Abstract

Polyurethane foam (PUF) is actively used for thermal insulation. The main characteristic of thermal insulation is effective thermal conductivity. We studied the effective thermal conductivity of six samples of PUF with different types and sizes of cells. In the course of the research, heat was supplied to the foam using an induction heater in three different positions: above, below, or from the side of the foam. The studies were carried out in the temperature range from 30 to 100 °C. The research results showed that for all positions of the heater, the parameter that makes the greatest contribution to the change in thermal conductivity is the cell size. Two open-cell foam samples of different sizes (d = 3.1 mm and d = 0.725 mm) have thermal conductivity values of 0.0452 and 0.0287 W/m⸱K, respectively, at 50 °C. In the case of similar cell sizes for any position of the heater, the determining factor is the type of cells. Mixed-cell foam (d = 3.28 mm) at 50 °C has a thermal conductivity value of 0.0377 W/m⸱K, and open-cell foam (d = 3.1 mm) at the same temperature has a thermal conductivity value of 0.0452 W/m⸱K. The same foam sample shows different values of effective thermal conductivity when changing the position of the heater. When the heater is located from below the foam, for example, mixed-cell foam (d = 3.4 mm) has higher values of thermal conductivity (0.0446 W/m⸱K), than if the heater is located from above (0.0390 W/m⸱K). There are different values of the effective thermal conductivity in the upper and lower parts of the samples when the heater is located from the side of the foam. At 80 °C the difference is 40% for the open-cell foam (d = 3.1 mm).

1. Introduction

Porous materials have been used in a number of areas, such as power engineering, construction, transport, gas adsorption, purification from organic pollutants, and more. These materials are stable, lightweight, and cheap, and they have a low density [1,2,3,4,5,6,7,8]. Polyurethane foam is the most common porous polymer and is used to insulate buildings and structures [9]. Polyurethane foam is resistant to chemicals and very durable. The use of polyurethane is, however, complicated by its combustibility. This difficulty can be overcome by introducing different types of flame retardant.

The thermal properties of PUF can change throughout the entire service life under the influence of such factors as humidity or exposure to low (less than 5 °C) or high (more than 70 °C) temperatures [10]. Berardi et al. [11] studied how the relative air humidity (40–95%) affected the effective thermal conductivity of PUF. The author determined the moisture content of the foam samples by measuring their masses at various values of air humidity, both in a dry state and when soaked in water. When the relative air humidity changed from 40 to 95%, the moisture content of the closed-cell foam changed from 0.7 to 5%. The thermal conductivity coefficient changed from 0.024 to 0.026 W/m⸱K at 10 °C. At the same relative humidity parameters, the moisture content of the open-cell changed from 2% to 41%, and the thermal conductivity increased from 0.039 to 0.61 W/m⸱K.

The thermal conductivity of foam is dependent on its cell type [12], cell size [13,14], and cell size distribution [15]. Insulation foam manufacturers produce closed-cell foams to achieve low thermal conductivity values. This reduces convective heat transfer. The air inside each closed cell is excellent heat insulation.

Porous materials have been much studied for their thermal properties [12,13,14,15,16].

König et al. [12] studied the thermal conductivity of foam glass samples with open and closed cells. Open-cell foams have higher thermal conductivity (from 0.0572 to 0.0656 W/m⸱K) than closed-cell foams (from 0.0375 to 0.0562 W/m⸱K) at a temperature of 10 °C.

Hasanzadeh et al. [13,14] studied the thermal conductivity of polymer foam using the response surface methodology. The authors investigated the effect of foam parameters, such as density and cell size on effective thermal conductivity, solid matrix thermal conductivity λs, gas phase thermal conductivity λg, and thermal radiation λr. As the density of the foam decreases, the thermal conductivity of the gaseous phase and the heat transfer by radiation increase, while the thermal conductivity of the solid matrix decreases. This is due to the fact that as the foam density decreases, the proportion of the solid matrix in the total volume decreases while the proportion of the gaseous phase increases. Increasing the foam density leads to an increase in effective thermal conductivity. The effect of cell size on the thermal conductivity of the polymer foam was also studied. The results showed that the effective thermal conductivity and its components (λs, λg, λr) decrease with a decrease in cell size.

Zhu et al. [15] studied the effect of the cell size distribution on the thermal conductivity of the porous media. The authors discovered that the uneven distribution of cell sizes led to an increase in effective thermal conductivity.

Kahlerras et al. [16] investigated the properties of PUF created by replacing the share (40–100%) of the petrochemical polyol with bio-polyol. The results showed that increased bio-polyol content from 40 to 100% led to an increase in the density of the PUF (from 25.3 to 150 kg/m3) and a decrease in the cell size (from 1470 μm to 290 μm). The thermal conductivity of PUF decreased from 32.1 to 24.6 W/m⸱K, as a result.

Kang et al. [17] used the finite element method to study heat transfer in a porous polymer material. The authors studied the effect of porosity on the thermal conductivity value. The results of the research showed that there is a correlation between the change in porosity and thermal conductivity: with an increase in porosity, the thermal conductivity decreases. The increase in thermal resistivity is because there are more voids filled with air. Air’s thermal conductivity is much lower than that of the solid matrix.

Hasanzadeh et al. [18,19] carried out numerical studies of the effect of foam density and cell size on the thermal conductivity of expanded polystyrene. The thermal conductivity of the foam decreases when the size of the cell is decreased. When the foam density is less than 20 kg/m3, radiative heat transfer forms a large contribution to the total heat transfer. When the foam density is high (more than 40 kg/m3) the key heat transfer mechanism is the thermal conductivity of the gaseous phase. A decrease in the effective thermal conductivity of the foam is caused by a decrease in cell size and an increase in density [20]. In their next works [21,22], Hasanzadeh et al. studied the effect of foam morphology (cell size, foam density, strut thickness) on radiative thermal conductivity. The results of the studies showed that an increase in foam density and a decrease in foam cells led to a significant decrease in radiative thermal conductivity. The same conclusions were reached by the authors of [23]. The density of the foam and the thickness of the struts also have a significant effect on the thermal conductivity of the solid matrix.

Liu et al. [24] studied how porosity and cell type affect the effective thermal conductivity of PUF. The results of the research showed that, regardless of the type of the cells, with an increase in porosity, the value of the effective thermal conductivity decreases.

