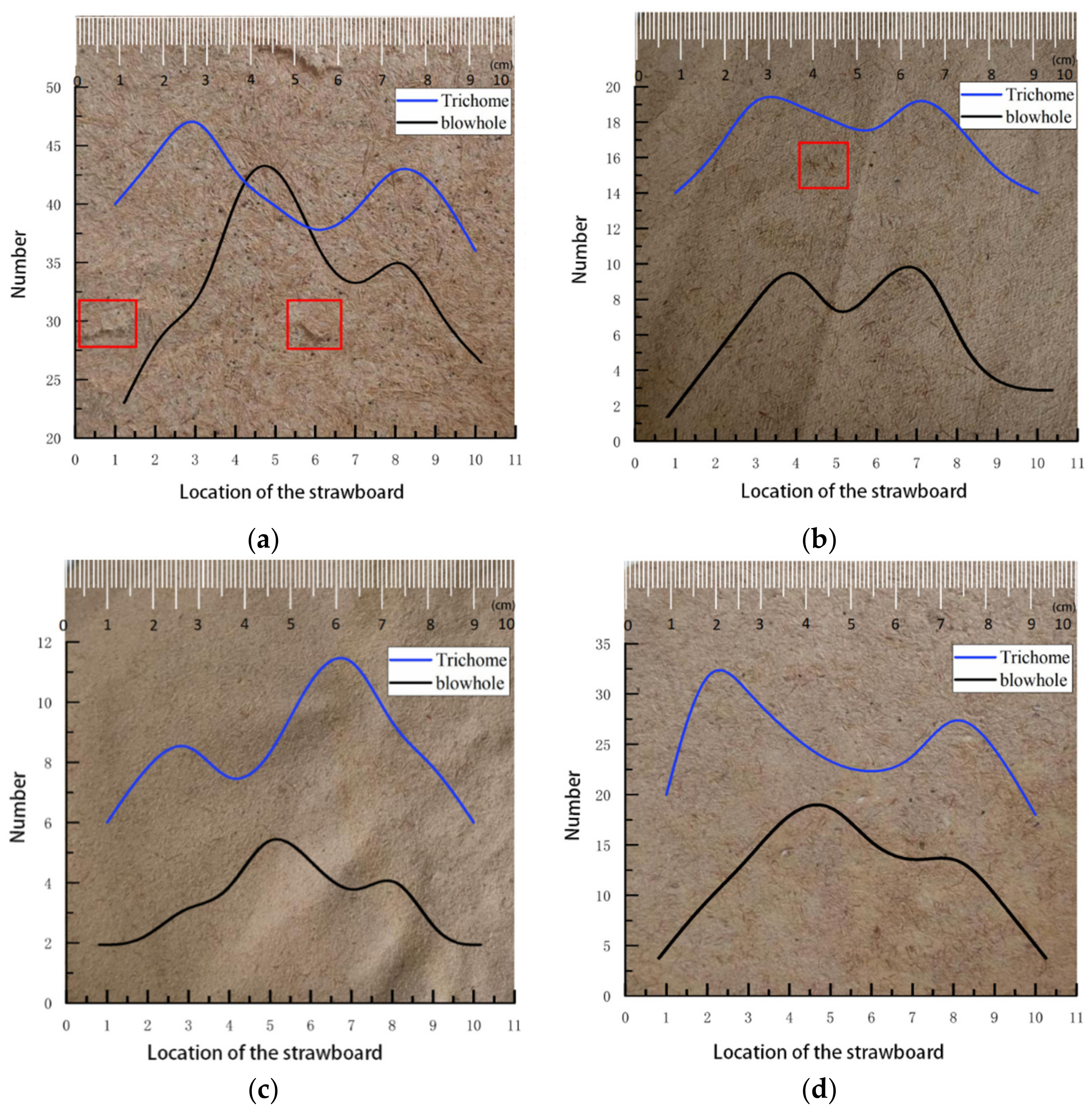

3.3.1. Effect of Twin-Screw Structure Parameters on the Straw Pulping Performance

3.3.2. Effect of Straw Moisture Content on Pulping Performance

3.3.3. The Effect of Screw Speed on Pulping Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Lai, D.Y.; Sardans, J.; Wang, C.; Datta, A.; Pan, T.; Zeng, C.; Bartrons, M.; Peñuelas, J. Rice straw incorporation affects global warming potential differently in early vs. late cropping seasons in Southeastern China. Field Crop. Res. 2015, 181, 42–51. [Google Scholar] [CrossRef]

