Downstream Torrefaction of Wood Pellets in a Rotary Kiln Reactor—Impact on Solid Biofuel Properties and Torr-Gas Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

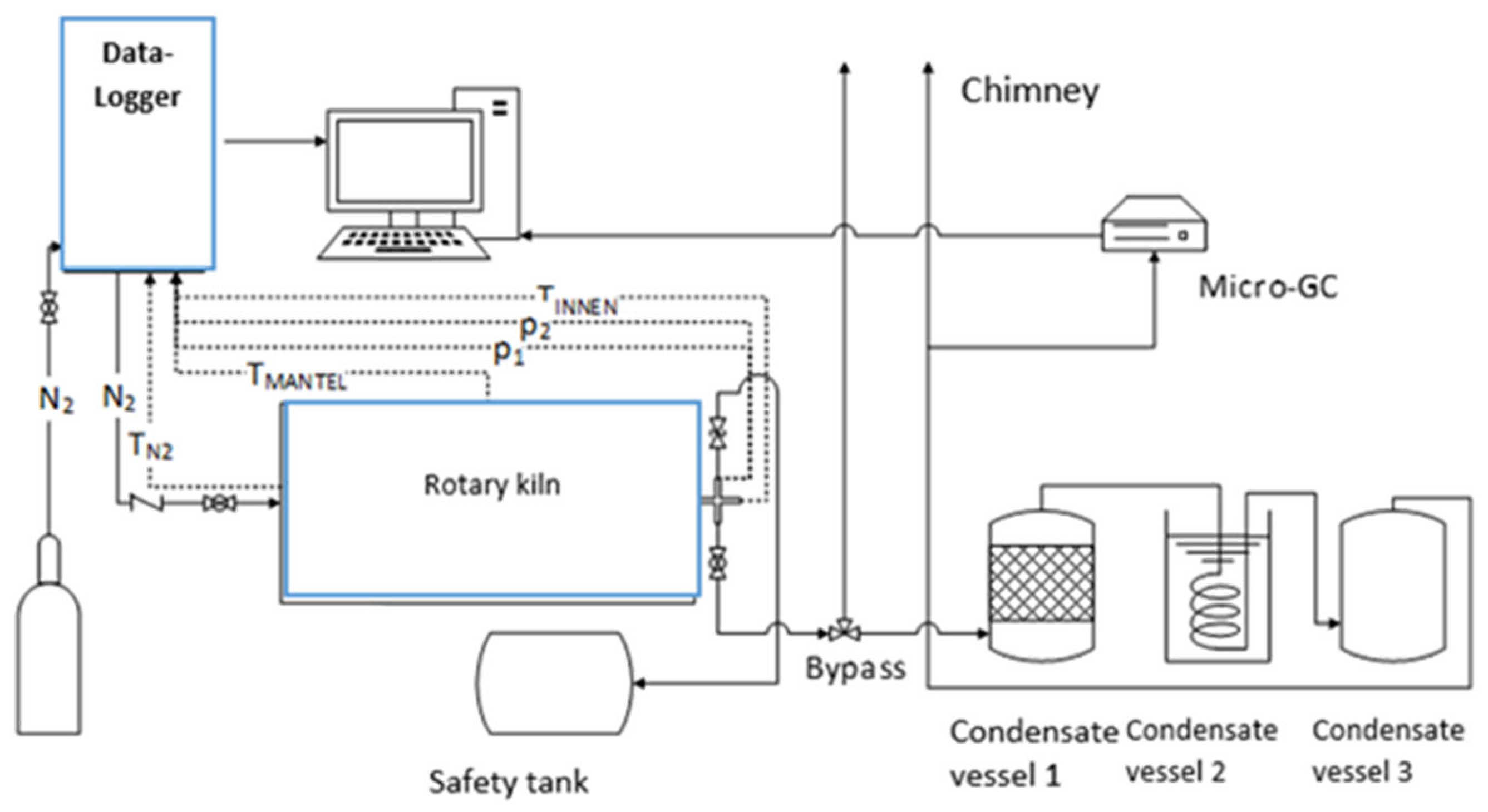

2.2. Torrefaction Experiments

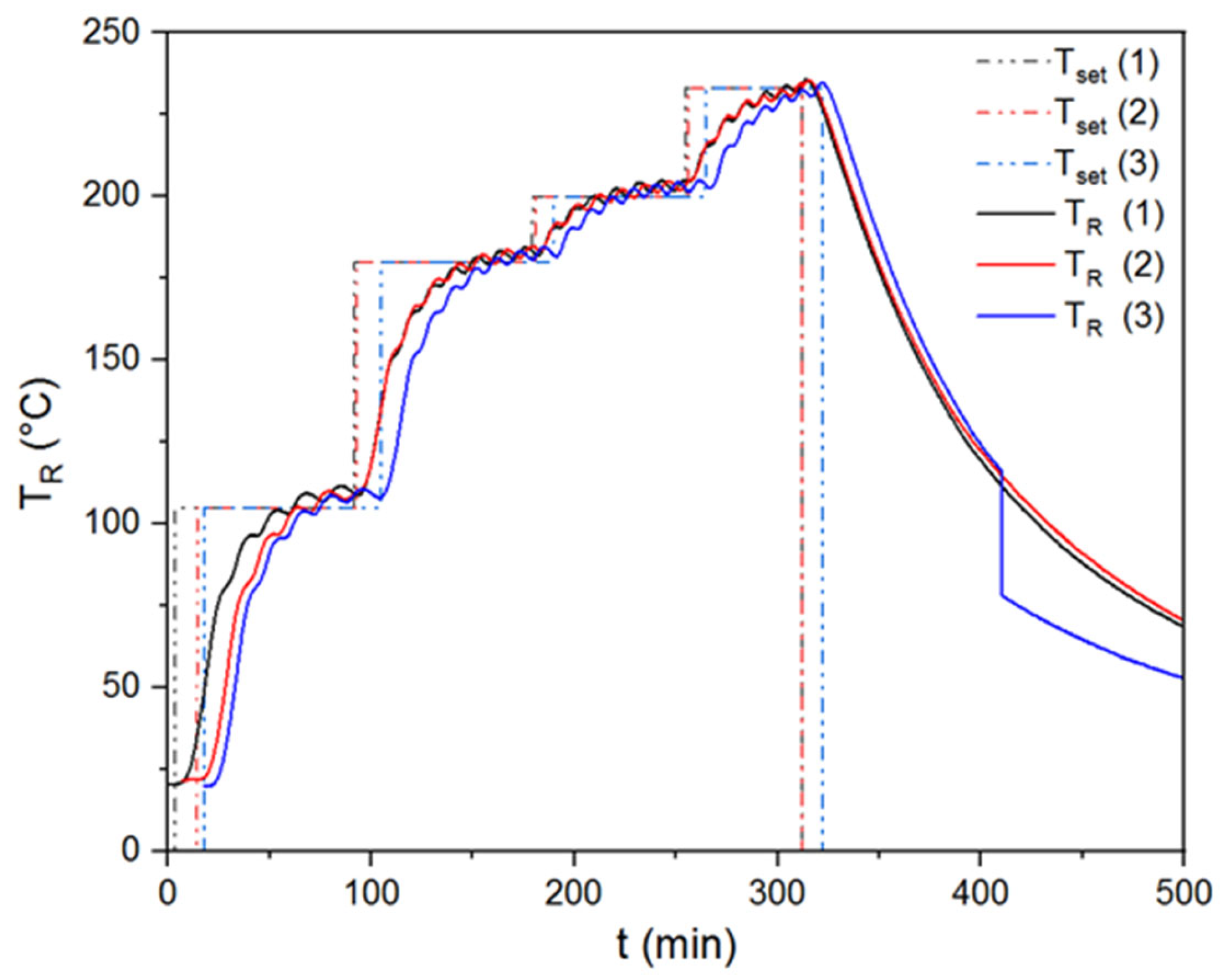

2.3. Reproducibility of the Torrefaction Experiments