Doğan et al. [25] investigated the effect of cell density on the effective thermal conductivity of expanded polystyrene. The research shows that a decrease in the effective thermal conductivity of the foam is caused by an increase in cell density.

There are many studies on the thermal properties of PUF and the effect of cell type, density, and porosity. However, it remains unclear which factor contributes the most to the change in thermal conductivity. The purpose of the study is to determine the most important factor in changing the effective thermal conductivity of PUF.

Research Motivation

Polyurethane foam has found wide application in the thermal insulation of buildings, structures, and pipelines. The primary characteristic of a thermal insulation material is its thermal conductivity. In order to minimize convective currents, heat is usually carried out from above. However, there are different ways to provide heat to thermal insulation in practice. In the case of a pipeline transporting a hot coolant, the thermal insulation is heated around the entire perimeter of the pipe. We studied how the thermal conductivity of PUF changed depending on the position of the heater, i.e., from above, from below, or from the side.

The thermal conductivity of PUF is affected by both the heat supplied and the morphological characteristics of the foam. An increase in cell size enhances the contribution of radiative heat transfer to the effective thermal conductivity of the foam. Choe et al. [26] studied the thermal conductivity of foams with different cell sizes (from 153 to 551 μm). The authors found that there is a threshold cell size (230 μm), above which radiative heat transfer makes a significant contribution to the effective thermal conductivity of PUF. This is explained by an increase in the wall thickness of the solid matrix as the cell size decreases with the same volume of gas. Our work studied samples with cell sizes exceeding the threshold value; therefore, the contribution of radiative heat transfer to the effective thermal conductivity of the foam cannot be neglected.

Heat transfer by convective flows also makes a significant contribution to the effective thermal conductivity value. Alvarez-Lainez et al. [27] studied the thermal conductivity of polyolefin foams with different cell sizes (0.630–3.294 mm). They found that, at small cell sizes, the contribution of convection to effective thermal conductivity was insignificant. When the cell size of closed-cell foam is less than 4 mm, convective heat transfer is not a significant factor in the effective thermal conductivity of the foam. When the cell size is over 4 mm, there are convective flows within each closed cell, increasing heat transfer (Figure 1). However, it is still unclear which factor–the type of cell or its size–has a greater impact on foam thermal conductivity.

Figure 1.

A picture of convective air currents inside a large closed cell.

2. Materials and Methods

2.1. The Thermal Conductivity of Porous Material

There are four different mechanisms that contribute to heat transfer through porous material: heat conduction through the solid phase (struts and cell walls), heat conduction through the gas phase inside the cells, convection, and radiative heat transfer. A porous material’s effective thermal conductivity is determined by the equation [28]:

where λt–total (effective) thermal conductivity of the porous material, λg–thermal conductivity of the gas phase inside the cells, λs–thermal conductivity of the solid matrix (cell walls and struts), λc characterizes heat transfer by convection inside the cells, λr determines radiative heat transfer.

λt = λg + λs + λc + λr,

2.2. The Parameters of the Studied Samples of Polyurethane Foams

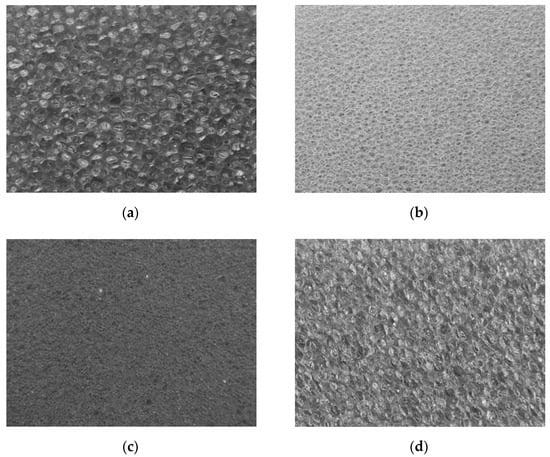

The main parameters of the polyurethane foams are presented in Table 1, and their pictures are shown in Figure 2. To determine the average cell sizes (Table 1) we obtained pictures of the studied foam samples using a microscope. The dimensions of 100 randomly selected cells were measured and averaged.

Table 1.

Parameters of the investigated samples of polyurethane foams.

Figure 2.

Pictures of the investigated polyurethane foam samples: (a) sample A; (b) sample B; (c) sample C; (d) sample D; (e) sample E; (f) sample F.

2.3. Experimental Setup

The characteristics of thermal insulation can be measured using traditional methods such as the guarded hot plate (GHP) and heat-flow meter (HFM) methods [29,30]. Sánchez-Calderón et al. [31] measured the thermal conductivity of various thermal insulation materials: extruded polystyrene (XPS), expanded polystyrene (EPS), polyurethane (PUR), polyethylene (PE). The sample was placed between hot and cold plates with specified temperatures maintained, and the thermal conductivity was measured using the heat-flow meter method. The authors then measured the heat flux passing from the hot plate to the cold one through the sample [32,33].

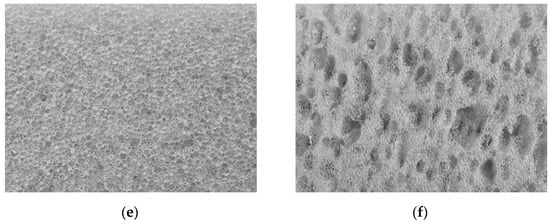

The laser flash method is used to measure the thermal conductivity of materials, such as highly porous ceramics, composites, and metals, at high temperatures. Another common method is the hot wire method, which is used to measure the thermal conductivity of liquids and gases [34]. Thus, there are several methods for measuring the thermal conductivity of a material, depending on whether heat is supplied from above or below the sample. However, there are no studies about the influence of heat input conditions on the material on the values of effective thermal conductivity. Insulating materials are used for the isolation of pipelines, air ducts, and the walls, floors, and ceilings of buildings. We investigated the change in the effective thermal conductivity of polyurethane foam samples at three different positions of the induction heater: from above, from below, or on the side of the foam (Figure 3). In the case of the position of the heater on the side, the measurements were carried out at two points (Figure 3c).

Figure 3.

The schemes of the experimental stand with different positions of the heater: (a) from above; (b) from below; (c) from the side.

The numbers (Figure 3) indicate: 1–induction heater; 2–aluminum plate; 3–test sample; 4–thermal insulation; 5–heat flux density sensor; 6–thermocouples; 7–the device for measuring heat flow; 8–temperature meter.