- Liang, J.J. Analysis on Comprehensive Utilization of Straw in Agricultural Area. In Proceedings of the 7th ICASS International Conference on Social Science and Information (SSI 2018), Lima, Peru, 27–29 December 2018; pp. 30–34. [Google Scholar]

- Hirani, A.H.; Javed, N.; Asif, M.; Basu, S.K.; Kumar, A. A review on first-and second-generation biofuel productions. In Biofuels: Greenhouse Gas Mitigation and Global Warming; Springer: New Delhi, India, 2018; pp. 141–154. [Google Scholar]

- Sun, M.; Wang, Y.; Shi, L. Environmental performance of straw-based pulp making: A life cycle perspective. Sci. Total Environ. 2017, 616–617, 753–762. [Google Scholar] [CrossRef] [PubMed]

- Weerasekara, N.S.; Powell, M.S.; Cleary, P.W.; Tavares, L.; Evertsson, M.; Morrison, R.; Quist, J.; de Carvalho, R. The contribution of DEM to the science of comminution. Powder Technol. 2013, 248, 3–24. [Google Scholar] [CrossRef]

- Tavares, L.M.; André, F.P.; Potapov, A.; Maliska, C. Adapting a breakage model to discrete elements using polyhedral particles. Powder Technol. 2019, 362, 208–220. [Google Scholar] [CrossRef]

- Tavares, L.M. Review and Further Validation of a Practical Single-Particle Breakage Model. KONA Powder Part. J. 2022, 39, 62–83. [Google Scholar] [CrossRef]

- Barrios, G.K.; Jiménez-Herrera, N.; Tavares, L. Simulation of particle bed breakage by slow compression and impact using a DEM particle replacement model. Adv. Powder Technol. 2020, 31, 2749–2758. [Google Scholar] [CrossRef]

- Tavares, L.M.; de Carvalho, R.M. Modeling breakage rates of coarse particles in ball mills. Miner. Eng. 2009, 22, 650–659. [Google Scholar] [CrossRef]

- Oliveira, A.; Rodriguez, V.; de Carvalho, R.; Powell, M.; Tavares, L. Mechanistic modeling and simulation of a batch vertical stirred mill. Miner. Eng. 2020, 156, 106487. [Google Scholar] [CrossRef]

- Tavares, L.M.; Rodriguez, V.A.; Sousani, M.; Padros, C.B.; Ooi, J.Y. An effective sphere-based model for breakage simulation in DEM. Powder Technol. 2021, 392, 473–488. [Google Scholar] [CrossRef]

- Zeng, Y.; Mao, B.; Jia, F.; Han, Y.; Li, G. Modelling of grain breakage of in a vertical rice mill based on DEM simulation combining particle replacement model. Biosyst. Eng. 2022, 215, 32–48. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, R.; Wang, Y.; Jiang, X.; Feng, W.; Wang, J. Simulation and Analysis of the Working Process of Soil Covering and Compacting of Precision Seeding Units Based on the Coupling Model of DEM with MBD. Processes 2022, 10, 1103. [Google Scholar] [CrossRef]

- Rahman, M.; Avelin, A.; Kyprianidis, K. An Approach for Feedforward Model Predictive Control of Continuous Pulp Digesters. Processes 2019, 7, 602. [Google Scholar] [CrossRef]

- Garzon, L.; Fajardo, J.I.; Rodriguez-Maecker, R.; Fernandez, E.D.; Cruz, D. Thermo-Mechanical and Fungi Treatment as an Alternative Lignin Degradation Method for Bambusa oldhamii and Guadua angustifolia Fibers. J. Fungi 2022, 8, 399. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.Z.; Kittikunakorn, N.; Zhang, Y.; Zhang, F. Mechanisms of twin screw melt granulation. J. Drug Deliv. Sci. Technol. 2021, 61, 102150. [Google Scholar] [CrossRef]