3. Results and Discussion

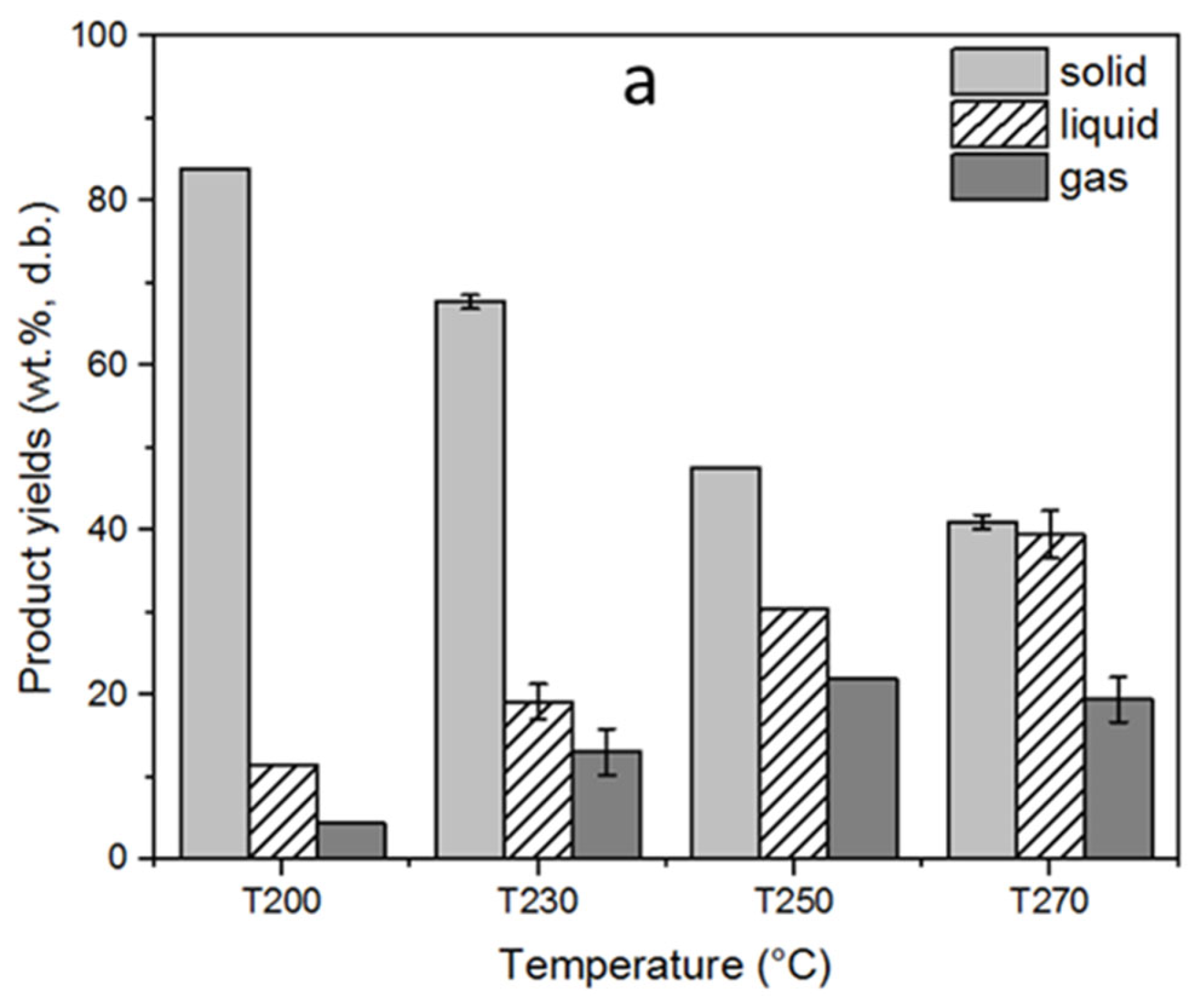

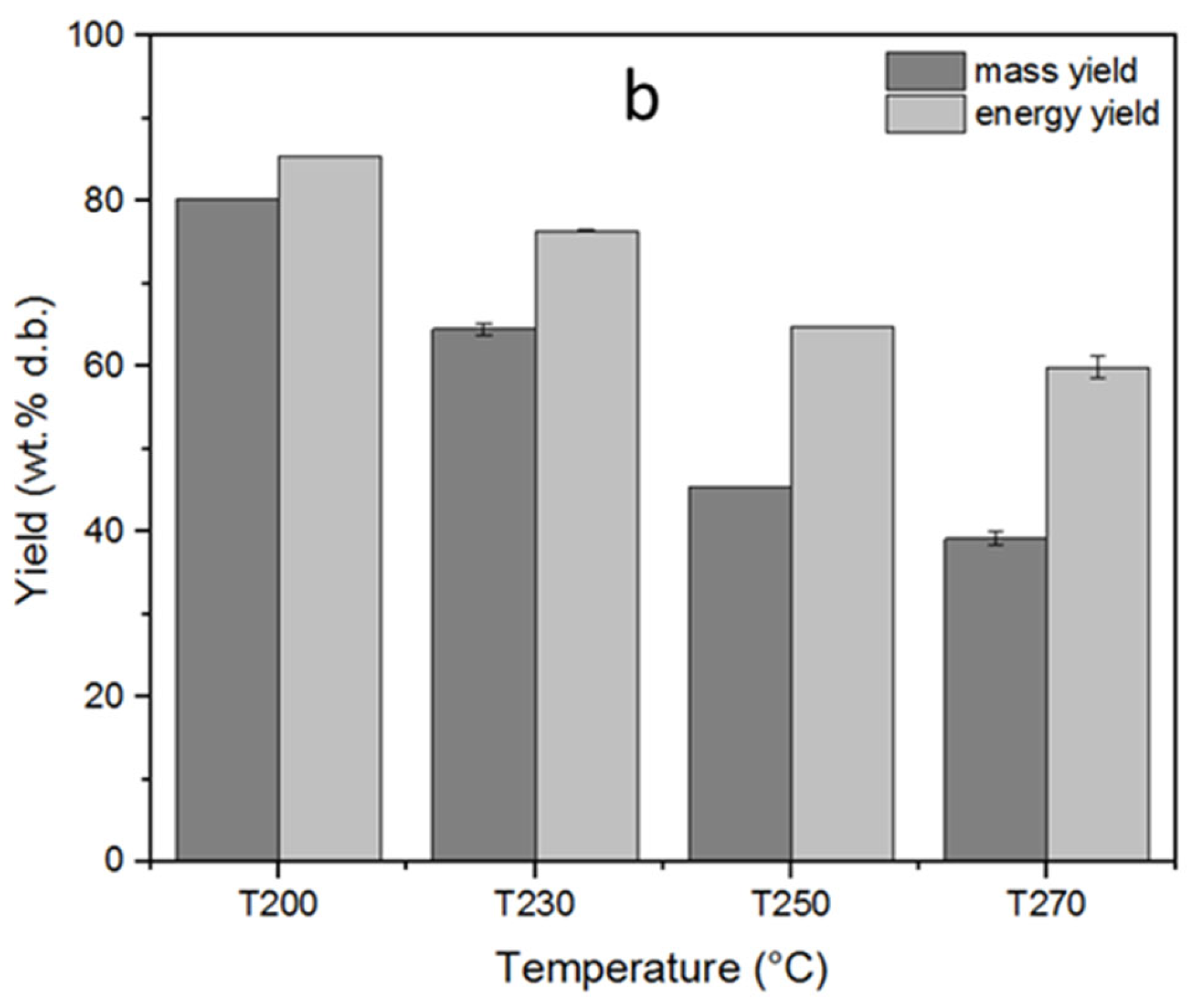

3.1. Product Yields of Torrefaction

3.2. Characteristics of Condensable and Non-Condensable Torr-Gas

3.3. Impact of Torrefaction Process on the Properties of Selected Wood Pellet Quality

3.4. Comparison with ISO Standards

4. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A1 | raw biomass pellet in ISO/TS-17225-2 |

| b.d.l. | below detection limit |

| d.b. | dry basis |

| DIN | Deutsches Institut für Normung |

| GC | gas chromatography |

| ISO | International Organization for Standardization |

| ISO/TS | International Organization for Standardization/Technical Specification |