Heat flux density sensors, which are a galvanic copper-constantan thermopile of several hundred series-connected thermocouples, were used to measure the heat flux density. The operation of the sensor is based on the additional wall principle. The limits of the relative error of the sensor are ±6%. K-type thermocouples were used to measure the temperature. The measurement error is 0.3%.

The measurements were carried out as follows. An aluminum plate was installed on the induction heater to ensure uniform heating of the PUF sample. The test sample has been placed on the aluminum plate, surrounded on three sides by thermal insulation. The thermal conductivities of the insulation and the studied samples have relatively close values. The first thermocouple was attached from the interior of the foam, between the aluminum plate and the foam. The second thermocouple and a heat flux density sensor were attached from the exterior of the foam, between the insulation and the foam. The measurements were carried out at the following heater temperatures: 50, 100, 120, 150, 200, 220, and 240 °C. In the course of experimental studies, the temperature difference was recorded using thermocouples and a temperature meter, and the heat flux was measured using a heat flux density sensor and a heat flow measuring device.

The studies were carried out at a constant temperature of 20 °C. The heater was set to a certain temperature from the range under study, for example, 50 °C. The stationary regime was reached by the first thermocouple located on an aluminum plate on the inner side of the foam. The readings of thermocouples and heat flow sensors were recorded under conditions of reaching a stationary regime when the surface temperature of the plate and foam did not change for a long period of time. Then the next temperature value was set on the heater, for example, 100 °C, and the experiment was repeated.

The thermal conductivity of the material was determined by Fourier law:

where λ–thermal conductivity of PUF, W/m⸱K; q–heat flux density, W/m2; δ–thickness of the PUF, m; T1–inner surface temperature, K; T2–outer surface temperature, K.

λ = q·δ/(T1 − T2),

3. Results and Discussion

3.1. Verification of the Measurements

We compared the results of our work with the results of other authors. Since this method is standard for measuring thermal conductivity, we only consider the case where the heater is located above.

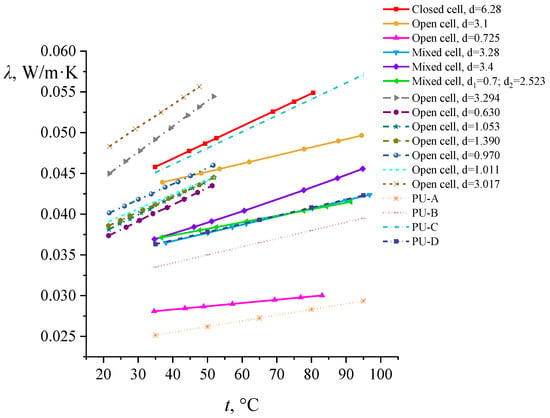

Alvarez-Lainez et al. [27] carried out experimental studies of the thermal conductivity of polyolefin foams with open cells of different sizes (0.63–3.294 mm). The density of the foam samples was in the range of 23.1 to 64.9 kg/m3. The studies were conducted at temperatures ranging from 24 to 50 °C. Our studies were performed at temperatures from 35 to 100 °C. The results of the research are presented in Figure 4. In the graphs here and below, “d” is the average cell size in mm. Our results were close to those of Alvarez-Lainez et al. within the temperature range from 35 to 50 °C. Open-cell foams with similar cell sizes (3.294 mm in Alvarez-Lainez et al. [27] and 3.1 mm in our research) show similar values of effective thermal conductivity: 0.050 W/m⸱K and 0.044 W/m⸱K, respectively, at t = 40 °C. The differences in the results of the studies can be explained by differences in the materials: polyurethane in our work, and polyolefin in [27].

Figure 4.

Comparison of graphs of thermal conductivity versus temperature from our work (solid lines) with that of Alvarez-Lainez et al. [27] and Berardi et al. [35] (dashed lines).

Berardi et al. [35] studied the thermal conductivity of polyurethane foams with different types of cells: closed (PU-A, PU-B) and open (PU-C, PU-D). Berardi et al. gave linear equations of thermal conductivity for each studied foam sample. Based on these equations, we plotted thermal conductivity graphs for the temperature range in which our measurements were made, namely from 35 to 95 °C. The results of our research and the research of Berardi et al. are presented in Figure 4. The densities of the foams studied by Berardi et al. were in the same range (from 6.83 to 35 kg/m3) as the densities of the foams studied in our work (from 17.69 to 29.88 kg/m3). This explains the close value of the results of our work and the work of Berardi. Open-cell foams (PU-C in [35] and open-cell foam, d = 3.1 mm in our research) show similar values of the effective thermal conductivity in the temperature range from 35 to 95 °C: the effective thermal conductivity values of the foam PU-C [35] are 0.0451–0.0571 W/m⸱K, the effective thermal conductivity values of the foam studied in our research are 0.0437–0.0497 W/m⸱K.

3.2. Results of the Measurements

The effective thermal conductivity was determined for all the samples described above. First, we present the results when the heater is placed above (Figure 4). Table 2 presents the results of measuring the effective thermal conductivity of polyurethane foam samples for the case when the heater is placed above.

Table 2.

The results of measuring the effective thermal conductivity of polyurethane foams in the case when the heater is placed above.

The sample with closed cells d = 6.28 mm shows high effective thermal conductivity values (from 0.0458 to 0.055 W/m·K) throughout the investigated temperature range. Due to the large size of the cells, heat transfer by radiation contributes more to the thermal conductivity of this sample. Authors of [26] state that the contribution of radiative heat transfer increases when cell size increases. In addition to radiation, convection also contributes to effective thermal conductivity. According to [27], closed-cell foams with a cell size greater than 4 mm contain convective flows (Figure 1). The average size of closed cells is d = 6.28 mm, which suggests the presence of convective flows within each cell. The increase in thermal conductivity is caused by convective flows.

The lowest thermal conductivity values (from 0.028 to 0.030 W/m⸱K) are observed for foam with open cells of diameter 0.725 mm. Another sample with open cells, but with a larger diameter (d = 3.1 mm), shows high thermal conductivity values (from 0.0439 to 0.0496 W/m⸱K). The difference in the thermal conductivity values of open-cell foams with different cell sizes increases from 36.4 to 37.5% with increasing temperature. The difference can be explained by the fact that in larger cells the contribution of radiative heat transfer to the value of effective thermal conductivity increases [26,27].

