1. Introduction

Various morphologies are produced during the solidification of substances, which affect the physical properties of materials. Therefore, understanding the impact of the growth environment on dendritic morphology is crucial for certain engineering applications [

1]. In the research of lithium batteries, dendritic deposited lithium can pierce through the separator and cause internal short circuits, while uniformly deposited lithium can lengthen the battery cycle life [

2]. Morphology control of deposited lithium is a major challenge for the development of lithium metal batteries. Available control methods are focused on the modification of an electrolyte with additives [

3], artificial SEI [

4], and nanostructured electrolytes [

5]. However, most of these methods are context dependent, and the dendrite growth mechanism still requires further clarification.

The dendrites growth process can be demonstrated by simulation techniques, which are convenient to investigate the influence of environmental parameters. For the formation process of lithium dendrite, many substances are involved due to the multi-component environment of the electrolyte solution [

6], which leads to the existence of several side reactions. A pure reaction-diffusion process of a single substance is simpler to simulate and can be considered as a foundation to study the essential mechanism of the multi-component system. A variety of morphologies can be produced by single-molecule water crystallization under different environmental conditions, which is a suitable alternative to studying the relationship between dendrite morphologies and parameters.

Some classical snowflake shapes are summarized through early experiments including artificial and natural ice crystals [

7]. Supersaturation and temperature have been proven to be two crucial factors related to the diversity of this phase transition process. More specifically, the temperature is the main factor to control the morphology of snowflakes, and supersaturation is more decisive in the growth rate. Although the types of snowflake morphology have been obtained by experiments, the underlying physical mechanism remains controversial. From the research on the physical dynamics of ice crystal growth, the formation of snowflakes represents an interaction effect at length scales ranging from the molecular to the macroscopic [

8], and it is largely controlled by a combination of molecular attachment kinetics on faceted surfaces and diffusion process of heat and particles [

9]. Numerous models are proposed to describe the growth process, such as the surface diffusion model of Mason [

10] and the layer nucleation rate theory by Nelson [

11].

Exploring the effect of physical parameters on dendritic structures by experiments is expensive in cost and time. The theoretical physical model can describe the snowflake growth data by calculating the condensation coefficient and growth rate, but it is limited in expressing the dendrite morphology intuitively. The dynamic simulation of the growth process of snowflakes provides a space-time evolution of dendrites morphologies. Cellular automaton and the phase-field method are the two dominant technologies for snowflake growth simulation.

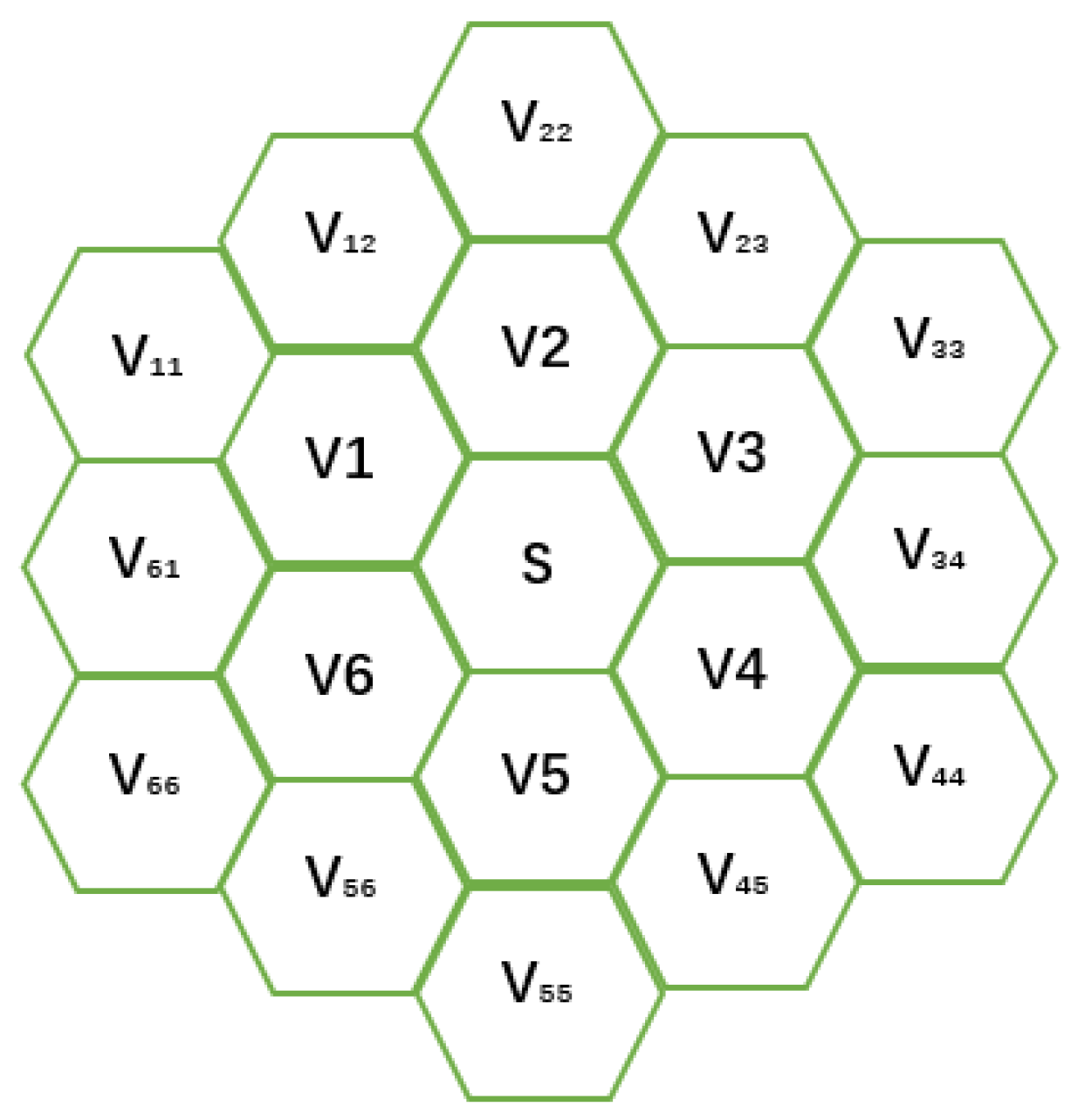

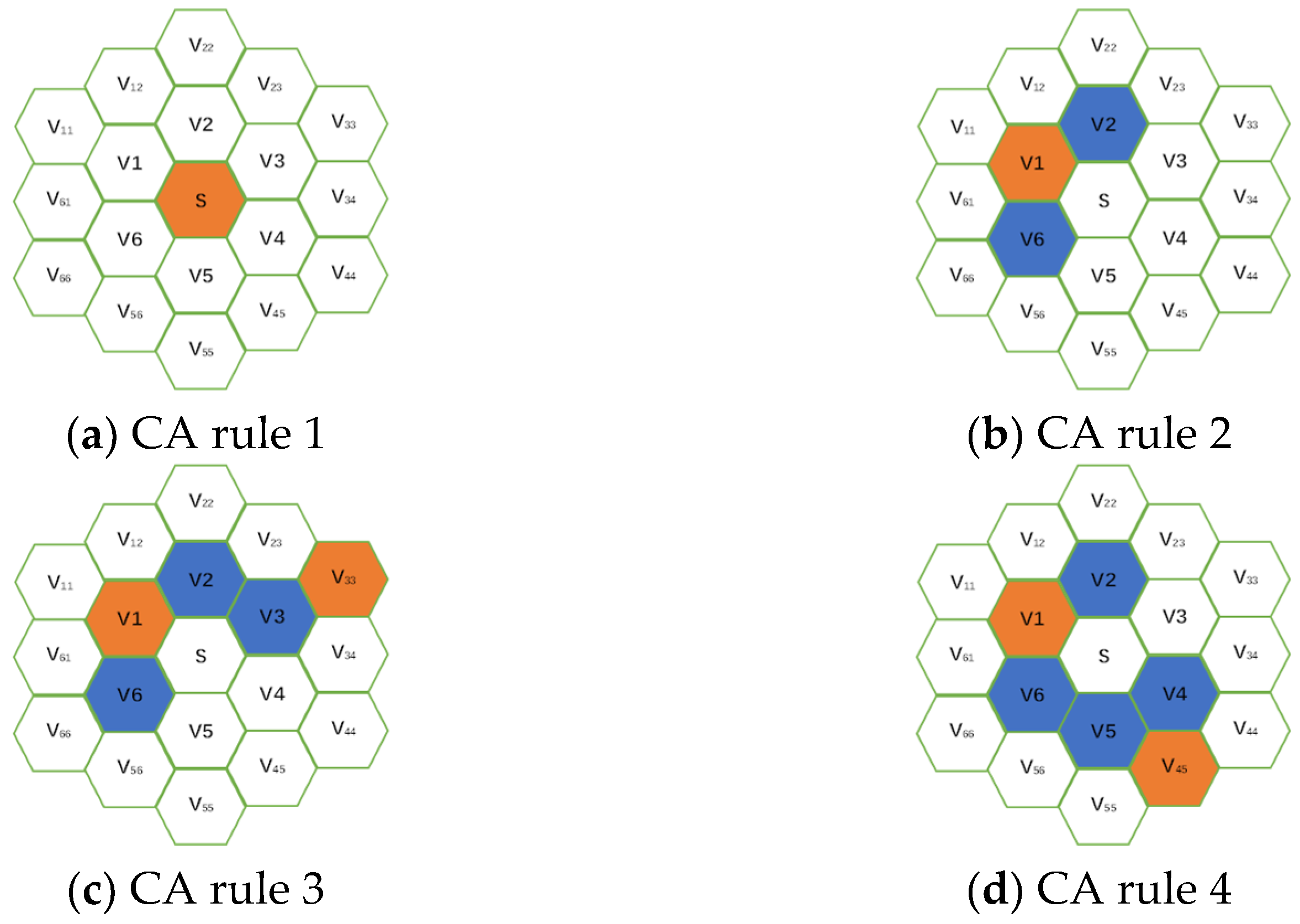

Cellular automata (CA) are computational algorithms that rely on a few relatively simple local rules and are realized through parallel computation, which was first proposed by von Neumann [

12]. The CA framework has been proven to be useful for complex systems simulations in various scientific fields, and one prominent research area is the crystallization process. Clifford [

13] established a CA model that was realized on hexagonal grids to generate abundant snowflake patterns, which is an effective tool to investigate different snowflake morphologies. Simple transformation rules of cells are applied in this model; however, this CA model is inapplicable in analyzing the actual environment condition influence. Based on the Clifford model, Liu [

14] explored the model parameters systematically and considered the vapor density and supersaturation, but no specific connection between model parameters and supersaturation was addressed. CA models perform well in reproducing the actual physical process, while it is intrinsically difficult to extrapolate to other similar processes by one transformation rule. Although constructing the transition functions based on intuition is an advantage, it reduces the interpretability of the model.