| LHV | lower heating value |

| n.d. | not detected |

| NCV | net calorific value |

| PM | particulate matter |

| t | time, min |

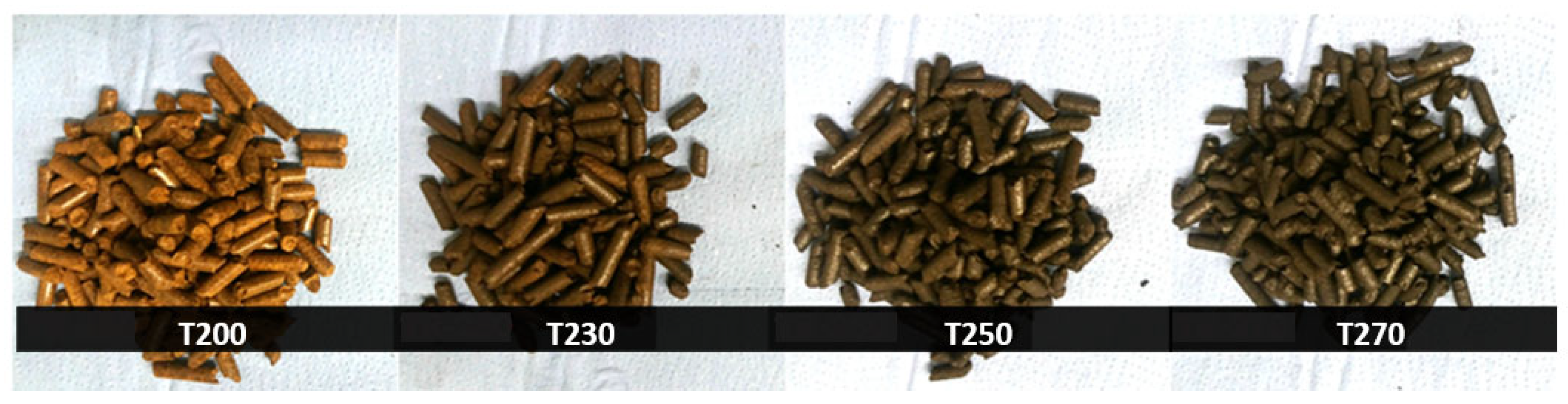

| T200 | set-up temperature at 200 °C |

| T230 | set-up temperature at 230 °C |

| T250 | set-up temperature at 250 °C |

| T270 | set-up temperature at 270 °C |

| Tj | temperature of the jacket, °C |

| TR | temperature of the reactor, °C |

| Tset | set temperature, °C |

| TW1a | thermally treated and densified biomass with calorific value ≥ 21 MJ/kg (as received) in ISO/TS-17225-8 |

| TW1b | thermally treated and densified biomass with calorific value ≥ 16.9 MJ/kg (as received) in ISO/TS-17225-8 |

| wt. | weight |

| Δmman | mass loss by weighing of mass manually before and after torrefaction |

References

- Acharya, B.; Sule, I.; Dutta, A. A review on advances of torrefaction technologies for biomass processing. Biomass Convers. Biorefinery 2012, 2, 349–369. [Google Scholar] [CrossRef]

- United Nations. Renewable energy—Powering a Safer Future. Available online: https://www.un.org/en/climatechange/raising-ambition/renewable-energy (accessed on 22 August 2022).

- Rosillo-Calle, F. A review of biomass energy—Shortcomings and concerns. J. Chem. Technol. Biotechnol. 2016, 91, 1933–1945. [Google Scholar] [CrossRef]

- Wannapeera, J.; Fungtammasan, B.; Worasuwannarak, N. Effects of temperature and holding time during torrefaction on the pyrolysis behaviors of woody biomass. J. Anal. Appl. Pyrolysis 2011, 92, 99–105. [Google Scholar] [CrossRef]

- Wang, L.; Riva, L.; Skreiberg, Ø.; Khalil, R.; Bartocci, P.; Yang, Q.; Yang, H.; Wang, X.; Chen, D.; Rudolfsson, M.; et al. Effect of Torrefaction on Properties of Pellets Produced from Woody Biomass. Energy Fuels 2020, 34, 15343–15354. [Google Scholar] [CrossRef]

- Gong, C.; Bryant, N.; Meng, X.; Bhagia, S.; Pu, Y.; Xin, D.; Bender Koch, C.; Felby, C.; Thygesen, L.G.; Ragauskas, A.; et al. Double bonus: Surfactant-assisted biomass pelleting benefits both the pelleting process and subsequent enzymatic saccharification of the pretreated pellets. Green Chem. 2021, 23, 1050–1061. [Google Scholar] [CrossRef]

- Kylili, A.; Christoforou, E.; Fokaides, P.A. Environmental evaluation of biomass pelleting using life cycle assessment. Biomass Bioenergy 2016, 84, 107–117. [Google Scholar] [CrossRef]

- Gaitán-Álvarez, J.; Moya, R.; Puente-Urbina, A.; Rodriguez-Zúñiga, A. Thermogravimetric, Devolatilization Rate, and Differential Scanning Calorimetry Analyses of Biomass of Tropical Plantation Species of Costa Rica Torrefied at Different Temperatures and Times. Energies 2018, 11, 696. [Google Scholar] [CrossRef]

- Thrän, D.; Witt, J.; Schaubach, K.; Kiel, J.; Carbo, M.; Maier, J.; Ndibe, C.; Koppejan, J.; Alakangas, E.; Majer, S.; et al. Moving torrefaction towards market introduction—Technical improvements and economic-environmental assessment along the overall torrefaction supply chain through the SECTOR project. Biomass Bioenergy 2016, 89, 184–200. [Google Scholar] [CrossRef]

- García, R.; Gil, M.V.; González-Vázquez, M.P.; Rubiera, F.; Pevida, C. Biomass Pelletization: Contribution to Renewable Power Generation Scenarios. In Production of Materials from Sustainable Biomass Resources; Biofuels and Biorefineries; Fang, Z., Smith, R., Jr., Tian, X.F., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; p. 9. [Google Scholar]

- Zanzi, R.; Majari, M.; Björnbom, E. Biomass pre-treatment by torrefaction. In Proceedings of the 16th European Biomass Conference and Exhibition, Valencia, Spain, 2–6 June 2008. [Google Scholar]

- SECTOR- Production of Solid Sustainable Energy Carriers from Biomass by Means of Torrefaction. Available online: https://www.sector-project.eu/home.1.0.html (accessed on 14 March 2022).