Mixed-cell foams show relatively close thermal conductivity values since they have similar cell sizes (d = 3.28 mm; d = 3.4 mm). Foam with small closed cells of 0.7 mm and large open holes with an average size of 2.523 mm, has values of effective thermal conductivity close to those of foam with mixed cells (d = 3.28 mm). This is explained by the presence of large holes that enhance the effect of radiative heat transfer λr (Equation (1)) on the effective thermal conductivity [26].

Thermal insulation is often used on pipelines, buildings, and structures to reduce heat loss. Therefore, heat input to thermal insulation can be carried out in different ways: from above, from below, from the side, and along the perimeter. The thermal conductivity of the material may be different in each case and may exceed the values declared by the manufacturer. To investigate this further, we also studied the cases where the heater is located below or on the side of the PUF.

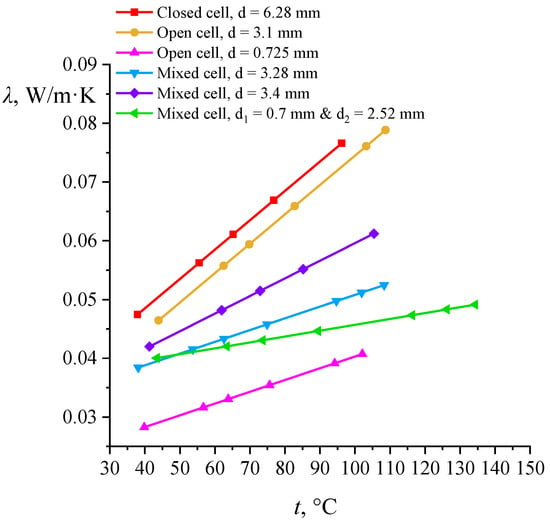

Figure 5 shows the results of measuring the effective thermal conductivity of the foams in the case when the heater is located below.

Figure 5.

Thermal conductivity of polyurethane foam samples as a function of temperature in the case when the heater is located below.

The high thermal conductivity of the sample with large closed cells (d = 6.28 mm) is explained by the influence of convective flows inside the cells, as well as the contribution of radiative heat transfer due to the large size of the cells [26,27].

The contribution of the thermal conductivity of the matrix λs, the thermal conductivity of the gas inside the cells λg, and the radiative heat transfer λr to the value of the effective thermal conductivity under different heating conditions remains unchanged, since these are parameters that depend not on the heat input conditions, but on the foam morphology. When the heater is located above, convection is minimal and can be neglected. In this case, the increase in the effective thermal conductivity values of the foams when the heater is located below relative to the thermal conductivity values obtained when the heater is located above is mainly explained by the increase in the contribution of convective heat transfer to the effective thermal conductivity values of foams when the heater is located below.

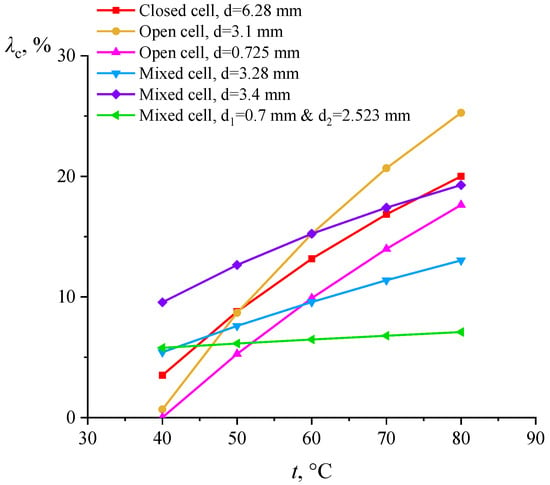

Figure 6 is a graph describing the contribution of the convective component as a percentage (%) of the effective thermal conductivity.

Figure 6.

The contribution of the convective component in percent (%) relative to the value of effective thermal conductivity.

Differences in the thermal conductivity of the samples when heated from above (Figure 4) and from below (Figure 5) are associated with the presence of convective flows when the heater is positioned from below. The contribution of convection to the total thermal conductivity of the foam changes with the heating temperature and foam morphology. The closed-cell foam d = 6.28 mm has thermal conductivity values of 0.0548 and 0.0685 W/m·K (at t = 80 °C), when the heater is located above or below, respectively. In this case, the contribution of convective heat transfer is 20%. The large cell size (6.28 mm) explains the significant contribution of convection to effective thermal conductivity. This is due to the recirculation of gas that occurs inside each cell.

Due to the absence of walls between cells, convective flows are free in open-cell foams. The larger the cell size, the greater the contribution of the effective thermal conductivity made by convection, which is confirmed by our studies. There are two samples of polyurethane foam with open cells of different sizes (3.1 mm and 0.725 mm). When the heater is located below, the contribution of convective heat transfer to the effective thermal conductivity is 25.27% (at t = 80°). Under the same conditions, the contribution of convection to the effective thermal conductivity of the foam with cells of 0.725 mm is 17.63%. Thus, the cell size affects the contribution of convective heat transfer to the effective thermal conductivity of the foam.

We estimate the contribution of convection to the total thermal conductivity of foams with mixed cells of similar sizes (3.28 mm and 3.4 mm). For the foam with cells of 3.28 mm, the contribution of convective heat transfer to the effective thermal conductivity is 13% at t = 80°. For the foam with cells of 3.4 mm, the contribution of convective heat transfer to the effective thermal conductivity is 19.28%. This percentage difference is explained by the predominance of open cells in the second foam sample (3.4 mm). Convective flows move freely through open cells; therefore, the contribution of convection to the effective thermal conductivity is higher for foam with cells of 3.4 mm.

Foam with a different morphology from other samples–small closed cells 0.7 mm and large holes 2.523 mm–shows a very slight increase in thermal conductivity when the heater is located from below relative to the values obtained when the heater is located from above. The increase in the effective thermal conductivity at t = 80 °C is only 7%. This can be explained by the morphology of the foam: despite the presence of large holes, small closed cells prevent the propagation of convective flows, which reduces the contribution of convection to the effective thermal conductivity of this sample.