- Pradhan, S.U.; Sen, M.; Li, J.; Litster, J.D.; Wassgren, C.R. Granule breakage in twin screw granulation: Effect of material properties and screw element geometry. Powder Technol. 2017, 315, 290–299. [Google Scholar] [CrossRef]

- Shirazian, S.; Darwish, S.; Kuhs, M.; Croker, D.M.; Walker, G. Regime-separated approach for population balance modelling of continuous wet granulation of pharmaceutical formulations. Powder Technol. 2018, 325, 420–428. [Google Scholar] [CrossRef]

- Bumm, S.H.; White, J.L.; Isayev, A.I. Glass fiber breakup in corotating twin screw extruder: Simulation and experiment. Polym. Compos. 2012, 33, 2147–2158. [Google Scholar] [CrossRef]

- Rol, F.; Belgacem, N.; Meyer, V.; Petit-Conil, M.; Bras, J. Production of fire-retardant phosphorylated cellulose fibrils by twin-screw extrusion with low energy consumption. Cellulose 2019, 26, 5635–5651. [Google Scholar] [CrossRef]

- Theng, D.; Arbat, G.; Delgado-Aguilar, M.; Ngo, B.; Labonne, L.; Evon, P.; Mutjé, P. Comparison between two different pretreatment technologies of rice straw fibers prior to fiberboard manufacturing: Twin-screw extrusion and digestion plus defibration. Ind. Crop. Prod. 2017, 107, 184–197. [Google Scholar] [CrossRef]

- Ho, T.T.T.; Abe, K.; Zimmermann, T.; Yano, H. Nanofibrillation of pulp fibers by twin-screw extrusion. Cellulose 2014, 22, 421–433. [Google Scholar] [CrossRef]

- Kępa, K.; Chaléat, C.M.; Amiralian, N.; Batchelor, W.; Grøndahl, L.; Martin, D.J. Evaluation of properties and specific energy consumption of spinifex-derived lignocellulose fibers produced using different mechanical processes. Cellulose 2019, 26, 6555–6569. [Google Scholar] [CrossRef]

- Espinosa, E.; Rol, F.; Bras, J.; Rodríguez, A. Production of lignocellulose nanofibers from wheat straw by different fibrillation methods. Comparison of its viability in cardboard recycling process. J. Clean. Prod. 2019, 239, 118083. [Google Scholar] [CrossRef]

- Liang, F.; Fang, G.; Jiao, J.; Deng, Y.; Han, S.; Shen, K.; Shi, Y.; Li, H.; Zhu, B.; Pan, A.; et al. The Use of Twin Screw Extruder Instead of Model Screw Device During Bamboo Chemo-mechanical Pulping. BioResources 2018, 13, 2487–2498. [Google Scholar] [CrossRef]

- Yang, X.; Wang, G.; Miao, M.; Yue, J.; Hao, J.; Wang, W. The Dispersion of Pulp-Fiber in High-Density Polyethylene via Different Fabrication Processes. Polymers 2018, 10, 122. [Google Scholar] [CrossRef]

- Kratky, L.; Jirout, T. Modelling of particle size characteristics and specific energy demand for mechanical size reduction of wheat straw by knife mill. Biosyst. Eng. 2020, 197, 32–44. [Google Scholar] [CrossRef]

- Yu, W.; Kai, W.; Yu, S. Effects of raw material particle size on the briquetting process of rice straw. J. Energy Inst. 2016, 91, 153–162. [Google Scholar]

- Lenaerts, B.; Aertsen, T.; Tijskens, E.; De Ketelaere, B.; Ramon, H.; De Baerdemaeker, J.; Saeys, W. Simulation of grain–straw separation by Discrete Element Modeling with bendable straw particles. Comput. Electron. Agric. 2014, 101, 24–33. [Google Scholar] [CrossRef]

- Molari, L.; Maraldi, M.; Molari, G. Non-linear rheological model of straw bales behavior under compressive loads. Mech. Res. Commun. 2017, 81, 32–37. [Google Scholar] [CrossRef]