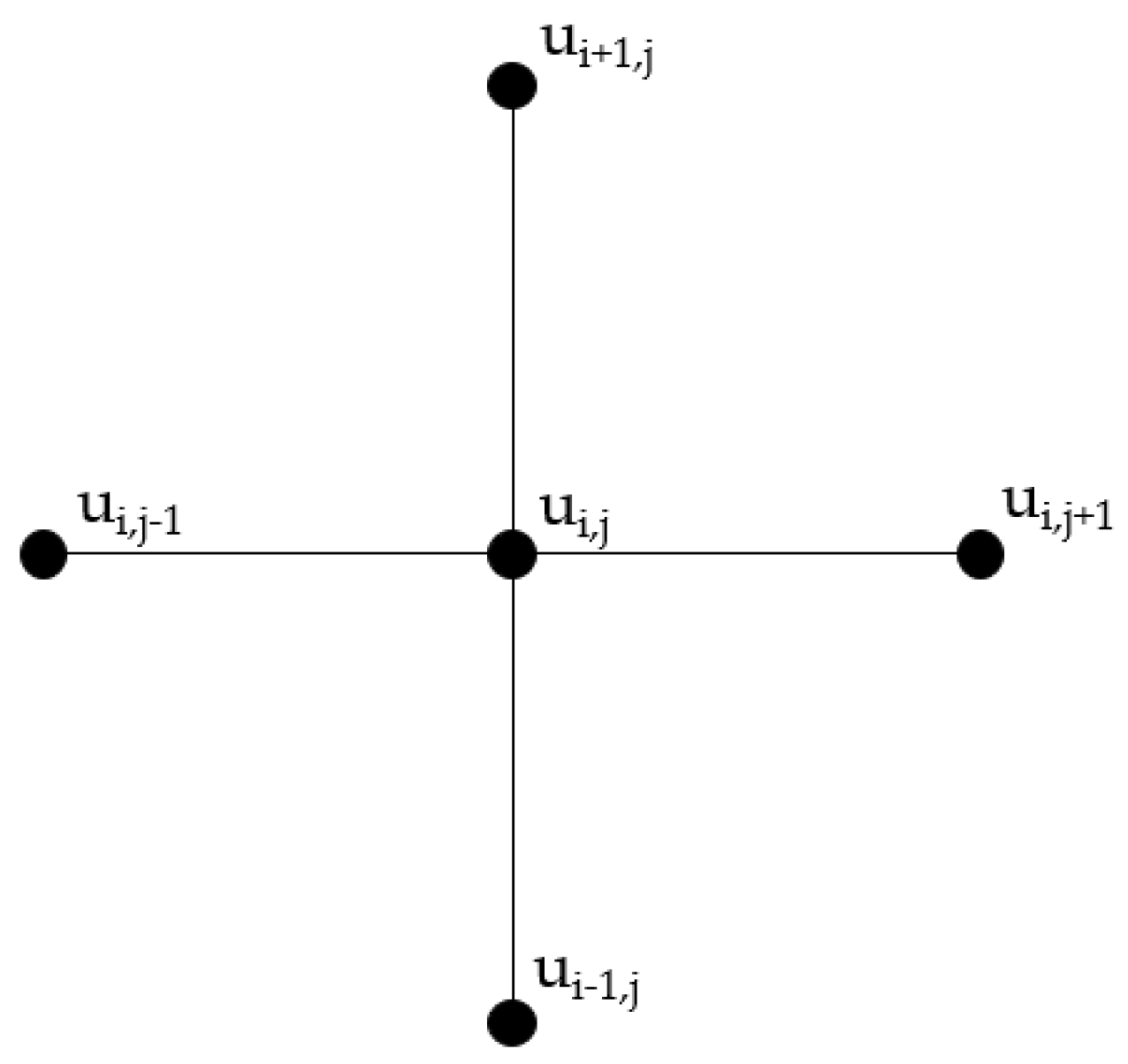

The phase-field method (PF) is a general technique to explore the interface evolution process derived from thermodynamic functions and kinetic equations [

15]. The interface can be tracked by introducing order parameters to represent different phase states, which allows us to study the evolution process of arbitrary complex morphology [

16]. PF was originally used to study the dendrite evolution process of the alloy solidification process by Kobayashi [

17], and the anisotropic parameters were introduced into the model to obtain the various dendrite morphology. Starting from the KKS [

18] model and anisotropic parameters, Chen [

19] simplified the free energy density with the dilute solution approximation method to construct the ice crystal PF model, and the effect of anisotropy on the formation of snowflakes was explored. G. Demange [

20] proposed a 3D snowflake PF model based on a single Lyapunov functional, and considered the role of vertical attachment dynamics in the growth process of ice crystals, the model combines the PF model and physical theory to improve the physical meaning. Although PF has achieved the simulation of the crystallization process by defining global equations compared to the more complex sharp-interface modeling methods [

21], the computational cost used for such free boundary problems is much higher than CA, especially concerning the complex multi-material phase transition processes, and it is almost impossible to identify the PDEs’ parameters from the experimental data.

In this paper, the PF and CA methods are adopted to simulate the snowflake growth process. Firstly, the influence of the parameters in both models on the final simulated snowflake patterns is discussed. Secondly, the snowflake morphologies produced by both methods are somewhat similar under different parameters, and the physical processes of these situations are explained to deepen the physical meaning of the parameters. The method of image recognition is adopted to obtain the snowflake growth rate of both simulation methods. The correspondence of model parameters from both methods are investigated by qualitative analysis. It is concluded that both models are similar in growth rate and the physical meaning of the parameters in CA can be illustrated by the comparison with PF. The results make it possible to combine the computational efficiency of CA with the advantages of an accurate solution of the PF method for subsequent research in crystallization.

3. Results and Discussion

Both methods are carried out in the environment of the Lenovo R9000P computer, in which the CA model is implemented in Python software, and the PF method is implemented in MATLAB.

3.1. Simulation Results of the CA Model

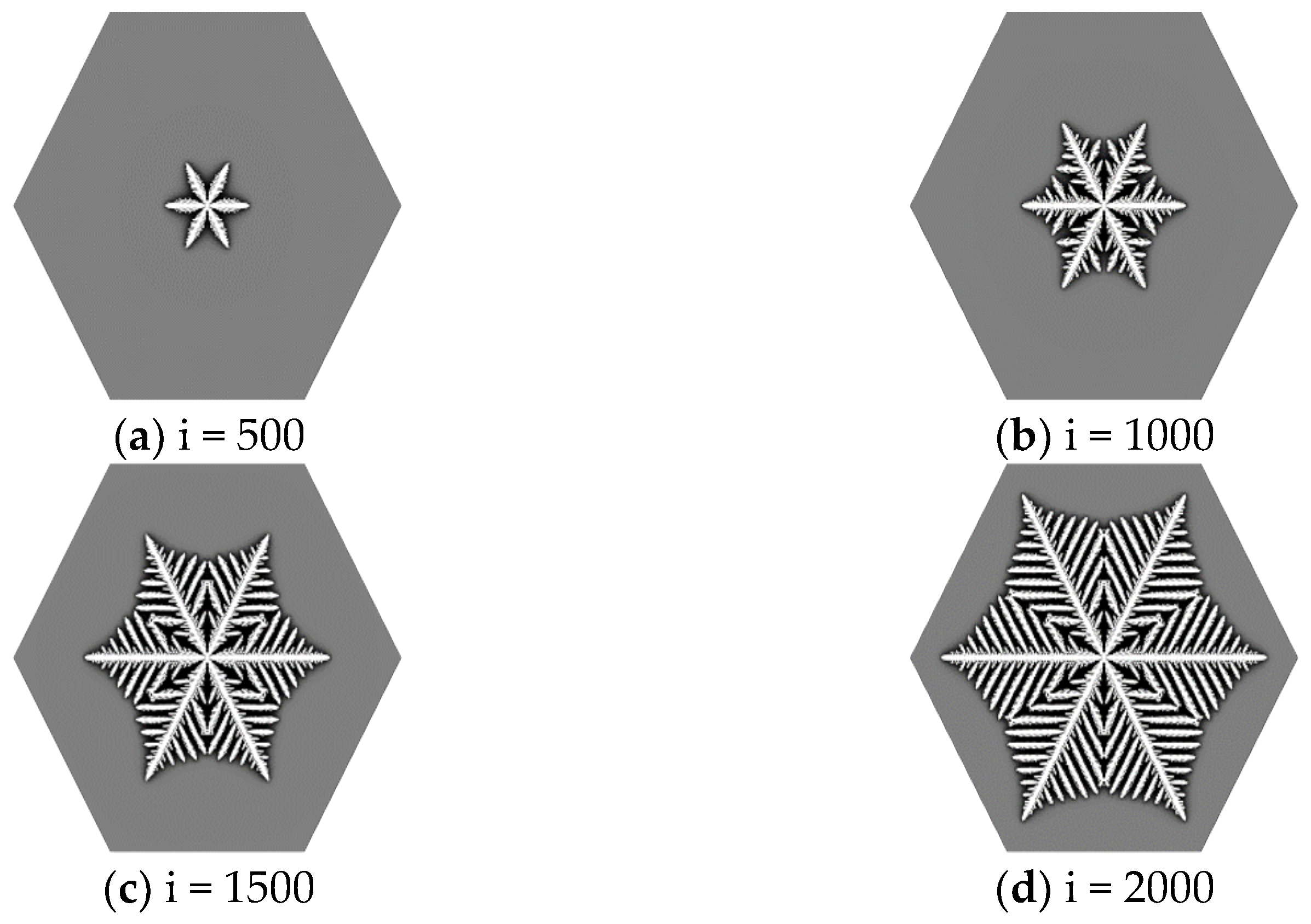

The model parameters of the CA model in the previous chapter are adopted so that the background water vapor parameter

is set to 0.5, the vertical growth parameter

is set to 0.00, and the number of iterations is set to 2000. The result is shown in

Figure 6.