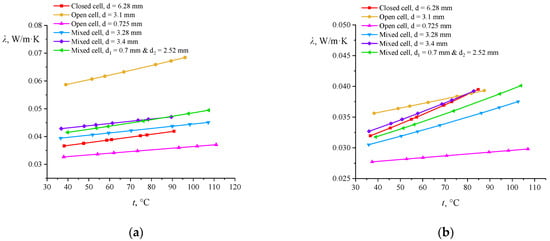

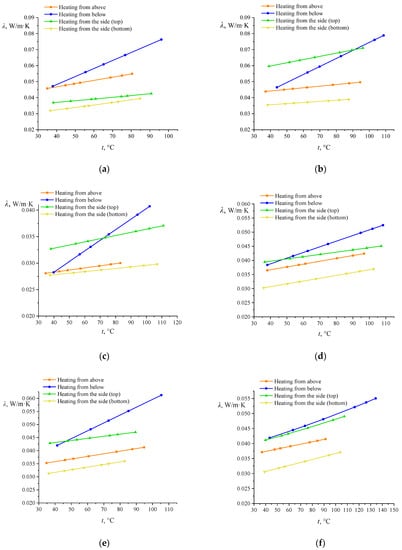

The thermal conductivity of the foams was studied in the case when the heater was located on the side, and the results are presented in Figure 7. The measurements were taken at the top (Figure 7a) and at the bottom (Figure 7b) of the foam.

Figure 7.

Thermal conductivity of polyurethane foam samples as a function of temperature in the case of heating from the side: (a) measurement results at the top of the sample; (b) measurement results at the bottom of the sample.

It is clear from Figure 7 that the effective thermal conductivity of all the foam studied at the upper and lower measurement points is different. The results of the experiments show significant differences in the effective thermal conductivity depending on the position and morphology of the material. The thermal conductivity of some foams practically does not change depending on the position of the heater, while the change in the thermal conductivity of other studied samples can be 20–40%. This study can be useful for choosing the heat-insulating material for buildings and structures.

The results of measurements at the top of the foam samples (Figure 7a) show that the foam with open cells d = 3.1 mm has the highest values of effective thermal conductivity (from 0.059 to 0.069 W/m·K). This sample shows the largest differences in the effective thermal conductivity values at the top and the bottom measurement points. The thermal conductivity of the foam at the top measurement point exceeds the thermal conductivity at the bottom measurement point by 39.22% (at t = 40 °C). The reason for this is the presence of convective flows within the foam, which can propagate freely due to the open-cell structure of the foam. The sample with open cells of a smaller size d = 0.725 mm shows the lowest values of effective thermal conductivity, while the results at the top and the bottom measurement points have slight differences: at the top measurement point 0.0328 W/m·K, at the bottom measurement point 0.0278 W/m·K (at t = 40 °C), the difference is 15.25%. This behavior can be explained by the small size of the cells of this foam (d = 0.725 mm), so the convective currents are difficult to propagate through cells of this size [27].

The closed-cell foam (d = 6.28 mm) shows very small differences in effective thermal conductivity when measured at the top and bottom points. The thermal conductivity of this sample does not change significantly: λ= 0.0388 W/m·K at the top measurement point and λ = 0.0354 W/m·K at the bottom measurement point at t = 60 °C, the difference is 8.69%. Such a small difference can be explained by the fact that the influence of convective flows inside the cells decreases in the case of heating from the side.

Foams with mixed cells (d = 3.28 mm; d = 3.4 mm) show relatively close thermal conductivity values. A sample with a larger cell size has a higher thermal conductivity value. This difference can be explained by the fact that the size of the cells directly affects the radiative heat transfer [27]. It is also worth noting that, open cells predominate in foam with cells of 3.4 mm, which influences the contribution of convection to effective thermal conductivity. With an increase in the proportion of open cells, the contribution of convection λc (Equation (1)) increases.

The foam sample with small closed cells d1 = 0.725 mm and large open holes d2 = 2.523 mm has thermal conductivity values at the level of foams with mixed cells. The presence of large holes in the foam enhances the contribution of radiative heat transfer to the value of effective thermal conductivity [26,27].

The largest difference in the values of effective thermal conductivity at the top and bottom measurement points (when the heater is located on the side) is observed for foam with open cells of 3.1 mm and reaches 40.91% at t = 80 °C. In foam with open cells of a smaller size (0.725 mm), the difference in thermal conductivity values is 17.6% at t = 80 °C.

Mixed-cell foams have significant differences in effective thermal conductivity values. At temperature t = 80 °C, this difference is: for foam with 3.28 mm cells −18.42%; for foam with 3.4 mm cells −16.2%; for foam with closed cells 0.7 mm and open holes 2.523 mm −20%.

Closed-cell foam has the smallest differences in the effective thermal conductivity values at the top and bottom measurement points (when the heater is located on the side).

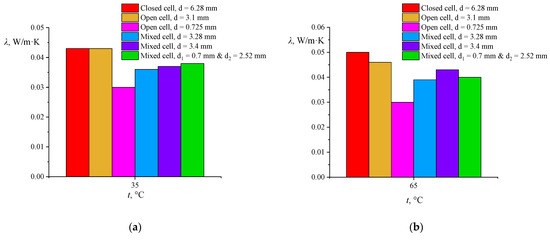

We studied how the effective thermal conductivity of each sample changes at different positions of the heater (Figure 8).

Figure 8.

Graphs of changes in the effective thermal conductivity of PUF at different positions of the heater: (a) closed-cell foam, d = 6.28 mm; (b) open-cell foam, d = 3.1 mm; (c) open-cell foam, d = 0.725 mm; (d) mixed-cell foam, d = 3.28 mm; (e) mixed-cell foam, d = 3.4 mm; (f) mixed-cell foam, d1 = 0.7 mm and d1 = 2.523 mm.

The sample with closed cells (Figure 8a) has high thermal conductivity values when heated from below (0.0485 W/m·K) and when heated from above (0.0468 W/m·K) at t = 40 °C. With the position of the heater on the side, the thermal conductivity of the closed-cell foam decreases: at the top of the foam, the thermal conductivity is 0.0368 W/m·K, at the bottom of the foam is 0.0324 W/m·K at t = 40 °C, the difference in thermal conductivity values at the top and bottom measurement points is 11.85%.

Measurement results for open-cell foams are shown in Figure 8b,c. The sample with cells of average size d = 3.1 mm (Figure 8b) shows high values of thermal conductivity (0.059–0.069 W/m·K) when the heater is located on the side, on the temperature range from 39 °C to 89 °C. When the temperature increases, the highest values of thermal conductivity (0.076 W/m·K at t = 103 °C) are observed when the heater is located below this foam sample. The same trend is observed for the foam with smaller-sized open cells d = 0.725 mm (Figure 8c). Both open-cell foam samples show lower thermal conductivity values when the heater is located above (heating from above) rather than when it is located below (heating from below). The lowest values of foam’s thermal conductivity are observed at the bottom measurement point when the heater is located on the side (heating from the side, bottom), which is explained by the movement of convective flows through open cells.