- Ghiasi, B.; Kumar, L.; Furubayashi, T.; Lim, C.J.; Bi, X.; Soo Kim, C.; Sokhansanj, S. Densified biocoal from woodchips: Is it better to do torrefaction before or after densification? Appl. Energy 2014, 134, 133–142. [Google Scholar] [CrossRef]

- Kumar, L.; Koukoulas, A.A.; Mani, S.; Satyavolu, J. Integrating Torrefaction in the Wood Pellet Industry: A Critical Review. Energy Fuels 2017, 31, 37–54. [Google Scholar] [CrossRef]

- Yu, S.; Park, J.; Kim, M.; Kim, H.; Ryu, C.; Lee, Y.; Yang, W.; Jeong, Y.-G. Improving Energy Density and Grindability of Wood Pellets by Dry Torrefaction. Energy Fuels 2019, 33, 8632–8639. [Google Scholar] [CrossRef]

- Manouchehrinejad, M.; Mani, S. Torrefaction after pelletization (TAP): Analysis of torrefied pellet quality and co-products. Biomass Bioenergy 2018, 118, 93–104. [Google Scholar] [CrossRef]

- Brachi, P.; Chirone, R.; Miccio, M.; Ruoppolo, G. Fluidized Bed Torrefaction of Commercial Wood Pellets: Process Performance and Solid Product Quality. Energy Fuels 2018, 32, 9459–9469. [Google Scholar] [CrossRef]

- Lee, Y.; Yang, W.; Chae, T.; Kang, B.; Park, J.; Ryu, C. Comparative Characterization of a Torrefied Wood Pellet under Steam and Nitrogen Atmospheres. Energy Fuels 2018, 32, 5109–5114. [Google Scholar] [CrossRef]

- Liu, X.; Yao, Z.; Zhao, L.; Song, J.; Jia, J. Torrefaction of Sorghum Straw Pellets in a Stationary Reactor with a Feeding Screw. Energy Fuels 2020, 34, 5997–6007. [Google Scholar] [CrossRef]

- Onsree, T.; Tippayawong, N. Torrefaction of Maize Residue Pellets with Dry Flue Gas. Bioenergy Res. 2020, 13, 358–368. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.J.; Oh, K.C.; La Cho, H.; Kim, M.J.; Jeong, I.S.; Lee, C.G.; Kim, D.H. Characteristic Analysis of Torrefied Pellets: Determining Optimal Torrefaction Conditions for Agri-Byproduct. Energies 2020, 13, 423. [Google Scholar] [CrossRef]

- Yılgın, M.; Duranay, N.; Pehlivan, D. Torrefaction and combustion behaviour of beech wood pellets. J. Therm. Anal. Calorim. 2019, 138, 819–826. [Google Scholar] [CrossRef]

- Nam, S.B.; Park, Y.S.; Kim, D.J.; Gu, J.H. Torrefaction Reaction Characteristic of Various Biomass Waste on Pilot Scale of Torrefaction Reaction System. Procedia Environment. Sci. 2016, 35, 890–894. [Google Scholar] [CrossRef]

- International Organisation for Standardardisation. Solid biofuels—Fuel specifications and classes—Part 8: Graded thermally treated and densified biomass fuels ISO/DIS 17225-8:2016, 2016 (ISO/DIS 17225-8:2016). Available online: https://www.iso.org/standard/71915.html (accessed on 14 March 2022).

- Chen, W.-H.; Zhuang, Y.-Q.; Liu, S.-H.; Juang, T.-T.; Tsai, C.-M. Product characteristics from the torrefaction of oil palm fiber pellets in inert and oxidative atmospheres. Bioresour. Technol. 2016, 199, 367–374. [Google Scholar] [CrossRef]

- Zeng, T. Standard Operating Procedures of Rotary Kiln, Internal Test Stand Documentation DBFZ. Leipzig 2015.

- Liebetrau, J. Measurement Toolkit Biogas: Methods for the determination of analytical and process parameters describing the biogas area. DBFZ 2013. Available online: https://www.energetische-biomassenutzung.de (accessed on 12 April 2022).

- Tumuluru, J.S.; Sokhansanj, S.; Hess, J.R.; Wright, C.; Boardman, R.D. A Review on Biomass Torrefaction Process and Product Properties for Energy Applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lin, B.-J.; Lin, Y.-Y.; Chu, Y.-S.; Ubando, A.T.; Show, P.L.; Ong, H.C.; Chang, J.-S.; Ho, S.-H.; Culaba, A.B.; et al. Progress in biomass torrefaction: Principles, applications and challenges. Prog. Energy Combust. Sci. 2021, 82, 100887. [Google Scholar] [CrossRef]

- Yoshida, T.; Nomura, T.; Gensai, H.; Watada, H.; Sano, T.; Ohara, S. Upgraded Pellet Making by Torrefaction—Torrefaction of Japanese Wood Pellets. J. Sustain. Bioenergy Syst. 2015, 5, 82–85. [Google Scholar] [CrossRef][Green Version]

- Manouchehrinejad, M.; van Giesen, I.; Mani, S. Grindability of torrefied wood chips and wood pellets. Fuel Process. Technol. 2018, 182, 45–55. [Google Scholar] [CrossRef]

- van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 31, 3458. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Wright, C.T.; Boardman, R.D. Biomass Torrefaction Process Review and Moving Bed Torrefaction System Model Development; Report Prepared for U.S. Energy Department, Idaho National Laboratory (INL) and Oak Ridge National Laboratory; Technical Report No. US201212%%980; U.S. Department of Energy: Oak Ridge, TN, USA, 2010. [Google Scholar] [CrossRef]

- Ferro Tito, D.; Vigouroux, V.; Grimm, A.; Zanzi, R. Torrefaction of agricultural and forest residues. In Proceedings of the Torrefaction of Agricultural and Forest Residues, Conference Cubasolar, Guantánamo, Cuba, 12–16 April 2004. [Google Scholar]

- Hang, S.; Zhao, Z.; Zheng, A.; He, F.; Huang, Z.; Li, H. Characterization of Products from Torrefaction of Sprucewood and Bagasse in an Auger Reactor. Energy Fuels 2012, 26, 7009–7017. [Google Scholar]

- Bergman, P.C.A.; Boersma, A.R.; Zwart, R.W.R.; Kiel, J.H.A. Torrefaction for Biomass Co-Firing in Existing Coal-Fired Power Stations; Energy Research Center of The Netherlands: Petten, The Netherlands, 2005. [Google Scholar]

- Bergman, P.C.A. Combined Torrefaction and Pelletisation: The TOP Process; Technical Report; ECN Biomass: Pettem, The Netherlands, 2005. Available online: https://www.osti.gov/etdeweb/biblio/20653915 (accessed on 18 September 2022).