It can be seen that the snowflake growth process is simulated by CA from the figures. The morphologies of snowflakes are greatly changed by different parameters. The simulated snowflake morphologies of different background parameters

are shown in

Figure 7 when the vertical growth parameter

is set to a constant 0.001.

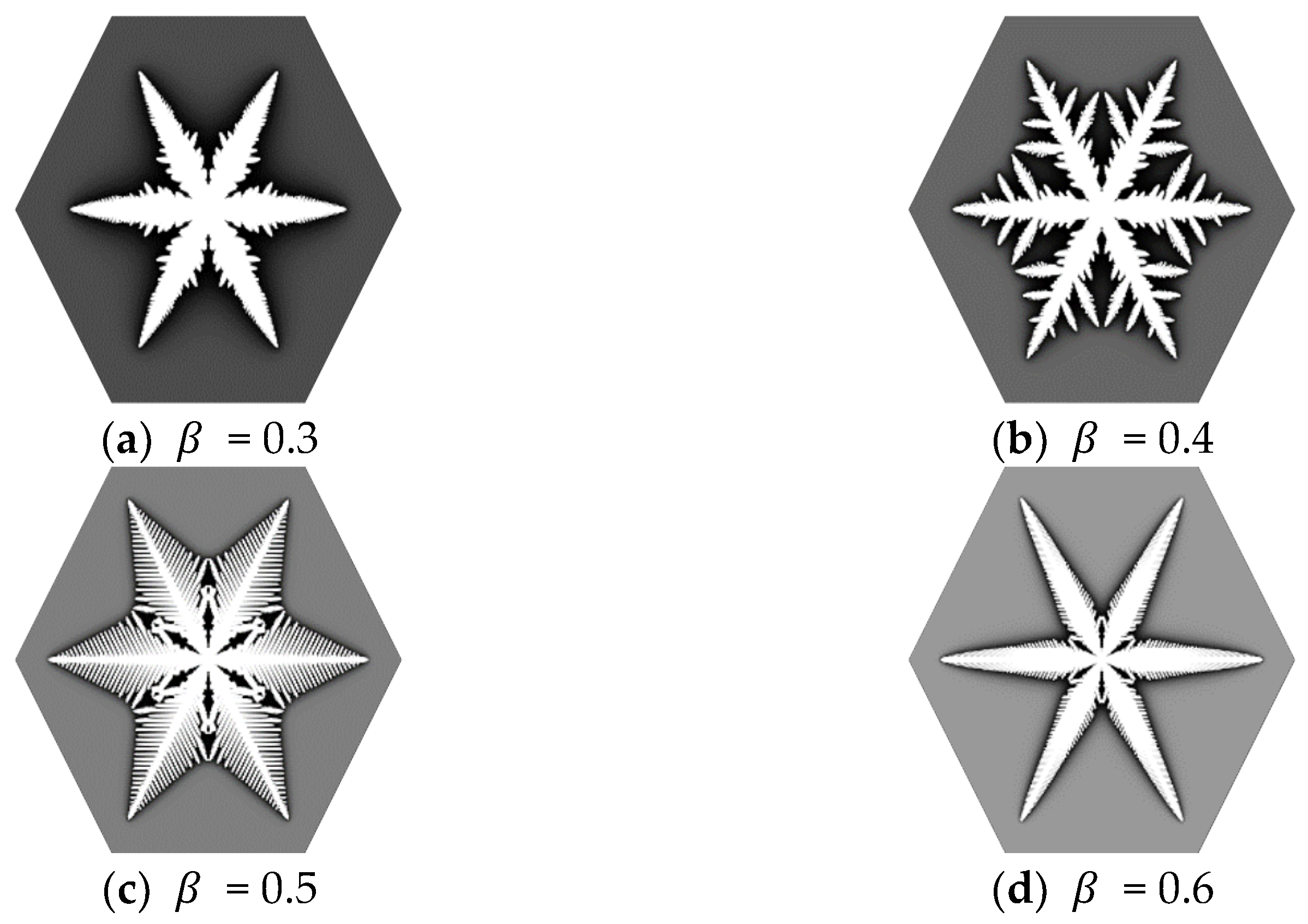

It can be seen from

Figure 7 that when the parameter

increases, the shape of the main crystal branch becomes thinner, and the growth of the side crystal branch increases. However, when

increases to a certain extent, the side branch slowly grows again. Snowflakes tend to have a sharper, more relaxed structure on the main branch. At the same time, the water vapor density

affects the growth rate of dendrites, and the decrease in

results in slower dendrite growth. The vertical growth parameter γ also has a great influence on the snowflake crystal morphology as shown in

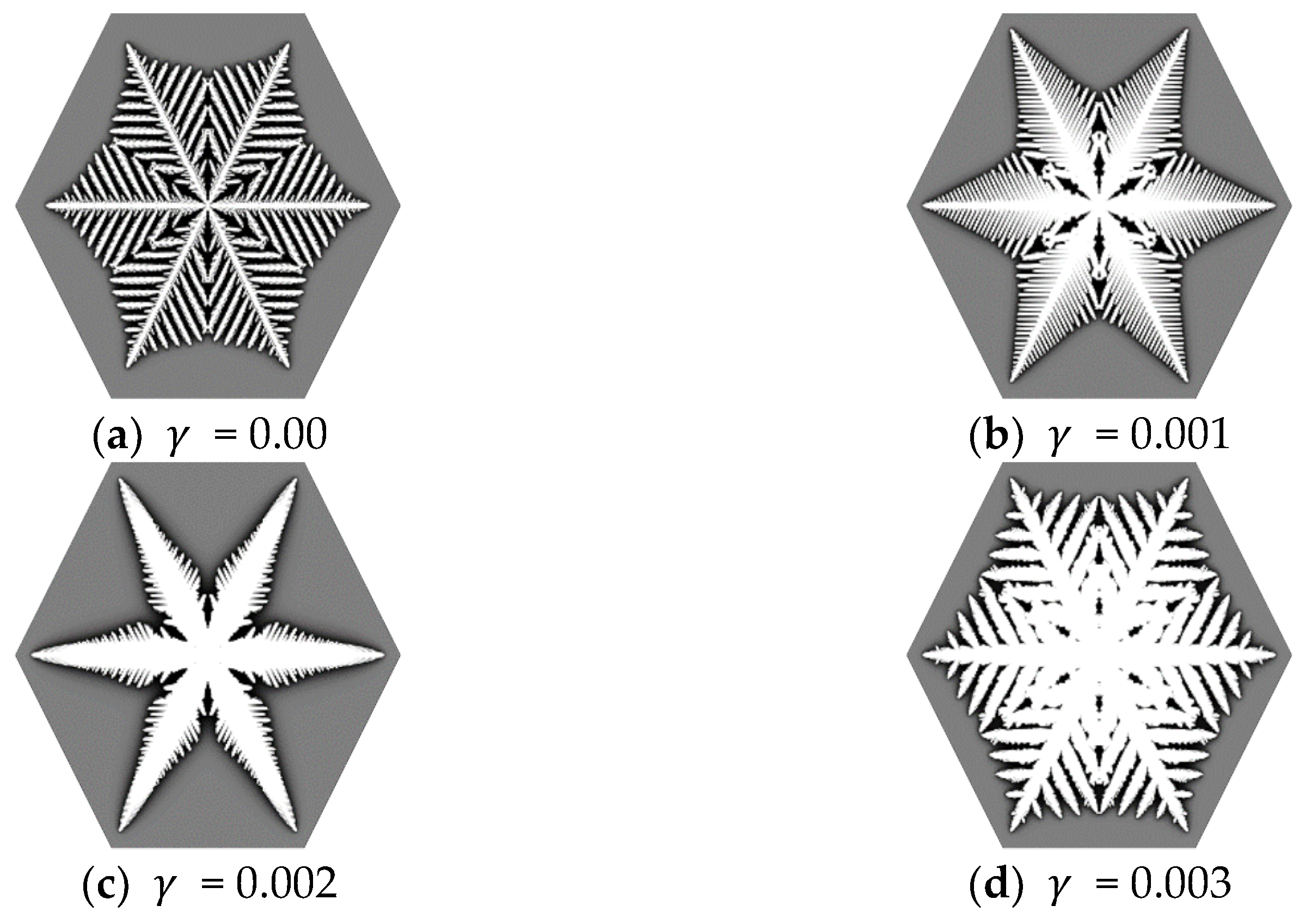

Figure 8; when

is set to 0.5, the effect of different

values on the snowflake morphologies are shown below.

It can be seen from

Figure 8 that the larger the vertical growth parameter

, the thicker the main branch, and the shorter and denser the side branches. However, after reaching a certain level, the snowflakes are more inclined to form a compact morphology; and as the parameter

continues to increase, a plate-like hexagonal snowflake is finally formed.