Mixed-cell foams (Figure 8d–f) are less affected by convective currents than open-cell foams. The proportion of open cells in these samples is noticeably smaller than that of open-cell foams, which negatively affects the heat transfer by convection. Furthermore, the cell size of these foams is not large enough for convective flows to arise inside closedcells. This explains the fact that for a larger range of temperatures studied, mixed-cell foams show higher thermal conductivity in the case of the heater from below than in the case of side heating (heating from the side, top).

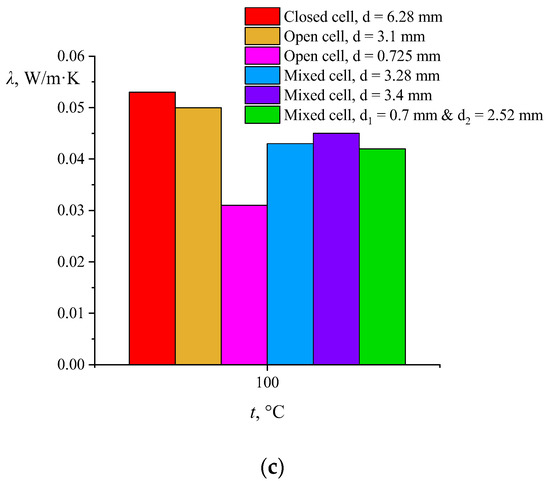

We studied how the effective thermal conductivity of the PUF samples changes at three different temperatures: 35 °C, 65 °C, and 100 °C. (Figure 9). The results are shown for the case where the heater is located above the sample, as this is the most common configuration for measuring thermal conductivity. At low temperatures (35 °C) closed-cell foam (d = 6.28 mm) and open-cell foam (d = 3.1 mm show close thermal conductivity values. This can be explained by the fact that in foam with closed large cells, the thermal conductivity is greatly affected by radiative heat transfer, as well as convective flows inside each cell. Foam with open cells of a smaller size (d = 0.725 mm) shows the lowest thermal conductivity values (0.030 W/m·K) due to the small cell size, which reduces radiative heat transfer. Mixed-cell foams have similar morphology, however, due to the larger cell size in the foam (d = 3.4 mm), the contribution of radiative heat transfer increases. So, the effective thermal conductivity of foam with cells of 3.4 mm is higher than the effective thermal conductivity of the foam cells of 3.28 mm. The foam with small closed cells d1 = 0.7 mm and open holes d2 = 2.523 mm shows interesting results. The thermal conductivity of this sample is 0.037 W/m·K and higher than the thermal conductivity of foams with mixed cells (d = 3.28 mm; d = 3.4 mm), despite the difference in cell sizes. This is explained by an increase in heat transfer by radiation due to the presence of large holes.

Figure 9.

Diagrams of effective thermal conductivity values of foams at different temperatures: (a) at low temperature 35 °C; (b) at an average temperature 65 °C; (c) at high temperature 100 °C.

It is important to note that the trend of change in the thermal conductivity of the foams at 65 °C and 100 °C remains unchanged (Figure 9b,c). The thermal conductivity of closed-cell foam (d = 6.28 mm) is greater than the thermal conductivity of open-cell foam (d = 3.1 mm). This is explained by the large contribution of radiative heat transfer in foam with larger cells. Foam with smaller open cells (d = 0.725 mm) show the lowest thermal conductivity values (0.030 W/m·K) among all studied samples due to the small size of the cells. Compared to low-temperature measurements (Figure 9a), we see a slight increase in the thermal conductivity of the mixed-cell foam with cells of d = 3.4 mm compared to other mixed-cell foams. This is due to the large contribution of radiative heat transfer for foam with large cells. It can also be seen that at the temperature of 100 °C, the mixed-cell foam (d = 3.28 mm) has higher thermal conductivity than the foam with two different cell types (d1 = 0.7 mm, d2 = 2.523 mm) due to the difference in cell sizes. Larger foam cells (d = 3.28 mm) contribute to an increase in the radiation component of thermal conductivity λr (Equation (1)).

The results of the work will be useful when choosing porous materials for the thermal insulation of buildings, structures, and pipelines. The research results will also be useful for manufacturers of porous heat-insulating materials for the development of materials with lower thermal conductivity values. Reducing heat loss in buildings and structures and during the transportation of energy carriers, will lead to a reduction in the consumption of energy resources and a reduction in the emissions of harmful substances. It will be interesting to further study multilayer thermal insulation with foams of various morphologies and combinations of other thermal insulation materials with foams.

4. Conclusions

The article presents studies of the effective thermal conductivity of polyurethane foams with different morphologies and with different positions of a heater. Foams with open, closed, and mixed cells were studied. The cell size varied from 0.7 to 6.28 mm. The heater was located above, below, or to the side of the foam. Experimental studies were carried out in the temperature range from 30 to 100 °C. The conclusions from the research results are presented below.

- 1.

- Verification of Experimental Data

The obtained values of thermal conductivity were verified with the measurement data of the authors Berardi et al. [35] and Alvarez-Lainez et al. [27]. Foams with open cells of similar sizes (3.294 mm in [27] and 3.1 mm in our work) have similar values of effective thermal conductivity: 0.050 W/m⸱K and 0.044 W/m⸱K, respectively, at a temperature of 40 °C. The slight difference in values is due to the fact that the authors of [27] studied polyolefin foams whereas we studied polyurethane foams.

Berardi et al. [35] studied open and closed-cell polyurethane foams. Pen-cell foams (PU-C [35] and foam with cells of d = 3.1 mm in our work) have similar thermal conductivity values: 0.0451 W/m⸱K for the PU-C sample and 0.0437 W/m⸱K for foam with cells of d = 3.1 mm, at t = 35 °C. The PU-B sample [35] at a temperature of 35 °C has a thermal conductivity value of 0.0335 W/m⸱K, which agrees well with the thermal conductivity value of the mixed-cell foam d = 3.28 mm studied in our work. The thermal conductivity of our sample at t = 35 °C is 0.0365 W/m⸱K. The slight difference is due to the fact that our foam sample contains open cells, which contribute to the transfer of heat by convective currents, respectively, so the thermal conductivity value of our sample is slightly higher.