- Tavares, L.M. Analysis of particle fracture by repeated stressing as damage accumulation. Powder Technol. 2009, 190, 327–339. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Zhang, T.; Huang, M. Effect of concentric and non-concentric threshing gaps on damage of rice straw during threshing for combine harvester. Biosyst. Eng. 2022, 219, 1–10. [Google Scholar] [CrossRef]

- Zhang, T.; Zhao, M.; Liu, F.; Tian, H.; Wulan, T.; Yue, Y.; Li, D. A discrete element method model of corn stalk and its mechanical characteristic parameters. BioResources 2020, 15, 9337–9350. [Google Scholar] [CrossRef]

- Meng, X.; Han, Y.; Jia, F.; Chen, P.; Xiao, Y.; Bai, S.; Zhao, H. Numerical simulation approach to predict the abrasion rate of rice during milling. Biosyst. Eng. 2021, 206, 175–187. [Google Scholar] [CrossRef]

- Zini, N.H.M.; de Rooij, M.B.; Bazr Afshan Fadafan, M.; Ismail, N.; Schipper, D.J. Extending the Double-Hertz Model to Allow Modeling of an Adhesive Elliptical Contact. Tribol. Lett. 2018, 66, 30. [Google Scholar] [CrossRef]

- Zhang, T.; Peng, W.; Shen, K.; Yu, S. AFM measurements of adhesive forces between carbonaceous particles and the substrates. Nucl. Eng. Des. 2015, 293, 87–96. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, L.; Gao, S.; Zhu, C.; Yan, Y.; Liu, X.; Li, L.; Chen, H. A Value-Added Utilization Method of Sugar Production By-Products from Rice Straw: Extraction of Lignin and Evaluation of Its Antioxidant Activity. Processes 2022, 10, 1210. [Google Scholar] [CrossRef]

- Jia, H.; Deng, J.; Deng, Y.; Chen, T.; Wang, G.; Sun, Z.; Guo, H. Contact parameter analysis and calibration in discrete element simulation of rice straw. Int. J. Agric. Biol. Eng. 2021, 14, 72–81. [Google Scholar] [CrossRef]

- Lai, Y.-H.; Sun, H.-C.; Chang, M.-H.; Li, C.-C.; Shyu, J.-G.; Perng, Y.-S. Feasibility of substituting old corrugated carton pulp with thermal alkali and enzyme pretreated semichemical mechanical rice straw pulp. Sci. Rep. 2022, 12, 3493. [Google Scholar] [CrossRef]

- Razzak, A.; Khiari, R.; Moussaoui, Y.; Belgacem, M.N. Cellulose Nanofibers from Schinus molle: Preparation and Characterization. Molecules 2022, 27, 6738. [Google Scholar] [CrossRef]

- Rol, F.; Karakashov, B.; Nechyporchuk, O.; Terrien, M.; Meyer, V.; Dufresne, A.; Belgacem, M.N.; Bras, J. Pilot-Scale Twin Screw Extrusion and Chemical Pretreatment as an Energy-Efficient Method for the Production of Nanofibrillated Cellulose at High Solid Content. ACS Sustain. Chem. Eng. 2017, 5, 6524–6531. [Google Scholar] [CrossRef]

- Guo, H.; Chang, J.; Yin, Q.; Wang, P.; Lu, M.; Wang, X.; Dang, X. Effect of the combined physical and chemical treatments with microbial fermentation on corn straw degradation. Bioresour. Technol. 2013, 148, 361–365. [Google Scholar] [CrossRef]

- Taheri, H.; Hietala, M.; Oksman, K. One-step twin-screw extrusion process of cellulose fibers and hydroxyethyl cellulose to produce fibrillated cellulose biocomposite. Cellulose 2020, 27, 8105–8119. [Google Scholar] [CrossRef]

- Robinson, J.; Aoun, H.K.; Davison, M. Determining moisture levels in straw bale construction. In Proceedings of the 3rd International Conference on Sustainable Civil Engineering Structures and Construction Materials—Sustainable Structures for Future Generations (SCESCM), Bali, Indonesia, 5–7 September 2016; pp. 1526–1534. [Google Scholar]