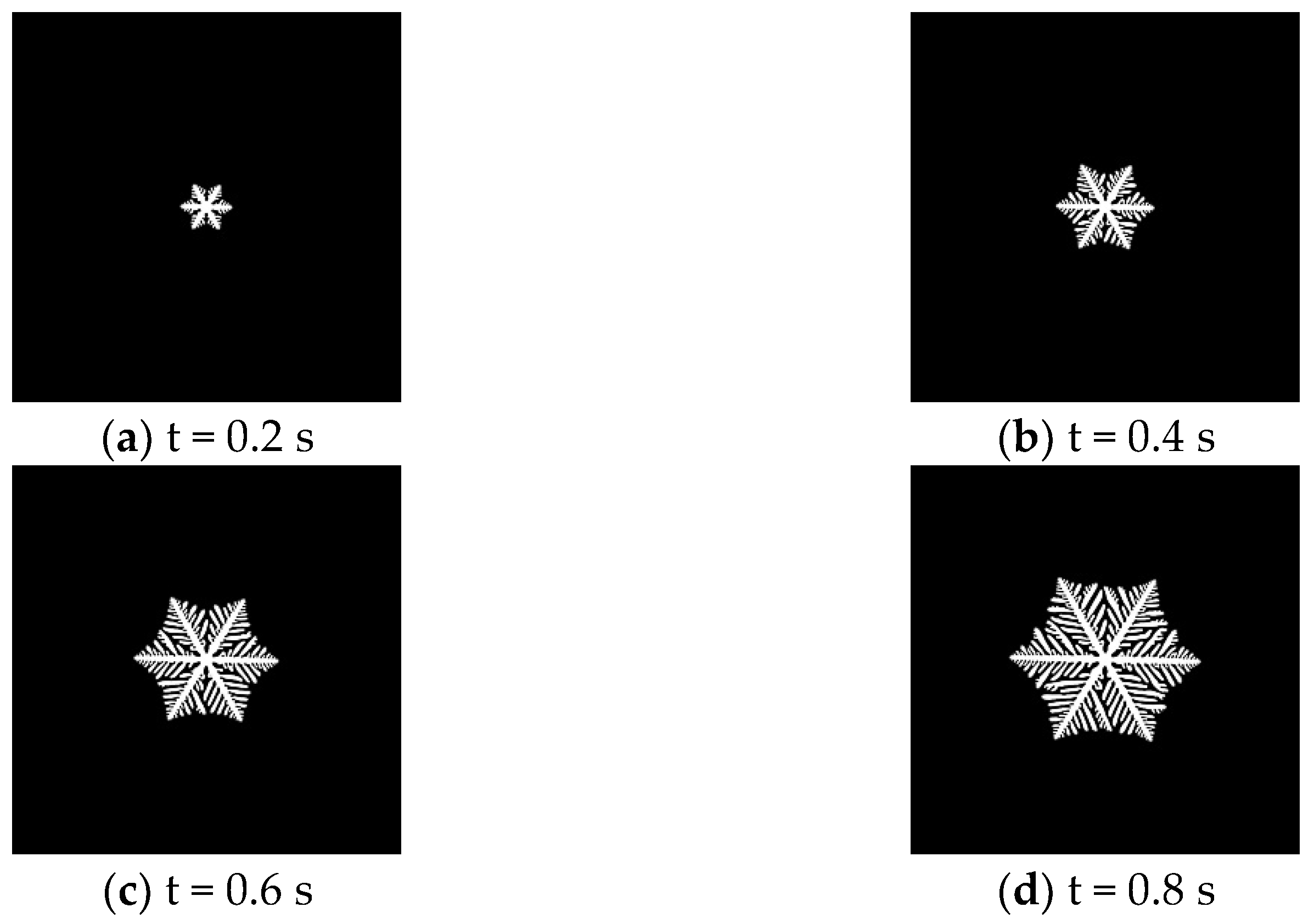

3.2. Simulation Results of the PF Method

According to the PF method described in

Section 2.2, the ice crystal growth process is simulated using the finite difference method, and the PF parameters use the data in

Table 1. The phase-field model simulates the evolution of the snowflake growth process over time, and the results are shown in

Figure 9.

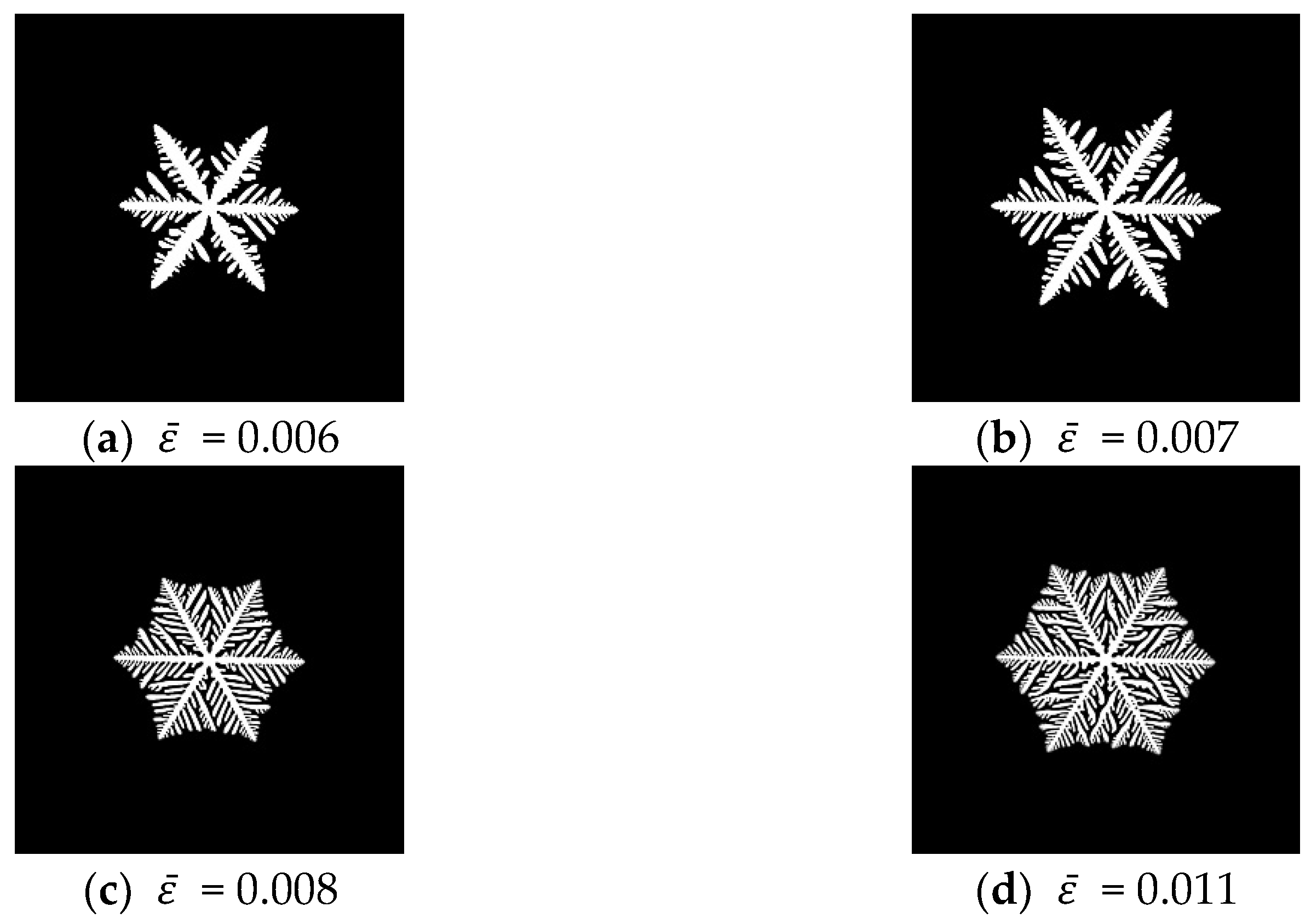

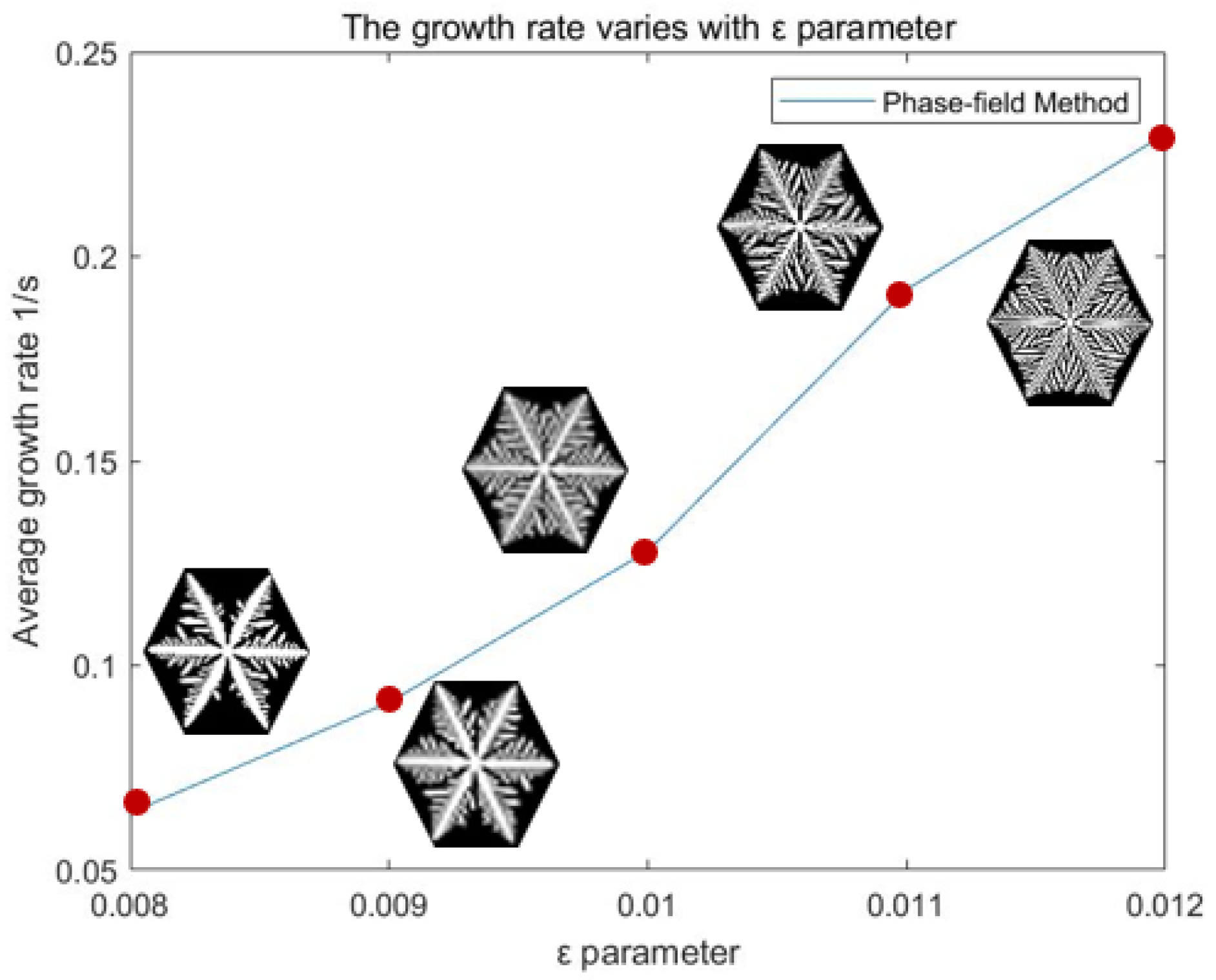

It can be seen that the PF method can also simulate the growth process of snowflakes, and the parameters in the PF method also affect snowflake morphology. The effect of the anisotropic gradient energy influence of coefficient ε is shown in

Figure 10.