- 2.

- Effect of Cell Size

The cell size has a significant effect on the effective thermal conductivity of polyurethane foam. Two foam samples with open cells of different sizes (3.1 mm and 0.725 mm) have thermal conductivity values of 0.0482 and 0.0299 W/m⸱K, respectively, at a temperature of 80 °C for the case when the heater is located above (we exclude the effect of convection). This difference is explained by the influence of the cell size on the radiative component of thermal conductivity: the larger the cell, the more heat is transferred by radiation. When the heater is located below, the contribution of the cell size to the change in effective thermal conductivity increases.

- 3.

- Effect of Cell Type

The research results show that at close cell sizes, the main parameter affecting the effective thermal conductivity of the foam is the cell type. Closed cells of small sizes (less than 4 mm) prevent the movement of convective flows, so the effective thermal conductivity of foams with a predominance of closed cells is lower than that of foams with open cells of the same size. We compared the thermal conductivity of mixed-cell foams (3.28 mm and 3.4 mm) and the thermal conductivity of open-cell foams (3.1 mm) of similar sizes. In the case, where the heater is located from below the convective component of thermal conductivity is added. The effective thermal conductivity of the open-cell foam is 0.0645 W/m⸱K at t = 80 °C. Mixed cell foams have lower effective thermal conductivity values, namely: 0.0468 W/m⸱K for foam with 3.28 mm cells and 0.0536 W/m⸱K for foam with cells of 3.4 mm. Thus, the type of polyurethane foam cells affects the value of effective thermal conductivity.

- 4.

- Influence of Heater Position

The results of the experiments show significant differences in the effective thermal conductivity depending on the position of the heater. We consider the differences in the values of the thermal conductivity of the foams in the cases of the position of the heater from above or below at a temperature of 80 °C. The values of effective thermal conductivity when the heater is located from below are higher than the values of effective thermal conductivity when the heater is located from above by 17–25% for open-cell foams, 13–19% for mixed-cell foams, and by 20% for large closed-cell foams. Thus, depending on the position of the heater, the same foam sample has different thermal conductivity values.

When the heater is located on the side of the foam, all samples have different thermal conductivity values at the top and bottom measurement points, which is explained by the movement of convective flows. In foams with mixed cells at a temperature of 80 °C, the difference between the thermal conductivity values at the top and bottom measurement points is 22.14–23.21%. In foams with open cells at t = 80 °C, this difference is 17.6 and 40.9% for foams with cells of 0.725 mm and 3.1 mm, respectively. Thus, when the heater is located on the side, the same sample has different values of effective thermal conductivity at the top and bottom measurement points.

These studies can form the basis for the development of recommendations for the use of thermal insulation in the construction of buildings and structures, as well as in the creation of new thermal insulation materials.

Author Contributions

Conceptualization, O.V.S. and S.A.S.; methodology, O.V.S. and S.A.S.; validation, O.V.S., S.A.S. and R.Z.S.; formal analysis, S.A.S., R.Z.S.; investigation, O.V.S. and S.A.S.; data curation, S.A.S., Y.V.V.; writing—original draft preparation, O.V.S., R.Z.S.; writing—review and editing, Y.V.V.; visualization, R.Z.S.; supervision, S.A.S., Y.V.V.; project administration, O.V.S.; funding acquisition, O.V.S. All authors have read and agreed to the published version of the manuscript.

Funding

The research was funded by the Russian Science Foundation, grant number 21-79-10406, https://rscf.ru/en/project/21-79-10406/ (accessed on 10 September 2022).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pai, A.R.; Puthiyaveettil Azeez, N.; Thankan, B.; Gopakumar, N.; Jaroszewski, M.; Paoloni, C.; Kalarikkal, N.; Thomas, S. Recent Progress in Electromagnetic Interference Shielding Performance of Porous Polymer Nanocomposites—A Review. Energies 2022, 15, 3901. [Google Scholar] [CrossRef]

- Bicy, K.; Anu Paul, P.; Kalarikkal, N.; Stephen, A.M.; Geethamma, V.G.; Rouxel, D.; Thomas, S. Effects of nanofillers on morphology and surface wetting of microporous polypropylene composite membranes. Mater. Chem. Phys. 2021, 257, 123742. [Google Scholar]

- Rastegarfar, N.; Behrooz, R.; Barikani, M. Characterization of polyurethane foams prepared from liquefied sawdust by crude glycerol and polyethylene glycol. J. Polym. Res. 2018, 25, 154. [Google Scholar] [CrossRef]

- Shaik, A.H.; Banerjee, S.; Rahaman, A.; Agashe, S.; Khan, A.; Chandan, M.R. One-step synthesis and characteristics of LiOH-castor oil based stable polyurethane foam. J. Polym. Res. 2021, 28, 220. [Google Scholar] [CrossRef]

- Wang, S.; You, F.; Hu, S.Q.; Zhou, Y.; Sun, W. Effects of Bulk Densities and Inlet Airflow Velocities on Forward Smoldering Propagation Properties of Flexible Polyurethane Foam. Procedia Eng. 2018, 211, 762–767. [Google Scholar] [CrossRef]

- Soloveva, O.V.; Solovyov, S.A.; Popkova, O.S. Modeling of the three-dimensional structure of open cell foam and analysis of the model quality using the example of pressure drop calculation. Uchenye Zap. Kazan. Universiteta. Seriya Fiz.-Mat. Nauk. 2018, 160, 681–694. [Google Scholar]

- Soloveva, O.; Solovev, S.; Yafizov, R. Hydrodynamics and convective heat transfer in open cell foam with micropores. Transp. Res. Procedia 2021, 54, 64–68. [Google Scholar] [CrossRef]

- Soloveva, O.V.; Solovev, S.A.; Yafizov, R.R. Study of the influence of the add of micropores on filtering characteristics of high porous structures. Ecol. Ind. Russ. 2020, 24, 39–43. [Google Scholar] [CrossRef]

- Ter-Zakaryan, K.A.; Zhukov, A.D.; Bobrova, E.Y.; Bessonov, I.V.; Mednikova, E.A. Foam Polymers in Multifunctional Insulating Coatings. Polymers 2021, 13, 3698. [Google Scholar]

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Berardi, U. The impact of aging and environmental conditions on the effective thermal conductivity of several foam materials. Energy 2019, 182, 777–794. [Google Scholar] [CrossRef]