- Lu, Z.; Hu, X.; Lu, Y. Particle Morphology Analysis of Biomass Material Based on Improved Image Processing Method. Int. J. Anal. Chem. 2017, 2017, 5840690. [Google Scholar] [CrossRef] [PubMed]

- Hänninen, T.; Thygesen, A.; Mehmood, S.; Madsen, B.; Hughes, M. Mechanical processing of bast fibres: The occurrence of damage and its effect on fibre structure. Ind. Crop. Prod. 2012, 39, 7–11. [Google Scholar] [CrossRef]

- Jing, X.; Zhang, X.; Bao, J. Inhibition Performance of Lignocellulose Degradation Products on Industrial Cellulase Enzymes During Cellulose Hydrolysis. Appl. Biochem. Biotechnol. 2009, 159, 696–707. [Google Scholar] [CrossRef]

- Xing, L.; Xu, M.; Pu, J. The Properties and Application of an Ultrasonic-Assisted Wheat Straw Pulp having Enhanced Tendency for Ash Formation. BioResources 2016, 12, 871–881. [Google Scholar] [CrossRef][Green Version]

- Jiang, H.; Liu, J.; Wang, H.; Yang, R.; Zhao, W.; Yang, D.; Yin, S.; Shen, L. Study on Combined Vacuum–Mechanical Defoaming Technology for Flotation Froth and Its Mechanism. Processes 2022, 10, 1183. [Google Scholar] [CrossRef]

- Nuengwang, W.; Srinophakun, T.R.; Realff, M.J. Real-Time Optimization of Pulp Mill Operations with Wood Moisture Content Variation. Processes 2020, 8, 651. [Google Scholar] [CrossRef]

- Quispe-Quispe, L.G.; Limpe-Ramos, P.; Arenas-Chávez, C.A.; Gomez, M.M.; Mejia, C.R.; Alvarez-Risco, A.; Del-Aguila-Arcentales, S.; Yáñez, J.A.; Vera-Gonzales, C. Physical and Mechanical Characterization of a Functionalized Cotton Fabric with Nanocomposite Based on Silver Nanoparticles and Carboxymethyl Chitosan Using Green Chemistry. Processes 2022, 10, 1207. [Google Scholar] [CrossRef]

- Gardea, F.; Glaz, B.; Riddick, J.; Lagoudas, D.C.; Naraghi, M. Energy Dissipation Due to Interfacial Slip in Nanocomposites Reinforced with Aligned Carbon Nanotubes. ACS Appl. Mater. Interfaces 2015, 7, 9725–9735. [Google Scholar] [CrossRef]

| Straw particle | Density ρ/(kg/m3) | 1440 |

| Poisson ratio | 0.25 | |

| Shear elastic modulus G/(Pa) | 1.5 × 106 | |

| Geometric model | Density ρ/(kg/m3) | 7800 |

| Poisson ratio | 0.35 | |

| Shear elastic modulus G/(Pa) | 8 × 1010 | |

| Particle-Particle | Recovery coefficient | 0.65 |

| Static friction coefficient | 0.18 | |

| Rolling friction coefficient | 0.01 | |

| Particle-Geometric mode | Recovery coefficient | 0.65 |

| Static friction coefficient | 0.15 | |

| Rolling friction coefficient | 0.01 |

| Spiral Sleeve Combination | Groove Angle Arrangement | ||

|---|---|---|---|

| PNPN | NPPN | 45°−30°−15° (WSR) | 15°−45°−30° (RWS) |

| PPNN | PNNN | 45°−15°−30° (WRS) | 45°−45°−15° (WWR) |

| PNNP | NPNN | 30°−45°−15° (SWR) | 45°−45°−30° (WWS) |

| NPNP | NNPN | 30°−15°−45°(SRW) | 30°−30°−45° (SSW) |

| NNPP | NNNP | 15°−30°−45° (RSW) | 30°−30°−15° (SSR) |

| Coding | Factors | ||

|---|---|---|---|

| Groove Angle A/(°) | Screw Speed B/(r/min) | Straw Moisture Content C/(%) | |

| −1.682 | 15 | 450 | 55 |

| −1 | 20 | 500 | 60 |

| 0 | 25 | 550 | 65 |

| 1 | 30 | 600 | 70 |

| 1.682 | 35 | 650 | 75 |

| Number | Factors | |||

|---|---|---|---|---|

| Groove Angle A/(°) | Screw Speed B/(r/min) | Straw Moisture Content C/(%) | Pulping Yield/% | |