It can be seen that with the increase in anisotropic gradient energy, the growth rate of the dendrite accelerates, the main branches become thinner, new branches are formed on the side branches, and the snowflakes are more inclined to form a compact and dense morphology. In addition, we also need to pay attention to the fact that the changes in parameters in the PF method are more regular than in the CA model. On the one hand, the parameters of the PF method obtain physical meaning; on the other hand, the neighbor rules of the CA model are difficult to derive a quantitative formula such as the PF method.

3.3. Comparison of the Simulation Results of the Two Models

There are three questions to be discussed in the pure water solidification problem: (1) the evolution of the solid fraction, (2) the evolution of the phase state, and (3) the interface geometry problem. They are investigated from different aspects by CA and PF. The solid fraction is described by the state value of lattices in the CA model, while it is specified by the order parameter in the PF model. The threshold values are specified to define the phase state by both methods. A hexagonal mesh is applied in CA to demonstrate the sixfold symmetry of ice crystal dendrite growth, which is described by the anisotropy function in PF. The dendrite growth process and various morphologies are simulated by both methods, and the relation of the model parameters is discussed below.

3.3.1. Comparison of the Growth Parameters of Two Methods

There are only two environmental parameters of the CA model, while many environmental parameters are included in the PF method, and these parameters are classified into the parameters and by the CA model. PF and CA are used to simulate the classical snowflake patterns in three different environments, and the physical interpretation of the model parameters is given to identify the relationship between the model parameters of the two methods.

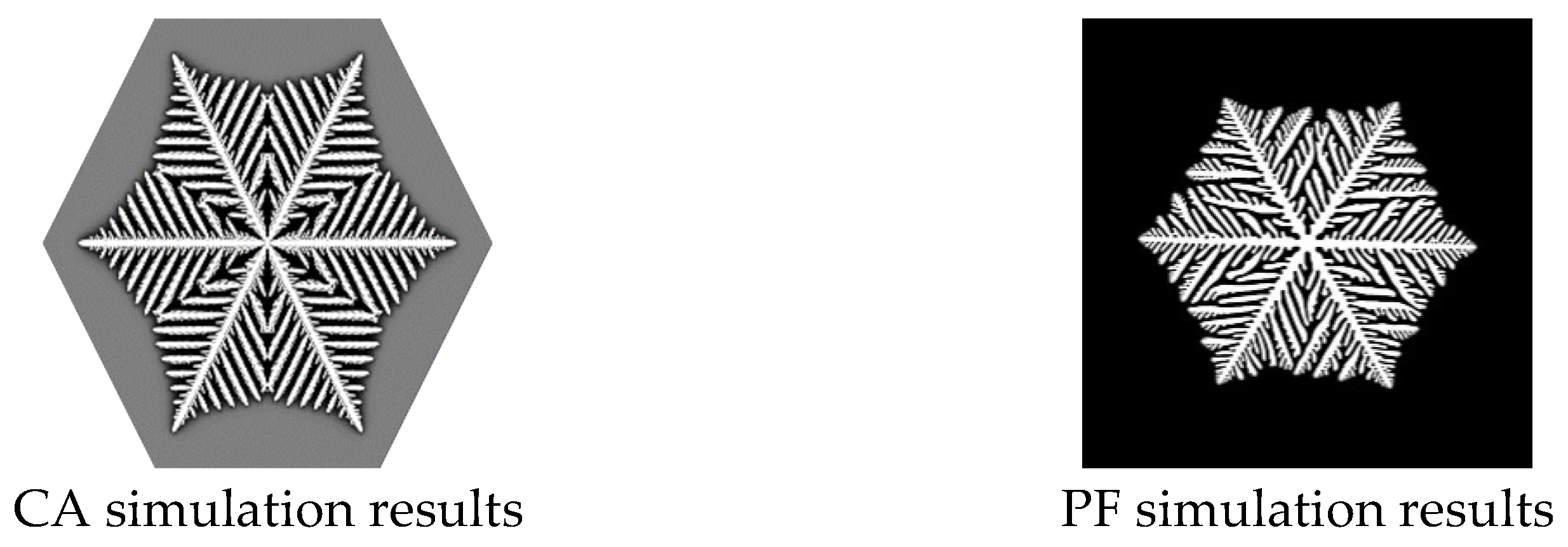

A classical snowflake pattern is simulated by CA and PF in

Figure 11. The

parameter and

parameter are set to 0.5 and 0, respectively, while the PF parameters are shown in

Table 1. The dendrite growth results with sixfold symmetry are simulated by both methods, and the secondary arms are arranged alternately in long and short forms, which can be seen in the simulation results. The simulation of this snowflake pattern by CA and PF shows significant similarity in the overall and microscopic morphologies.