- Zhang, Y.; Chen, F.; Chen, D.; Cen, K.; Zhang, J.; Cao, X. Upgrading of biomass pellets by torrefaction and its influence on the hydrophobicity, mechanical property, and fuel quality. Biomass Conv. Bioref. 2020, 40, 153. [Google Scholar] [CrossRef]

- Pollex, A.; Zeng, T.; Khalsa, J.; Erler, U.; Schmersahl, R.; Schön, C.; Kuptz, D.; Lenz, V.; Nelles, M. Content of potassium and other aerosol forming elements in commercially available wood pellet batches. Fuel 2018, 232, 384–394. [Google Scholar] [CrossRef]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. A review on torrefied biomass pellets as a sustainable alternative to coal in power generation. Renew. Sustain. Energy Rev. 2014, 40, 153–160. [Google Scholar] [CrossRef]

- International Organisation for Standardardisation. Solid Biofuels-Fuel Specifications and Classes-Part 2: Graded Wood Pellets, 2nd ed.; Berlin, V., Ed.; DIN Deutsches Institut für Normung e; Beuth Verlag GmbH: Berlin, Germany, 2021; Available online: http://www.beuth.de/ (accessed on 14 March 2022).

- Cutz, L.; Tiringer, U.; Gilvari, H.; Schott, D.; Mol, A.; de Jong, W. Microstructural degradation during the storage of biomass pellets. Commun. Mater. 2021, 2, 16013. [Google Scholar] [CrossRef]

- Zeng, T.; Weller, N.; Pollex, A.; Lenz, V. Blended biomass pellets as fuel for small scale combustion appliances: Influence on gaseous and total particulate matter emissions and applicability of fuel indices. Fuel 2016, 184, 689–700. [Google Scholar] [CrossRef]

- Zeng, T.; Pollex, A.; Weller, N.; Nelles, M. Blended biomass pellets as fuel for small scale combustion appliances: Effect of blending on slag formation in the bottom ash and pre-evaluation options. Fuel 2018, 212, 108–116. [Google Scholar] [CrossRef]

- Dizaji, H.B.; Zeng, T.; Hölzig, H.; Bauer, J.; Klöß, G.; Enke, D. Ash transformation mechanism during combustion of rice husk and rice straw. Fuel 2022, 307, 121768. [Google Scholar] [CrossRef]

| Fuel | Reactor | Temperature (°C) | Residence Time (min) | Aim of the Study | Ref. |

|---|---|---|---|---|---|

| Wood pellets | FB | 210–310 | 15–30–60 | Studying the effect of torrefaction temperature and hold time on improving energy density and grindability of wood pellets | [15] |

| Wood pellets | EF | 230–290 | 30 | Studying the effect of torrefaction temperature on torrefied wood pellet quality and co-products | [16] |

| Wood pellets | FBR | 200–250 | 7–15 | Studying the influence of fluidized bed torrefaction treatment at different temperatures and holding times on the distribution and the composition of products; the quality of torrefied pellets; and process performance | [17] |

| Wood pellets | FB | 230–300 | 240 | Comparison of torrefied wood pellet characteristics under inert and steam atmosphere | [18] |

| Sorghum Straw Pellets | FB | 230–330 | 20 | Studying the effects of temperature and rotating speed of a feeding screw on the key performance parameters of torrefaction in a stationary reactor with a fixed tube furnace | [19] |

| Maize residue pellets | FB | 220–300 | 10–20–30–40 | Studying effects of temperature, residence time, and the presence of CO2 on products’ yields, distribution, and product properties | [20] |

| Pellets of pepper stems, perilla stems, chaff, and coffee spent ground | EF | 210–290 | 30 | Studying the optimal torrefaction conditions for agri-by products | [21] |

| Beech wood sawdust pellets | TR | 220–260–300 | 10 | Studying torrefaction of pellets at different temperatures and investigations into their combustion behavior | [22] |

| Empty fruit bunch Wood pellets Rice husks | RK | 265 | 30 | Characterization of torrefaction reactions of different waste biomasses in a pilot-scale reactor | [23] |

| Oil palm fiber pellets | EF | 275–350 | 30 | Studying the effects of torrefaction temperature and atmosphere (inert and oxidative) on product quality and heating value | [25] |

| Parameters | Methods | Devices |

|---|---|---|

| Fuel analyses | ||

| Water content | DIN EN 14774-2 | Drying oven: BINDER, Series: FD |

| Mechanical durability | DIN EN 15210-1 | Bioenergy TUMBLER 3000 |

| Bulk density | DIN EN 15103 | 5 L beaker and KERN PCB |

| Fines | DIN EN 15149-1 | |

| Sample splitting | DIN EN 14780 | Riffler: HAVER RT 75, Diameter-75 mm |

| C, H, N, S | DIN EN 15104 | Elementary Modell Vario Macro Cube |

| Cl | DIN EN 15289, DIN EN ISO 10304-1 | Ion chromatography Dionex, Thermo Modell ICS 1100 |

| Ash content | DIN EN 14775 | Nabertherm Incinerator LV15/11 P330 |

| Volatile matter | DIN EN 15148 | Nabertherm Incinerator LV15/11 P330 |

| Net calorific value | DIN EN 14918 | Bomb Calorimeter Parr 6300 |

| Major and minor elements | DIN EN 15290 DIN EN 15297 | Thermo Scientific iCAP 6300 |

| Condensable gas analyses | ||

| Water content | DIN EN 14346 | Coulometric Karl-Fischer-Titrator ECH, Analytic Jena Modell Aqua 40.00 |

| Condensable volatiles content | [27] | Gas-chromatography (Agilent 7980A) Head-Space-sampler (PerkinElmer Turbo Matrix 110) |