- König, J.; Lopez-Gil, A.; Cimavilla-Roman, P.; Rodriguez-Perez, M.A.; Petersen, R.R.; Østergaard, M.B.; Iversen, N.; Yue, Y.; Spreitzer, M. Synthesis and properties of open- and closed-porous foamed glass with a low density. Constr. Build. Mater. 2020, 247, 118574. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Doniavi, A.; Lee, R.E. Multi-objective optimization of heat transfer mechanisms of microcellular polymeric foams from thermal-insulation point of view. Therm. Sci. Eng. 2019, 9, 21–29. [Google Scholar] [CrossRef]

- Rezgar, H.; Taher, A.; Ali, D.; Richard, E.L. Thermal conductivity of low density polyethylene foams Part I: Comprehensive study of theoretical models. J. Therm. Sci. 2019, 28, 745–754. [Google Scholar] [CrossRef]

- Zhu, J. Impact of size distribution of cell model on the effective thermal conductivity of saturated porous media. Int. J. Thermophys. 2020, 41, 34. [Google Scholar] [CrossRef]

- Kahlerras, Z.; Irinislimane, R.; Bruzaud, S.; Belhaneche-Bensemra, N. Elaboration and Characterization of Polyurethane Foams Based on Renewably Sourced Polyols. J. Polym. Environ. 2020, 28, 3003–3018. [Google Scholar] [CrossRef]

- Kang, S.; Choi, J.Y.; Choi, S. Mechanism of Heat Transfer through Porous Media of Inorganic Intumescent Coating in Cone Calorimeter Testing. Polymers 2019, 11, 221. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Doniavi, A.; Rostami, M. A prediction model using response surface methodology based on cell size and foam density to predict thermal conductivity of polystyrene foams. Heat Mass Transf. 2019, 55, 2845–2855. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Doniavi, A.; Eungkee Lee, R. Thermal-insulation performance of low density polyethylene (LDPE) foams: Comparison between two radiation thermal conductivity models. Polyolefins J. 2018, 6, 13–21. [Google Scholar]

- Hu, F.; Wu, S.; Sun, Y. Hollow-structured materials for thermal insulation. Adv. Mater. 2019, 31, 1801001. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Fathi, S.; Azdast, T.; Rostami, M. Theoretical Investigation and Optimization of Radiation Thermal Conduction of Thermal-Insulation Polyolefin Foams. Iran. J. Mater. Sci. Eng. 2020, 17, 58–65. [Google Scholar]

- Hasanzadeh, R.; Azdast, T.; Doniavi, A. Thermal conductivity of low-density polyethylene foams part II: Deep investigation using response surface methodology. J. Therm. Sci. 2020, 29, 159–168. [Google Scholar] [CrossRef]

- Buahom, P.; Wang, C.; Alshrah, M.; Wang, G.; Gong, P.; Tran, M.P.; Park, C.B. Wrong expectation of superinsulation behavior from largely-expanded nanocellular foams. Nanoscale 2020, 12, 13064–13085. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, X. Thermal conductivity analysis of high porosity structures with open and closed pores. Int. J. Heat Mass Transf. 2022, 183, 122089. [Google Scholar] [CrossRef]

- Doğan, B.; Tan, H. The numerical and experimental investigation of the change of the thermal conductivity of expanded polystyrene at different temperatures and densities. Int. J. Polym. Sci. 2019, 2019, 6350326. [Google Scholar] [CrossRef]

- Choe, H.; Choi, Y.; Kim, J.H. Threshold cell diameter for high thermal insulation of water-blown rigid polyurethane foams. J. Ind. Eng. Chem. 2019, 73, 344–350. [Google Scholar] [CrossRef]

- Alvarez-Lainez, M.; Rodriguez-Perez, M.; De Saja, J.A. Thermal conductivity of open-cell polyolefin foams. J. Polym. Sci. B Polym. Phys. 2008, 46, 212–221. [Google Scholar] [CrossRef]

- Notario, B.; Pinto, J.; Solorzano, E.; de Saja, J.A.; Dumon, M.; Rodríguez-Pérez, M.A. Experimental validation of the Knudsen effect in nanocellular polymeric foams. Polymer 2015, 56, 57–67. [Google Scholar] [CrossRef]

- Baldinelli, G.; Bianchi, F.; Gendelis, S.; Jakovics, A.; Morini, G.L.; Falcioni, S.; Fantucci, S.; Serra, V.; Navacerrada, M.A.; Diaz, C.; et al. Thermal conductivity measurement of insulating innovative building materials by hot plate and heat flow meter devices: A Round Robin Test. Int. J. Therm. Sci. 2019, 139, 25–35. [Google Scholar] [CrossRef]

- Rasmussen, E.; Stacey, C.; Koenen, A.; Kurkinen, E.L.W. Comparative Testing of Thermal Conductivity for Thermal Insulation Products: The European Keymark Experience for More than 50 Equipment at 25 Test Institutes. In Proceedings of the 32nd International Thermal Conductivity Conference, Purdue University, West Lafayette, IN, USA, 27 April–1 May 2014. [Google Scholar]

- Sánchez-Calderón, I.; Merillas, B.; Bernardo, V.; Rodríguez-Pérez, M.Á. Methodology for measuring the thermal conductivity of insulating samples with small dimensions by heat flow meter technique. J. Therm. Anal. Calorim. 2022, 147, 12523–12533. [Google Scholar] [CrossRef]

- Ruuska, T.; Vinha, J.; Kivioja, H. Measuring thermal conductivity and specific heat capacity values of inhomogeneous materials with a heat flow meter apparatus. J. Build. Eng. 2017, 9, 135–141. [Google Scholar] [CrossRef]

- Kim, D.; Lee, S.; Yang, I. Verification of thermal conductivity measurements using guarded hot plate and heat flow meter methods. J. Korean Phys. Soc. 2021, 78, 1196–1202. [Google Scholar] [CrossRef]

- Hammerschmidt, U.; Hameury, J.; Strnad, R.; Turzó-Andras, E.; Wu, J. Critical review of industrial techniques for thermal-conductivity measurements of thermal insulation materials. Int. J. Thermophys. 2015, 36, 1530–1544. [Google Scholar] [CrossRef]

- Berardi, U.; Madzarevic, J. Microstructural analysis and blowing agent concentration in aged polyurethane and polyisocyanurate foams. Appl. Therm. Eng. 2020, 164, 114440. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).