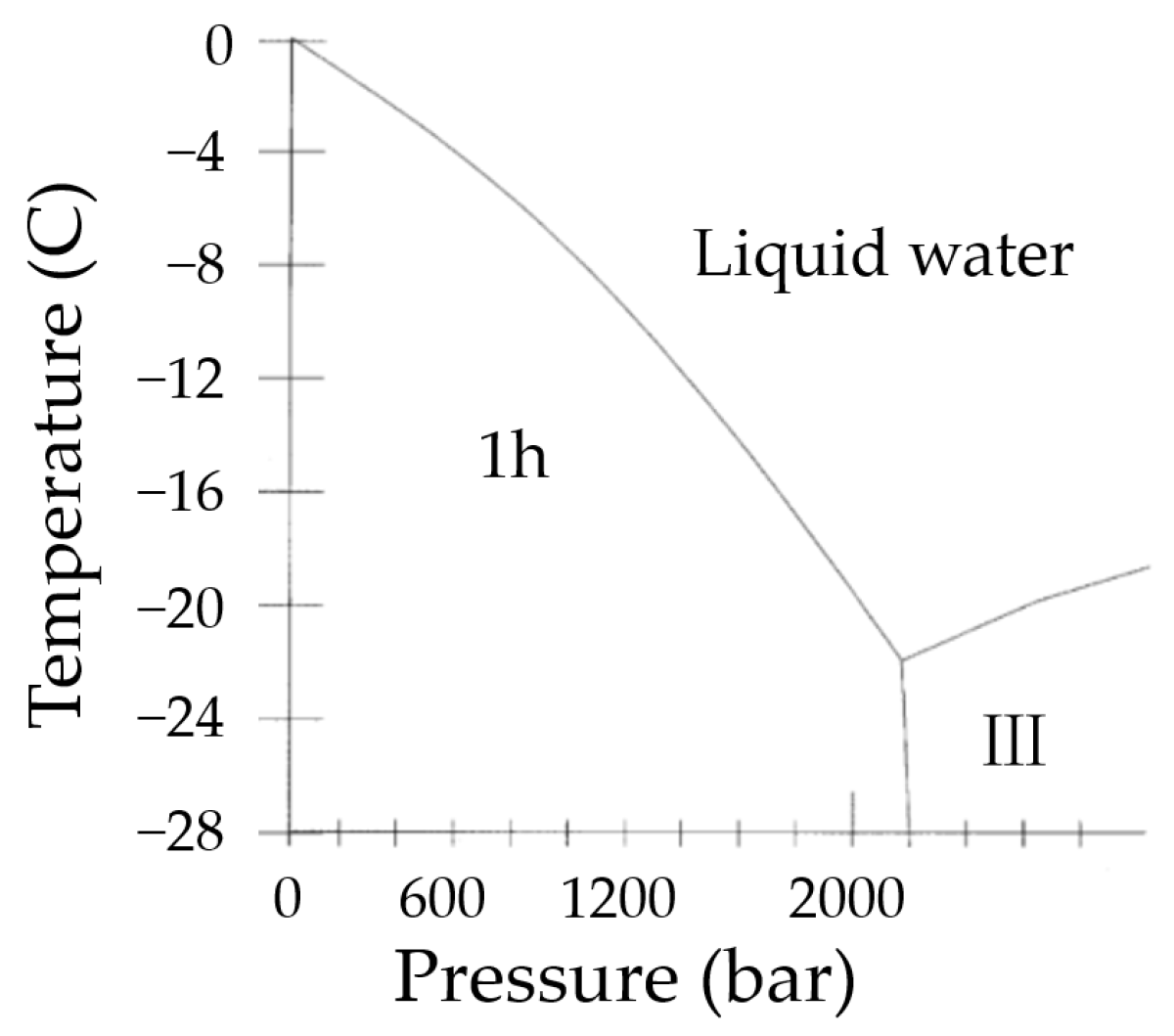

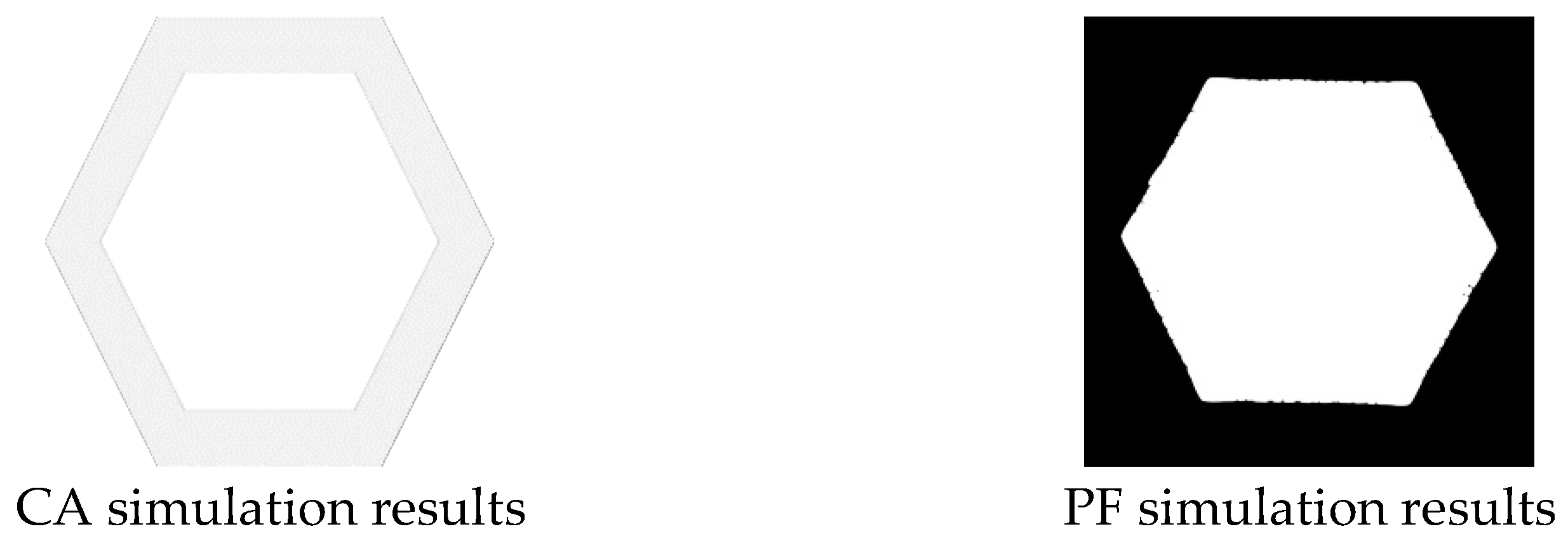

In addition to the classical simulation of hexagonal symmetric snowflake dendrite morphology, the hexagonal snowflake is another common snowflake pattern and usually occurs at lower temperatures according to the experiments [

7]. Dendrite free is considered as a special form of dendrite, and the relationship between parameters and the morphology of dendrite is worth investigating. In the CA model, the initial background state value

is adjusted to 0.95 and the

parameter is set to 0.05, which can simulate the hexagonal plate snowflake. In the PF model, dimensionless latent heat K is adjusted to 1 after testing, and other parameters are consistent with those in

Table 1; the morphology of hexagonal snowflakes can also be obtained. These simulation results are shown in

Figure 12. It should be noted that there are two ways to simulate a hexagonal snowflake by CA, and the other way is to set the

parameter to 1, which makes all the lattices crystalline, while the

parameter does not play any role. It can be observed that the growth process of snowflakes is indeed in the form of hexagonal growth by the former model parameters. However, the colors of the crystallization region and the liquid phase region in the simulation results are close to each other due to the high

value, which makes it difficult to distinguish. In the PF model, the growth of snowflakes gradually changes from dendrite growth to plate growth by continuously decreasing the value of K, which is similar to the growth model of the CA model. By analyzing the physical meaning of K, it can be seen that the latent heat generated by the phase transition in the process of snowflake growth will affect the formation of the secondary arm and cause the change in morphology.

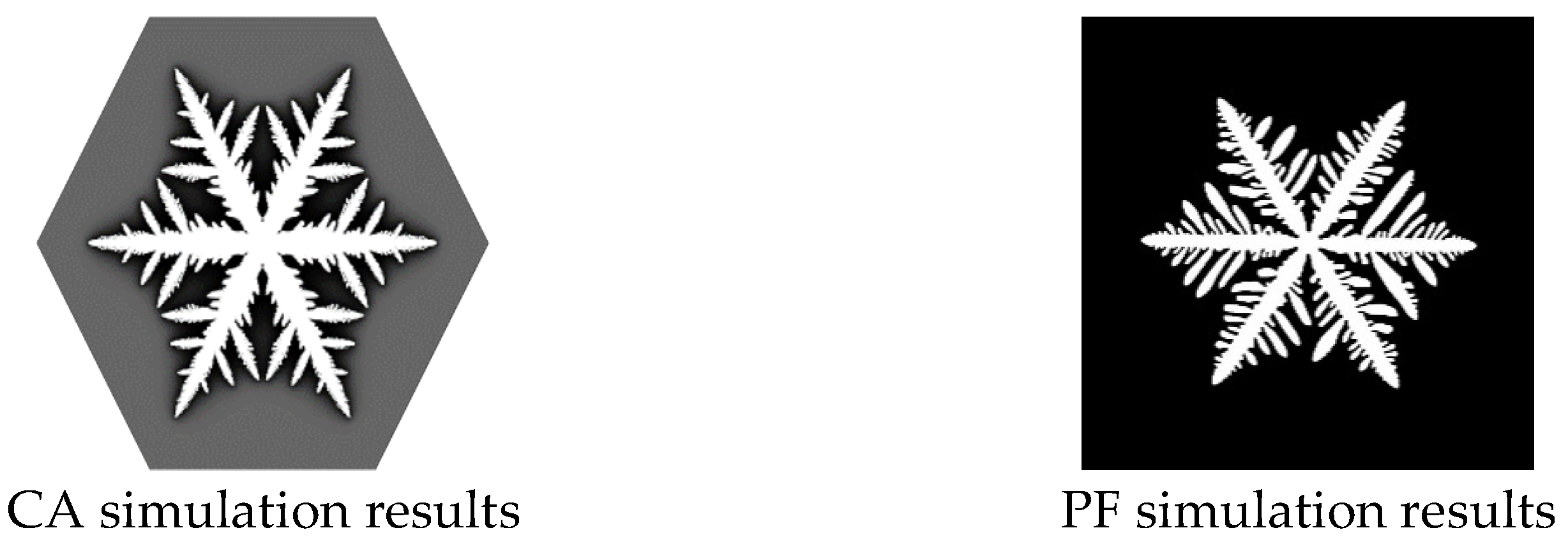

The simulation of the CA model is another classical snowflake pattern when the

parameter of the CA model is set to 0.4, and the

parameter is set to 0.01. The PF method can simulate a similar snowflake pattern when the mean anisotropic gradient energy coefficient is set to 0.007 and other parameters are adopted in

Table 1. As shown in

Figure 13, the primary branches are thicker than the snowflakes in

Figure 11, and the secondary arms are distributed at wide intervals. The mean anisotropic gradient energy coefficient is proved to adjust the morphologies of snowflake dendrite. According to the above comparison, the background parameter

and the vertical growth parameter

in CA have some connection with the dimensionless latent heat K and the anisotropy parameter

in PF.

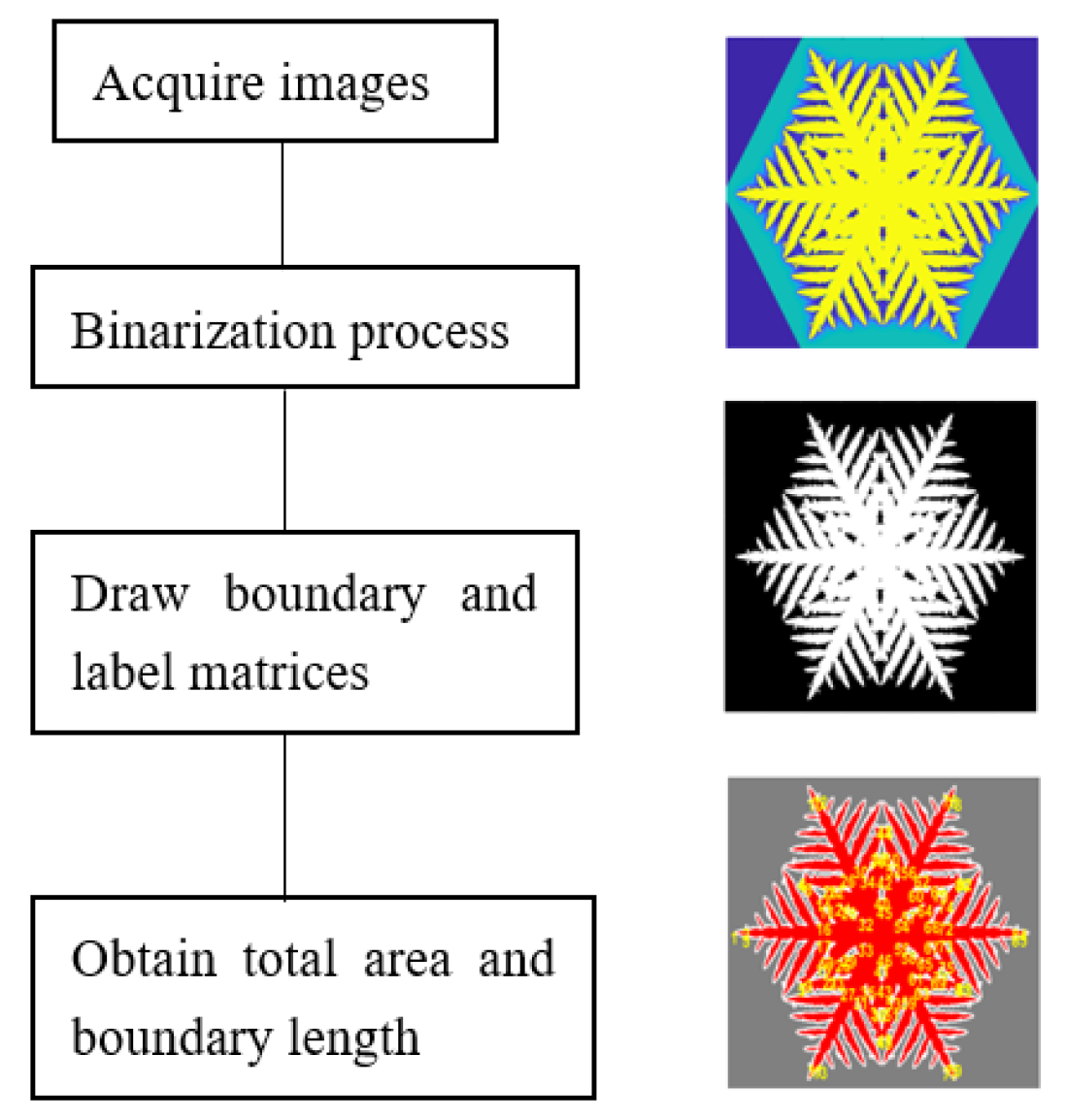

3.3.2. Verification of Growth Similarity of Two Methods by Growth Rate

The MATLAB image recognition techniques are used to obtain the crystal side length and total area in the snowflake growth process. The dendrite morphology figures are binarized, and the boundary and total growth area of the dendrite can be obtained by using the built-in boundary identification function. The specific process is shown in

Figure 14.