| Non-condensable gas analyses | ||

| Calibration of test gas | DIN EN ISO 614 | GCM Micro Box II |

| Label | Set Temp. (°C) | TR (°C) | Difference of Tj from TR (°C) | (Tj + TR)/2 (°C) | Δmman (%) | ||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | Min | Max | Mean | Min | Max | Mean | |||

| T200 | 200 | 200 | 200 | 204 | 26 | 15 | 37 | 213 | 12 |

| T230 (avg.) | 230 | 232 | 230 | 234 | 30 | 20 | 44 | 247 | 29 |

| T250 | 250 | 251 | 248 | 253 | 31 | 20 | 48 | 266 | 50 |

| T270 (avg.) | 270 | 269 | 267 | 272 | 29 | 13 | 46 | 283 | 57 |

| T200 | T230 | T250 | T270 | |

|---|---|---|---|---|

| Formic acid | 1.16 | 1.66 (0.25) | 2.13 | 2.29 (0.03) |

| Acetic acid | 6.70 | 9.60 (0.33) | 9.54 | 10.0 (0.09) |

| Propionic acid | 0.37 | 0.62 (0.04) | 0.82 | 0.92 (0.06) |

| Furfural | 0.64 | 0.64 (0.07) | 0.67 | 0.68 (0.03) |

| Methanol | 1.27 | 1.26 (0.21) | 2.13 | 2.46 (0.40) |

| Water | 89.6 | 89.7 (0.46) | 84.4 | 83.2 (0.55) |

| Rest | 0.18 | 0.18 (0.42) | 0.36 | 0.42 (0.01) |

| T200 | T230 | T250 | T270 | |

|---|---|---|---|---|

| CO | 6.34 | 30.7 (1.890) | 37.6 | 26.1 (3.801) |

| CO2 | 93.6 | 69.2 (1.898) | 62.2 | 73.3 (3.711) |

| CH4 | - | 0.08 (0.032) | 0.22 | 0.64 (0.096) |

| H2 | 0.03 | 0.03 (0.003) | 0.04 | 0.03 (0.006) |

| ISO 17225-2 | ISO 17225-8 | Wood Pellet | T200 | T230 | T250 | T270 | |||

|---|---|---|---|---|---|---|---|---|---|

| Property Class | Unit | A1 | TW1a | TW1b | A1 | TW1b | TW1a | TW1a | TW1a |

| Moisture content | wt.% | ≤10 | ≤8 | ≤10 | 5.22 | 0.82 | 0.31 (0.03) | 0.24 | 0.13 (0.03) |

| Ash content | wt.%, d.b. | ≤0.7 | ≤1.2 | ≤1.2 | 0.22 | 0.31 | 0.41 (0.03) | 0.59 | 0.72 (0.04) |

| Volatile matter | wt.%, d.b. | - | - | - | 84.50 | 79.60 | 70.10 (0.35) | 51.90 | 41.60 (0.18) |

| Fixed carbon | wt.%, d.b. | - | - | - | 15.30 | 20.20 | 29.57 (0.37) | 47.60 | 57.87 (0.11) |

| Mechanical durability | wt.% | ≥98.0 | ≥97.5 | ≥97.5 | 99.10 | 98.60 | 96.80 | 96.10 | 95.70 |

| Fines | wt.% | ≤1.0 | ≤1.0 | ≤1.0 | 0.90 | 1.40 | 3.15 | 3.90 | 4.30 |

| Net calorific value * | MJ/kg | ≥16.5 | ≥21.0 | ≥16.9 | 18.00 | 20.10 | 22.60 | 27.20 | 29.10 |

| Bulk density | kg/m3 | ≥600 | ≥700 | ≥700 | 651.0 | 608.0 | 543.1 | 418.4 | 372.2 |

| C | wt.%, d.b. | - | - | - | 51.40 | 54.20 | 59.90 (0.32) | 71.00 | 75.20 (0.05) |

| H | wt.%, d.b. | - | - | - | 6.28 | 5.40 | 5.80 (0.02) | 4.51 | 4.29 (0.03) |

| O (by difference) | wt.%, d.b. | - | - | - | 41.90 | 40.00 | 33.70 (0.32) | 23.70 | 19.60 (0.11) |

| N | wt.%, d.b. | ≤0.3 | ≤0.5 | ≤0.5 | 0.080 | 0.030 | 0.047 (0.01) | 0.070 | 0.070 (0.01) |

| S | wt.%, d.b. | ≤0.04 | ≤0.04 | ≤0.04 | 0.008 | 0.007 | 0.015 (0.002) | 0.0015 | 0.0015 (-) |

| Cl | wt.%, d.b. | ≤0.02 | ≤0.03 | ≤0.03 | 0.174 | 0.129 | 0.176 (0.02) | 0.250 | 0.178 (0.02) |

| Cd | mg/kg, d.b. | ≤0.5 | ≤0.5 | ≤0.5 | 0.201 | 0.268 | 0.332 (0.03) | 0.420 | 0.541 (0.014) |

| Cr | mg/kg, d.b. | ≤10 | ≤10 | ≤10 | 0.706 | 0.589 | 2.73 (2.84) | 0.601 | 1.514 (1.47) |

| Cu | mg/kg, d.b. | ≤10 | ≤10 | ≤10 | 0.877 | 0.971 | 1.327 (0.09) | 1.620 | 1.647 |

| Pb | mg/kg, d.b. | ≤10 | ≤10 | ≤10 | b.d.l. | b.d.l. | b.d.l. | b.d.l. | b.d.l. |

| Zn | mg/kg, d.b. | ≤100 | ≤100 | ≤100 | 11.10 | 11.20 | 15.53 (1.86) | 21.80 | 23.55 (2.33) |

| Ca | mg/kg, d.b. | - | - | - | 867 | 880 | 1116 (5.77) | 1560 | 1910 (-) |

| K | mg/kg, d.b. | - | - | - | 701 | 658 | 627 (27.6) | 954 | 1056 (58.89) |

| Mg | mg/kg, d.b. | - | - | - | 136 | 130 | 165 (2.08) | 228 | 274 (3.61) |

| Na | mg/kg, d.b. | - | - | - | 51.7 | 72.4 | 50.9 (0.77) | 71.7 | 77.1 (7.73) |