| 1 | 1 | 1 | 1 | 91.4 |

| 2 | 1 | 1 | −1 | 82.8 |

| 3 | 1 | −1 | 1 | 88.9 |

| 4 | 1 | −1 | −1 | 90.5 |

| 5 | −1 | 1 | 1 | 89.3 |

| 6 | −1 | 1 | −1 | 86.7 |

| 7 | −1 | −1 | 1 | 88.3 |

| 8 | −1 | −1 | −1 | 85.4 |

| 9 | 1.682 | 0 | 0 | 92.5 |

| 10 | −1.682 | 0 | 0 | 84.2 |

| 11 | 0 | 1.682 | 0 | 89.3 |

| 12 | 0 | −1.682 | 0 | 91.3 |

| 13 | 0 | 0 | 1.682 | 87.7 |

| 14 | 0 | 0 | −1.682 | 92.1 |

| 15 | 0 | 0 | 0 | 83.4 |

| 16 | 0 | 0 | 0 | 85.5 |

| 17 | 0 | 0 | 0 | 87.4 |

| 18 | 0 | 0 | 0 | 90.9 |

| 19 | 0 | 0 | 0 | 89.6 |

| Source | Sum of Squares | Freedom | Mean Square | p |

|---|---|---|---|---|

| Model | 1894.46 | 9 | 210.5 | <0.0001 |

| A | 7.03 | 1 | 7.03 | 0.0076 |

| B | 81.92 | 1 | 81.92 | 0.0035 |

| C | 30.03 | 1 | 30.03 | 0.0051 |

| AB | 0.04 | 1 | 0.04 | 0.9269 |

| AC | 0.0025 | 1 | 0.0025 | 0.9817 |

| BC | 12.96 | 1 | 12.96 | 0.0305 |

| A² | 260.29 | 1 | 260.29 | 0.0001 |

| B² | 1130.74 | 1 | 1130.74 | <0.0001 |

| C² | 219.03 | 1 | 219.03 | 0.0002 |

| Residual | 30.93 | 7 | 4.42 | / |

| Lack of fit | 22.57 | 3 | 7.52 | 0.1239 |

| Error | 8.36 | 4 | 2.09 | / |

| Total value | 1925.39 | 16 | / | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, H.; Gong, Y.; Zhao, N.; Zhang, L.; Lv, D.; Ren, D. Simulation and Experimental Validation on the Effect of Twin-Screw Pulping Technology upon Straw Pulping Performance Based on Tavares Mathematical Model. Processes 2022, 10, 2336. https://doi.org/10.3390/pr10112336

Cheng H, Gong Y, Zhao N, Zhang L, Lv D, Ren D. Simulation and Experimental Validation on the Effect of Twin-Screw Pulping Technology upon Straw Pulping Performance Based on Tavares Mathematical Model. Processes. 2022; 10(11):2336. https://doi.org/10.3390/pr10112336

Chicago/Turabian StyleCheng, Huiting, Yuanjuan Gong, Nan Zhao, Luji Zhang, Dongqing Lv, and Dezhi Ren. 2022. "Simulation and Experimental Validation on the Effect of Twin-Screw Pulping Technology upon Straw Pulping Performance Based on Tavares Mathematical Model" Processes 10, no. 11: 2336. https://doi.org/10.3390/pr10112336

APA StyleCheng, H., Gong, Y., Zhao, N., Zhang, L., Lv, D., & Ren, D. (2022). Simulation and Experimental Validation on the Effect of Twin-Screw Pulping Technology upon Straw Pulping Performance Based on Tavares Mathematical Model. Processes, 10(11), 2336. https://doi.org/10.3390/pr10112336