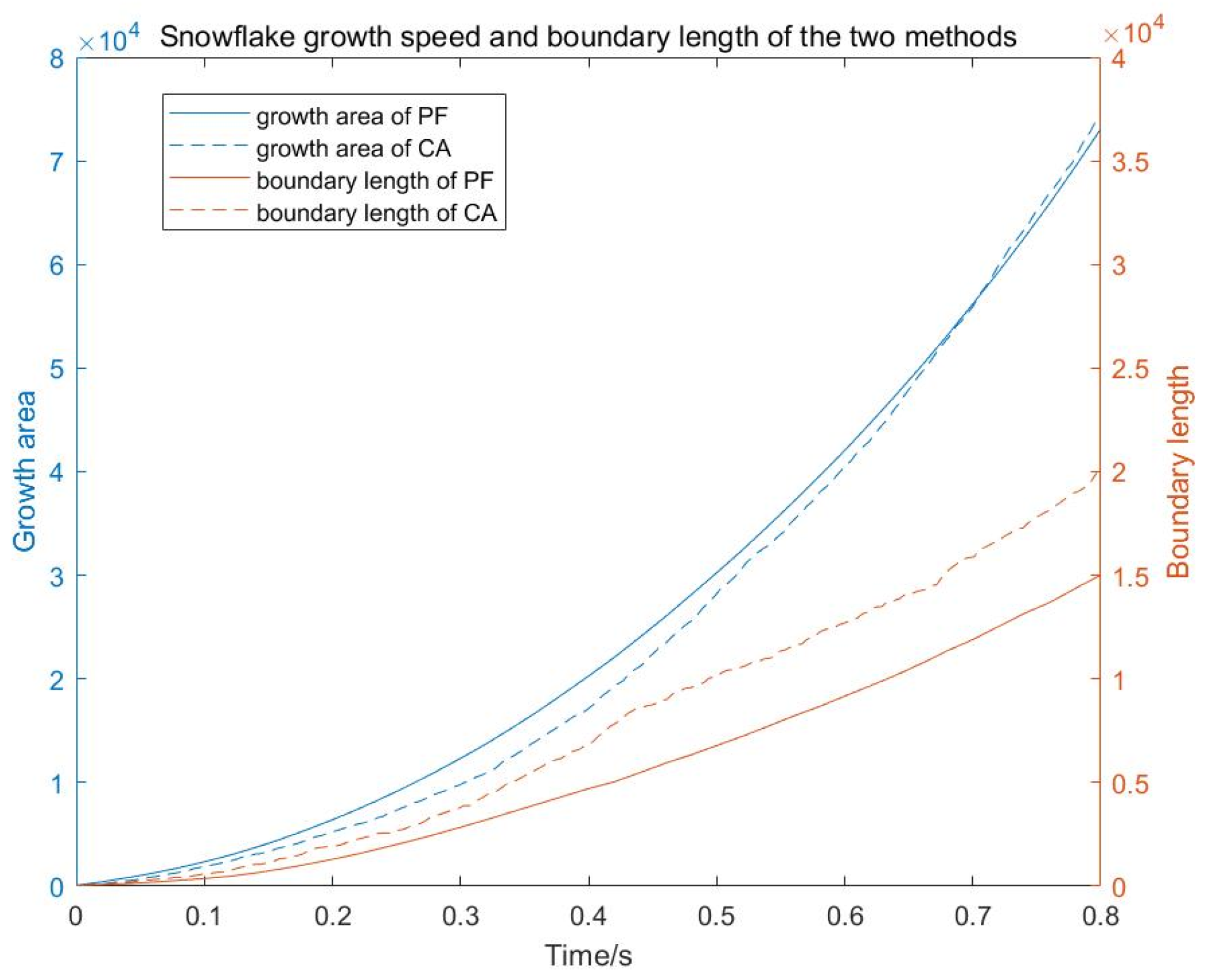

According to the comparison of snowflake morphologies in

Section 3.3.1, the classical snowflake pattern in

Figure 11 can be simulated by both the CA and PF methods, and the growth areas and boundary length of the snowflake growth process are obtained by the image recognition techniques. The simulated images of CA and PF are unified to the same pixel size of 800 × 800, and the growth curves of both simulation methods have similar parabolic growth trends. Since PF represents the evolution process by discrete time, while CA takes the number of iterations, it is considered to multiply a time scaling factor with the CA model’s iteration numbers to obtain a uniform time scale. The iteration number of the CA model is corresponding to the physical time of the PF model with the same growth area, then the time of one iteration can be obtained through dividing the physical time by iteration number. The time scaling factor is set to 0.00048 s for one iteration, in which the growth rate in CA is matched with that in PF. As shown in

Figure 15, the horizontal axis is the discrete time of PF, and the left vertical axis is the growth area of the image pixels. The similarity of the morphology and growth rate of classical snowflakes simulated by CA and PF is proved. In addition to the comparison in area, we also compared the total boundary length of the images as shown in

Figure 15. The right axis is the boundary length of the simulation. The boundary length of the results from the CA model is larger than that of the PF method. It can be seen that there are abundant small dendrites formed on the side branches from the comparison picture in

Figure 11.

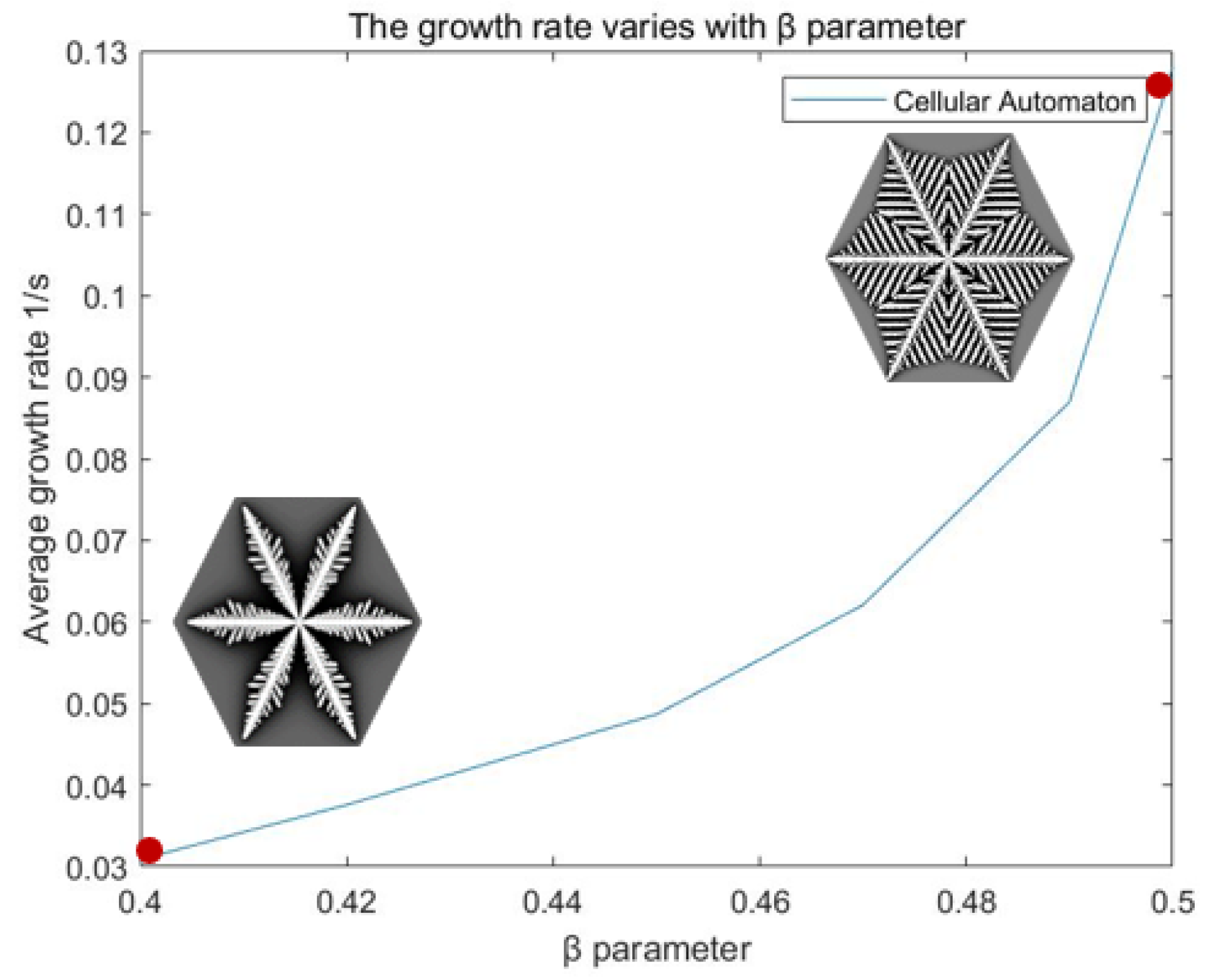

In addition to the classical snowflake morphologies simulation, the parameters of CA are considered to be interpreted physically by PF. The classical snowflake obtained above is taken as the benchmark case, and the two parameters of CA are finely adjusted to simulate different results. The parameters of PF are systematically compared to obtain the relationship with CA parameters. In the CA model, the environmental parameter

is set to 0 and the morphologies of snowflakes do not change obviously when the

parameter is reduced from 4.9, and the growth rate of the secondary arm is slower than that of the primary arm. However, the average growth rate of snowflakes is significantly slower as shown in

Figure 16. The vertical axis is normalized, and the horizontal axis is the discrete time of PF obtained from the previous time scaling factor multiplied by the number of iterations of CA. In the PF model, the growth rate also slows down when the dimensionless latent heat is increased from 1.8 to 2.5, and the morphologies are almost the same, as shown in

Figure 17. It is concluded that the

parameter of CA and the K parameter in PF have qualitatively similar properties in this small range.