| P | mg/kg, d.b. | - | - | - | 69.7 | 28.2 | 37.3 (2.15) | 53.0 | 60.9 (0.64) |

| Si | mg/kg, d.b. | - | - | - | 208 | n.d. | n.d. | n.d. | n.d. |

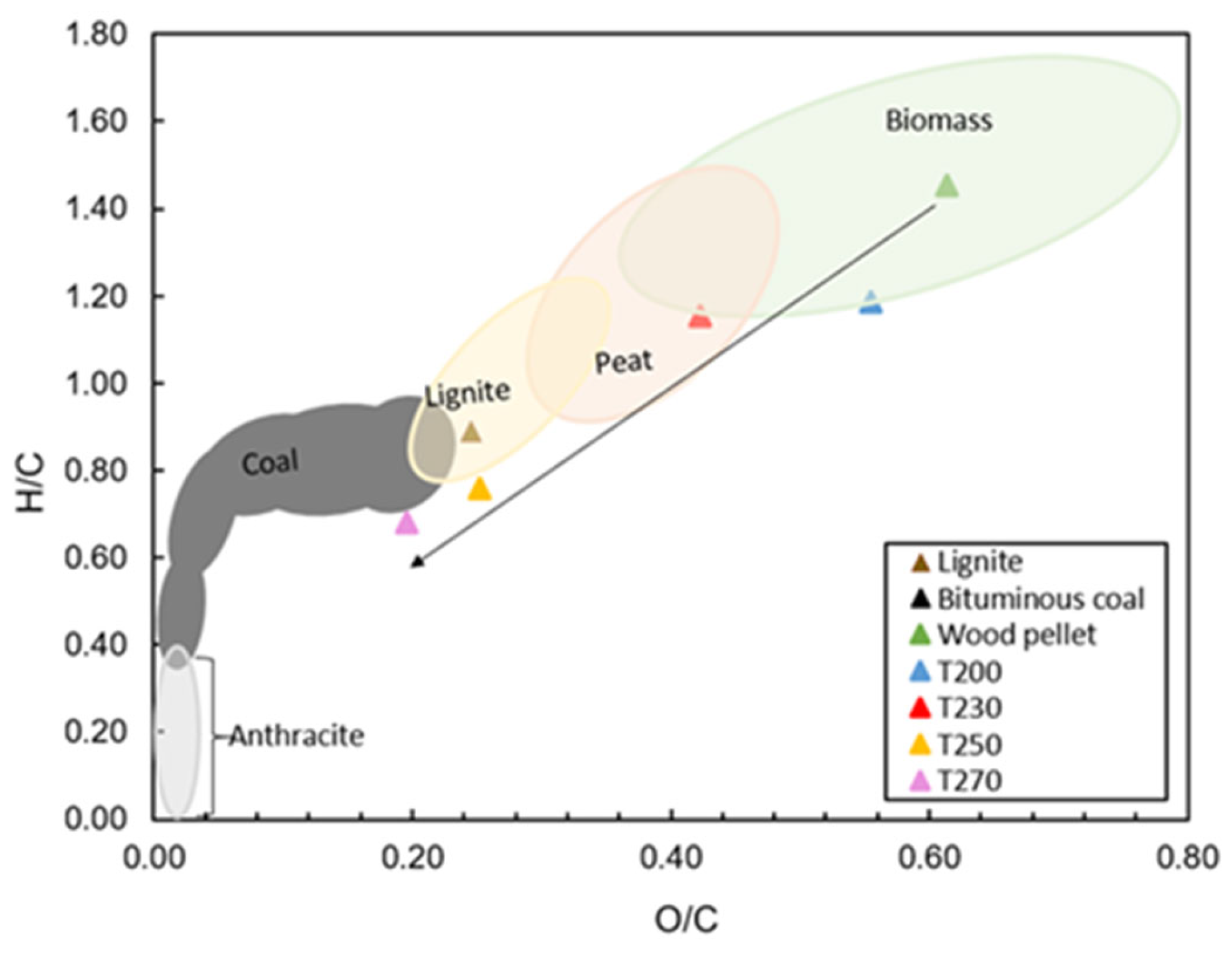

| O/C | - | - | - | - | 0.61 | 0.55 | 0.42 | 0.25 | 0.20 |

| H/C | - | - | - | - | 1.46 | 1.19 | 1.15 | 0.76 | 0.68 |

| Energy density ** | (GJ/m3) | - | - | - | 11.73 | 12.24 | 12.26 | 11.37 | 10.83 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mutlu, Ö.; Roy, P.; Zeng, T. Downstream Torrefaction of Wood Pellets in a Rotary Kiln Reactor—Impact on Solid Biofuel Properties and Torr-Gas Quality. Processes 2022, 10, 1912. https://doi.org/10.3390/pr10101912

Mutlu Ö, Roy P, Zeng T. Downstream Torrefaction of Wood Pellets in a Rotary Kiln Reactor—Impact on Solid Biofuel Properties and Torr-Gas Quality. Processes. 2022; 10(10):1912. https://doi.org/10.3390/pr10101912

Chicago/Turabian StyleMutlu, Özge, Poulami Roy, and Thomas Zeng. 2022. "Downstream Torrefaction of Wood Pellets in a Rotary Kiln Reactor—Impact on Solid Biofuel Properties and Torr-Gas Quality" Processes 10, no. 10: 1912. https://doi.org/10.3390/pr10101912

APA StyleMutlu, Ö., Roy, P., & Zeng, T. (2022). Downstream Torrefaction of Wood Pellets in a Rotary Kiln Reactor—Impact on Solid Biofuel Properties and Torr-Gas Quality. Processes, 10(10), 1912. https://doi.org/10.3390/pr10101912