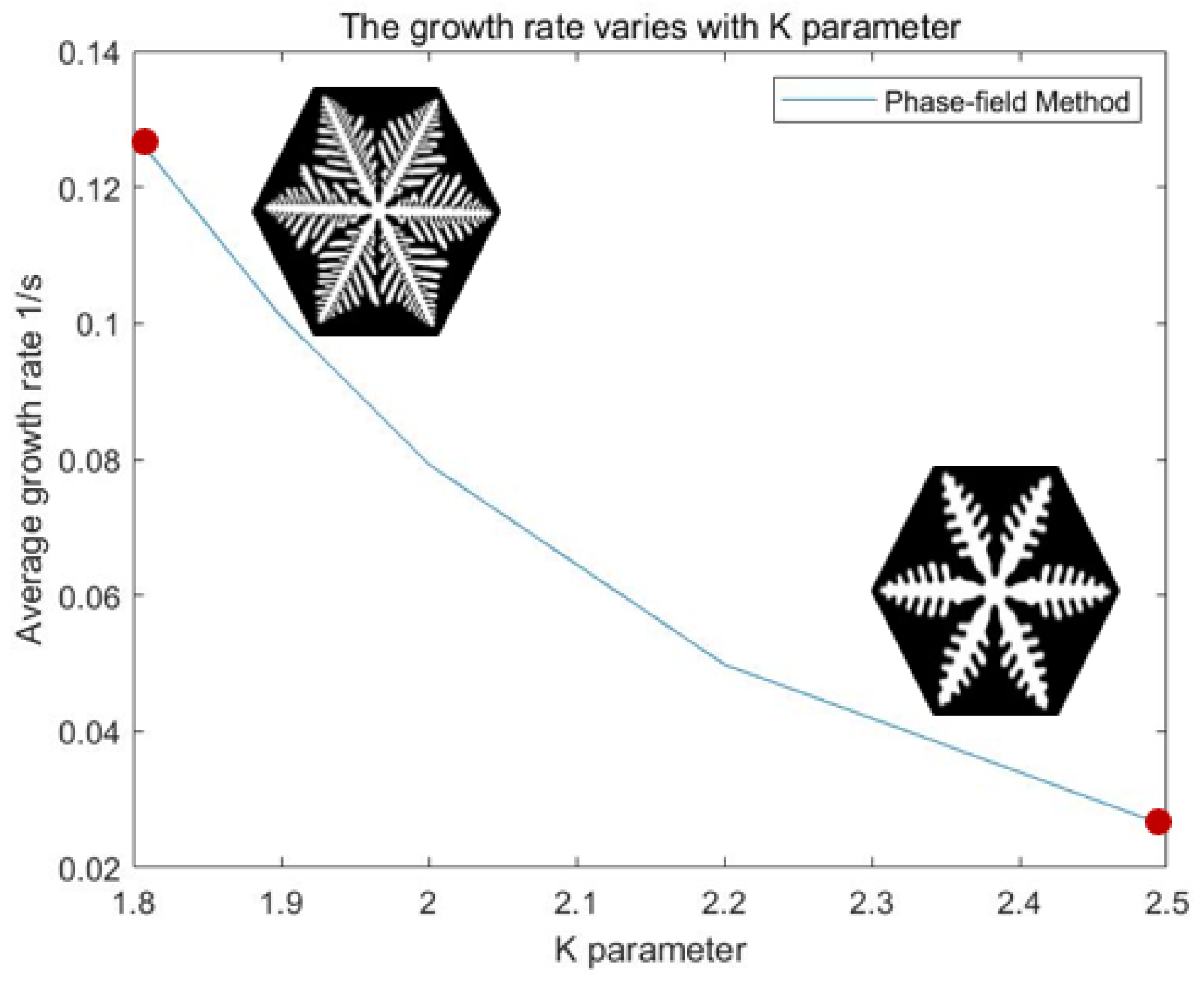

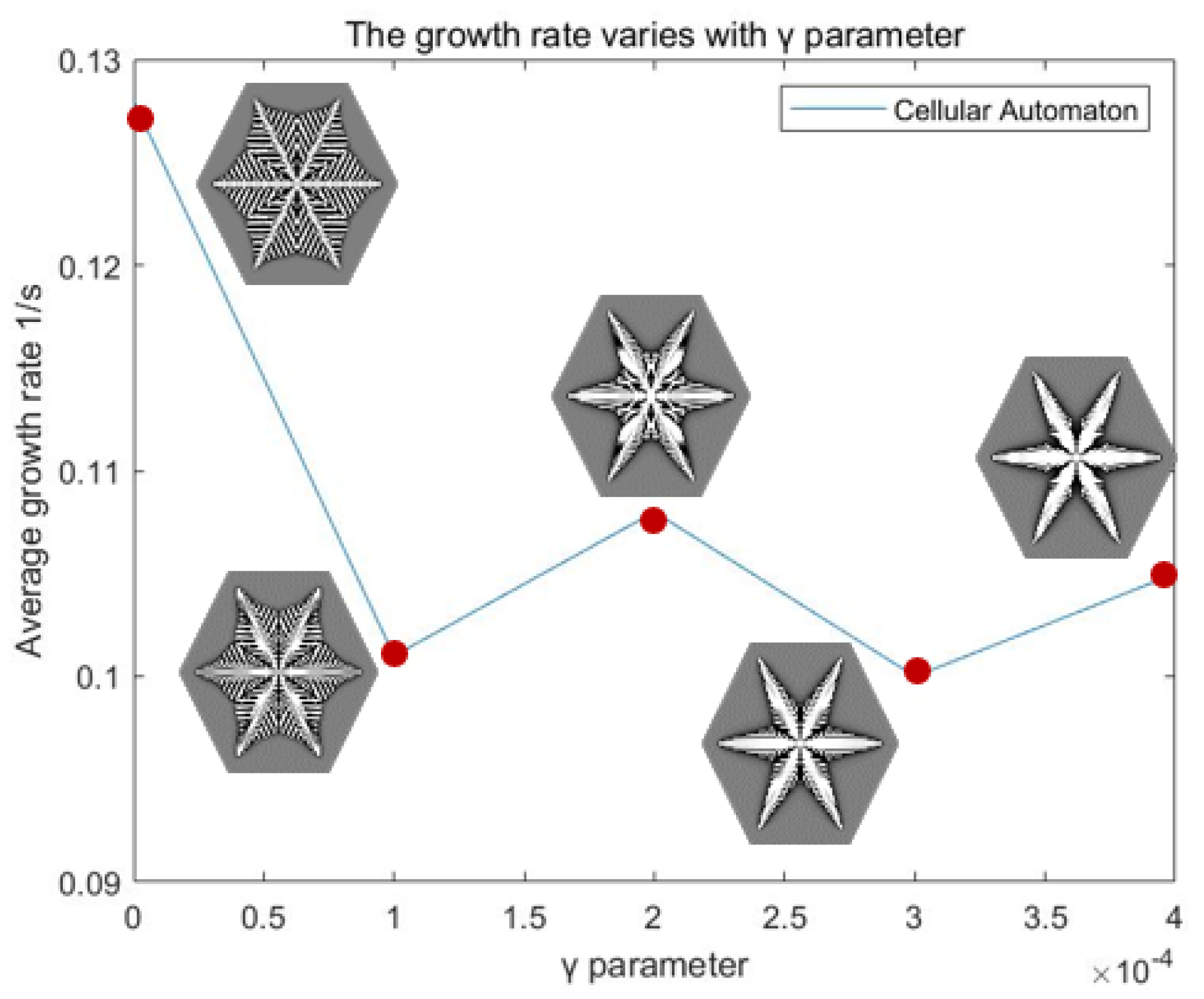

The

parameter in CA represents the environment condition that improves the state value of the solid phase component with a constant value, while the situation is not considered in the PF model. The snowflake growth processes of the CA model with a fixed

parameter and an adjusted

parameter are simulated in

Figure 18. The average growth rates of different snowflake simulations are quite similar, while the morphologies of snowflakes show that the primary branches are gradually thickened and the growth of the secondary arms slow down. The

parameter is mainly responsible for regulating the dendrite morphology of snowflakes according to the simulation results. In the PF model, the anisotropic parameter

also affects the morphology of snowflakes. The mean anisotropic gradient energy coefficient of PF is adjusted with other parameters unchanged to obtain different snowflakes, as shown in

Figure 19. Although the parameter

has an influence on the growth rate of dendrites, the trend of the overall morphology is similar to the adjustment of the

parameter. According to the detailed qualitative and partial quantitative verification and systematic comparison, the background parameter 𝛽 is related to the dimensionless latent heat K, and both parameter

γ in CA and parameter

in PF can affect the morphologies of snowflakes. Although the changes in these parameters do not correspond to each other perfectly due to the complex parameter coupling problems, they are indeed related qualitatively.